Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

179results about How to "Uniform viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

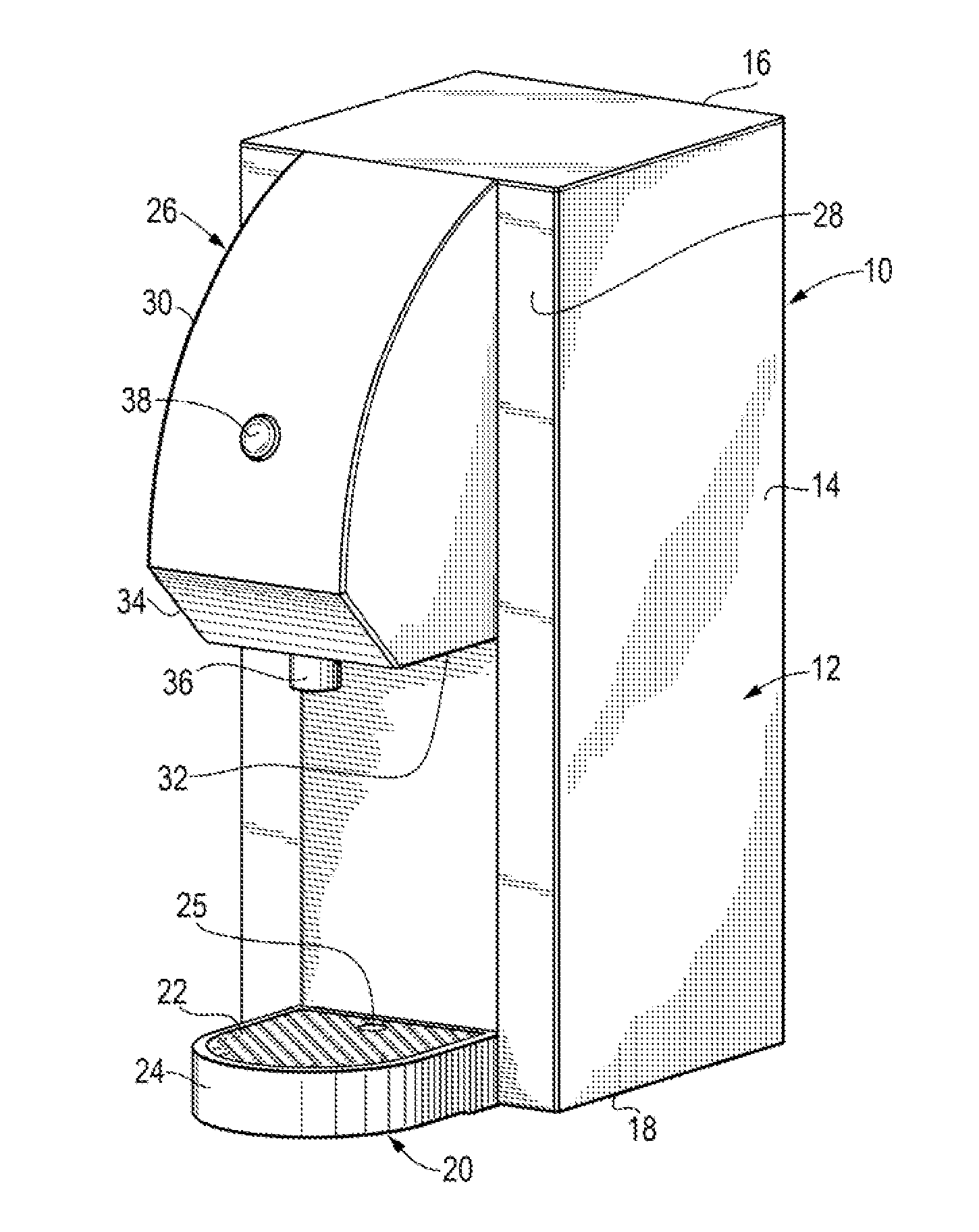

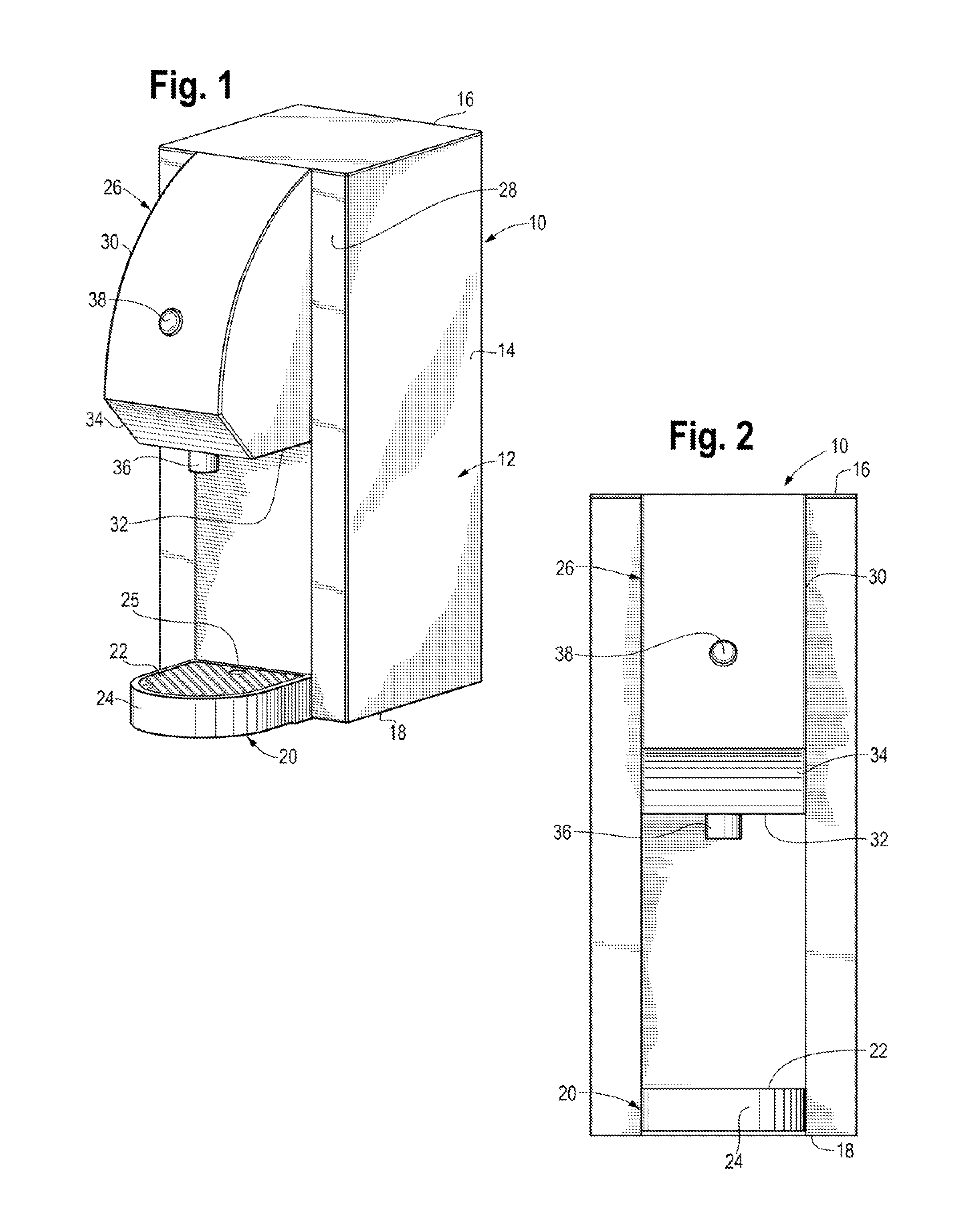

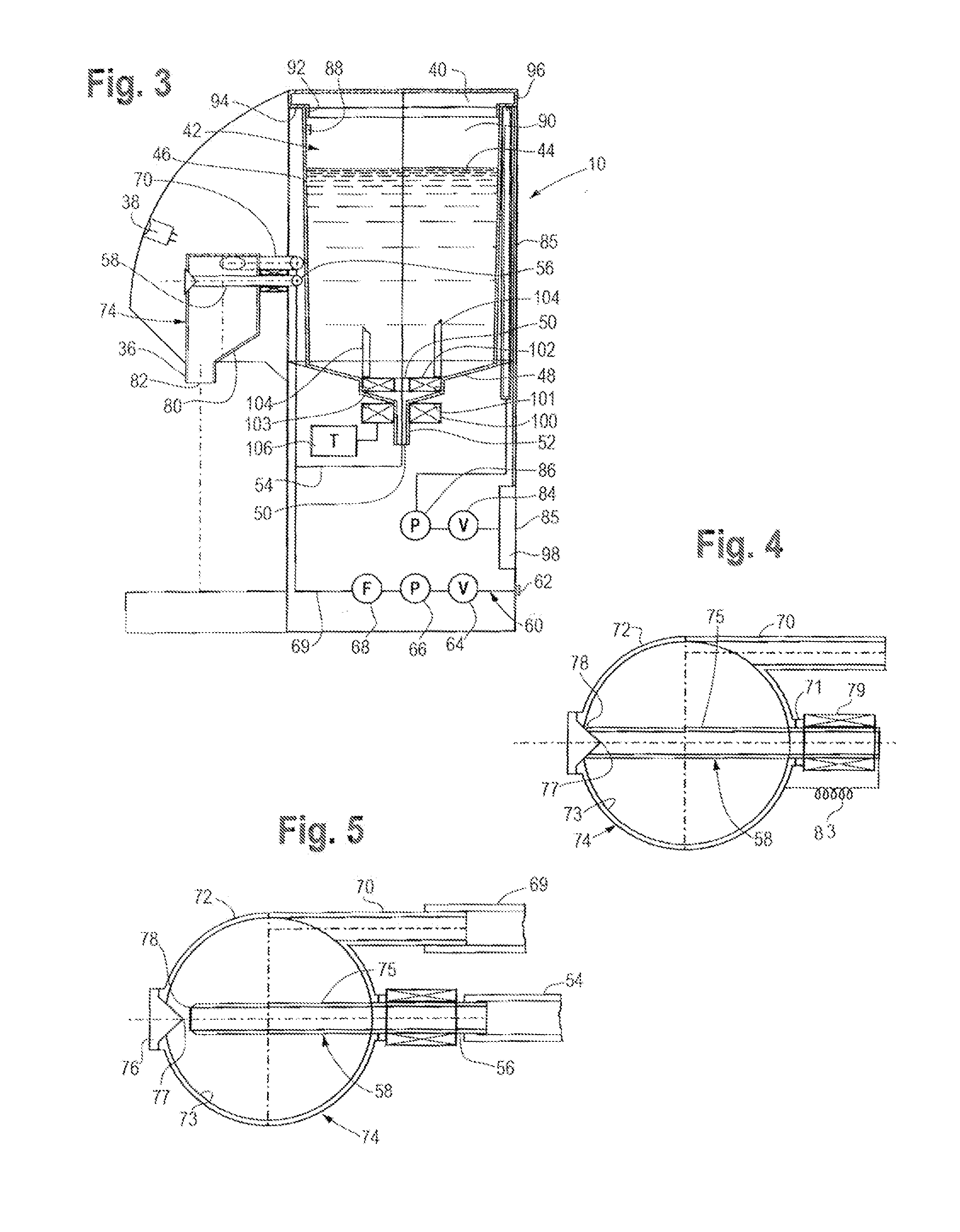

Liquid beverage concentrate mixing beverage dispenser and method

ActiveUS8881948B1Easy maintenanceUniform viscosityBeverage vesselsLiquid transferring devicesNitrogenEngineering

An automated mixing drink dispenser (10) establishes a preselected feed rate of concentrate from a concentrate hopper (42) and ratio of concentrate to mixing water fed into a mixing chamber (42) through the Venturi effect created by swirling water fed into a mixing chamber (42) at a preselected water pressure (66) and preselected regulated flow rate (68) associated with the preselected feed rate of the concentrate. Concentrate is fed to a mixing chamber (42) from a concentrate hopper (42) having an open drain hole (50) openly connected to the mixing chamber (42). A stirring mechanism (106, 100, 101, 102, 104) mechanically mixes the concentrate within the concentrate hopper (42) to maintain a uniform density and viscosity and a gas pressure mechanism (92, 94, 96, 86) maintains a uniform head pressure of concentrate to facilitate maintenance of the preselected concentrate flow rate over time. Nitrogen gas in air is pumped through a nitrogen passing filter to fill the space (90) above the concentrate to both maintain head pressure and to reduce deterioration of the concentrate due to interaction with oxygen.

Owner:FOOD EQUIP TECH

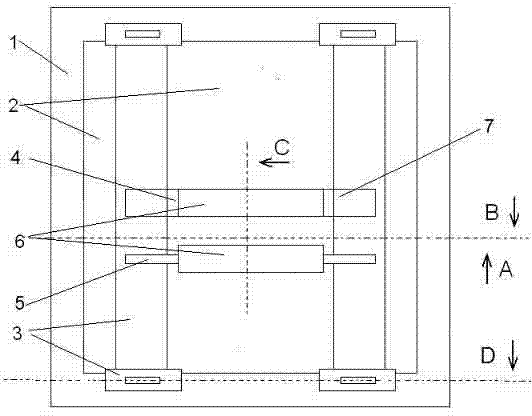

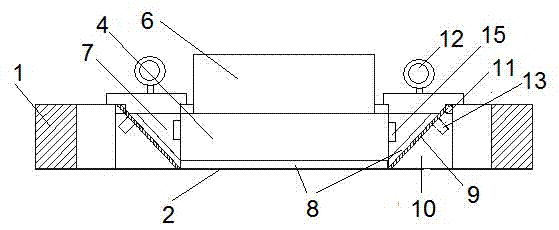

Screen printing device for solar batteries

InactiveCN102336051ASimple structural designLittle impact on deformabilityFinal product manufactureScreen printersScreen printingSlurry

The invention discloses a screen printing device for solar batteries. The screen printing device comprises a printing scraper, an auxiliary scraper, a feed back knife and a printing screen. The device is characterized in that two baffle structures are mounted on the printing screen, at two sides close to the ends of the printing scraper, wherein each baffle structure is mainly composed of a baffle surface, a baffle frame and an installation rack; the bottom of the baffle surface is in split type contact with a screen surface, or adhered to the screen surface through a flexible material; edges of the feed back knife, the printing scraper and the auxiliary scraper are in seamless contact with the baffle surface; a printing head drives the scrapers and the feed back knife to contact the baffle surface in a sliding manner, so that the paste moves in a range defined by the baffle surfaces at the two sides, the scraper and the feed back knife, and slurry is prevented from flowing to the two sides; and the device can ensure uniform fluidity, viscosity and thixotropy of the slurry and avoid the local drying and waste of the slurry, thereby improving electrode printing efficiency and printing quality.

Owner:NANCHANG UNIV

Linear low-density polyethylene composition

ActiveCN102477180AUniform viscosityEliminate cracksLow-density polyethyleneLinear low-density polyethylene

The invention relates to a linear low-density polyethylene composition comprising components of, by weight: 50-98 parts of linear low-density polyethylene with a density of 0.918-0.922g / cm<3> and a melt flow index of 0.1-10g / 10min, 0.5-45 parts of low-density polyethylene with a density of 0.910-0.925g / cm<3> and a melt flow index of 0.1-30g / 10min, 0.5-45 parts of high-density polyethylene with a density of 0.941-0.970g / cm<3> and a melt flow index of 0.5-10g / 10min, 0.5-45 parts of polypropylene with a density of 0.830-0.910g / cm<3> and a melt flow index of 0.5-50g / 10min, 0.1-20 parts of an ethylene-vinyl acetate copolymer with a density of 0.926-0.939g / cm<3>, 0.01-1 part of a rheology modifying agent, and 0.5-20 parts of a compatibilizing agent with a melt flow index of 0.5-50g / 10min. With the composition, extrusion processing performance can be effectively improved, a melt fracture phenomenon can be eliminated, and the compatibility can be improved. With the composition, the strength, flexibility and aging resistance of a product can be improved. The composition can be used for producing films, drip irrigation tapes, and pipes with various specifications.

Owner:XINJIANG TIANYE WATER SAVING IRRIGATION SYST

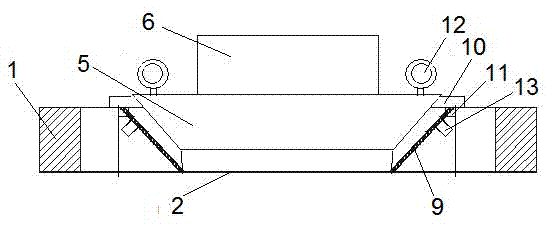

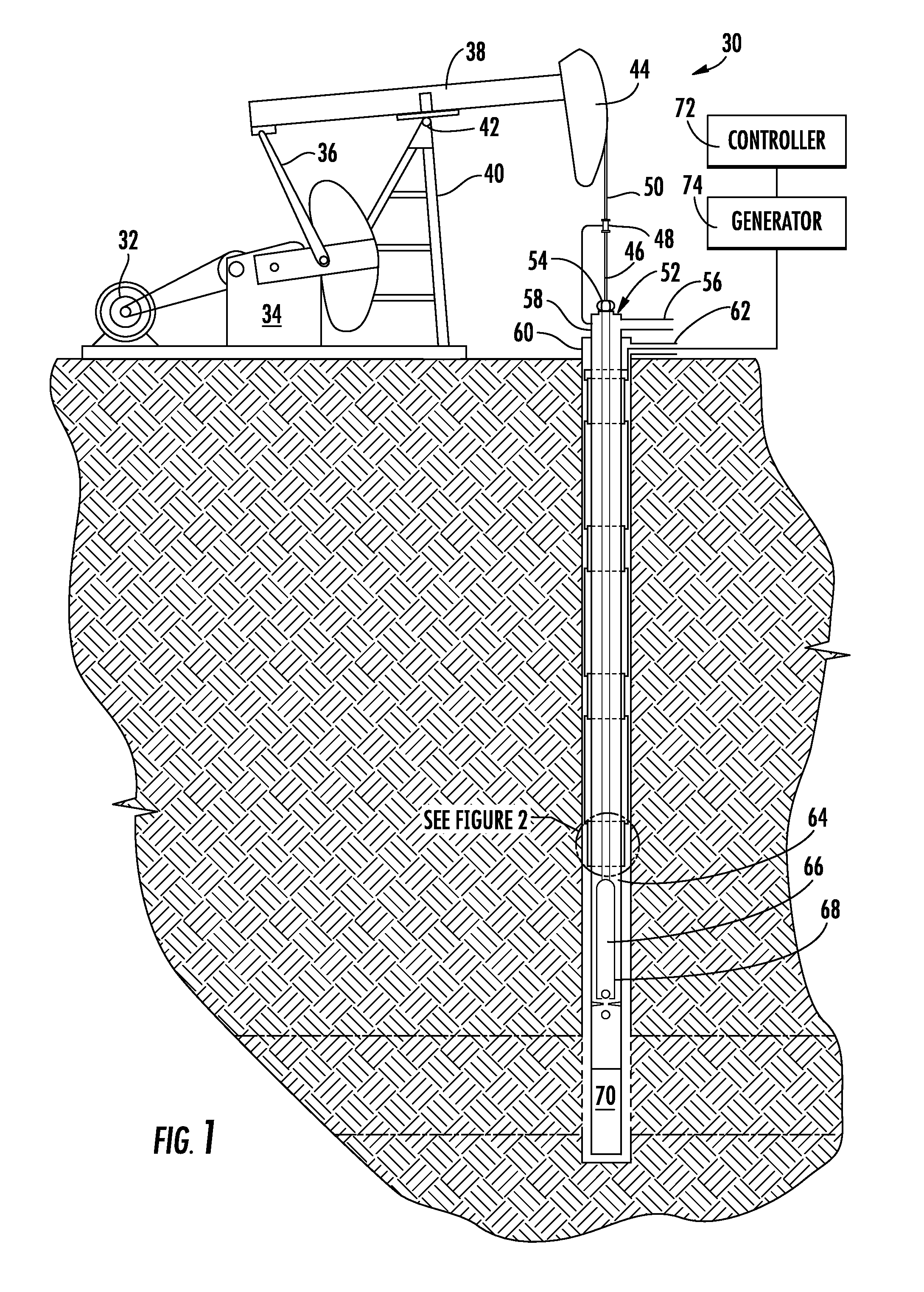

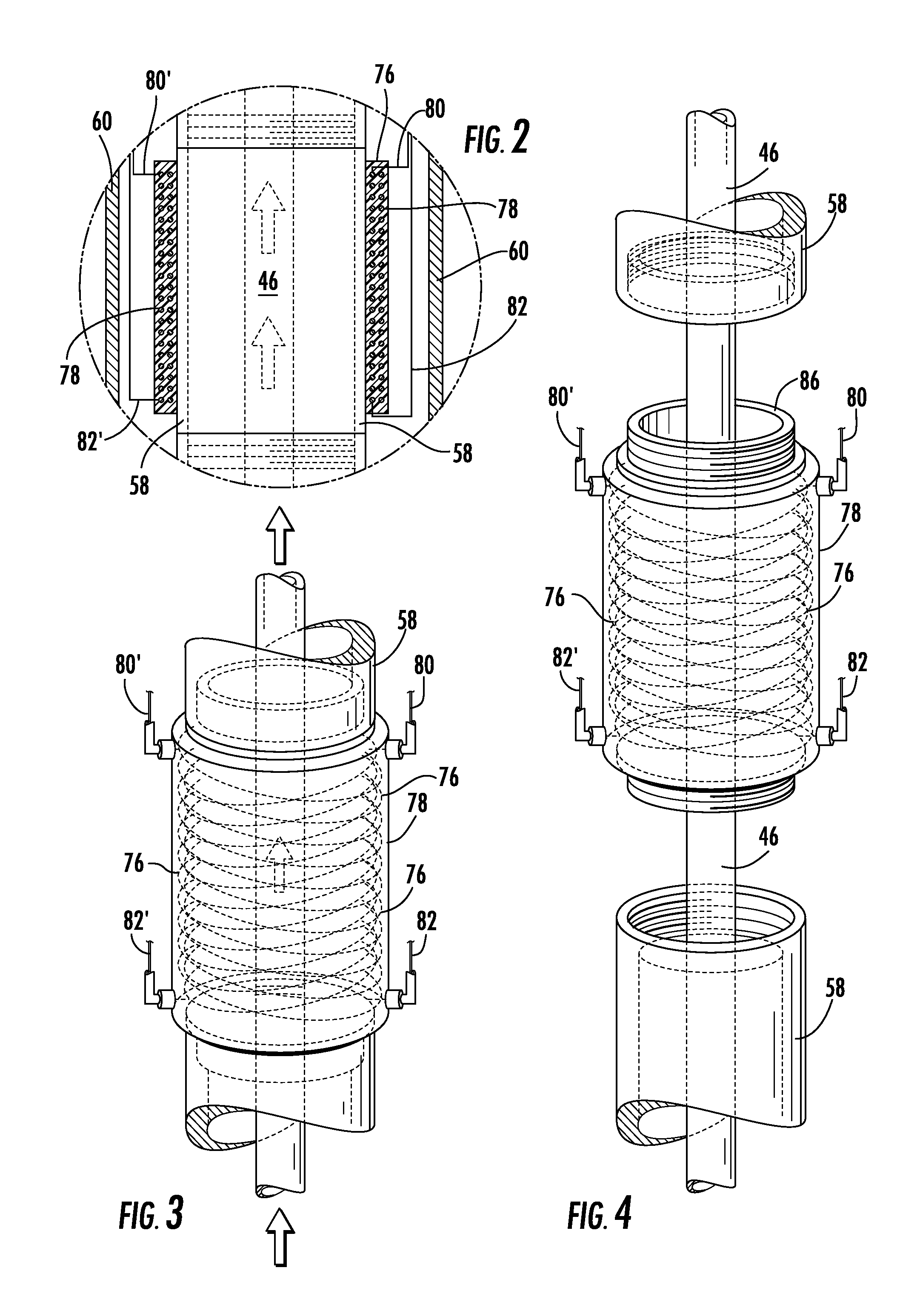

Apparatus and method for magnetically conditioning fluids

InactiveUS20130192682A1Increase oil extractionAvoid corrosionWater treatment parameter controlSpecific water treatment objectivesElectrical conductorEngineering

