Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

354 results about "X-ray photoelectron spectroscopy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

X-ray photoelectron spectroscopy (XPS) is a surface-sensitive quantitative spectroscopic technique that measures the elemental composition at the parts per thousand range, empirical formula, chemical state and electronic state of the elements that exist within a material. Put more simply, XPS is a useful measurement technique because it not only shows what elements are within a film but also what other elements they are bonded to. This means if you have a metal oxide and you want to know if the metal is in a +1 or +2 state, using XPS will allow you to find that ratio. However at most the instrument will only probe 20nm into a sample.

Magnetic tape

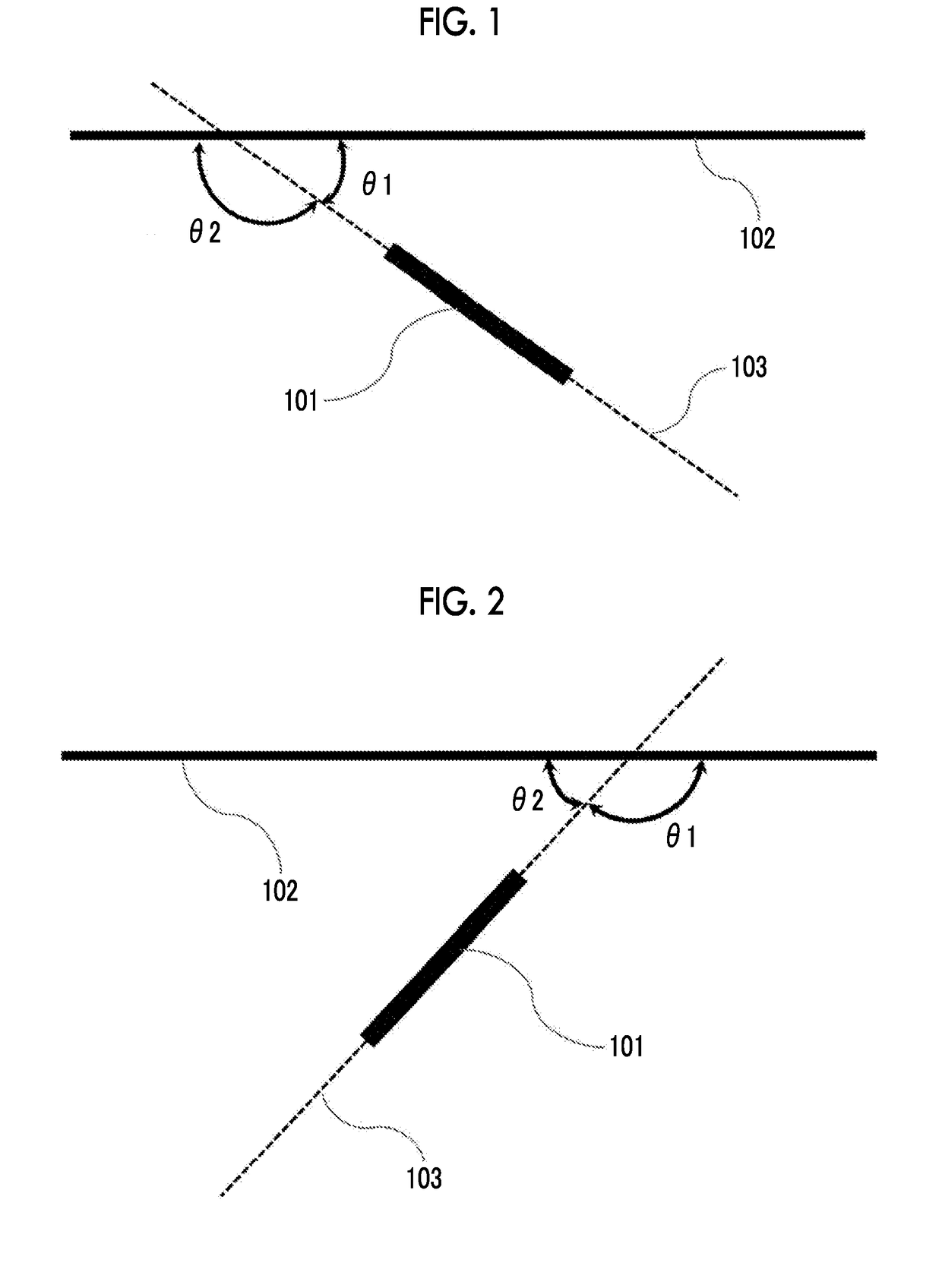

Provided is a magnetic tape in which ferromagnetic powder included in a magnetic layer is ferromagnetic hexagonal ferrite powder having an activation volume equal to or smaller than 1,600 nm3, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and an abrasive, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %, and a tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to the surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

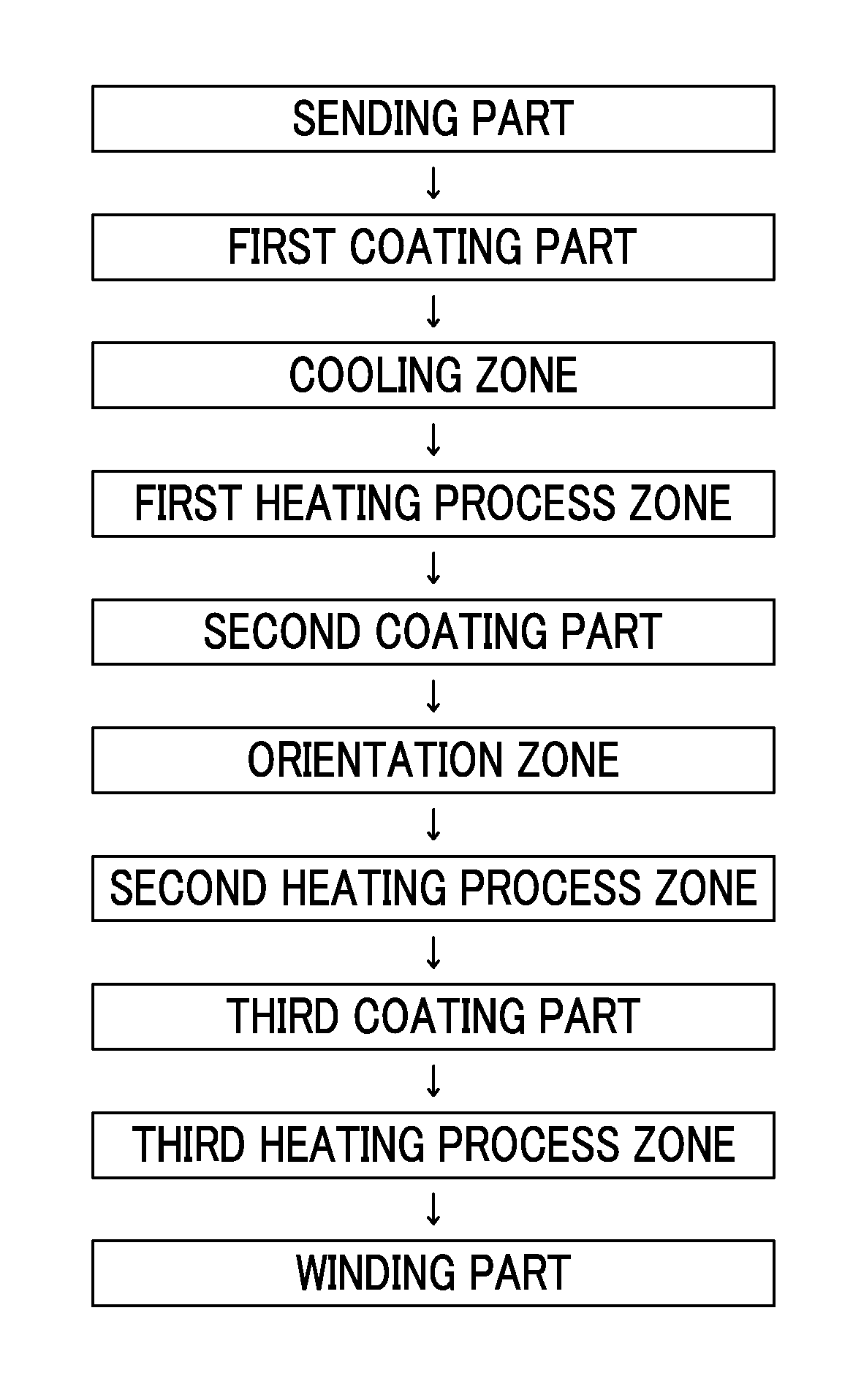

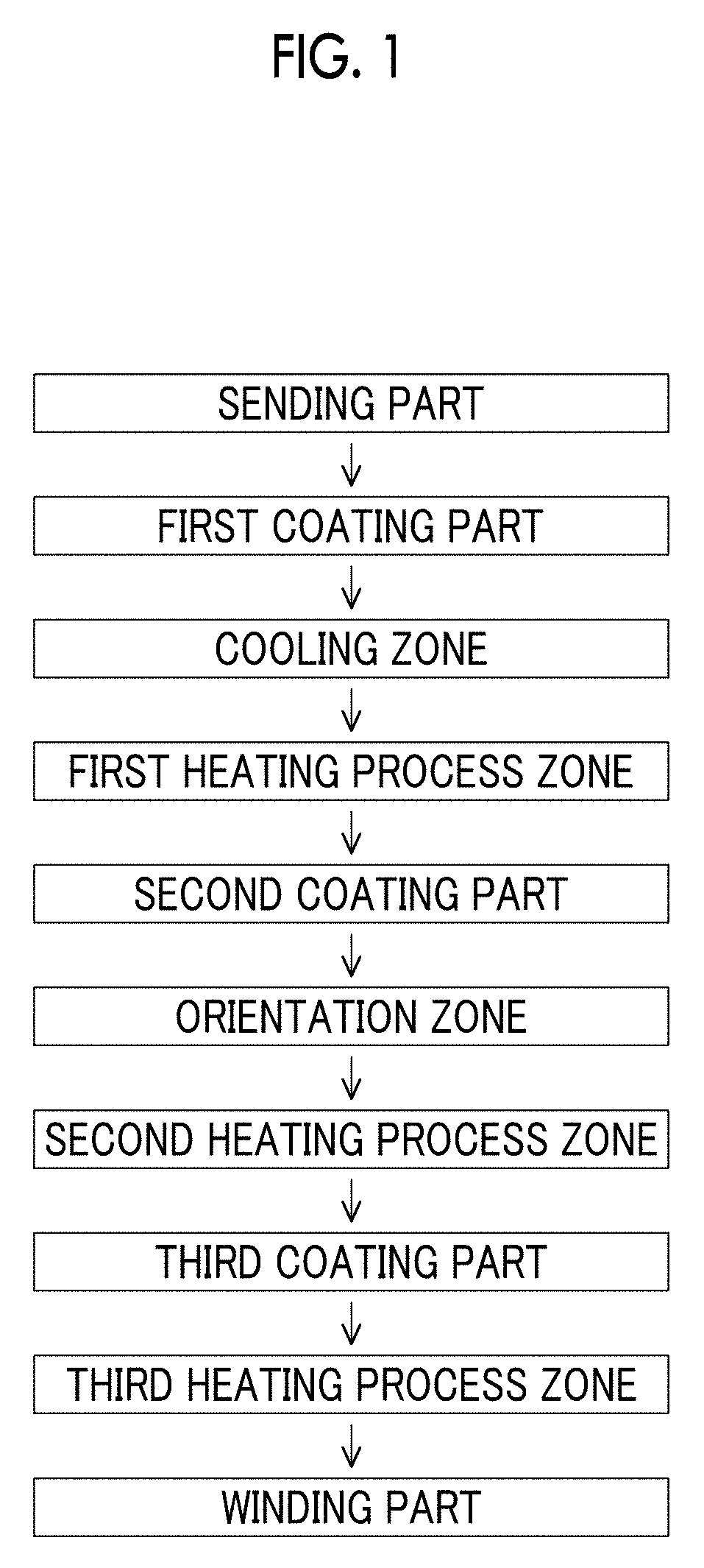

Magnetic tape and method of manufacturing the same

ActiveUS9711174B2Reduce thicknessIncrease recording capacityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

