Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49results about How to "Viscosity loss is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

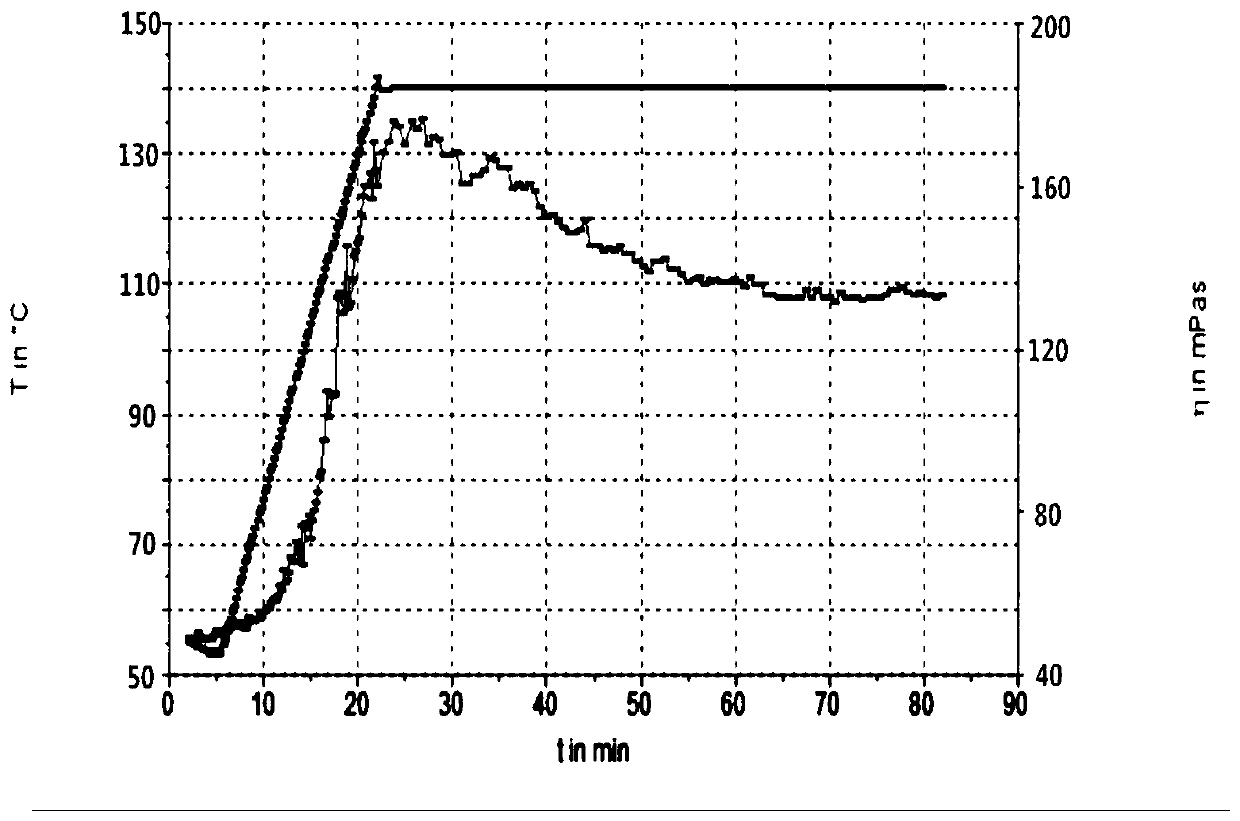

Preparation method of polyacrylamide nano composite fracturing fluid

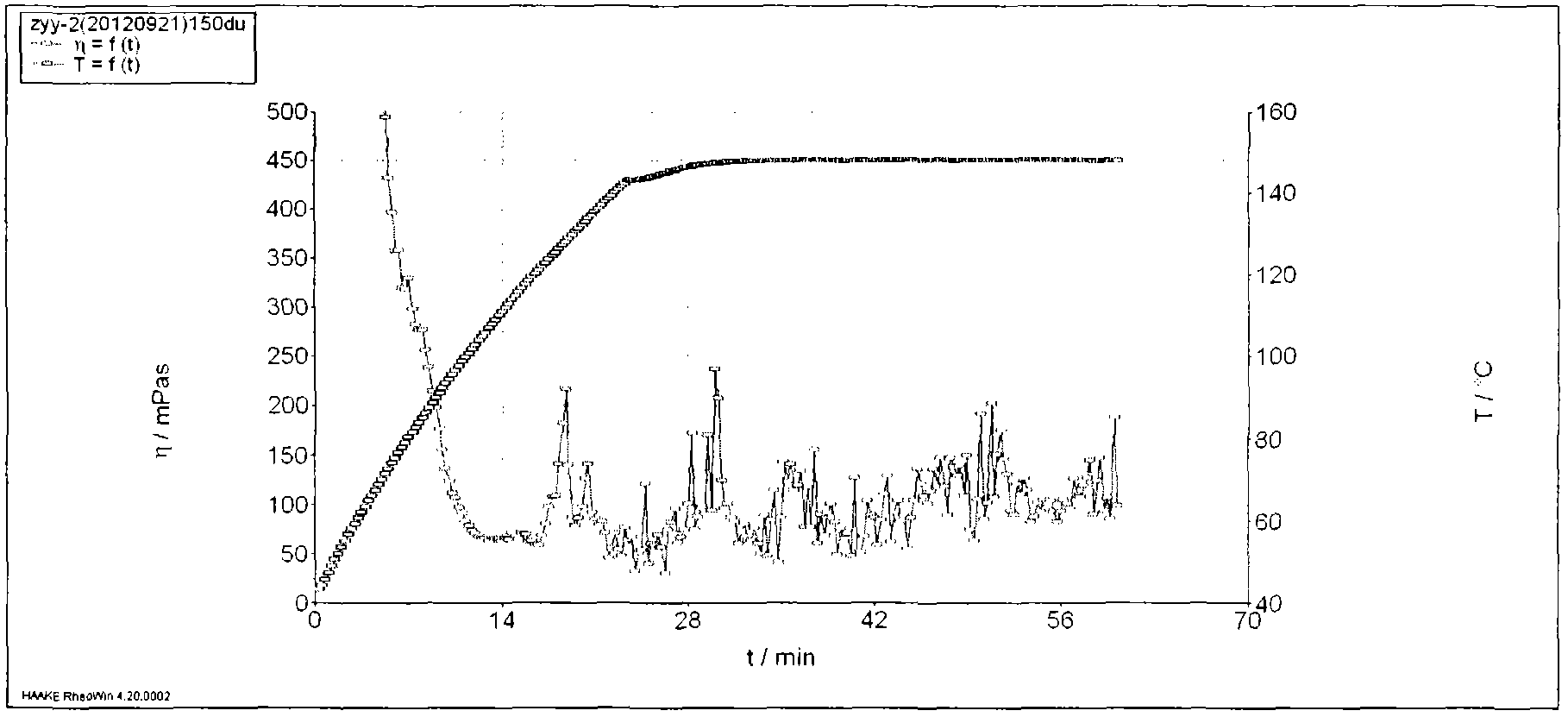

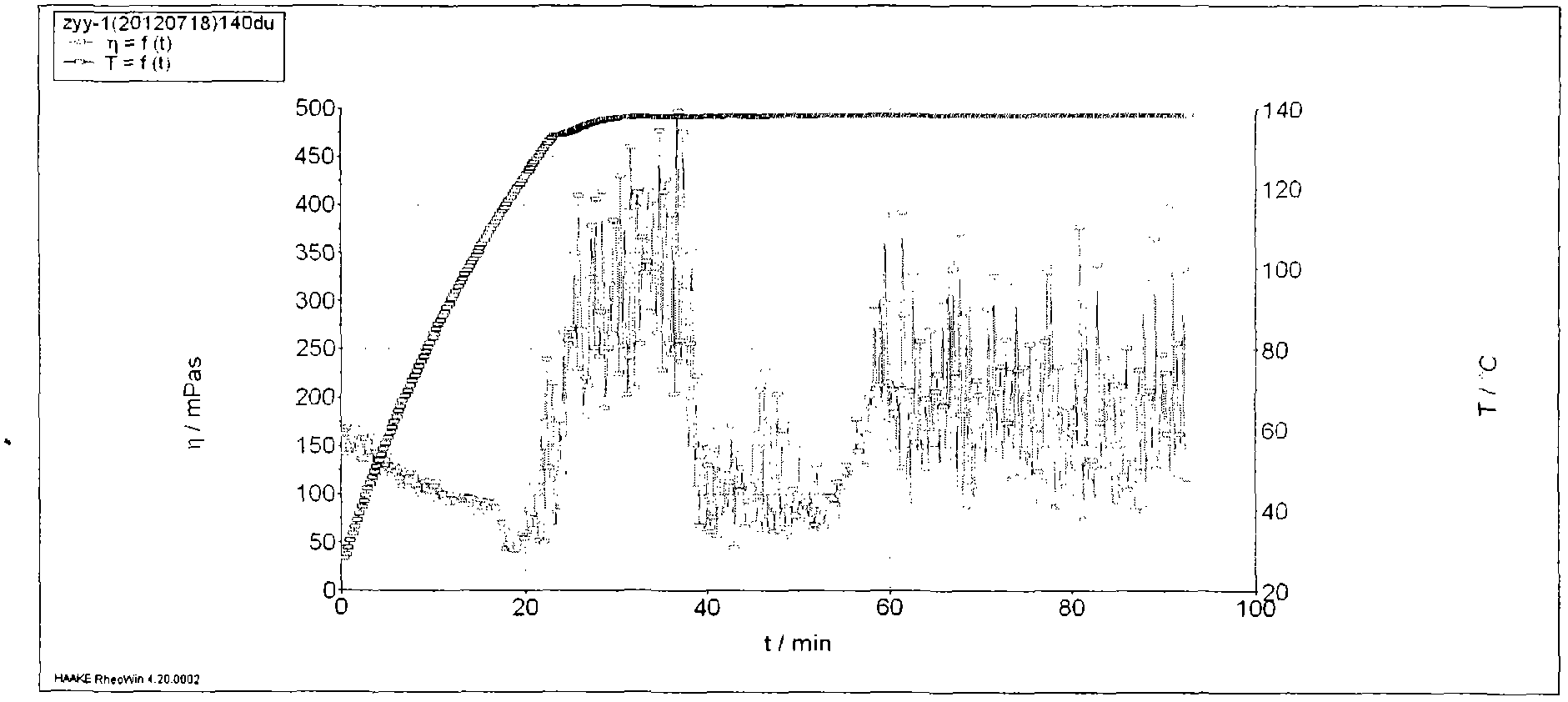

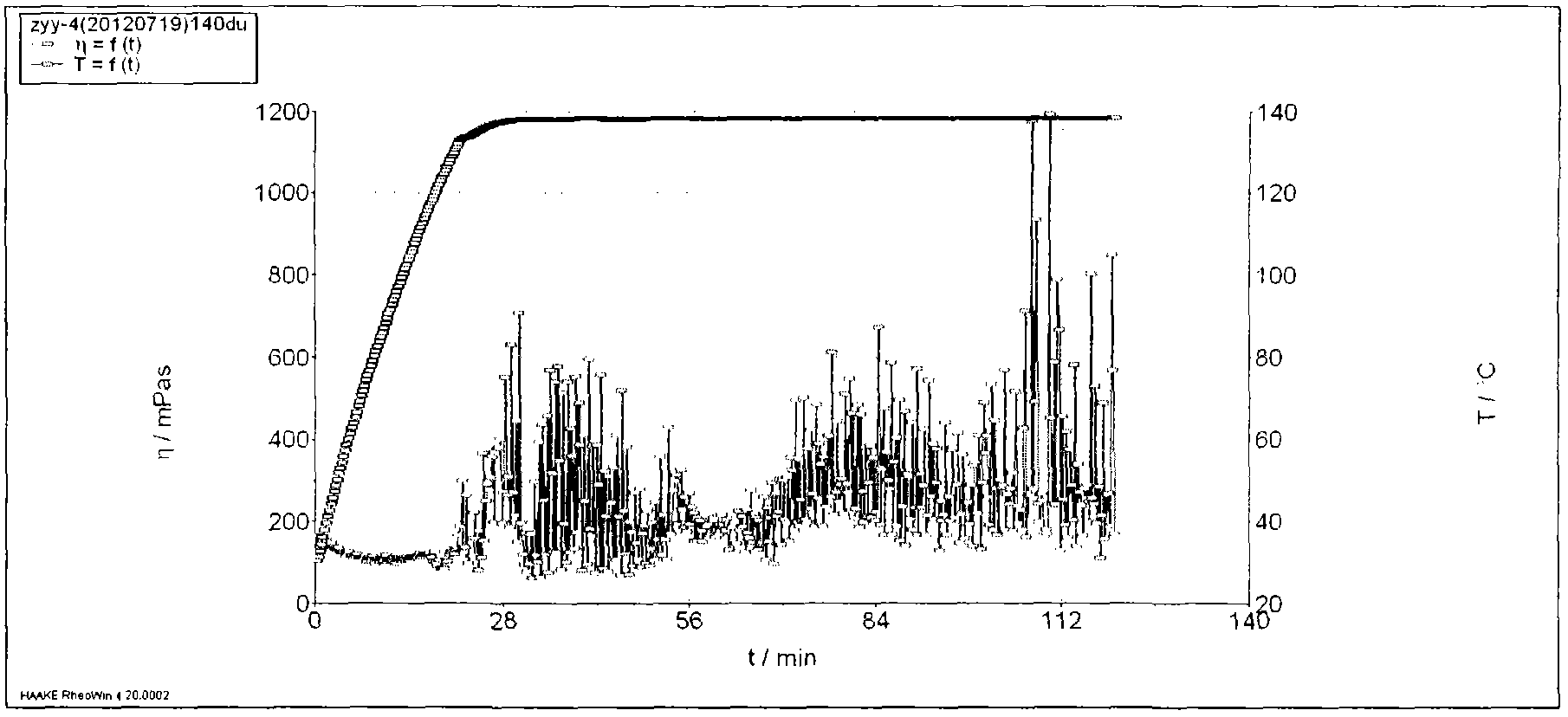

ActiveCN104109525AHigh temperature resistantSalt resistantDrilling compositionIn situ polymerizationFracturing fluid

The invention adopts polyacrylamide and a nano inorganic phase to prepare a polyacrylamide nano composite material through an in-situ polymerization method and then forms a fracturing fluid thickening agent. The nano inorganic phase is prepared by mixing the products of intercalation reactions between an organic long-chain intercalator and layered silicate with magnesium nitrate and aluminum nitrate. The nano inorganic phase, acrylamide monomer, a coupling agent, a complexing agent, an initiator, an oxidant, a reductant, a cosolvent, an auxiliary agent, and deionized water form a suspension fluid reaction system, and the polyacrylamide nano composite material is formed after the polymerization-intercalation composite reactions. The polyacrylamide nano composite material with a mass percentage of 0.25% is taken as the thickening agent, and then is mixed with a crosslinking agent with a mass percentage of 0.20%, a gel breaker with a mass percentage of 0.20%, and other auxiliary agents to form a fracturing fluid system. The system is sheared for 70 minutes under a shearing speed of 170 s<-1> at a temperature of 150 DEG C so as to form a fracturing fluid with a viscosity larger than 50 mPa.s, and the fracturing fluid has the characteristics of high temperature resistance, shearing resistance, low frictional resistance, complete glue breaking effect, and good compatibility with the formation fluid.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

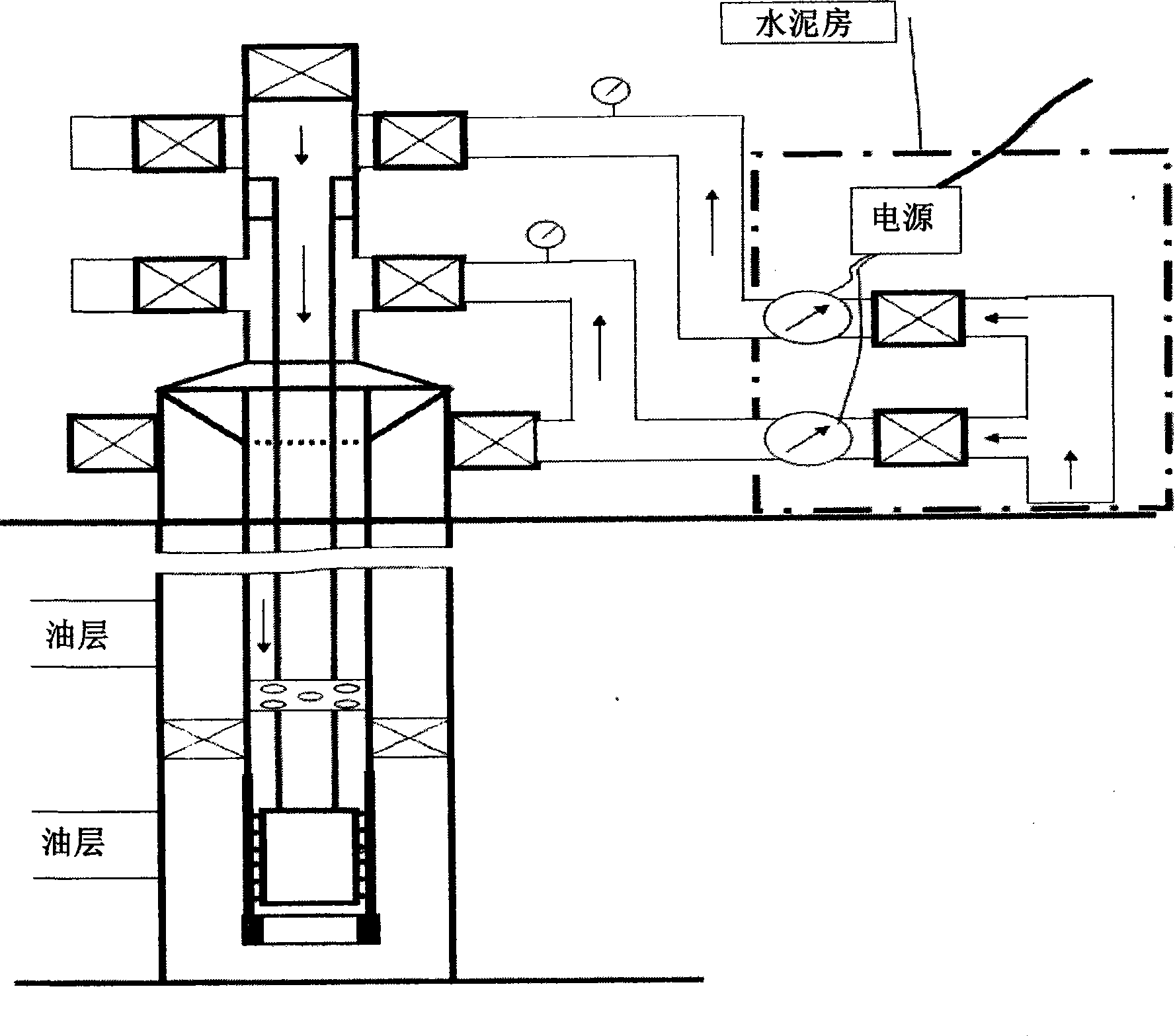

On-line injection profile-control and flooding-control method and device

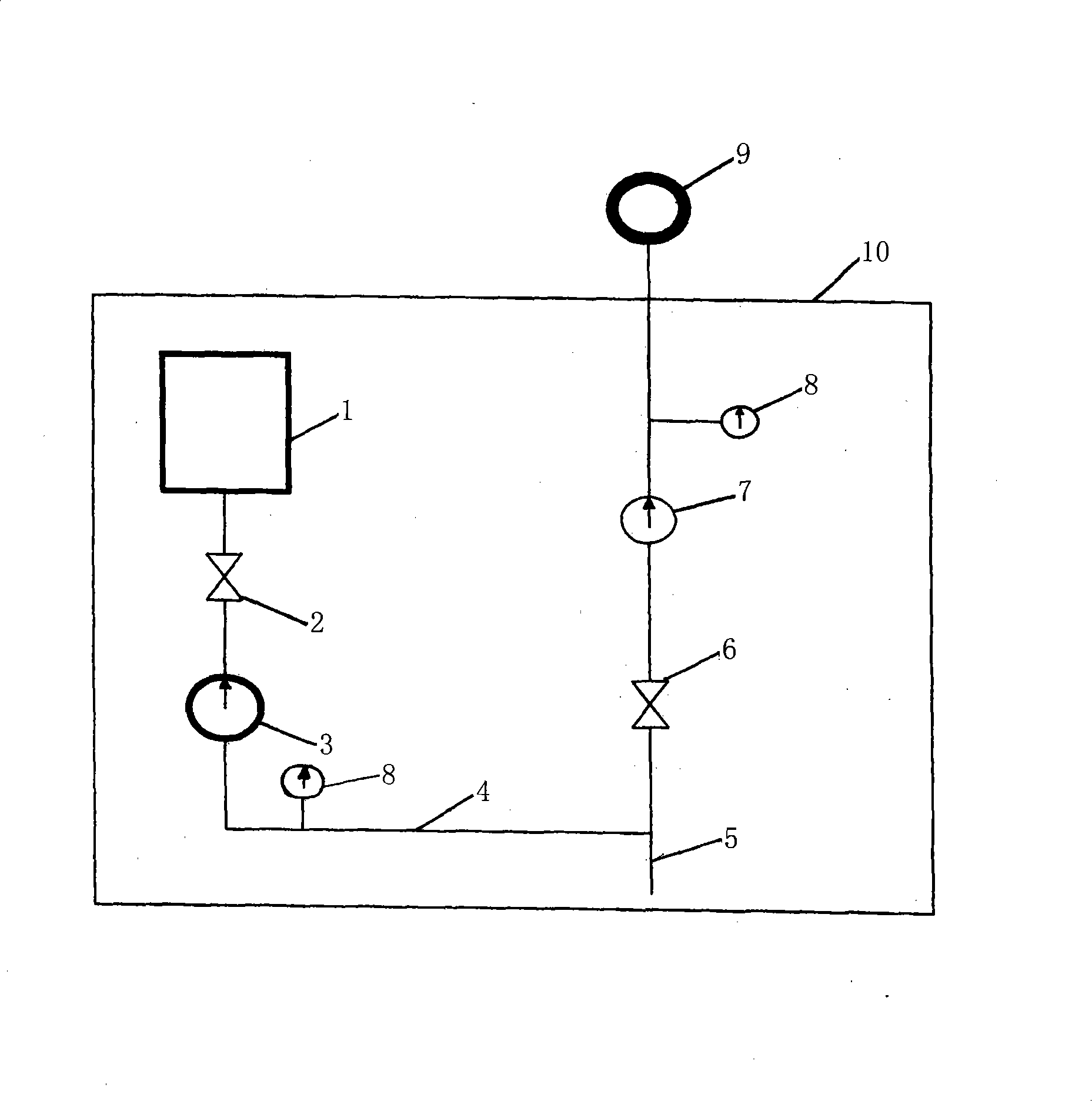

InactiveCN101245699ARealize Regulatory ControlStable and reliable concentrationFluid removalLine tubingLiquid storage tank

The invention relates to a method and a device for injecting profile control online. The method includes that a plugging agent is injected in a water injection well. The plugging agent injected in the water injection well is injected online and the steps are that: (A) the plugging agent is stored into a liquid storage tank; (B) the plugging agent is simultaneously injected along with the injected water by a special injection device; (C) the plugging agent is mixed into an online water injection pipeline through a metering plunger pump; (D) the plugging agent is mixed with the injected water in the water injection pipeline, injected into the well together and reach an oil layer; (E) the total injecting flow and injecting pressure on the well opening are measured by a flowmeter and a pressure gauge. The device includes the liquid storage tank, a control valve, the metering plunger pump, an injection agent tube, the water injection pipeline, a throttle valve, the flowmeter, the pressure gauge and the water injection well. One end of the injection agent tube is connected on the water injection pipeline and the other end is connected with the metering plunger pump, the control valve and the liquid storage tank in sequence. The water injection pipeline is connected with the water injection well through the throttle valve and the flowmeter. The method and the device have the function of controllable water injection and simultaneous injection and are broadly applied into the water injection technique of petroleum exploitation.