Methods and apparatus for fluid conditioning to reduce scaling, inactivate microbes, reduce surface tension, maintain fluid composition, and improve pumping are provided for use in treating crude petroleum, industrial water, agricultural water, municipal water supplies, or any fluid flow system and comprise electromagnets of variable control that can be powered or in which a current can be induced by a permanent magnet. Magnetic field direction and intensity can be selected depending on the nature of the fluid and in some embodiments, the field can be varied during operation, including pulsing and variably selecting one or more field directions and intensities, or combinations thereof, during operation. A non-magnetic fluid transfer conduit section has at least one conductor assembly mounted about the section. In one embodiment, the conductor assembly comprises a concentric, tilted double helix coil or multipole coil. If desired, one or more rotating or reciprocating permanent magnets may be located in magnetic field contact with one or more multipole conductor assemblies and rotated or reciprocated to induce a current in the multipole conductor assembly, thereby to induce a magnetic field in the conductor assembly.

Owner:ENVIRONMENTAL TECH INT

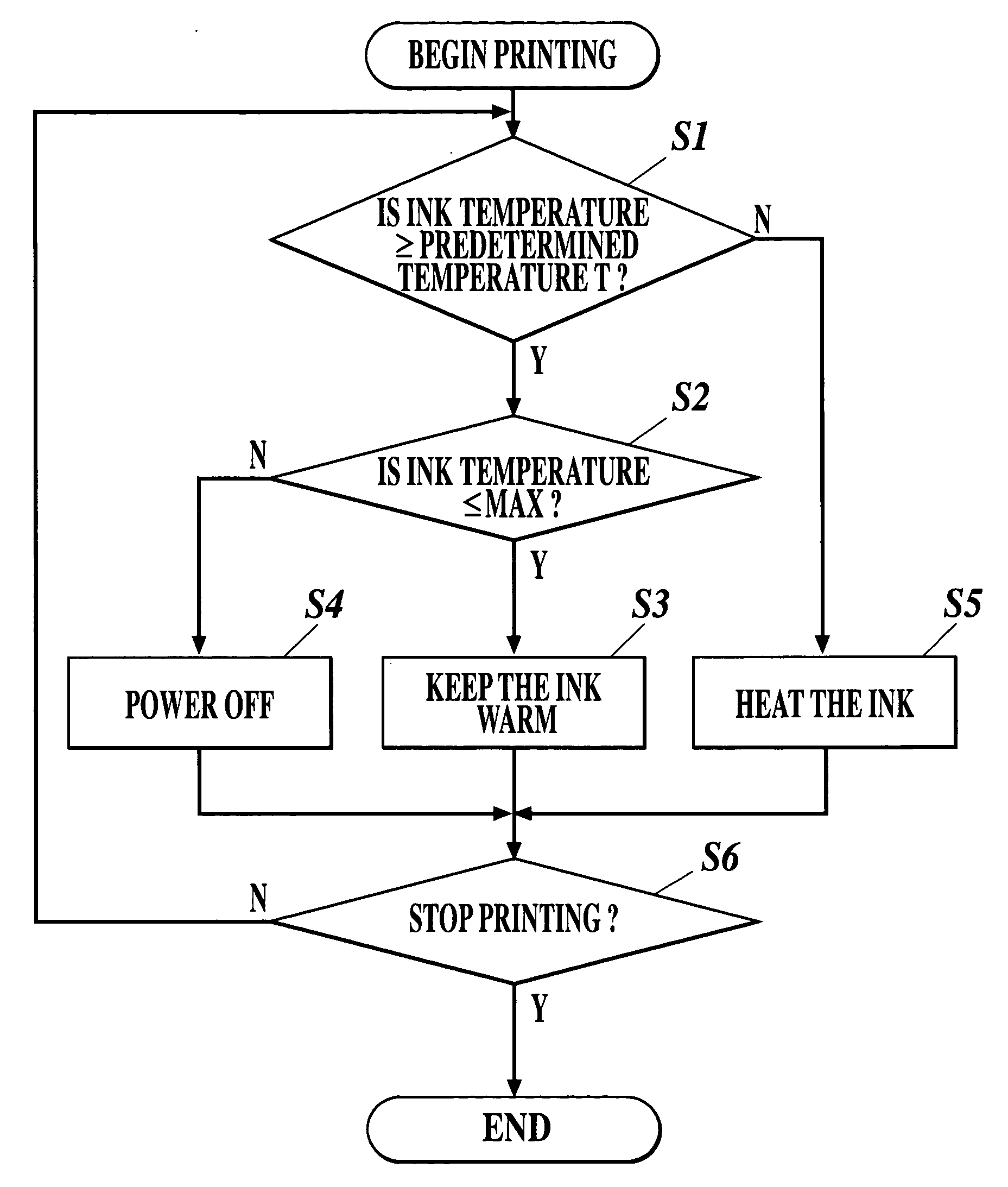

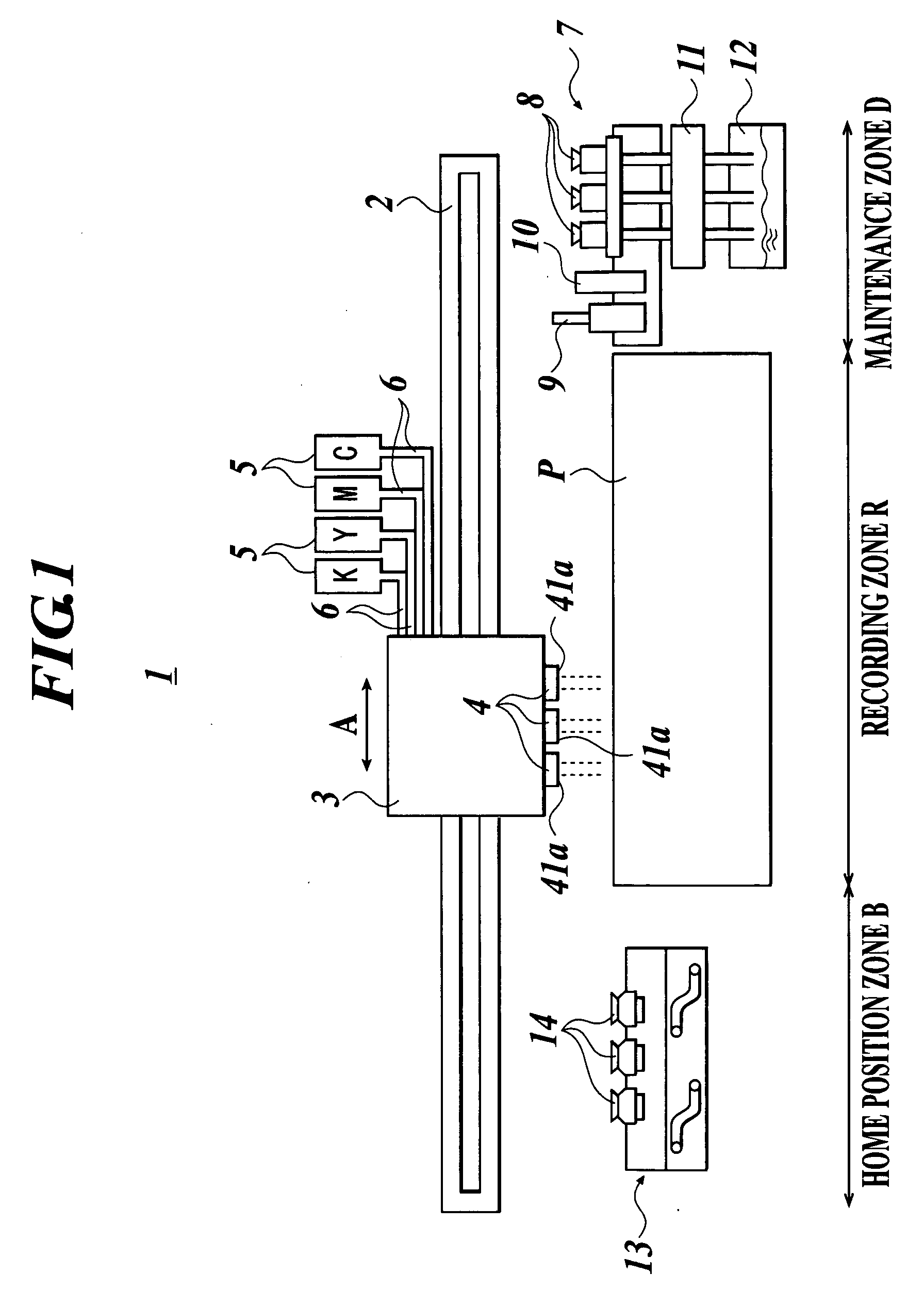

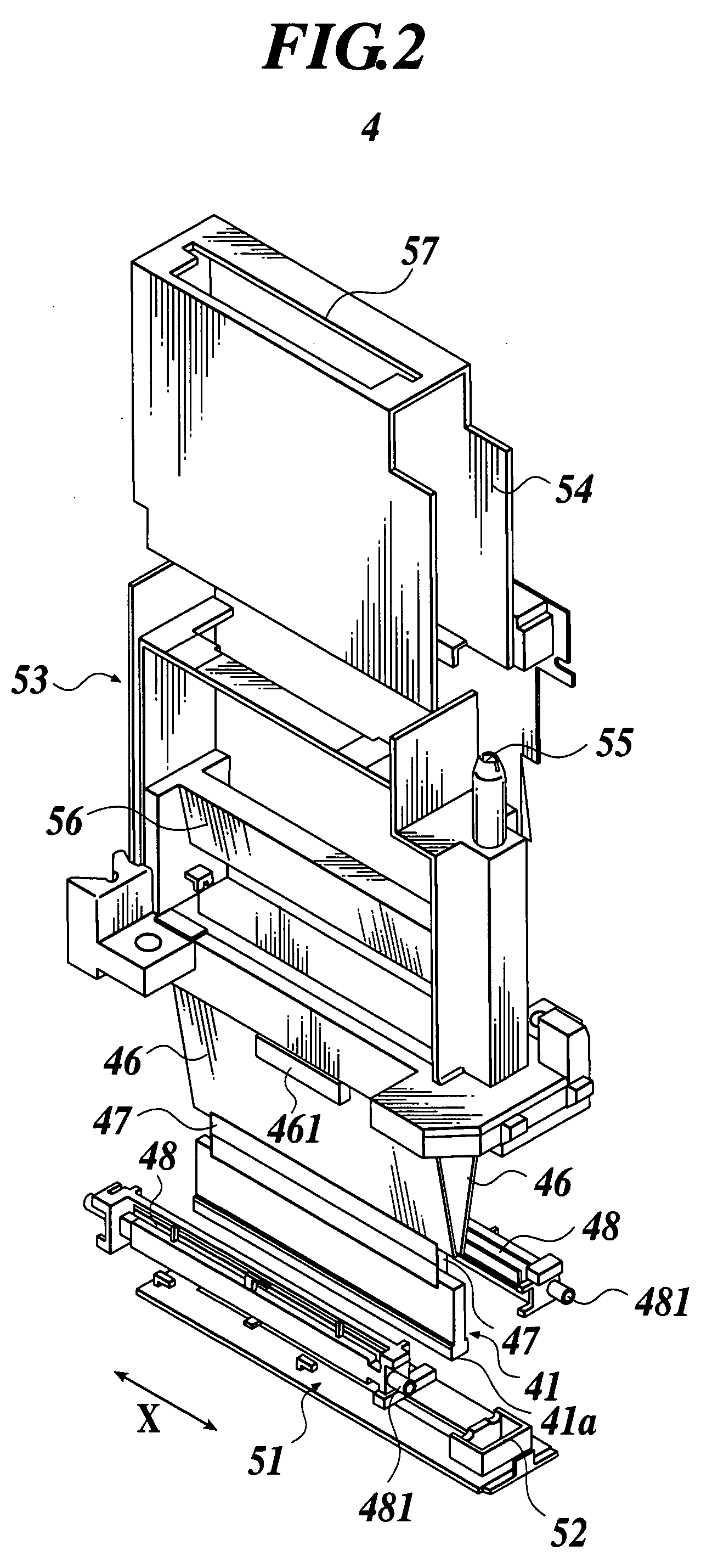

Inkjet head

ActiveUS20050052485A1Uniform ink dropletsUniform viscosityOther printing apparatusSpray nozzleEngineering

An inkjet head having: an inkjet head chip having ink jetting openings which are lined up to form a nozzle row on a front surface of the inkjet head chip; a manifold attached securely to a side of the inkjet head chip and leading ink to the inkjet head chip; and an ink heater which is in thermal contact through the manifold with ink in the manifold and which varies in heat generation density in a direction of the nozzle row.

