Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

960 results about "Fatty acid amide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

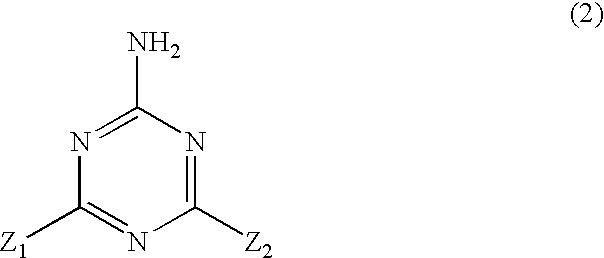

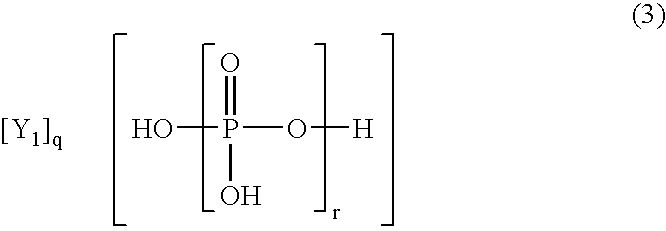

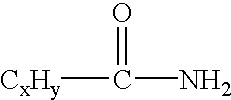

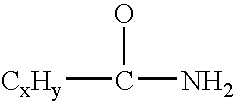

Fatty acid amides (FAAs) are amides formed from a fatty acid and an amine. In nature, many FAAs have ethanolamine as the amine component. Also known as N-acylethanolamines, they contain the functionality RC(O)N(H)CH₂CH₂OH. A well known example is anandamide. Other fatty acid amides are fatty acid primary amides (FAPAs). They contain the functionality RC(O)NH₂). Oleamide is an example of this class of FAPAs.

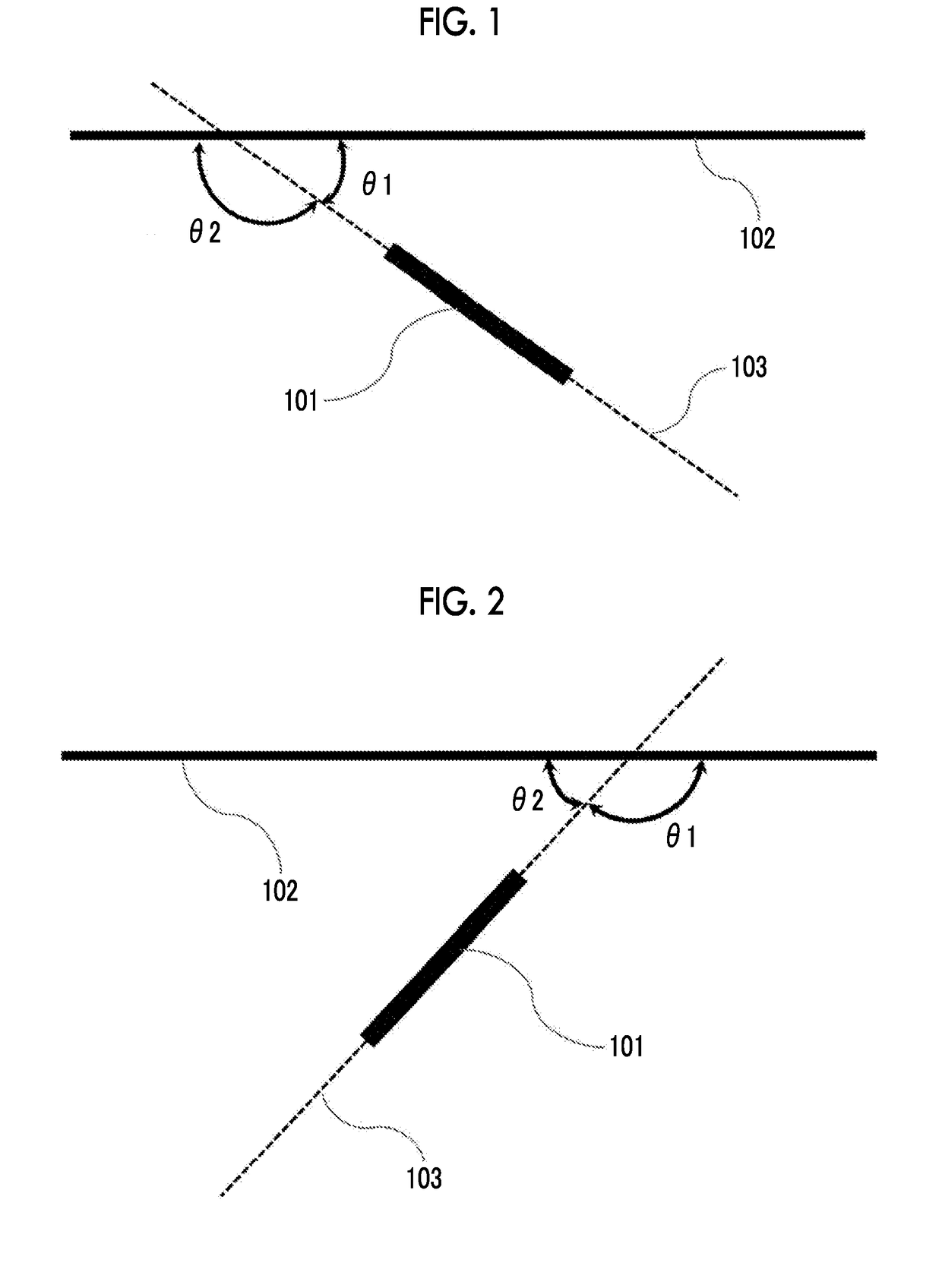

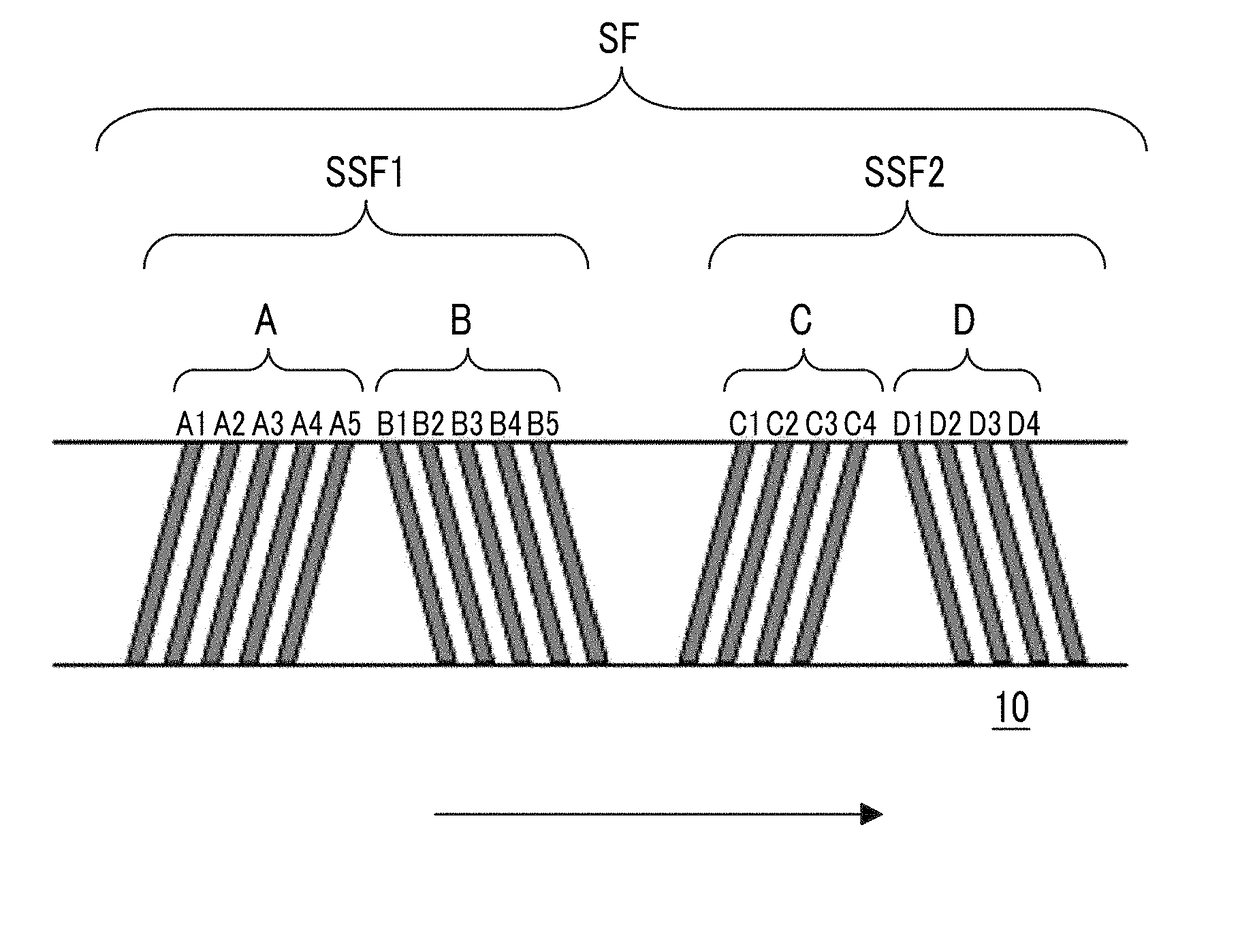

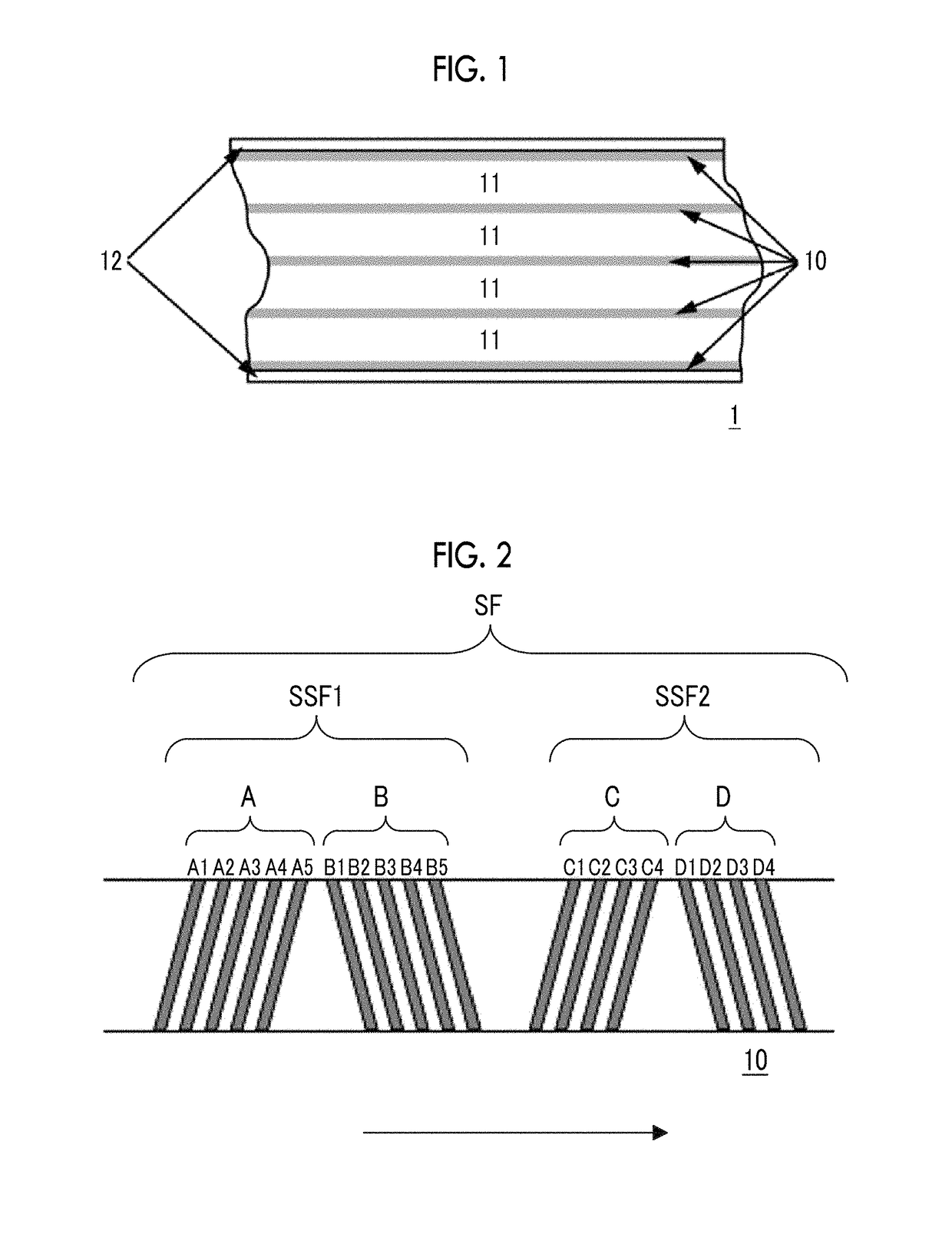

Magnetic tape

Provided is a magnetic tape in which ferromagnetic powder included in a magnetic layer is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and an abrasive, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to the surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