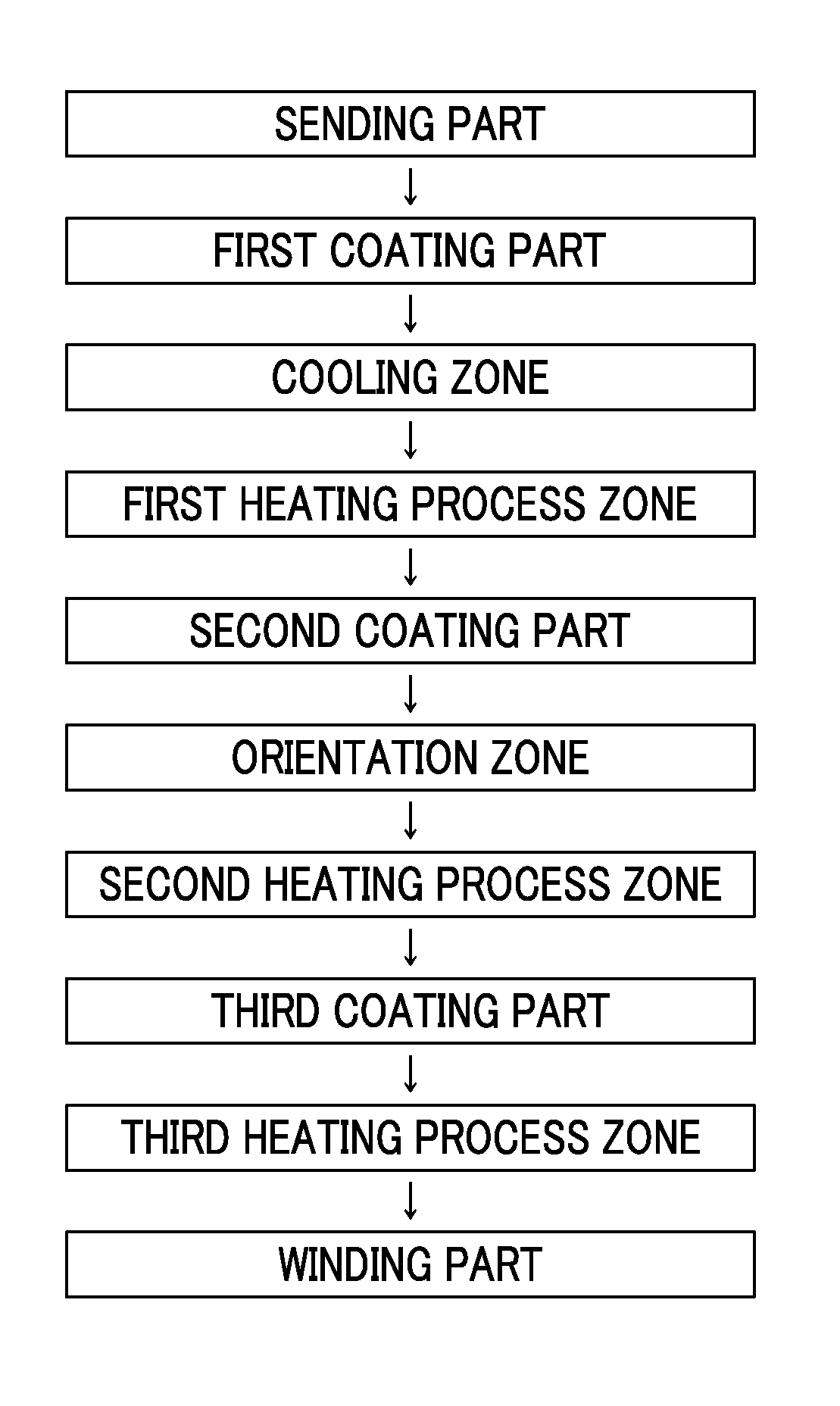

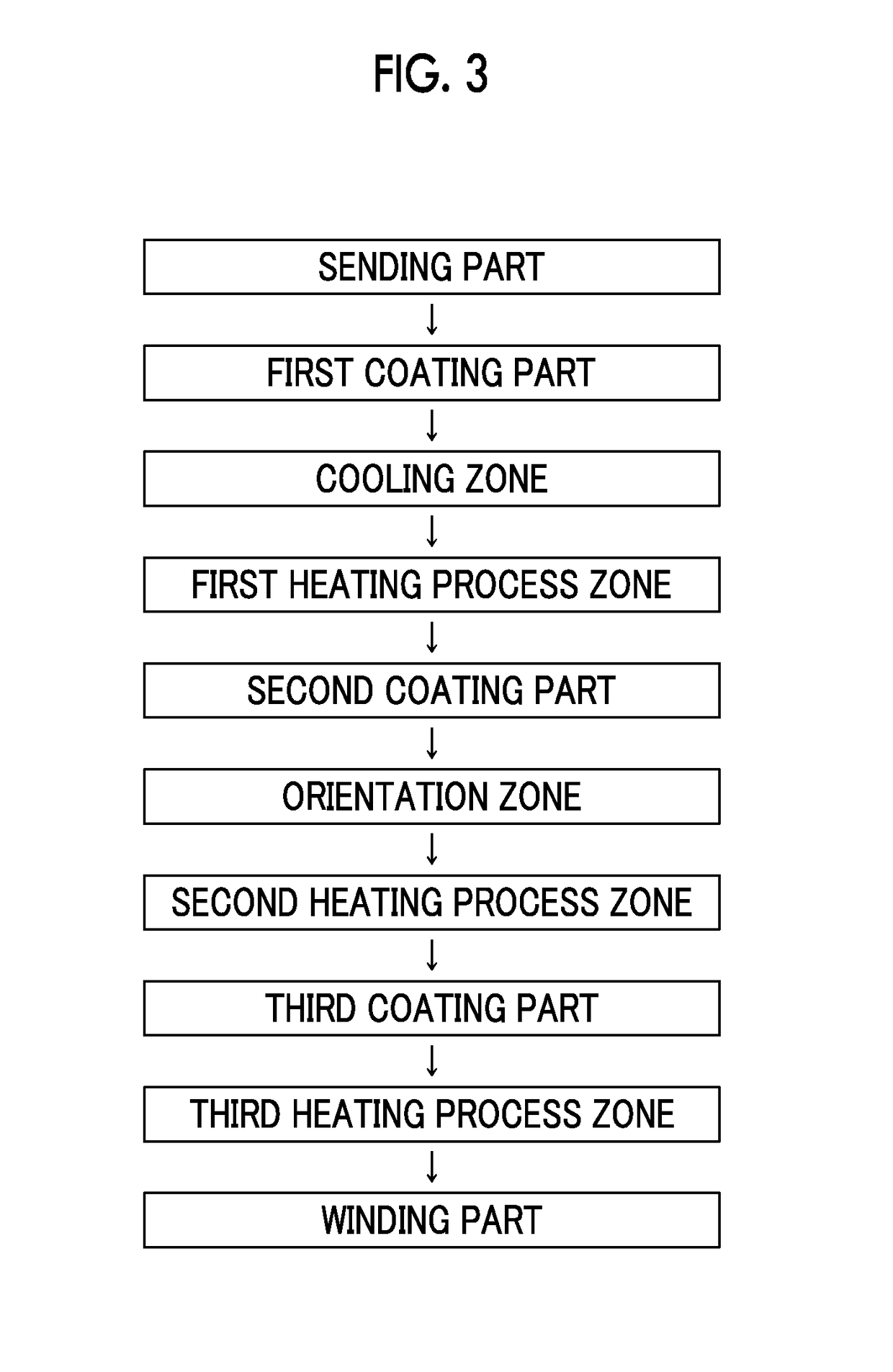

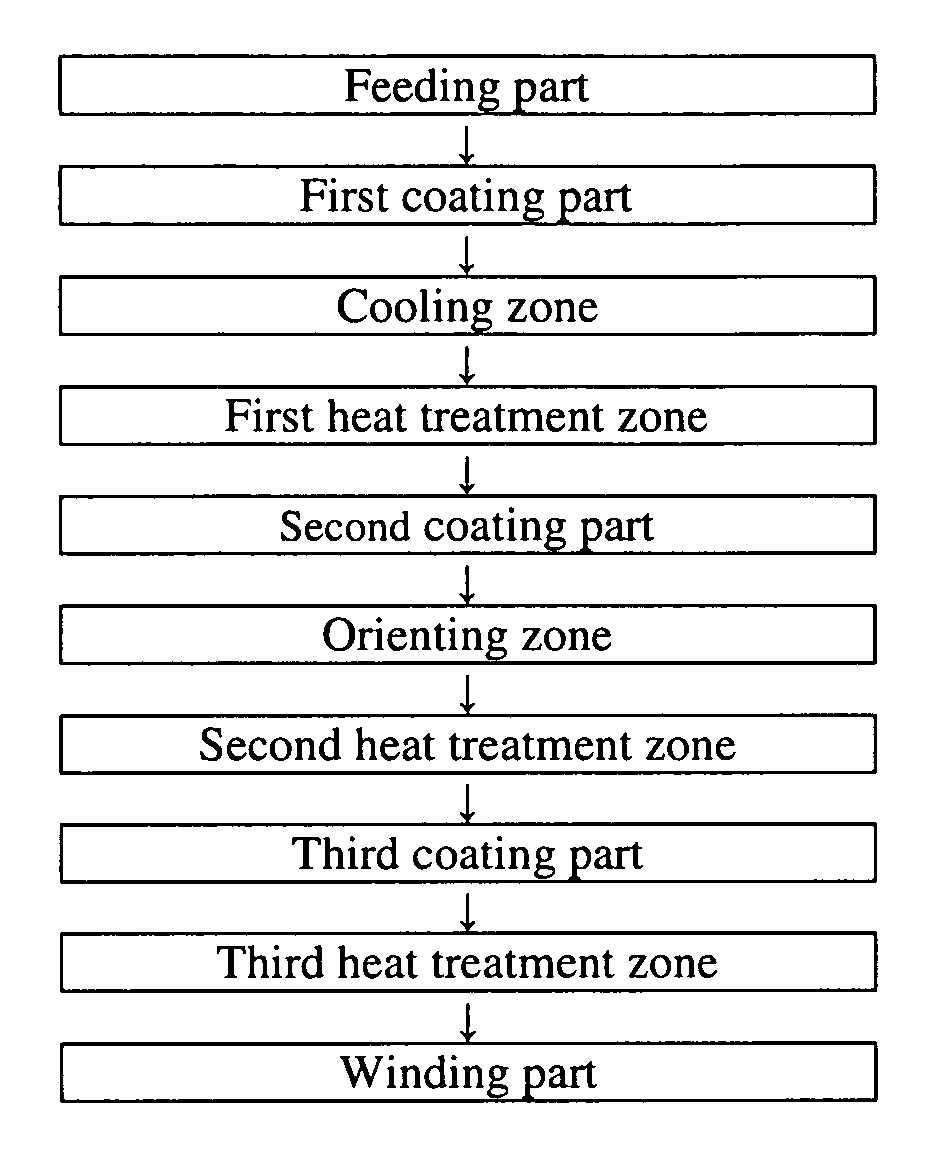

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein a total thickness of the magnetic tape is less than or equal to 4.80 μm; at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the magnetic layer side of the magnetic tape is greater than or equal to 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9721605B2Avoid it happening againImprove the immunityBase layers for recording layersRecord information storageMedicineMagnetic tape

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20170372741A1Improve running stabilitySuitable compatibilityProtective coatings for layersRecord information storageMagnetic tapeX-ray

Provided is a magnetic tape in which a thickness of a back coating layer is equal to or smaller than 0.20 μm, a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees, is equal to or greater than 35 atom %, full widths at half maximum of spacing distribution measured by optical interferometry regarding the surface of the back coating layer before and after performing a vacuum heating with respect to the magnetic tape are respectively greater than 0 nm and equal to or smaller than 10.0 nm, and a difference between a spacing measured after performing the vacuum heating and a spacing measured before performing the vacuum heating is greater than 0 nm and equal to or smaller than 8.0 nm.

Owner:FUJIFILM CORP

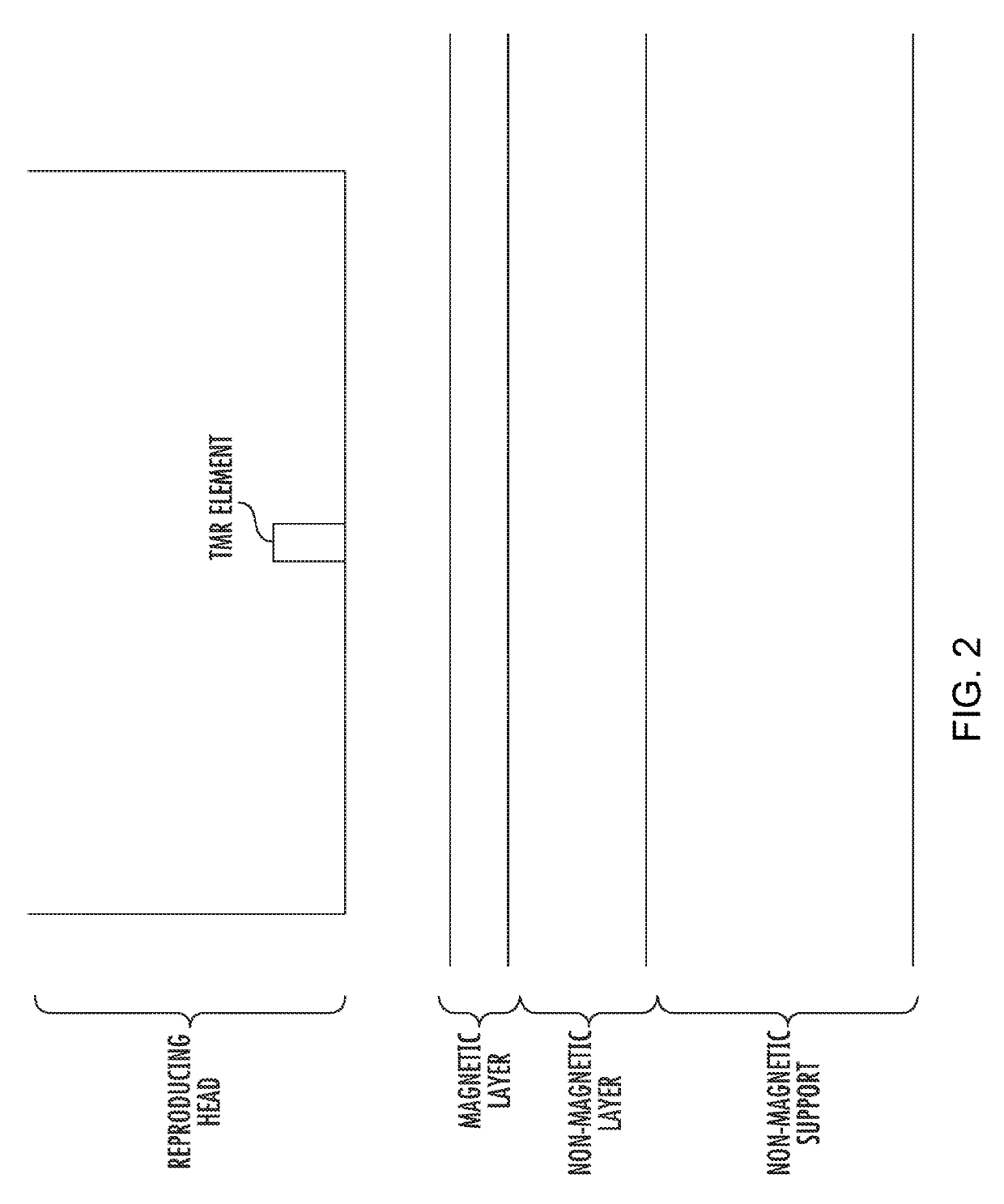

Magnetic tape device and magnetic reproducing method

ActiveUS20180286450A1Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a magnetic tape including a magnetic layer; and a TMR head (reproducing head), in which an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170358318A1Improve surface smoothnessImproved head positioning accuracyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, in which the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160189740A1Avoid it happening againImprove the immunityBase layers for recording layersTape carriersMagnetic tapeNon magnetic

Provided is a magnetic tape, which comprises, on a nonmagnetic support, a nonmagnetic layer comprising nonmagnetic powder and binder, and on the nonmagnetic layer, a magnetic layer comprising ferromagnetic powder and binder; wherein at least the magnetic layer comprises one or more components selected from the group consisting of a fatty acid and a fatty acid amide; a quantity of components selected from the group consisting of a fatty acid and a fatty acid amide per unit area of the magnetic tape among components that are extracted from a surface on the magnetic layer side of the magnetic tape is less than or equal to 15.0 mg / m2, and a concentration of carbon, C, that is obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on the surface on the magnetic layer side of the magnetic tape is greater than or equal to 50 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372743A1Restrain output decreaseImprove accuracyBase layers for recording layersAlignment for track following on tapesMagnetic tapeX-ray

The magnetic tape includes a non-magnetic layer including non-magnetic powder and a binder on a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binder on the non-magnetic layer, the total thickness of the non-magnetic layer and the magnetic layer is equal to or smaller than 0.60 μm, the magnetic layer includes a timing-based servo pattern, one or more components selected from the group consisting of fatty acid and fatty acid amide are at least included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and magnetic tape device

ActiveUS20170372726A1Improve surface smoothnessReduce frequencyAlignment for track following on tapesRecord information storageMagnetic tapeX-ray

The magnetic tape includes a magnetic layer having ferromagnetic powder and a binder on a non-magnetic support, in which a total thickness of the magnetic tape is equal to or smaller than 5.30 μm, the magnetic layer includes a timing-based servo pattern, a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, one or more components selected from the group consisting of fatty acid and fatty acid amide are included in the magnetic layer, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 45 atom %.

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS9704527B2Increase coefficient of frictionReduced stabilityRecord information storageMetals or alloysMagnetic tapeNon magnetic

Owner:FUJIFILM CORP

Magnetic tape and method of manufacturing the same

ActiveUS20160247530A1Improve running stabilityReduce coefficient of frictionRecord information storageMetals or alloysMagnetic tapeTotal thickness

The magnetic tape has on one surface of a nonmagnetic support a magnetic layer containing ferromagnetic powder and binder, and on the other surface of the nonmagnetic support, a backcoat layer containing nonmagnetic powder and binder, wherein the total thickness of the magnetic tape is less than or equal to 4.80 μm, the backcoat layer contains one or more components selected from the group consisting of a fatty acid and a fatty acid amide, and a C—H derived carbon, C, concentration calculated from a C—H peak area ratio in a C1s spectrum obtained by X-ray photoelectron spectroscopy conducted at a photoelectron take-off angle of 10 degrees on a surface on the backcoat layer side of the magnetic tape ranges from 35 to 60 atom %.

Owner:FUJIFILM CORP

Magnetic tape device and magnetic reproducing method

ActiveUS20180182429A1Avoid it happening againAvoiding characteristicMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

Magnetic tape

ActiveUS20190027174A1Improve surface smoothnessAvoid it happening againRecord information storageTape carriersIn planeX-ray

Provided is a magnetic tape in which an Ra measured regarding a surface of a magnetic layer is equal to or smaller than 1.8 nm, Int(110) / Int(114) of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical squareness ratio of the magnetic tape is 0.65 to 1.00, the back coating layer includes one or more kinds of component selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the back coating layer at a photoelectron take-off angle of 10 degrees is equal to or greater than 35 atom %.