Owner:KONICA MINOLTA INC

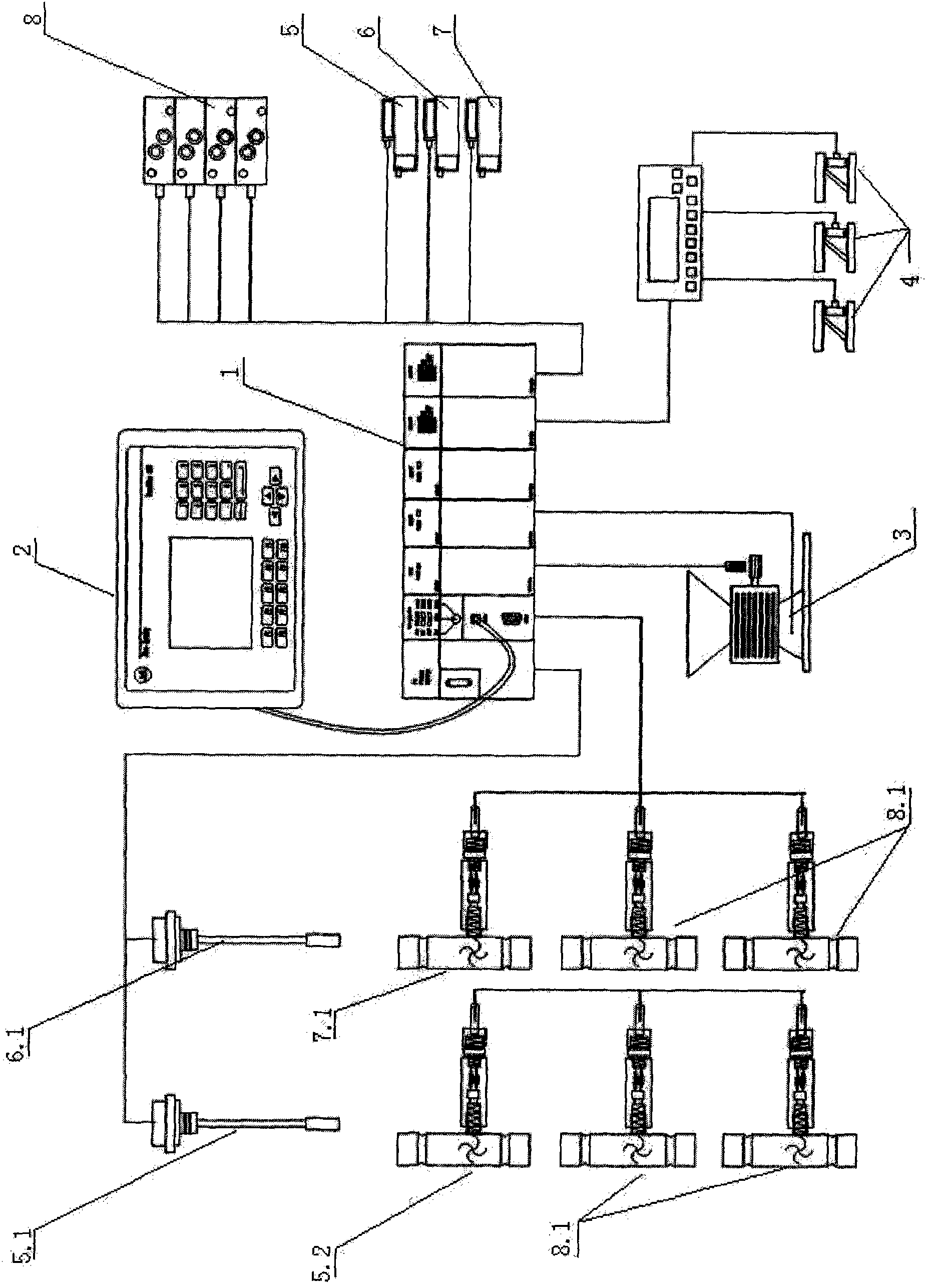

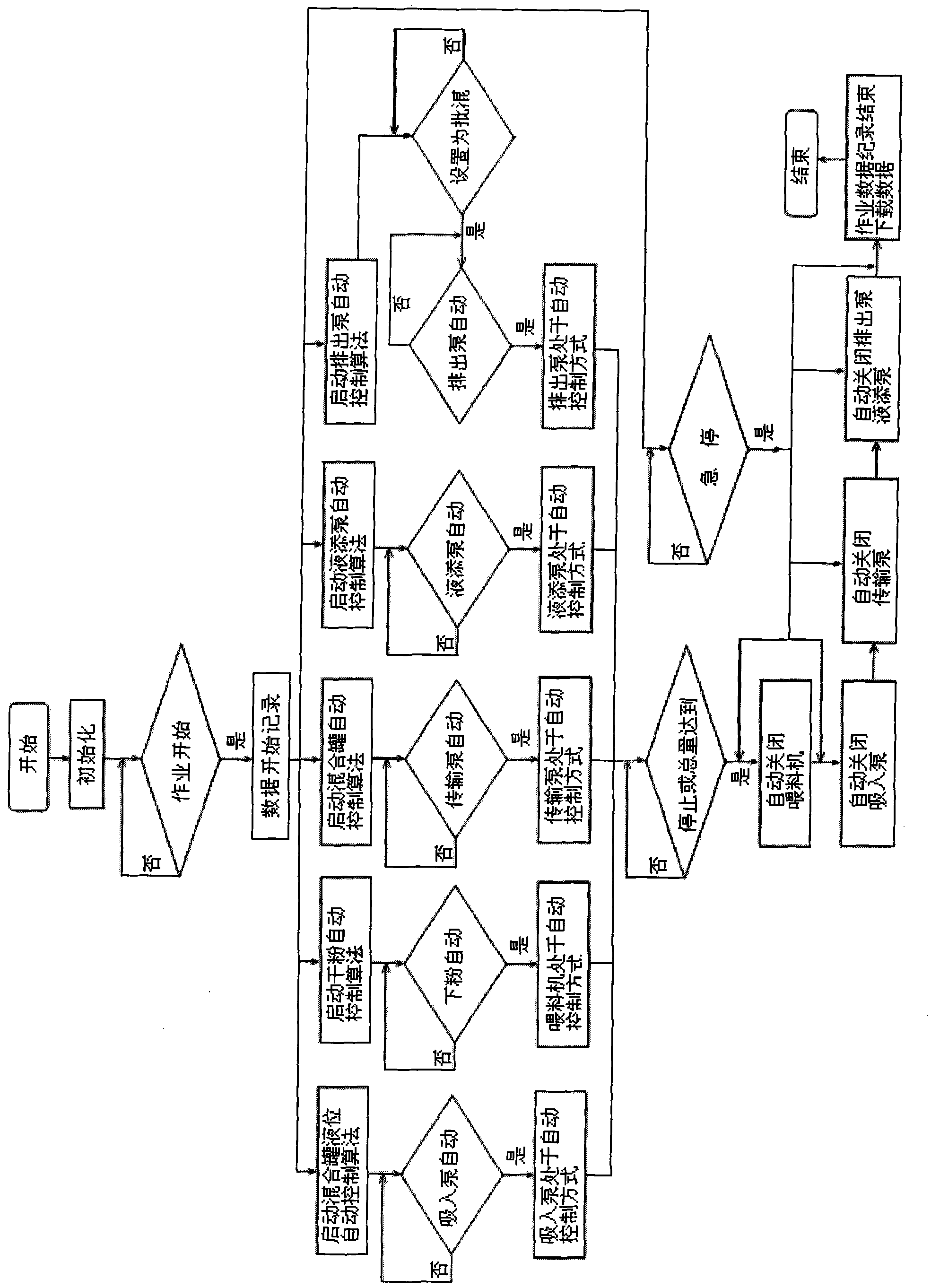

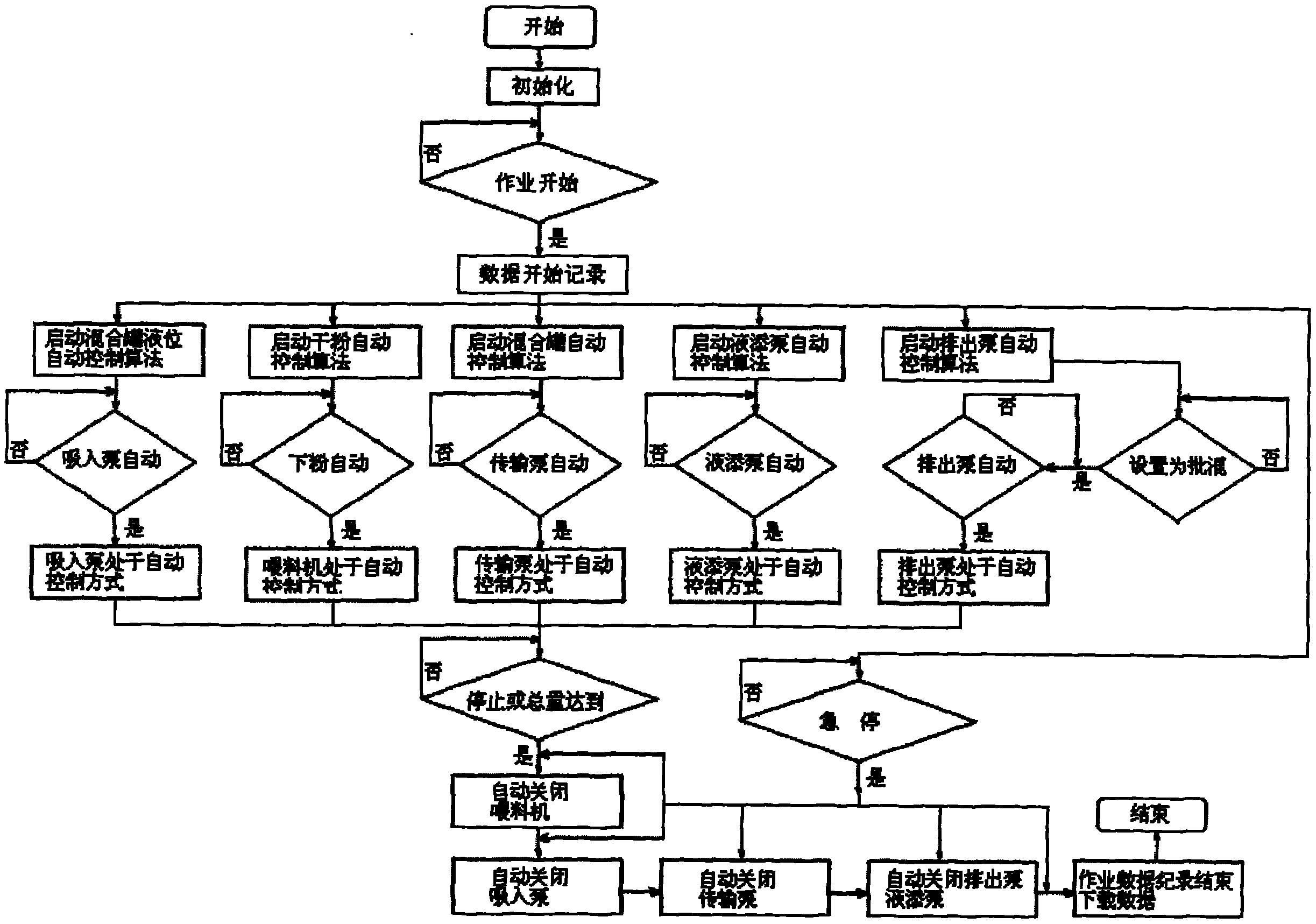

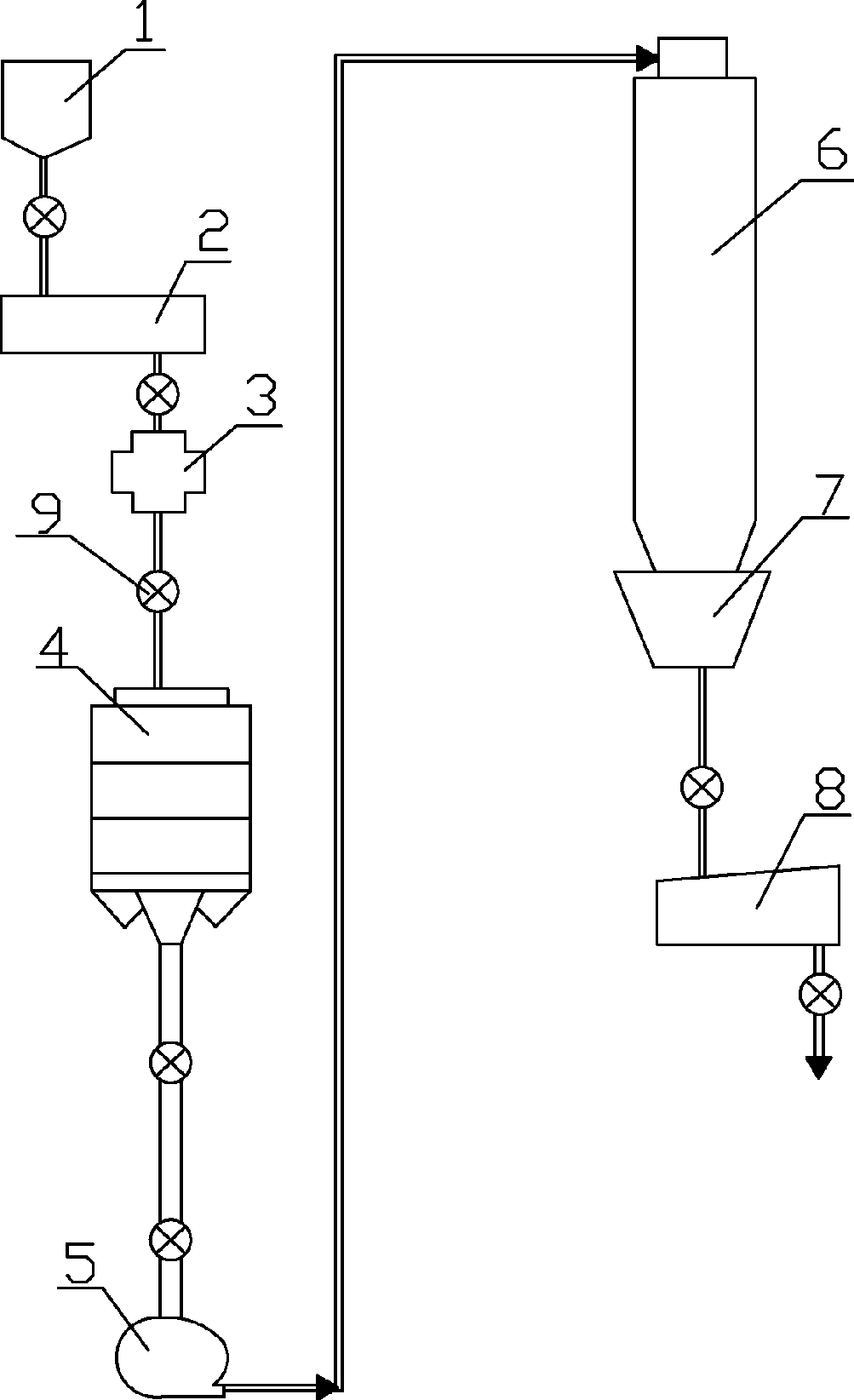

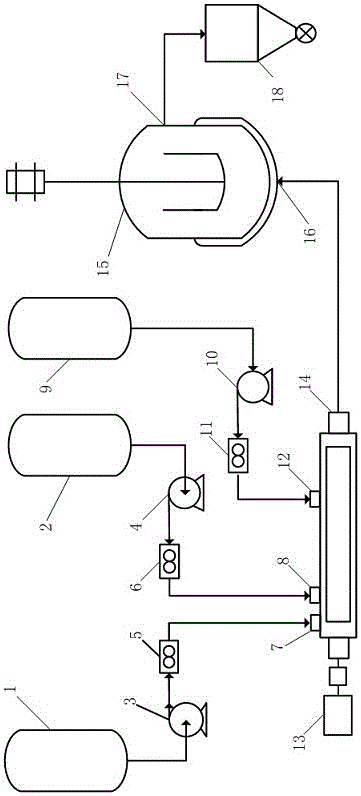

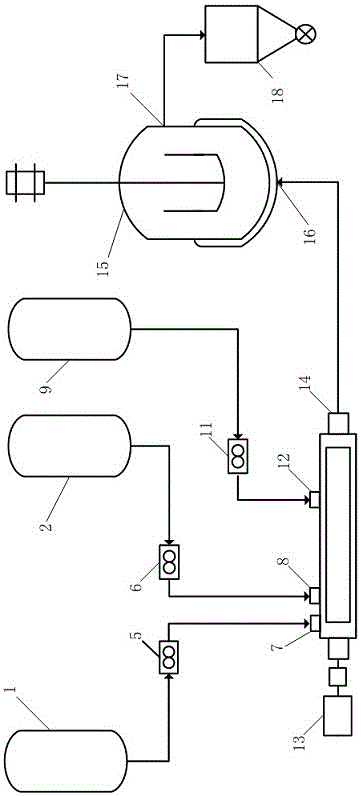

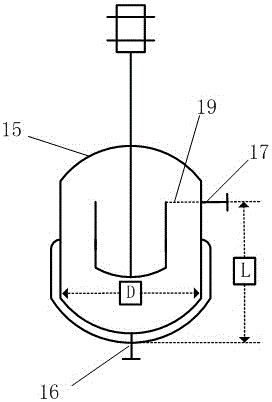

Automatic blending control method of oil field fracturing fluid

The invention relates to an automatic blending control method of oil field fracturing fluid, which is mainly used for automatic blending control of fracturing fluid during fracturing operation of the oil field. In the method, the powder blanking speed is controlled by adjusting the output rate of a feeder; the clear water suction flow is controlled by adjusting a clean water suction pump so as to control the liquid level of a mixing tank; the liquid level of a hydration tank is controlled by adjusting a conveying pump; the flow of the fluid feed pump is adjusted according to the actual discharge flow and the set fluid feed proportion; and a discharge pump is controlled according to the actual discharge flow and the set discharge flow. The method can not only realize accurate, continuous and even charging and high-quality continuous liquid preparation, effectively remove water bag powder, but also can realize automatic control of a computer, and ensures that the matching and mixing speed is adjusted in real time and the fluid matching parameter is stored and recycled.

Owner:四机赛瓦石油钻采设备有限公司 +1

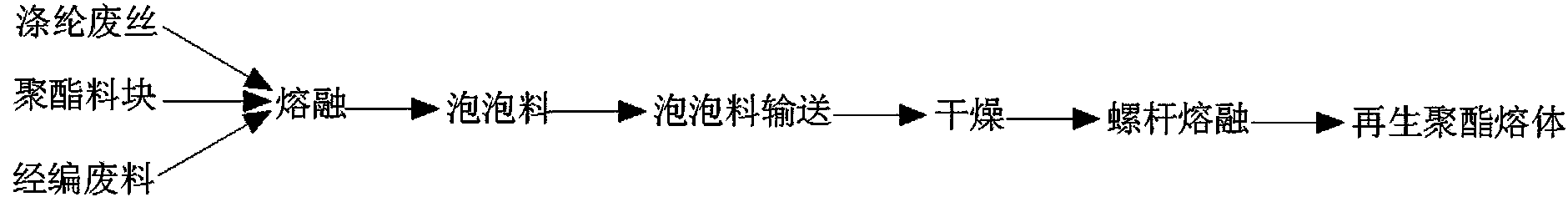

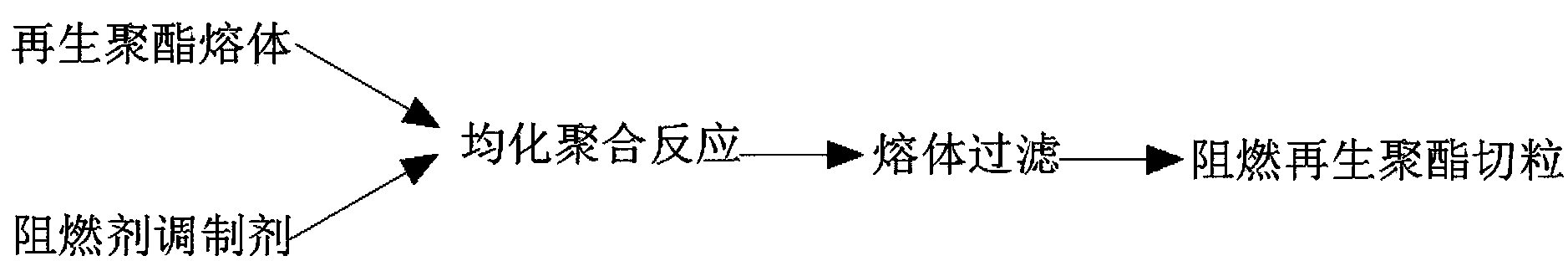

Production method of phosphorus copolymerization flame-retardant regenerated polyester chip and industrial yarn of the polyester chip

ActiveCN104017195ADoes not affect the molecular skeleton structureImprove hydrolytic stabilityProductsReagentsYarnPolyester

The invention relates to a production method of a phosphorus copolymerization flame-retardant regenerated polyester chip and industrial yarn of the polyester chip, and belongs to the technical field of flame-retardant polyester industrial yarn production. The production method includes: preparation of the flame-retardant regenerated polyester chip, solid polymerization, spinning and drafting heat setting, in particular, the method includes steps of: drying after a polyester waste material is melt to form a bubble material, melting by a screw to form regenerated polyester melt, adding a flame-retardant adjusting agent and a catalyst into the regenerated polyester melt, performing homogenization and polymerization, filtering the melt, granulating to obtain the flame-retardant regenerated polyester chip, spinning after the chip is subjected to solid polymerization for tackifying, and performing drafting heat setting to obtain a finished product. By adoption of the production method, molecular chain end-capping in an esterification reaction is avoided, and the reaction is performed step by step. In addition, the polyester chip is suitable for solid polymerization. The viscosity of the chip can be largely increased and suitable for processing and production of the polyester industrial yarn. By the flame-retardant processing for the regenerated polyester, the waste material is regenerated, and has a novel function, so that the method has a profound meaning.

Owner:浙江金汇特材料有限公司

Production process of bamboo-dissolving pulp

ActiveCN102127877AIncreased alkali consumptionExtended cook cycleCellulose material pulpingAcid treatmentManufacturing engineering

The invention provides a production process of bamboo-dissolving pulp, relating to a treatment method in the field of textile chemical fiber. The process comprises the following procedures of: preparing materials; steaming and pre-hydrolyzing; exchanging steaming and boiling; hermetically screening; bleaching in oxygen-alkali; carrying out acid treatment; manufacturing paper with pulp; and the like. The bamboo-dissolving pulp produced by the invention has the advantages of good product quality, uniform viscosity, high alphacellulose content, high whiteness, yellowing resistance, low pentaose content and good reaction performance and is favorable to production of post-procedures, chlorine-free bleaching and environment-friendly production.