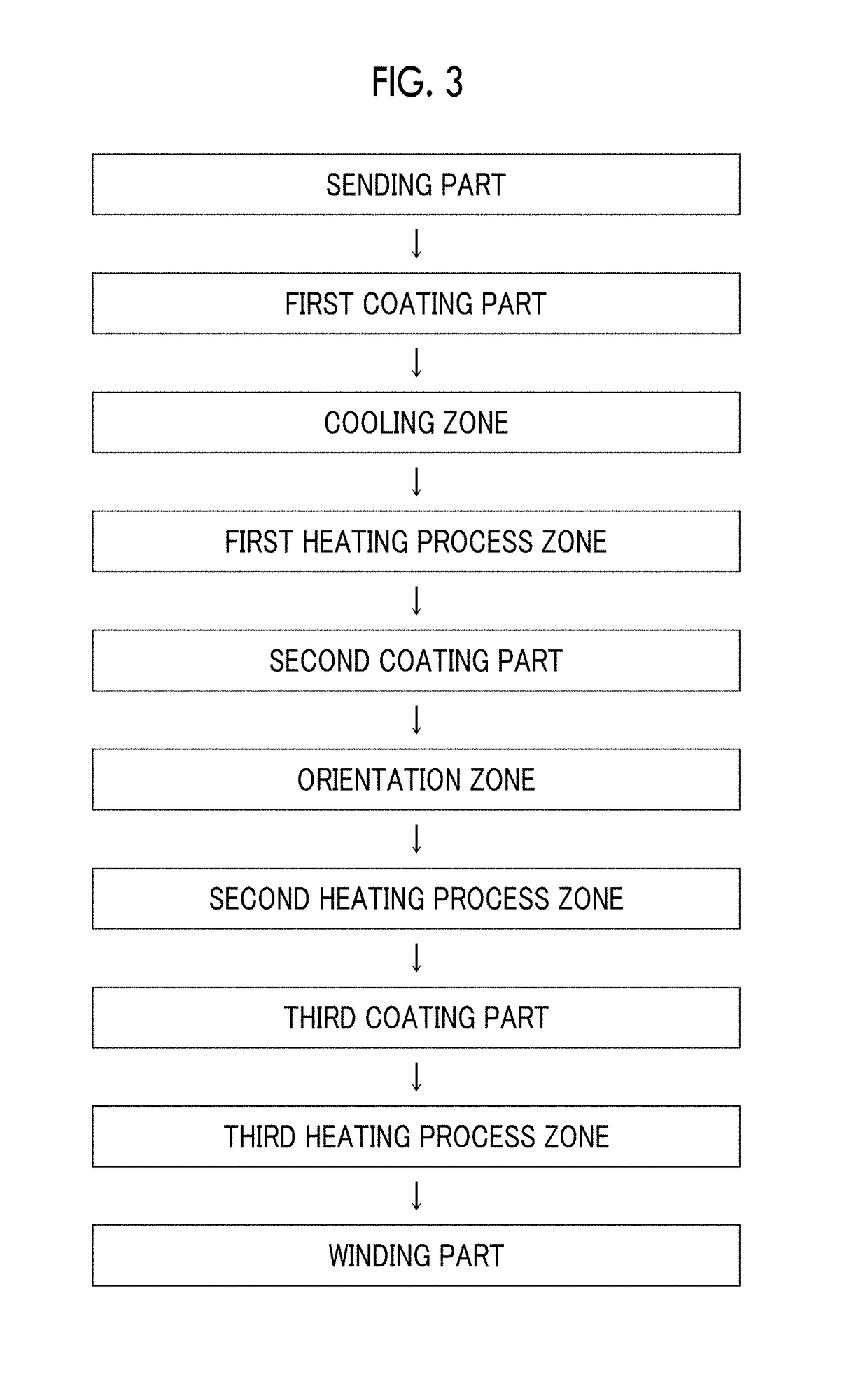

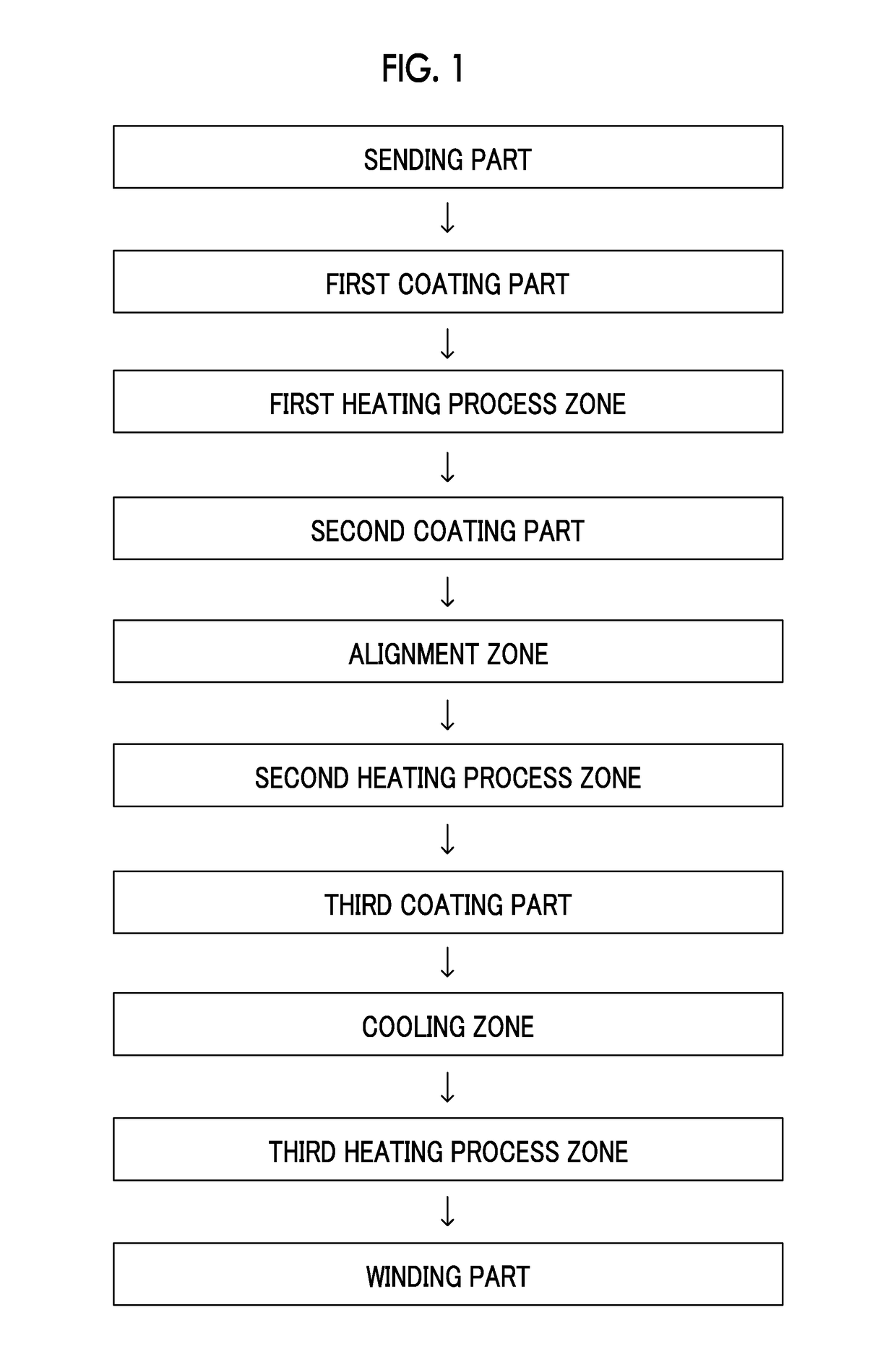

Magnetic tape and method of manufacturing the same

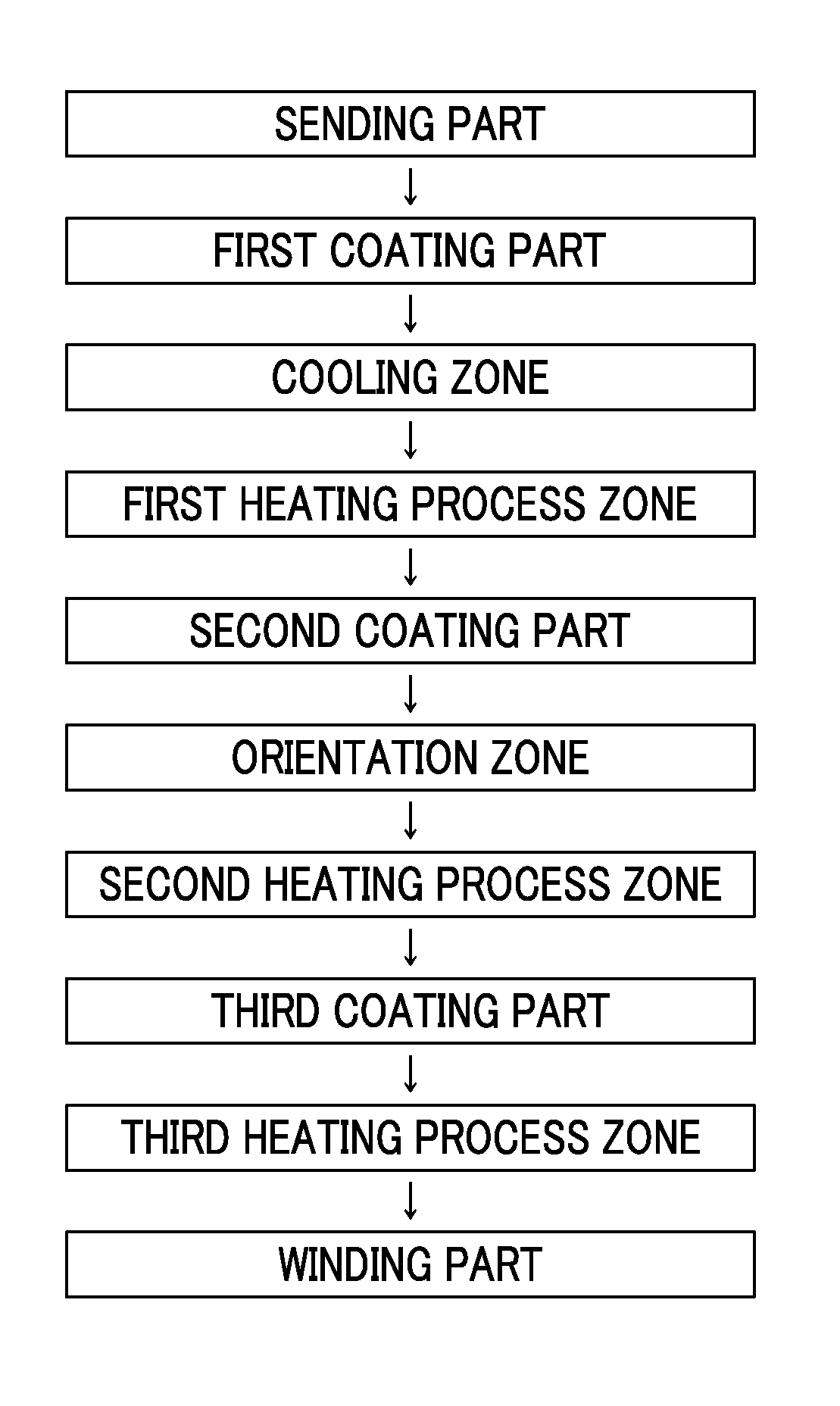

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

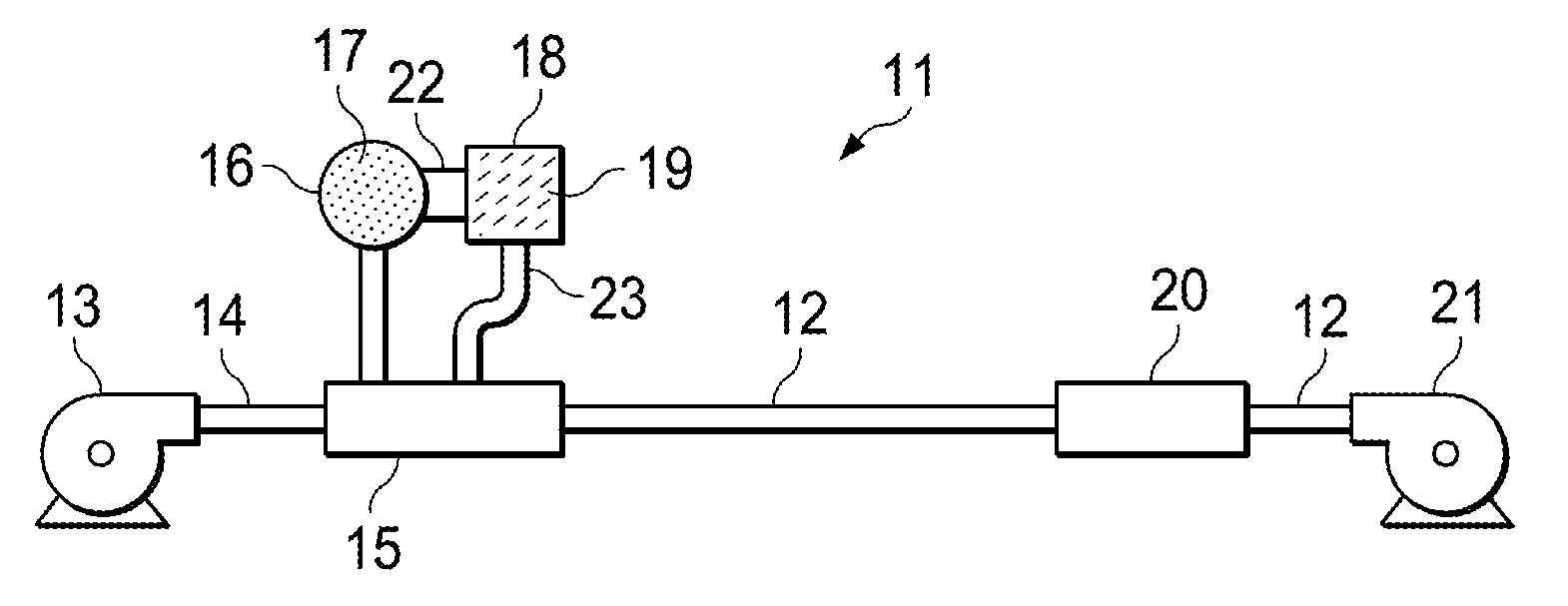

Magnetic tape device and head tracking servo method

ActiveUS9984716B1Avoid it happening againImprove accuracyProtective coatings for layersTape carriersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a servo head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the servo head is a TMR head, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes a servo pattern, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on a surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9721605B2Avoid it happening againImprove the immunityBase layers for recording layersRecord information storageMedicineMagnetic tape

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20170032812A1Increase the lengthReduce thicknessRecord information storageMaterials with non-metallic substancesMagnetic tapeNon magnetic

The magnetic tape has a magnetic layer containing ferromagnetic powder and binder on one surface of a nonmagnetic support, and has a backcoat layer containing nonmagnetic powder and binder on the other surface thereof, wherein the magnetic layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; the backcoat layer has a thickness of less than or equal to 0.30 μm and contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a magnetic layer side C—H derived C concentration is greater than or equal to 45 atom %; and a backcoat layer side C—H derived C concentration is greater than or equal to 35 atom %.

Owner:FUJIFILM CORP

Magnetic recording medium and magnetic recording and reproducing device

ActiveUS20190103133A1Excellent electromagnetic conversion characteristicAvoid it happening againMaterials with ironBase layers for recording layersIn planeX-ray

Provided are a magnetic recording medium, in which a magnetic layer includes a ferromagnetic hexagonal ferrite powder, a binding agent, an oxide abrasive, an intensity ratio Int(110) / Int(114) obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio is 0.65 to 1.00, one or more kinds of component selected from the group consisting of fatty acid and fatty acid amide is contained in a magnetic layer side portion on the non-magnetic support, a C—H derived C concentration of the magnetic layer is 45 atom % to 65 atom %, and an average particle diameter of the oxide abrasive obtained from a secondary ion image obtained by irradiating the surface of the magnetic layer with a focused ion beam is 0.04 μm to 0.08 μm, and a magnetic recording and reproducing device including this magnetic recording medium.

Owner:FUJIFILM CORP

Oily cosmetic composition in aerosol form

InactiveUS20080031908A1Process stabilityHappy to useCosmetic preparationsHair cosmeticsParaffin waxSolid particle

Aerosol product containing an oily composition containing at least one oil, and at least one hydrocarbon compound having a melting point greater than or equal to 30° C., the compound being in the form of solid particles and one or more propellants. The hydrocarbon compound can notably be a paraffin or a fatty acid amide. Used for cleaning and / or make-up removal of the skin and / or of the hair, care of the skin and / or of the hair, for protecting the skin against the sun, and for make-up of the skin.

Owner:LOREAL SA

Magnetic tape and method of manufacturing the same

ActiveUS9959894B2Solve the lack of durabilityHigh densityTape carriersRecord information storageMedicineMagnetic tape

The magnetic tape comprises a nonmagnetic layer comprising nonmagnetic powder and binder on a nonmagnetic support, and comprises a magnetic layer comprising ferromagnetic powder and binder on the nonmagnetic layer, wherein a fatty acid ester, a fatty acid amide, and a fatty acid are contained in either one or both of the magnetic layer and the nonmagnetic layer, with the magnetic layer and nonmagnetic layer each comprising at least one selected from the group consisting of a fatty acid ester, a fatty acid amide, and a fatty acid, a quantity of fatty acid ester per unit area of the magnetic layer in extraction components extracted from a surface of the magnetic layer with n-hexane falls within a range of 1.00 mg / m2 to 10.00 mg / m2, and a weight ratio of the quantity of fatty acid ester per unit area of the magnetic layer to a combined total of a quantity of fatty acid amide and a quantity of fatty acid, quantity of fatty acid ester / (quantity of fatty acid amide+quantity of fatty acid), per unit area of the magnetic layer falls within a range of 1.00 to 3.00 in the extraction components.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170358318A1Improve surface smoothnessImproved head positioning accuracyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160189740A1Avoid it happening againImprove the immunityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372743A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372726A1Improve surface smoothnessReduce frequencyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which a total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160247530A1Improve running stabilityReduce coefficient of frictionRecord information storageMetals or alloysMagnetic tapeTotal thickness

The magnetic tape has on one surface of a nonmagnetic support a magnetic layer containing ferromagnetic powder and binder, and on the other surface of the nonmagnetic support, a backcoat layer containing nonmagnetic powder and binder, wherein the total thickness of the magnetic tape is less than or equal to 4.80 μm, the backcoat layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the backcoat layer side of the magnetic tape ranges from 35 to 60 atom %.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182429A1Avoid it happening againAvoiding characteristicMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Laser sinter powder with a metal salt and a fatty acid derivative, process for its production, and moldings produced from this laser sinter powder

InactiveUS20050027050A1Improve the immunityMaintain good propertiesAdditive manufacturing apparatusFibre treatmentSelective laser sinteringPolyamide

The present invention relates to a sinter powder composed of polyamide which also comprises metal salts of weak acids, in particular metal carbonates, and fatty acid derivatives, in particular fatty acid esters or fatty acid amides, to a process for laser sintering, and also to moldings produced from this sinter powder. The moldings formed using the powder of the invention have marked advantages in appearance and in surface finish when compared with conventional products, especially when recyclability in the selective laser sintering (SLS) process is taken into account. Moldings produced from recycled sinter powder of the invention moreover also have markedly improved mechanical properties when compared with moldings based on recycled conventional nylon-12 powders, in particular in terms of modulus of elasticity and tensile strain at break. These moldings also have a density approaching that of injection moldings.

Owner:EVONIK DEGUSSA GMBH

Magnetic tape

ActiveUS20190027174A1Improve surface smoothnessAvoid it happening againRecord information storageTape carriersIn planeX-ray

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, the back coating layer includes one or more kinds of component selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 35 atom %.

