Acrylic acid-acrylamide-allyl polyether copolymer and preparation method thereof

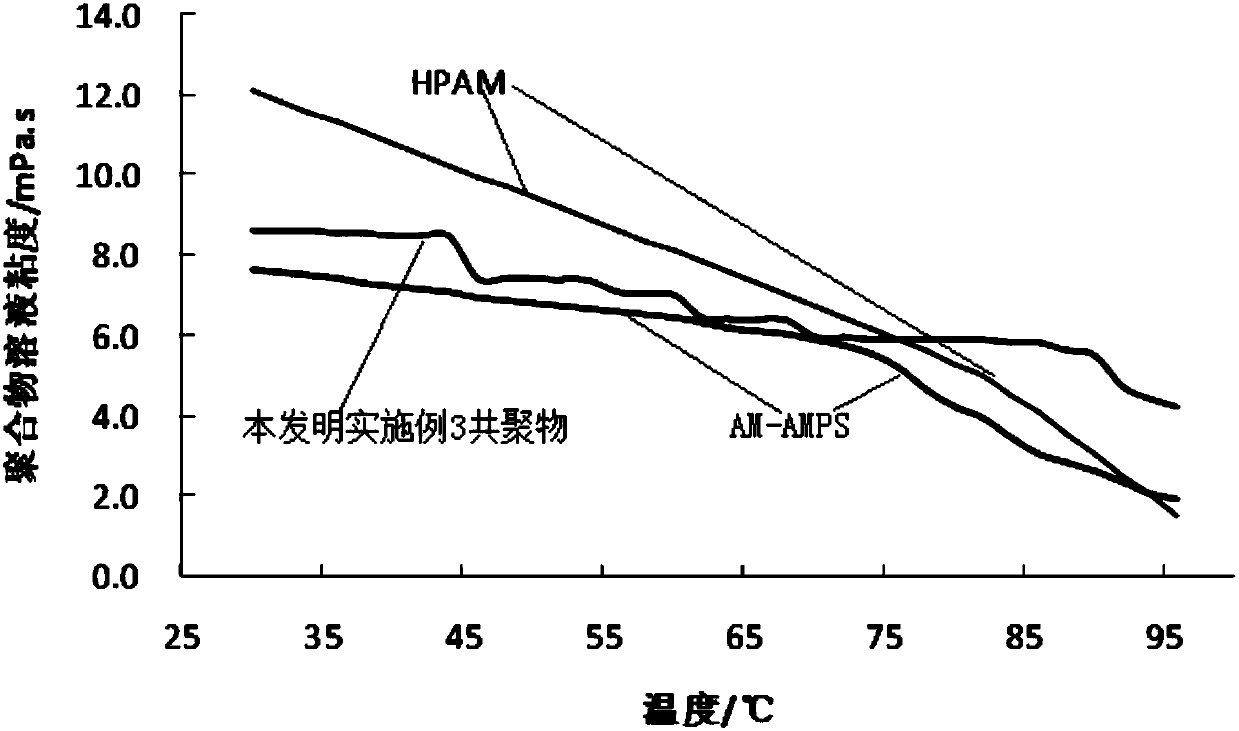

A technology of allyl polyether and allyl polyoxyethylene ether, which is applied in the field of acrylic acid-acrylamide-allyl polyether copolymer and its preparation, and can solve the problems of excessive viscosity drop, difficult copolymerization, poor water solubility, etc. problem, to achieve the effects of small viscosity loss, reduced viscosity loss, and excellent high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

[0080] A kind of preparation method of acrylic acid-acrylamide-allyl polyether copolymer, comprises the steps:

[0081] Take 40mL of deionized water and put it in a sealed bag, pour the weighed acrylic acid (AA) into the sealed bag and stir evenly, adjust the pH value to 7-8 with 0.1mol / L sodium hydroxide solution;

[0082] Add the weighed acrylamide (AM) and allyl polyether (APEG and APPG), stir evenly, and pass nitrogen for 30 minutes to fully discharge the oxygen in the container and the solution;

[0083] Add the weighed initiator, stir evenly, then put the sealing bag into the water bath after sealing, at T 1 react at temperature;

[0084] Then the water bath was heated to T 2 , continuous reaction, to obtain colloidal polymer;

[0085] After drying, crushing and sieving, an acrylic acid-acrylamide-allyl polyether copolymer is obtained.

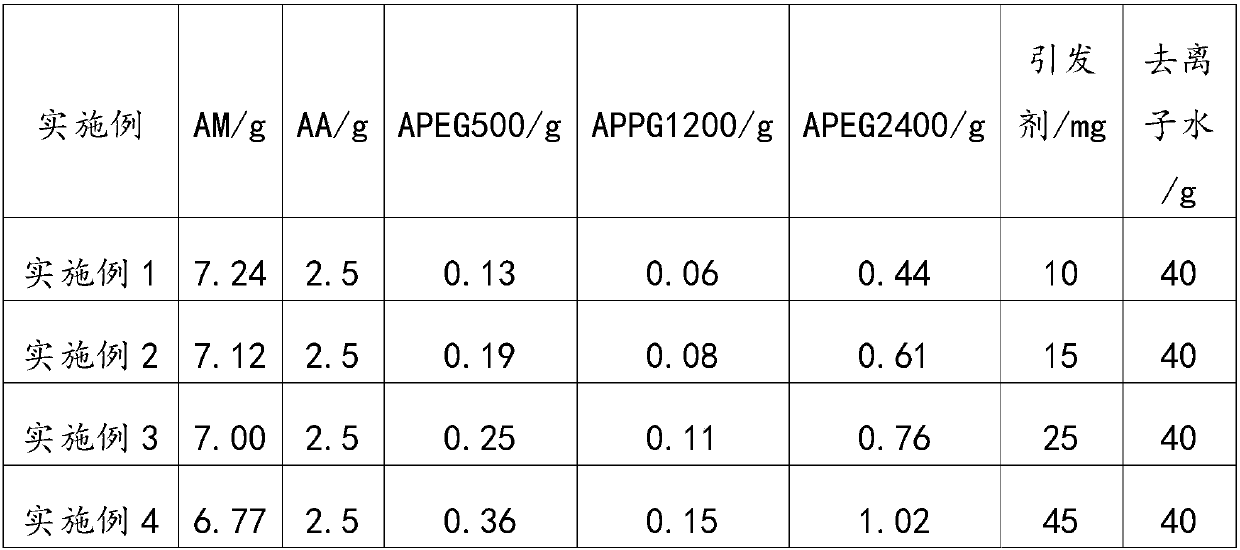

[0086] The reaction raw material consumption of the embodiment of the present invention 1-4 is as shown in table 1

[0087]

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com