Owner:YIBIN GRACE GROUP CO LTD

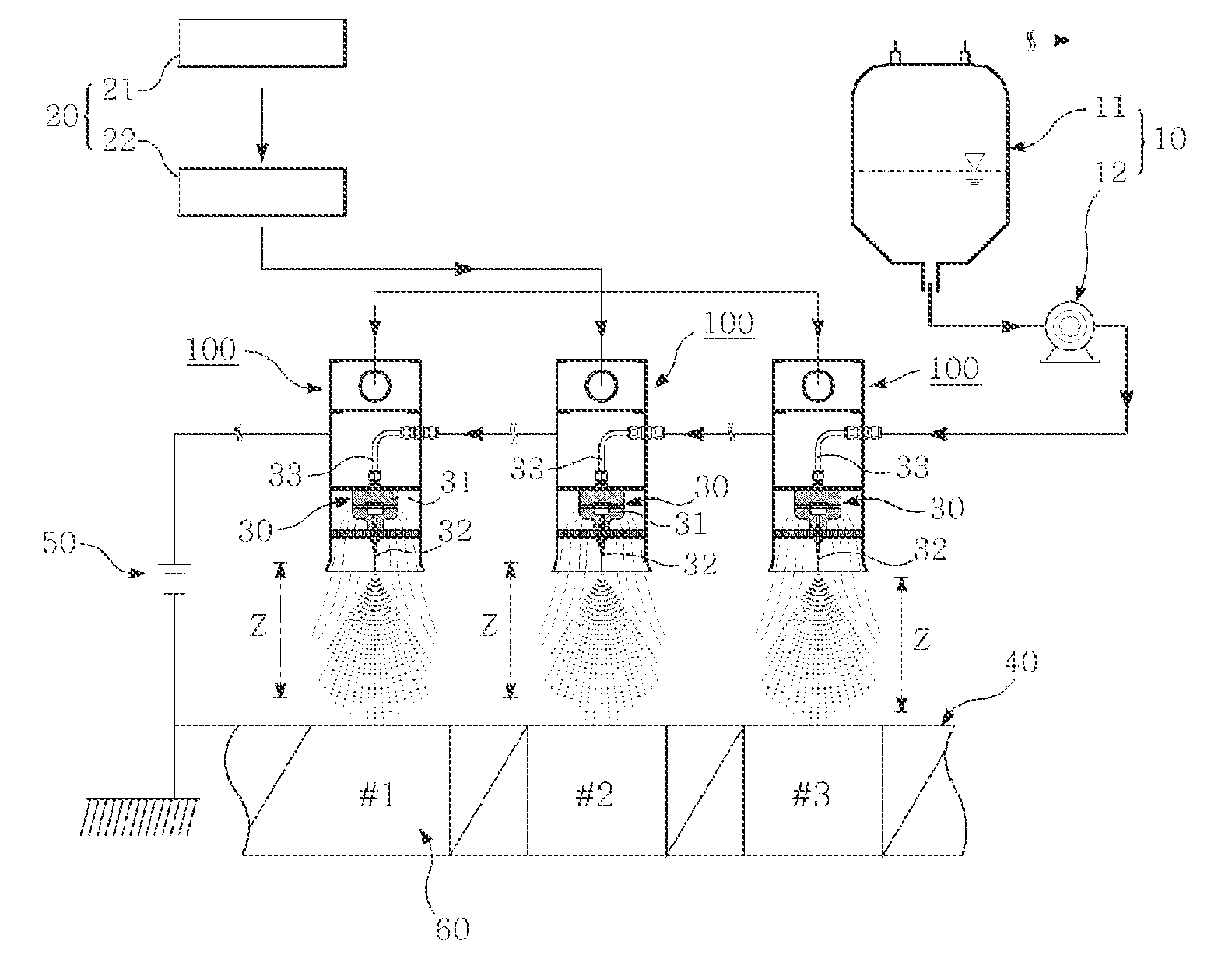

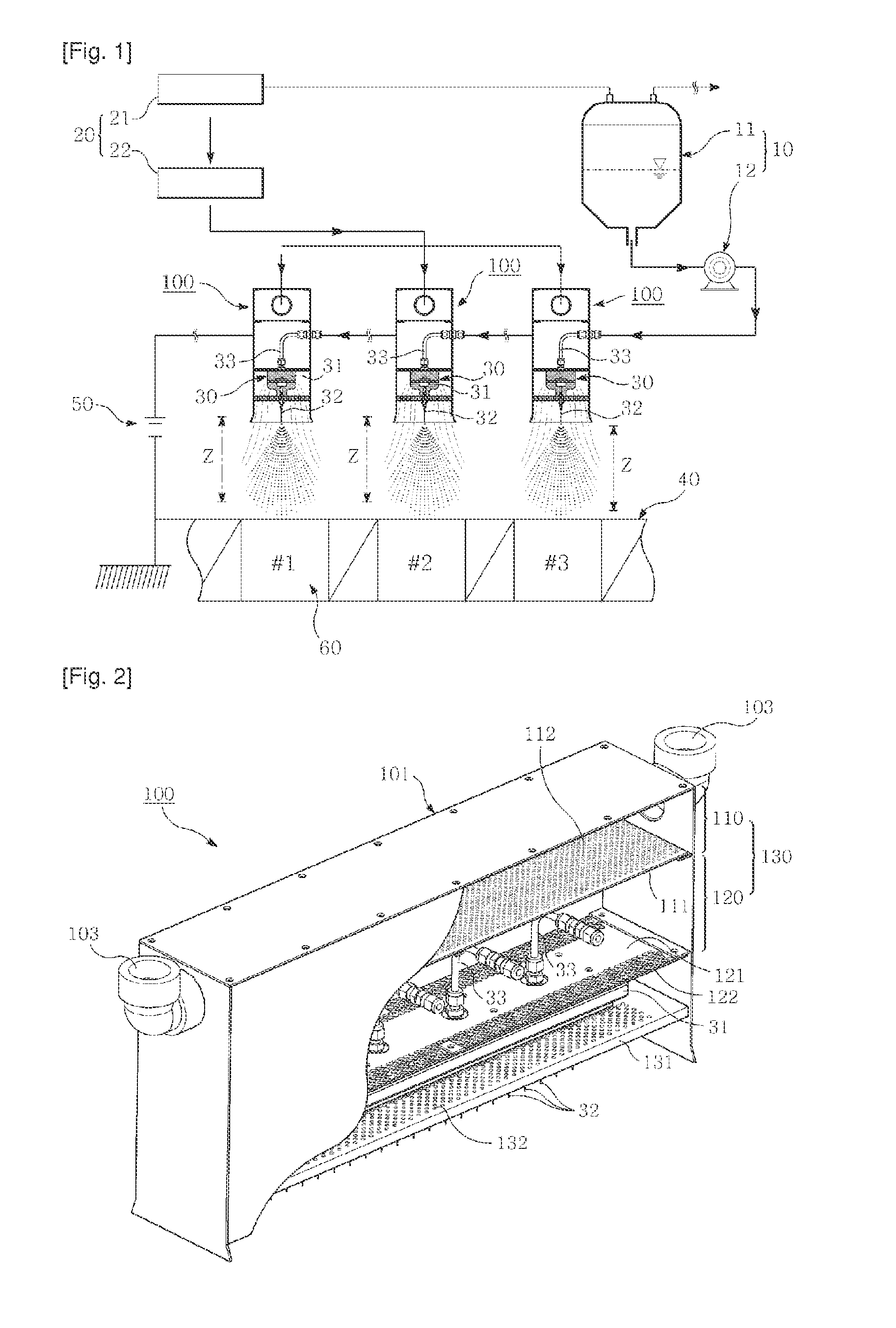

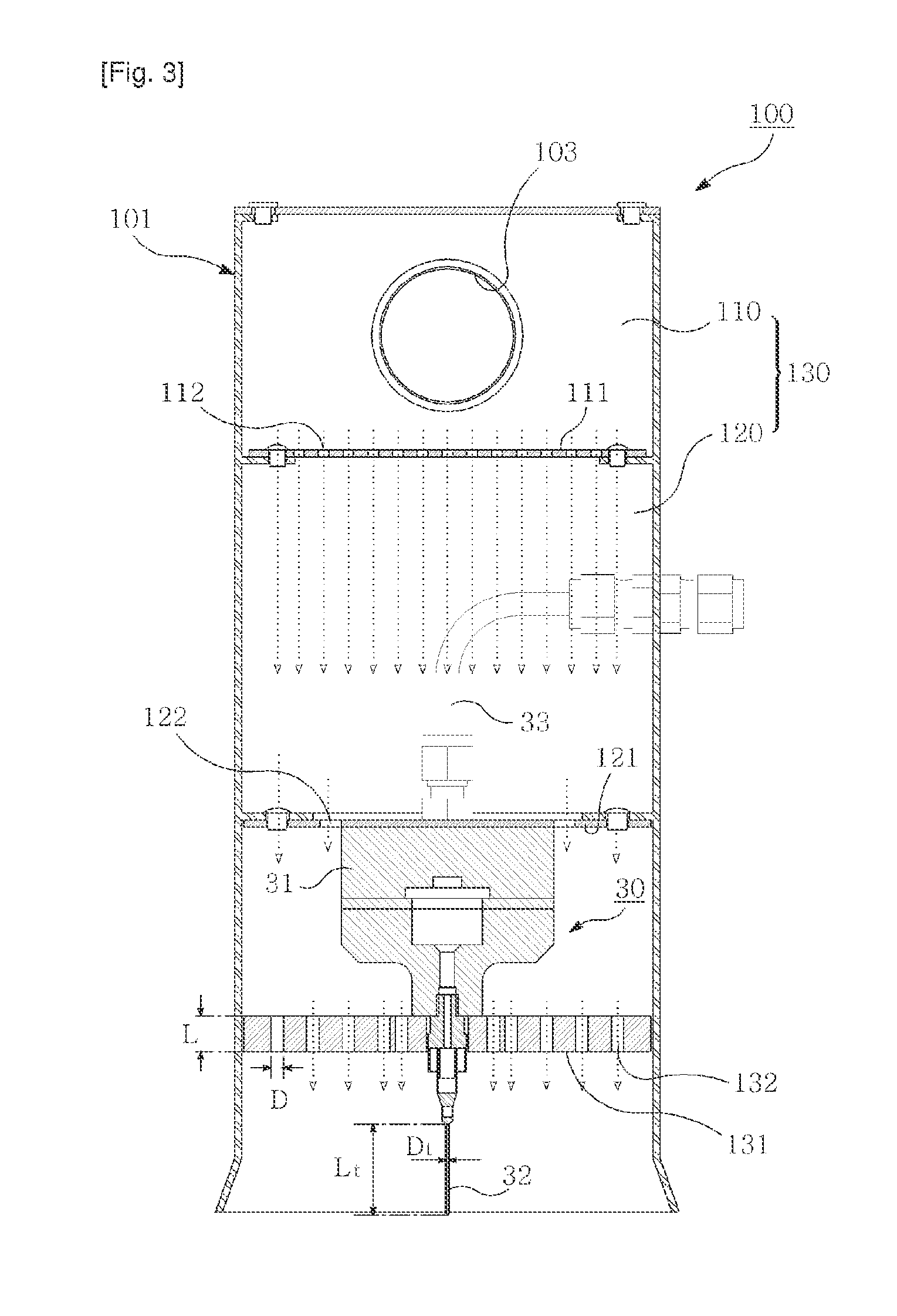

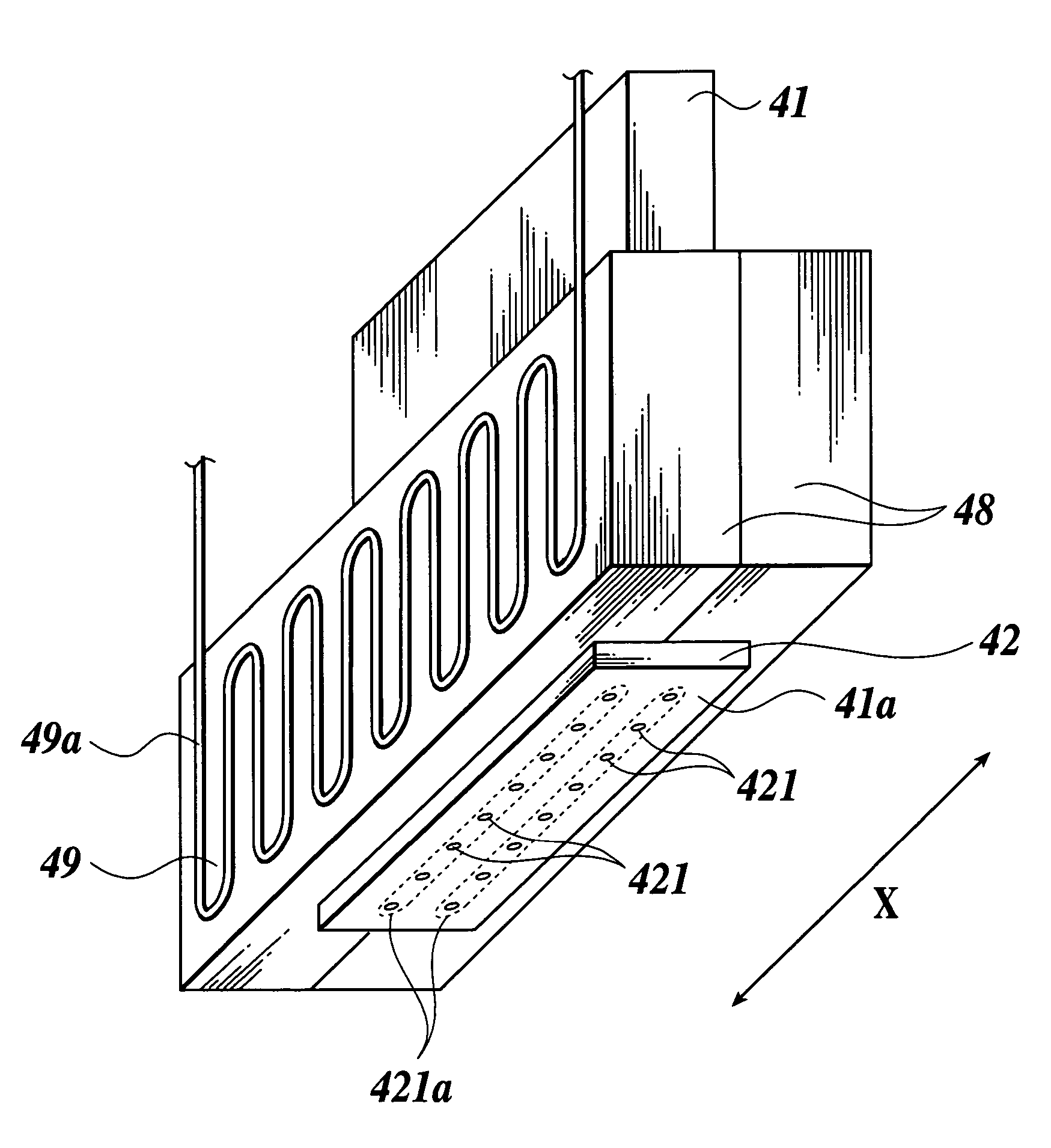

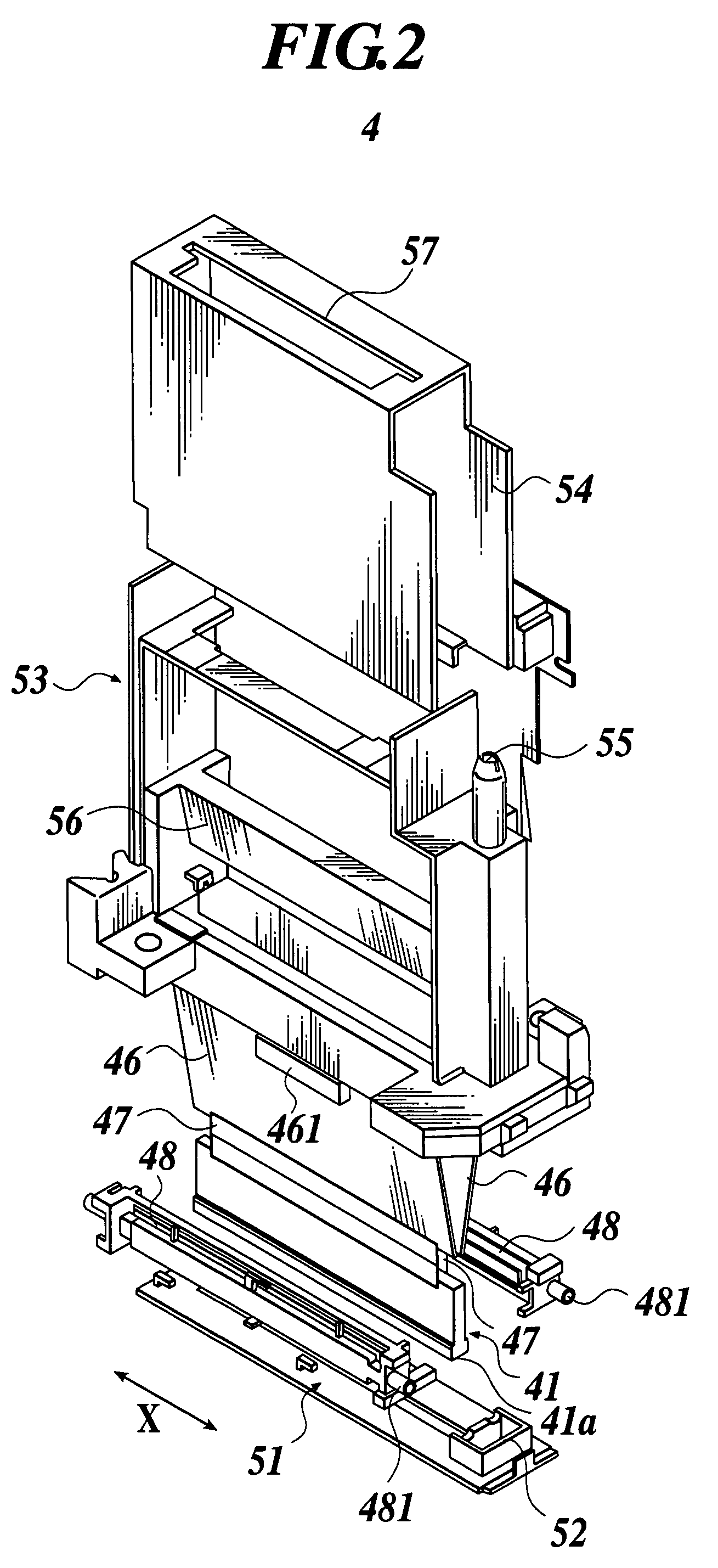

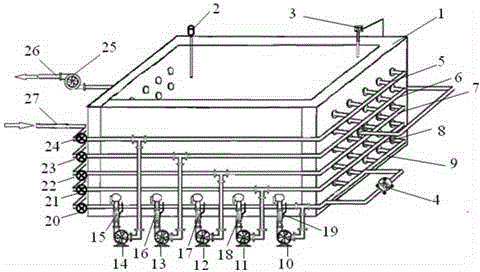

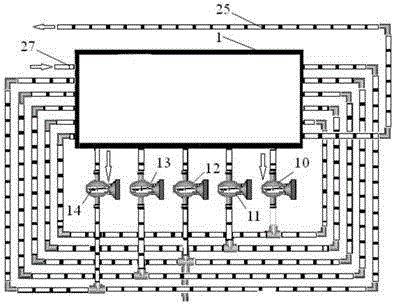

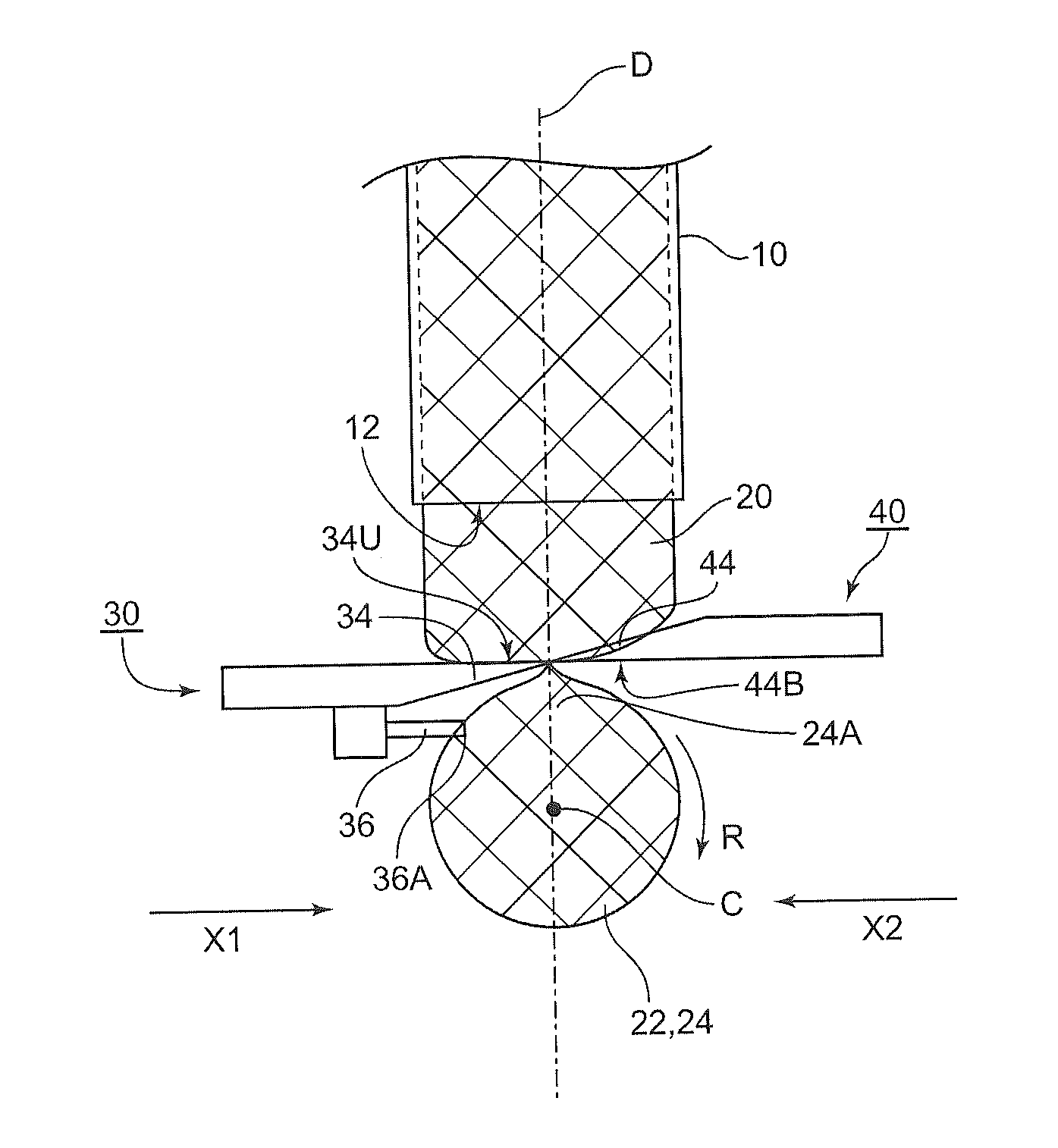

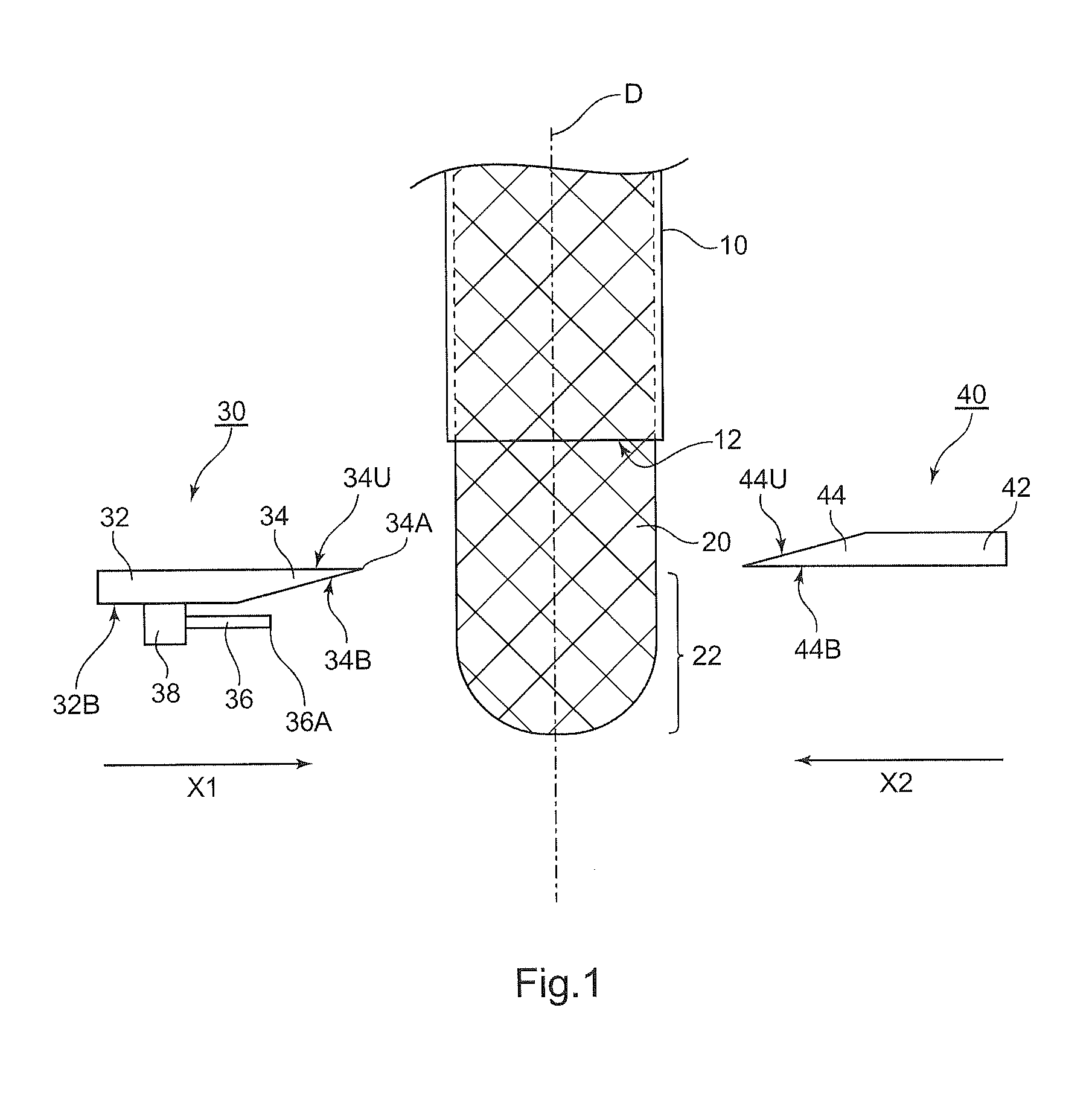

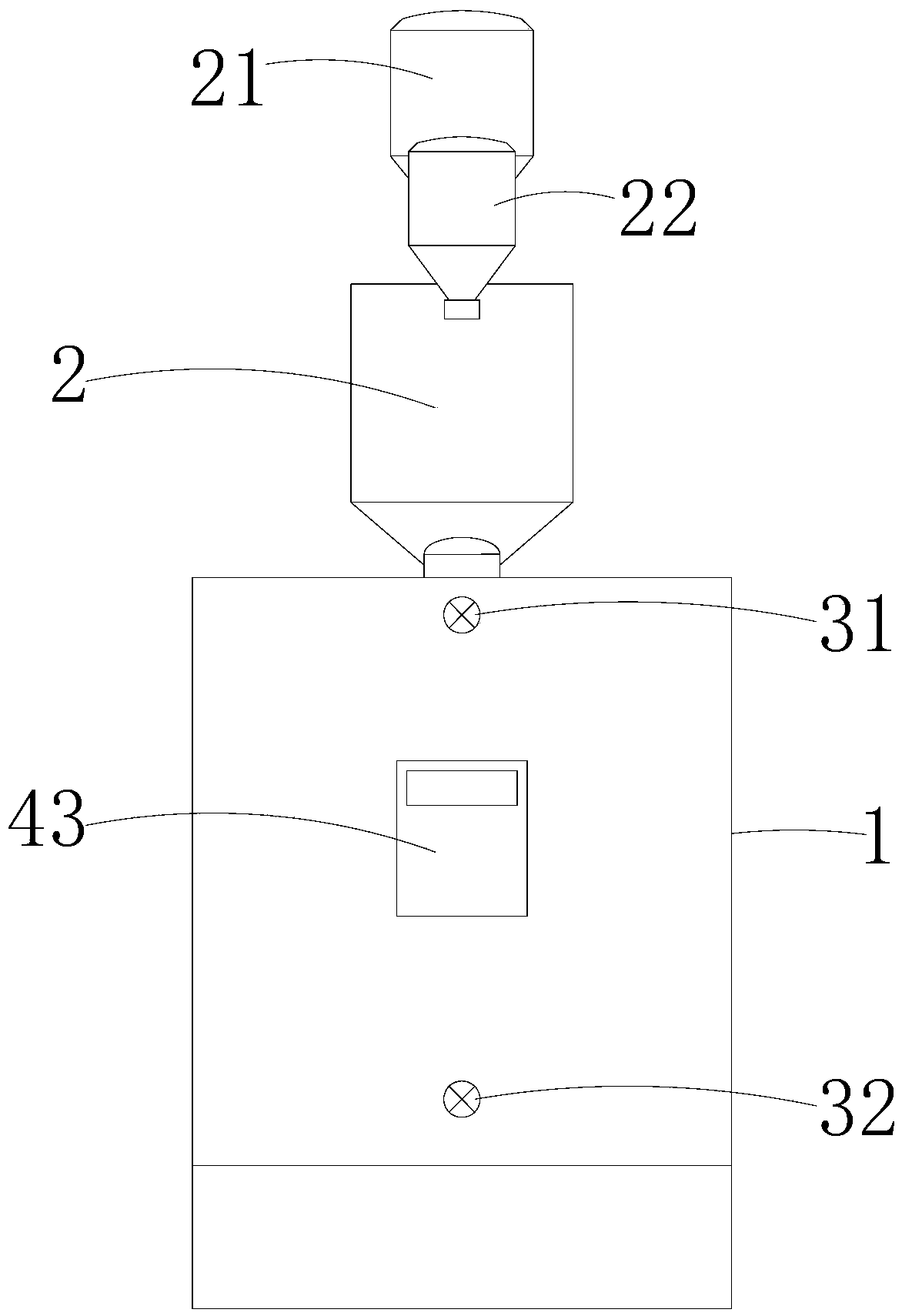

Electrospinning apparatus for producing nanofibres and capable of adjusting the temperature and humidity of a spinning zone

InactiveUS20130011508A1Uniform and small diameterImprove productivityConfectioneryWood working apparatusThermodynamicsSpinning

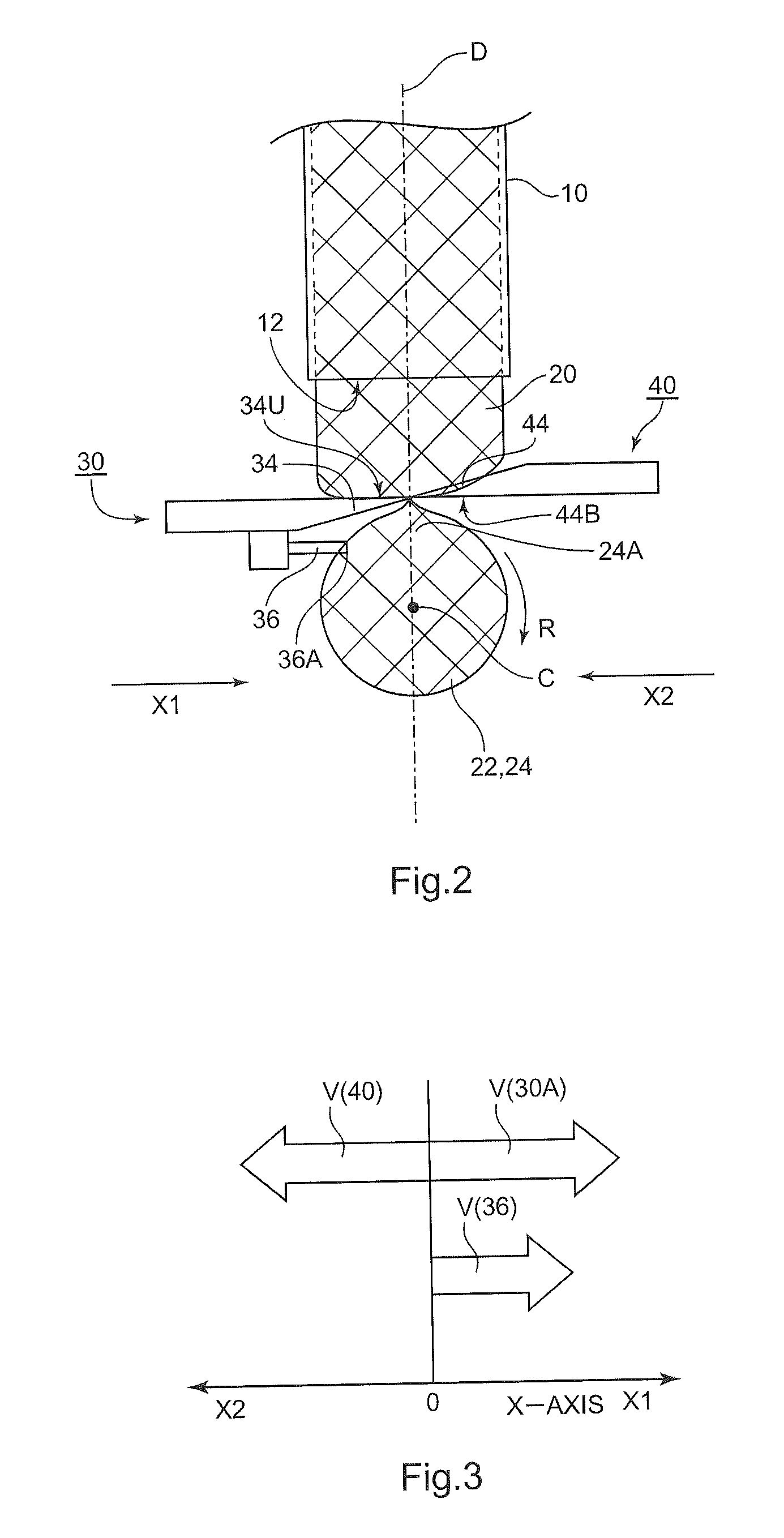

Provided is an electrospinning apparatus for producing nanofibers, including: a spinning solution supply unit (10); a spinning unit (30) that includes spinning nozzles (32) and a nozzle block (31) in which the spinning nozzles (32) are equidistantly arranged and supported; a nanofiber-collecting unit (40) which collects nanofibers spun from the spinning unit (30); a power supply (50) which forms an electric field in a spinning zone (Z); a process gas supply unit (20) which generates and supplies process gas to control the temperature and humidity of the spinning zone (Z) to a range appropriate for electrospinning conditions for nanofibers; and a process gas laminar flow distribution device (100) which fractionates the process gas supplied from the process gas supply unit (20), into laminar flows within the process gas laminar flow distribution device (100), and distributes the process gas from an upper portion of the spinning unit (30) to the spinning zone (Z).

Owner:FIBRANE

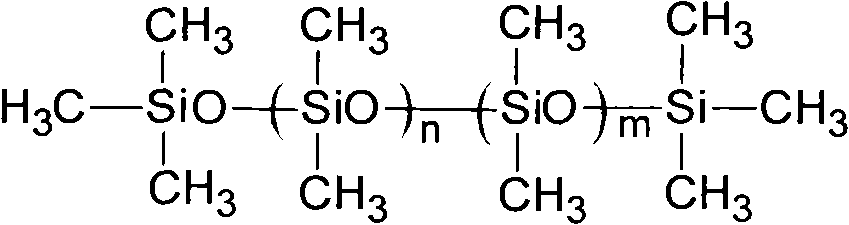

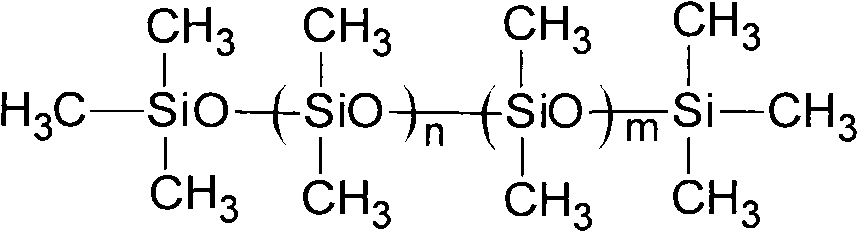

Silicone oil electric force compound grease and preparation method thereof

InactiveCN102024505AImprove high temperature resistanceImprove low temperature resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilicone oilMetal powder

The invention discloses electric force compound grease and a preparation method thereof. The silicone oil electric force compound grease mainly comprises silicon oil, white carbon black and conductive metal powder, wherein the white carbon black is subject to surface treatment with a lipophilic processing agent. The silicone oil electric force compound grease comprises the following components in parts by weight: 100 parts of silicon oil, 20-33 parts of precipitated silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent, or the silicone oil electric force compound grease is also composed of the following components in parts by weight: 100 parts of silicon oil, 10-15 parts of fumed silica subject to the surface treatment with the lipophilic processing agent, 65-90 parts of conductive metal powder, 0-2 parts of stabilizing agent and 0-2 parts of anti-oxygen agent. The silicone oil electric force compound grease disclosed by the invention has the advantages of high dropping point temperature, good attachment property, stable rationalizing property, long service life and good economic property.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV +2

Production of foamed aluminium alloy deformed piece by secondary foam

The invention carried out a process to produce foamed aluminium alloy with the secondary foaming. The process is: first to melt the aluminium alloy and add the Ca into the molten, then adding into the titanium hydride to get the first foamed aluminium alloy, next to heat the first alloy and make it preformed unit, last to foam the preformed unit and cool to get the secondary foamed aluminium alloy.

Owner:SOUTHEAST UNIV

Inkjet head

ActiveUS7207641B2Uniform ink dropletsUniform viscosityOther printing apparatusEngineeringThermal contact