Owner:DONGYING SHIDA COMPREHENSIVE TECH

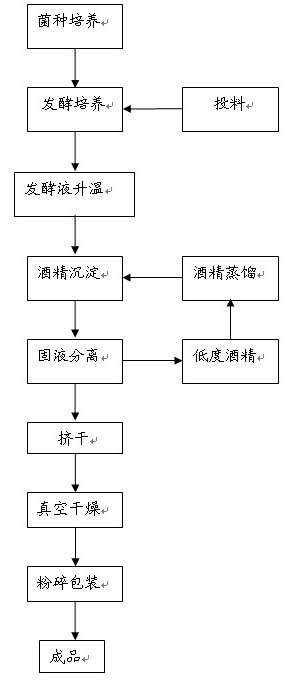

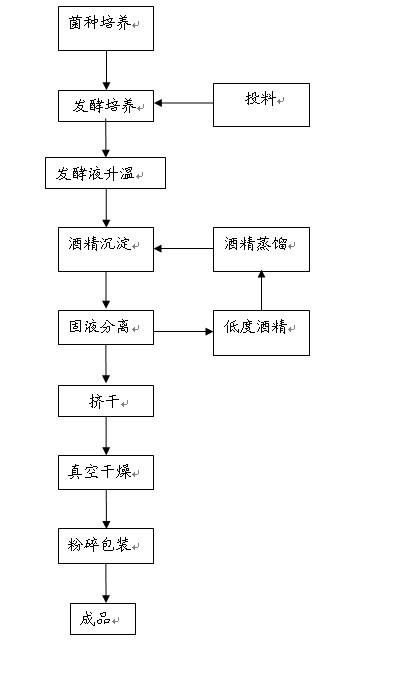

Xanthomonas, preparation method thereof and method thereof for producing temperature resistant xanthan gum polysaccharide

ActiveCN101906390AImprove temperature resistanceViscosity loss is smallBacteriaMutant preparationBiotechnologyXanthomonas campestris

The invention discloses a xanthomonas Xanthomonassp. S-96#, preparation method thereof and a method thereof for producing temperature resistant xanthan gum polysaccharide, including seed selection of temperature resistant high viscosity strain, expanding culture of seed, fermentation and extraction processing steps. The strain of the invention has good temperature resistance, the produced xanthan gum polysaccharide product has stable quality, the viscosity of the product after being heated is obviously higher than similar product, application indexes are excellent, and the original production process of similar products is improved, production process is safe, thus being capable of substituting the existing xanthan gum product and being widely applied to the petroleum development industries requiring high viscosity under high temperature condition.

Owner:ORDOS ZHONGXUAN BIOCHEM

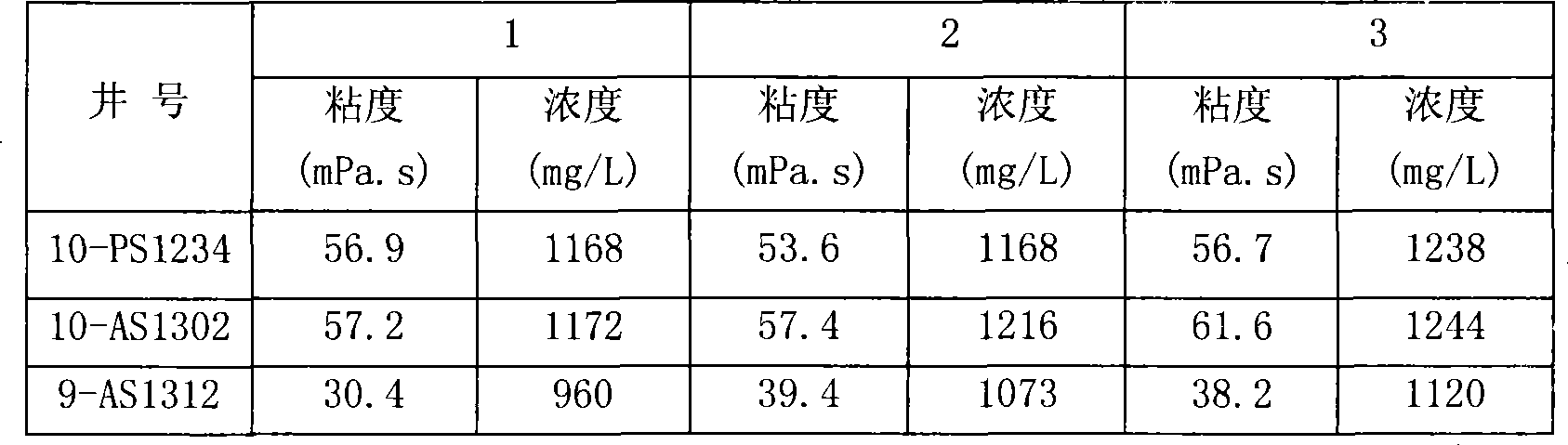

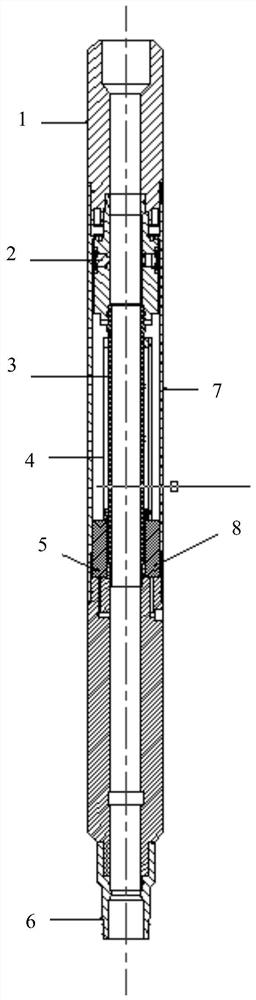

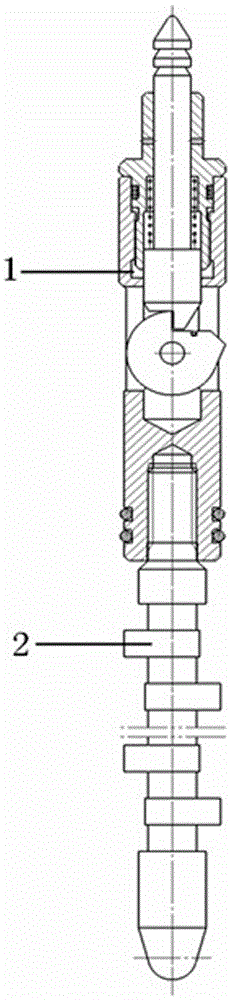

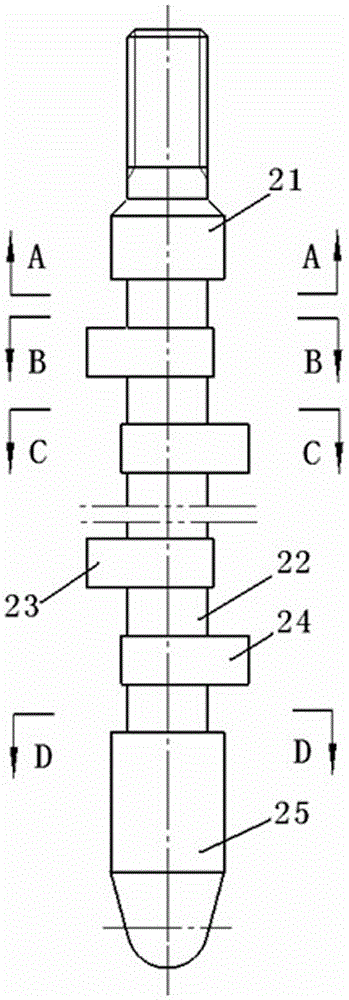

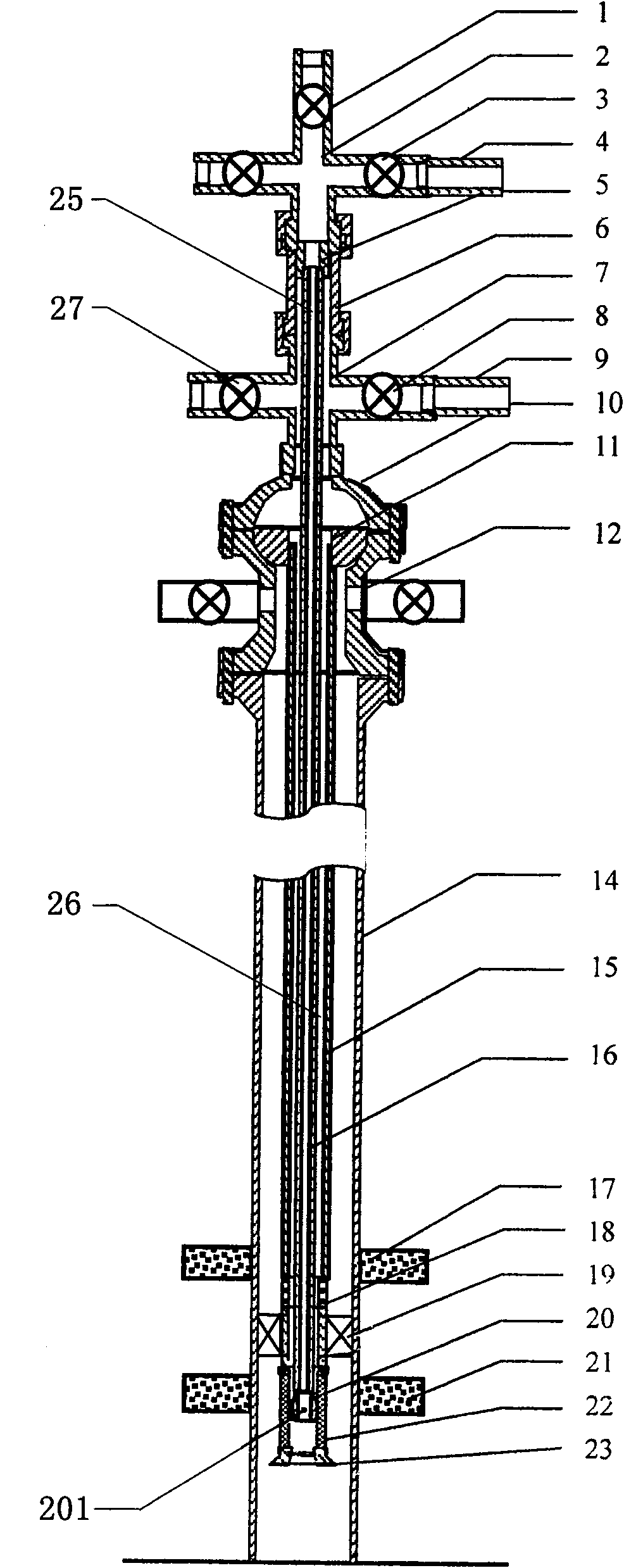

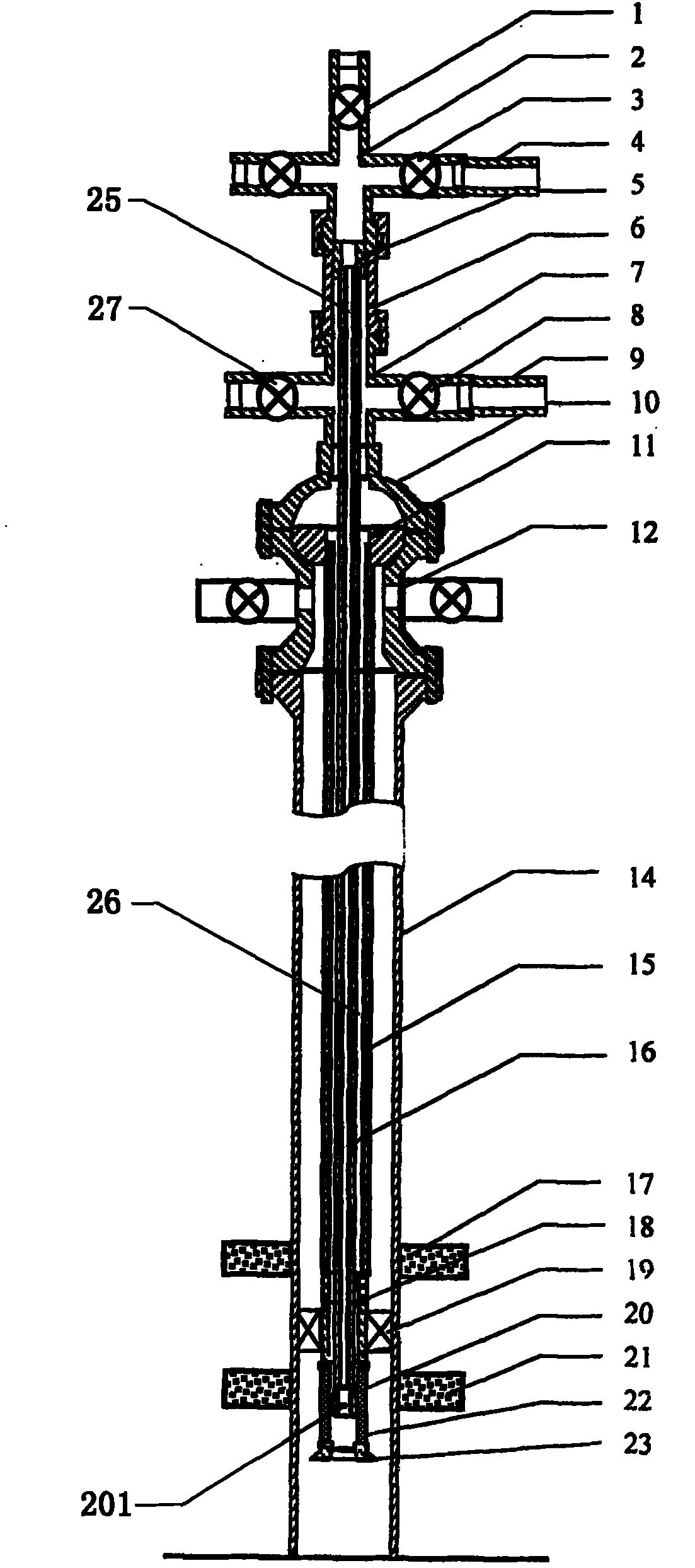

Liquid passing type electric-control layered polymer filling device

InactiveCN102747994AViscosity loss is smallAccurate measurementSurveyFluid removalEngineeringPressure sensor

The invention provides a liquid passing type electric-control layered polymer filling device, which relates to underground polymer driving equipment and solves the problems of the existing underground polymer filling equipment that the working efficiency is low, the viscosity loss is great and the continuous adjustment cannot be realized. A motor reducer drives a screw rod to rotate; a screw moves up and down along the screw rod; a valve core continuously moves in a pipe body of the valve core up and down along with the screw; a lower pressure sensor is mounted in a vertical hole, and an upper pressure sensor is arranged in a circuit board hole; radial through holes are formed on the side walls of a lower central pipe and the pipe body of the valve core; a solution outlet is arranged on the side wall of a cable connector body; and a cable penetrates from a cable through hole of an upper connector, and then stretches out from a through hole of a lower pressing sealing body after passing through a cable through hole of a cable sealing body, a cable hole, a cable through hole of an output shaft connecting body, an inner cavity of a cable shell and a through hole of a bottom cable shell. The liquid passing type electric-control layered polymer filling device disclosed by the invention is used for filling polymers to extract oil.

Owner:HARBIN INST OF TECH

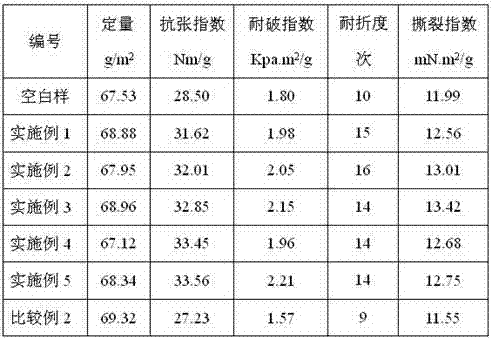

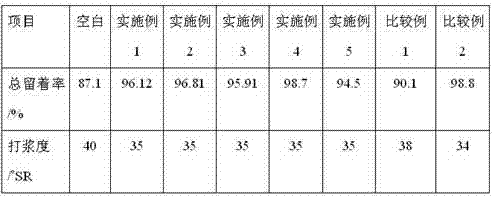

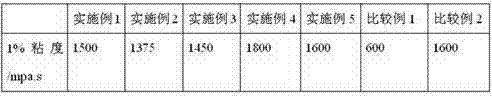

Multi-functional guar gum derivative for papermaking and preparation method and application for multi-functional guar gum derivative

InactiveCN102329398AViscosity loss is smallImprove performanceReinforcing agents additionPaper/cardboardPulp (paper)Guar gum

The invention provides a multi-functional guar gum derivative for papermaking and a preparation method and application for the multi-functional guar gum derivative. The preparation method comprises the following steps of: synthesizing an urea solution and epoxy chloropropane to obtain an amido nonionic etherifying agent, and mixing a mixed salt solution of sodium sulfite and sodium hydrogensulfite, an emulsifier and epoxy chloropropane to obtain a sulfonate anionic etherifying agent; and synthesizing the amido nonionic etherifying agent and / or the sulfonate anionic etherifying agent, a cationic etherifying agent and guar gum powder to obtain the guar gum derivative under the condition that an inorganic alkaline solution is added in multiple steps. The guar gum derivative contains a quaternary ammonium cationic group and an amido nonionic group or a sulfonate anionic group, and can remarkably improve retention and filtration aiding properties, pulp drainability and mechanical properties of paper products when used as a retention and filtration aid or a reinforcing agent in the papermaking industry. The guar gum derivative prepared by the method has higher molecular weight and lowerviscosity loss; meanwhile, by the preparation method, the reaction time is short and etherification efficiency is high.