Owner:FUJIFILM CORP

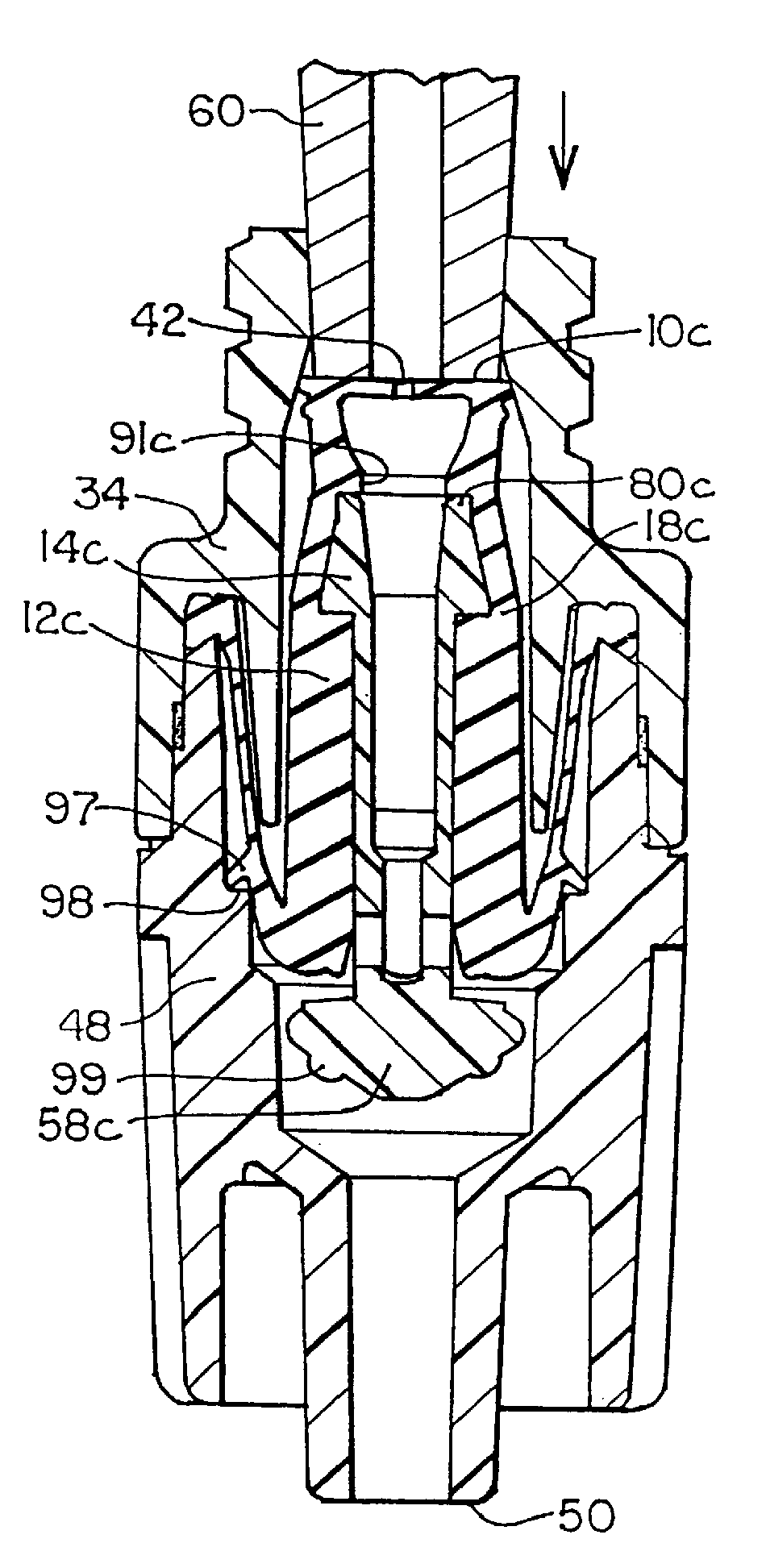

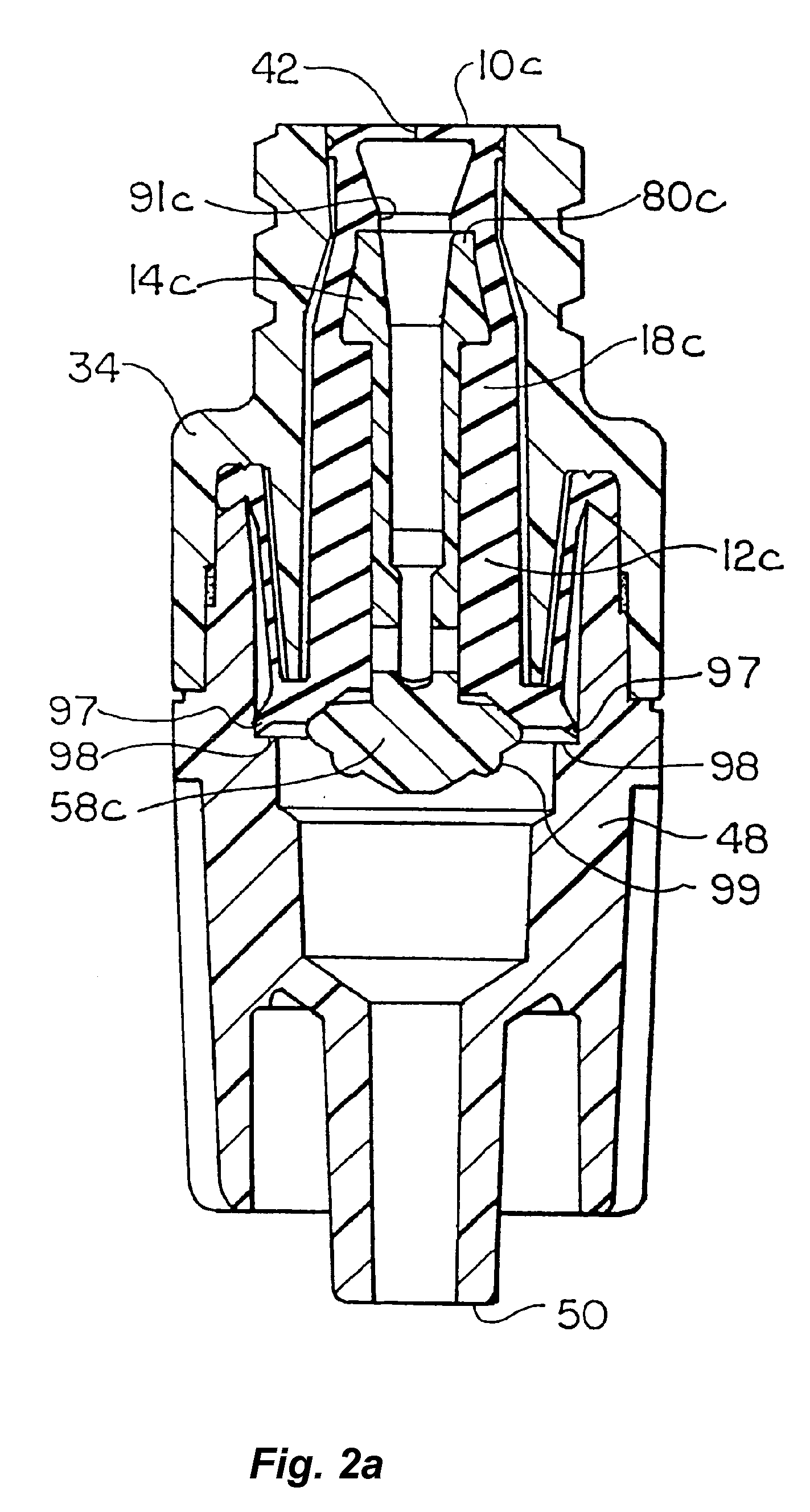

Self-Lubricating Elastomeric Components for Use in Medical Devices

A device includes an elastomer component that has a molecular scaffold. The molecular scaffold defines interstitial spaces. The component is impregnated with a vegetable oil carrying a fatty acid amide to impart a lubrication to the component and thereby impart a resistance to adhering to a surface of the component. In an illustrative device, a valve includes an elastomeric member that includes a vegetable oil and a fatty acid amide. A method for manufacturing such a device and a precursor for use in manufacturing are also disclosed.

Owner:NP MEDICAL

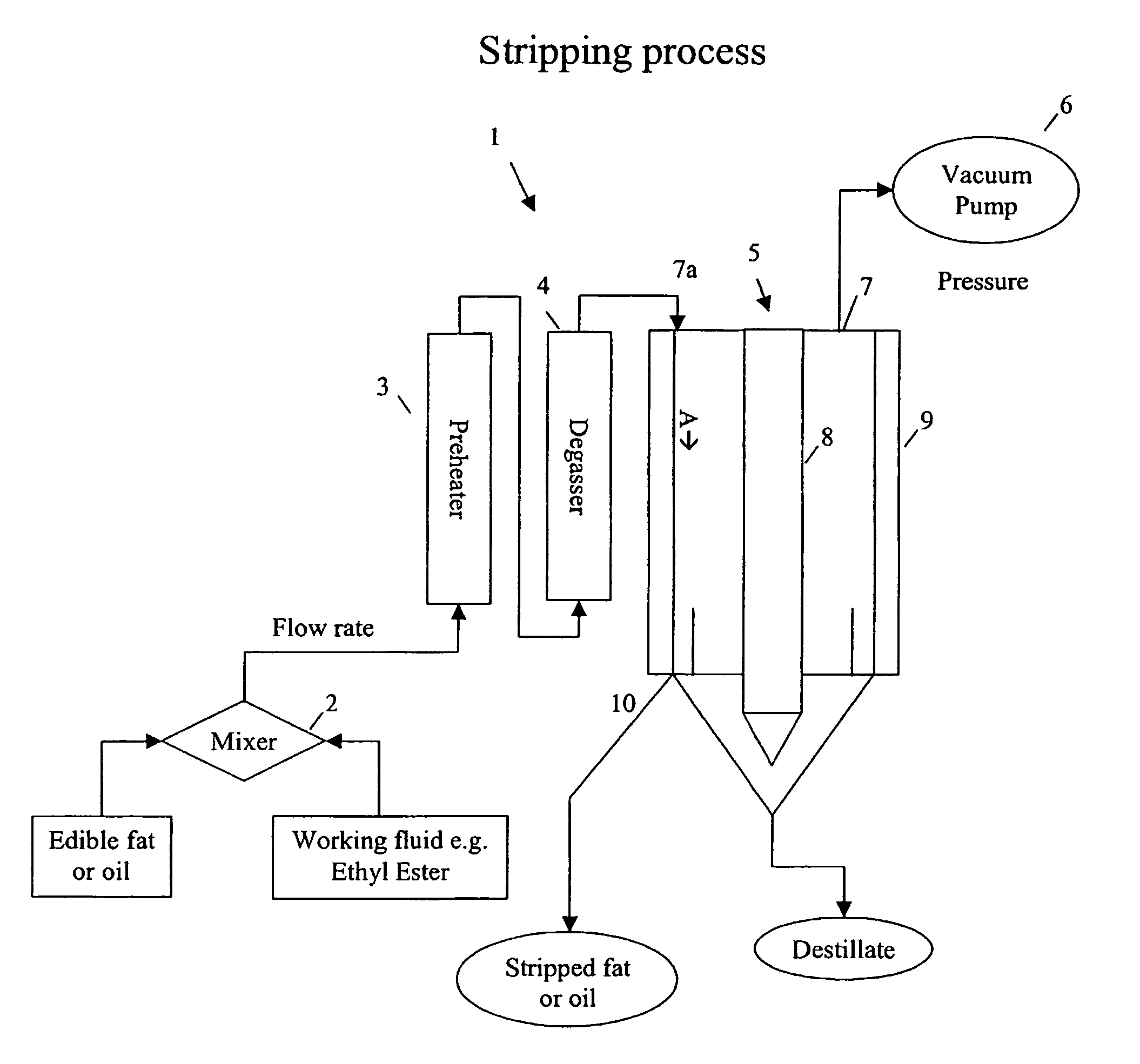

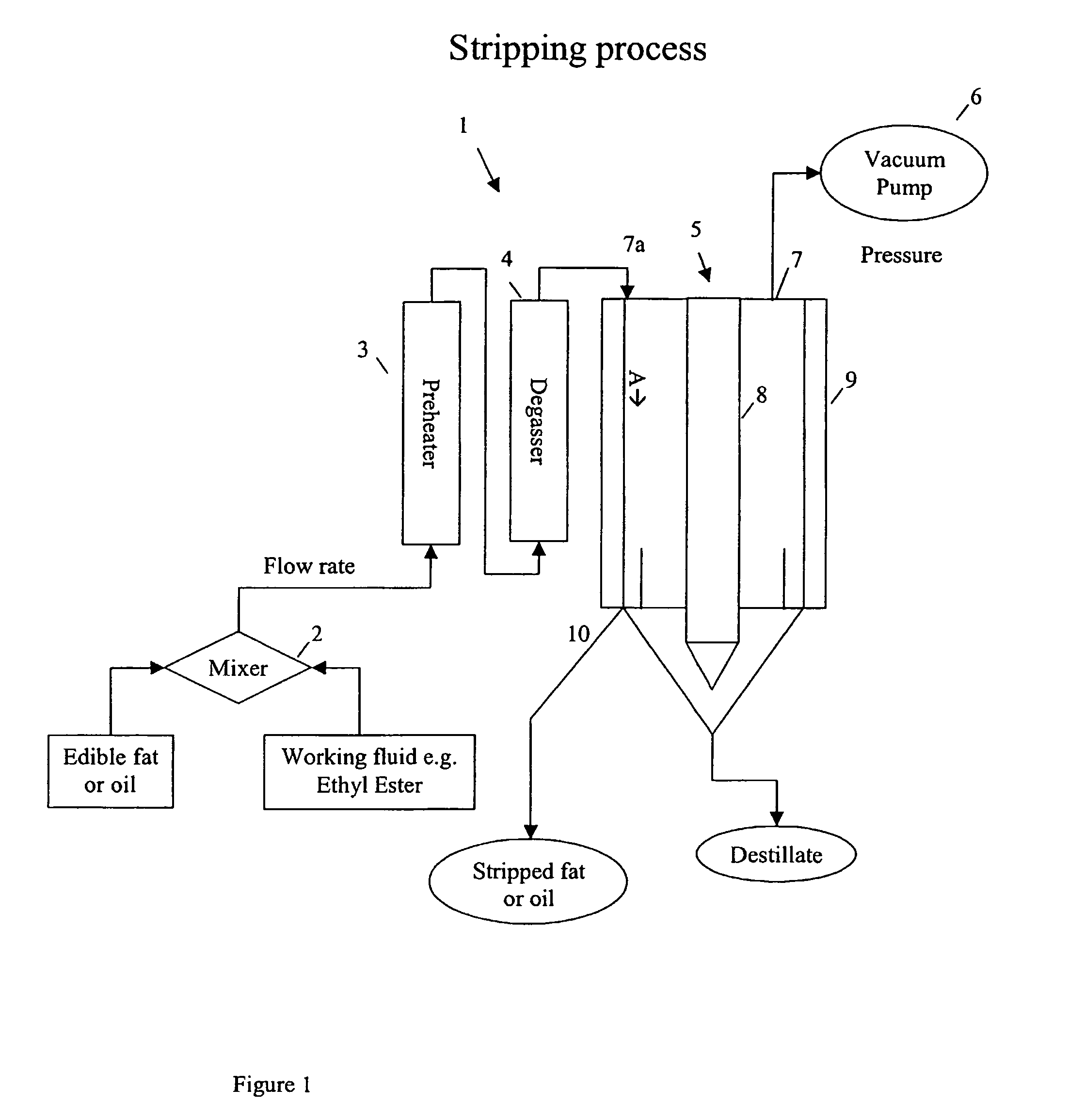

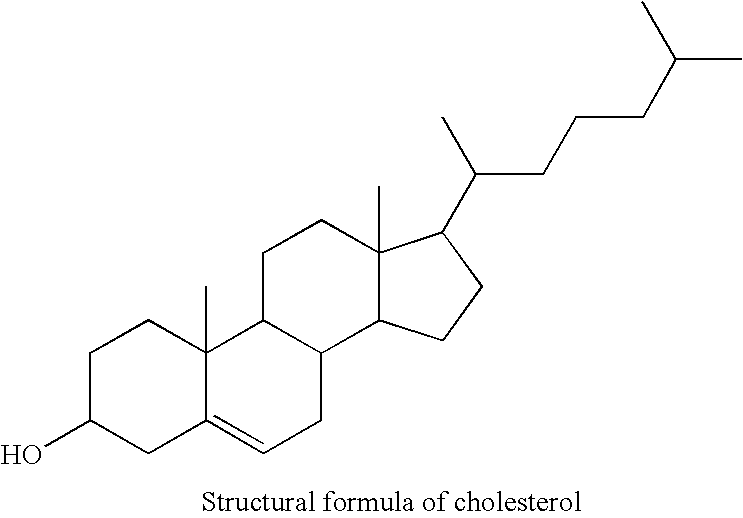

Process for decreasing the amount of cholesterol in a marine oil using a volatile working fluid

ActiveUS7678930B2Lower cholesterol levelsPoint becomes highCosmetic preparationsNervous disorderWorking fluidFree form

The invention relates to a process for decreasing the amount of cholesterol in a mixture comprising a marine oil, the marine oil containing the cholesterol, which process comprises the steps of adding a volatile working fluid to the mixture, where the volatile working fluid comprises at least one of a fatty acid ester, a fatty acid amide and a hydrocarbon, and subjecting the mixture with the added volatile working fluid to at least one stripping processing step, in which an amount of cholesterol present in the marine oil in free form is separated from the mixture together with the volatile working fluid. The present invention also relates to a volatile cholesterol decreasing working fluid and a health supplement and a pharmaceutical, based on a marine oil, prepared according to the process mentioned above.

Owner:PRONOVA BIOPHARMA NORGE

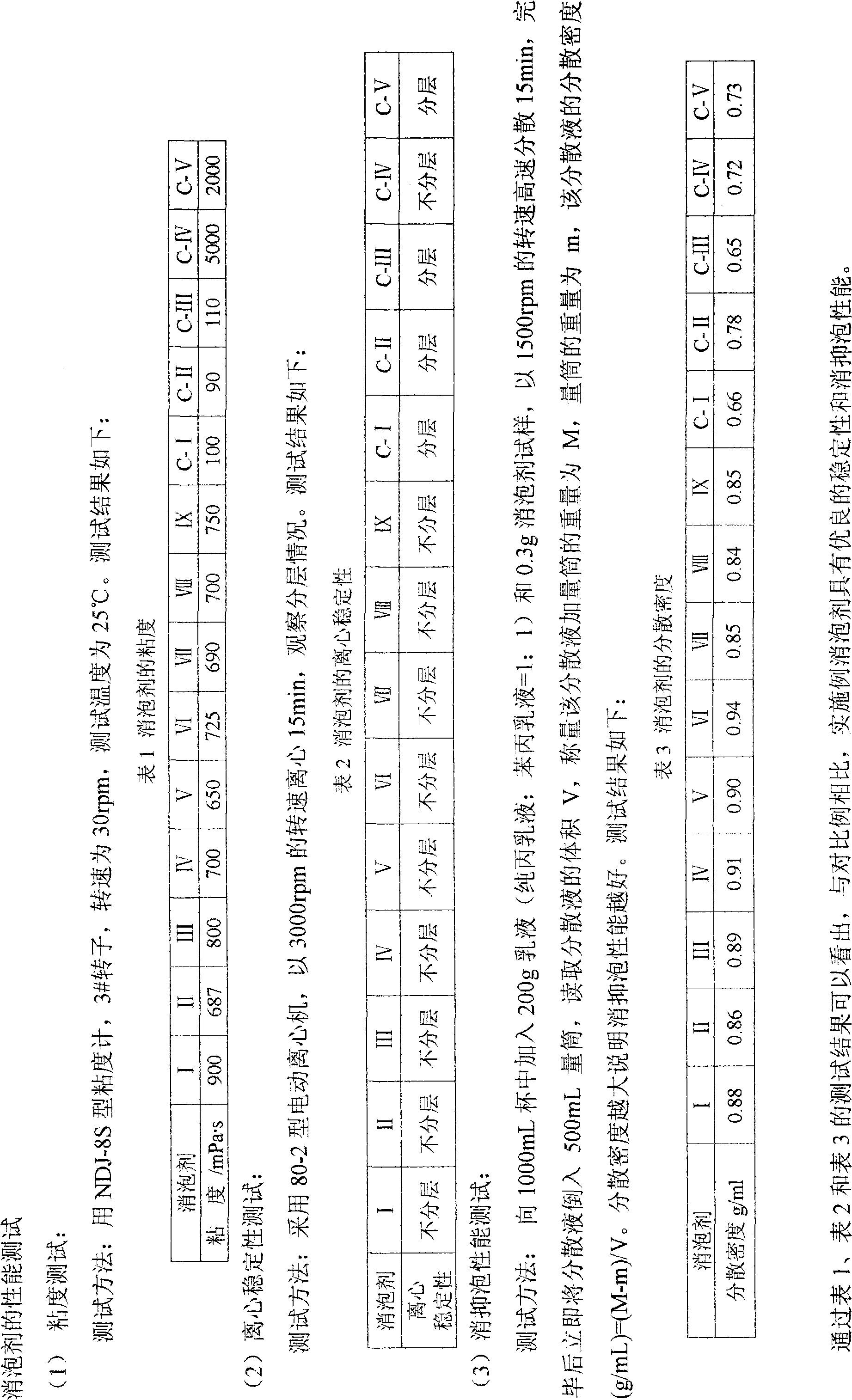

Mineral oil defoaming agent and preparation method thereof

ActiveCN101991975AImprove performanceGood defoaming performanceFoam dispersion/preventionBlack liquorSewage

The invention provides a mineral oil defoaming agent comprising mineral oil, a fatty acid metal soap, fatty acid amide, white carbon black, a defoaming auxiliary agent and an emulsifying agent. The invention has the technical scheme that the fatty acid metal soap, the fatty acid amide and the white carbon black are simultaneously selected as defoaming substances and a method mixing the defoaming substances into the mineral oil is changed, thus the stability and the foam removing and depressing properties of the mineral oil defoaming agent are improved. The mineral oil defoaming agent has better foam removing and depressing effects in the processes of papermaking black liquor, coating, sewage treatment, latex, cleaning, and the like.

