A kind of lubricating oil additive and preparation method thereof

A lubricating oil additive and oil solvent technology, which is applied in the field of lubricating oil, can solve the problems of less types of long-term lubricating oil and unsatisfactory performance, and achieve the effects of increasing driving safety, improving viscosity drop, and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

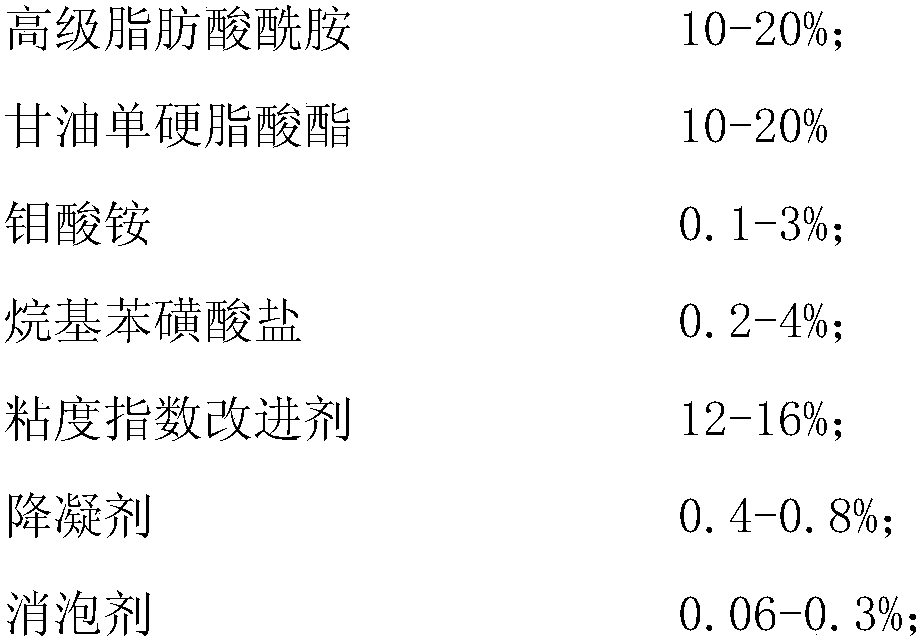

[0035] Example 1. A lubricating oil additive comprising the following components by weight percentage:

[0036]

[0037] The rest are oil solvents. The oil solvent is base oil. The base oil is an ultra-high viscosity index base oil, a neutral oil, or a mixture of the two in any proportion; preferably, the base oil is a mixture of an ultra-high viscosity index base oil and a neutral oil in a ratio of 1 to 5:1. The mass ratio of the composition of the mixture. The ultra-high viscosity index base oil is preferably UHVI 6; the neutral oil is preferably 500SN.

[0038] The higher fatty acid amide is lauramide. Alkylbenzenesulfonate is a catalyst in this lubricant formulation.

[0039] The metal detergent comprises by weight: 6 parts of calcium alkylbenzene sulfonate synthesized by base number, 0.2 part of polyisobutenyl succinimide, 3 parts of isooctyl phosphate, 1 part of stearate, dihydroxy 5 parts of polymethylvinyl siloxane, 2 parts of calcium hydroxide, 5 parts of bor...

Embodiment 2

[0057] Example 2. A lubricating oil additive comprising the following components by weight percentage:

[0058]

[0059] The higher fatty acid amide is lauramide palmitoylaminopropyl dimethyl tertiary amine.

[0060] The metal detergent includes by weight: the metal detergent includes by weight: 11 parts of base value synthetic calcium alkylbenzene sulfonate, 1 part of polyisobutenyl succinimide, 8 parts of isooctyl phosphate , 5 parts of stearate, 10 parts of dihydroxy polymethyl vinyl siloxane, 6 parts of calcium hydroxide, 9 parts of borated polyisobutenyl succinimide, 15 parts of neutral oil, long chain linear type 6 parts of high base value synthetic magnesium sulfonate of alkylbenzene, 10 parts of pentaerythritol, 4 parts of long-chain linear alkylbenzene high base value synthetic magnesium sulfonate, 11 parts of zinc stearate, borated high molecular weight polyisobutenyl butyl 8 parts of diimide; 6 parts of chlorinated paraffin, 8 parts of benzotriazole amine.

[...

Embodiment 3

[0076] Example 3. A lubricating oil additive comprising the following components by weight percentage:

[0077]

[0078] The higher fatty acid amide is oleic acid diethanolamide. The alkylbenzene sulfonate is calcium alkylbenzene sulfonate.

[0079] The metal cleaning agent includes by weight: the metal cleaning agent includes by weight: 8 parts of calcium alkylbenzene sulfonate synthetic base number, 1 part of polyisobutenyl succinimide, 5 parts of isooctyl phosphate , 3 parts of stearate, 8 parts of dihydroxy polymethyl vinyl siloxane, 4 parts of calcium hydroxide, 6 parts of borated polyisobutenyl succinimide, 12 parts of neutral oil, long chain linear type 4 parts of high base value synthetic magnesium sulfonate of alkylbenzene, 8 parts of pentaerythritol, 3 parts of long-chain linear alkylbenzene high base value synthetic magnesium sulfonate, 6 parts of zinc stearate, borated high molecular weight polyisobutenyl butyl 6 parts of diimide; 4 parts of chlorinated paraf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear stability index | aaaaa | aaaaa |

| shear stability index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com