Owner:SOUTH CHINA UNIV OF TECH +2

Production method for semi-dull denier high-oriented yarn of nylon 6

InactiveCN1807710AImprove efficiencySoft touchMelt spinning methodsMonocomponent polyamides artificial filamentYarnNylon 6

The invention discloses a nylon 6 half extinction thin denier high orienting filament producing method, which comprises the following steps: (1) fusion, leading raw material of nylon 6 half extinction section into screw extruder through bin to melt, making raw material to present molten state into spinning flux; (2) spinning, putting spinning flux in spinning box; compressing in component part to form fiber group after measuring; (3) cooling, cooling fibre group through cross air blasting, bean and chimney; (4) modeling, making cooled fibre group to cool and form with the treatment of pre-whirling, cold drawing, heat setting, whirling and drawing. The invention simplifies the producing method, which reduces the cost.

Owner:JIANGSU WENFENG CHEM FIBER GROUP

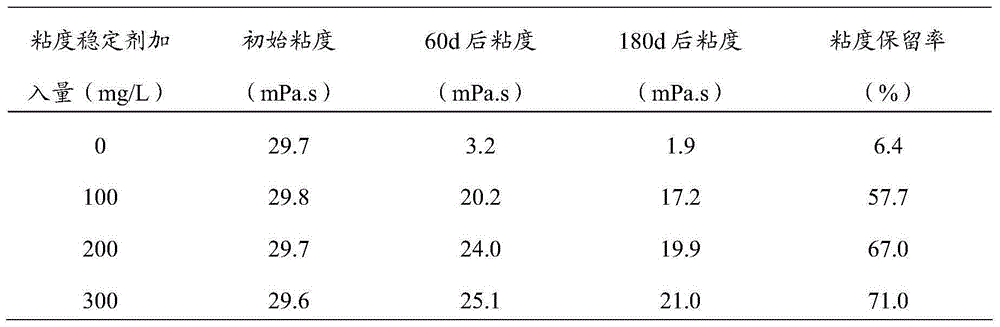

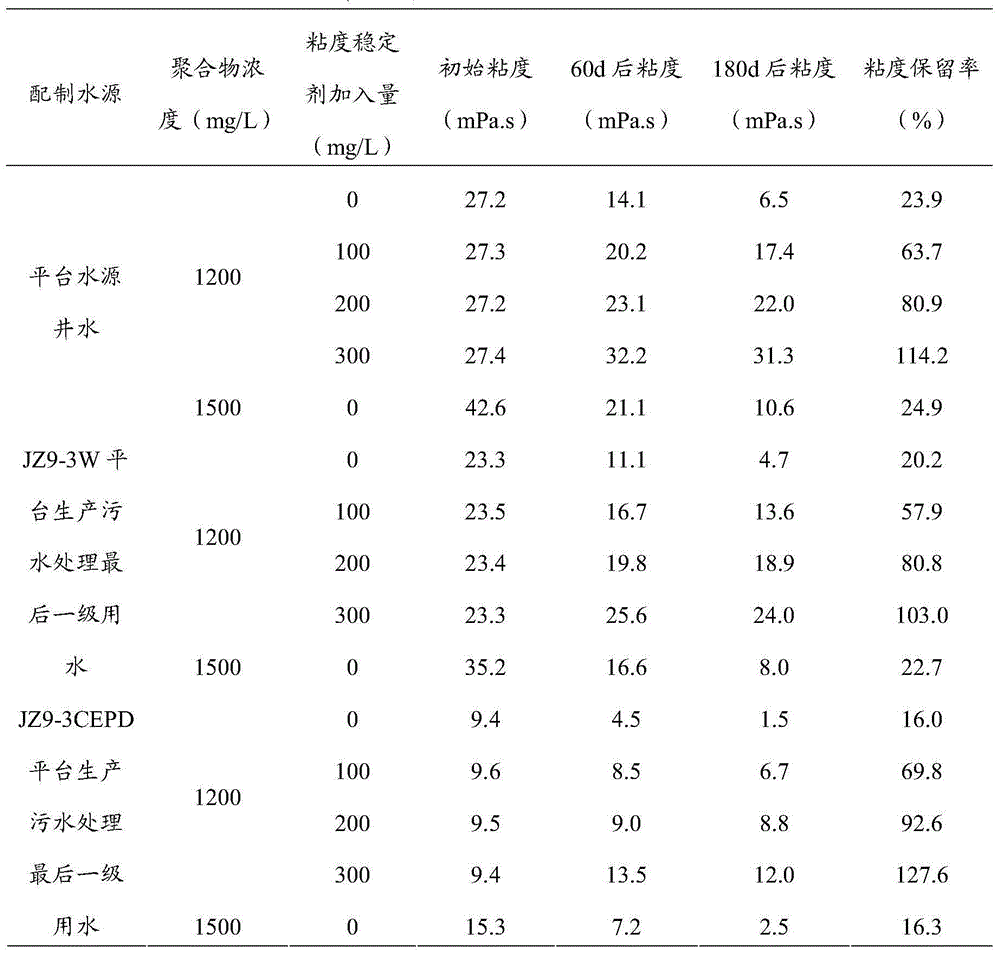

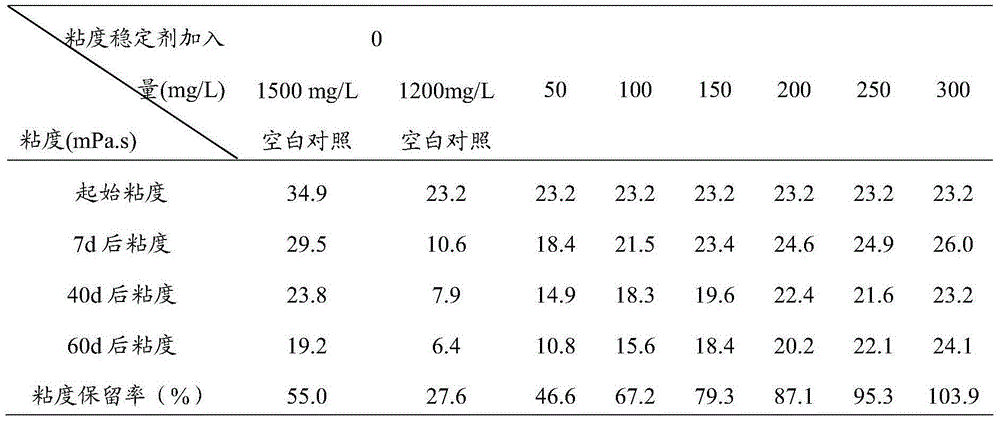

Viscosity stabilizer and application thereof

ActiveCN105086978AInhibit or slow down the formationEliminate curlingDrilling compositionWater basedSilanes

The invention provides a viscosity stabilizer and application thereof. The viscosity stabilizer comprises the following components in percentage by weight: 8-15% of an -SH containing antioxidant, 0.3-5% of an epoxy silane crosslinker, 1-5% of a metal ion complexing agent and the balance of water. Compared with the prior art, through the -SH containing antioxidant, an oxygen free radical can be directly reduced to inhibit or slow down the formation of free radicals at an initiation stage, the epoxy silane crosslinker can react with amino, carboxyl and hydroxy in a water-based system, and the metal ion complexing agent can realize effective complexing of high-valence metal ions in a complexing solution to eliminate polymer coiling caused by the metal ions, so that through the interaction of the three components, the loss of viscosity of a polymer solution prepared from oil field waste water can be reduced, the stability of the polymer solution is improved, and a purpose of improving the oil displacement efficiency is realized.

Owner:华鼎鸿基采油技术服务(北京)有限公司

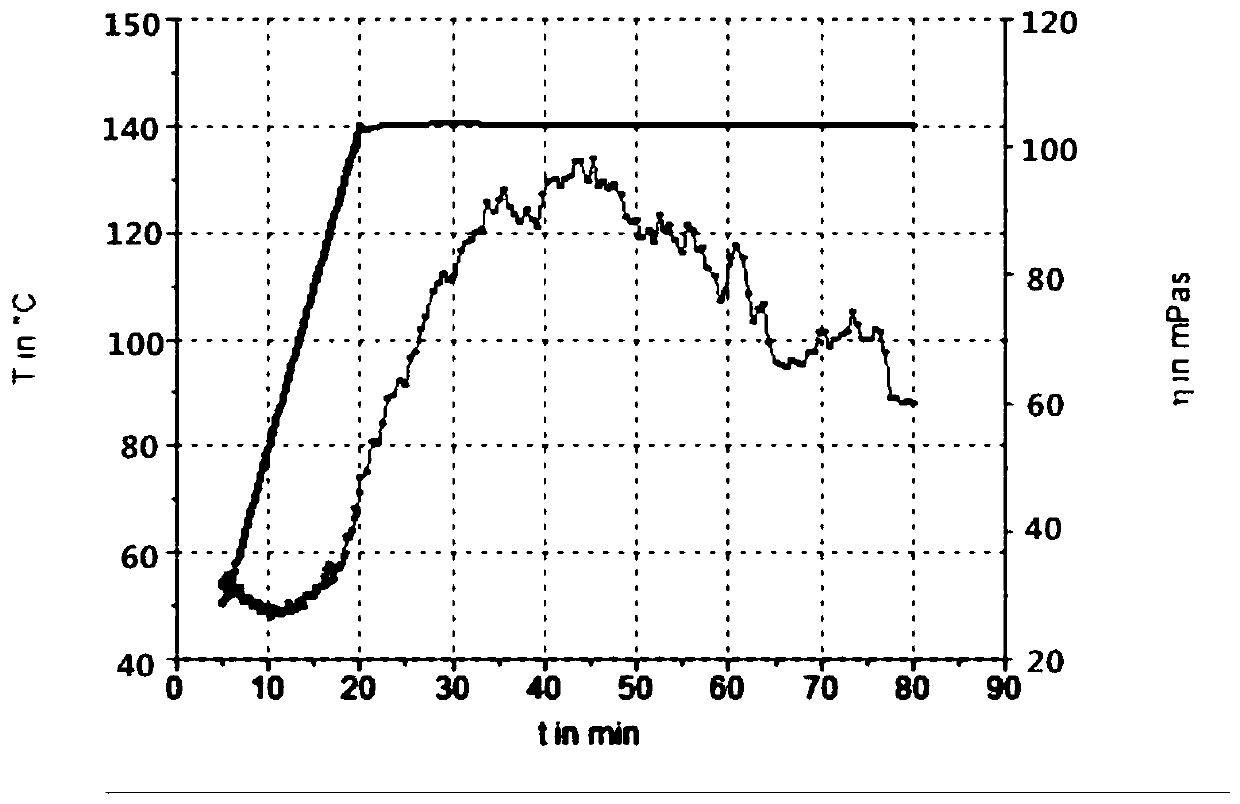

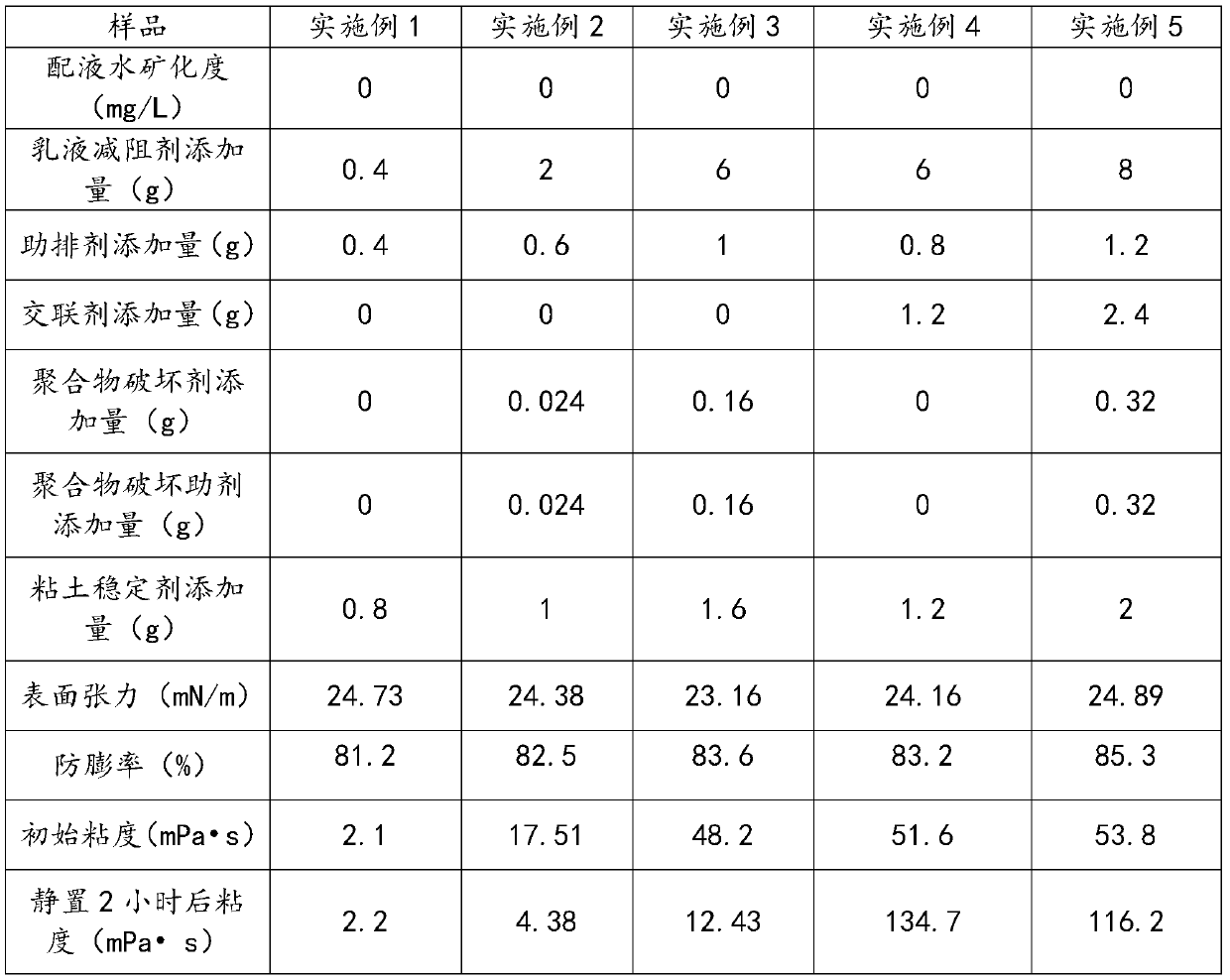

Multifunctional emulsion-type salt-tolerant fracturing fluid and production method thereof

InactiveCN110437817AMolecular structure is complexGood drag reduction effectDrilling compositionEmulsionFracturing fluid

The invention relates to the technical field of fracturing reformation of oil and gas reservoirs, in particular to multifunctional emulsion-type salt-tolerant fracturing fluid and a production methodthereof. The multifunctional emulsion-type salt-tolerant fracturing fluid comprises the following raw materials in parts by weight: 0.1-2 parts of an emulsion drag reducer, 0.1-0.3 part of a cleanup additive, 0.2-0.5 part of a clay stabilizer, 0-0.6 part of cross-linking agents, 0-0.08 part of polymer breakers, 0-0.08 part of polymer breaking assistants and 100 parts of water, wherein the emulsiondrag reducer is hyperbranched amphoteric polyacrylamide and a derivative of the hyperbranched amphoteric polyacrylamide. According to the multifunctional emulsion-type salt-tolerant fracturing fluidand the production method thereof, through synergism of the emulsion drag reducer and the components, the fracturing fluid with excellent comprehensive performance of temperature resistance, salt tolerance, shear resistance, anti-swelling performance and the like is obtained so that different requirements of a reservoir can be met.