An inkjet head having: an inkjet head chip having ink jetting openings which are lined up to form a nozzle row on a front surface of the inkjet head chip; a manifold attached securely to a side of the inkjet head chip and leading ink to the inkjet head chip; and an ink heater which is in thermal contact through the manifold with ink in the manifold and which varies in heat generation density in a direction of the nozzle row.

Owner:KONICA MINOLTA INC

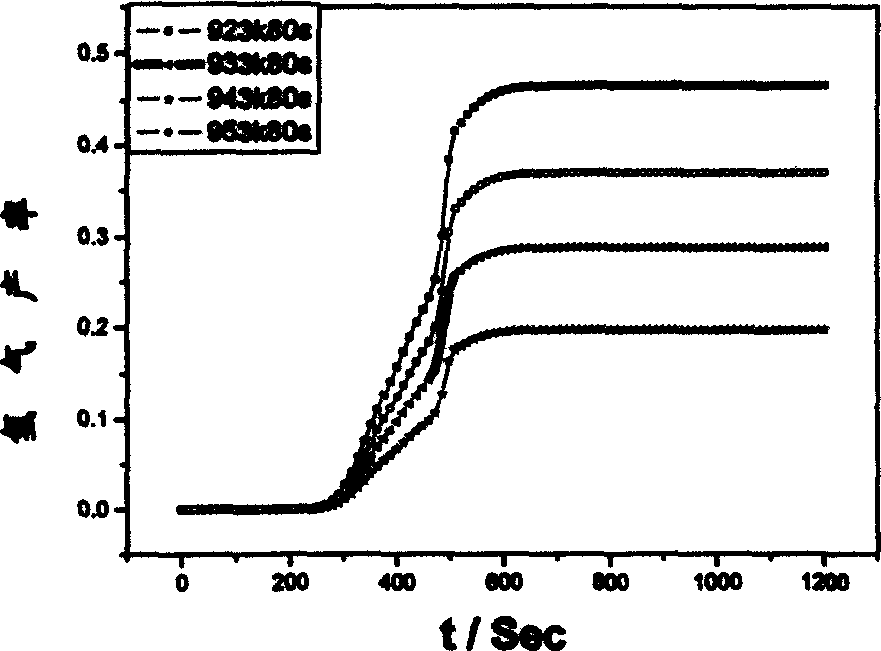

Polyacrylonitrile copolymer spinning solution and preparation method thereof

ActiveCN103421141AImprove the forceEnhanced mass transferFibre chemical featuresSpinning solutions preparationPolymer scienceAcrylonitrile

The invention relates to a polyacrylonitrile copolymer spinning solution and a preparation method thereof. In the invention, copolymerization reaction is performed on acrylonitrile in a tubular reactor containing a static mixer component; the tubular reactor, which contains the static mixer component and has the characteristics of mass transfer, efficient heat transfer, continuous and stable reaction and no mechanical stirring, is adopted to prepare the polyacrylonitrile copolymer spinning solution with high molecular weight and narrow molecular weight distribution. The polyacrylonitrile copolymer spinning solution is obtained after copolymerization reaction is performed on reaction liquid composed of monomers, a radical initiator and a solvent, wherein the percent concentration by weight of the monomers in the reaction liquid is 15% to 20%; the weight of the radical initiator is 0.4% to 1% of that of the monomers; the solvent is in balancing amount; the monomers are an acrylonitrile monomer and a comonomer. The dynamic viscosity of the polyacrylonitrile copolymer spinning solution provided by the invention is 200 to 800 Pa.S, and the molecular weight distribution is 1.5 to 2.6.

Owner:INST OF CHEM CHINESE ACAD OF SCI

High-elongation special-shaped polyamide fiber 66 and production method thereof

ActiveCN106811818AProcess stabilityUniform viscosityNew-spun product collectionMonocomponent copolyamides artificial filamentChemistryFormic acid

The invention discloses high-elongation special-shaped polyamide fiber 66 and a production method thereof. The production method includes steps of nylon 66 saline solution, high-temperature concentration, high-pressure reaction, flash depressurization, fusion continuous polymerization, spinning, cooling, oiling, second-time drafting, loosening thermoforming and winding. Formic acid relative viscosity of the polyamide fiber 66 is 72-80, breaking strength is 3.0-4.0g / D, elongation at break is 40-50%, hot air shrinkage percentage of 177 DEG Cx2min is 3.0-5.0%, and monofilament linear density is 6-20dtex. The h igh-elongation special-shaped polyamide fiber 66 has the advantages of moderate strength, light weight, fatigue resistance, impact resistance, wear resistance, softness and easiness in processing, thereby being widely applied in the field of high-grade sports goods; a gap in the high-elongation special-shaped polyamide fiber 66 is filled in, and quality of the polyamide fiber 66 is up to international advanced level, so that the polyamide fiber 66 has high social and economic benefit.

Owner:SHEN MA INDUSTRY CO LTD

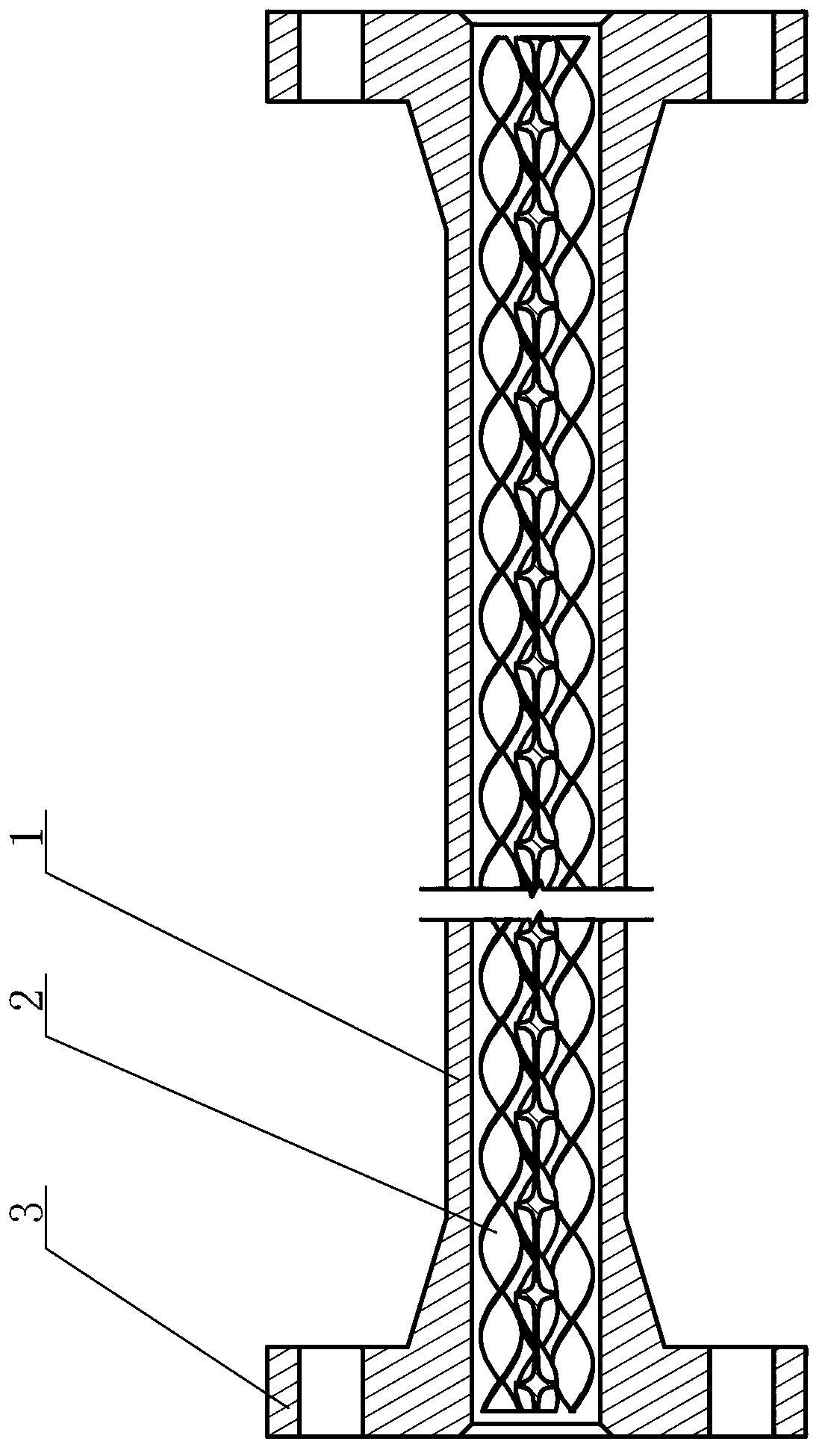

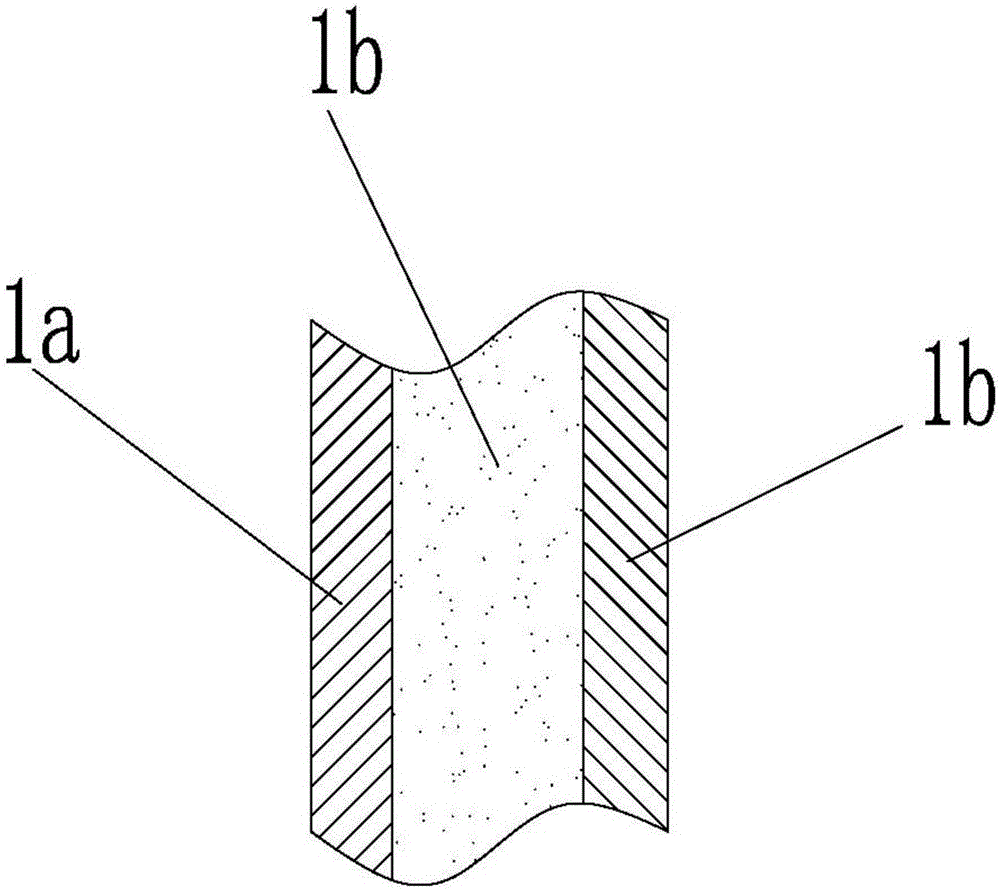

Spiral low-shear static mixer

InactiveCN103252182AAvoid mechanical shearComponent distribution is evenFlow mixersPulp and paper industryStatic mixer

The invention discloses a spiral low-shear static mixer, relates to a static mixer and in particular relates to a spiral low-shear static mixer. The invention aims to solve the problem that the conventional static mixer is high in viscosity loss and non-ideal in uniform mixing effect. The spiral low-shear static mixer comprises a tube shell and seven spiral mixing units, wherein the seven spiral mixing units are inserted into the tube shell; and the central line of each spiral mixing unit along the length direction is parallel to the central line of the tube shell along the length direction. The spiral low-shear static mixer is used for mixing polymer mother solution and water.