Owner:FUJIFILM CORP

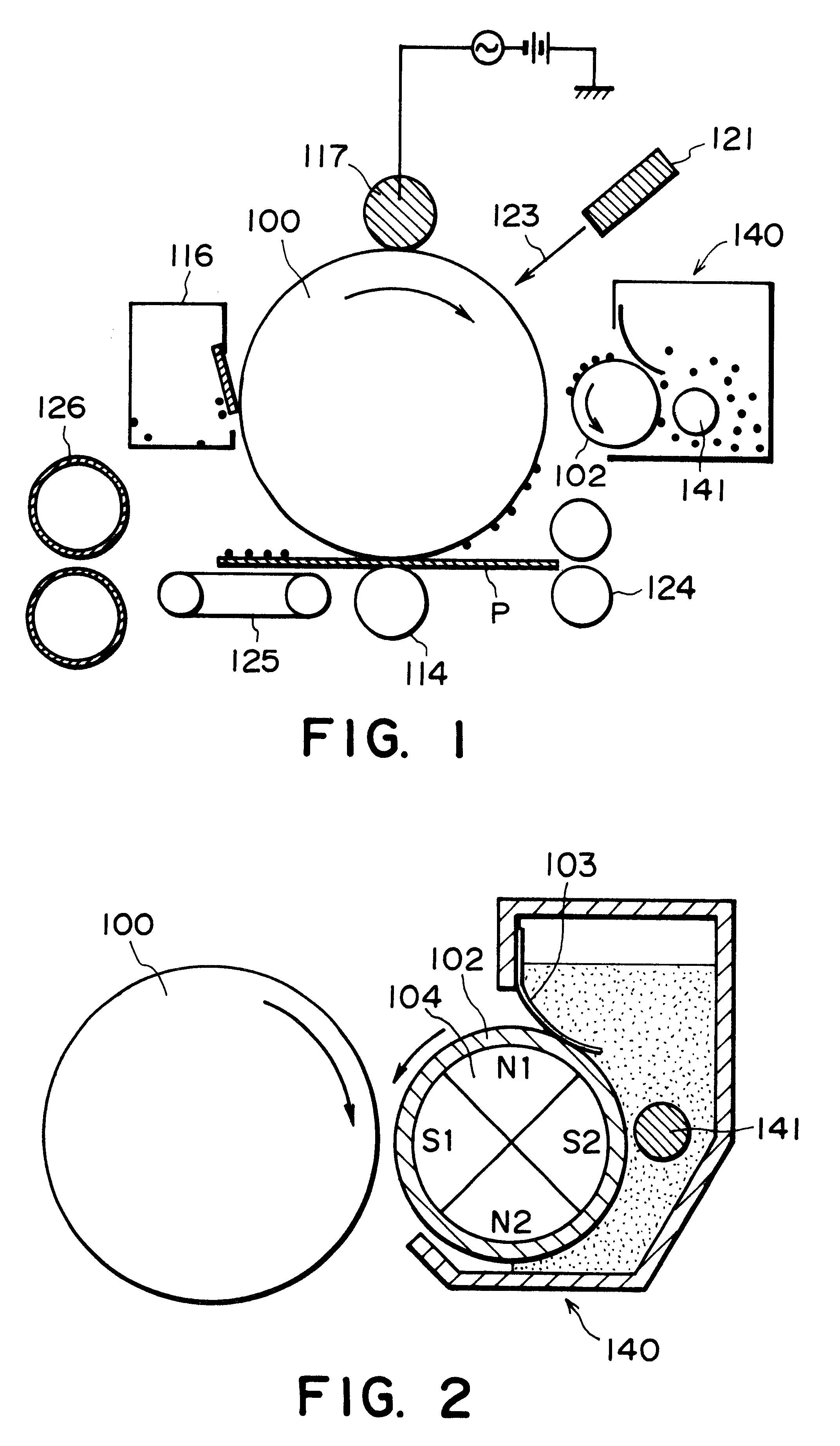

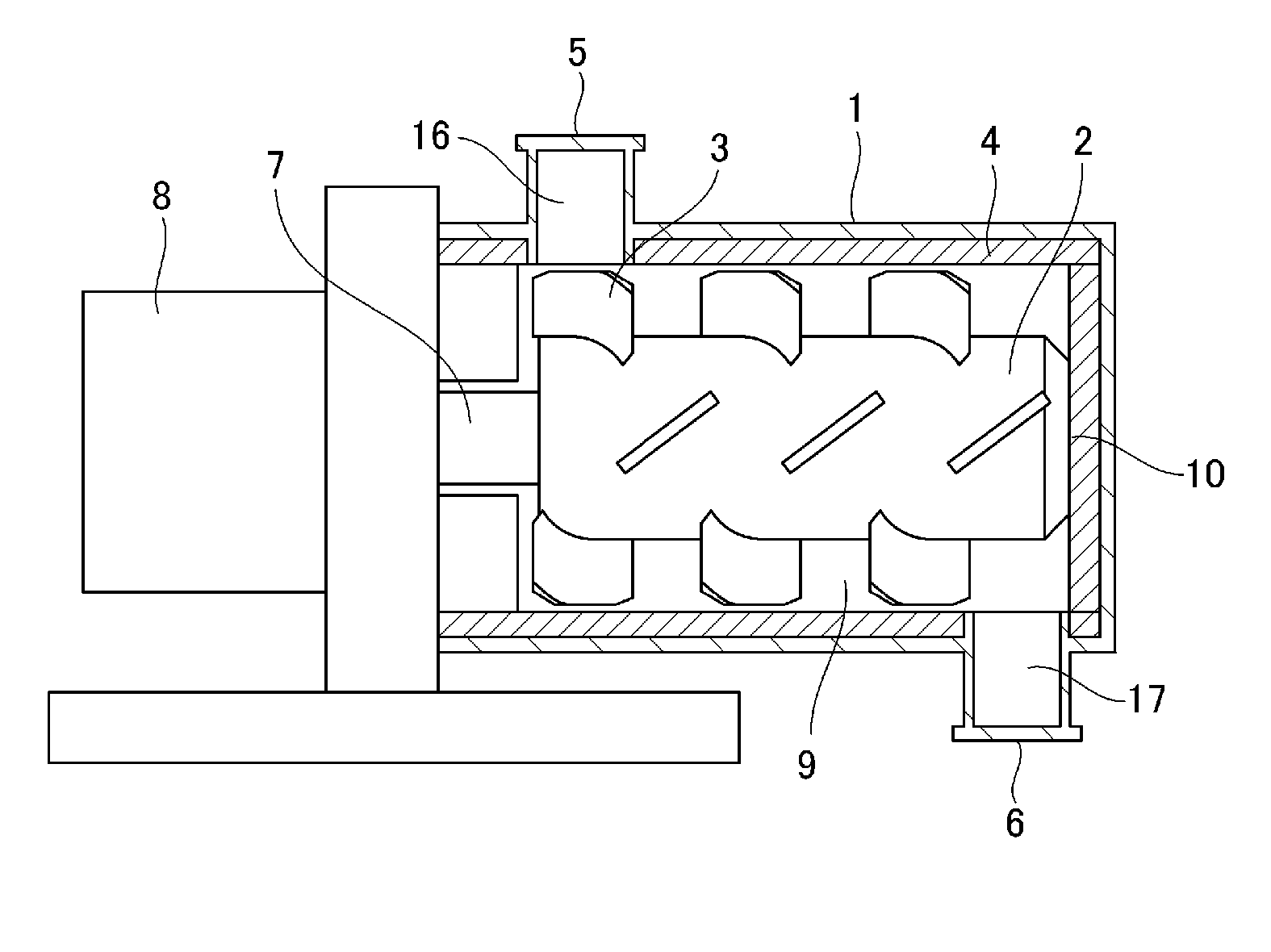

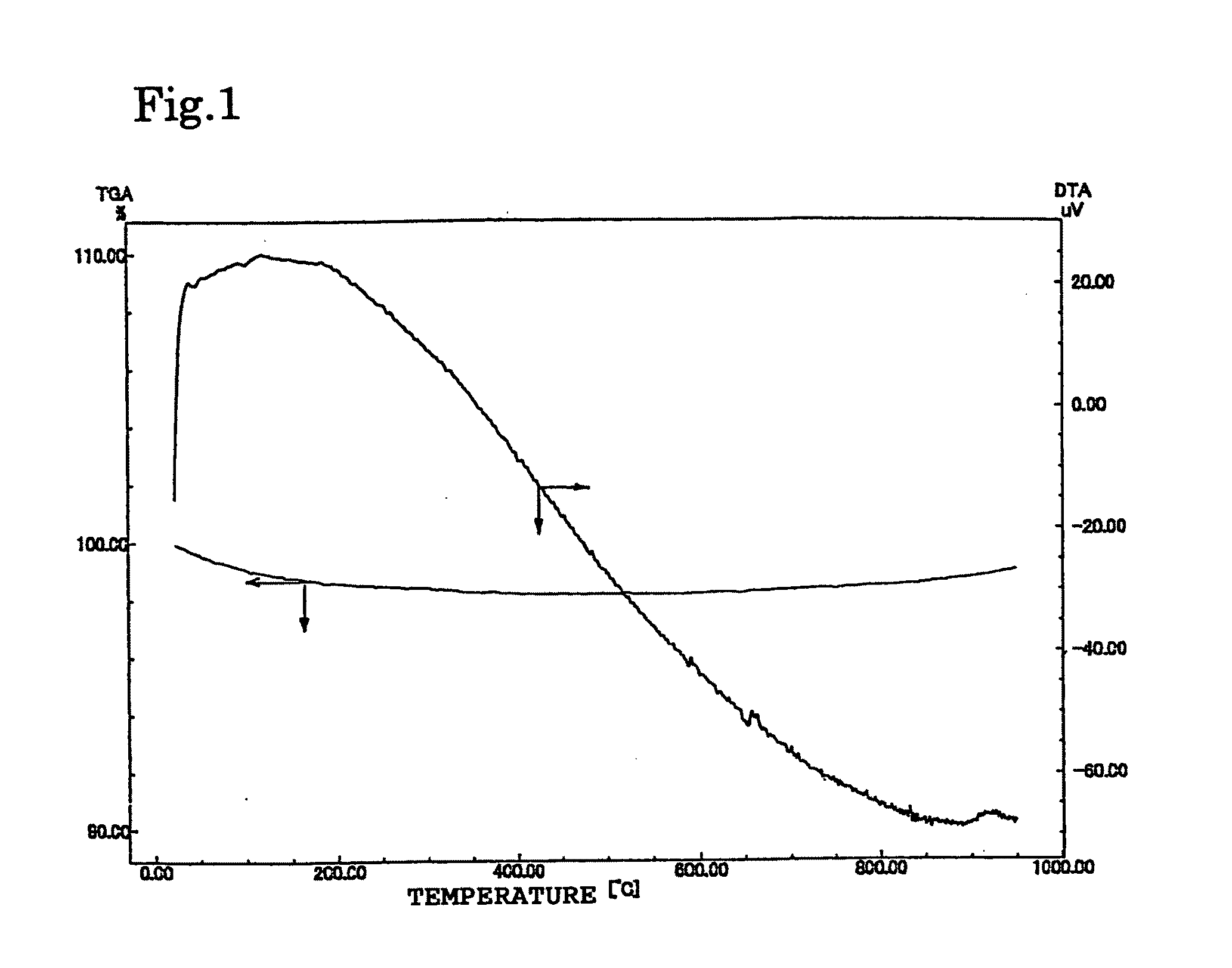

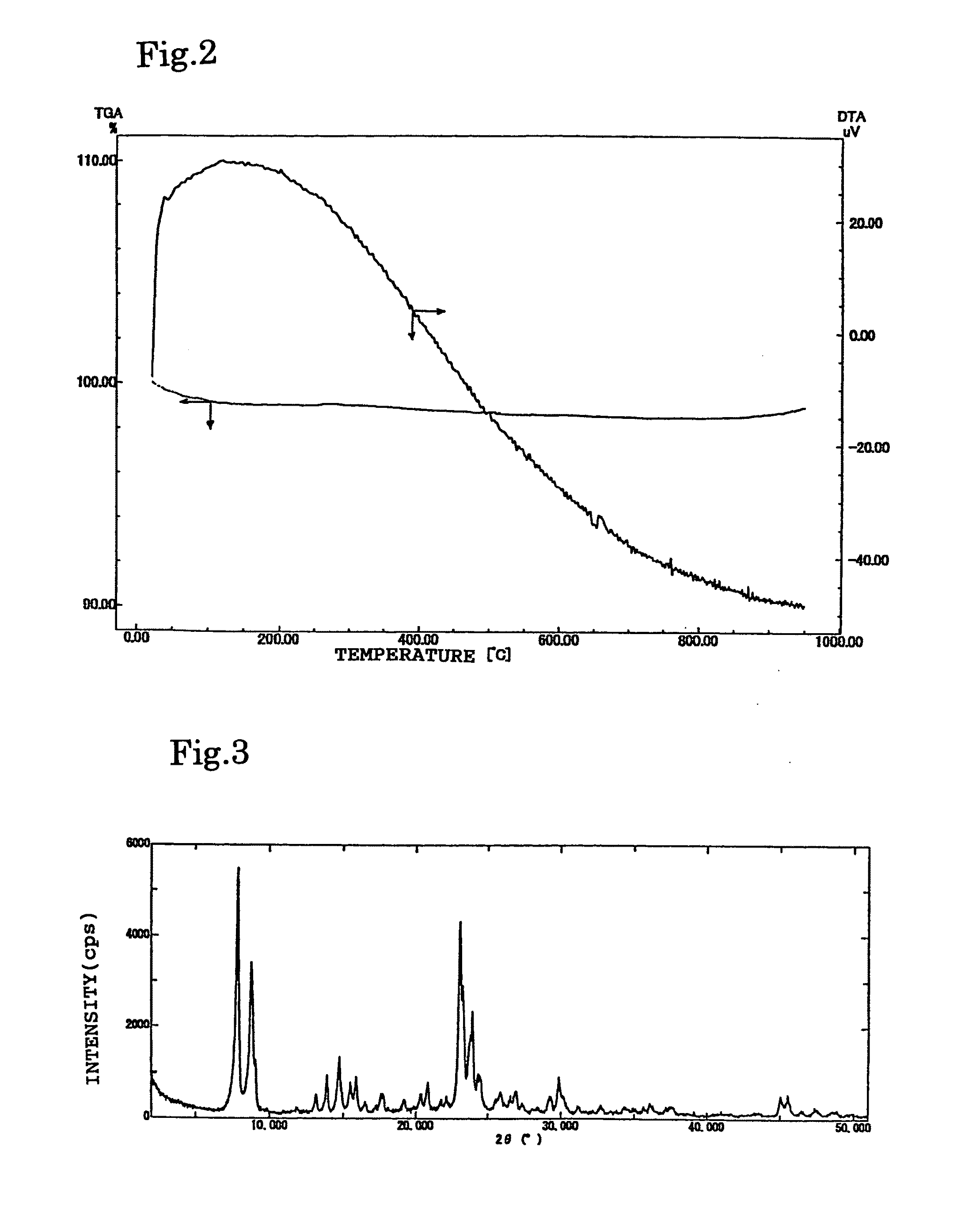

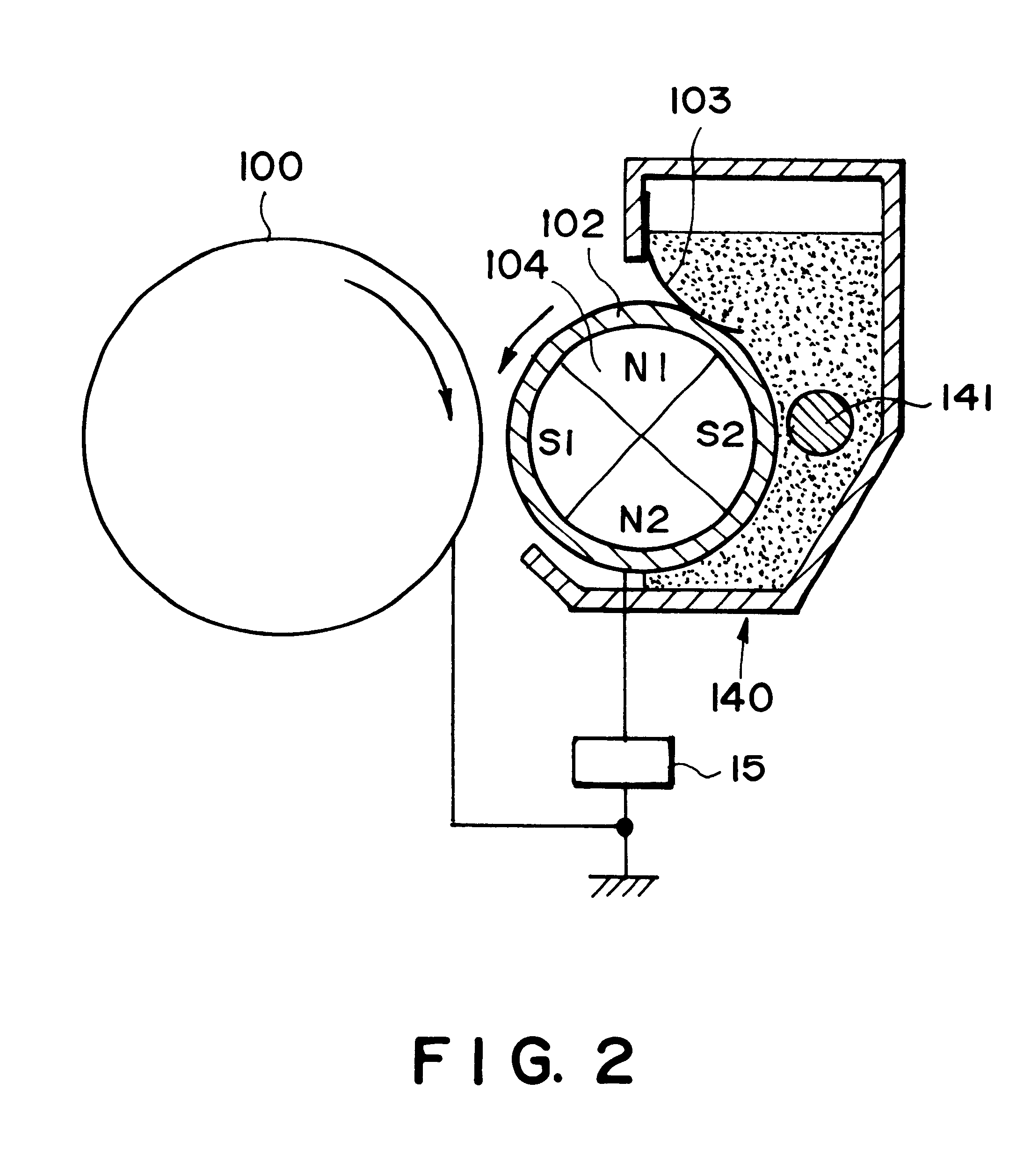

Magnetic toner, process for production thereof, and image forming method, apparatus and process cartridge using the toner

InactiveUS6465144B2Reduce wastePerformance and recoveryDevelopersElectrographic process apparatusMagnetizationX-ray

A magnetic toner includes: magnetic toner particles each comprising at least a binder resin and magnetic toner, and inorganic fine powder. The magnetic toner has an average circularity of at least 0.970, and a magnetization of 10-50 Am2 / kg at a magnetic field of 79.6 kA / m. The magnetic powder comprises at least magnetic iron oxide. The magnetic toner particles retain carbon in an amount of A and iron in an amount of B at surfaces thereof as measured by X-ray photoelectron spectroscopy, satisfying: B / A<0.001. The binder resin comprises a resin formed by polymerization of a monomer comprising at least styrene monomer. The magnetic toner has a residual styrene monomer content of less than 300 ppm, and contains at least 50% by number of toner particles satisfying a relationship of: D / C<=0.02, wherein C represents a volume-average particle size of the magnetic toner, and D represents a minimum distance between the surface of