Owner:CHINA PETROCHEMICAL CORP +3

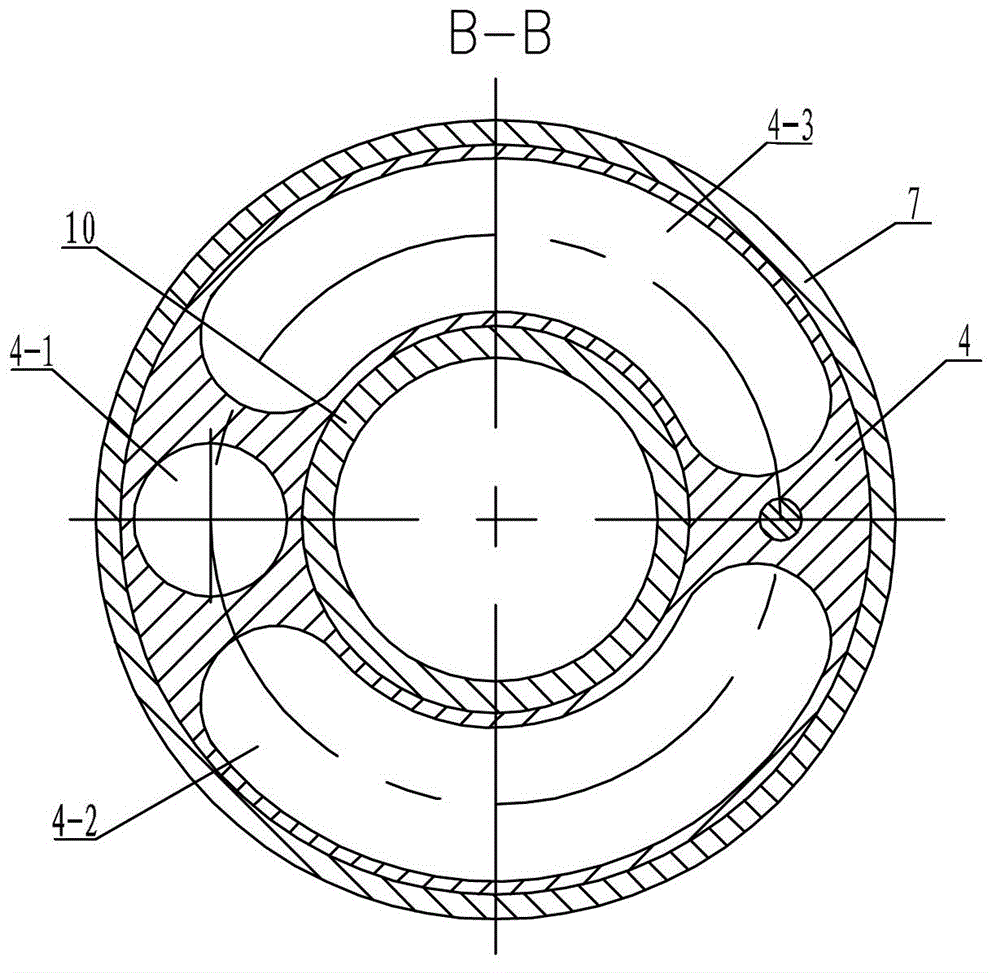

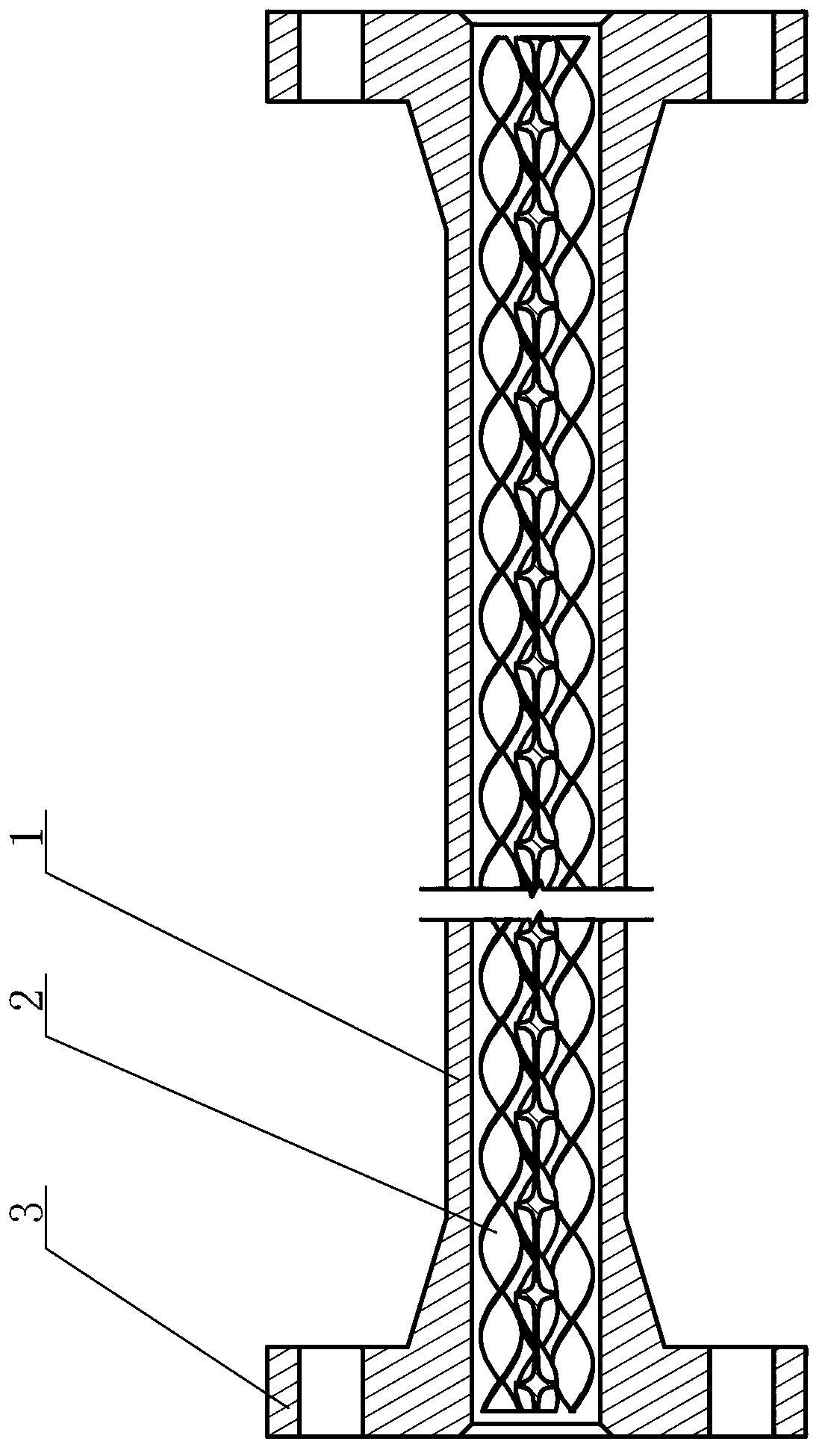

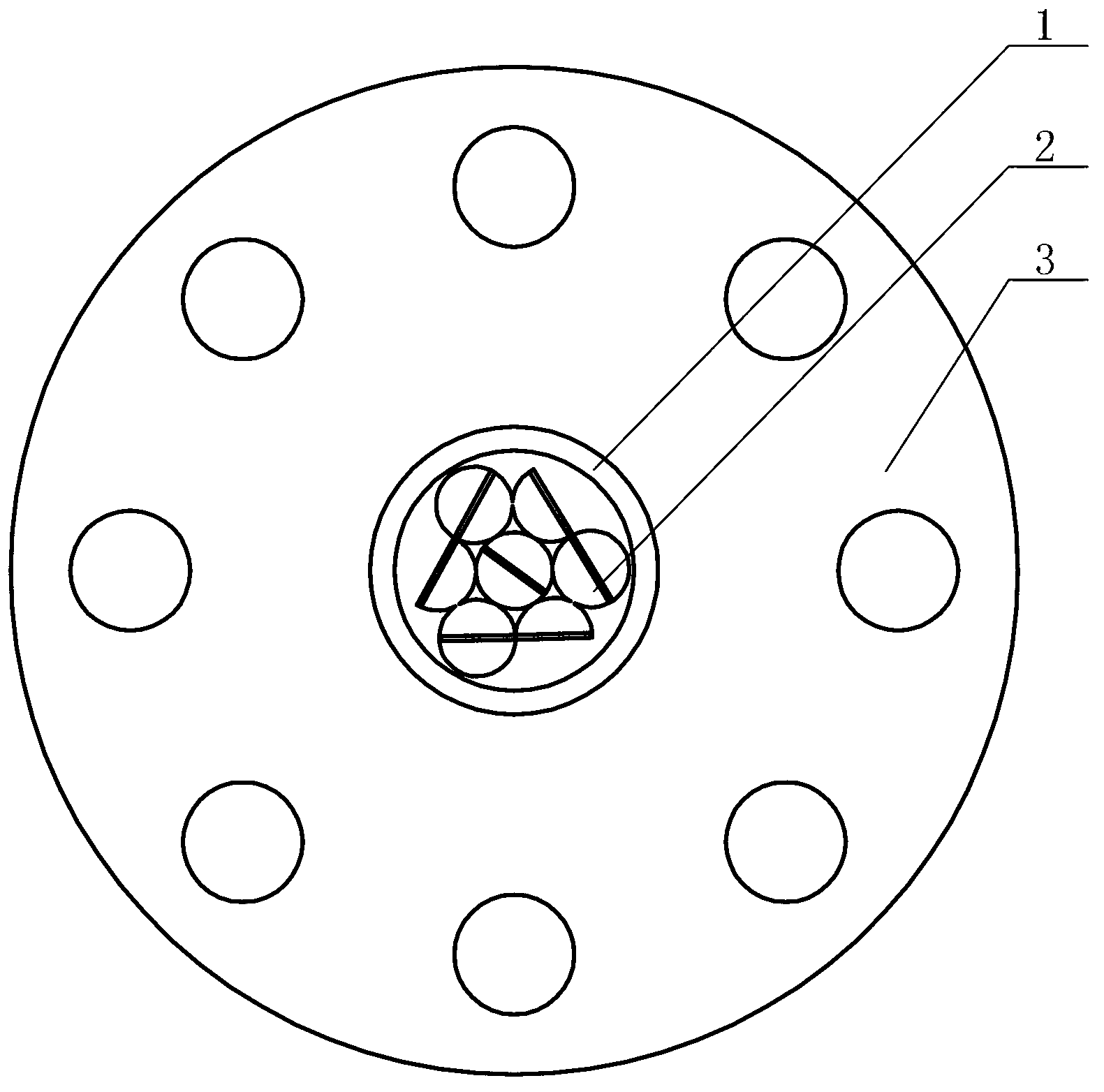

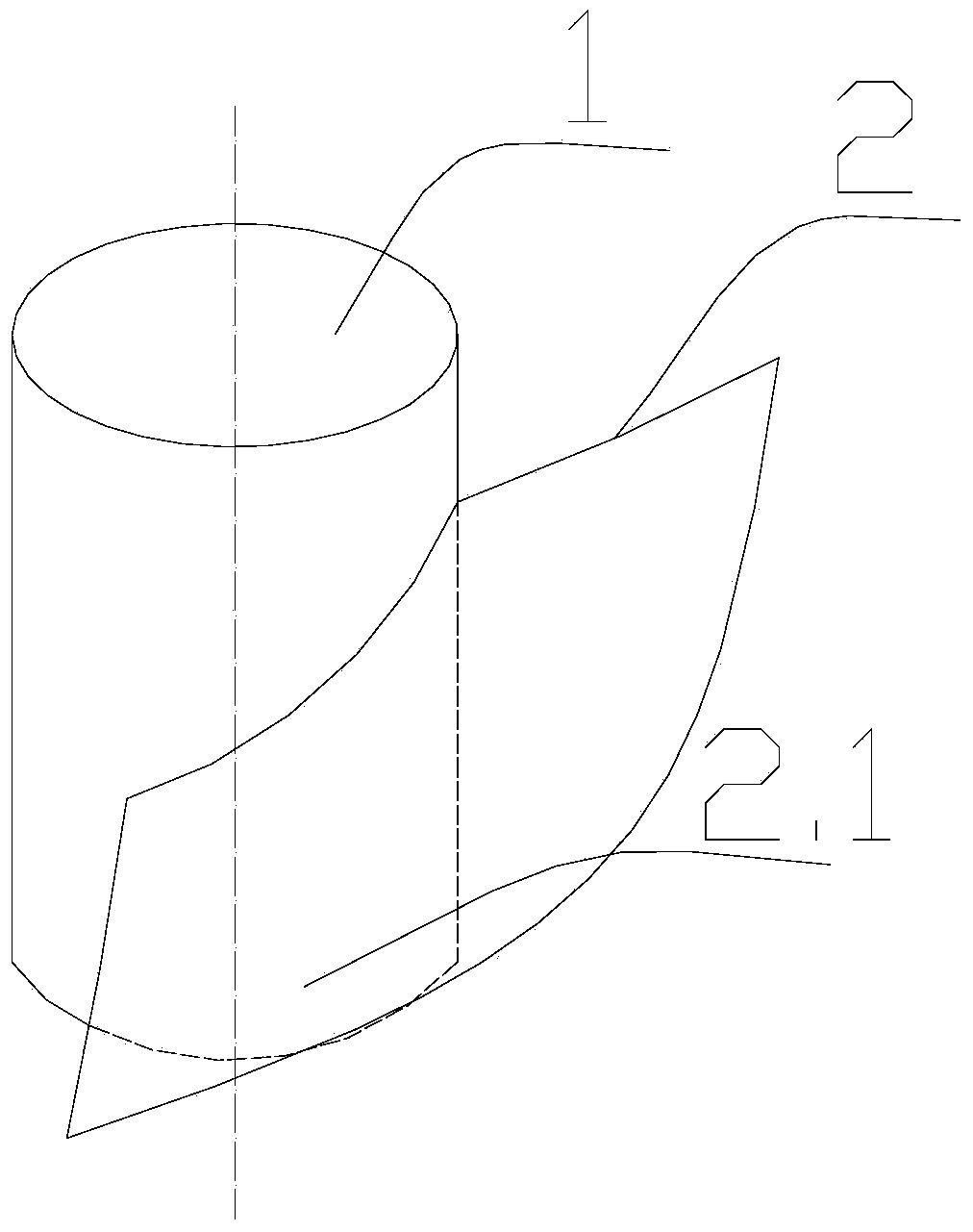

Spiral low-shear static mixer

InactiveCN103252182AAvoid mechanical shearComponent distribution is evenFlow mixersPulp and paper industryStatic mixer

The invention discloses a spiral low-shear static mixer, relates to a static mixer and in particular relates to a spiral low-shear static mixer. The invention aims to solve the problem that the conventional static mixer is high in viscosity loss and non-ideal in uniform mixing effect. The spiral low-shear static mixer comprises a tube shell and seven spiral mixing units, wherein the seven spiral mixing units are inserted into the tube shell; and the central line of each spiral mixing unit along the length direction is parallel to the central line of the tube shell along the length direction. The spiral low-shear static mixer is used for mixing polymer mother solution and water.

Owner:HARBIN BOHUA TECH

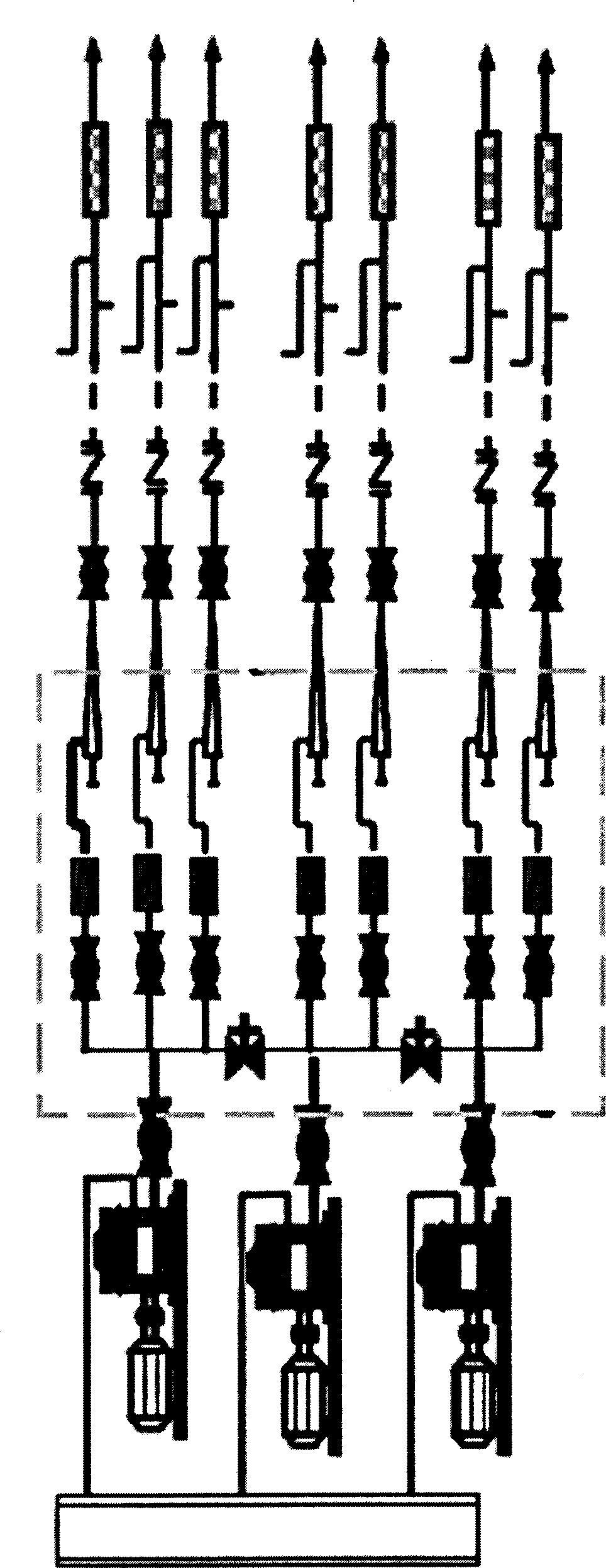

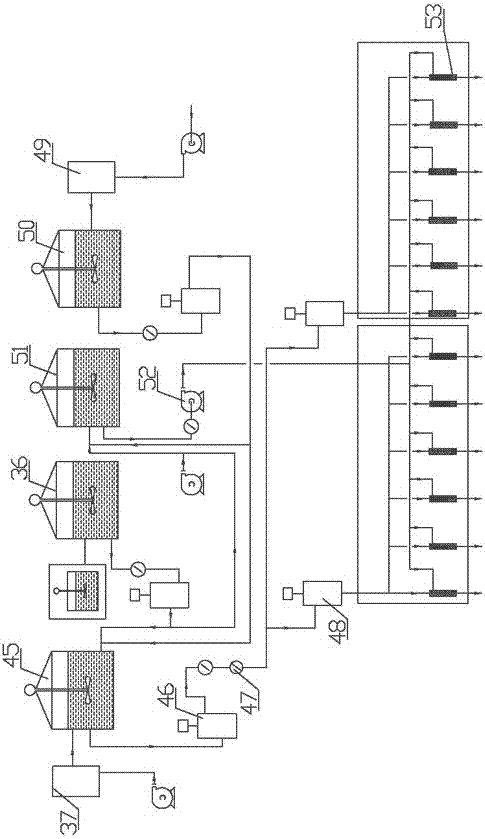

Proportion regulating and injecting system

The intention discloses a proportion regulating and injecting system which comprises a pressure pump, a plurality of pump heads are arranged on the pressure pump, each pump head corresponds to an injection well, is provided with a flux regulating mechanism which can control the flux of chemical agent solution, is independently communicated with a high-pressure valve group pipeline which can transport and monitor the state of the chemical agent solution, the output end of the high-pressure valve group pipeline is connected with a high-pressure water pipeline, and an output port of the high-pressure valve group pipeline is communicated with a static mixer; the chemical agent solution is diluted by water according to a set proportion; after diluent is further evenly mixed in the static mixer, the diluent is injected into an injection well. The invention directly completes the flow regulation of the chemical agent solution through the output of the pressure head, cancels a link that the chemical agent solution is regulated by valves to realize the flow distribution in the original one-pump multiple-well technology, simplifies the one-pump multiple-well technology, saves oil-field chemical area ground investment and reduces viscosity loose of the chemical agent solution of the injection link.

Owner:大庆德美特尔能源科技有限公司

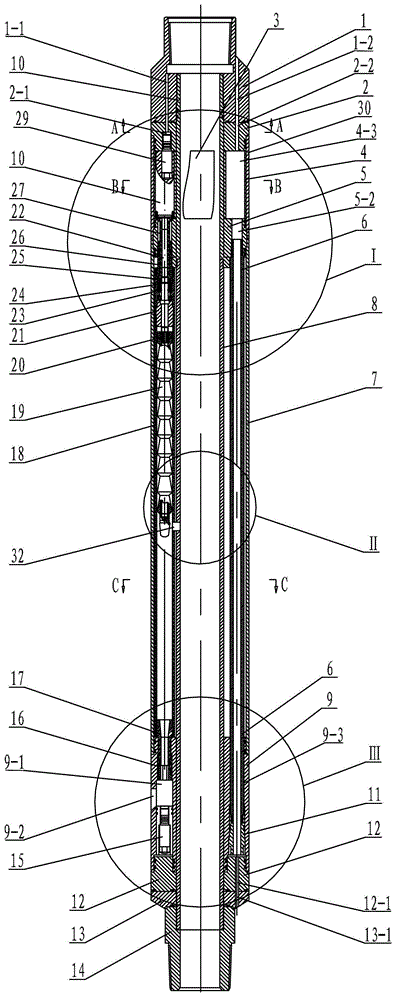

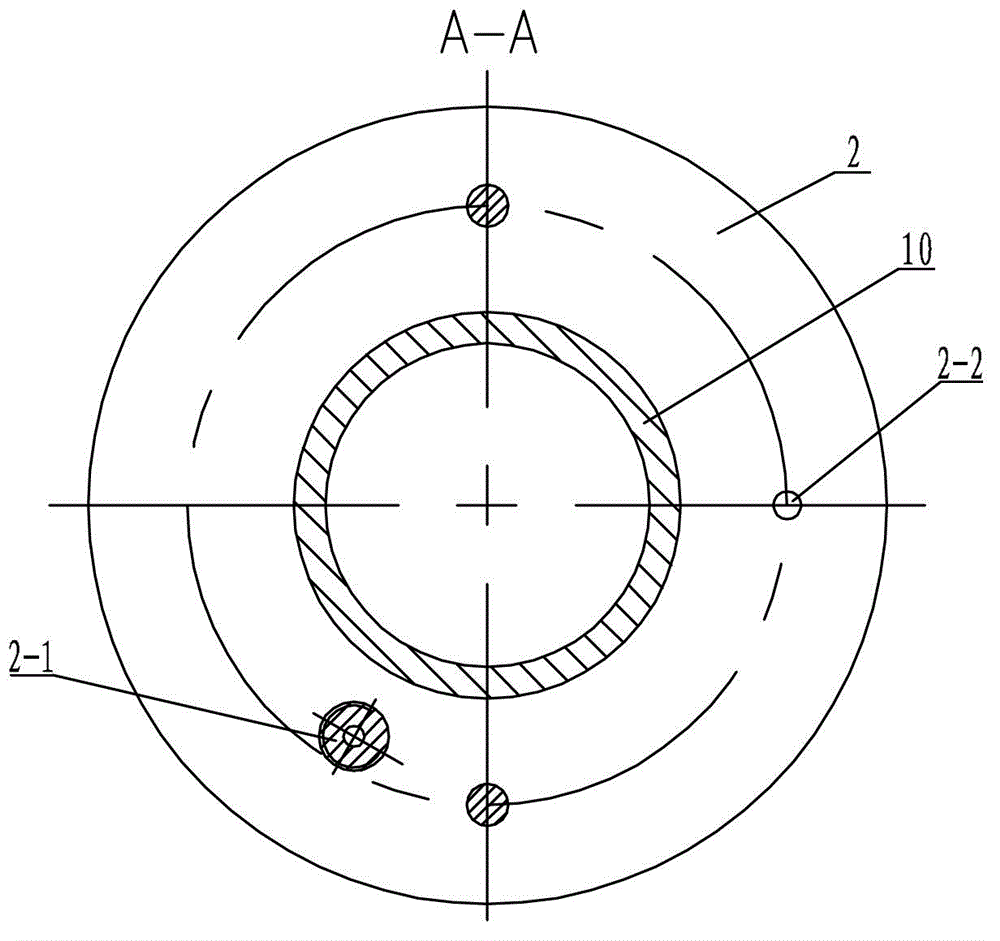

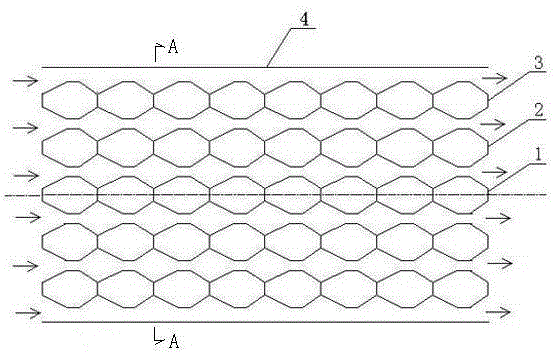

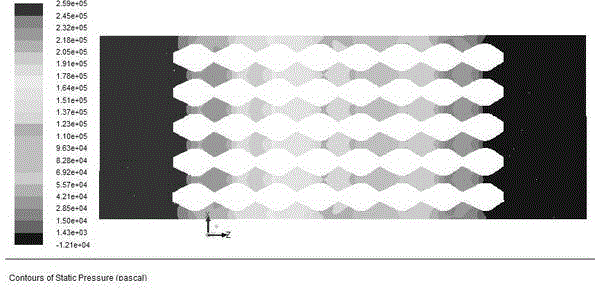

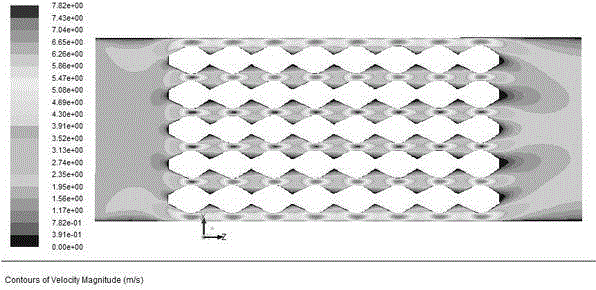

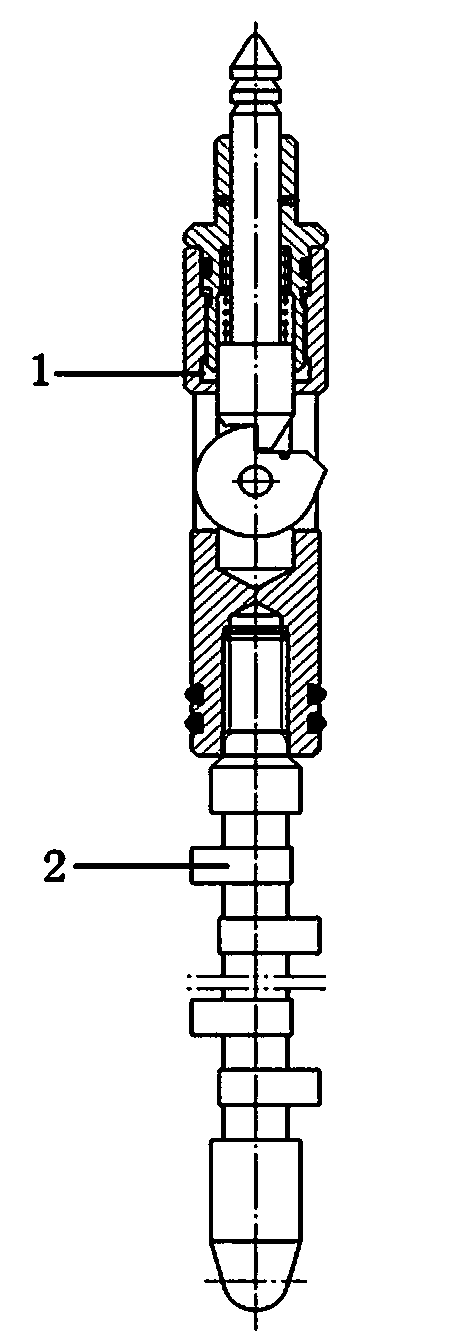

Novel partial pressure injection tool

ActiveCN104806213AIncrease the cross-sectional areaViscosity loss is smallFluid removalEngineeringViscosity

The invention relates to a novel partial pressure injection tool. The novel partial pressure injection tool is a depressurizing groove formed by coaxially sheathing a throttling core, an inner throttling ring pillar, an outer throttling ring pillar and an outer cylinder from inside to outside; the throttling core, the inner throttling ring pillar, and the outer throttling ring pillar are variable cross-section; the throttling core is formed by orderly connecting eight spindle shaped grooves with equal groove distance; the shape of the inner throttling ring pillar is the same as that of the outer throttling ring pillar; the inner throttling ring pillar and the outer throttling ring pillar are formed by orderly connecting eight spindle shaped ring grooves with equal groove distance; the spindle shaped grooves of the throttling core is corresponding to the spindle shaped ring grooves of the inner throttling ring pillar one by one, and the spindle ring grooves of the inner throttling ring pillar are corresponding to the spindle shaped ring grooves of the outer throttling ring pillar one by one; the longitudinal section of the spindle shaped ring grooves along the length direction is in the shape of spindle, and the longitudinal section of the spindle shaped grooves of the throttling core along the length direction is also in the shape of spindle; an annular gap between the inner throttling ring pillar and the throttling core is equal to the ring gap between the outer throttling ring pillar and the inner throttling ring pillar; the annular gap between the outer cylinder and the outer throttling ring pillar is slightly more than the annular gap. The novel partial pressure injection tool reduces the shear failure effect on ternary composite solution, and reduces the viscosity loss of flowing through the depressurizing groove.