Owner:HARBIN BOHUA TECH

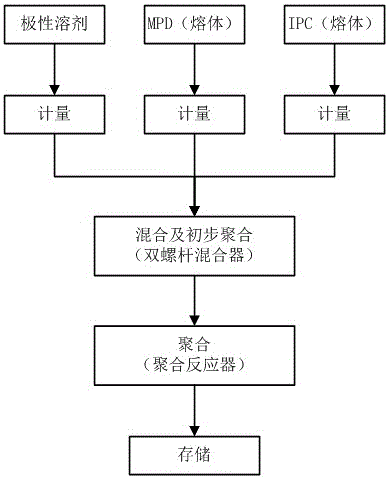

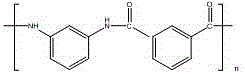

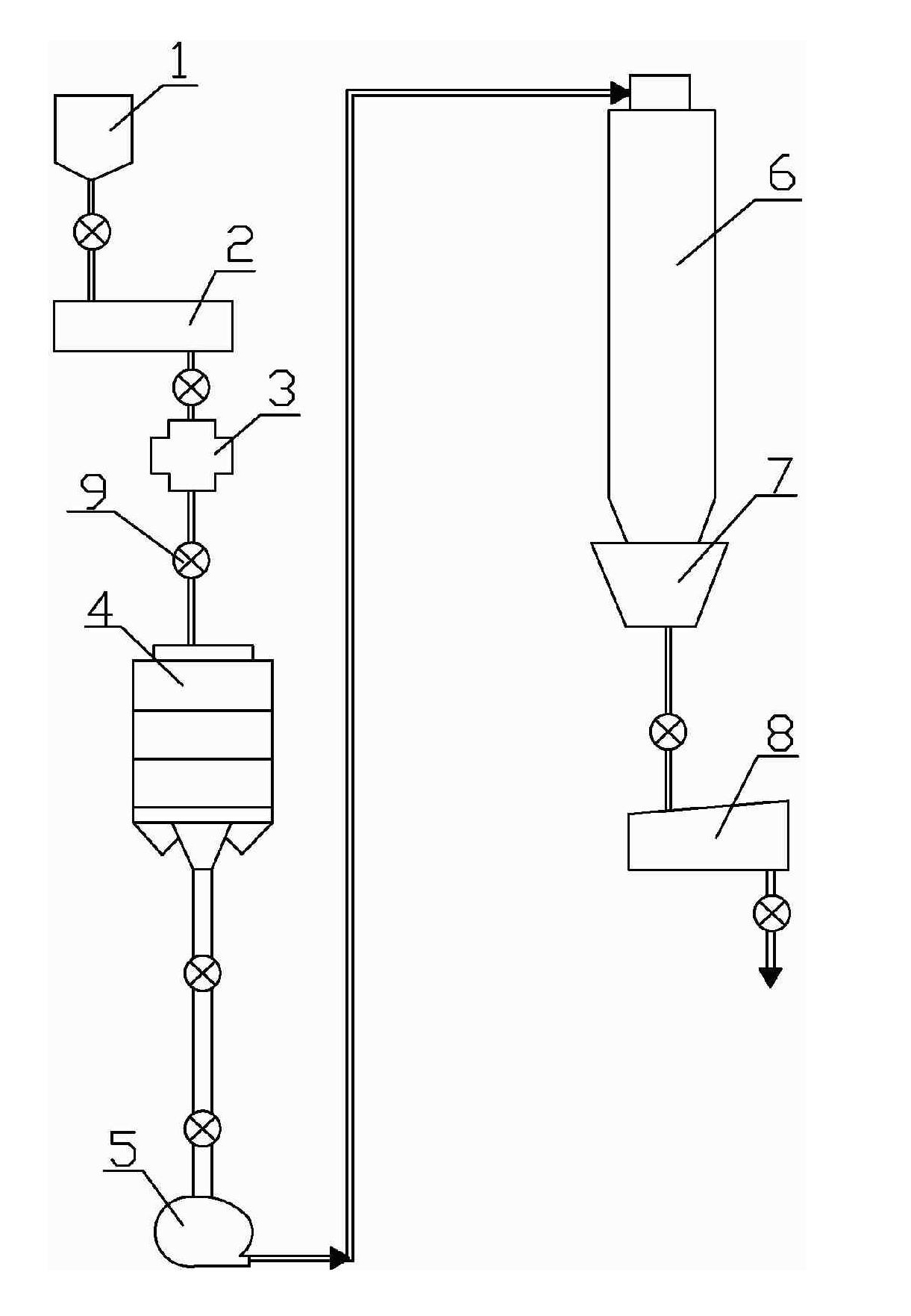

Method for continuously preparing highly-pure poly(m-phenylene isophthalamide) resin solution

The invention relates to a method for continuously preparing a highly-pure poly(m-phenylene isophthalamide) resin solution. The method comprises the following steps: respectively metering and conveying a polar solvent, m-phenylenediamine and m-phthaloyl chloride, allowing above materials to enter a double screw mixer, mixing the materials, carrying out a preliminary reaction to generate oligomer, allowing the oligomer to enter a polymerization reactor from the bottom end, continuously carrying out the reaction for a period of time, and allowing the formed poly(m-phenylene isophthalamide) resin solution to flow out from the upper lateral part of the polymerization reactor. The method can reduce at least one double screw reactor needed in the prior art, reduces the device investment cost, and realizes continuous preparation of the poly(m-phenylene isophthalamide) resin solution with uniform viscosity and high purity.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

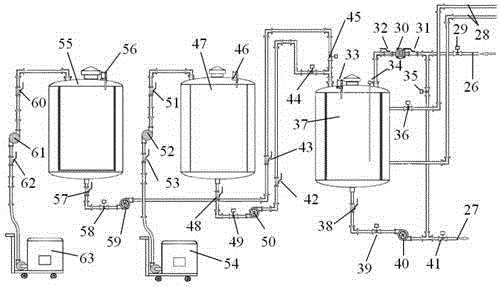

Glue solution circulation equipment used for large-scale honeycomb core glue dipping technology

The invention relates to glue solution circulation equipment used for a large-scale honeycomb core glue dipping technology. The glue solution circulation equipment comprises an inner circulation system and an outer circulation system of a glue tank, wherein the inner circulation system of the glue tank is characterized by comprising the glue tank, a temperature sensor, a liquid sensor and a circulation pipeline. The outer circulation system of the glue tank is characterized by comprising a raw agent tank and a liquid level sensor, a raw glue tank and a liquid level sensor, a glue mixing tank and a liquid level sensor, a temperature sensor, a movable tank car, a pneumatic valve, a glue supplementary tank, a glue return pump and the like. According to the automatic glue solution circulation equipment, the time needed for uniformly mixing a glue solution is short, the efficiency is high, the manual cost can be reduced, the operation is simple and convenient, the automation degree is high, the temperature, liquid level and viscosity of the glue solution of the glue tank can be automatically controlled, and the requirement for efficiently and uniformly impregnating large honeycomb cores in batches is satisfied.

Owner:AVIC COMPOSITES

Ni-mh battery positive electrode paste smelting and mixing process

InactiveCN109860512AThe refining process is simple and feasibleImprove filling uniformityElectrode manufacturing processesNickel accumulatorsNickel–hydrogen batteryIon

The present invention provides a Ni-mh battery positive electrode paste smelting and mixing process. Dry powder materials, a binder, a dispersing agent and deionized water are weighed in proportion, the dry powder materials are arranged in a smelting and mixing vessel for low-speed uniform mixing, the deionized water is added into the smelting and mixing vessel at twice, the mixture is subjected to stirring and paste scrapping, the binder and the dispersing agent are added into the smelting and mixing vessel in order for respective uniform stirring, and finally, the smelting and mixing vesselis subjected to vacuum supply while stirring to prepare a Ni-mh battery positive electrode paste, the amount of the deionized water added in the first time is 68-84% of the amount required by the deionized water, the amount of the deionized water added in the second time is the rest of the amount of the deionized water. The Ni-mh battery positive electrode paste smelting and mixing process is simple and feasible, can reduce the smelting and mixing time and is good in paste uniformity.

Owner:先进储能材料国家工程研究中心有限责任公司

Preparation method and using method of anti-stripping exterior wall putty powder

The invention discloses a preparation method and a using method of anti-stripping exterior wall putty powder. The preparation method comprises the following steps of: step one, adding 6-8 parts of talcum powder, 2-4 parts of white bentonite and 12-14 parts of white portland cement to a pulverizer so as to be pulverized to obtain powder less than 150 meshes; step two, mixing the obtained powder, 40-44 parts of diatomite, 7-9 parts of high-strength gypsum powder and 6-8 parts of titanium dioxide, placing the mixture in a pulverizer so as to be pulverized for 10-15 minutes, then adding 2-3 parts of hydroxypropyl methyl cellulose, and pulverizing for 5-10 minutes again; step three, sieving the powder obtained in the step two by using a screen mesh with 320 meshes, wherein sieve residue is the anti-stripping exterior wall putty powder. The using method comprises the following steps of: placing the anti-stripping exterior wall putty powder in a container, adding water to the putty powder in the proportion of the exterior wall putty powder to the water being 10: (2-3), adding a right amount of pigment according to the color of an exterior wall, soaking for 40-60 minutes, and then stirring the mixture for 5-10 minutes by adopting a stirrer for blade coating.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

