Water-based cutting fluid for vermicular cast iron processing, and dilution solution thereof

A water-based technology for vermicular graphite cast iron, which is applied in the field of water-based cutting fluid and its dilution fluid for vermicular graphite cast iron processing, can solve the problems that vermicular graphite cast iron is not suitable and cannot reduce the difficulty of vermicular graphite cast iron processing, and achieves good cooling performance, Reduced machining time and excellent lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

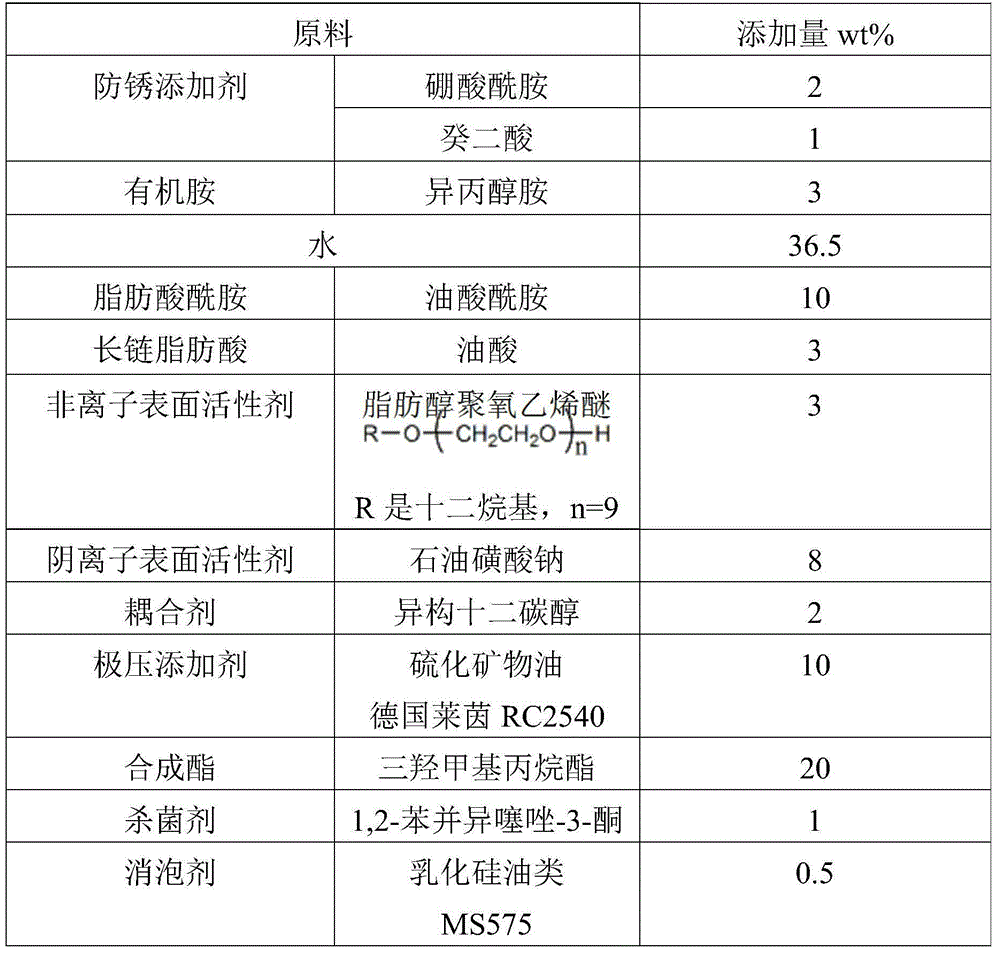

[0028] raw material:

[0029]

[0030] Heat and dissolve all raw materials and stir evenly to obtain water-based cutting fluid for vermicular graphite cast iron.