Owner:NORTHEAST GASOLINEEUM UNIV

Green bleaching method of sulfate bagasse slurry

InactiveCN104313933AImprove bleaching effectViscosity loss is smallPulp bleachingChlorine dioxideOrganic chloride compound

The invention belongs to the technical field of pulping papermaking, and relates to an efficient green sulfate bagasse slurry bleaching method. The bleaching method comprises: (1) pretreatment with an acid or a chelating agent; (2) bleaching with ozone; and (3) bleaching with hydrogen peroxide. According to the present invention, the bleaching method completely adopts the oxygen-containing bleaching agent to replace the traditional chlorine-containing bleaching agent, such that the generation and the emission of the adsorbable organic chloride are completely eliminated, the clean production of the green bleaching of the sulfate bagasse slurry is achieved, and characteristics of environmental protection and health on human are provided; the use amount of the clear water is saved by more than 50-80% compared with the existing bleaching method; compared with the construction investment of the same scale bleaching adopting chlorine dioxide, the construction investment of the bleaching method of the present invention can be saved by 30-50%; compared with the production cost of per ton of the slurry of the bleaching adopting chlorine dioxide, the production cost of per ton of the slurry of the bleaching method of the present invention can be saved by 300-500 yuan; and the obtained bleached sulfate bagasse slurry has the good quality, wherein the whiteness achieves more than 83% ISO, the viscosity achieves more than 550-600 ml / g, and the obtained bleached sulfate bagasse slurry is especially for papermaking the high-end and sanitary household paper.

Owner:SOUTH CHINA UNIV OF TECH

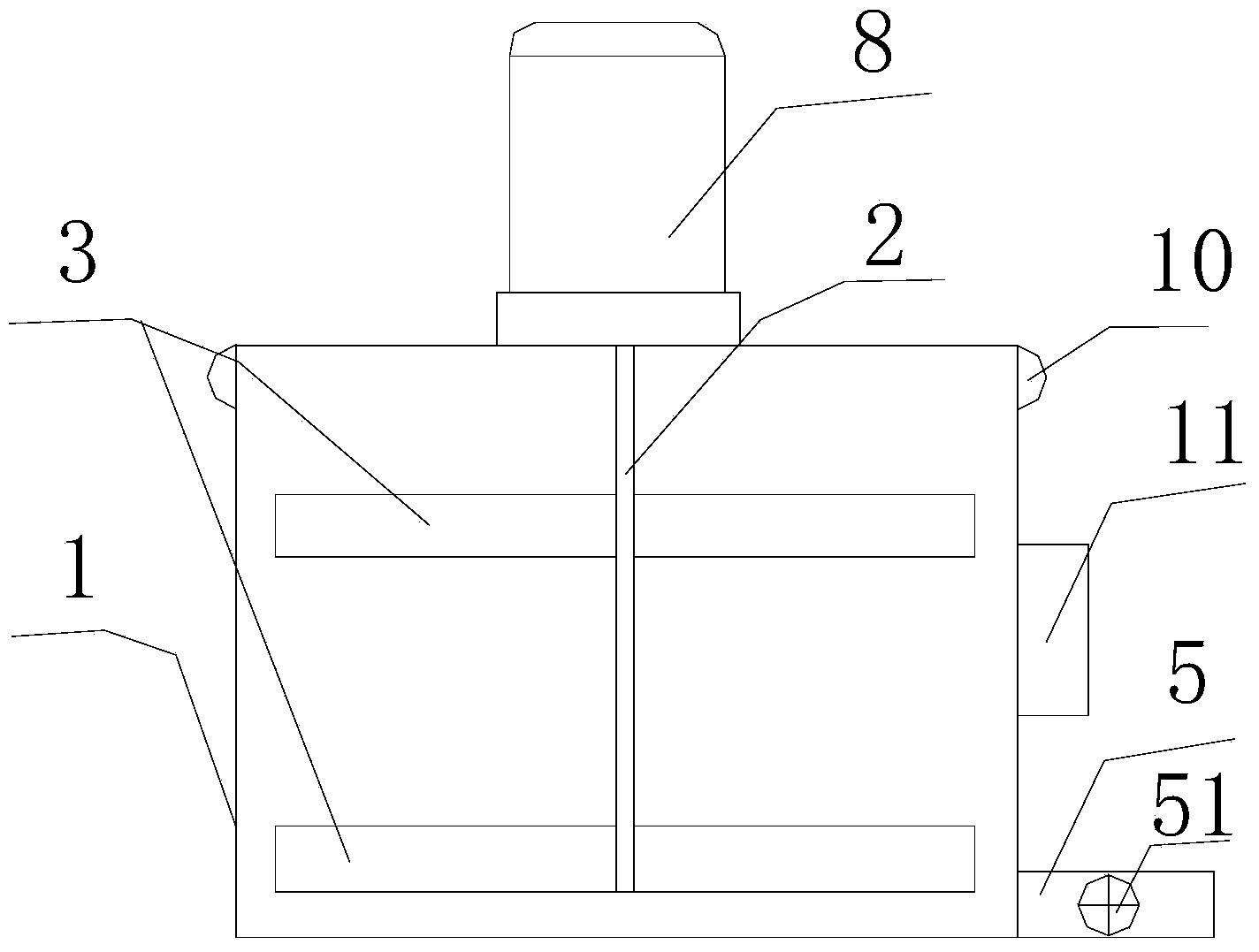

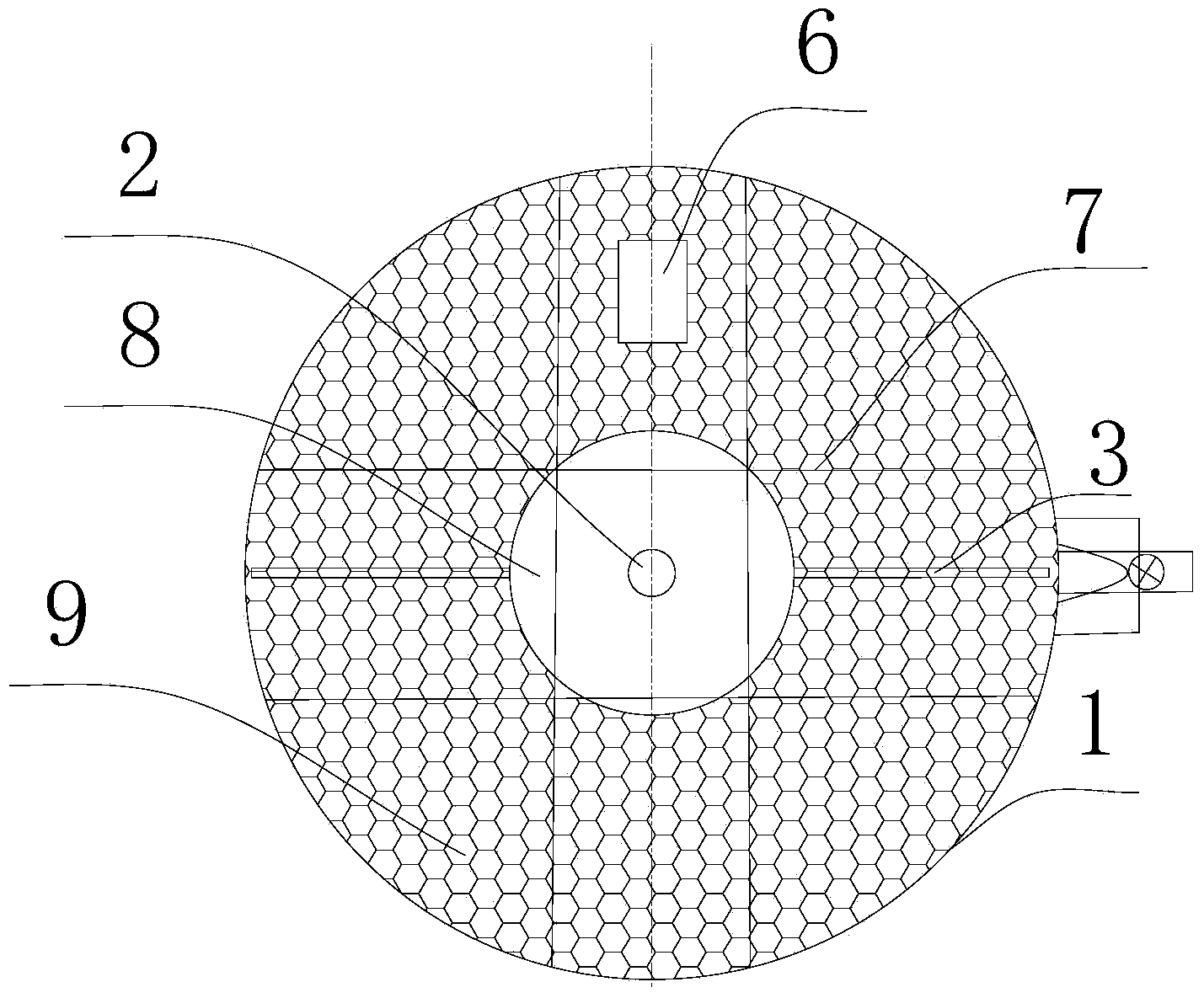

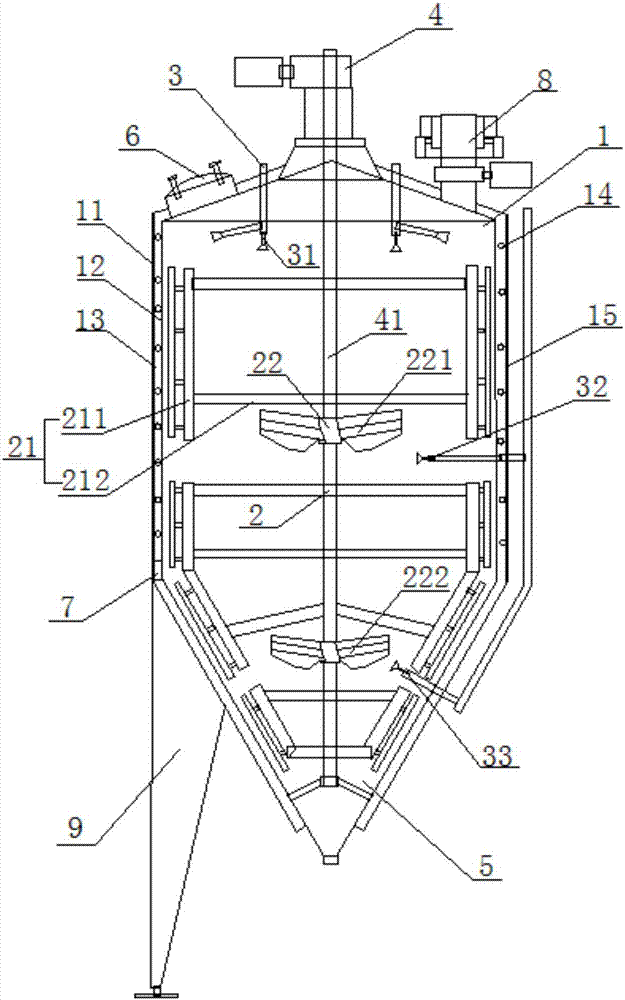

Curing tank for preparing water shutoff and profile control agent

The invention provides a curing tank for preparing a water shutoff and profile control agent, which solves the problem of overlarge viscosity loss in a process of preparing the water shutoff and profile control agent by an existing curing tank for preparing the water shutoff and profile control agent. The curing tank for preparing the water shutoff and profile control agent, provided by the invention, comprises a tank body with an inner cavity, and a stirring unit arranged in the inner cavity of the tank body, wherein the stirring unit comprises a rotating shaft, and at least one layer of blade group; the upper part of the rotating shaft is rotatably arranged on the tank body around an axial line of the rotating shaft, each layer of blade group comprises one or more blades located in a plane vertical to the axial direction of the rotating shaft, each blade is fixedly connected to the rotating shaft, and the outer wall surface of each blade, which faces towards the rotating direction of the rotating shaft, is parallel with the axial line of the rotating shaft. By adopting the curing tank for preparing the water shutoff and profile control agent, provided by the invention, the viscosity of the water shutoff and profile control agent in the preparation process can be lowered.

Owner:PETROCHINA CO LTD

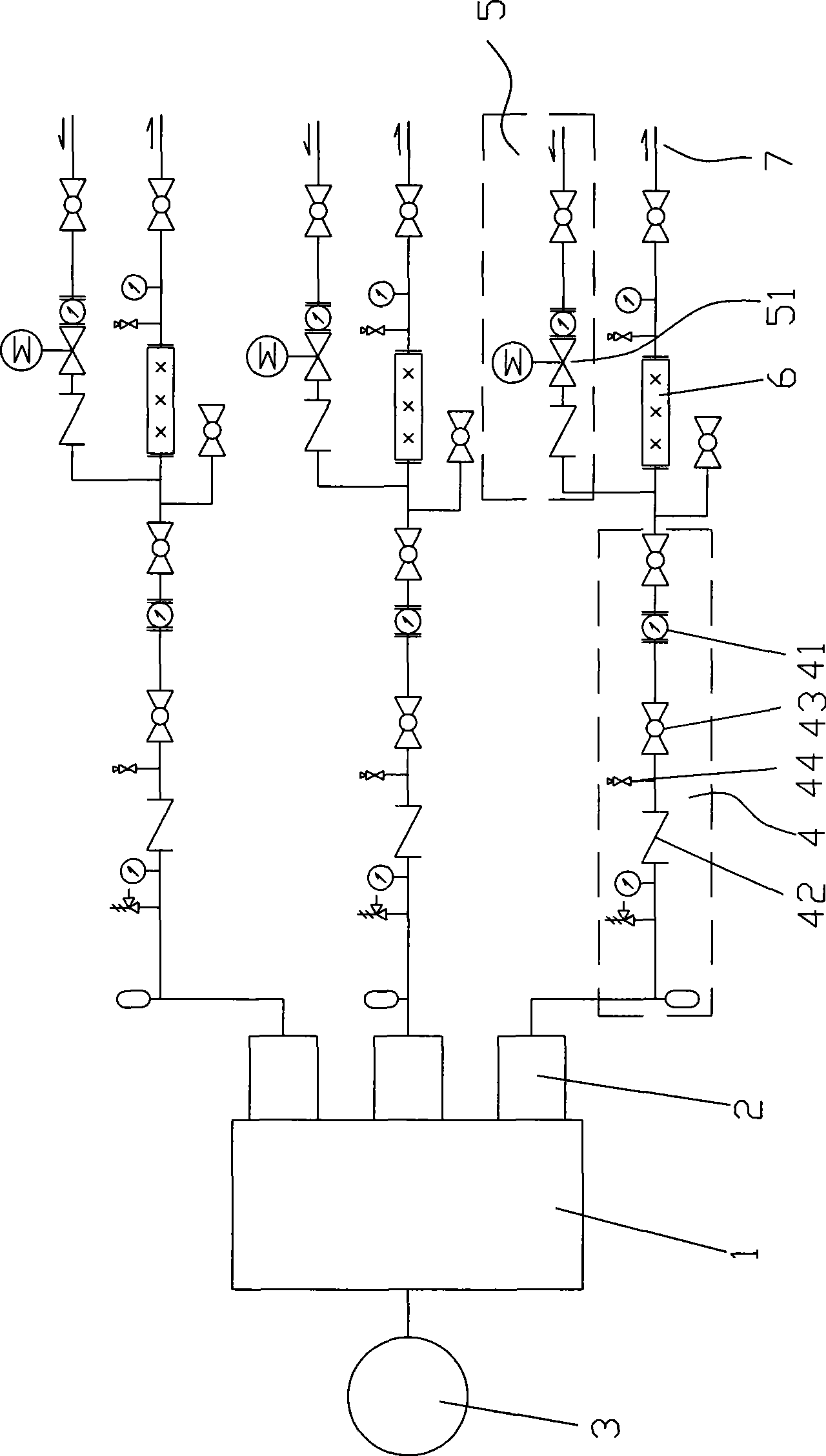

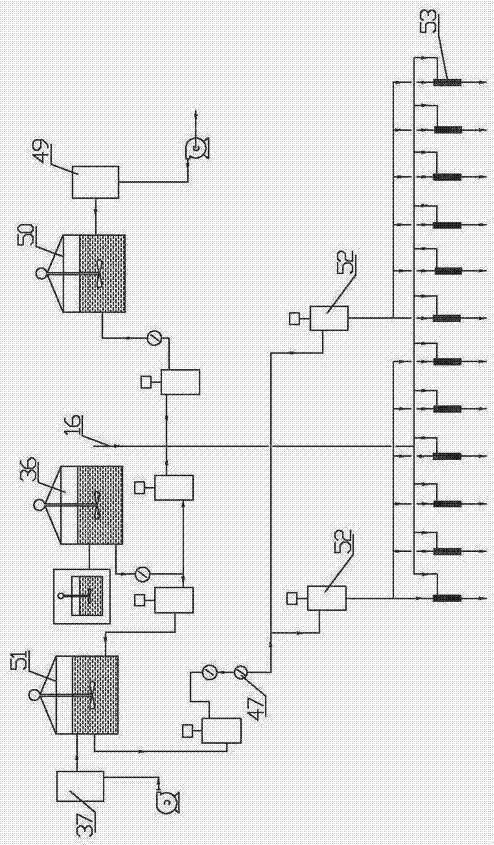

Single-pump single-well weak alkali ternary injection device with two-stage concentration regulation and application method thereof

ActiveCN107143318AViscosity loss is smallReduce concentration errorsFluid removalProgrammable logic controllerInstability

The invention relates to the technical field of weak alkali ternary injection distribution processes, in particular to a single-pump single-well weak alkali ternary injection device with two-stage concentration regulation and an application method thereof. The single-pump single-well weak alkali ternary injection device with two-stage concentration regulation comprises an AS (alkali-surfactant) storage tank, an S storage tank, an SP (surfactant-polymer) storage tank and a PLC (programmable logic controller); the AS storage tank is provided with an alkali mother liquid inlet, a first surfactant mother liquid inlet and a first water inlet, and the S storage tank is provided with a second surfactant mother liquid inlet and a second water inlet. The single-pump single-well weak alkali ternary injection device with two-stage concentration regulation and the application method thereof have the advantages that viscosity loss and concentration error of a surface target liquid can be decreased, the concentration of a polymer can be regulated flexibly by injecting surfactant solution, an alkali and a surfactant are distributed at a low-pressure end so that the prepared AS mixed liquid has uniform and stable alkali concentration, and the alkali concentration instability problem due to drip mixing of the alkali and surfactant at the high-pressure water end in the prior art is solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