Owner:JIANGSU SIXIN SCI-TECH APPL RES INST CO LTD

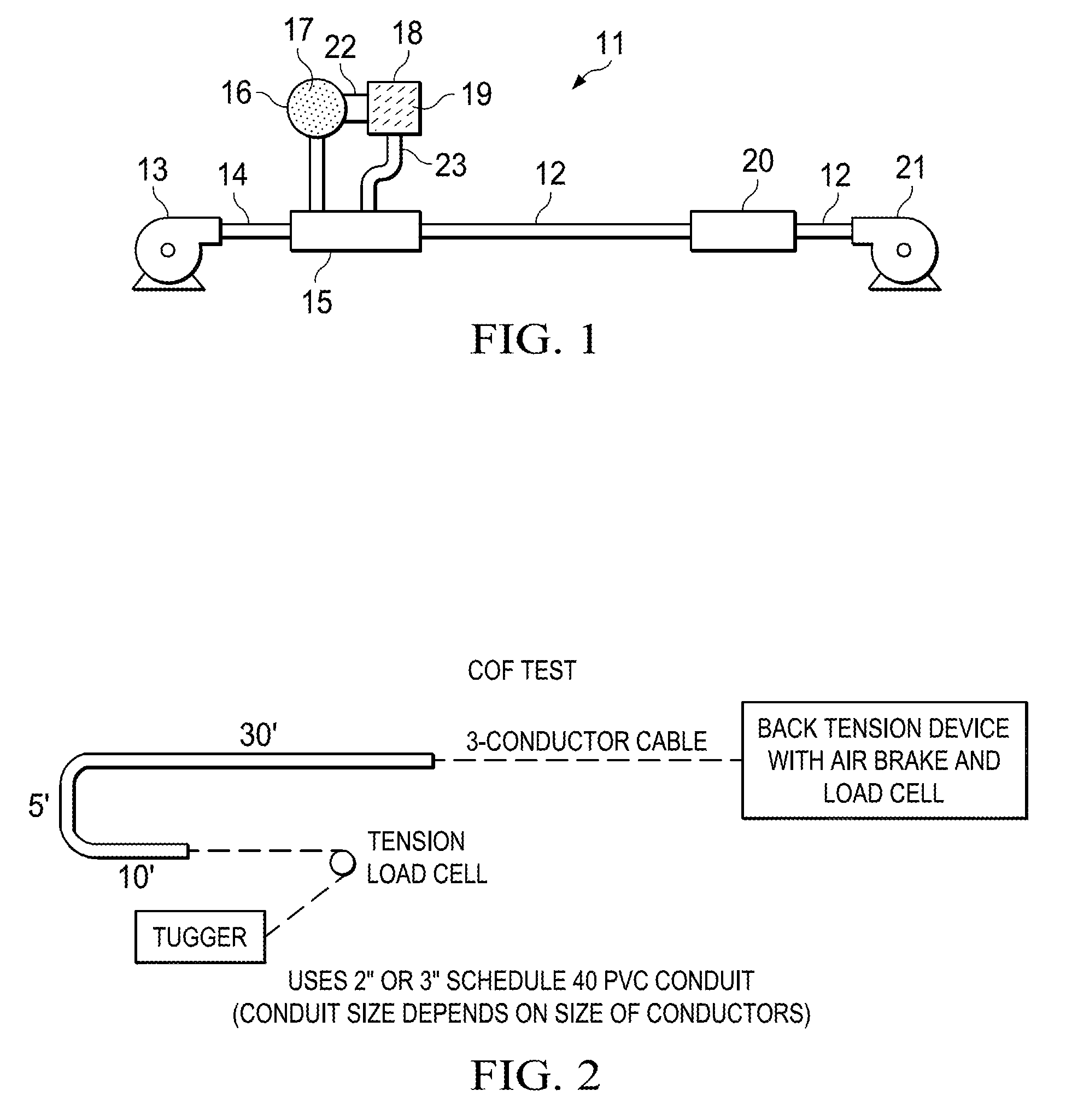

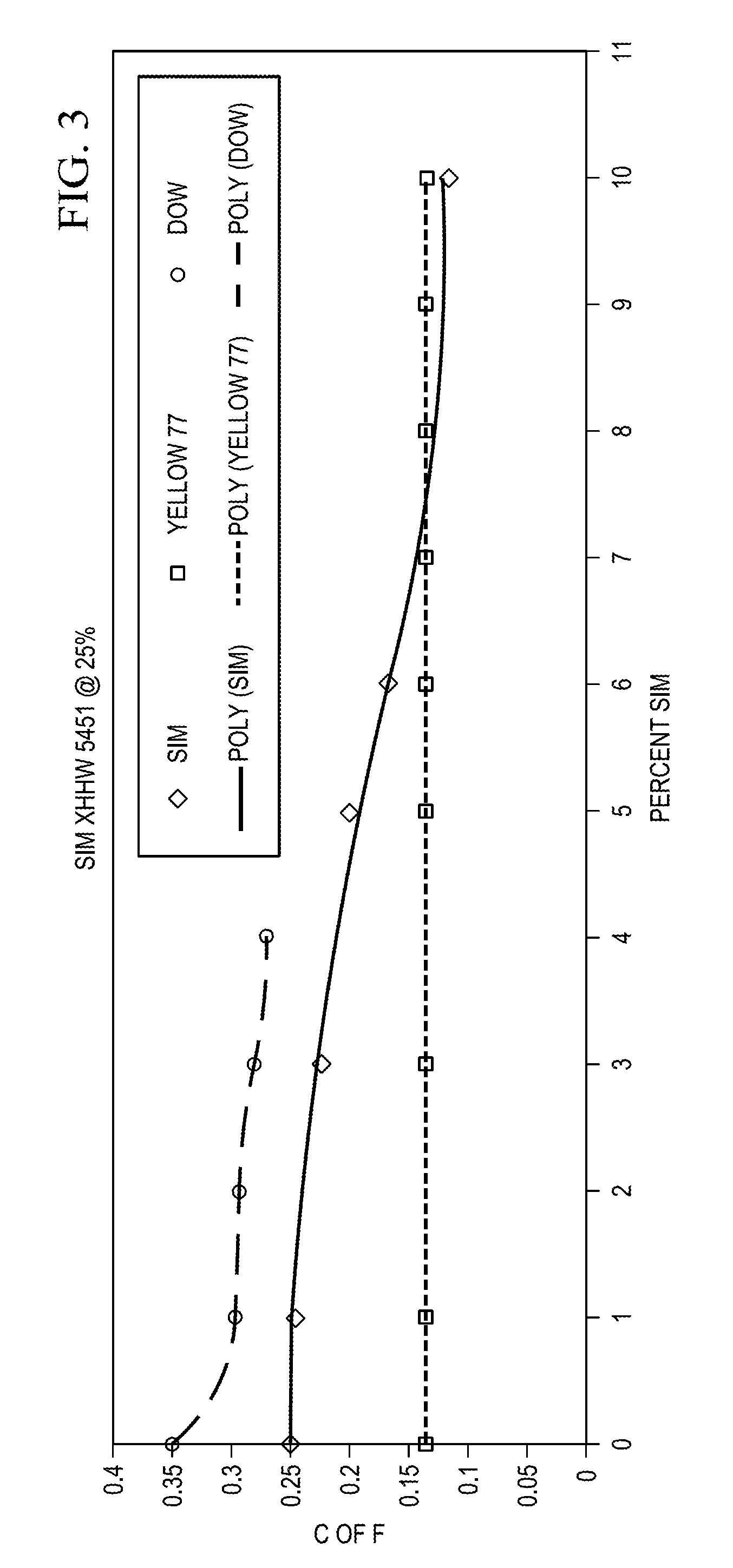

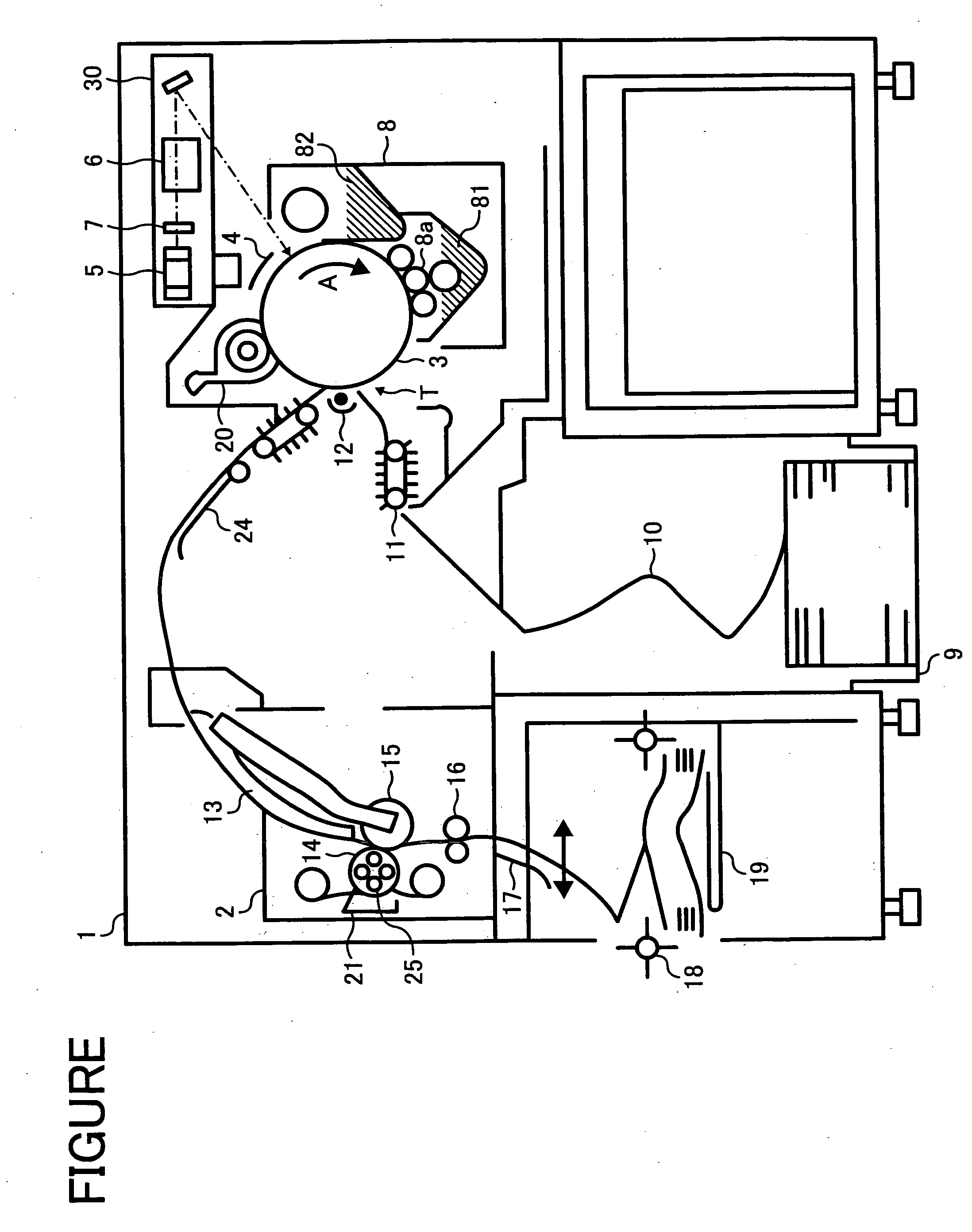

Electrical Cable Having Crosslinked Insulation With Internal Pulling Lubricant

ActiveUS20100236811A1Reduce tensionHigh viscosityPlastic/resin/waxes insulatorsBottlesElectrical conductorPower cable

Electrical power cable having a reduced surface coefficient of friction and required installation pulling force, and the method of manufacture thereof, in which the central conductor core, with or without a separate insulating layer, is surrounded by a sheath of crosslinked polyethylene. A high viscosity, high molecular weight silicone based pulling lubricant or fatty acid amide pulling lubricant is incorporated by alternate methods with the polyethylene to form a composition from which the outer sheath is extruded, and is effective to reduce the required pulling force on the cable during installation.

Owner:SOUTHWIRE CO LLC

Nonwoven fabric, process for producing the same, sanitary material and sanitary supply

InactiveUS20030157859A1Feel goodSuitable for useLayered productsAbsorbent padsStatic friction coefficientPolyolefin

Polyolefin resin-based non-woven fabric characterized by containing a fatty acid amide compound, and by having a static friction coefficient of 0.1 to 0.4. Production of such non-woven fabric is achieved by subjecting, for example, non-woven fabric containing 0.05 to 1 wt. % erucamide to an aging treatment at 30 to 60° C. for 5 to 50 hours.

Owner:IDEMITSU UNITECH CO LTD

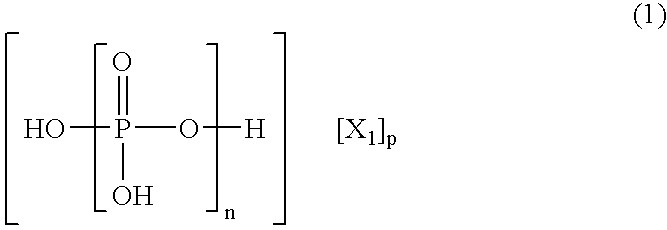

Toner, developer, and image forming apparatus

ActiveUS20070141498A1Good low temperatureHot offset resistanceDevelopersPolyesterCompound (substance)

A toner is provided including a binder resin; a release agent; a colorant; and a fatty acid amide compound, wherein the binder resin includes: an amorphous polyester (A) having a softening point of from 70 to 140° C.; an amorphous polyester (B) having a softening point of from 120 to 190° C.; and a crystalline polyester (C), and wherein the following relationship is satisfied: TmC<Tm(Asp), wherein TmC represents a softening point of the crystalline polyester (C) and Tm (Asp) represents a softening point of the fatty acid amide compound; and a developer and an image forming apparatus using the toner.

Owner:RICOH KK

Plastic films containing a fragrance and an odor barrier material within and a method for their production

InactiveUS6921581B2Extended shelf lifePrevents the fragrance from dissipatingFibre treatmentSynthetic resin layered productsChemical compositionPlastic film

A plastic film comprised of a polymer material, fragrance, and a waxy chemical composition for imparting to the film substantial impermeability to odors. A method for producing such films including the steps of: adding a liquid fragrance to highly porous polymer pellets; adding a waxy chemical composition to the fragrance and polymer; blending the polymer, fragrance, and waxy composition mixture; adding additional polymer to the blended mixture; extruding the resultant composition, thereby forming pellets; mixing the pellets with additional polymer; and forming a film therefrom. A plastic film, produced according to this method, for packaging or for masking unpleasant odors, comprising polyethylene or polypropylene, a fragrance, and a bis fatty-acid amide is also disclosed.

Owner:SAKIT

Flame retardant composition and flame retardant resin composition containing the composition

InactiveUS20050256234A1Improve flame retardant performanceTextile shapingCarboxylic acidFire retardant

A flame retardant composition includes, as essential components having two specified types of phosphate compounds; silicon dioxide or metal oxides; and at least one member selected from among higher aliphatic carboxylic acids, metal salts of higher aliphatic carboxylic acid, higher fatty acid amide compounds, and esters between mono- or polyhydric alcohols and higher aliphatic carboxylic acids. This flame retarder composition is free from secondary agglomeration, and does not need incorporation of a halogenated flame retarder that when blended in a synthetic resin, releases harmful gas at combustion. The flame retardant composition enables imparting flame retardant properties to synthetic resins with the use of a small amount of flame retarder.

Owner:ADEKA CORP

Environment-protection flame-proof electrostatic resistance polypropylene material and method for producing the same

The invention relates to an environmental-friendly polypropylene material with flame resistance and antistatic capacities, which comprises parts by weight of components that: 100pbw of pp resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers and 10-30 portions of antistatic agent. The PP resin is high fluidity homopolymerization PP; the flame retardant is deca-diphenylethane; the flame-retardant synergist is antimony trioxide; the filler is 2000 meshes talcum powder; the antistatic agent is conductive carbon black; lubrication dispersing agent is aethylenum double fatty acid amide TAS-2A. The preparation method of the material is that: according to the part by weight, 100 portions of PP resin, 30-50 portions of flame retardant, 10-20 portions of flame-retardant synergist, 40-60 portions of fillers, 10-30 portions of antistatic agent and 1-10 portions of lubrication dispersant are weighted and mixed in a high-speed mixer for 3 to 5 minutes, and after mixing, the mixed raw materials are molten, squeezed and made into particles in a parallel twin-screw extruder. The polypropylene material of the invention has the advantages of good mechanical intensity, antistatic effect, flame resistance and being environment-friendly.