a magnetic toner particle and magnetic powder particles contained in the magnetic toner particle. Owing to the above features, the magnetic toner can exhibit good electrohotographic performances, including excellent chargeability and little transfer-residual toner, even in a cleanerless-mode image forming system.

Owner:CANON KK

Magnetic tape device and magnetic reproducing method

ActiveUS10410666B2Improve smoothnessImprove surface smoothnessMaterials with ironRecord information storageIn planeX-ray

The magnetic tape device includes a magnetic tape including a magnetic layer; and a TMR head (reproducing head), in which an intensity ratio of a peak intensity of a diffraction peak of a (110) plane with respect to a peak intensity of a diffraction peak of a (114) plane of a hexagonal ferrite crystal structure obtained by an X-ray diffraction analysis of the magnetic layer by using an In-Plane method is 0.5 to 4.0, a vertical direction squareness ratio of the magnetic tape is 0.65 to 1.00, Ra measured regarding a surface of the magnetic layer is equal to or smaller than 2.0 nm, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

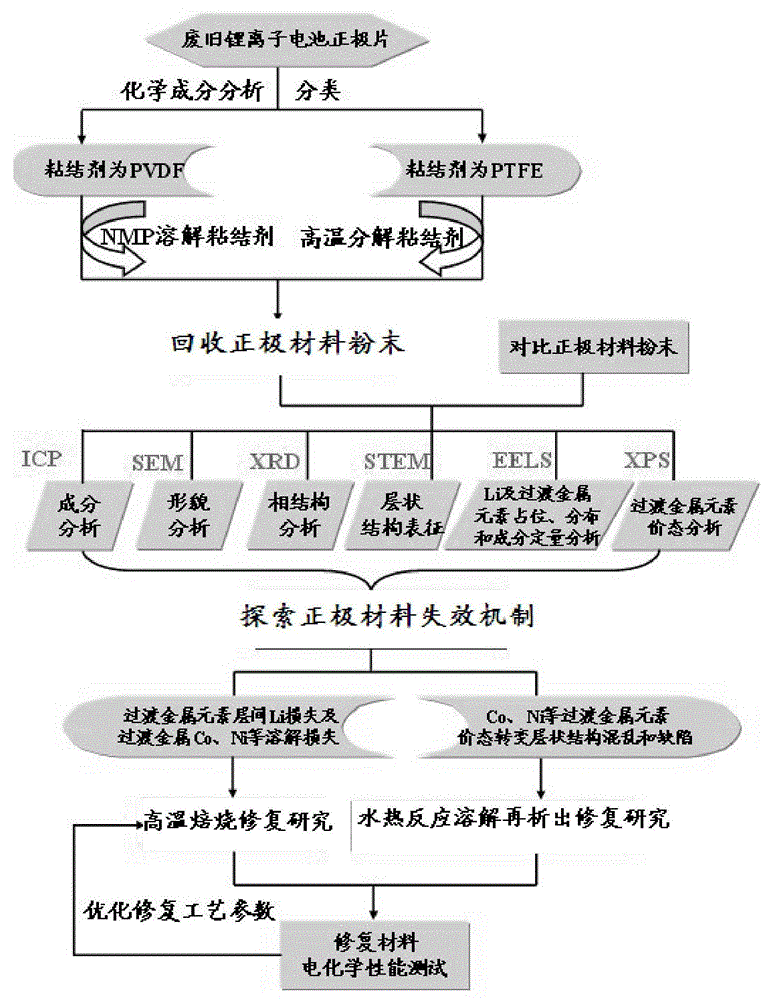

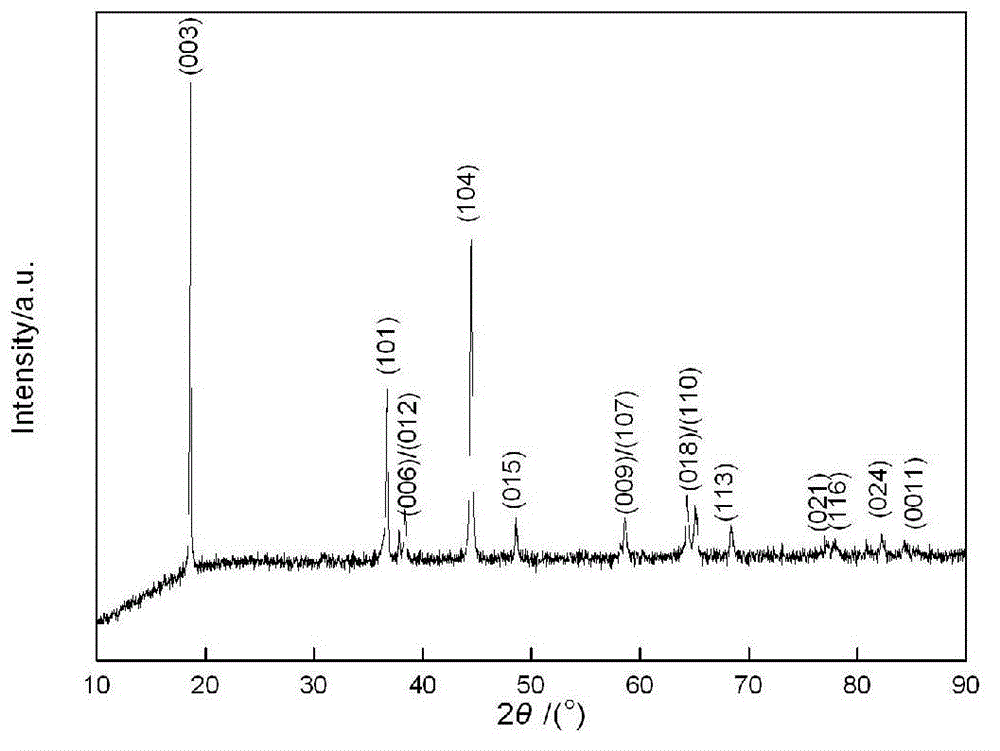

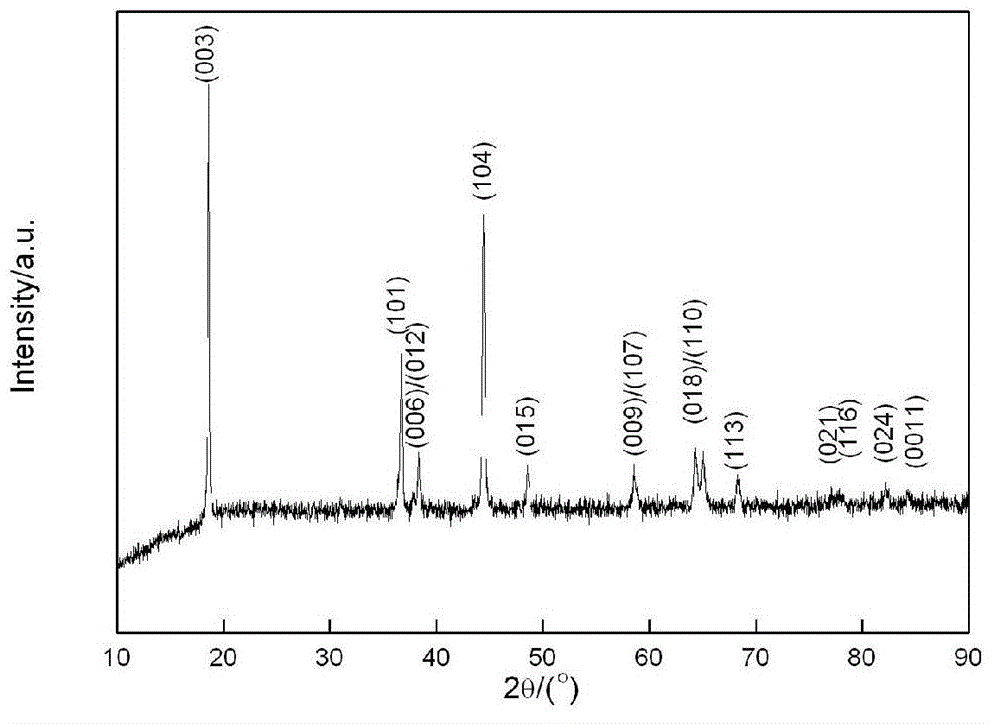

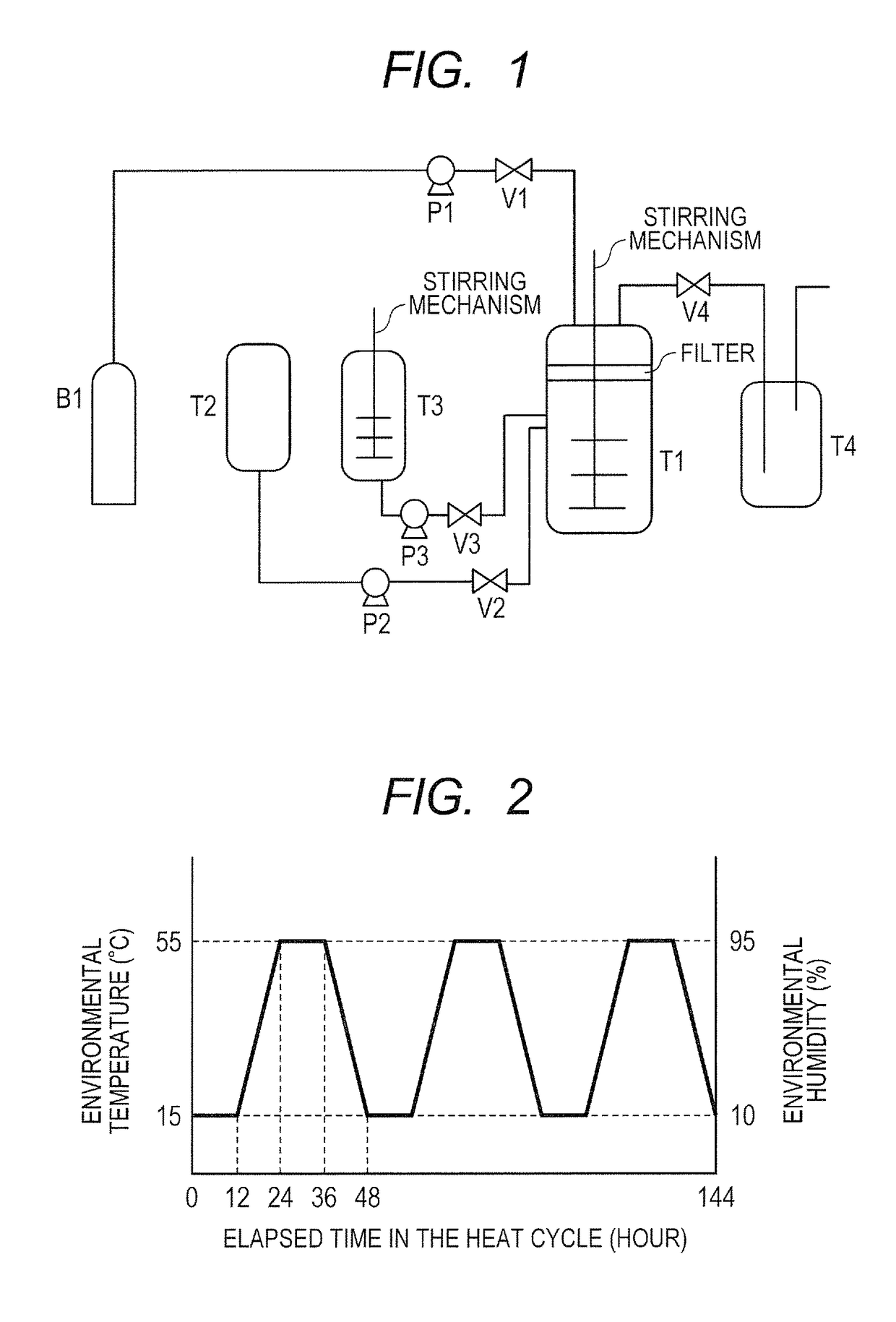

Method for direct recovery and restoration of lithium ion battery positive electrode material

