Spiral low-shear static mixer

A static mixer and spiral mixing technology, applied in fluid mixers, mixers, chemical instruments and methods, etc., can solve the problems of large viscosity loss and unsatisfactory uniform mixing effect, so as to reduce viscosity loss and avoid mechanical shearing. The effect of shear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

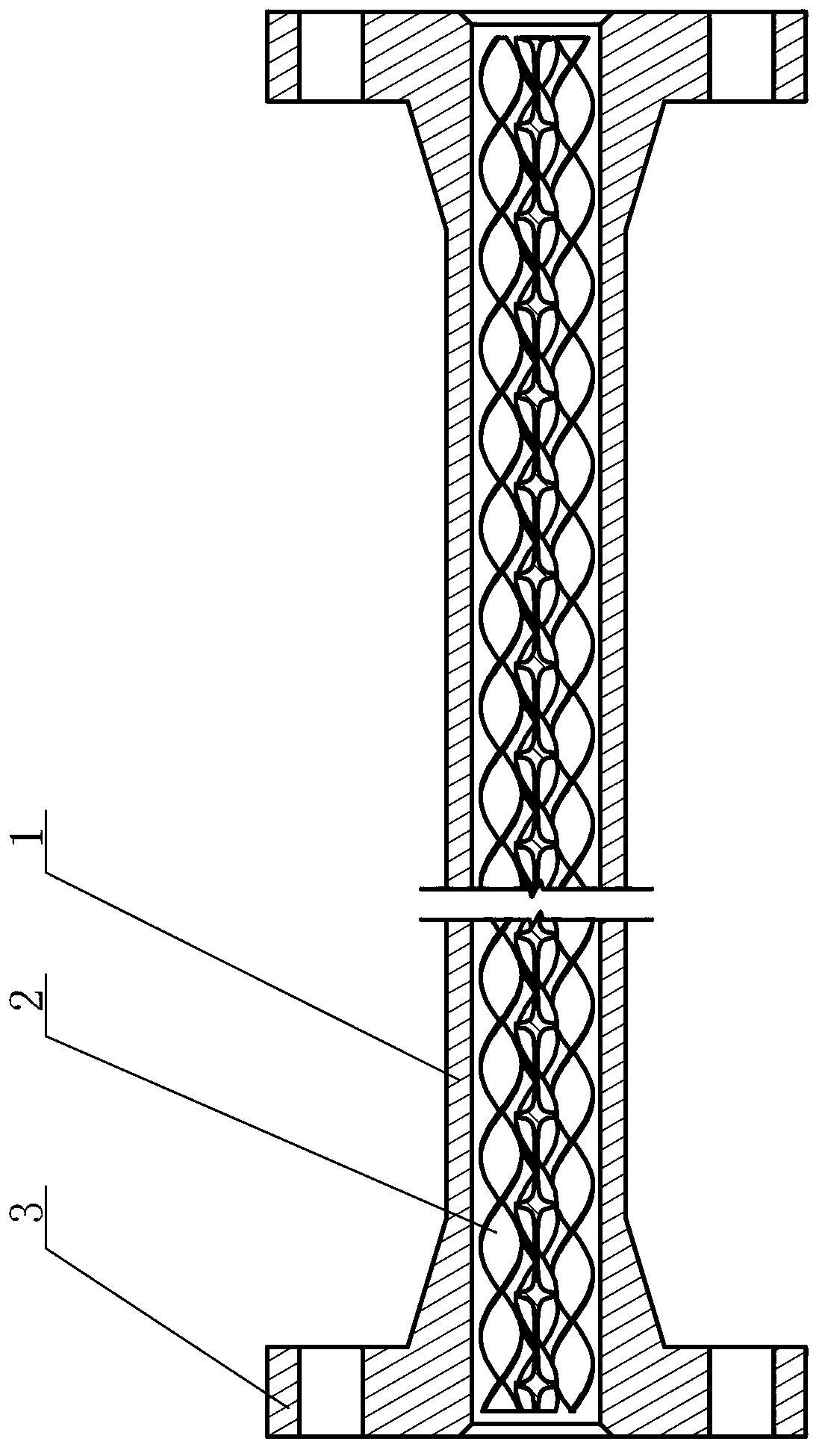

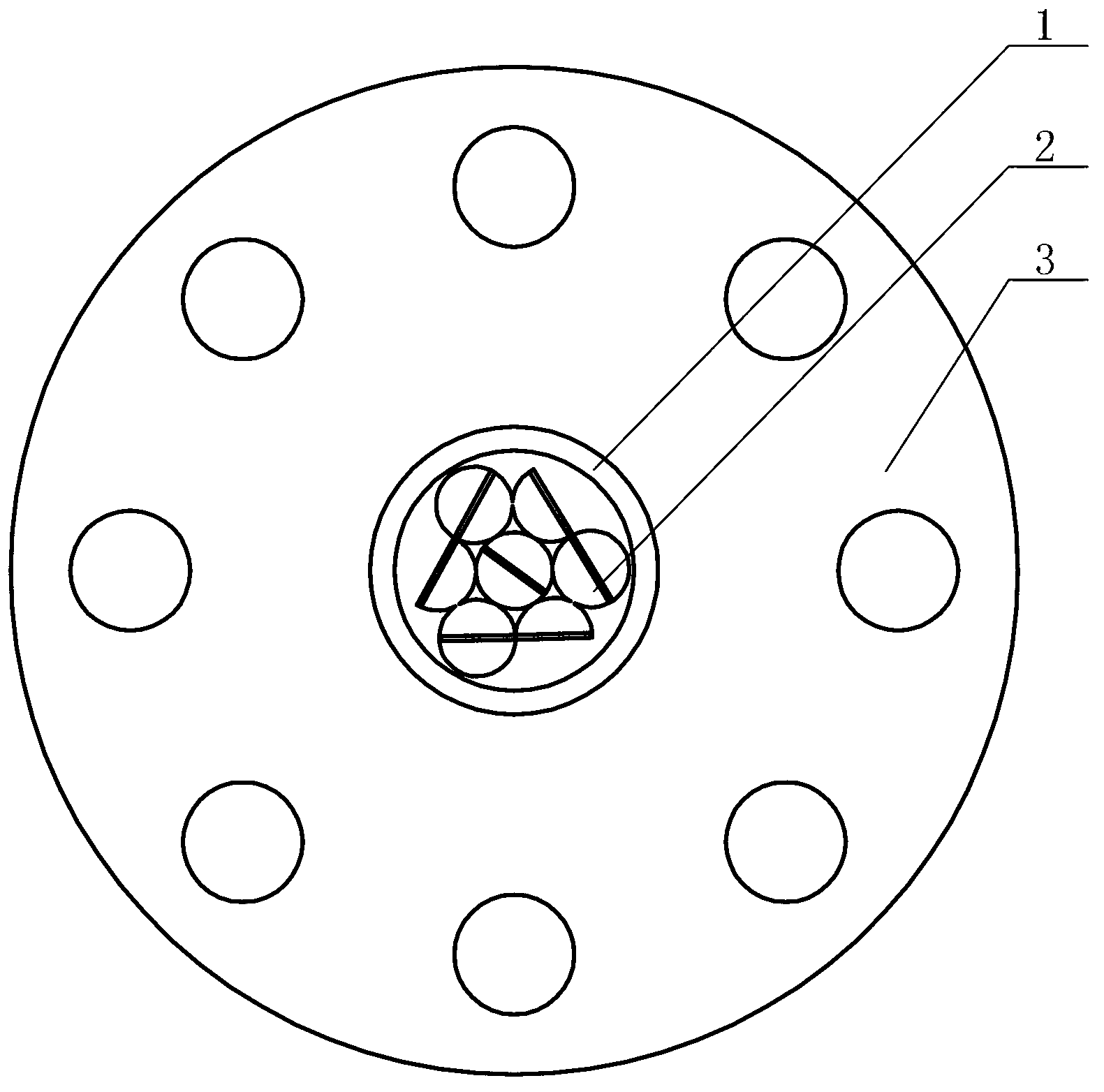

[0007] Specific implementation mode one: combine figure 1 and figure 2 To illustrate this embodiment, a helical low-shear static mixer described in this embodiment includes a shell 1 and seven helical mixing units 2, and the seven helical mixing units 2 are inserted in the shell 1, and each helical The centerline of the mixing unit 2 along the length direction is parallel to the centerline of the tube shell 1 along the length direction.

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the spiral low-shear static mixer described in this embodiment further includes two connecting flanges 3 , and one connecting flange 3 is respectively installed at both ends of the shell 1 .

[0009] Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, each helical mixing unit 2 of a kind of helical low-shear static mixer described in this embodiment is the helical mixing unit 2 that stainless steel is made, and each helical mixing unit 2 is made up of several helical blades head to tail It is made by connecting, and several helical blades are connected end to end to form a whole.

[0011] Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com