Owner:ANHUI KEJU NEW MATERIALS

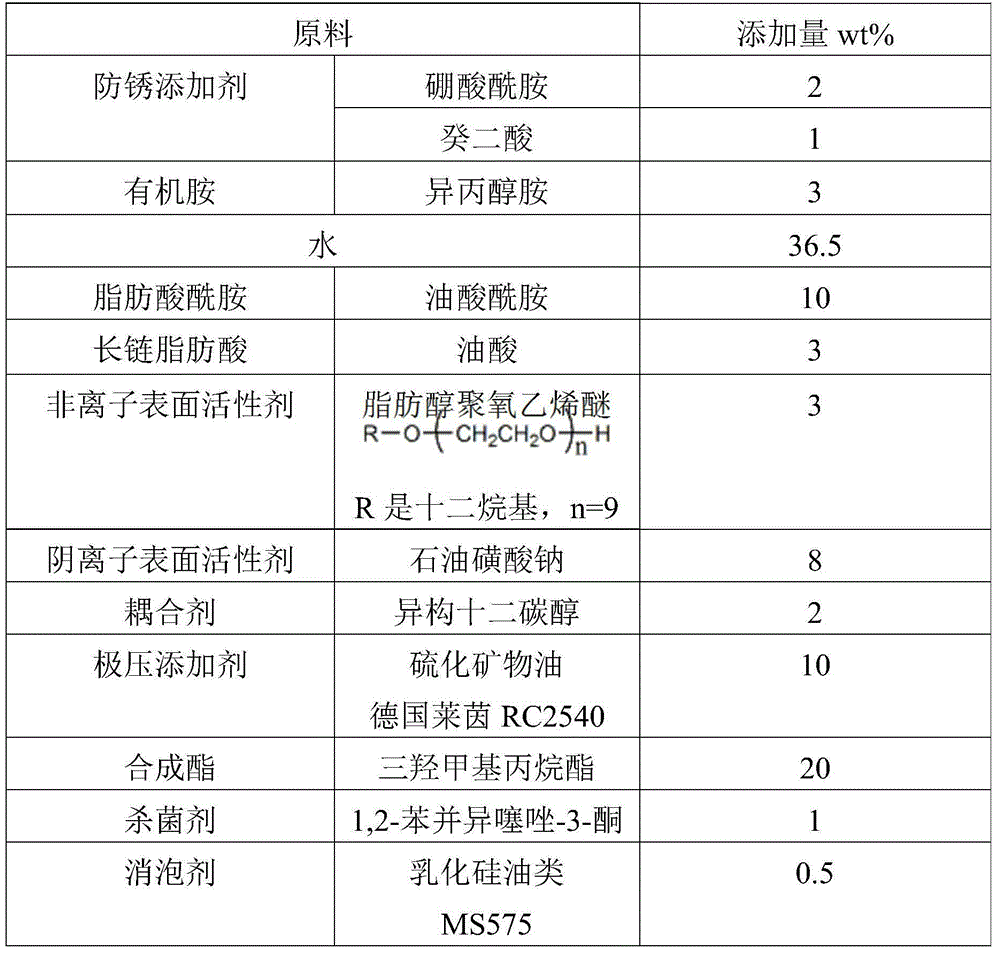

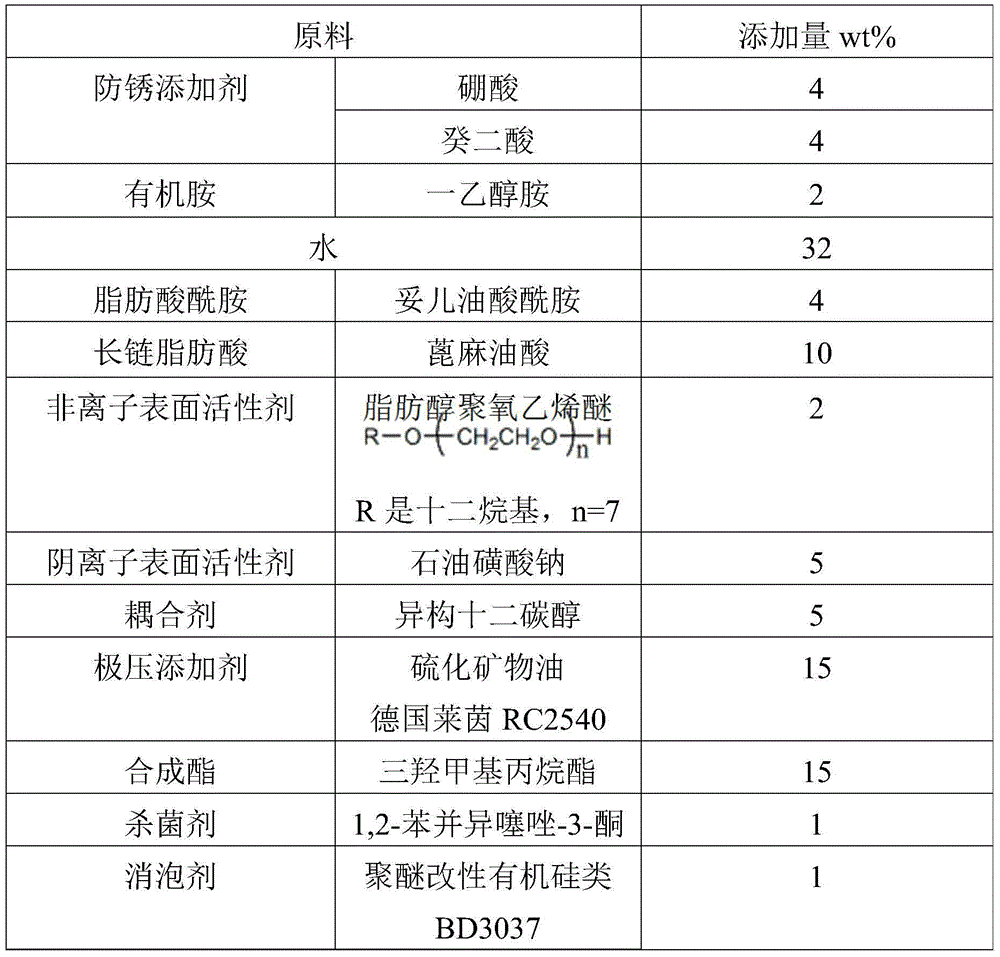

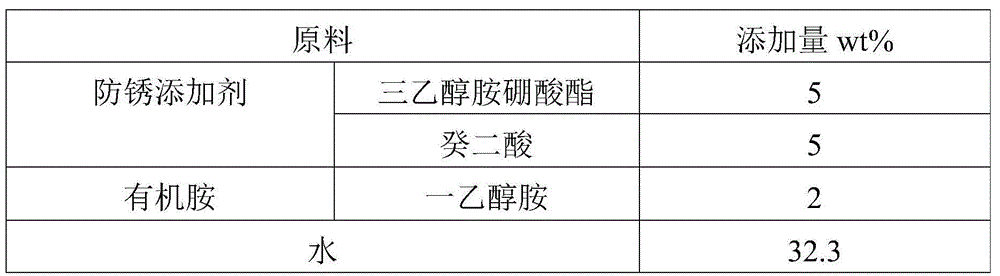

Water-based cutting fluid for vermicular cast iron processing, and dilution solution thereof

ActiveCN104877749AImprove the lubrication effectImprove cooling effectLubricant compositionWater basedNitro compound

The present invention discloses a water-based cutting fluid for vermicular cast iron processing, and a dilution solution thereof. The water based cutting fluid comprises 3-10% of an anti-rust additive, 4-10% of fatty acid amide, 2-3% of organic amine, 3-10% of long-chain fatty acid, 2-5% of fatty alcohol polyoxyethylene ether, 5-8% of petroleum sodium sulfonate, 1-5% of a coupling agent, 10-15% of an extreme pressure additive, 15-20% of a synthetic ester, 1-2% of a sterilization agent, 0.5-1.0% of an anti-forming agent, and 32-45% of water, wherein the anti-rust additive is a boric acid anti-rust additive and dicarboxylic acid, and the coupling agent is a fatty alcohol and / or aliphatic ether. The water-based cutting fluid of the present invention has characteristics of good lubrication performance, good cooling performance, good anti-rust property, no chlorine, diamine, nitrite and other nitro compounds, no environmental pollution, no irritating odor, easy cutting, easy powder settlement, and effective cutter service life prolonging.