ActiveCN103915661AAvoid leachingPrevent extractionWaste accumulators reclaimingProcess efficiency improvementLiquid wasteCharge discharge

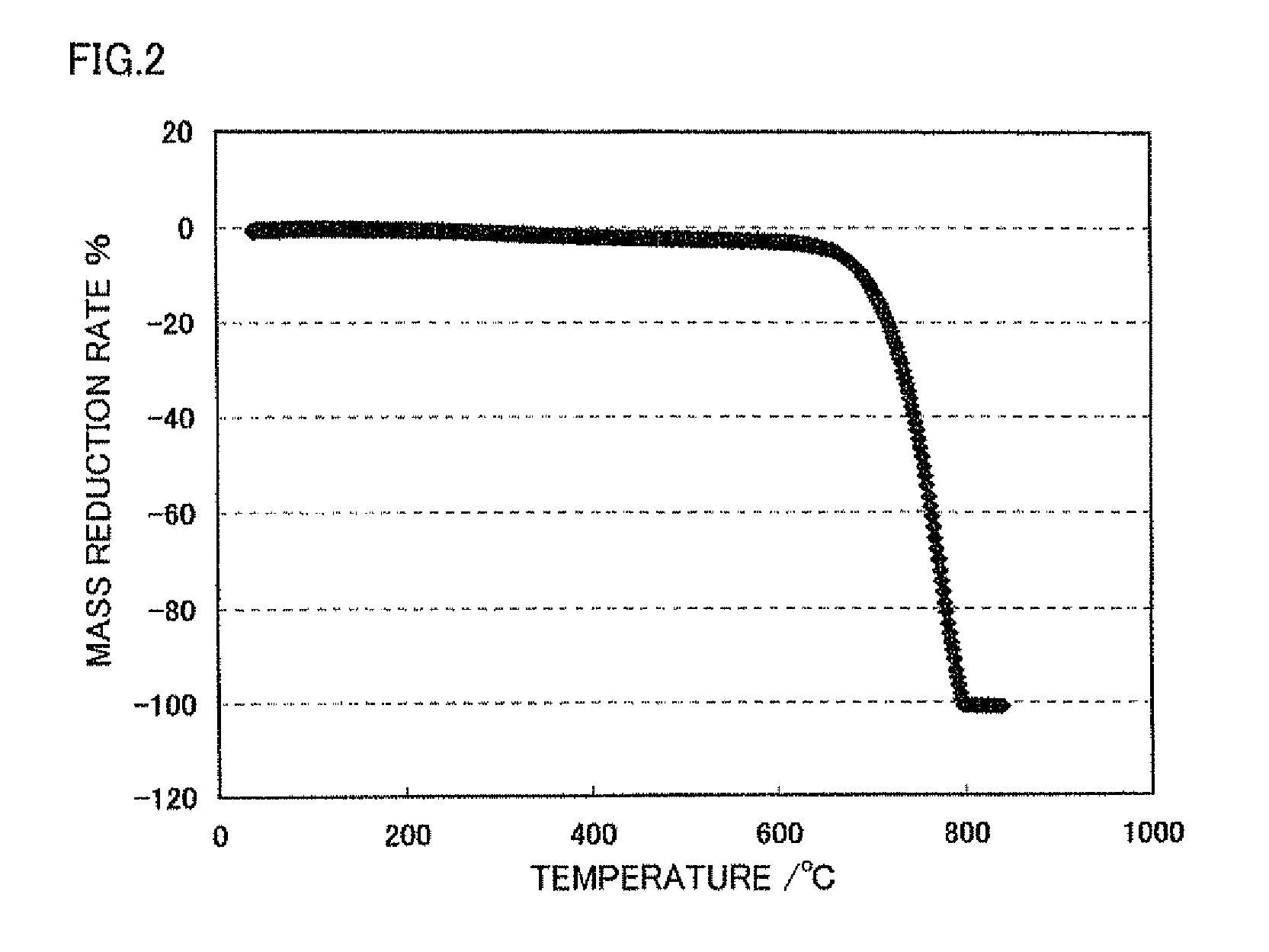

The invention discloses a method for direct recovery and restoration of a lithium ion battery positive electrode material, and belongs to the field of resource recycling. According to the method, waste positive electrode pieces of lithium cobaltate or lithium nickel manganese cobalt multi-element layered oxide or a positive electrode piece leftover material and defective products are used as a positive electrode material; the materials are classified according to the type of binder by component analysis, the binder is directly damaged, cleaning and separation of the positive electrode material and a current collector are realized; by use of a heavy liquid separation principle, the positive electrode and a conductive agent are separated; the positive electrode failure mechanism is studied by use of SEM (scanning electron microscope), XRD (X-ray diffraction), STEM (scanning transmission electron microscope), XPS (X-ray photoelectron spectroscopy) and other analysis means; chemical components of the positive electrode material with the layered structure not damaged can be repaired by high temperature roasting, the layered structure of the positive electrode material with disordered and defective crystal lattice can be repaired by dissolving with a hydrothermal reaction and then precipitation, and the positive electrode material with good charge discharge performances can be again obtained. The method avoids the dissolving leaching process, reduces waste liquid generation, and simplifies the technological process.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