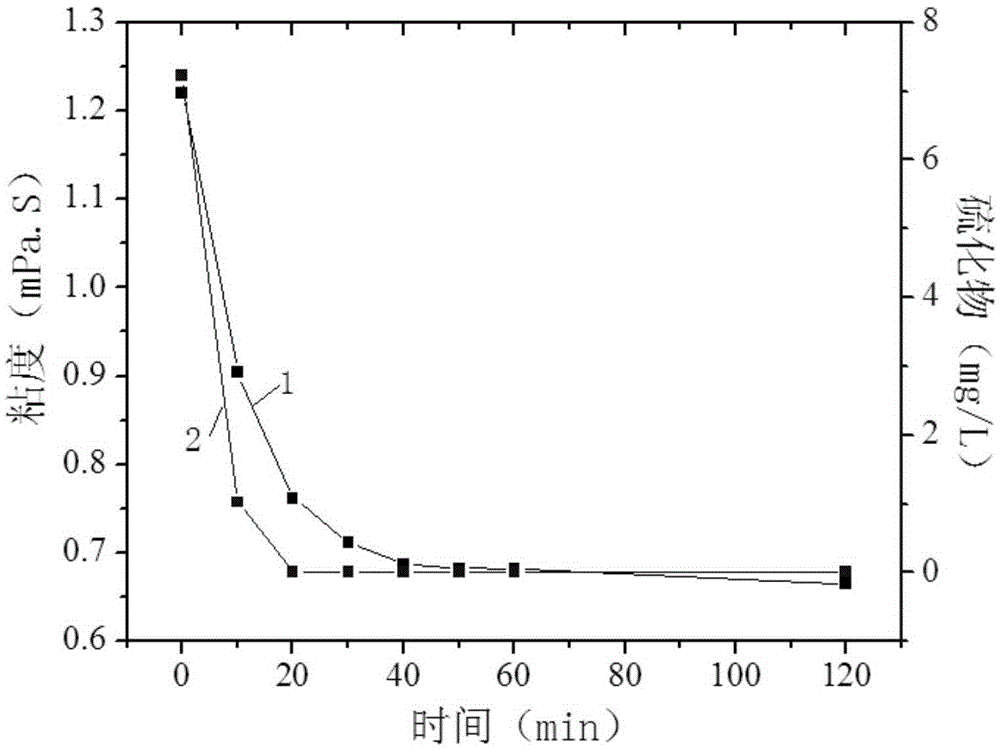

Processing method of confecting polymer water through oxidization method

InactiveCN105417810ARemoval of reducing substancesEliminate the influence of water quality indicators such as viscosityWaste water treatment from quariesWater treatment parameter controlPolymer scienceSewage

The invention discloses a processing method of confecting polymer water through oxidation method and relates to the field of oilfield confecting polymer water processing. In the prior art, the polymer sewage is used to replace clean water for injection allocation, and the viscosity of prepared polymer solution is reduced. In order to solve the problem mentioned above, an oxidization method is adopted to process polymer-containing sewage so as to make sure that the polymer-containing water can completely replace the clean water to prepare a polymer solution. The method comprises the following steps: introducing confecting polymer water into a reactor, at the same time, introducing ozone into the reactor, and carrying out a treatment for 10 to 60 minutes. Through the oxidization treatment, the reducing substances in confecting polymer water are effectively removed, the processed confecting polymer water can completely replace clean water, the using amount of clean water is reduced, and the viscosity of prepared polymer is not changed.

Owner:HARBIN INST OF TECH

Yogurt fermentation tank

InactiveCN107047761AViscosity loss is smallImprove efficiency during cleaningMilk preparationCleaning using liquidsDrive shaftPulp and paper industry

The invention discloses a yogurt fermentation tank. The tank comprises a tank body, a stirring device, a CIP washing device and a motor transmission gear. The motor transmission gear is mounted on the top of the tank body, the bottom of the tank body is arranged as a cone bottom, the vertex angle of the cone is 30-90 degrees, the stirring device comprises a frame type stirring mechanism and a blade stirring mechanism which are mounted on a transmission shaft 41 in the tank body, and the CIP washing device comprises three groups of spray headers which are respectively installed on the top, in the middle and at the bottom of the inner wall of the tank body. Compared with the prior art, the detects are overcome by the yogurt fermentation tank that when high viscosity yogurt is stirred by a traditional fermentation tank, the viscosity losses are large and mouthfeel and shape are poor, and therefore the quality of yogurt is improved; at the same time, the stirring time is shortened, and the power consumption is reduced; the CIP washing effect and washing efficiency are improved, and the risk caused by fermentation tank contamination can be effectively reduced.

Owner:BRIGHT DAIRY & FOOD

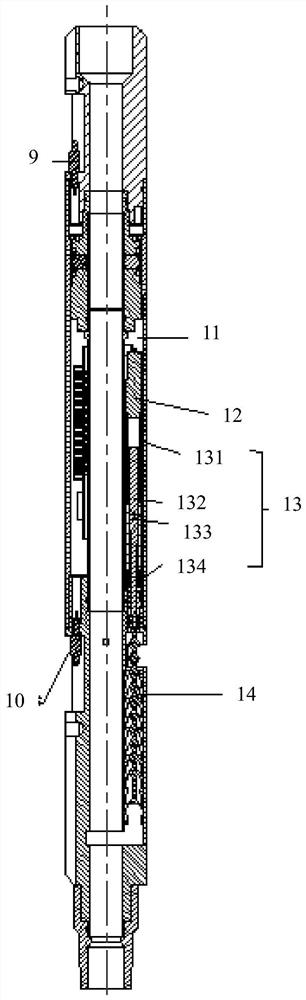

Layered polymer injection distributor, polymer intelligent layered injection system and application

ActiveCN111749663ASave adjustment timeGuaranteed dispensing pass rateFluid removalThermodynamicsPolymer flood

The invention provides a layered polymer injection distributor, a polymer intelligent layered injection system and an application. The polymer intelligent layered injection system involves a polymer intelligent layered injection pipe column and a ground control box; and the polymer intelligent layered injection pipe column comprises an oil pipe, a plurality of packers and a plurality of layered polymer injection distributors, wherein the packers and the layered polymer injection distributors are alternately arranged on the oil pipe, and the plurality of packers and the plurality of layered polymer injection distributors are connected with the ground control box through cables. In the process of carrying out polymer flooding intelligent layered injection by using the layered polymer injection distributors and the polymer intelligent layered injection system, a work vehicle is not needed, real-time monitoring and intelligent control of the down-hole injection pressure and flow parametersof a polymer layered injection well can be realized, the layered injection qualification rate can be guaranteed for a long time, the adjustment time of the single-well flow can be reduced, the operation amount is reduced, and the operation cost is reduced.

Owner:PETROCHINA CO LTD

Suspended fruit grain drinking yoghurt and preparation method thereof

The invention discloses suspended fruit grain drinking yoghurt and a preparation method thereof. The suspended fruit grain drinking yoghurt comprises the following raw materials in percent by weight:5-10% of jam, 0.5-1% of a whey protein powder, 0.1-0.3% of a yolk powder, 8-10% of white granulated sugar, 0.4-0.6% of a stabilizer and the balance of fresh milk according to the mass percentage. Moreover, the invention further discloses the preparation method of the suspended fruit grain drinking yoghurt. The preparation method of the suspended fruit grain drinking yoghurt comprises the followingsteps: 1) emulsifying and shearing, 2) cooling, 3) diluting a solution with water to a volume, 5) homogenizing, 6) fermenting, 7) breaking of emulsion, 8) secondary homogenizing, 9) adding the jam, and 10) filling. The suspended fruit grain drinking yoghurt and the preparation method thereof, disclosed by the invention, have the advantages that the prepared suspended fruit grain drinking yoghurthas the advantages of low viscosity, good flowability and smooth mouth feel; the stability and the quality of the flowability can be guaranteed in the preparation process; obvious water bleeding and layering phenomenon cannot be caused; and the production cost can also be reduced.

Owner:广州风行乳业股份有限公司

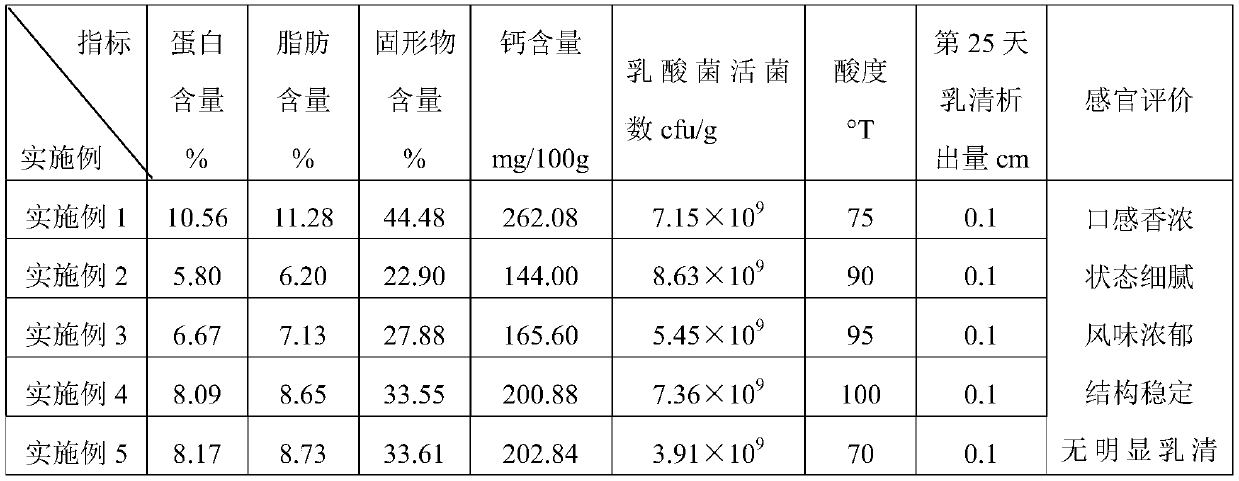

High-protein additive-free yoghourt and preparation method thereof

PendingCN110870504AHigh nutritional valueIncrease proteinMilk preparationOther dairy technologyBiotechnologyFood additive

The invention discloses high-protein additive-free yoghourt and a preparation method thereof. The preparation method comprises the following steps: (1) uniformly mixing raw milk and white granulated sugar, preheating, homogenizing, sterilizing and cooling the mixture, inoculating the mixture with lactic acid bacteria as starters, and fermenting the milk to obtain yogurt, (2) separating whey from the yoghurt through a separator to obtain high-protein additive-free yoghurt, and (3) adding or not adding auxiliary materials such as fruit grains (or jam), honey and nuts into the high-protein additive-free yoghourt, and carrying out filling, refrigerating and inactivation to obtain the high-protein additive-free yoghourt. The high-protein additive-free yoghourt has protein content of 5.8 to 11.02%, fat content of 6.2 to 11.78%, solid content of 22.4-44.98%, calcium content of 145-273 mg / 100mL, the viable count of lactic acid bacteria of larger than or equal to 109 CFU / mL and acidity of 70-100 degrees T, the nutrition is rich, the state is thick, the taste is fine, smooth and fragrant, no food additive is contained, and whey is not separated out within the quality guarantee period.

Owner:BRIGHT DAIRY & FOOD CO LTD

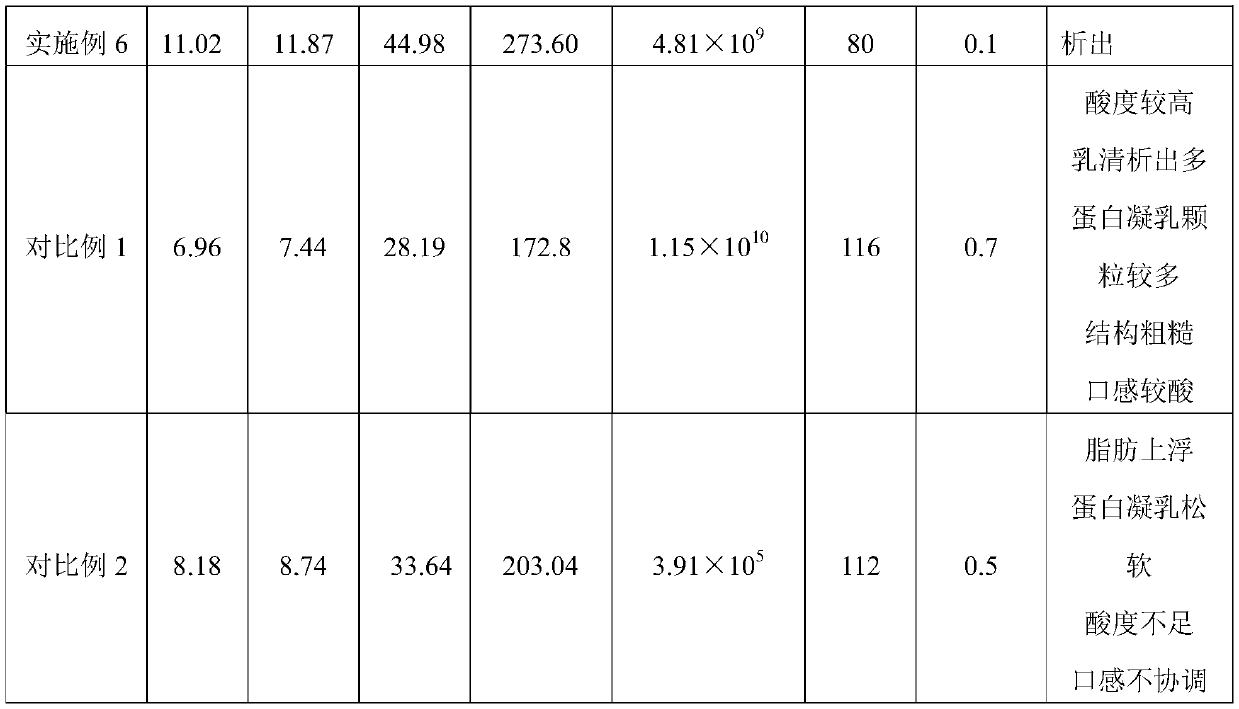

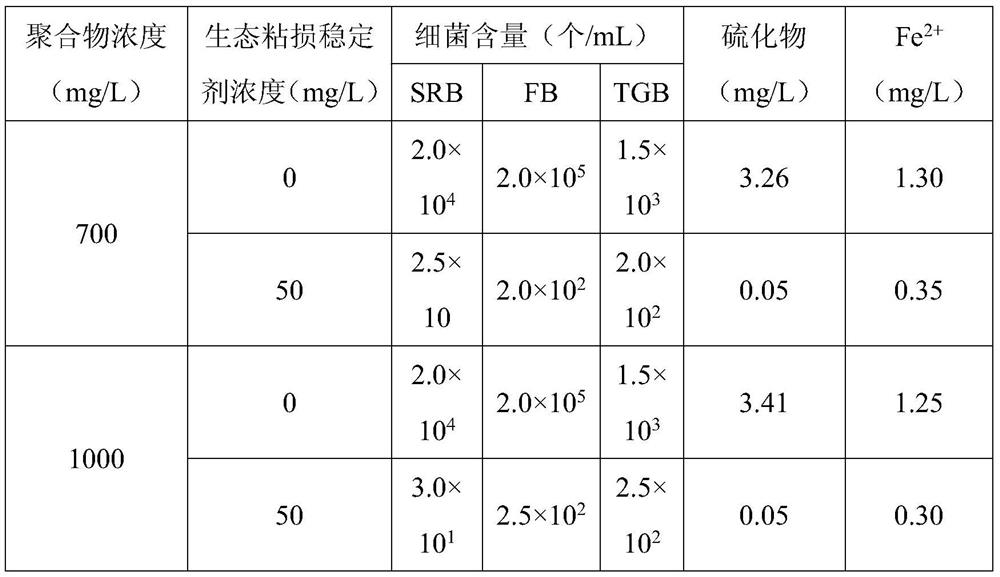

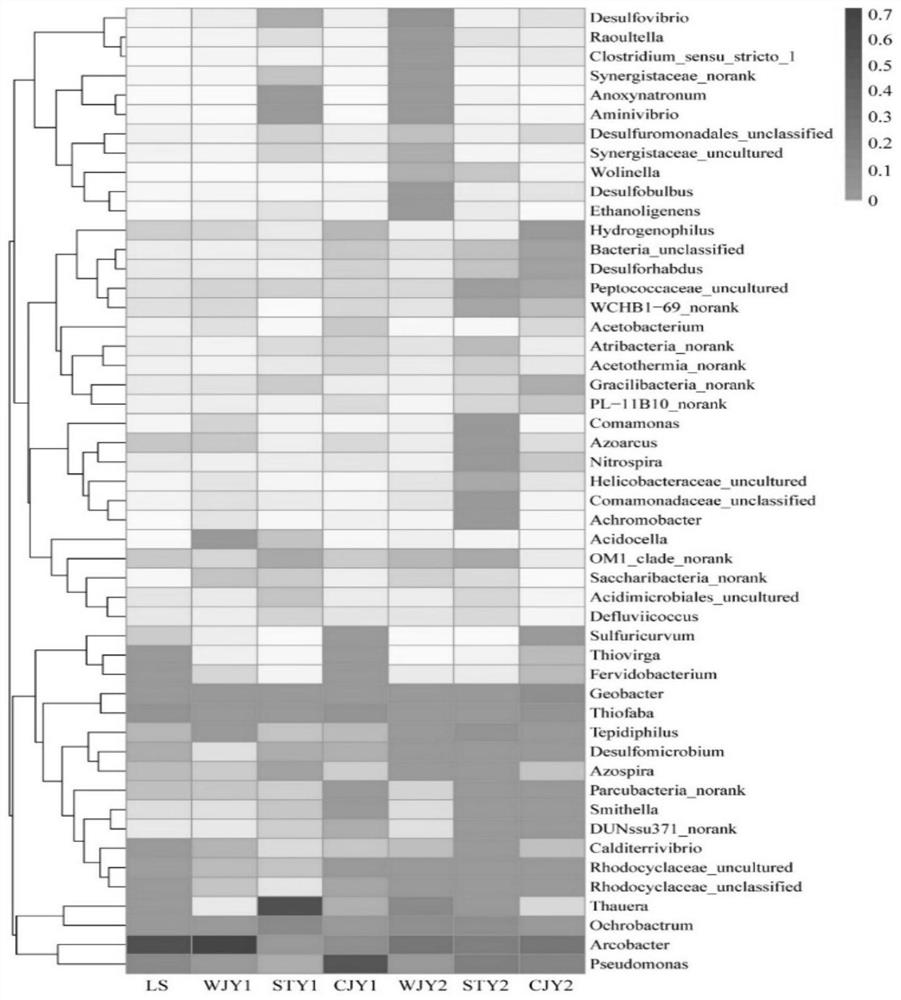

Method for reducing viscosity loss by regulating and controlling microbial community structure composition in polymer prepared from oilfield produced water

PendingCN111662700AReduce utilizationViscosity loss is smallDrilling compositionNitrite saltEnvironmental chemistry

The invention discloses a method for reducing viscosity loss by regulating and controlling microbial community structure composition in a polymer prepared from oilfield produced water, relates to a method for reducing viscosity loss of a polymer prepared from oilfield produced water, and aims to solve the technical problem of polymer viscosity reduction caused by sulfate reducing bacteria. By adding nitrate and nitrite, the ecological niche of denitrifying bacteria can be improved, the ecological niche of sulfate reducing bacteria is reduced, and the community composition of microorganisms inthe injection allocation system is changed so that the viscosity loss of a polymer is reduced. According to the invention, the number of sulfate reducing bacteria in the injection allocation system isreduced, the utilization of the polymer by the sulfate reducing bacteria is reduced, the viscosity loss of the polymer is reduced, and the effective viscosity of the polymer is ensured. According tothe method, sulfate reducing bacteria in the injection allocation system can be effectively inhibited, and no harm is caused to beneficial bacteria in an oil field system. The method is used for reducing the viscosity loss of the polymer prepared from the oilfield produced water.