Owner:上海德润宝特种润滑剂有限公司

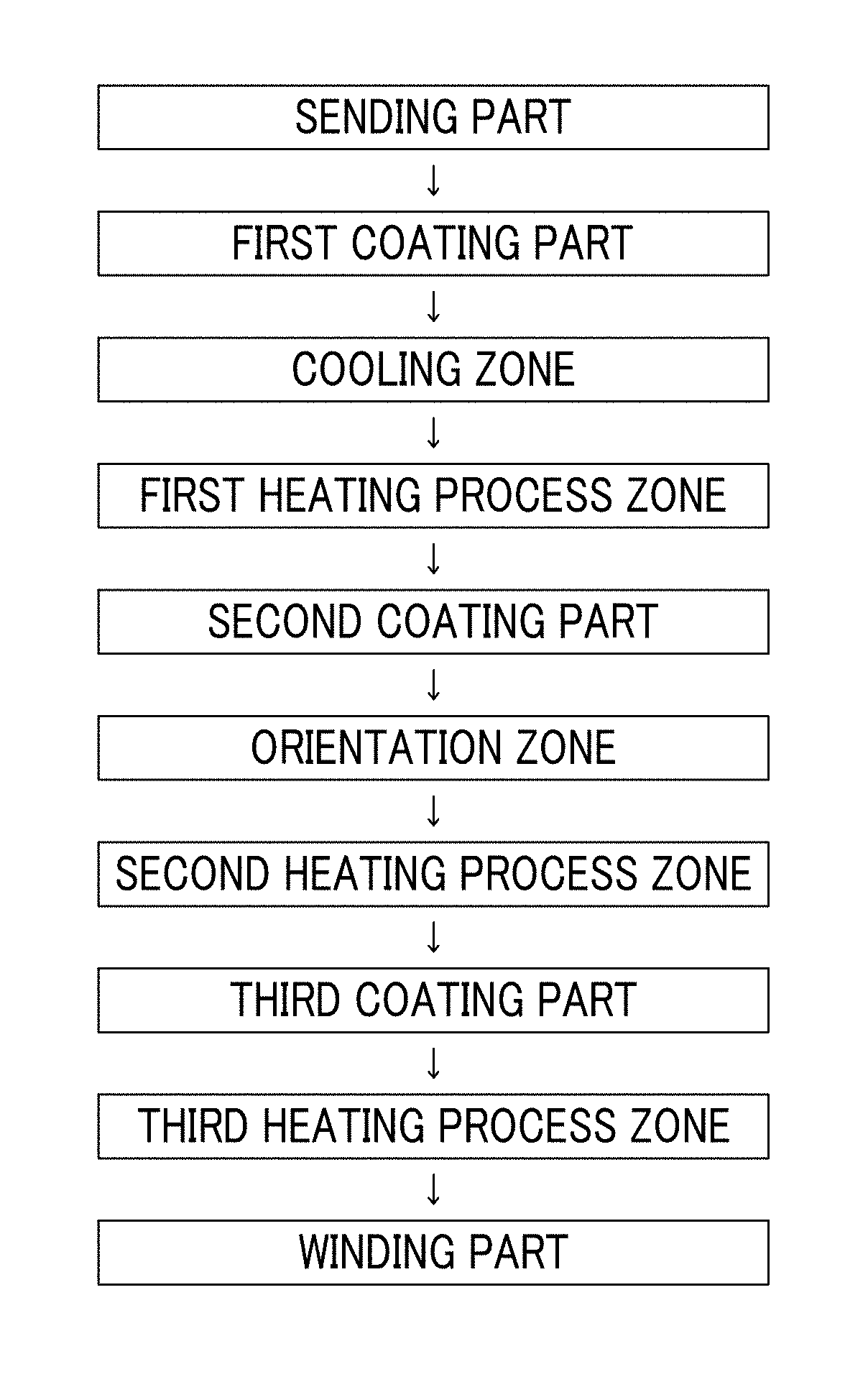

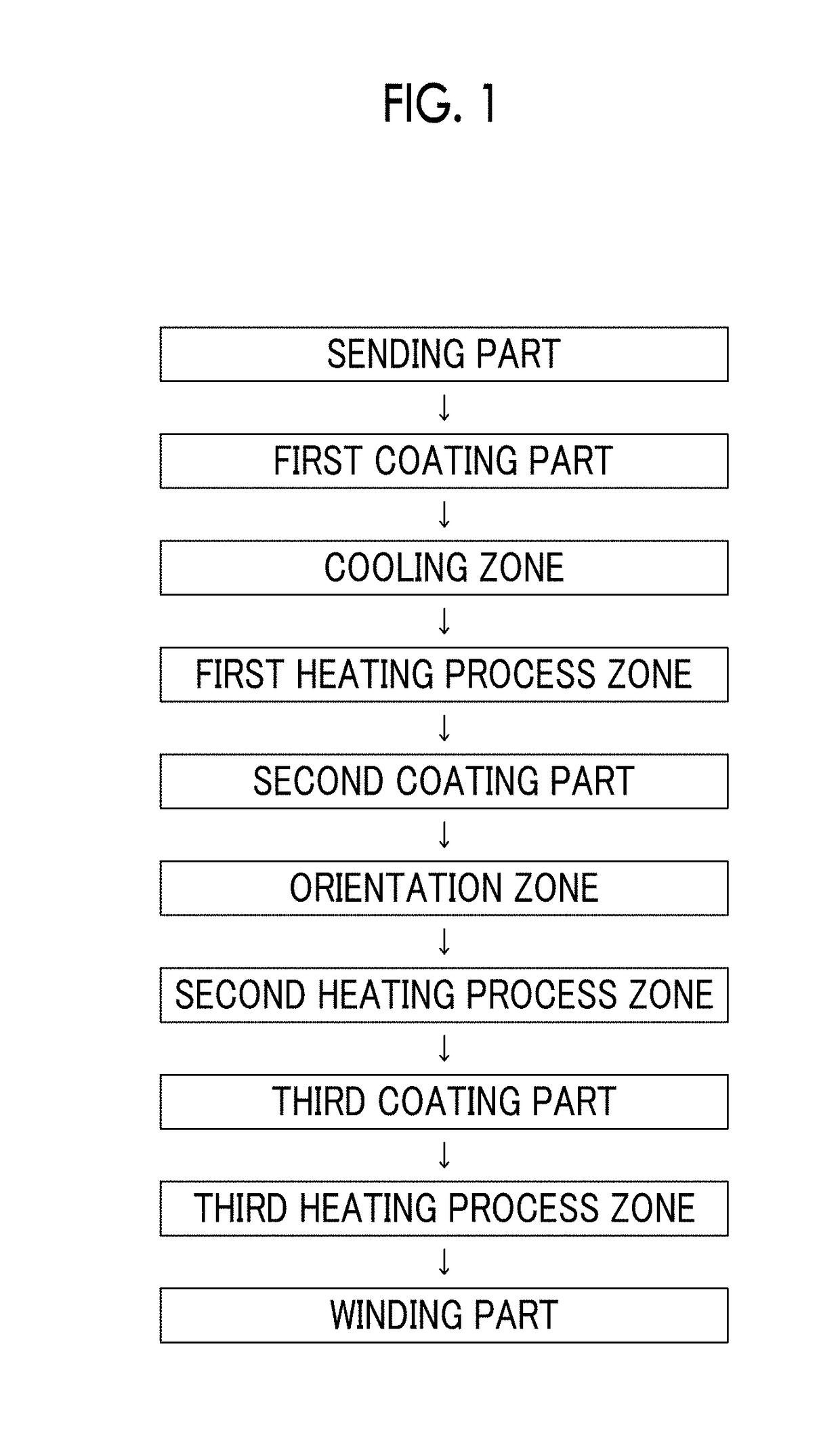

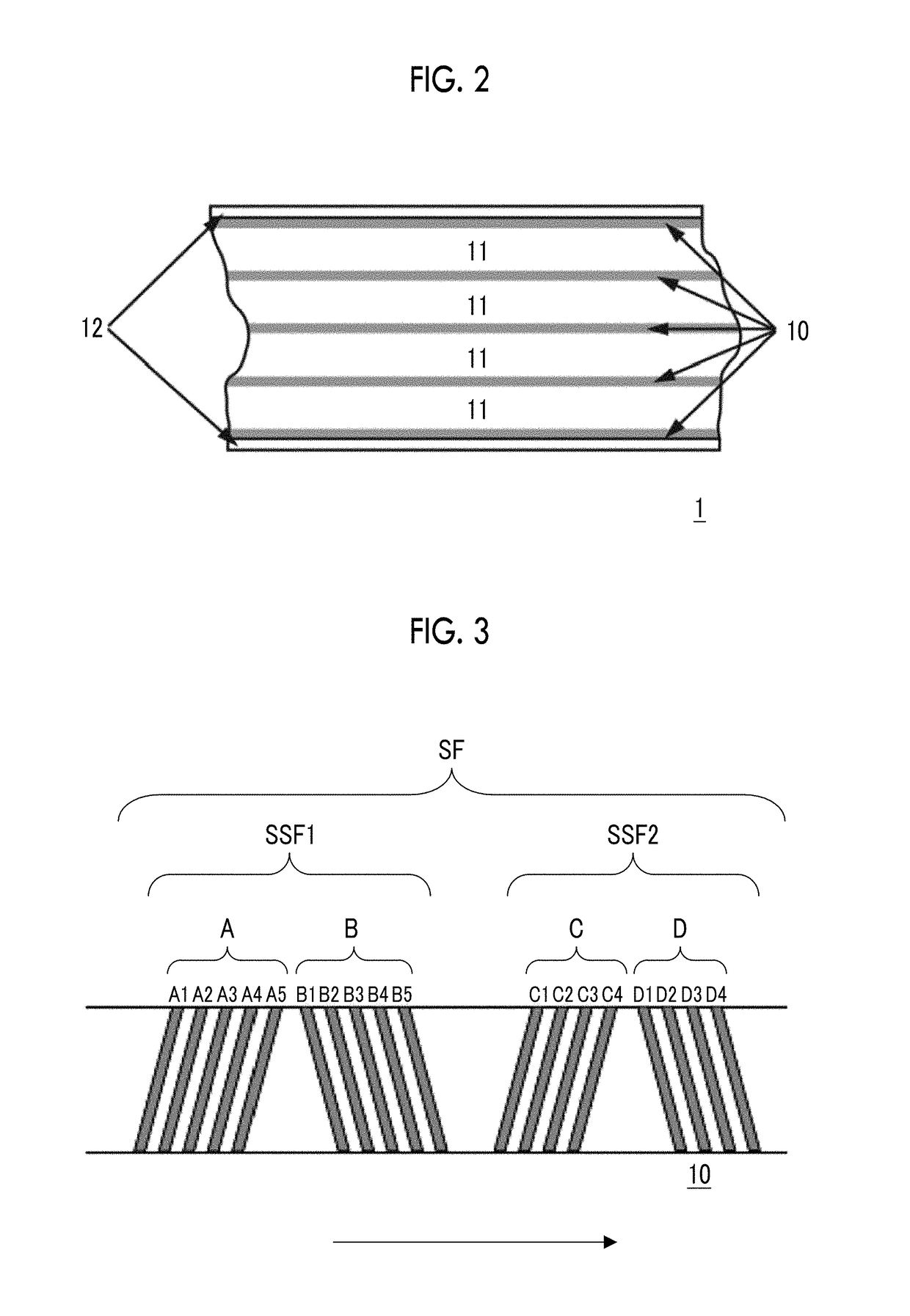

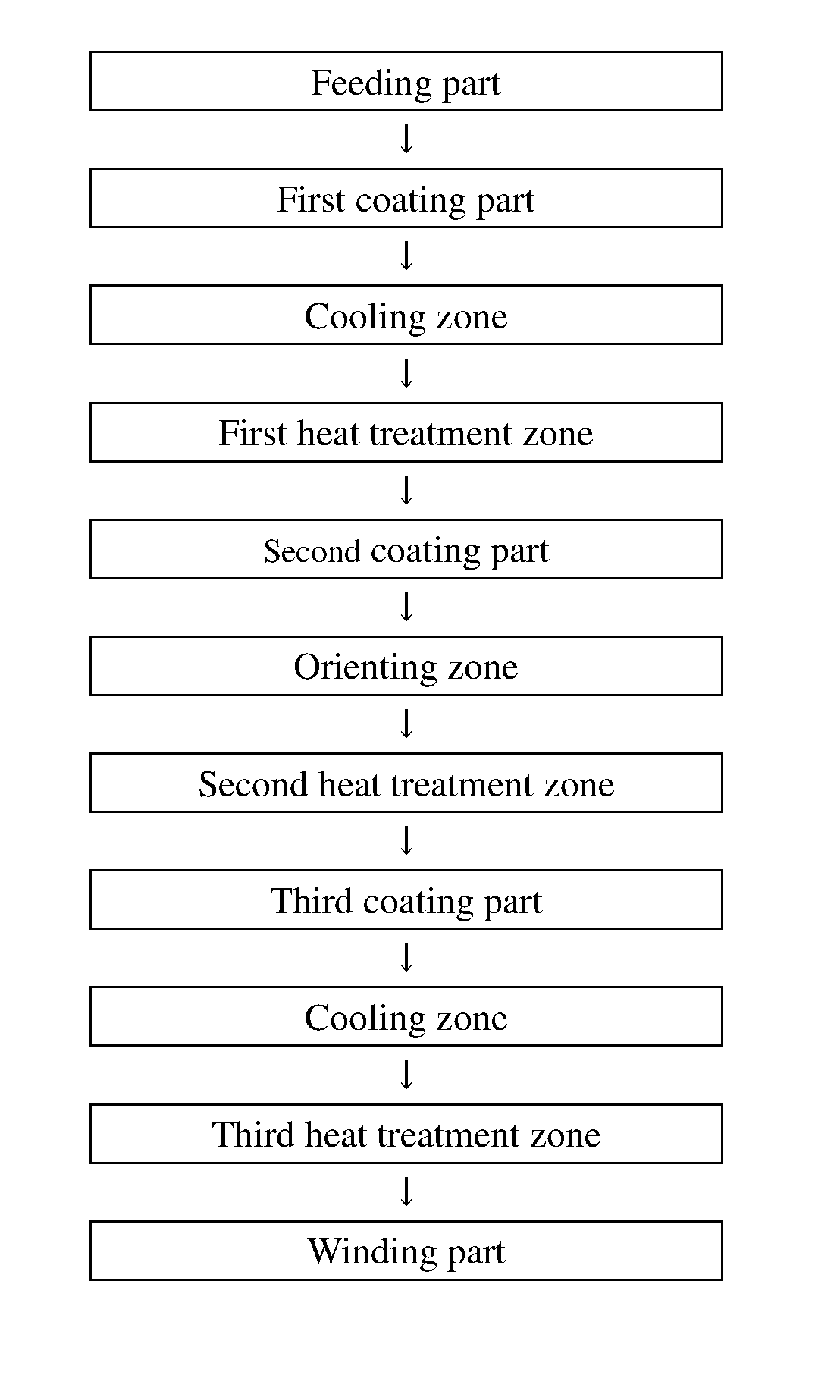

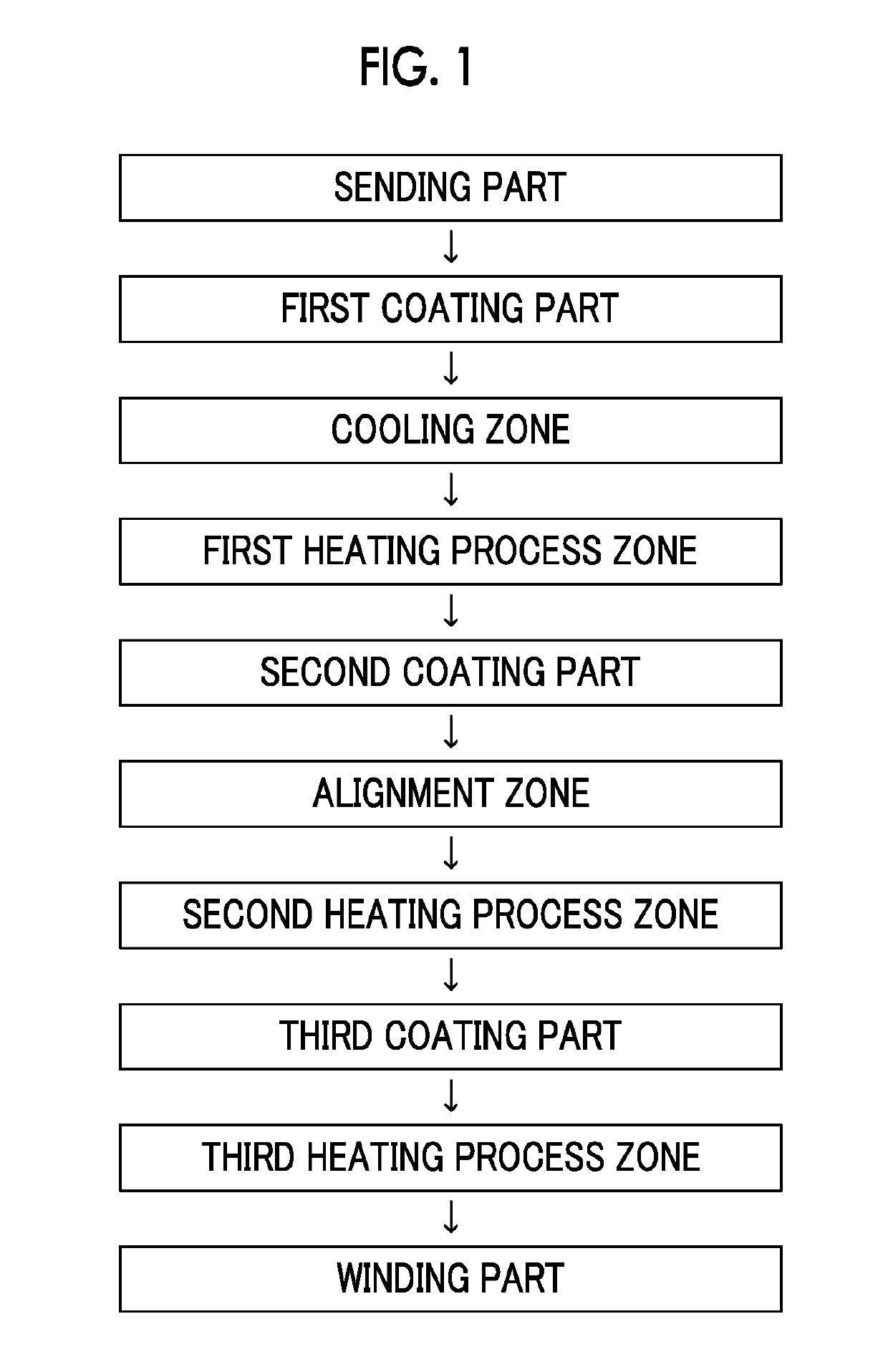

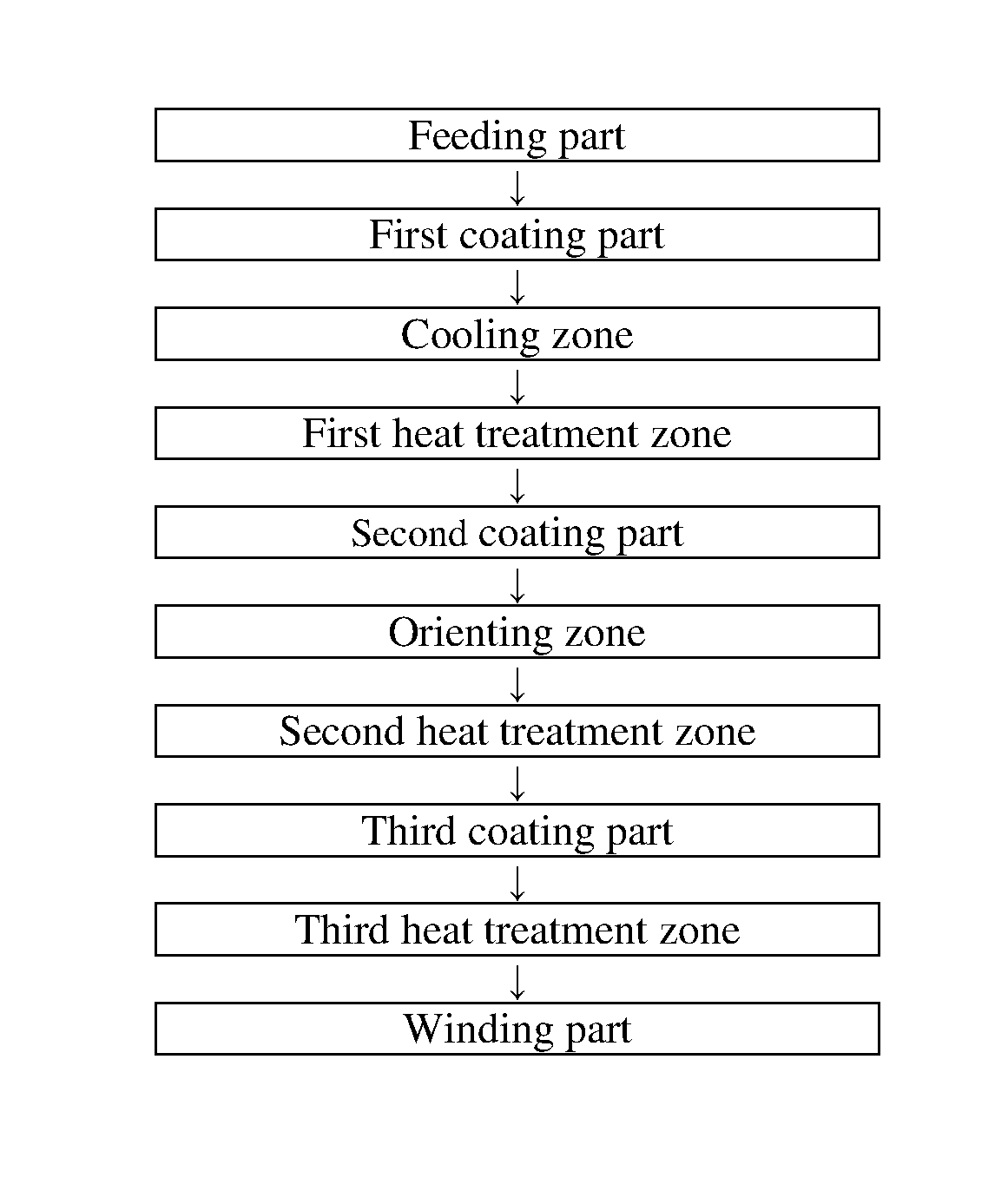

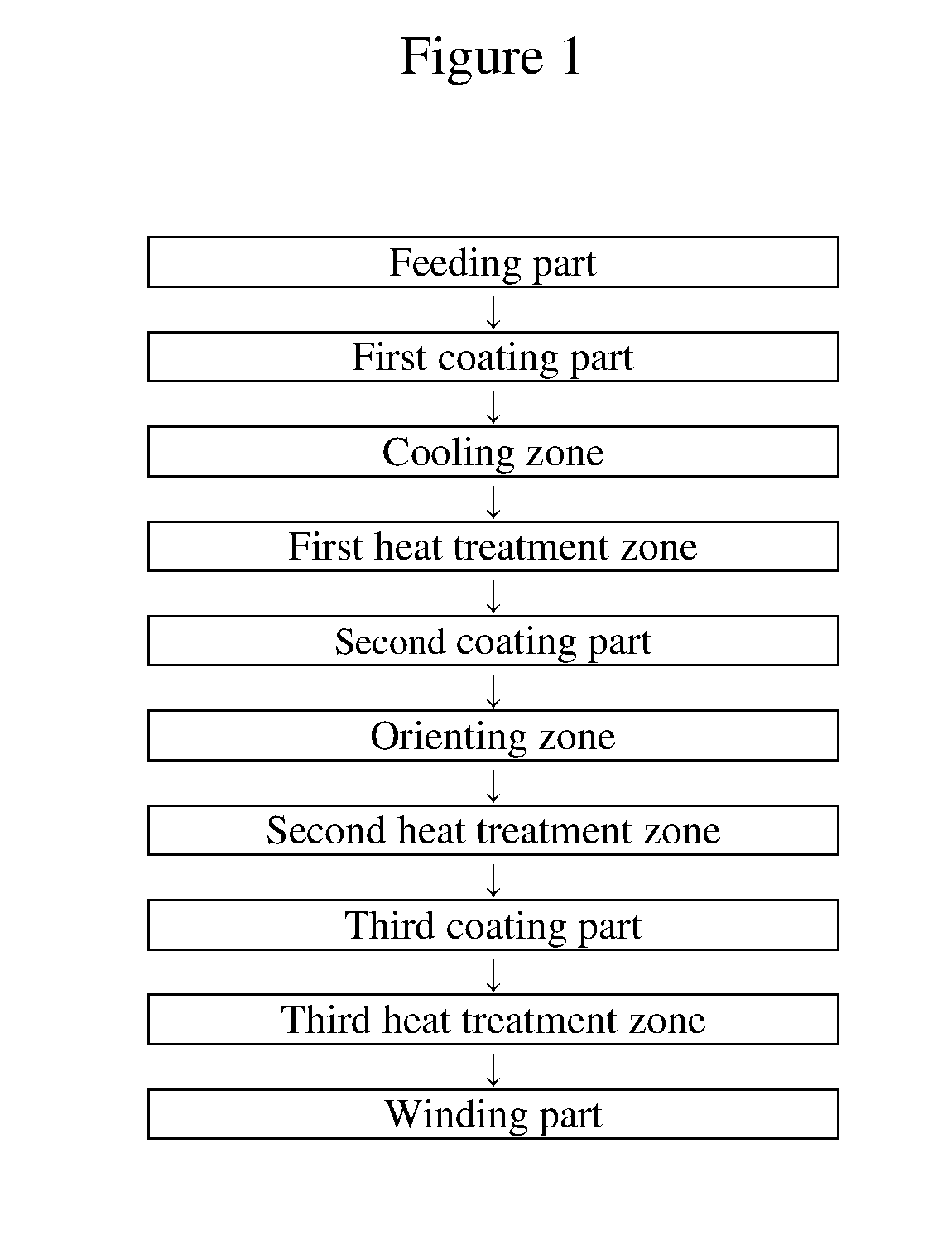

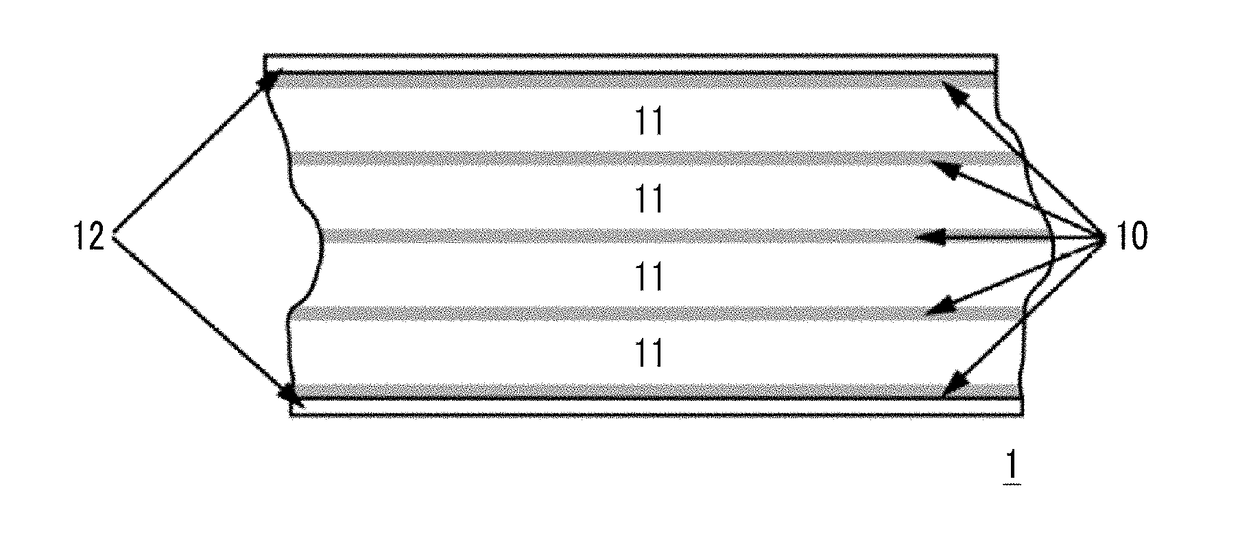

