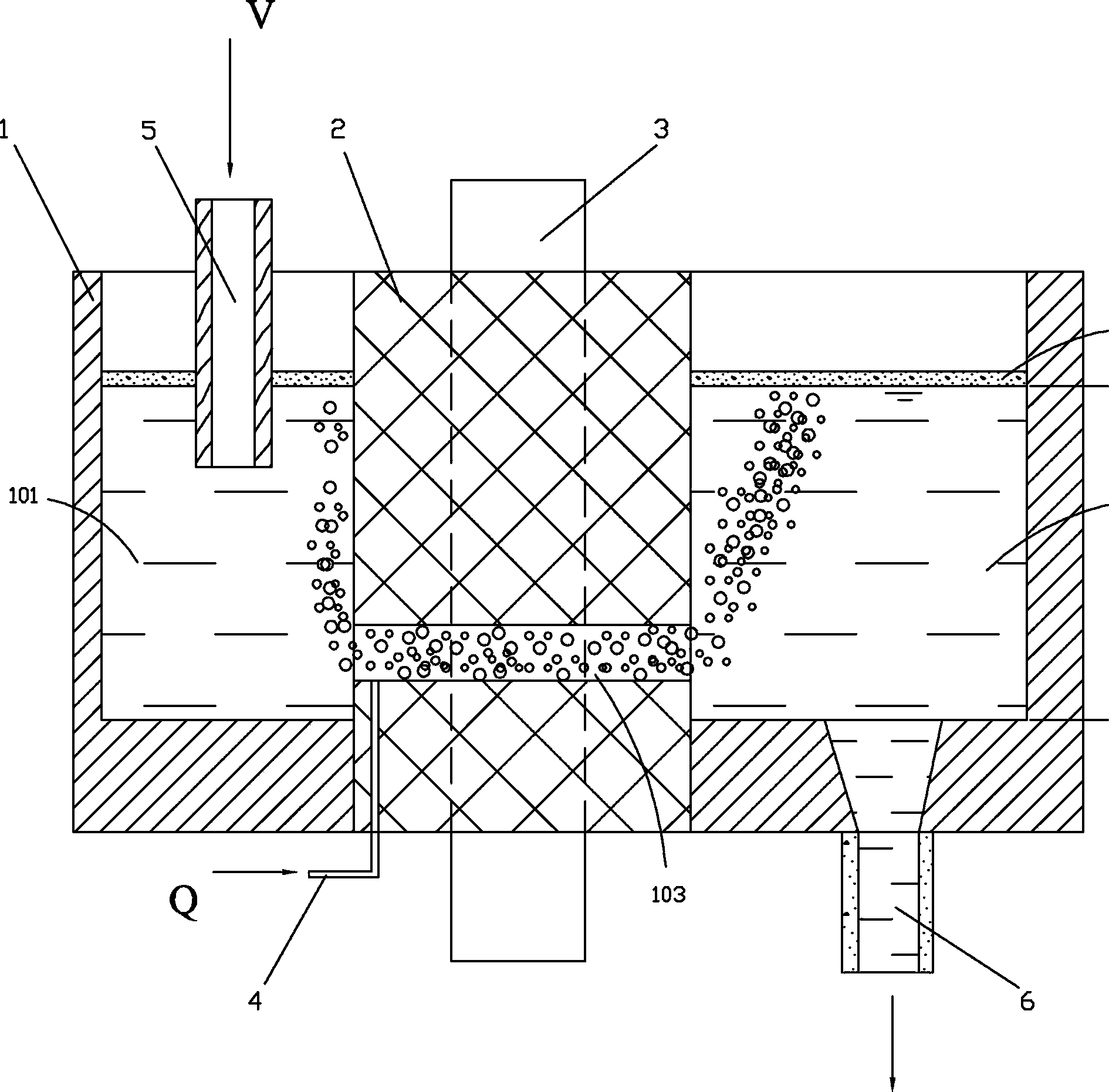

Channel type induction heating pouring basket and pouring method thereof

A technology of induction heating and casting method, which is applied in the direction of casting equipment, metal processing equipment, casting molten material container, etc., can solve the problems of freezing in the submerged nozzle, serious segregation, increase of inclusion defects in continuous casting billet, etc., and achieve stability Flow state, effect of mitigating scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] After the ladle is poured, the superheat of the molten steel is 45 degrees, and the molten steel enters the tundish steel cavity 101 from the long nozzle 5, and enters the tundish steel cavity 102 through the channel 103; after 3 minutes, the tundish steel cavity 101 and the steel cavity Mold slag is put into cavity 102 to form slag layer 104; molten steel pouring flow rate is 0.3t / min, open gas blowing pipe 4 at the bottom of the tundish, and blow in argon gas, and the flow rate of argon gas is controlled at 0.2NM 3 / h. Turn on the induction heater 3 to heat the molten steel in the channel 103. After 20 minutes, the continuous casting enters the tail stock, stop the induction heater 3 for heating, close the nozzle 6 stopper on the side of the pouring cavity 102, and the casting ends.

Embodiment 2

[0035]After the ladle is poured, the superheated degree of molten steel is 30 degrees. After 5 minutes, mold slag is put into the tundish bearing cavity and pouring cavity respectively to form a slag layer; Trachea, blowing argon, the flow of argon is controlled at 0.5NM 3 / h. Turn on the induction heater to heat the molten steel in the channel. After 30 minutes, the continuous casting enters the tail blank, stop the induction heater to heat, turn off the stopper, and the casting ends.

Embodiment 3

[0037] After the ladle is poured, the superheated degree of the molten steel is 35 degrees. After 6 minutes, pour mold slag into the steel chamber of the tundish and the pouring chamber respectively to form a slag layer; the pouring flow rate of the molten steel is 2t / min, and the blowing pipe at the bottom of the tundish is opened , blowing argon, the flow of argon is controlled at 1NM 3 / h. Turn on the induction heater to heat the molten steel in the channel. After 35 minutes, the continuous casting enters the tail blank, stop the induction heater to heat, turn off the stopper, and the casting ends.

[0038] The tundish is widely used in the production process of the continuous casting process. The present invention can be applied to the structural design of various tundishes, which can greatly remove the content of inclusions in molten steel and increase the purity of molten steel in molten steel, thereby achieving stable pouring the goal of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com