Embodiment 2

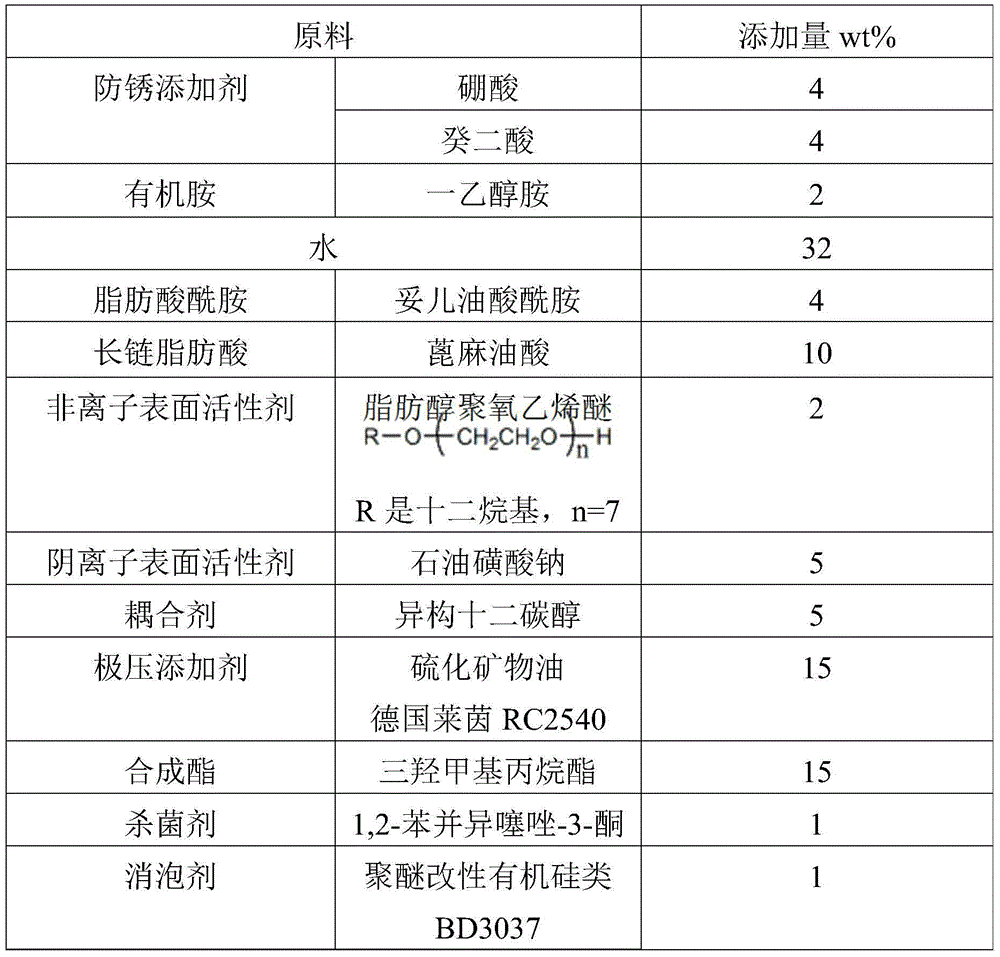

[0032] raw material:

[0033]

[0034] Heat and dissolve all raw materials and stir evenly to obtain water-based cutting fluid for vermicular graphite cast iron.

Embodiment 3

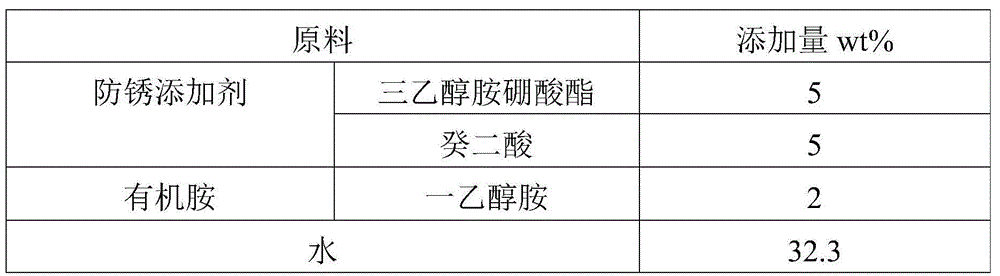

[0036] raw material:

[0037]

[0038]

[0039] Heat and dissolve all raw materials and stir evenly to obtain water-based cutting fluid for vermicular graphite cast iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com