Hot-melt-type marking coating and preparation method thereof

A marking paint, hot-melt technology, applied in rosin paint, reflection/signal paint, anti-fouling/underwater paint, etc., can solve the problem of poor reflective visual effect, cracking of the marking paint layer, and cracking of the marking paint Cracking and other problems, to achieve the effect of short film-forming curing time, fast drying time and moderate curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

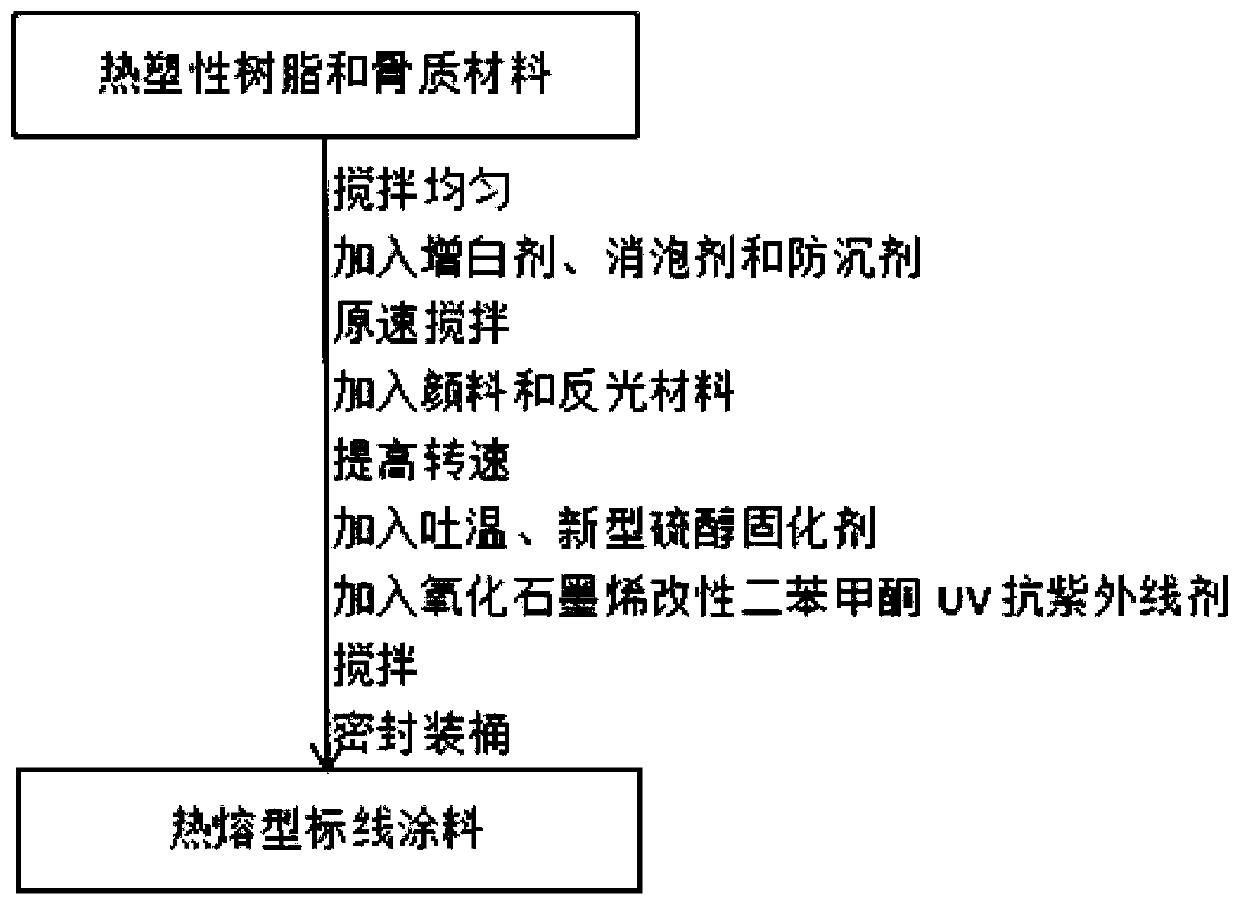

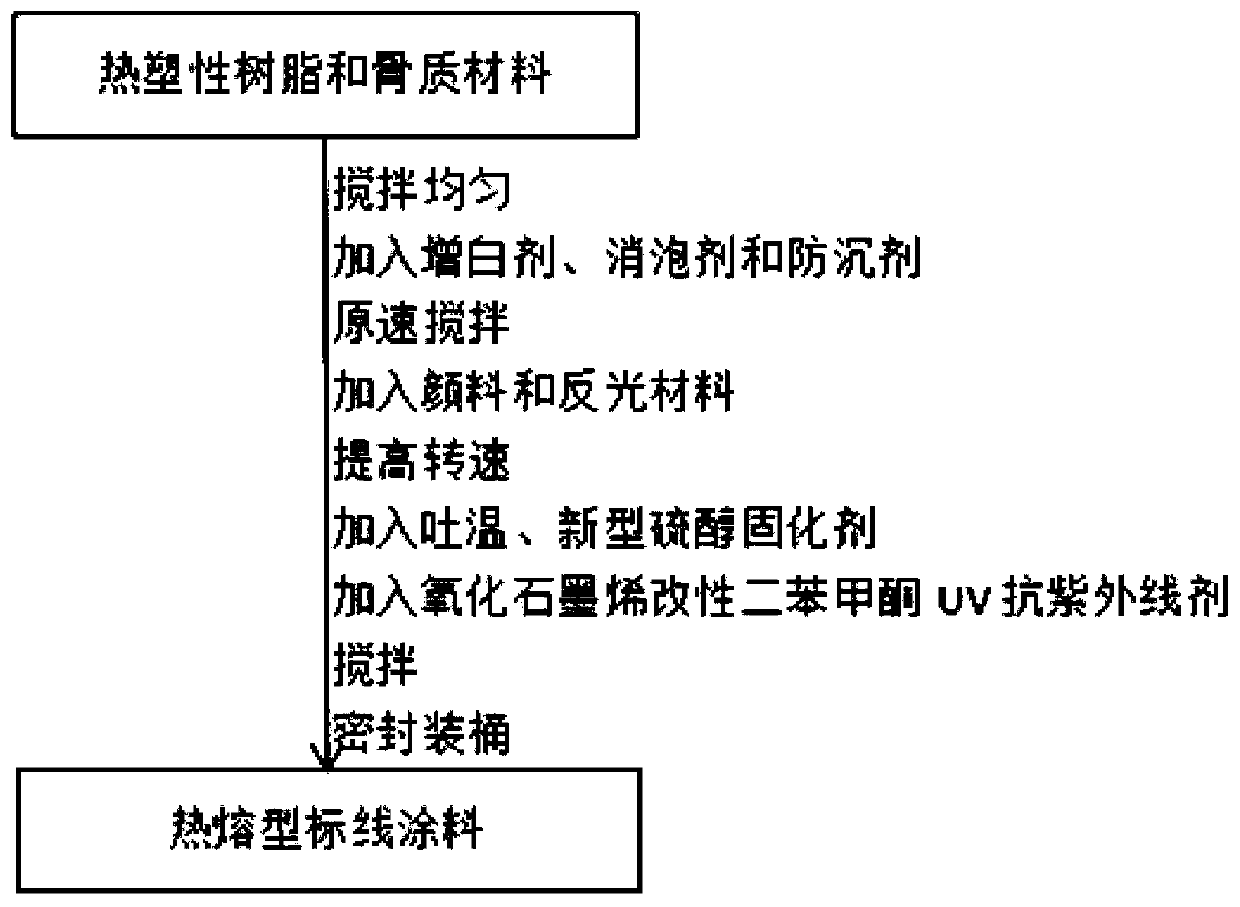

Method used

Image

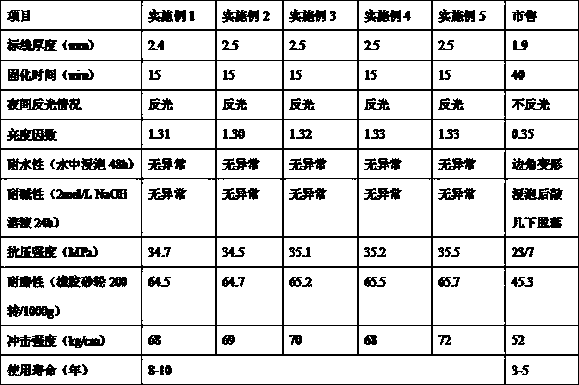

Examples

Embodiment 1

[0031] Raw material composition (parts by weight): 80 parts of petroleum resin, 20 parts of bone material, 5 parts of pigment, 3 parts of glass microspheres, 0.02 part of phenylpyrazoline derivative, 0.01 part of emulsified silicone oil, 2 parts of new mercaptan curing agent , 1 part of polyolefin wax, 1 part of Tween and 0.03 part of graphene oxide modified benzophenone UV anti-ultraviolet agent;

[0032] The bone material comprises calcium carbonate, talcum powder, quartz sand and ceramic particles, and the bone material comprises calcium carbonate, talc powder, quartz sand and ceramic particles in a mass ratio of 1:1:1:2;

