Separation method for cupric oxide and copper sulfide mixed ore

A technology of copper oxide ore and copper sulfide, applied in the direction of solid separation, etc., can solve the problems of difficult operation, unstable leaching recovery rate, low recovery rate of copper sulfide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

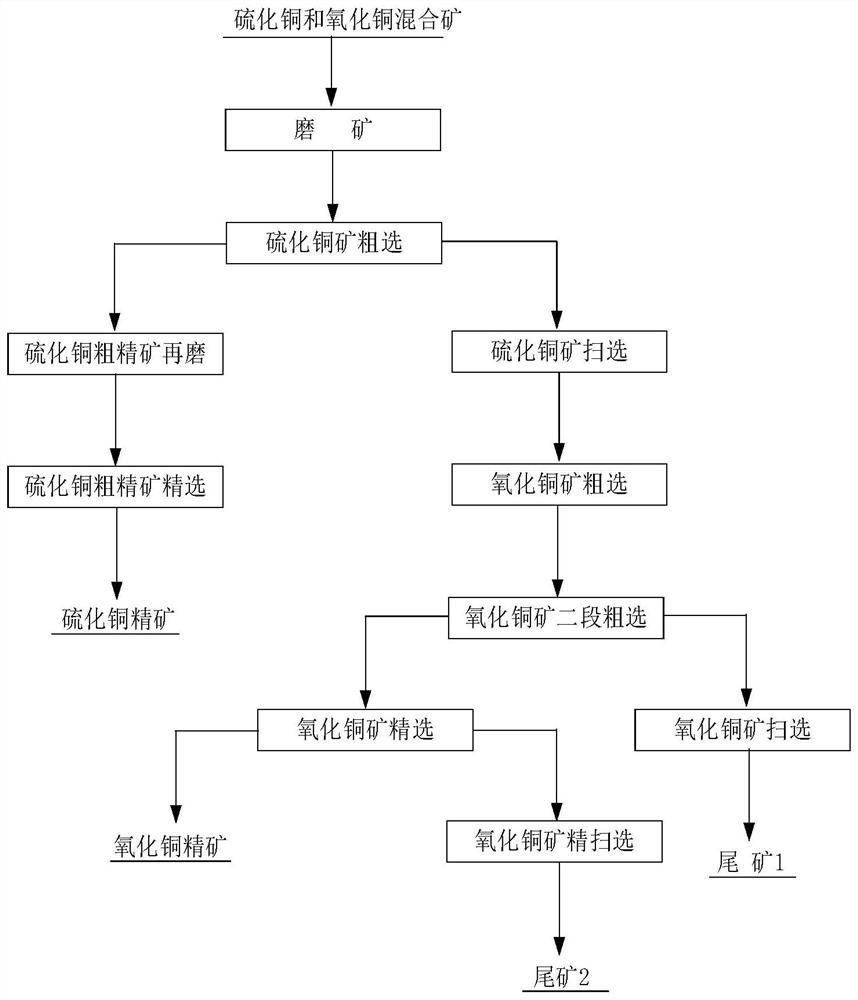

Image

Examples

Embodiment 1

[0058] S1 Grinding

[0059] A mixed ore of copper sulfide ore and copper oxide ore, the raw ore Cu grade is 2.0%, of which copper sulfide ore accounts for 60%, and copper oxide ore accounts for 40%. Among them, copper sulfide exists in the form of fine particles, and the copper oxide ore is embedded in the particle size >0.074mm accounted for 70%, and embedded particle size <0.020mm in copper sulfide ore accounted for 60%. Coarsely grind the mixed ore of copper sulfide ore and copper oxide ore, and grind the ore to a fineness of less than 0.074mm, accounting for 70%.

[0060] S2 copper sulfide ore roughing

[0061] In ore pulp, add collector, regulator and foaming agent to carry out copper sulfide ore flotation, use butyl xanthate as copper sulfide collector, the consumption of rough selection section is 100g / t (medicine consumption is all in the embodiment of the present invention Calculated per ton of ore, the same below), lime is used as a regulator, and the amount used i...

Embodiment 2

[0070] S1 Grinding

[0071] A mixed ore of copper sulfide ore and copper oxide ore, the raw ore Cu grade is 1.5%, of which copper sulfide ore accounts for 70%, and copper oxide ore accounts for 30%. Among them, copper sulfide exists in the form of fine particles, and the copper oxide ore is embedded in the particle size >0.074mm accounted for 70%, and embedded particle size <0.020mm in copper sulfide ore accounted for 60%. Coarsely grind the mixed ore of copper sulfide ore and copper oxide ore to a fineness of 65% ore below 0.074mm.

[0072] S2 copper sulfide ore roughing

[0073] Add collectors, adjusters and foaming agents to the pulp for flotation of copper sulfide ore, use the combination of butyl xanthate and Z-200 as copper sulfide collector, the rough selection amount is 60g butyl xanthate+ 40g Z-200 / t, lime is used as a regulator, the amount used in the roughing stage is 500g / t, methyl isobutyl carbinol is used as a foaming agent, the amount used in the roughing stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com