Owner:HUACHEN ENVIRONMENTAL PROTECTION ENERGY (GUANGZHOU) CO LTD

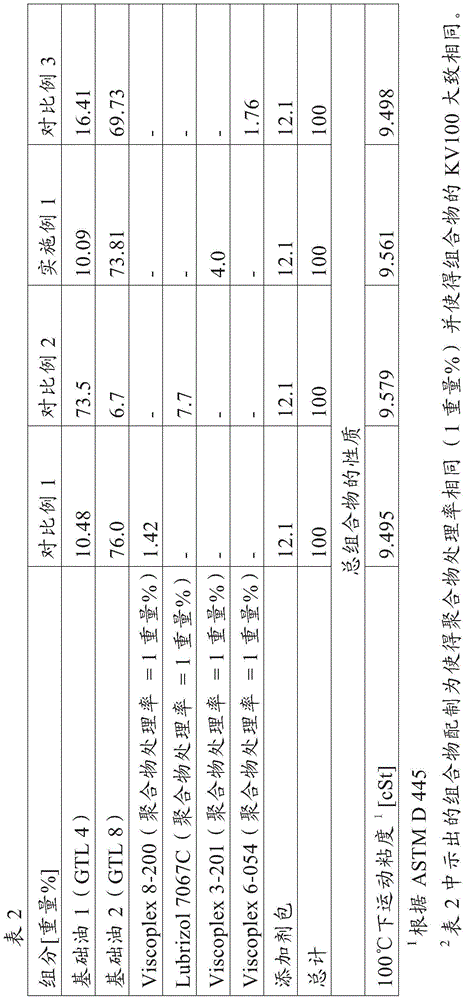

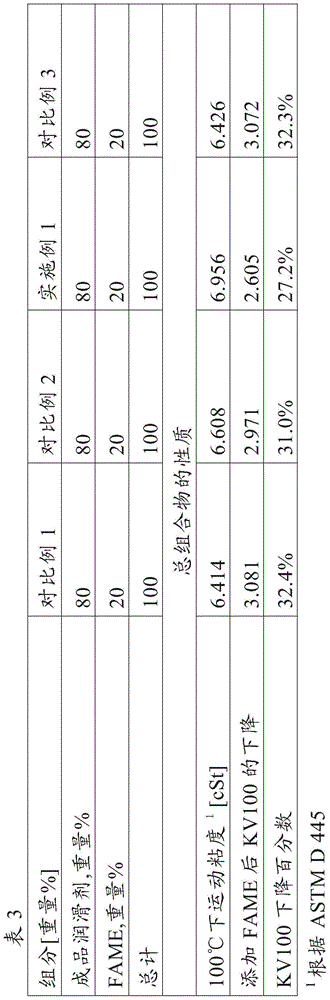

Lubricating composition

ActiveCN105189713AViscosity loss is smallBiofuelsLiquid carbonaceous fuelsExternal combustion engineCrankcase

Use of a comb polymer for reducing the loss in viscosity of a lubricating composition for the crankcase of an internal combustion engine, wherein the internal combustion engine is fuelled by a fuel composition comprising a fatty acid alkyl ester.

Owner:SHELL INT RES MAATSCHAPPIJ BV

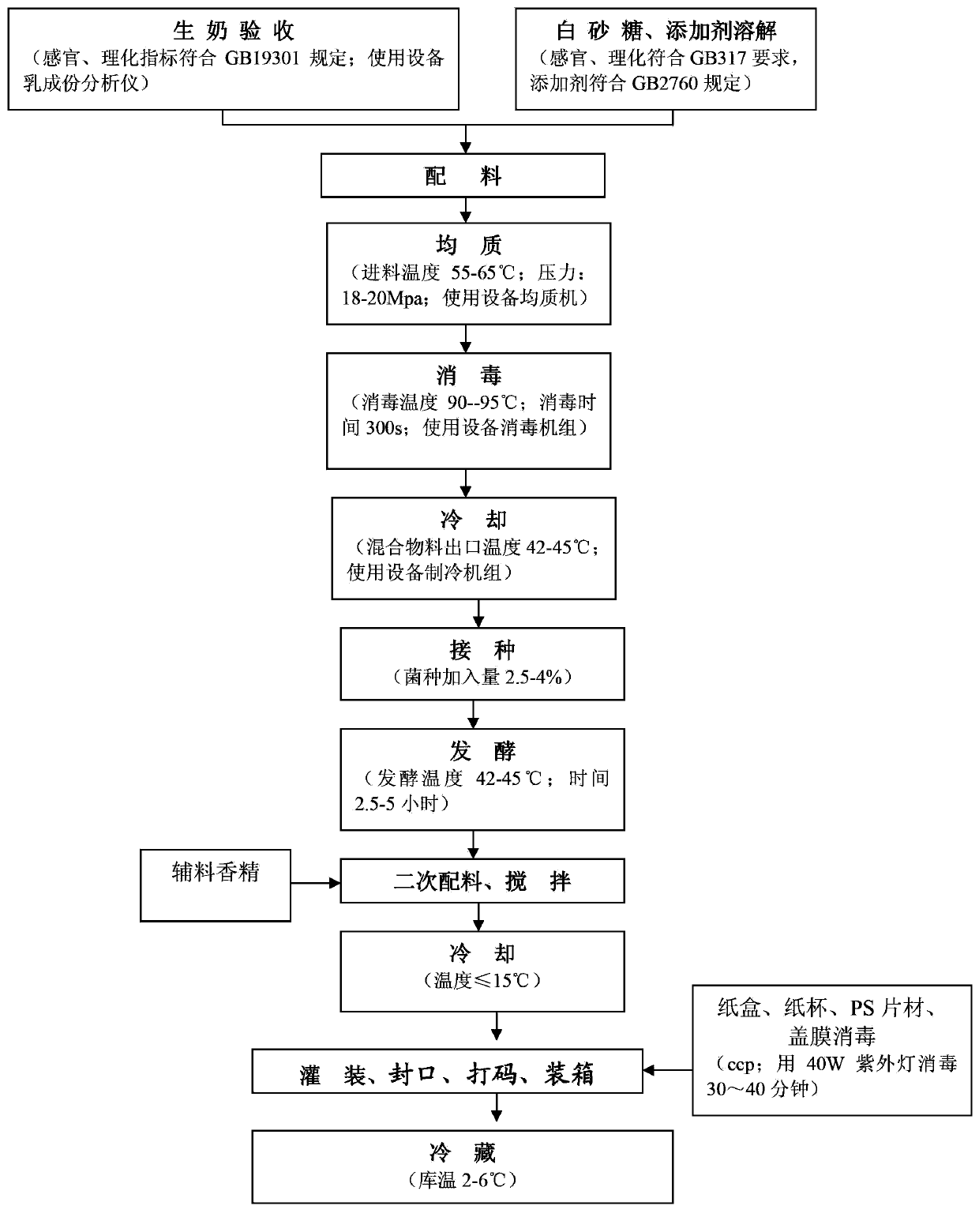

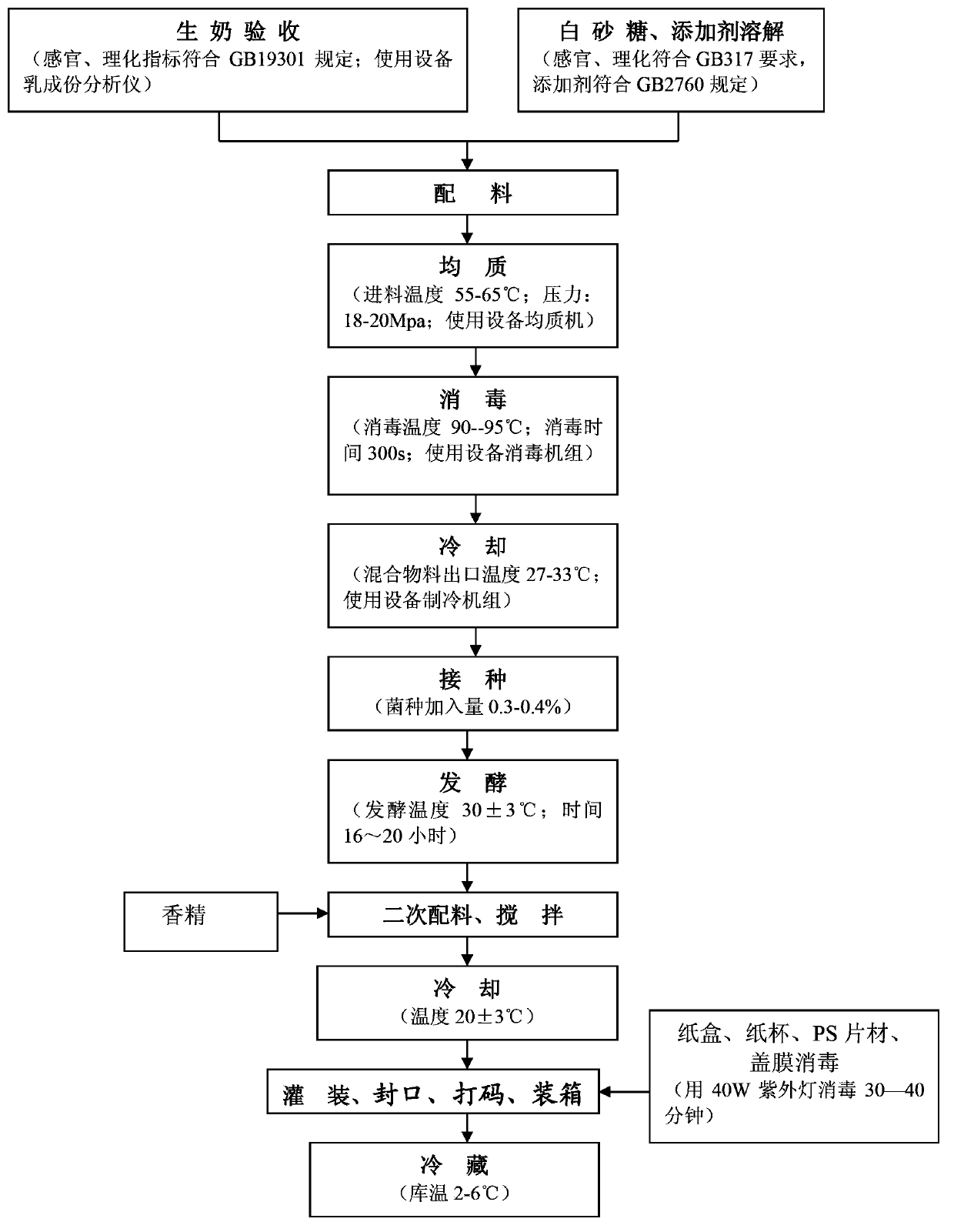

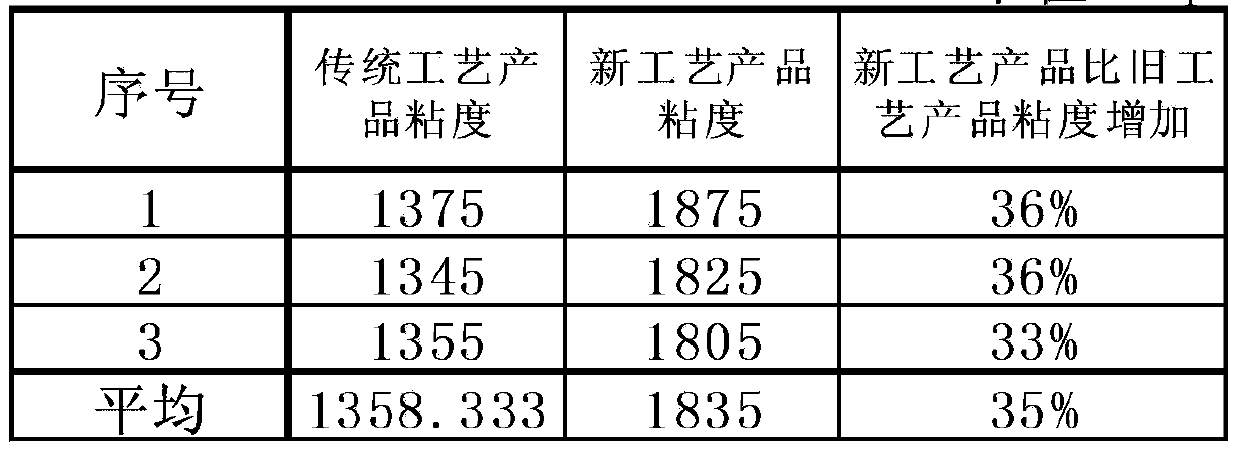

Preparation method for disturbing yoghurt

InactiveCN103385296ADelayed fermentationImprove labor efficiencyMilk preparationMixed materialsRefrigeration

The invention relates to a preparation method for disturbing yoghurt. The preparation method comprises the following successive steps: acceptance inspection of raw milk; acceptance inspection of accessory materials; batching; homogenization; sterilization; primary cooling; inoculation; fermentation; secondary batching; stirring; secondary cooling; filling; sealing; coding; binning; and refrigeration; wherein temperature for primary cooling and inoculation is 27 to 33 DEC C, a strain accounting for 0.3 to 0.4% (wt%) of a mixed material is inoculated, fermentation is carried out in a fermentation cylinder at a temperature of 30 + / - 3 DEG C for 16 to 20 h and is terminated when acidity reaches 65 to 70 DEG C T, and fermentation broth is cooled to a temperature of 20 + / - 3 DEG C in secondary cooling. Compared with inoculation temperature of 42 to 45 DEG C in a traditional process, inoculation temperature the invention is controlled to be 27 to 33 DEG C, so the fermentation speed of the yoghourt decreases, acidity slowly increases, an acidity generation speed is slowed down, and acidity of the yoghourt can be better controlled in actual operation; with the preparation method, the quality of the produced yoghourt is improved and stable, fermentation can be reasonably carried out at night, on-duty time of a worker is shortened, and labor efficiency is improved.

Owner:YANGZHOU YANGDA KANGYUAN DAIRY

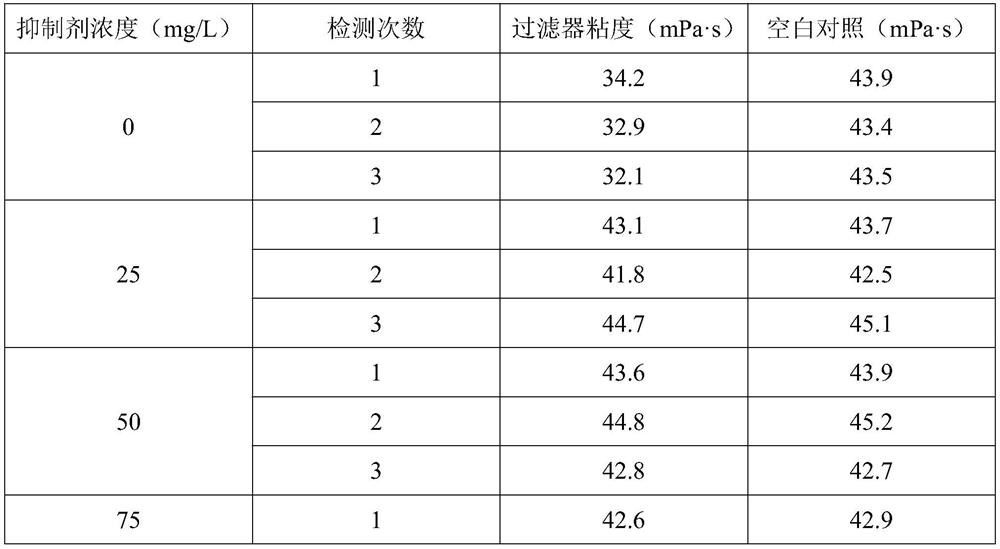

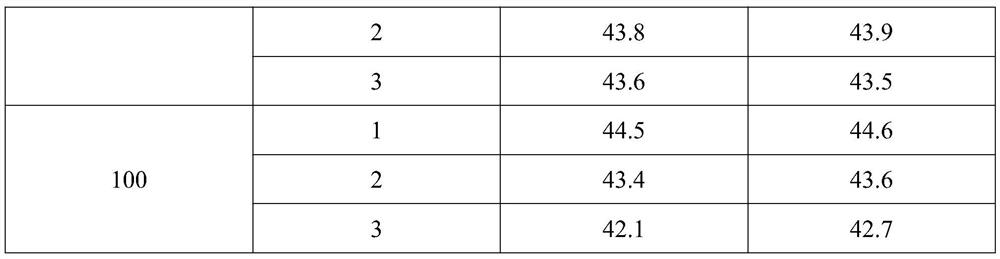

Oilfield polymer viscosity loss inhibitor and use method thereof

PendingCN111662699AReduce bacteria contentReduce concentrationDrilling compositionMaterials sciencePolymer

The invention discloses an oilfield polymer viscosity loss inhibitor and a use method thereof, relates to an oilfield polymer viscosity loss inhibitor and a use method thereof, and aims to solve the problems of unstable viscosity and large loss of the polymer in the process of injecting the prepared polymer into the underground in the prior art. The auxiliary agent is prepared from nitrite, sodiumhydroxide, nutrient elements, a synergistic inhibitor and water in percentage by mass. The oilfield polymer viscosity loss inhibitor is used for preparing polymer mother liquor and diluting polymersand then used for oil exploitation.

Owner:HUACHEN ENVIRONMENTAL PROTECTION ENERGY (GUANGZHOU) CO LTD

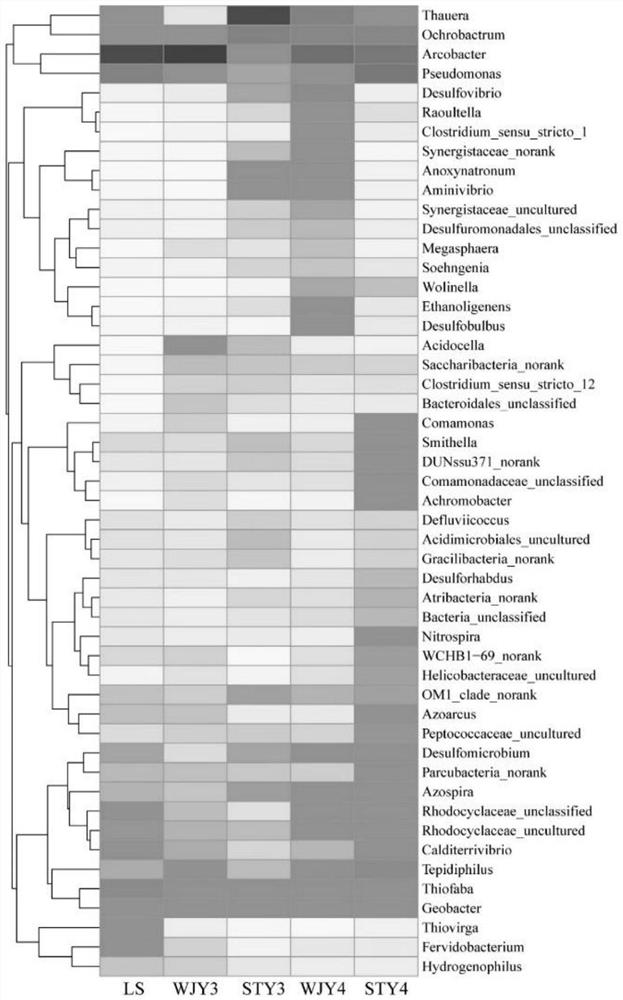

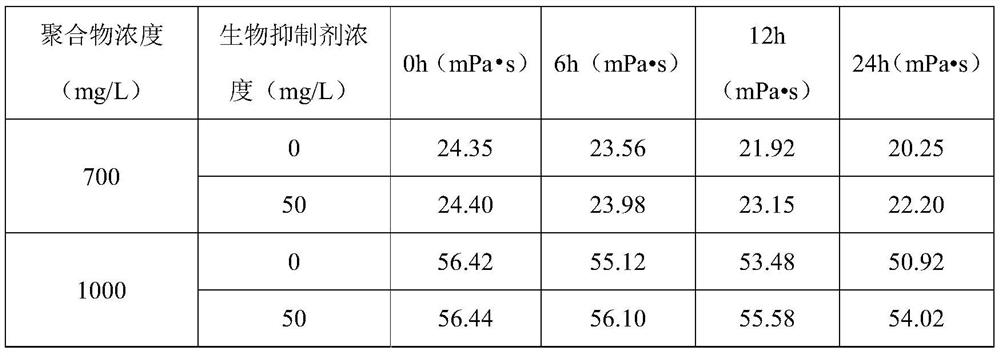

Biological inhibitor suitable for controlling polymer viscosity loss in virtue of ecological regulation thought and use method thereof

PendingCN111621270AViscosity loss is smallGuaranteed uptimeDrilling compositionDenitrifying bacteriaOil field

The invention discloses a biological inhibitor suitable for controlling polymer viscosity loss in virtue of an ecological regulation thought and a using method thereof. The invention aims to solve theproblem of polymer viscosity loss caused by sulfate reducing bacteria in an oil field injection allocation system. The biological inhibitor is composed of denitrifying bacterium fermentation liquor,nutrient elements and water. When in use, the biological inhibitor is pumped into oilfield produced water for polymer preparation, then polymer mother liquor is prepared, and a polymer is diluted andthen used for oilfield exploitation. The biological inhibitor provided by the invention can effectively inhibit sulfate reducing bacteria in an injection allocation system, and does not cause harm tobeneficial bacteria in an oil field system. The biological inhibitor is applied to the field of oilfield polymer flooding.