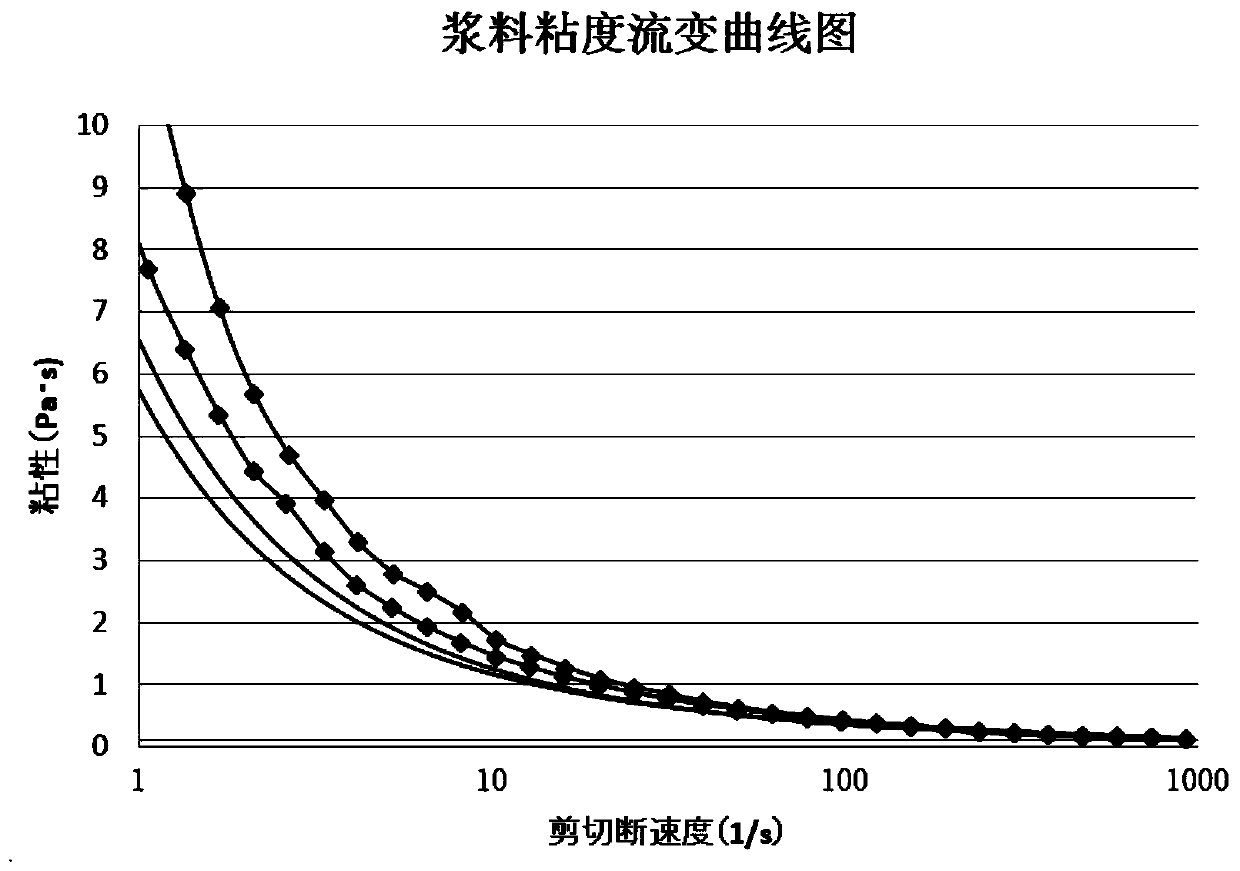

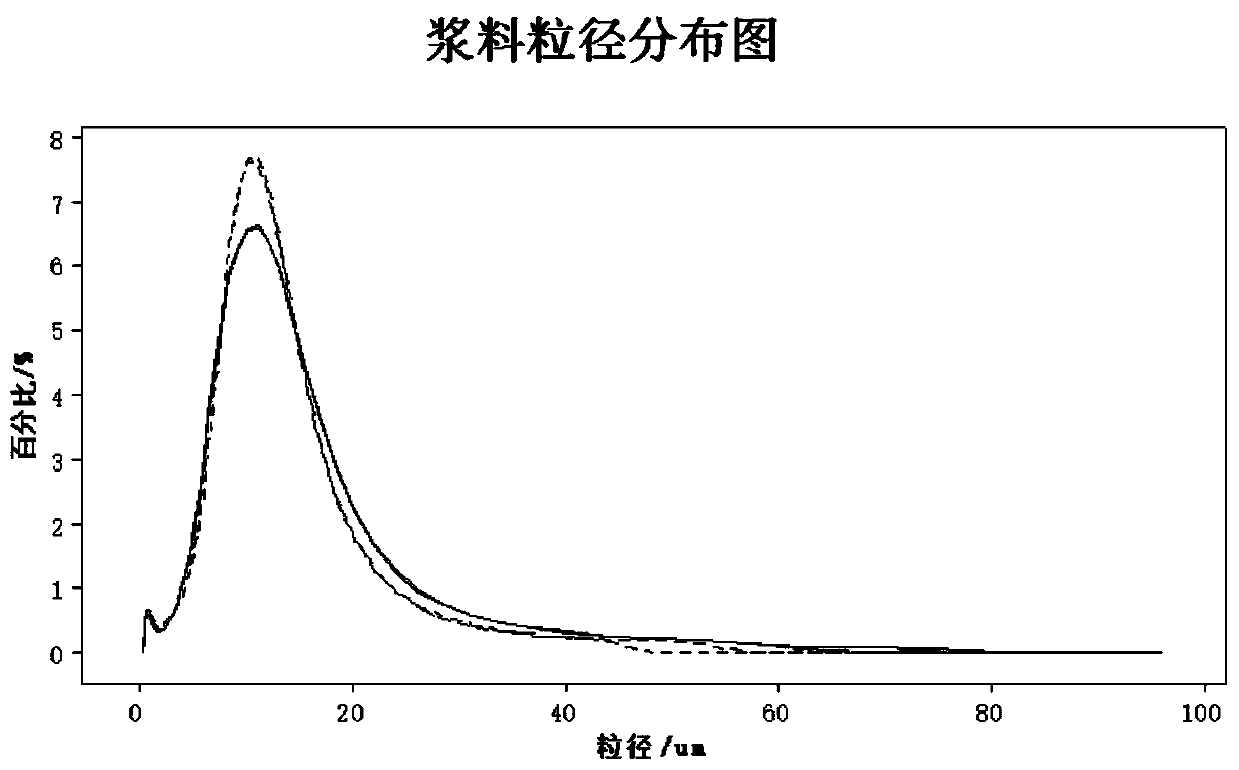

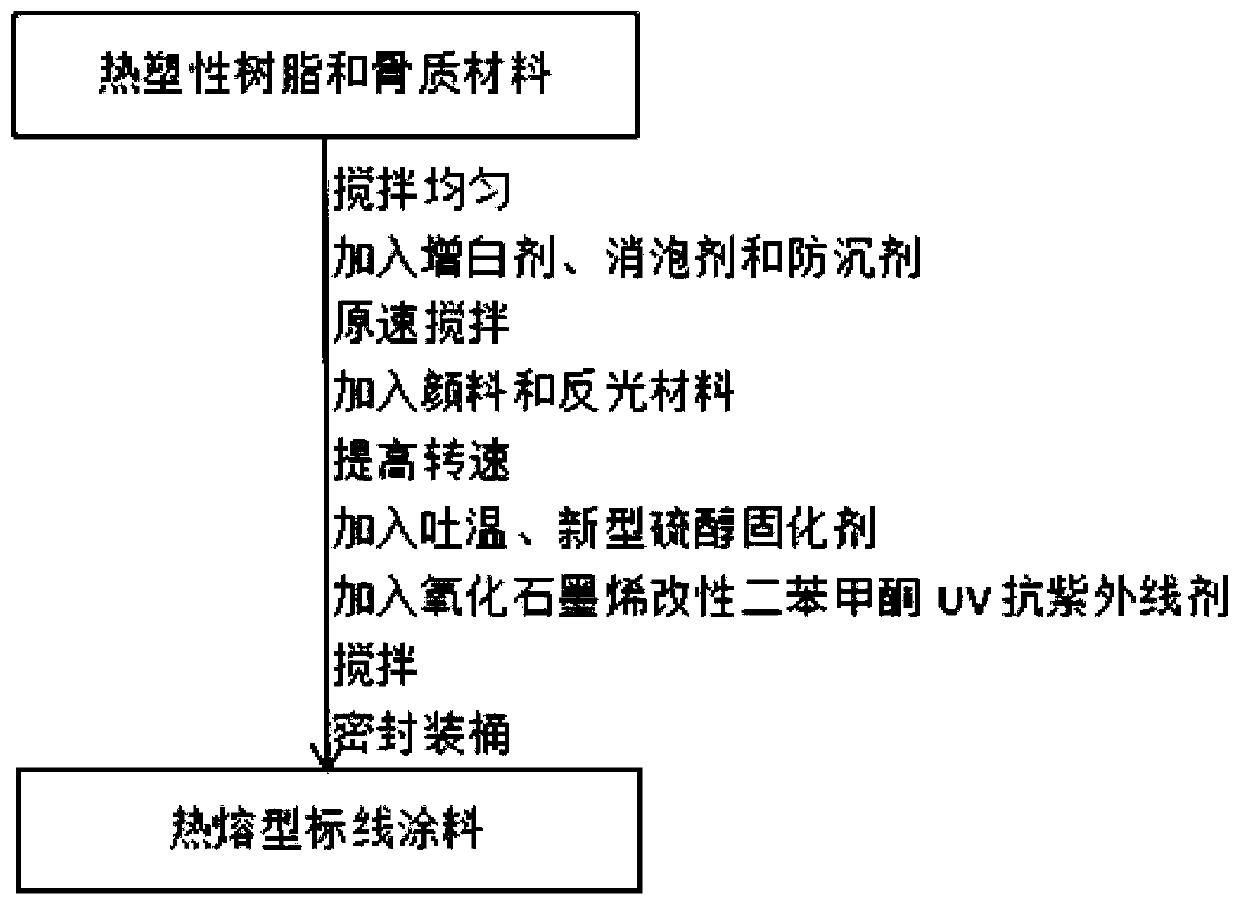

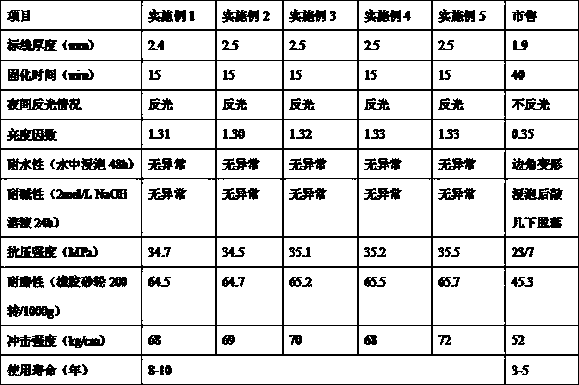

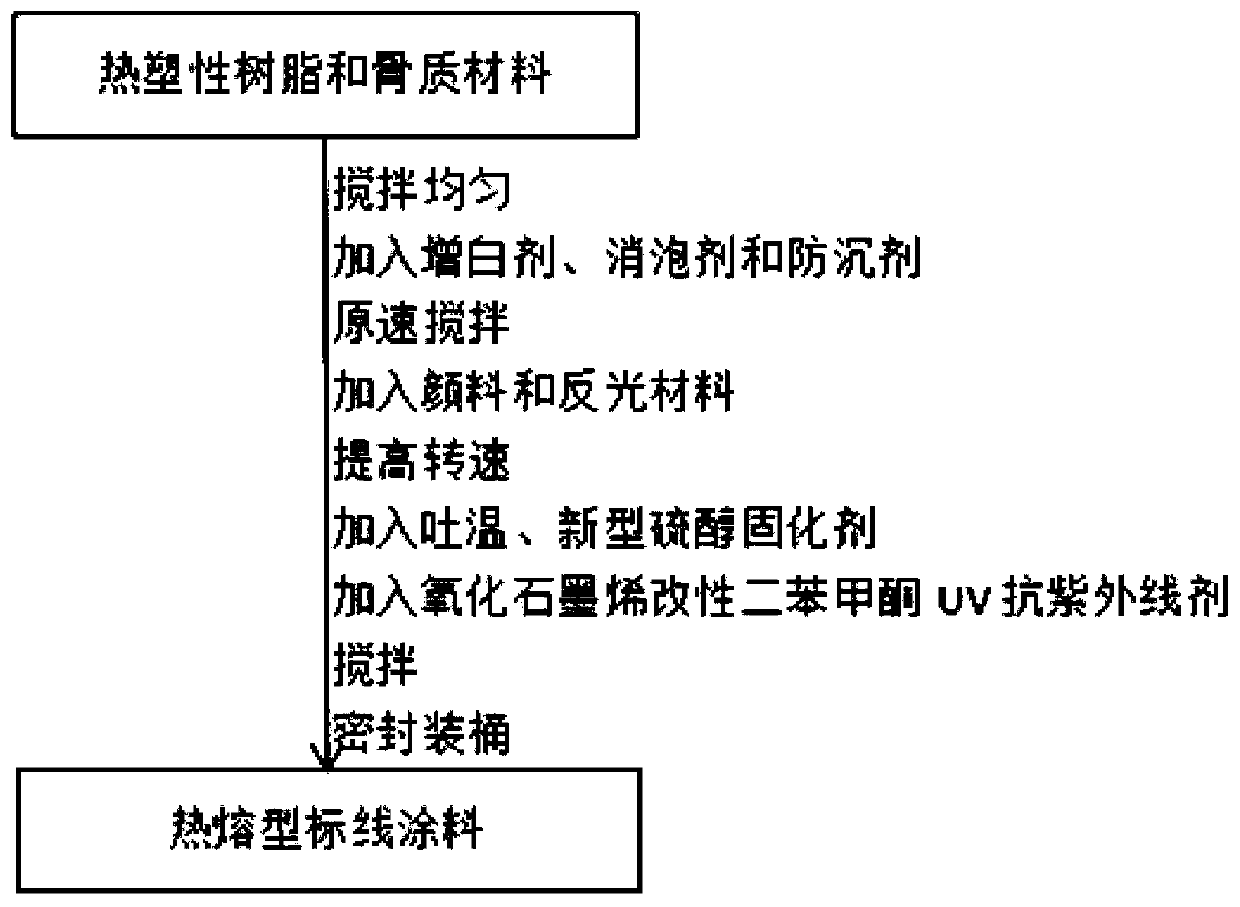

Hot-melt-type marking coating and preparation method thereof

InactiveCN109971296AImprove tensile propertiesIncrease elasticityAntifouling/underwater paintsRosin coatingsWhitening AgentsHot melt

The invention provides a hot-melt-type marking coating. The coating is prepared from, by weight, 80-120 parts of thermoplastic resin, 20-40 parts of a bone material, 5-15 parts of pigments, 3-10 partsof a reflective material, 0.02-0.05 part of a whitening agent, 0.01-0.03 part of a defoaming agent, 2-6 parts of a novel mercaptan curing agent, 1-2 parts of an anti-settling agent, 1-4 parts of Twain and 0.03-0.06 part of a graphene-oxide-modified benzophenone UV anti-ultraviolet agent. The hot-melt-type marking coating prepared by means of the method has the advantages of being short in film forming and curing time and drying time, good in stain resistance, great in dustproof property, excellent in reflection effect, uniform in viscosity and good in anti-shedding performance after long-termstorage, safe, environmentally friendly, long in service life and the like, and has a broad application prospect.

Owner:天华交通建设集团有限公司

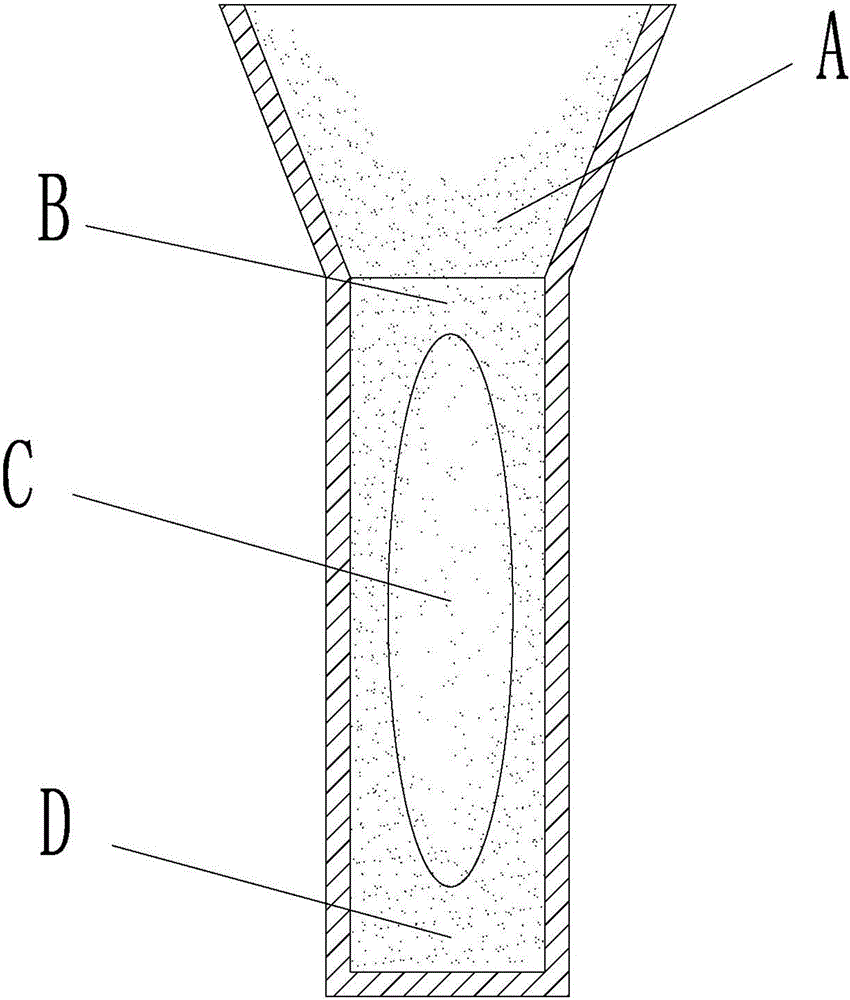

Method for manufacturing glass blank, method for manufacturing magnetic recording medium substrate and method for manufacturing magnetic recording medium

InactiveUS20110283739A1Small thickness deviationImprove flatnessGlass drawing apparatusGlass forming apparatusMolten glassRecording media

Provided are a method of manufacturing a glass blank, the method including press-molding a molten glass gob under a state in which a separation mark formed on an upper surface of the molten glass gob faces at least one of the molding surface sides of a pair of press molds arranged facing each other in a horizontal direction, when the molten glass gob falls into a space between the pair of press molds, and a method of manufacturing a magnetic recording medium substrate and a method of manufacturing a magnetic recording medium, both using the glass blank.

Owner:HOYA CORP

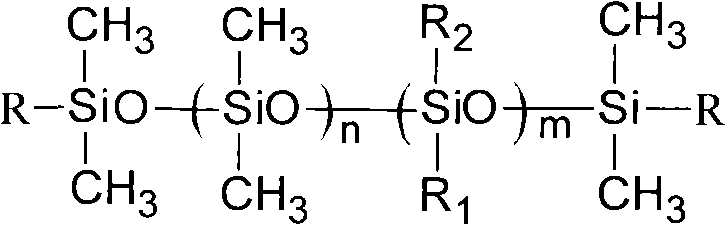

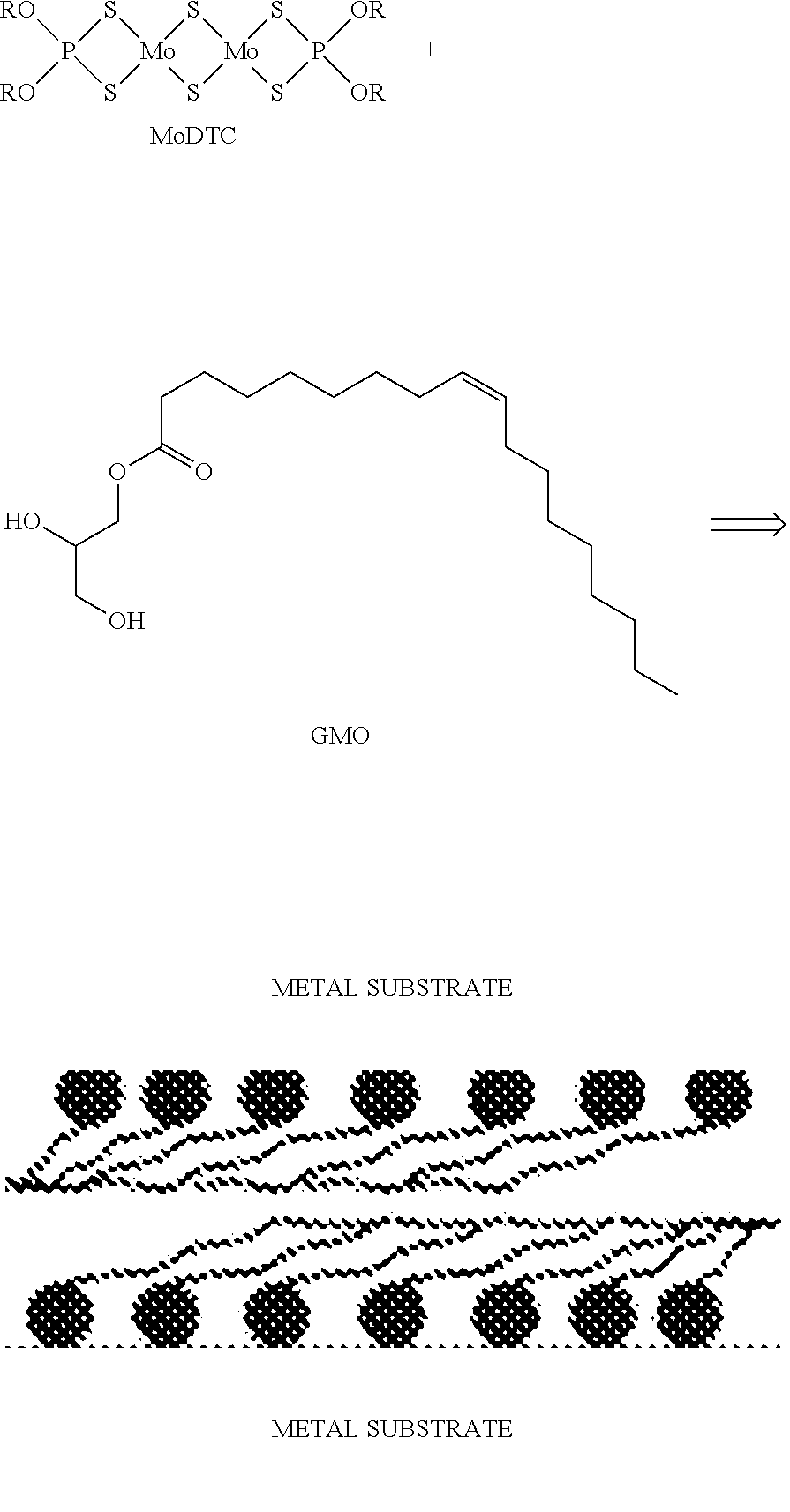

Diesel engine oil composition for improving fuel efficiency and endurance performance

ActiveUS20160108336A1Improve fuel efficiencyMaximizing friction reductionAdditivesFriction reductionPolystyrene

Disclosed is a novel diesel engine oil composition for fuel efficiency and endurance performance. The diesel engine oil composition may maximize frictional resistance and wear resistance by facilitating the formation of a lubricating film on a metal surface, extend an oil change cycle with excellent engine protection ability, and improve fuel efficiency due to friction reduction. The diesel engine oil composition include: base oil; a calcium-based or magnesium-based sulfonate detergent dispersant; a viscosity index improver selected from the group consisting of a diene copolymer, a polystyrene-diene copolymer and a hydrogenated polystyrene-diene copolymer; and a low friction agent including molybdenum dithiocarbamate (MoDTC) and glycerol monooleate (GMO).

Owner:HYUNDAI MOTOR CO LTD

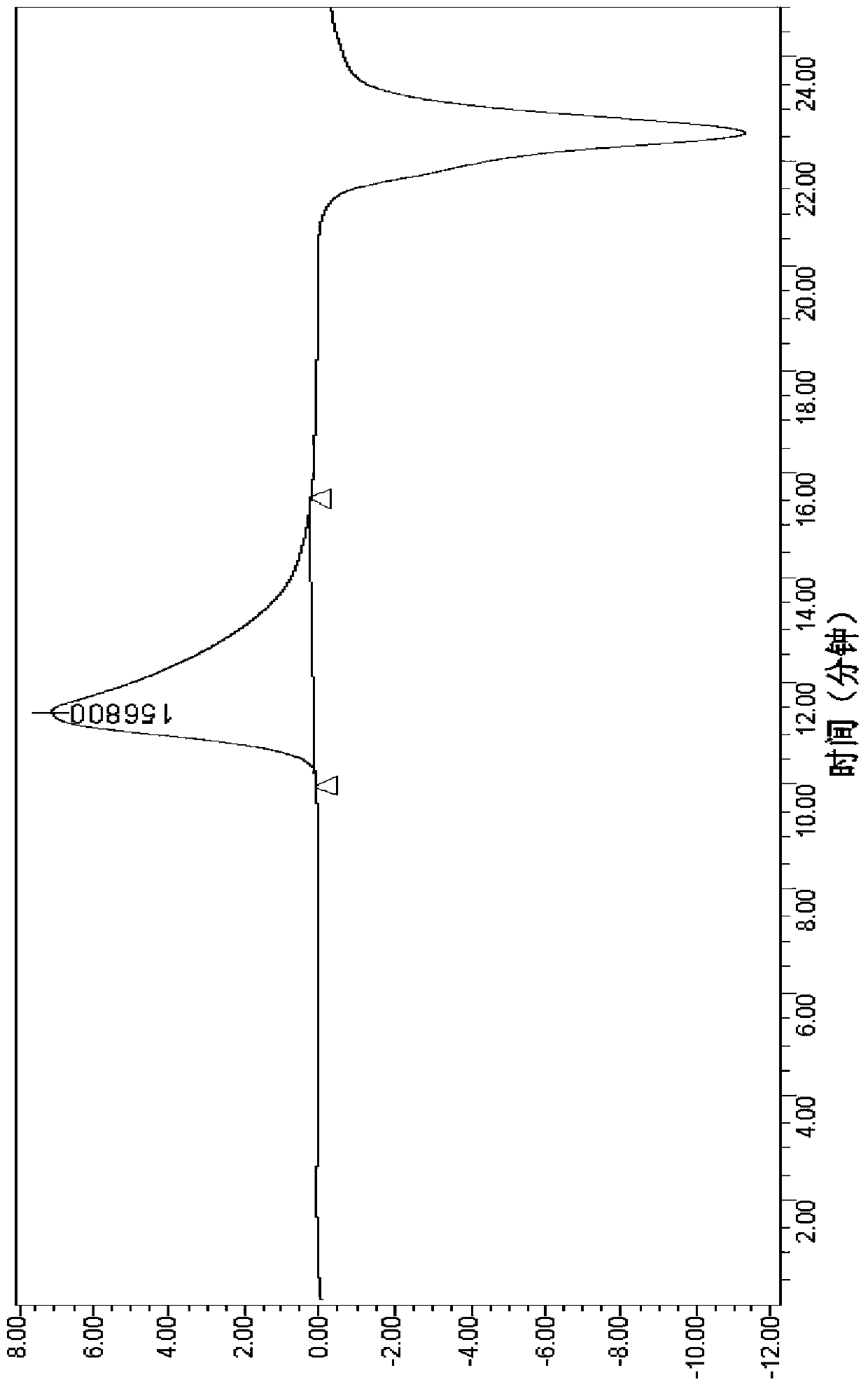

Preparation method of modified lithium ion battery graphite cathode material

InactiveCN106495143ALow curing temperatureUniform viscosityCarbon compoundsCell electrodesPhenolLithium-ion battery

The invention discloses a preparation method of a modified lithium ion battery graphite cathode material. Graphite and asphalt are crushed and mixed to obtain asphalt coated graphite precursor powder after heat treatment, and the asphalt coated graphite precursor powder is subjected to high-temperature heat treatment, natural cooling and then classification under protection of N2 to obtain modified graphite A. Water-soluble thermosetting phenol resin is diluted and heated, the modified graphite A is added into the resin, and the modified graphite A and the resin are sufficiently stirred to obtain solution B. The solution B is filtered, dried, cured, carbonized and classified to obtain the modified lithium ion battery graphite cathode material. Raw materials are cheap and easy to get, the preparation method is simple in process, mild in condition, convenient in operation and high in safety, the prepared material is excellent and stable, and performance parameter range is wide and easily controlled. The material has an application prospect in the field of electronic products, power vehicles, solar and wind power generation and the like.

Owner:SHANGHAI SHANSHAN TECH CO LTD +1

Coating for non-shrinkage-cavity fusion cast brick heating insulated feeder head

The invention relates to a coating for a non-shrinkage-cavity fusion cast brick heating insulated feeder head. The problems of fusion and bonding of a feeder head and a brick body and low utilization rate of the feeder head can be effectively solved. According to the technical scheme, the coating comprises a ground coating with which the inner surface of the heating insulated feeder head is coated and a surface coating with which the surface of the ground coating is coated. The ground coating is prepared from, by weight, 49-51% of a first composition and 49-51% of water, wherein the first composition is prepared from, by weight, 92-94% of graphite powder, 3.9-4.1% of cryolite, and 2.9-3.1% of bentonite; the surface coating is prepared from, by weight, 65-67% of a second coating, 4.4-4.6% of cryolite, 1.4-1.6% of iron oxide powder, 0.9-1.1% of bentonite and 2.9-3.1% of xanthan gum. The coating is reasonable in formula, effectively solves the problem of the post-casting fusion and bonding phenomenon, greatly recycles feeder head materials, and has the good social and economic benefits.