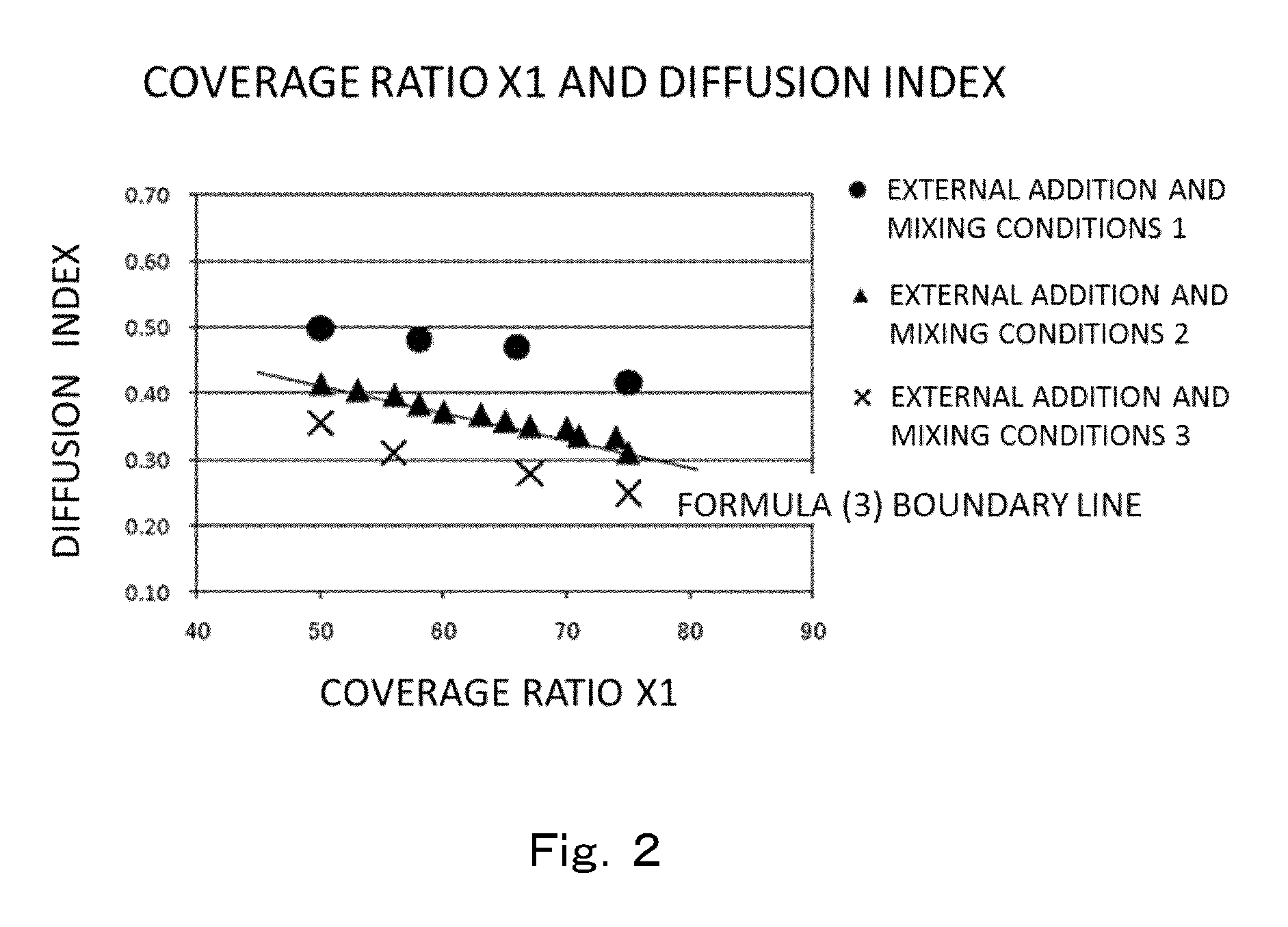

Toner

Owner:CANON KK

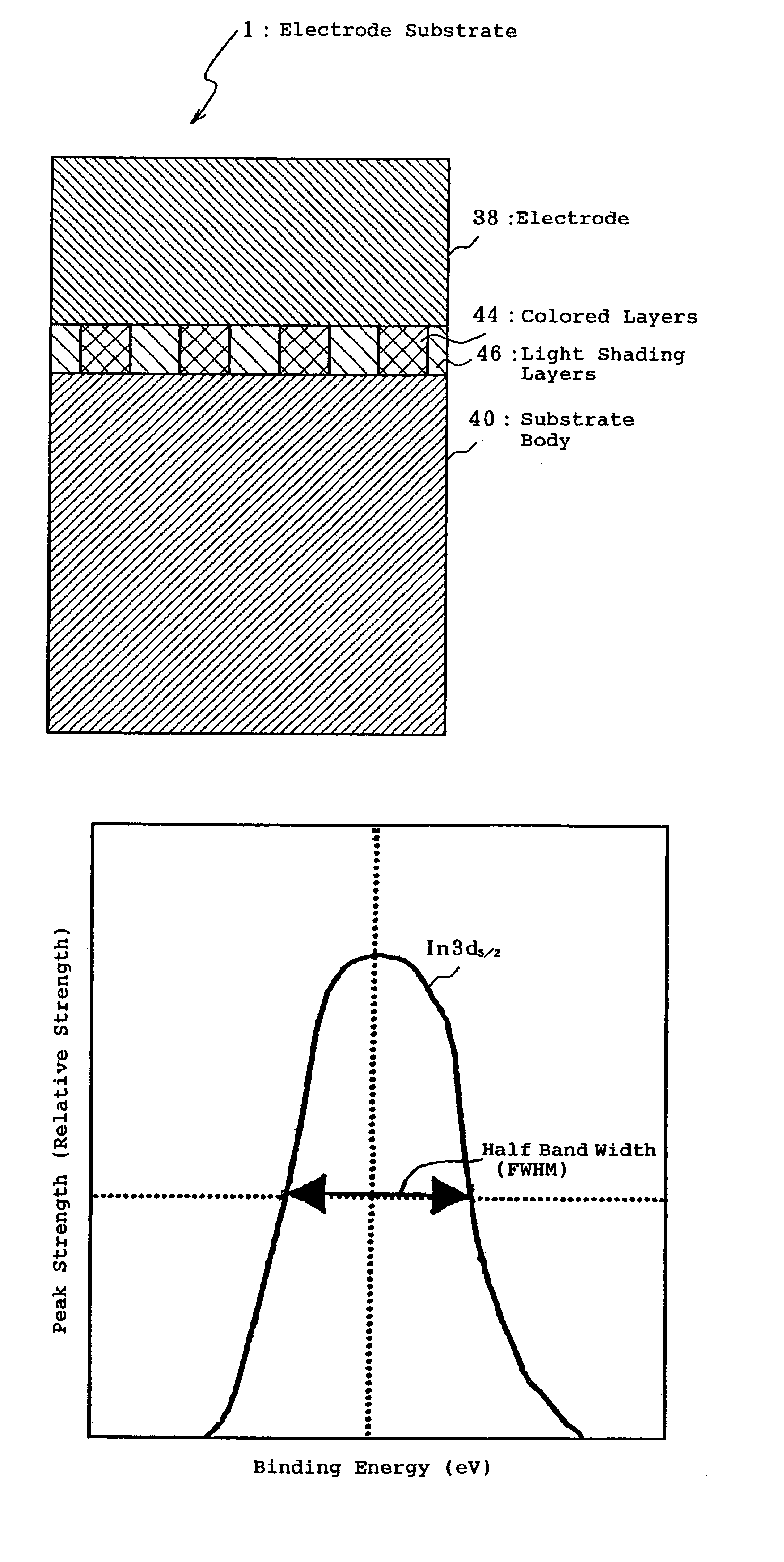

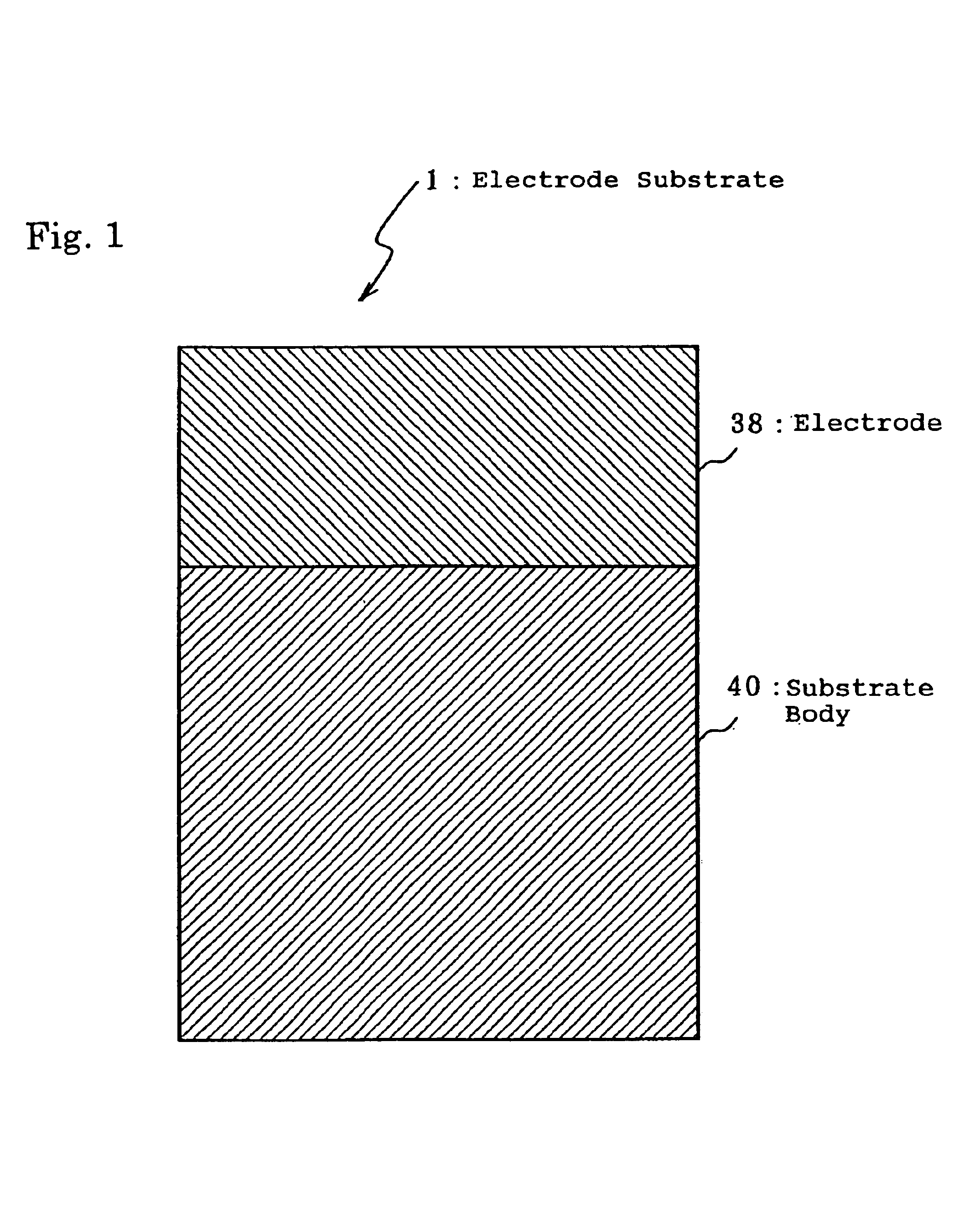

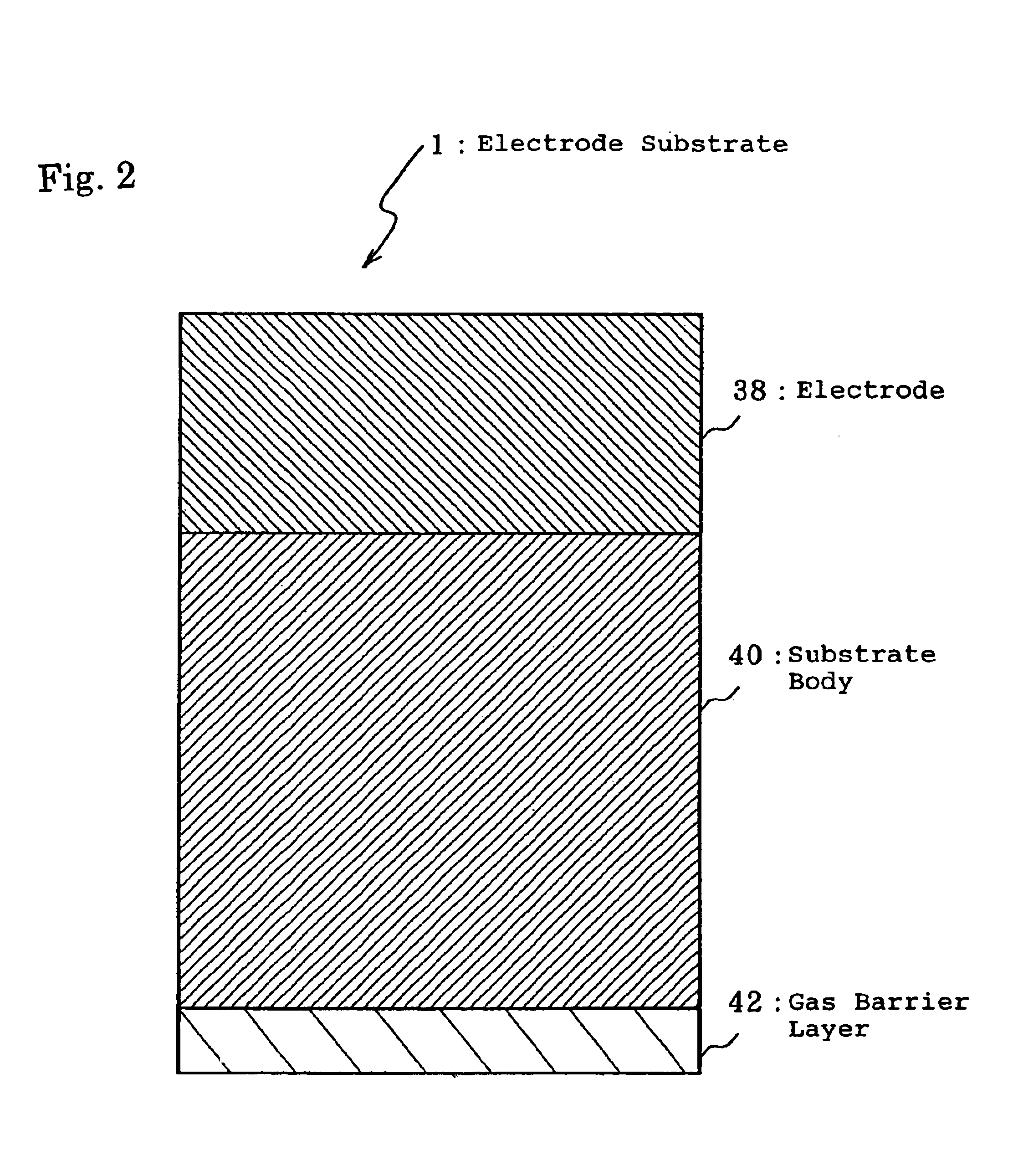

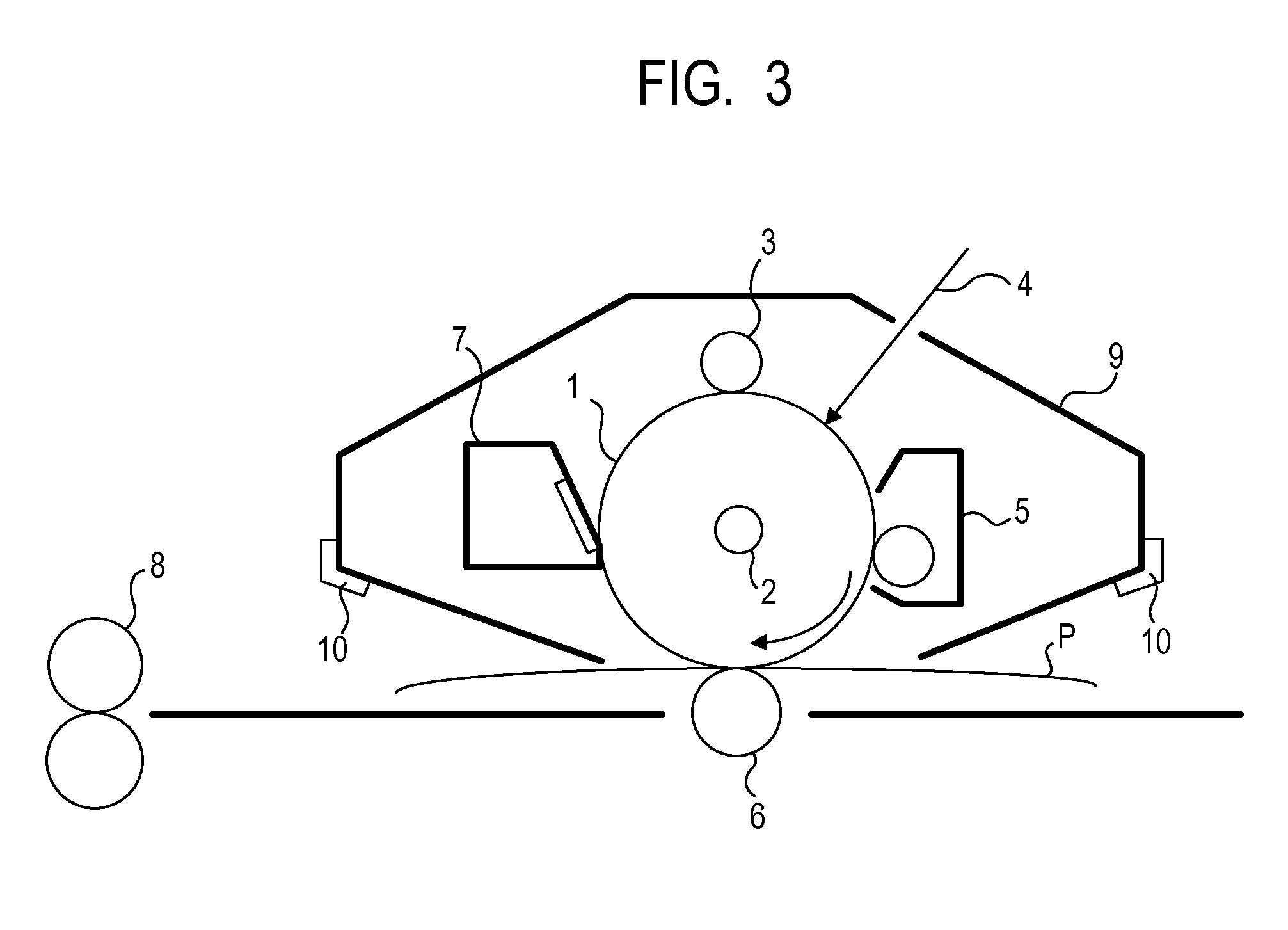

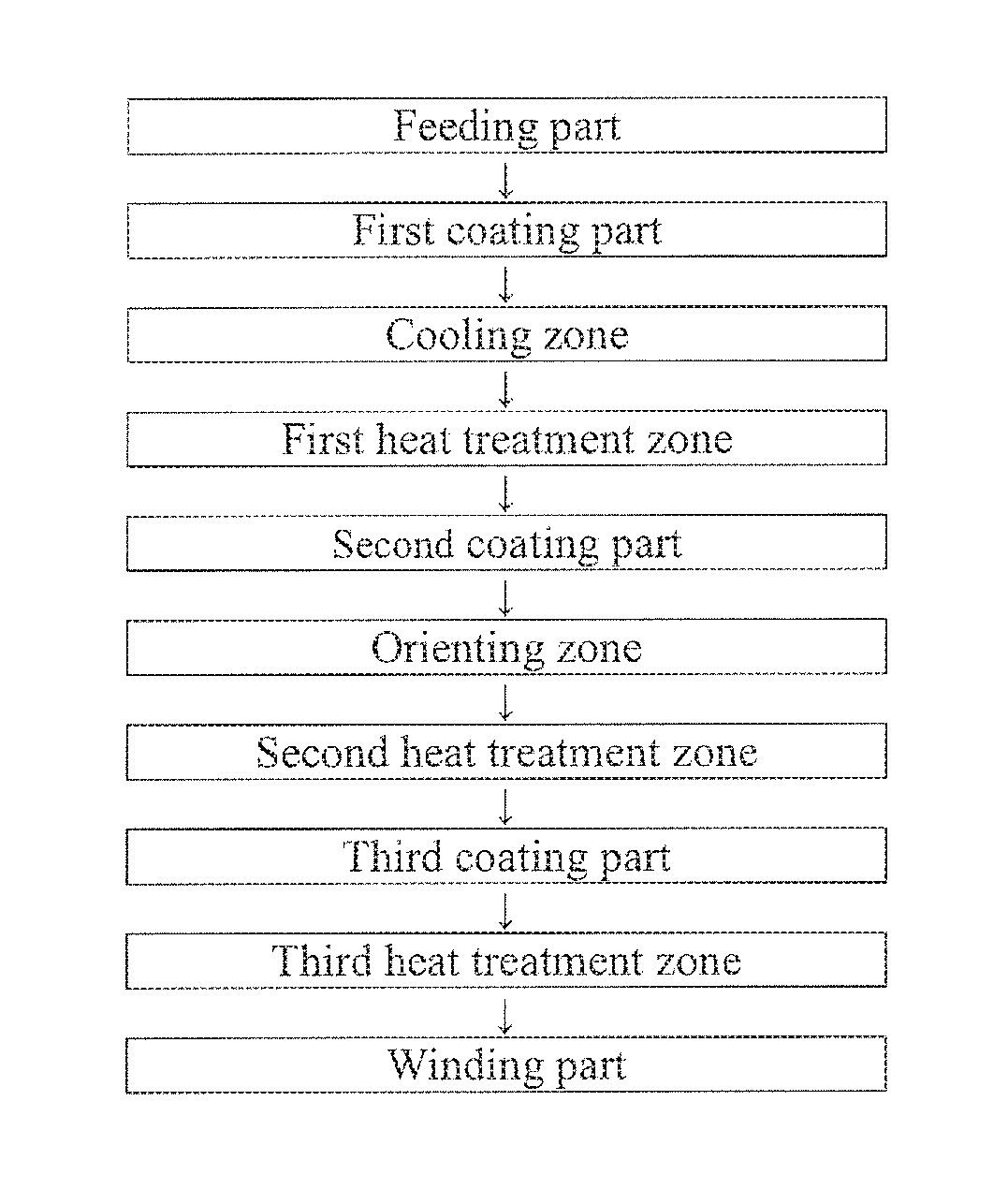

Electrode substrate and production method thereof

InactiveUS6963383B2Reduce probabilityImprove electrical stabilityConductive layers on insulating-supportsVacuum evaporation coatingCompound (substance)Peak value

An electrode substrate comprising; an electrode comprising a compound containing an In atom and a substrate body, wherein a half band width ratio [In3d5 / 2]h / [In3d5 / 2]n is from 0.9 to 1.2 wherein [In3d5 / 2]h is a half band width of a 3d5 / 2 orbit spectral peak of an In atom in the surface of the electrode, and [In3d5 / 2]n is a half band width of a 3d5 / 2 orbit spectral peak of an In atom in the interior of the electrode, the spectral peaks being measured by X-ray photoelectron spectroscopy: and the method for the production thereof.

Owner:IDEMITSU KOSAN CO LTD

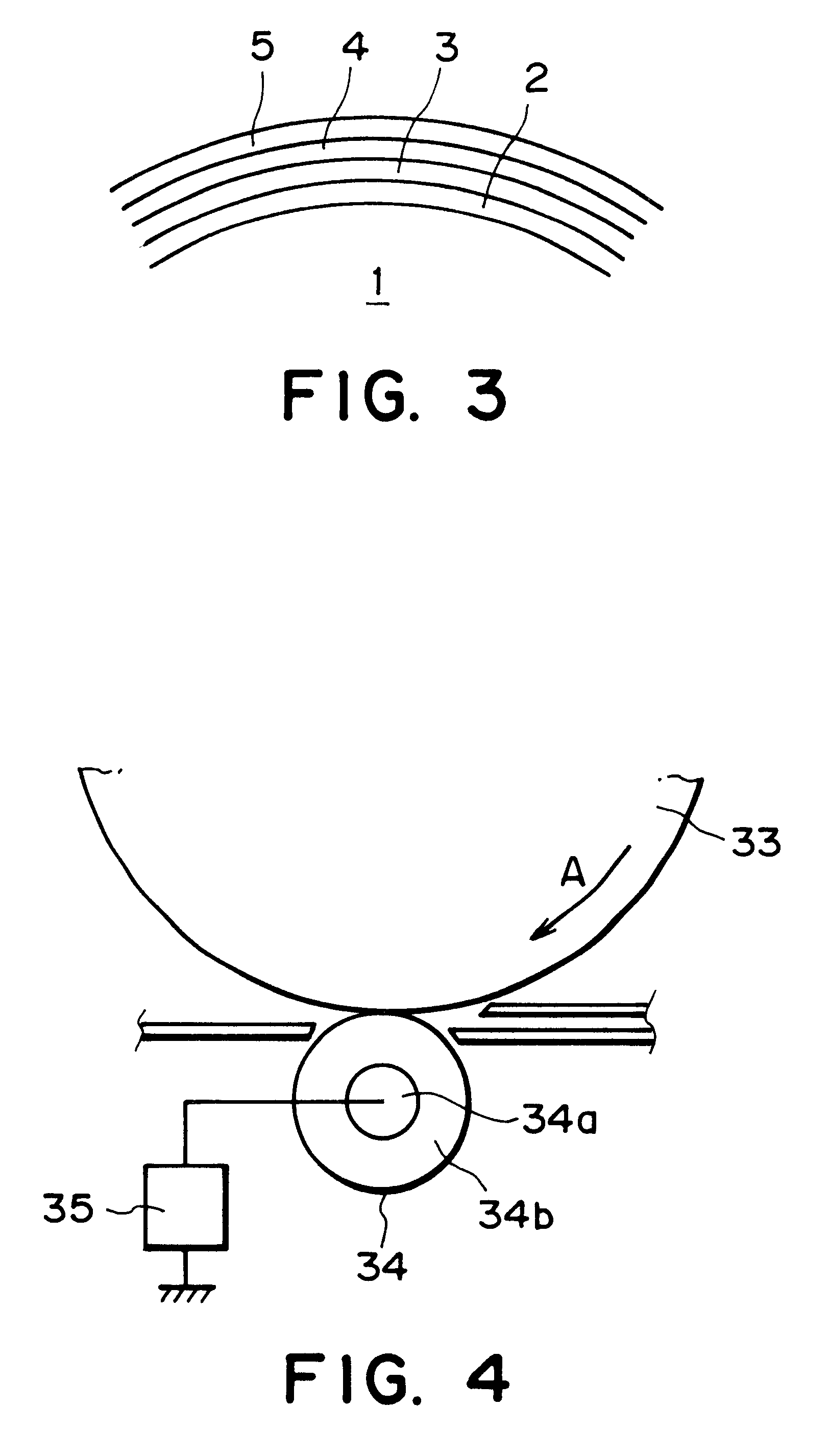

Electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveUS9029054B2Long-term variationElectrographic process apparatusNitrogenElectron transporting layer

An electron transporting layer is a cured layer including carbon atoms, nitrogen atoms and oxygen atoms. When ratios of the number of carbon atoms, ratios of the number of nitrogen atoms, and ratios of the number of oxygen atoms are analyzed at 10 points by an X-ray photoelectron spectroscopy (ESCA), the respective standard deviations, σ(C), σ(N) and σ(O), of the ratios of the number of carbon atoms, the ratios of the number of nitrogen atoms and the ratios of the number of oxygen atoms satisfy the following expressions (1) to (3):σ(C)≦1.5 (1),σ(N)≦1.5 (2),andσ(O)≦1.5 (3).