Owner:HUACHEN ENVIRONMENTAL PROTECTION ENERGY (GUANGZHOU) CO LTD

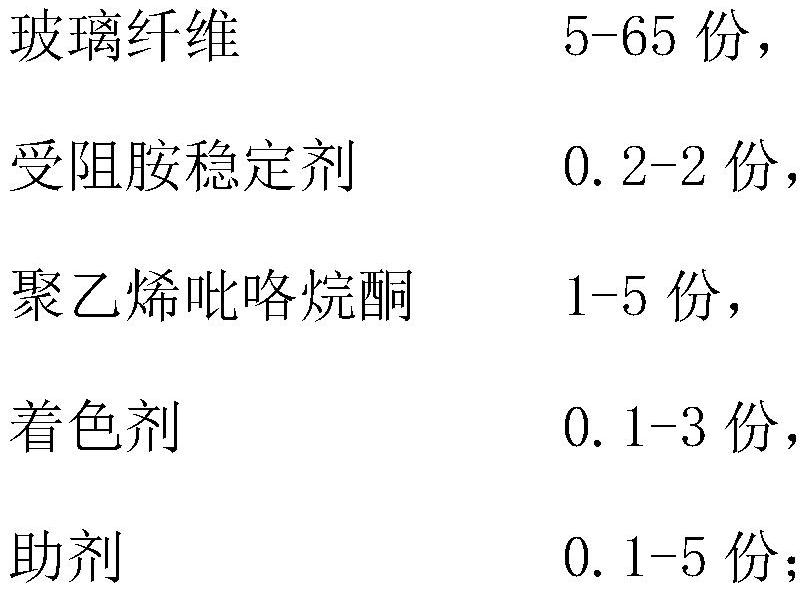

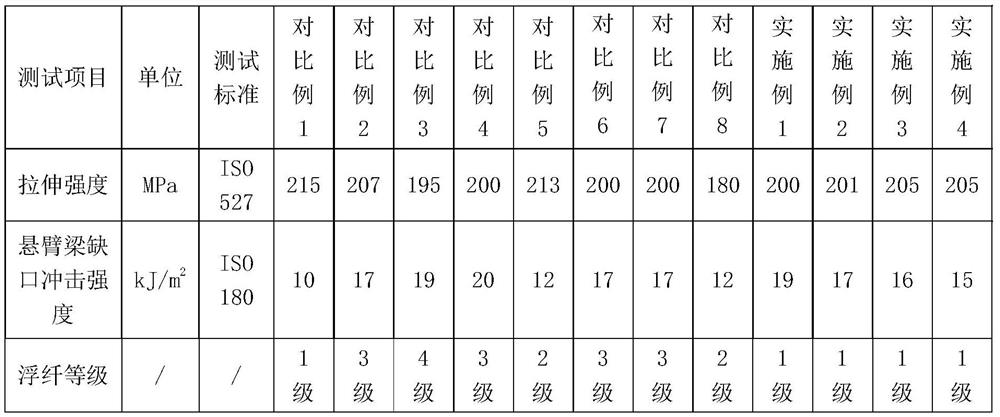

A low floating fiber, high impact strength polyamide composite material

The invention provides a polyamide composite material with low floating fiber and high impact strength. The composite material is made of the following raw materials in parts by weight: 20-93.6 parts of polyamide resin, 5-65 parts of glass fiber, hindered amine stabilizer 0.2-2 parts, 1-5 parts of polyvinylpyrrolidone, 0.1-3 parts of colorant, 0.1-5 parts of auxiliary agent. The polyamide composite material with low floating fiber and high impact strength described in the present invention uses polyamide resins with the same structural formula and different relative viscosities for compounding, and simultaneously adds hindered amine stabilizers and polyvinylpyrrolidone, which are combined with nylon molecules Hydrogen bonds can be formed between them, which can improve the floating fiber problem on the surface. The hindered amine stabilizer and polyvinylpyrrolidone also interacted before, so that the polyamide composite can maintain a high impact strength performance.

Owner:TIANJIN KINGFA NEW MATERIAL

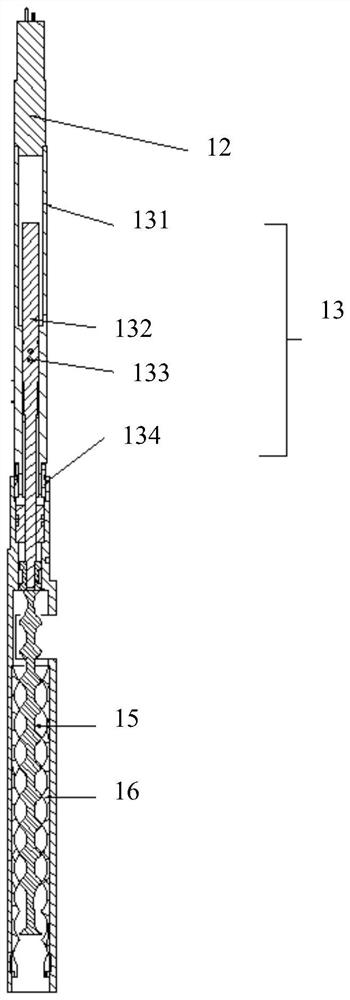

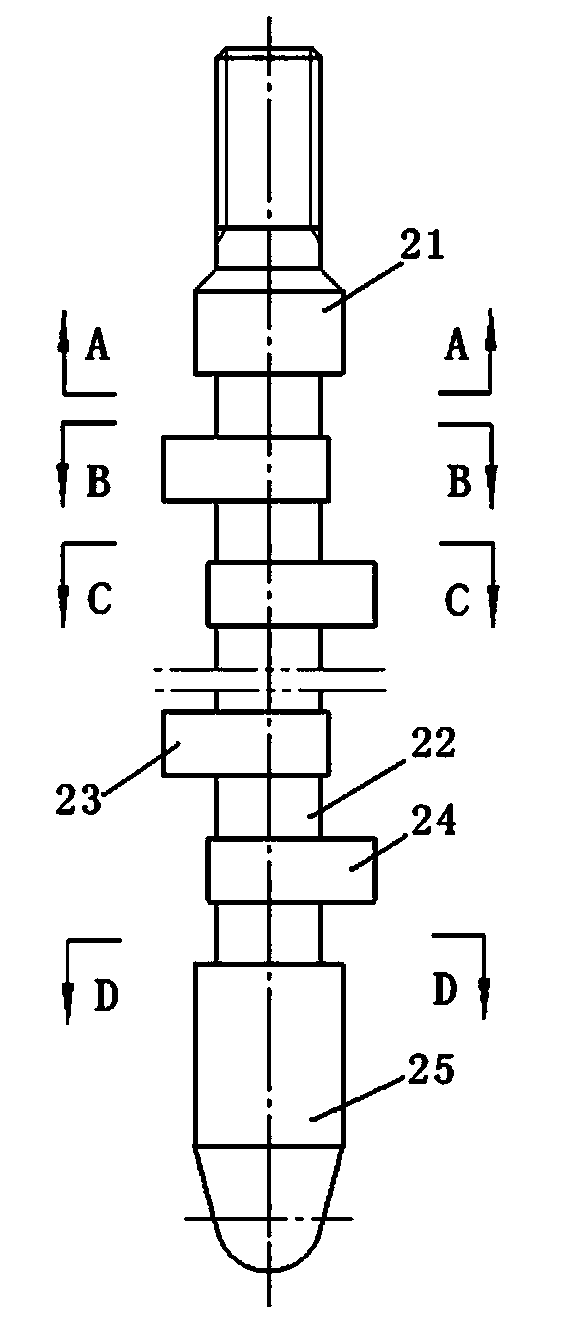

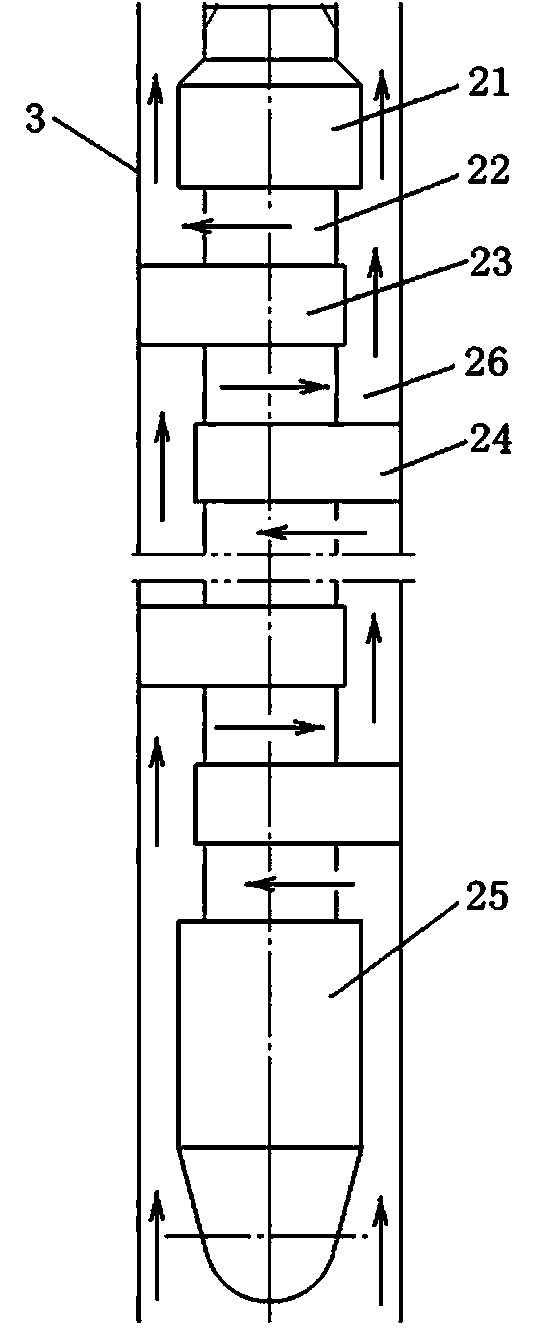

Flow plug for chemical flooding stratified injection

A flow plug for chemical flooding stratified injection is composed of an upper connector (1) and a flow plugging core (2), wherein the upper connector (1) and the flow plugging core (2) are connected in a threaded mode and then arranged in an eccentric hole of a chemical flooding stratified injection device. The flow plug is characterized in that the flow plugging core (2) is matched with the inner smooth surface of the eccentric hole to form a labyrinth flow passage (26). By means of the action of the labyrinth flow passage, a flow field of liquid flow is distributed repeatedly for multiple times to consume energy, and resistance is generated to control flow of chemical liquid. Therefore, flow is controlled, viscosity loss of the chemical liquid passing through a flow control device is small, and stability of the chemical liquid is retained. Accordingly, the flow plug serves as an important measure to improve chemical flooding effect.

Owner:大庆康盛石油节能科技开发有限公司

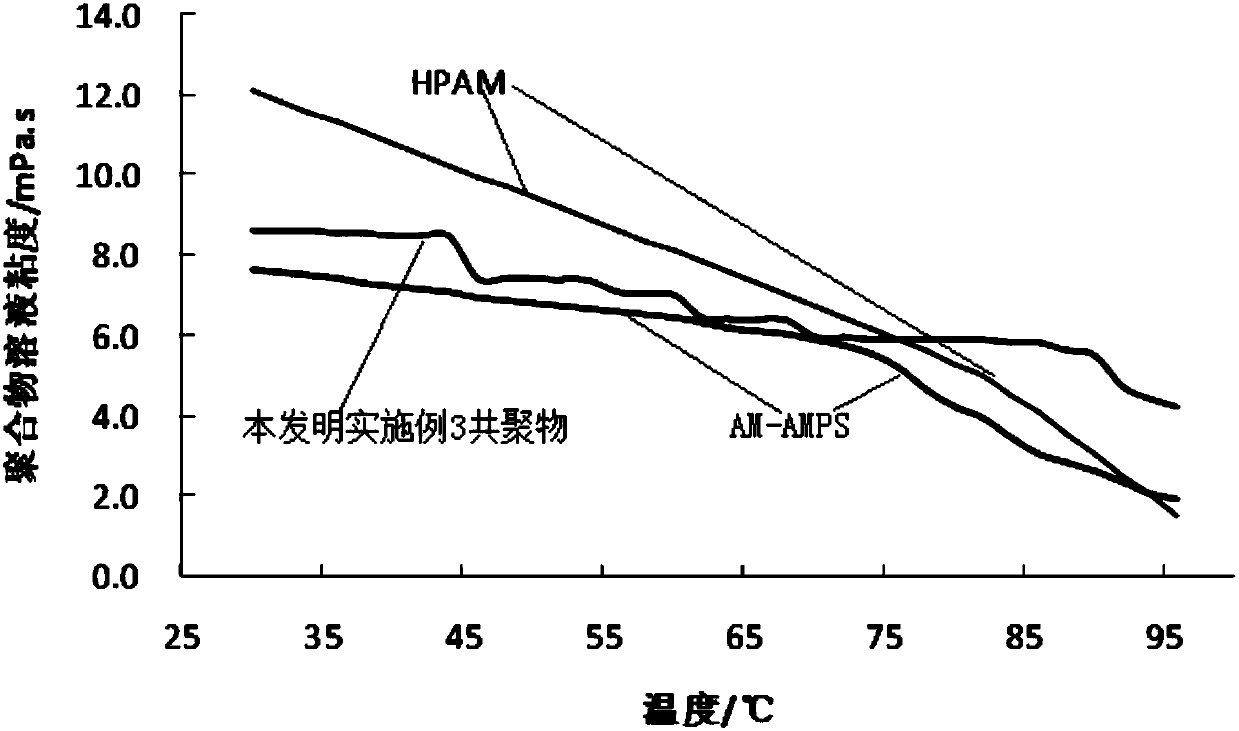

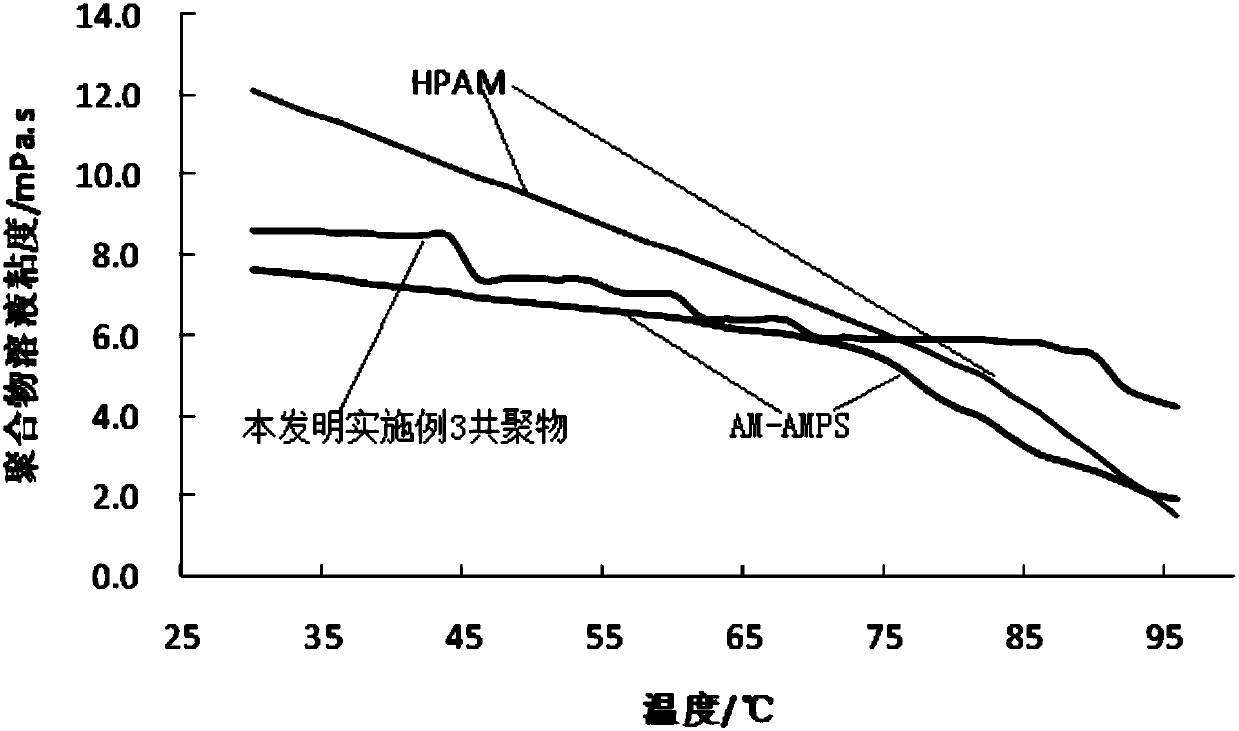

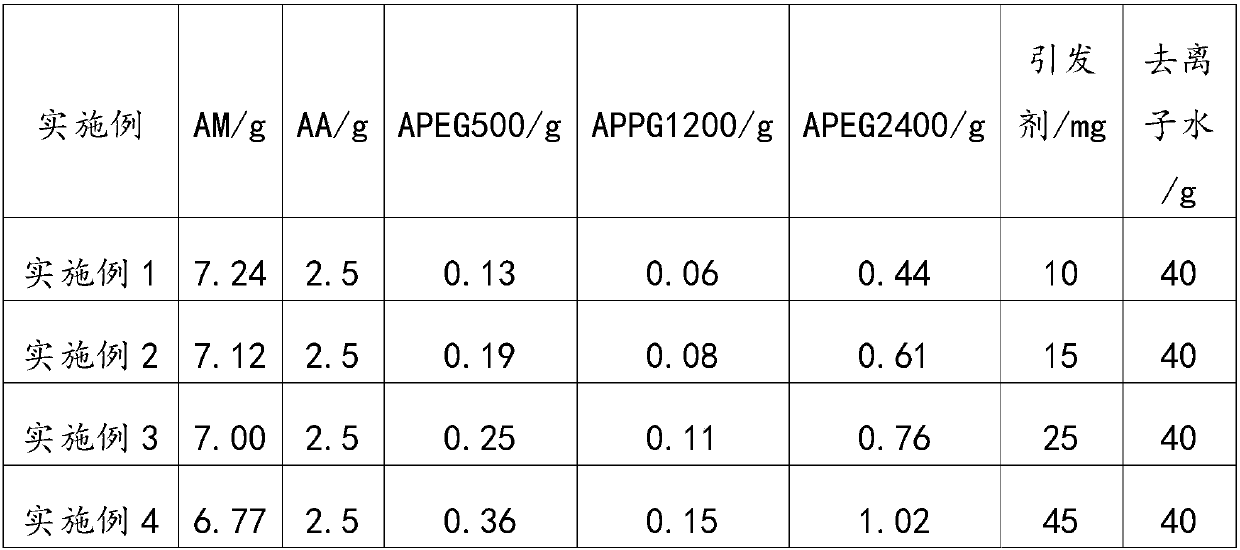

Acrylic acid-acrylamide-allyl polyether copolymer and preparation method thereof

The invention provides an acrylic acid-acrylamide-allyl polyether copolymer and a preparation method thereof. The acrylic acid, acrylamide and allyl polyether with different molecular weights are used as raw materials to prepare the acrylic acid-acrylamide-allyl polyether copolymer. The viscosity reduction phenomenon of the obtained copolymer under a high-temperature condition can be effectively improved, the viscosity loss is reduced, and higher use requirements are met. The acrylic acid-acrylamide-allyl polyether copolymer is excellent in high temperature resistance, the viscosity reduction speed at high temperature is low and the viscosity loss is low.

Owner:FUSHUN DRAGON CHEM PLANT

A layered injection choke for chemical flooding

ActiveCN104196499BViscosity loss is smallGuaranteed stabilityFluid removalUpper jointFluid viscosity

Owner:大庆康盛石油节能科技开发有限公司

Stratified injection tubular pile

InactiveCN101074602BMinimize the problem of greatly reduced viscosity retentionReduce delamination errorFluid removalPolymerPetroleum engineering

The invention provides a hierarchical pouring polymer tube column which can avoid blocking and difficult cast. The tube column includes the out pouring oil tube and the inner pouring oil tube set in the out pouring oil tube, the inner / outer flow passage connected to the different oil layer in the inner pouring ploy oil tube and between the inner and out tube. The top of the inner and outer flow passage are connected with the pump station by the pouring polymer controlling device. The inner flow passage is connected with the oil layer by the closed interpolator and the outer flow passage is connected with the oil layer by the big duct sieve vessel. The pouring control device is the low sheared valve. The invention can be used in the hierarchical pouring oil extraction production.

Owner:SINOPEC SHENGLI OILFIELD

Drinkable yoghurt with suspended fruit particles and preparation method thereof

The invention discloses a drinking type yoghurt with suspended fruit particles and a preparation method thereof. The suspended fruit drinking yoghurt is composed of the following raw materials in mass percentage: 5%-10% of jam, 0.5%-1% of whey protein powder, 0.1%-0.3% of egg yolk powder, 8%-10% of white sugar, Stabilizer 0.4% ~ 0.6% and the balance of fresh milk. Also disclosed is a method for preparing the suspended fruit drinking yoghurt, comprising the following steps: 1) emulsification and shearing; 2) cooling; 3) constant volume; 4) homogenization; 5) pasteurization; 6) fermentation; 7) Demulsification; 8) Secondary homogenization; 9) Adding jam; 10) Filling. The present invention prepares a suspended fruit drinking yoghurt, which has low viscosity, good fluidity and smooth taste, and the preparation process can ensure the stability and quality of the yoghurt without obvious water separation and stratification. It can also save production costs.

Owner:广州风行乳业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com