Owner:郑州远东耐火材料有限公司

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

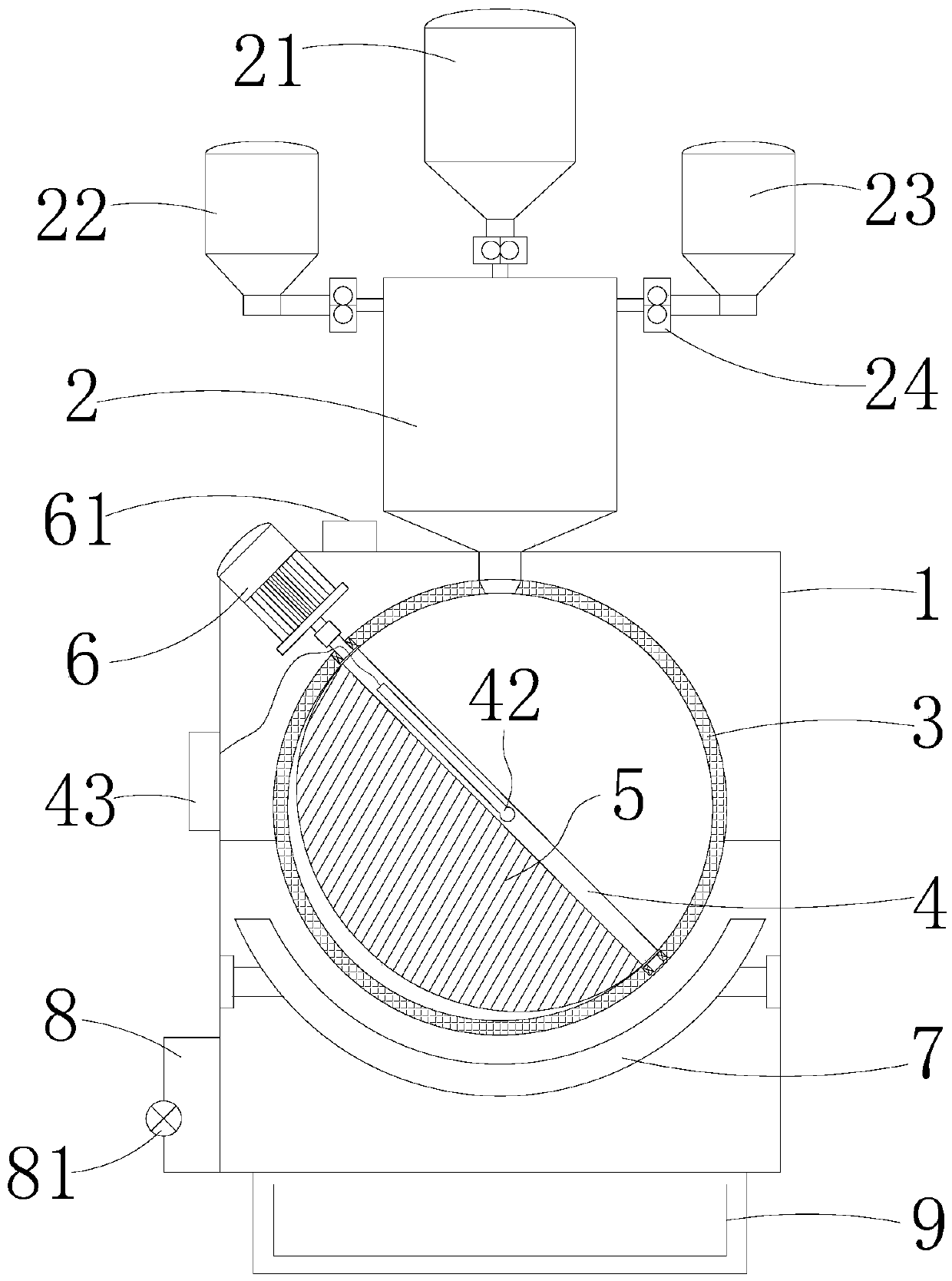

Gelatin melting device with controllable gelatin solution viscosity

ActiveCN105498605AViscosity is easy to controlReasonable structureTransportation and packagingMixer accessoriesElectricityCombustion

The invention discloses a gelatin melting device with controllable gelatin solution viscosity. The gelatin melting device comprises a furnace body, a static stirring device, a spherical heating furnace, a rotating rod, a viscometer, a semicircular stirring plate, a motor, a combustion grate, an air supply device and a collection box, wherein the static stirring device is fixedly mounted at the upper end of the furnace body; a gelatin charging barrel, a pure water charging barrel and an auxiliary charging barrel are mounted on the static stirring device; a metering pump is connected between the static stirring device and each of the gelatin charging barrel, the pure water charging barrel and the auxiliary charging barrel; the spherical heating furnace is mounted in the furnace body; the rotating rod is obliquely mounted in a cavity of the spherical heating furnace; the semicircular stirring plate is fixedly connected with the rotating rod; the viscometer is fixedly connected onto the rotating rod and electrically connected with a viscosity indicator; the combustion grate is mounted below the spherical heating furnace; the air supply device is mounted on the side edge of the lower end of the furnace body. The gelatin melting device is simple in structure and realizes the effects that the viscosity of a pharmaceutical gelatin solution is controllable and a gelatin dipping forming effect is improved.

Owner:ZHEJIANG SHICHENG CAPSULE CO LTD

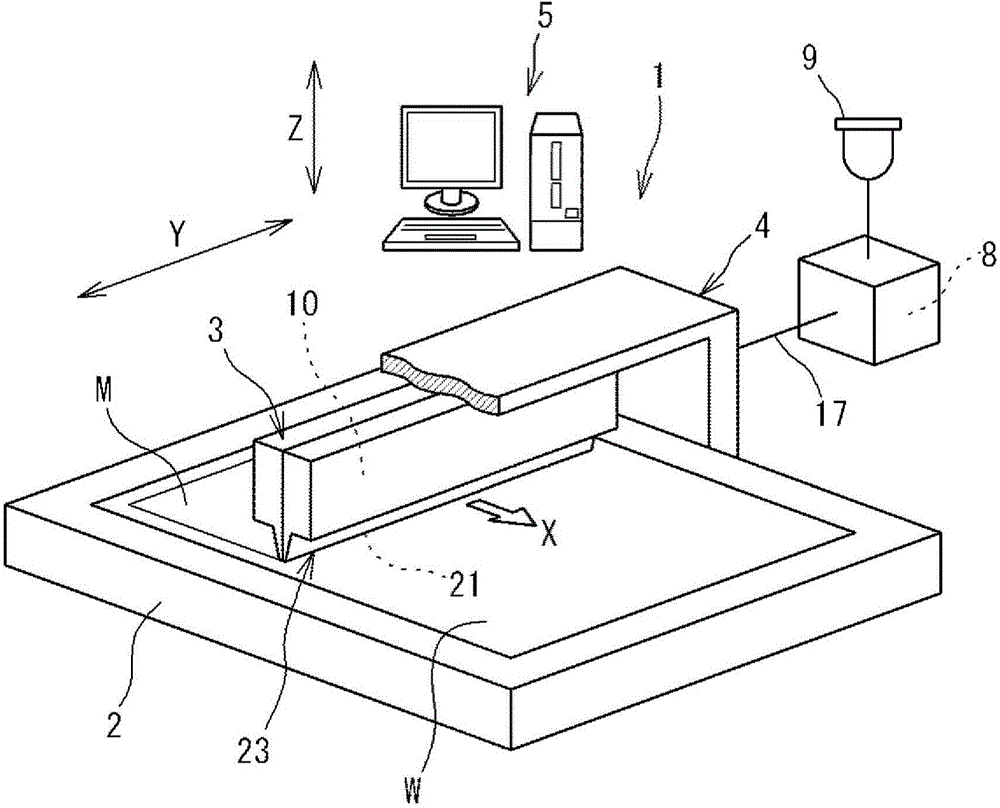

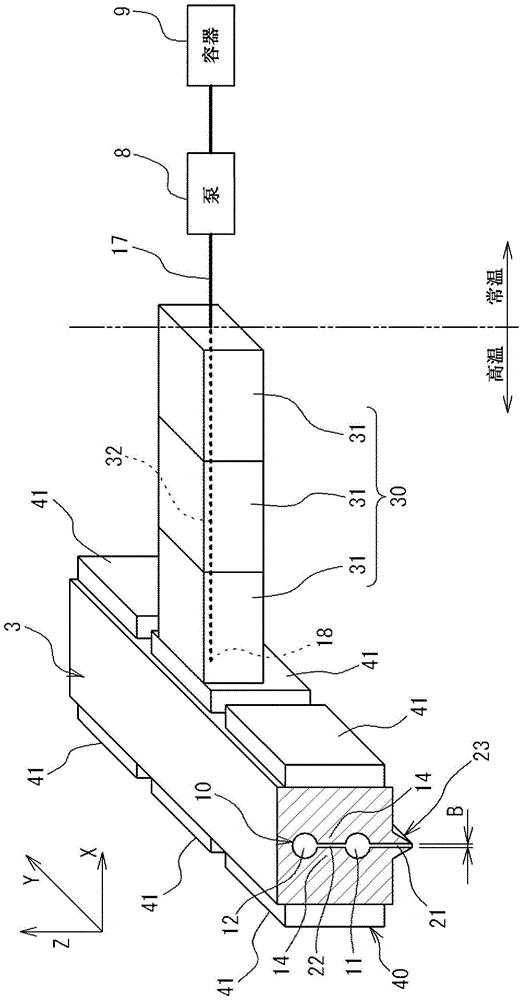

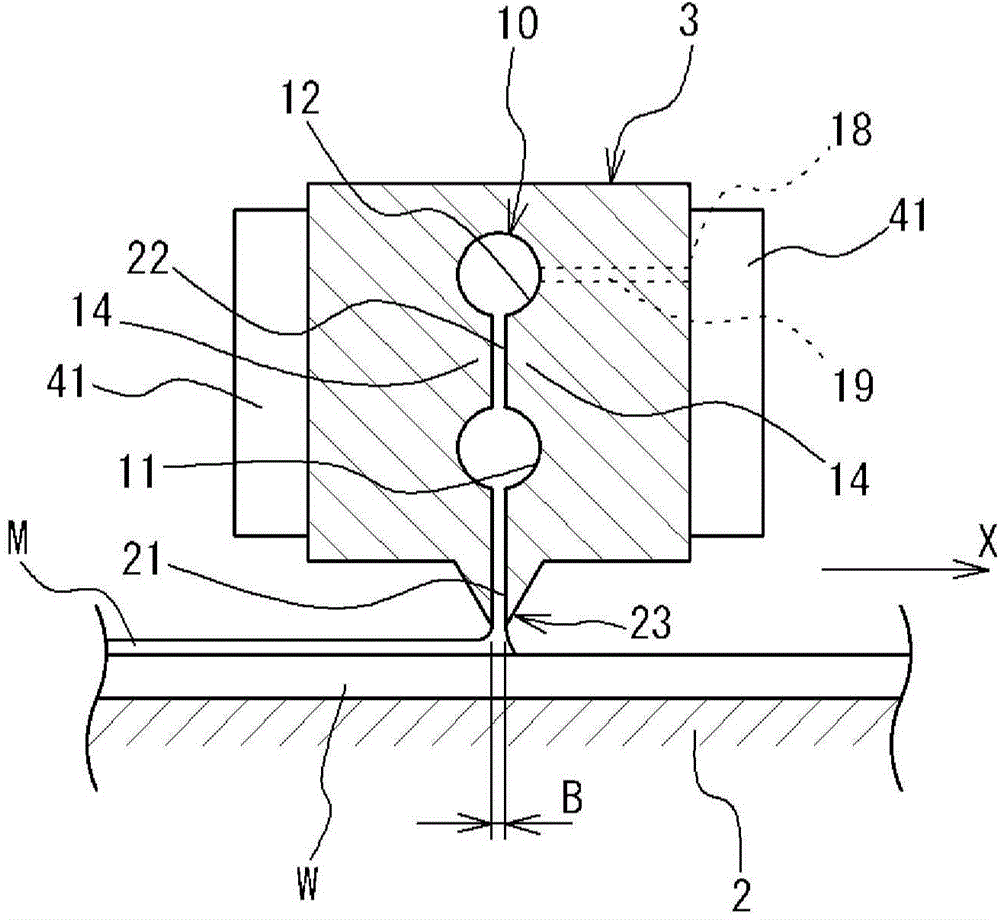

Coating device and coating method

ActiveCN104661759AReduce resistanceImprove productivityPretreated surfacesCoatingsSpray nozzlePolymer chemistry

The present invention forms a coating film on a substrate with good precision and at high speed even when coating a coating solution of relatively high viscosity on the substrate. Specifically, the coating device (1) is provided with a tank (9) for storing the coating solution and a nozzle (3) in which a slit (21) for discharging the coating solution supplied from the tank (9) is formed. The coating solution is coated on the substrate by discharging the coating solution from the slit (21). The coating device (1) is provided with a temperature-raising unit (30) for raising the temperature of the coating solution supplied from the tank (9) and a temperature-homogenizing unit (40) for homogenizing the temperature of the coating solution, the temperature of which has been raised by the temperature-raising unit, prior to discharging the coating solution from the slit (21).

Owner:TORAY ENG CO LTD

Chitosan gel for removing acne scars as well as preparation method and medical application thereof

InactiveCN103040729AUniform viscosityUniform adhesionOrganic active ingredientsAerosol deliveryPimpleTreatment acne

The invention relates to chitosan gel for removing acne scars. The chitosan gel for removing acne scars is obtained by mixing chitosan with specific molecular weight and degree of deacetylation, glycerol, acidifier and purified water in a gelatinization manner and then sterilizing. The chitosan gel for removing acne scars, provided by the invention, has good adhesive power, uniform colour and lustre and stability, and has the advantages of good curative effect, safety, natural property, good biocompatibility and the like when used for treating acnes, pimples and seborrheic dermatitis and preventing acne scars. The invention also relates to a preparation method and application of the chitosan gel for removing acne scars.

Owner:FUZHOU QIANZHENG PHARMA

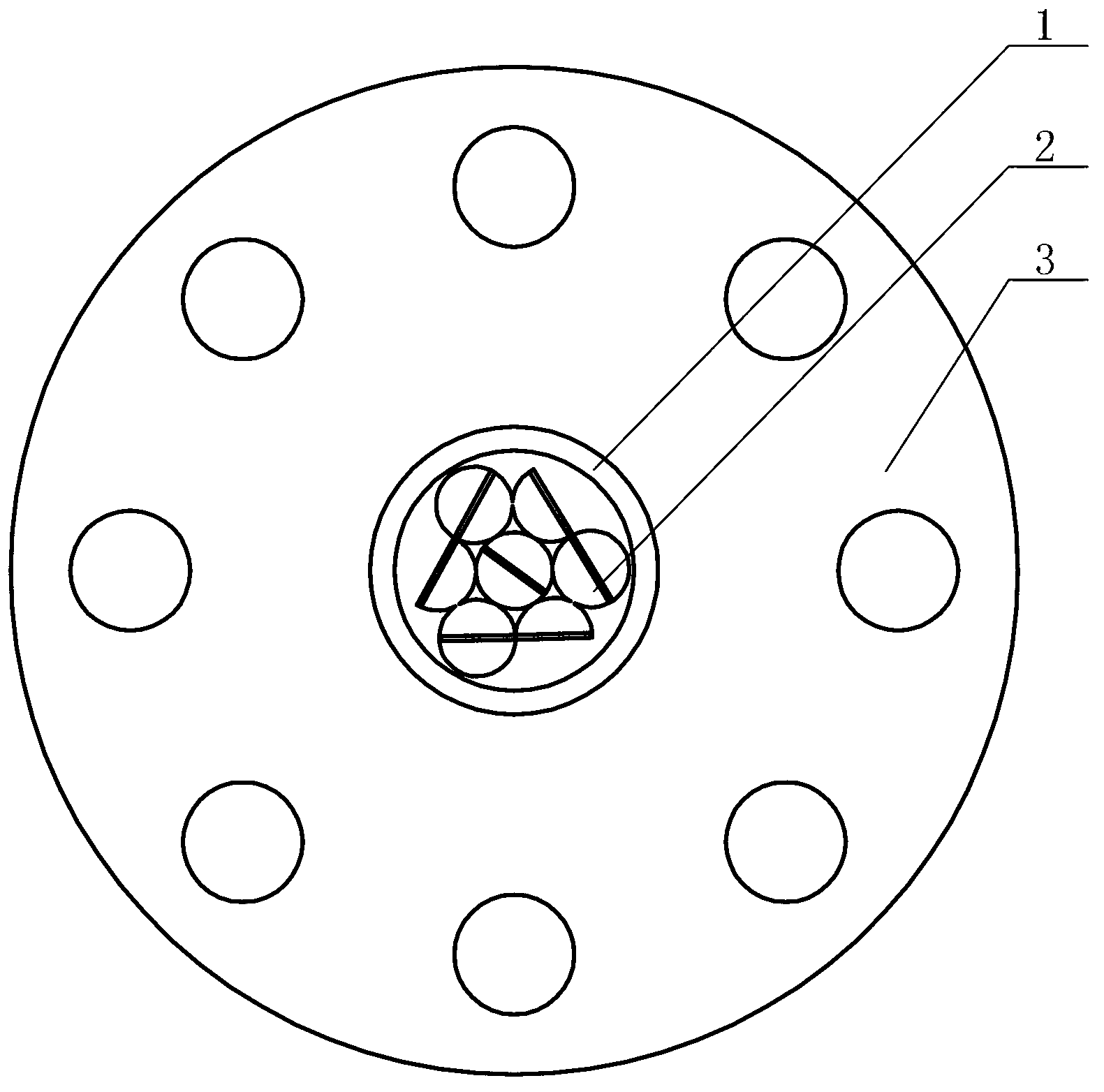

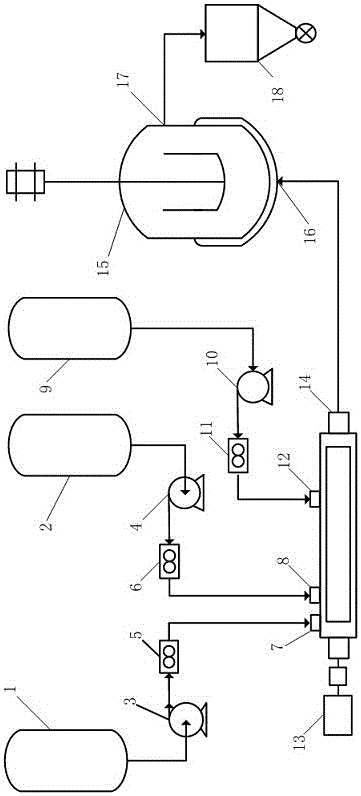

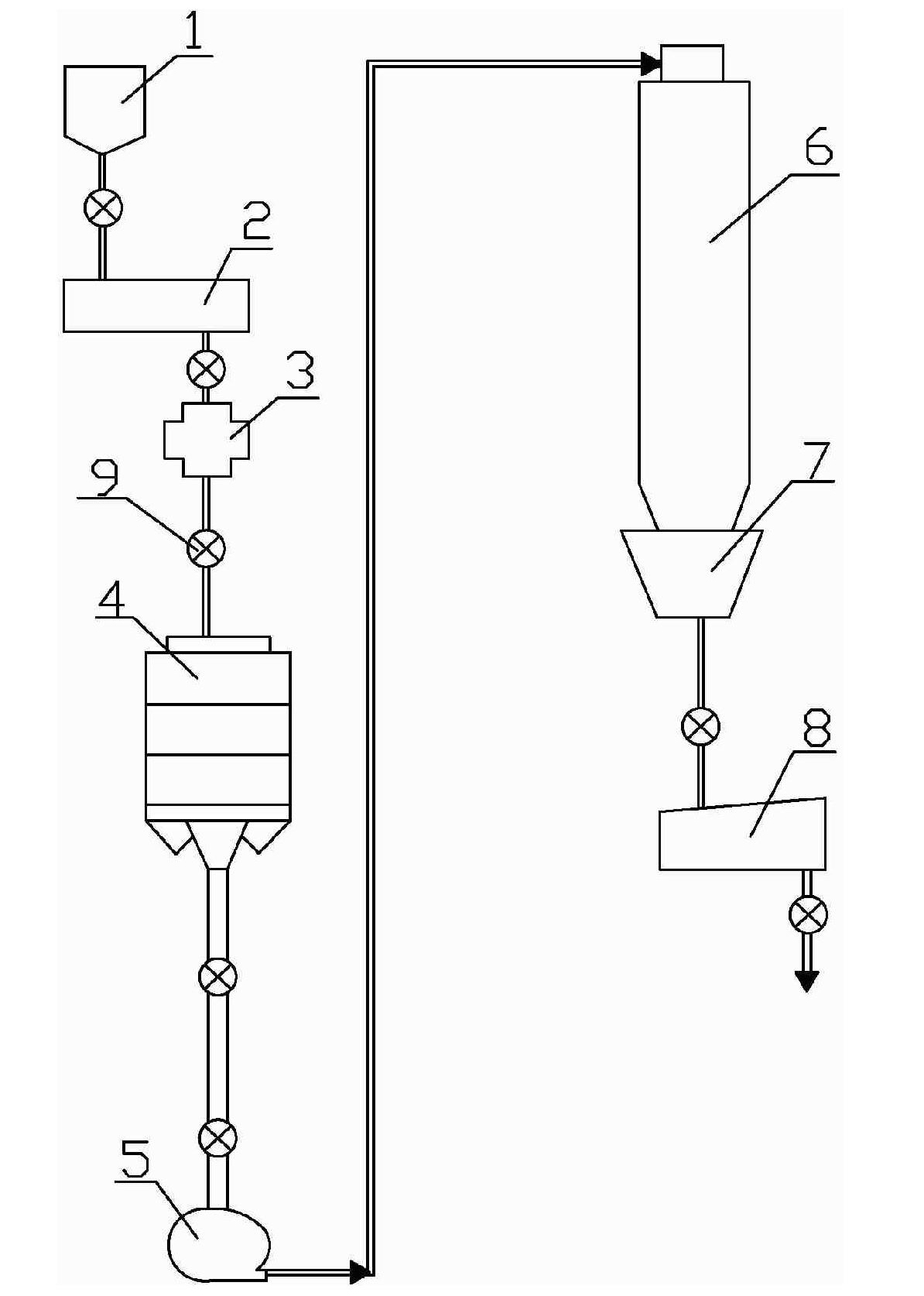

Device for continuously preparing high-purity polyisophthaloyl metaphenylene diamine resin solution

ActiveCN106076232ALow costSame dwell timeChemical/physical/physico-chemical stationary reactorsFeed devicesChlorideSolvent

The invention relates to a device for continuously preparing a high-purity polyisophthaloyl metaphenylene diamine resin solution. The device comprises a solvent metering conveying system, an m-phenylenediamine metering conveying system, an m-phthaloyl chloride metering conveying system, a double-screw mixer and a polymerization reactor, wherein the double-screw mixer is cooperated with the polymerization reactor for use; the polymerization reactor adopts a mode that materials are fed from the bottom and discharged from the upper side part; the investment cost of equipment is reduced; the polyisophthaloyl metaphenylene diamine resin solution with uniform viscosity can be continuously prepared.

Owner:SHANGHAI HUIBO NEW MATERIAL SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com