[0033]The pigments include white pigments and yellow pigments with a mass ratio of 1:1, the white pigments are rutile titanium dioxide, and the yellow pigments are chrome yellow.

[0034] Described graphene oxide modified benzophenone UV anti-ultraviolet agent adopts following method to prepare:

[0035] S1. Using the improved Hummers method to prepare ...

Embodiment 2

[0040] Raw material composition (parts by weight): 120 parts of acrylic resin, 40 parts of bone material, 15 parts of pigment, 10 parts of glass microspheres, 0.05 part of benzimidazole derivative, 0.03 part of polyoxypropylene glyceryl ether, 6 parts of new thiol curing agent part, 2 parts of modified hydrogenated castor oil, 4 parts of Tween and 0.06 part of graphene oxide modified benzophenone UV anti-ultraviolet agent;

[0041] The bone material comprises calcium carbonate, talcum powder, quartz sand and ceramic particles, and the bone material comprises calcium carbonate, talc powder, quartz sand and ceramic particles in a mass ratio of 1:1:1:2;

[0042] The pigments include white pigments and yellow pigments with a mass ratio of 1:1, the white pigments are rutile titanium dioxide, and the yellow pigments are chrome yellow.

[0043] Described graphene oxide modified benzophenone UV anti-ultraviolet agent adopts following method to prepare:

[0044] S1. Using the improved...

Embodiment 3

[0049] Composition of raw materials (parts by weight): 90 parts of terpene resin, 25 parts of bone material, 7 parts of pigment, 5 parts of glass microspheres, 2 parts of naphthalimide derivatives, 0.02 parts of polyoxypropylene polyoxyethylene glyceryl ether , 0.03 parts of new mercaptan curing agent, 1.2 parts of FP-100, 2 parts of Tween and 0.04 parts of graphene oxide modified benzophenone UV anti-ultraviolet agent;

[0050] The bone material comprises calcium carbonate, talcum powder, quartz sand and ceramic particles, and the bone material comprises calcium carbonate, talc powder, quartz sand and ceramic particles in a mass ratio of 1:1:1:2;

[0051] The pigments include white pigments and yellow pigments with a mass ratio of 1:1, the white pigments are rutile titanium dioxide, and the yellow pigments are chrome yellow.

[0052] Described graphene oxide modified benzophenone UV anti-ultraviolet agent adopts following method to prepare:

[0053] S1. Using the improved Hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com