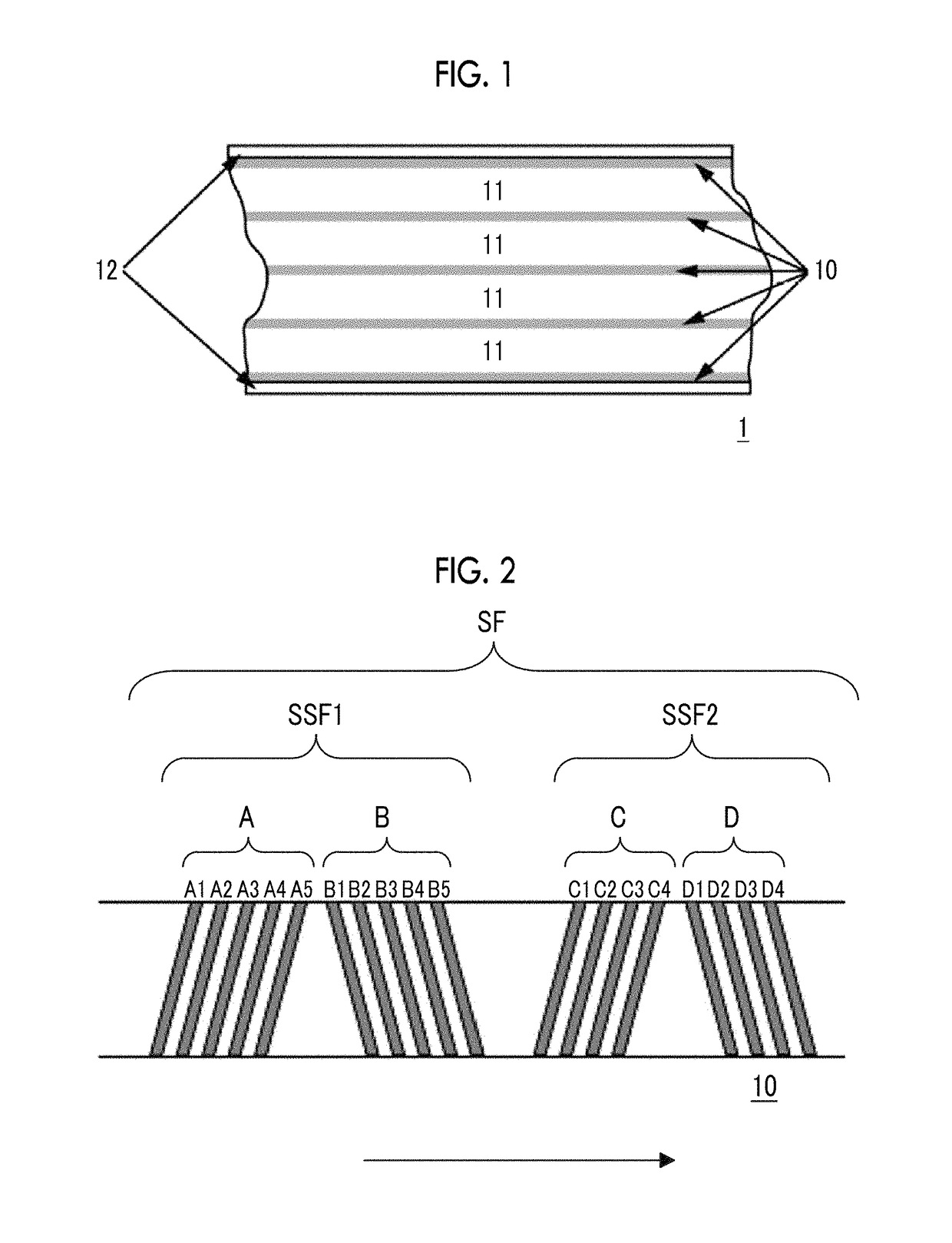

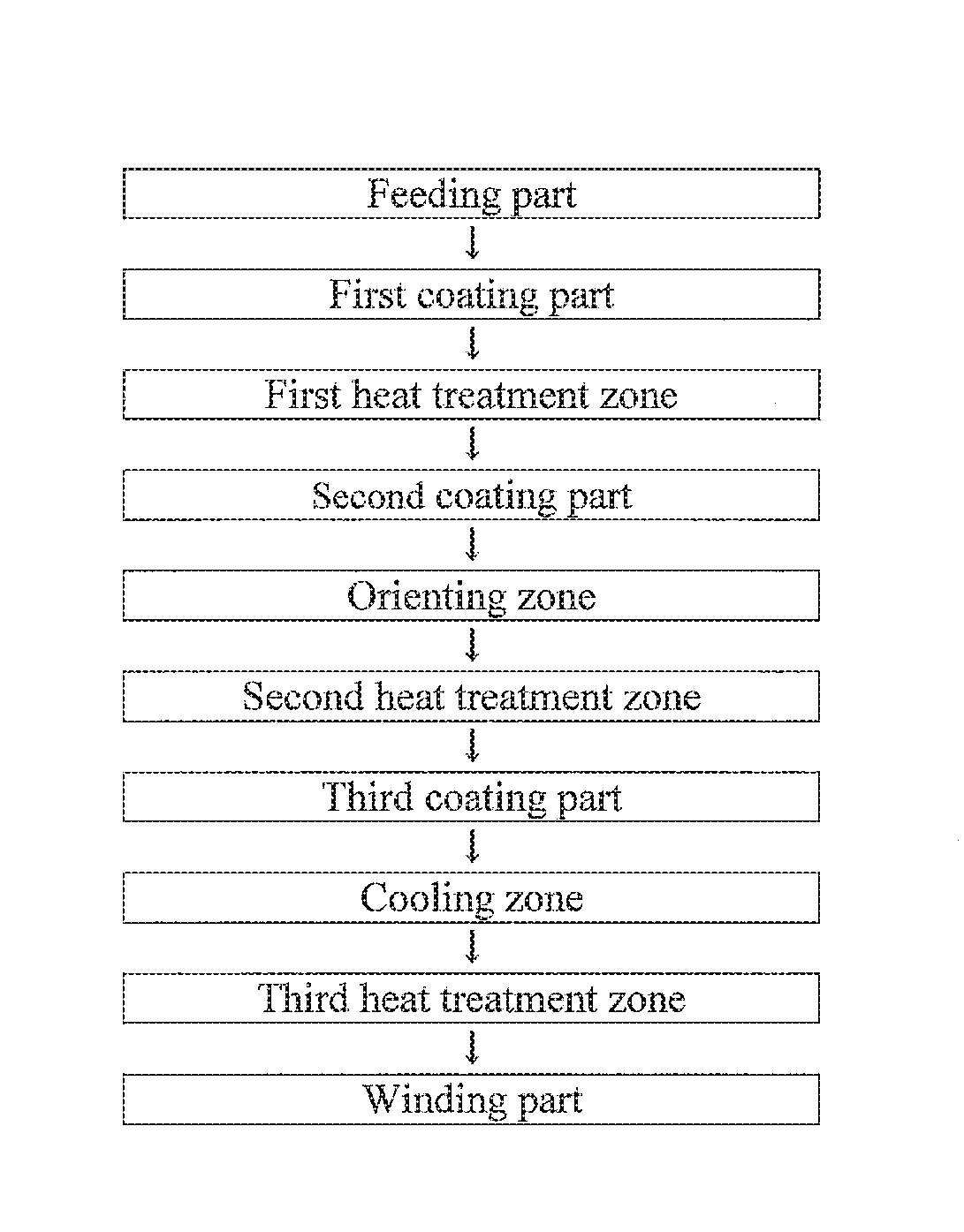

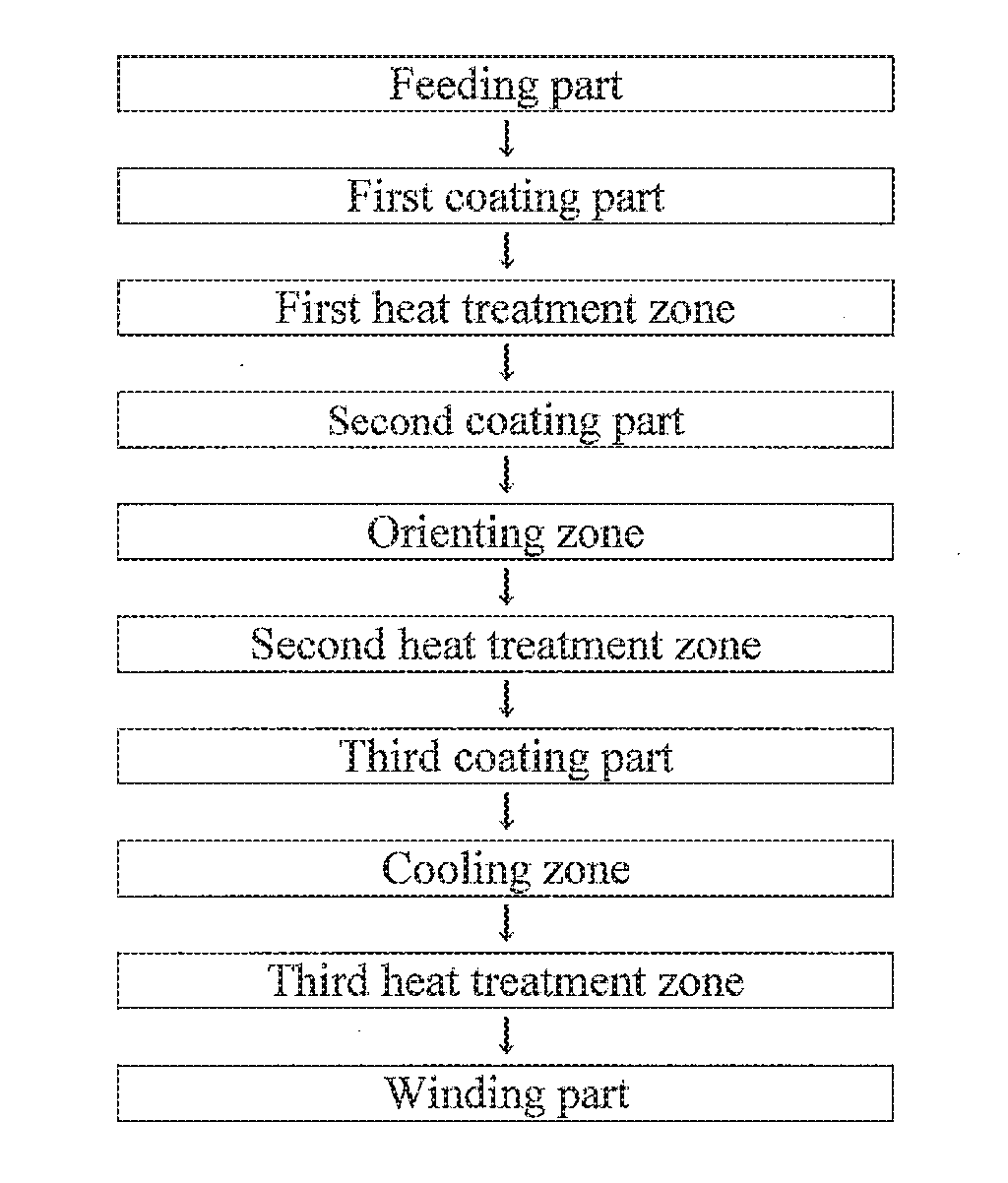

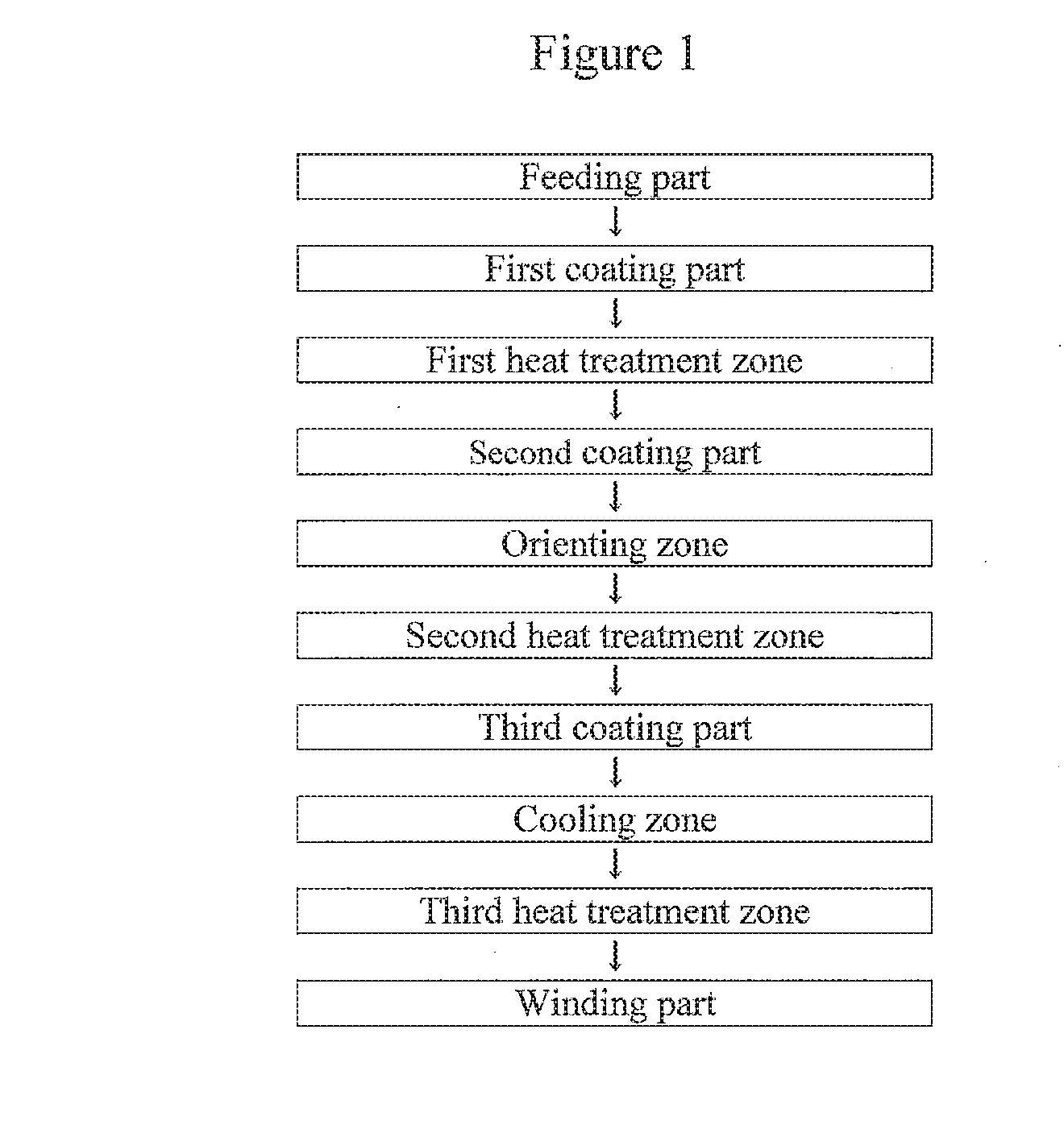

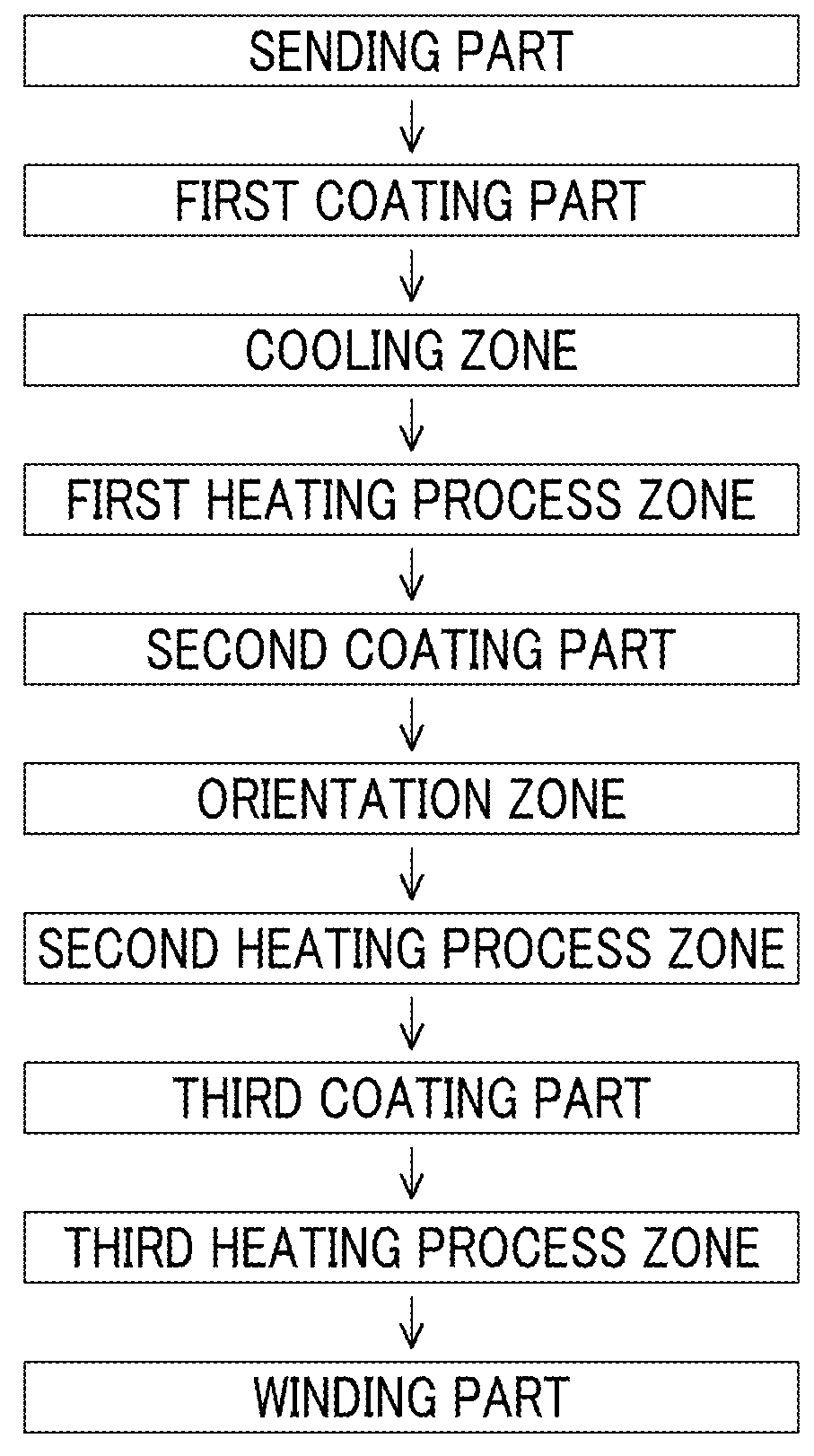

Magnetic tape including characterized magnetic layer, tape cartridge, recording and reproducing device, and method of manufacturing