Owner:CANON KK

Magnetic tape including characterized magnetic layer, tape cartridge, recording and reproducing device, and method of manufacturing

ActiveUS10522180B2Shorten the timeIncrease delivery speedBase layers for recording layersTape carriersMagnetic tapeMaterials science

Owner:FUJIFILM CORP

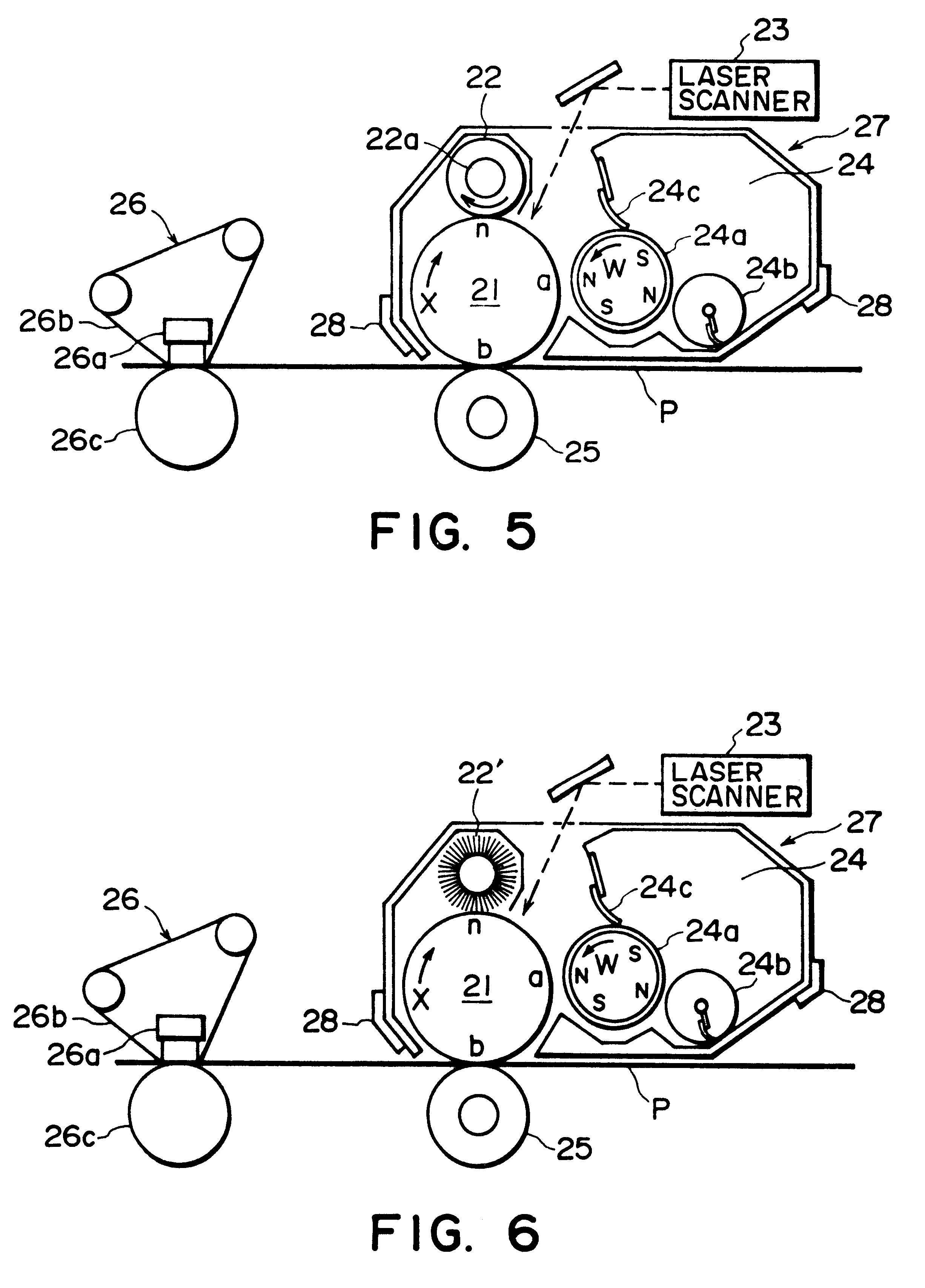

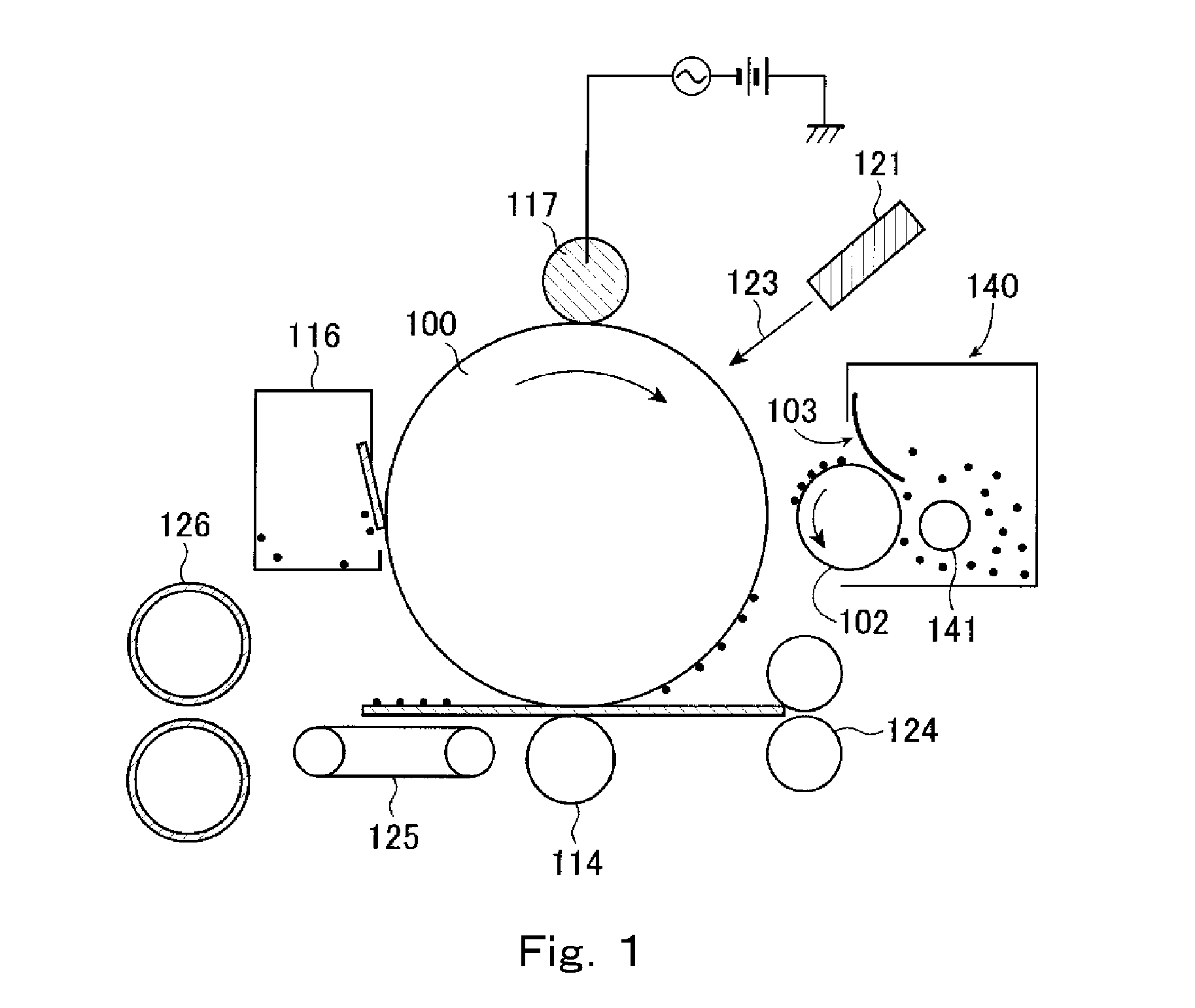

Carrier, developer using the carrier, and developing device, image forming method, image forming apparatus and process cartridge using the developer

A carrier for use in a two component developer for developing an electrostatic latent image is provided. The carrier includes a particulate core material; and a cover layer located on a surface of the core material and including a silicone resin and barium sulfate. The cover layer includes Ba and Si at an atomic ratio of from 0.01 to 0.08 as determined by X-ray photoelectron spectroscopy.

Owner:RICOH KK

Methods for Identification of Materials Causing Corrosion on Metallic Substrates within ZPGM Catalyst Systems

InactiveUS20150004709A1Improve catalytic performanceChemical analysis using catalysisMaterial analysis using wave/particle radiationHigh concentrationMetal catalyst