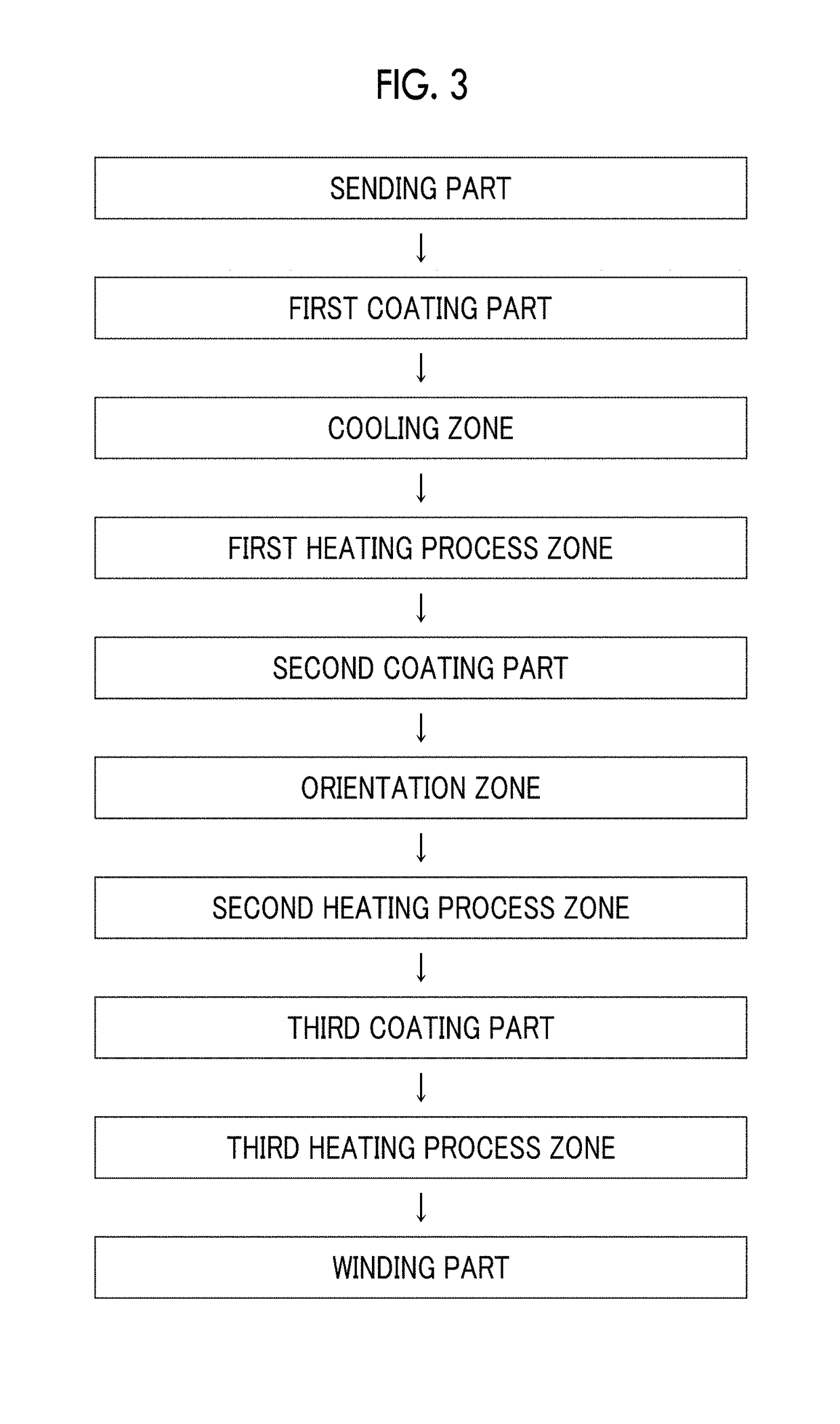

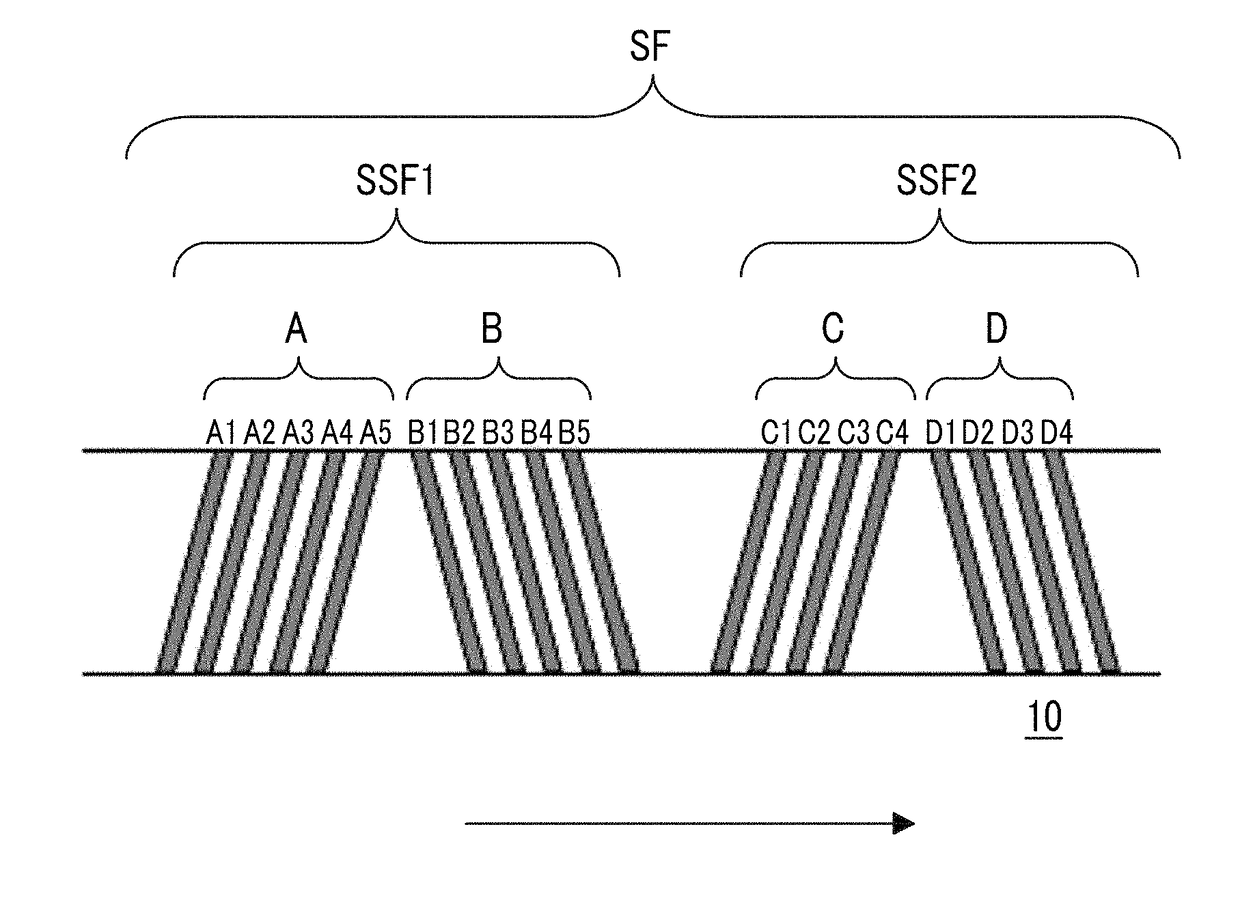

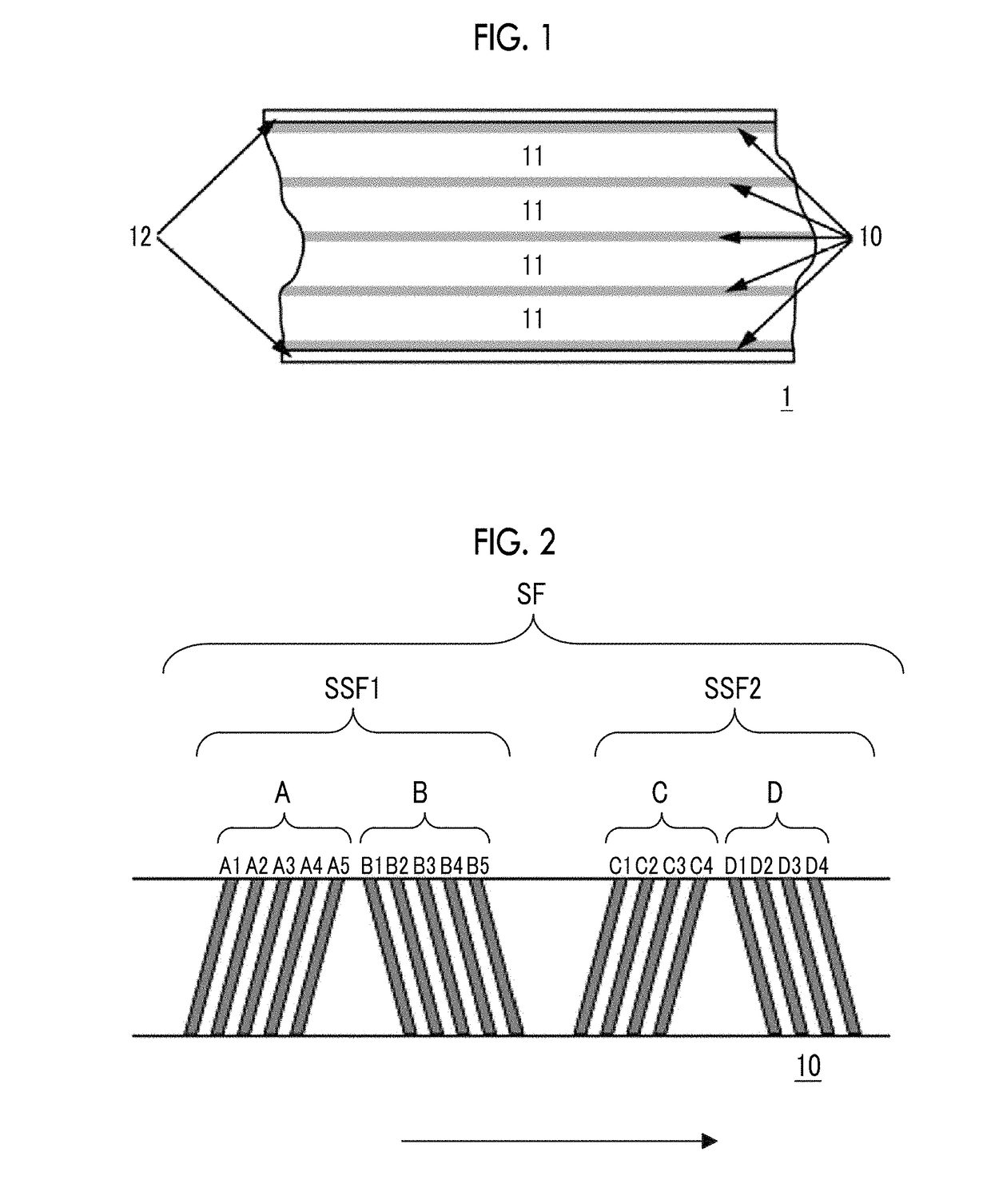

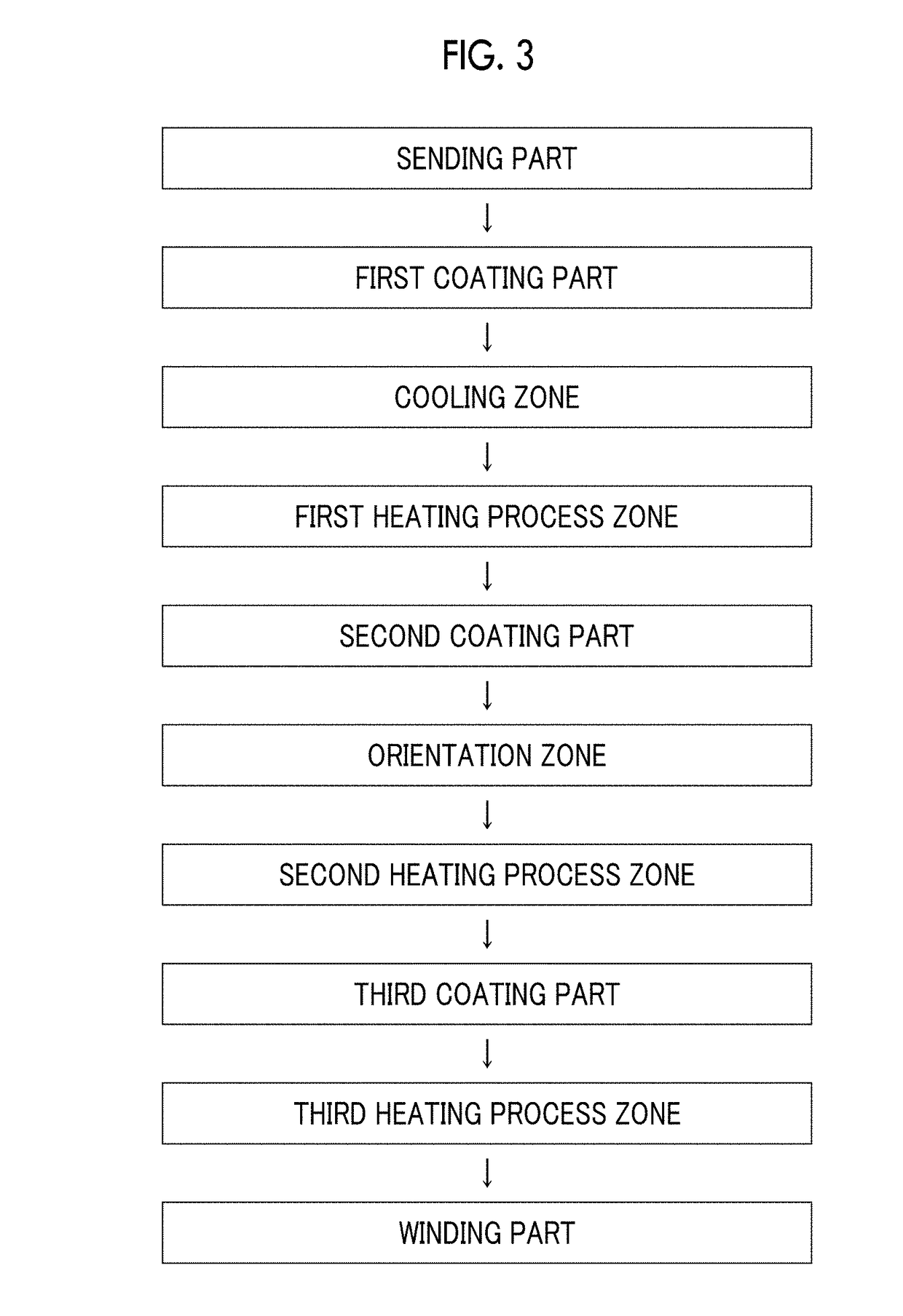

ActiveUS10522180B2Shorten the timeIncrease delivery speedBase layers for recording layersTape carriersMagnetic tapeMaterials science

Owner:FUJIFILM CORP

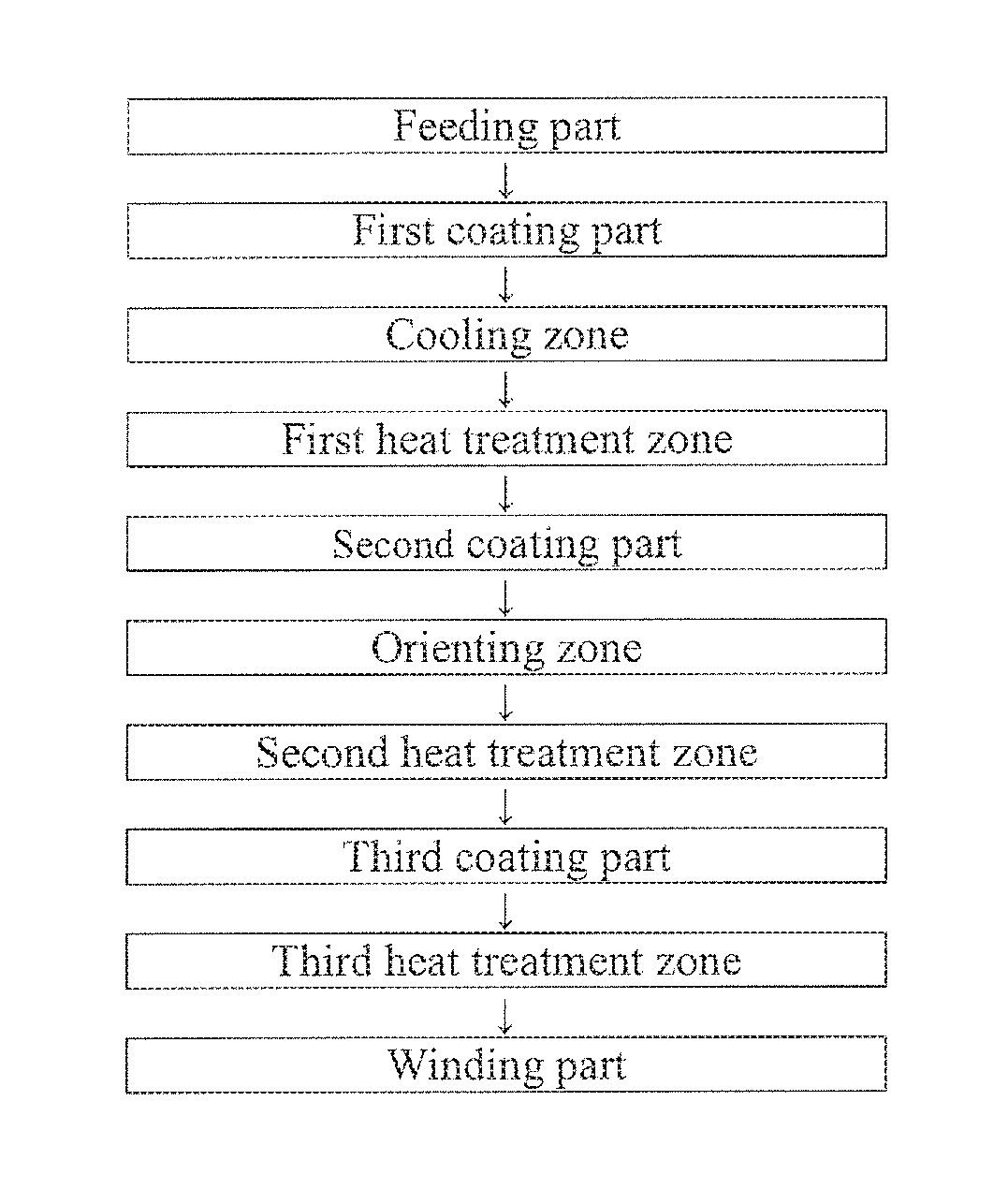

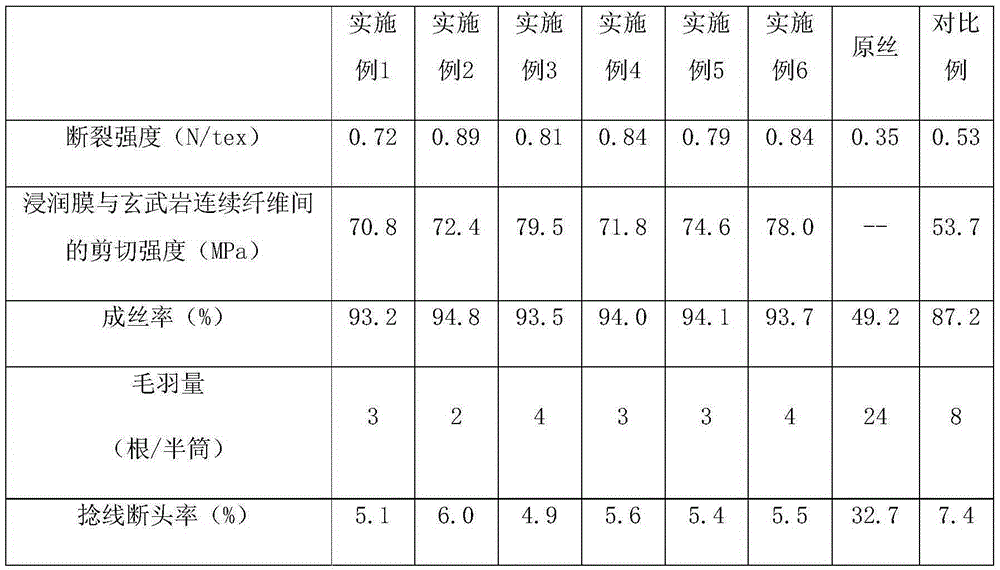

Special nano-modified impregnating compound for basalt continuous fiber and preparation method of special nano-modified impregnating compound

The invention provides a special nano-modified impregnating compound for basalt continuous fiber and a preparation method of the special nano-modified impregnating compound. The preparation method comprises specific operation steps as follows: (1), citric acid is added to a deionized aqueous solution, the PH (potential of hydrogen) value of a citric acid aqueous solution is adjusted to range from 3 to 4, the mixture is stirred at a high speed, a silane coupling agent is slowly and dropwise added, the mixture is stirred until the silane coupling agent is completely hydrolyzed, and a clear and transparent hydrolyzed coupling agent is obtained; (2), organosilicone-modified acrylic ester and a polyester resin emulsion are diluted by 10-20 times with deionized water respectively and then are mixed and uniformly stirred, and a diluted film forming agent is obtained, monodispersed nano-silica and titanium dioxide particles are added, the mixture is heated, stirred and cooled at the room temperature, and the film forming agent containing nano particles is obtained; (3), fatty acid amide acetate, aliphatic ester sulfate and a quaternary ammonium salt cationic antistatic agent are added to deionized water, the PH value of the solution is adjusted, the hydrolyzed coupling agent and the film forming agent containing the nano particles are added respectively, the mixture is stirred uniformly and left to stand to be defoamed, and the special nano-modified impregnating compound for the basalt continuous fiber is obtained.

Owner:江门市新会区美亚化工有限公司

Thermoplastic constructs with improved softness

InactiveUS7238313B2Monocomponent polypropylene artificial filamentWoven fabricsCombined usePolymer chemistry

The present invention is directed to the combined use of first and second fatty acid amides to improve the softness of a thermoplastic polymer construct. A combination of fatty acid amides is provided in the blend ratio of about 10 to 90 percent by weight of a first fatty acid amide and 90 to 10 percent by weight of a second fatty acid amide. The first and second fatty acid amides are compounded into a thermoplastic polymer carrier resin and, preferentially, produced as concentrate pellets containing 0.5 to 75 percent by weight total fatty acid amide loading. The concentrate pellets are introduced into a thermoplastic polymer base, to form a thermoplastic resin, at a letdown level in the range of about 1 to 15 percent, with the range of 2 to 10 percent being preferred, and the range of 3 to 6 percent being most preferred.

Owner:AVINTIV SPECIALTY MATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com