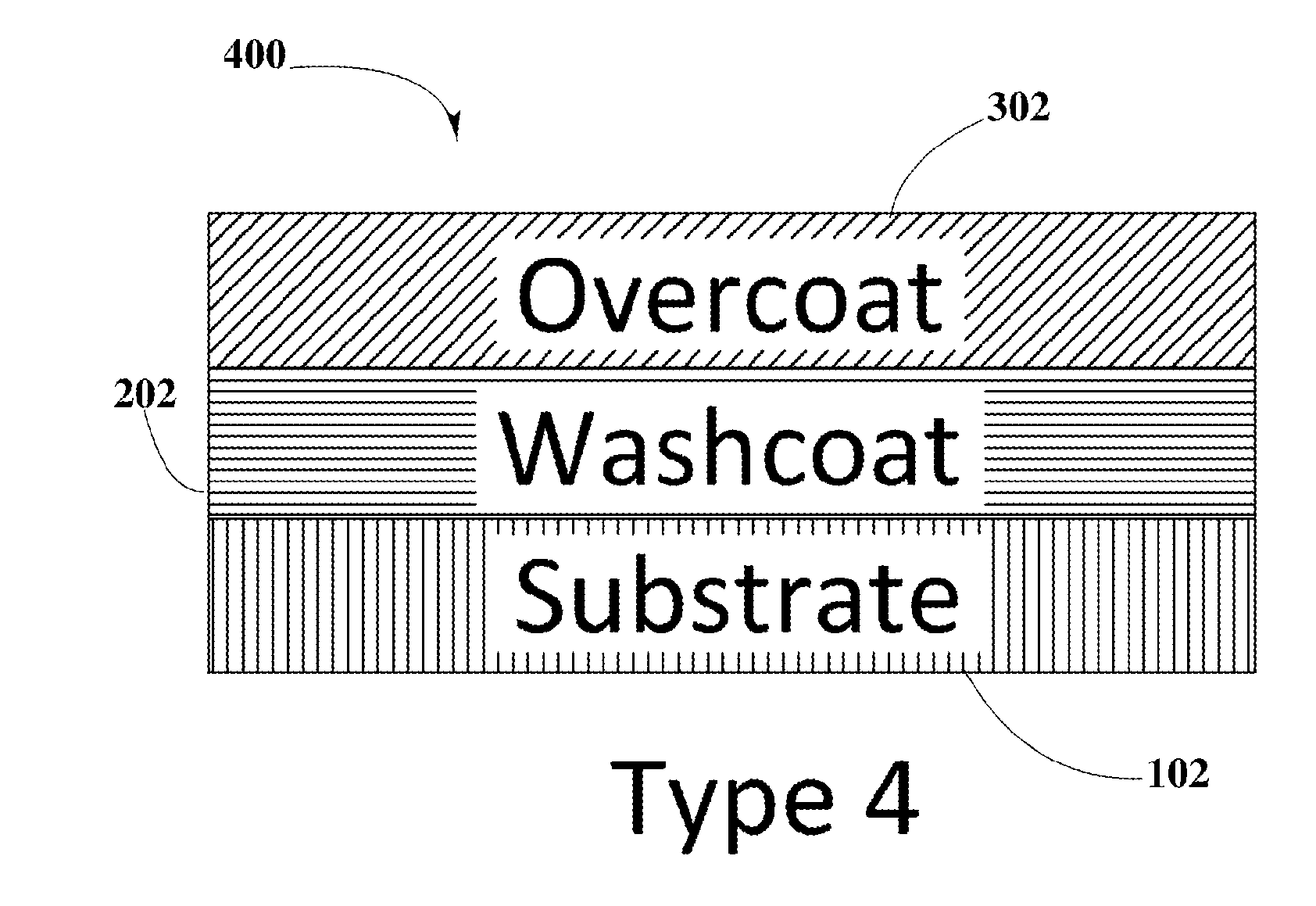

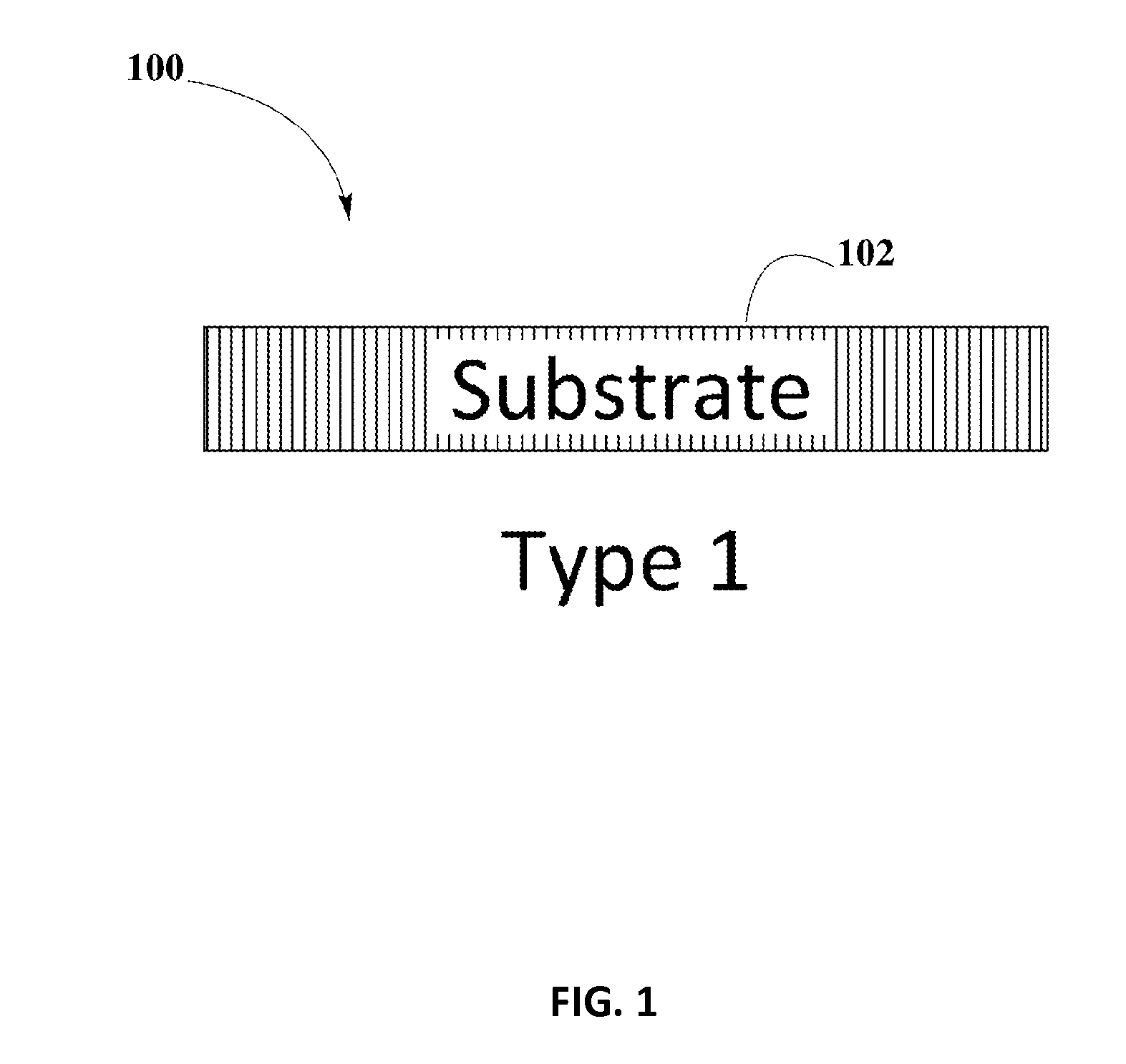

The present disclosure provides an identification process which may employ various identification techniques on Zero platinum group metal (ZPGM) catalyst systems, in order to identify responsible materials for the formation of corrosion material, such as hexavalent chromium compounds. Identification analysis, such as X-ray diffraction analysis (XRD), X-ray fluorescence (XRF), and X-ray Photoelectron Spectroscopy (XPS) may be performed on various thermally treated ZPGM catalyst systems, such as in bare substrate, substrate with one type of ZPGM in washcoat, a substrate with one type of ZPGM in overcoat and substrate combination of ZPGM metals in both washcoat and overcoat. Results of identification analysis may show that regardless of metal catalyst (for example Ag, Cu, Ce), hexavalent chromium (Cr6+) may be formed on aged catalysts systems, which may be due to the high concentration of chromium in substrate. Therefore, corrosion and production of hexavalent chromium may initiate from elements found in the substrate and not from elements within the ZPGM metal catalysts.

Owner:CLEAN DIESEL TECHNOLOGIES

Magnetic tape having characterized magnetic layer and hexagonal ferrite powder

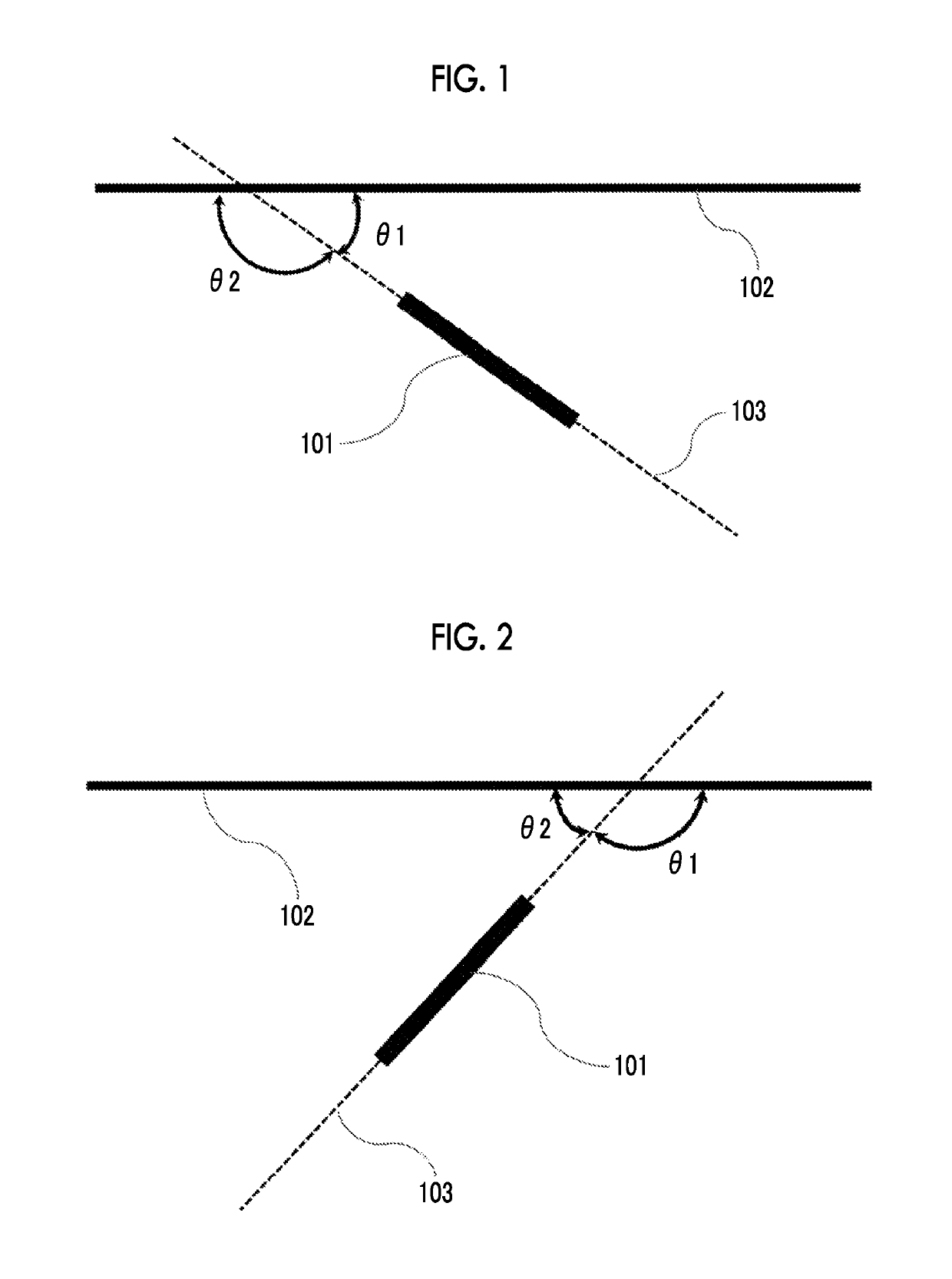

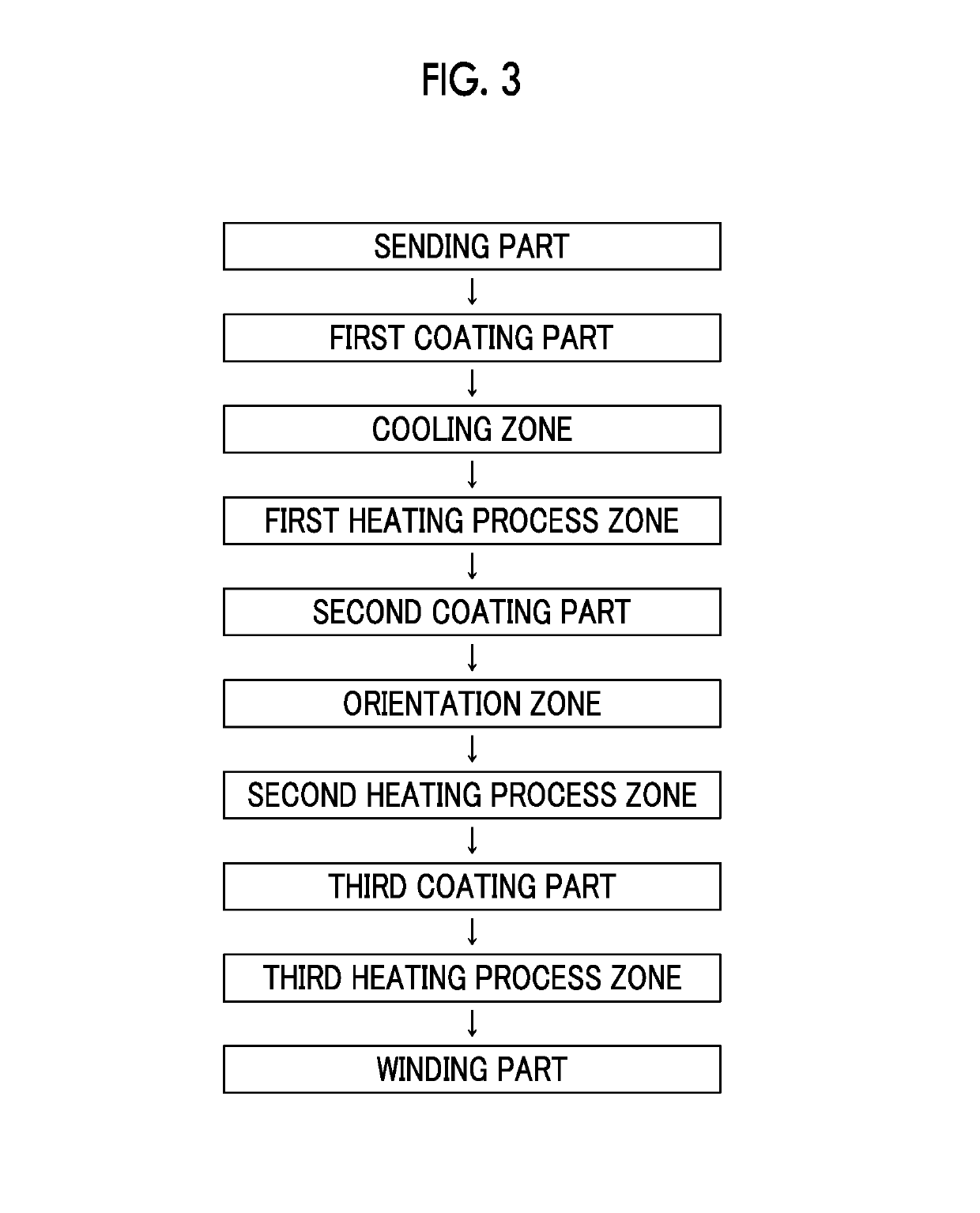

A magnetic tape is provided in which ferromagnetic powder included in a magnetic layer is ferromagnetic hexagonal ferrite powder having an activation volume less than or equal to 1,600 nm3. The magnetic layer includes one or more components selected from a fatty acid and a fatty acid amide, and an abrasive. The C—H derived C concentration calculated from the C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is greater than or equal to 45 atom %. Also, the tilt cos θ of the ferromagnetic hexagonal ferrite powder with respect to the surface of the magnetic layer acquired by cross section observation performed by using a scanning transmission electron microscope is 0.85 to 1.00.

Owner:FUJIFILM CORP

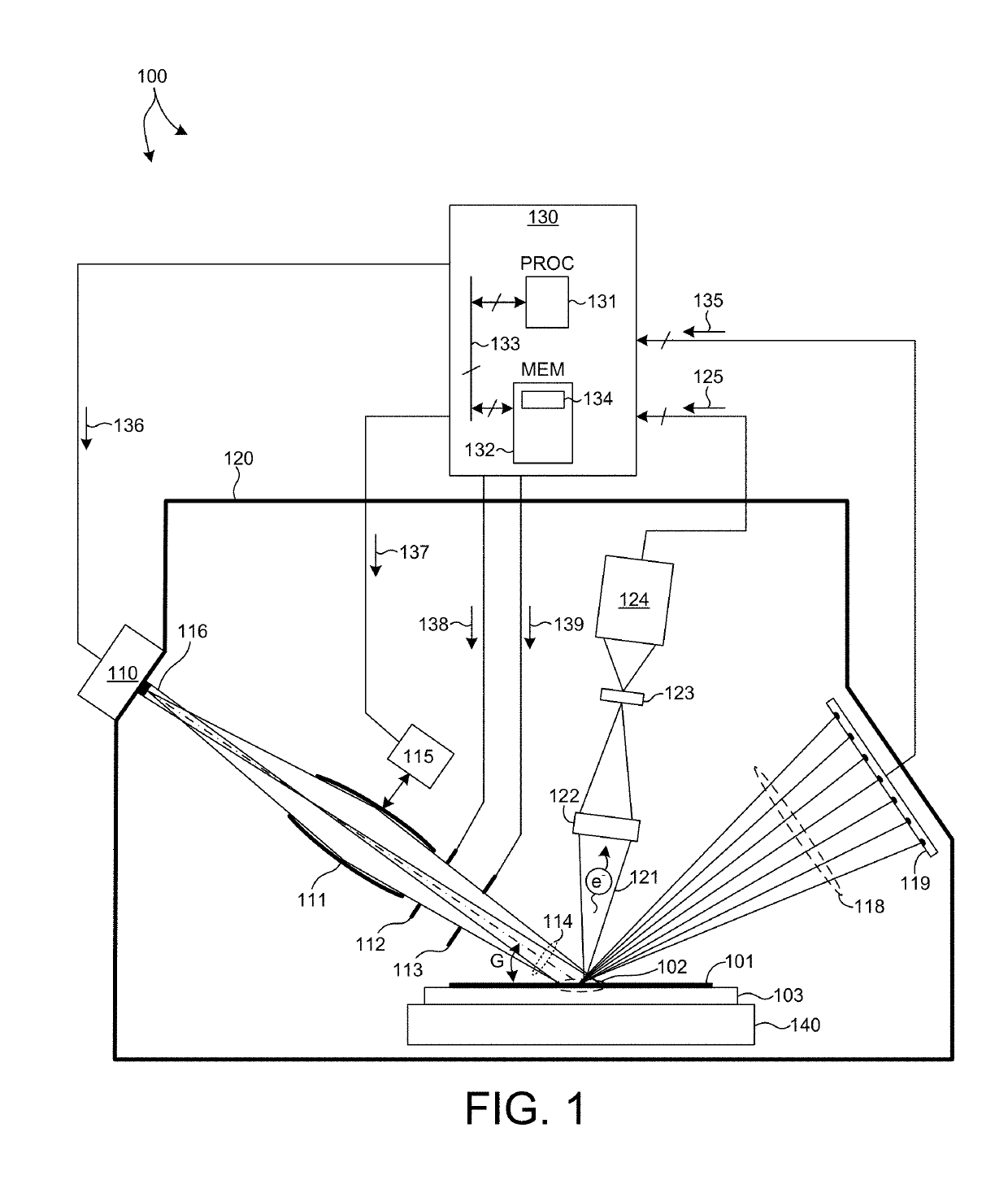

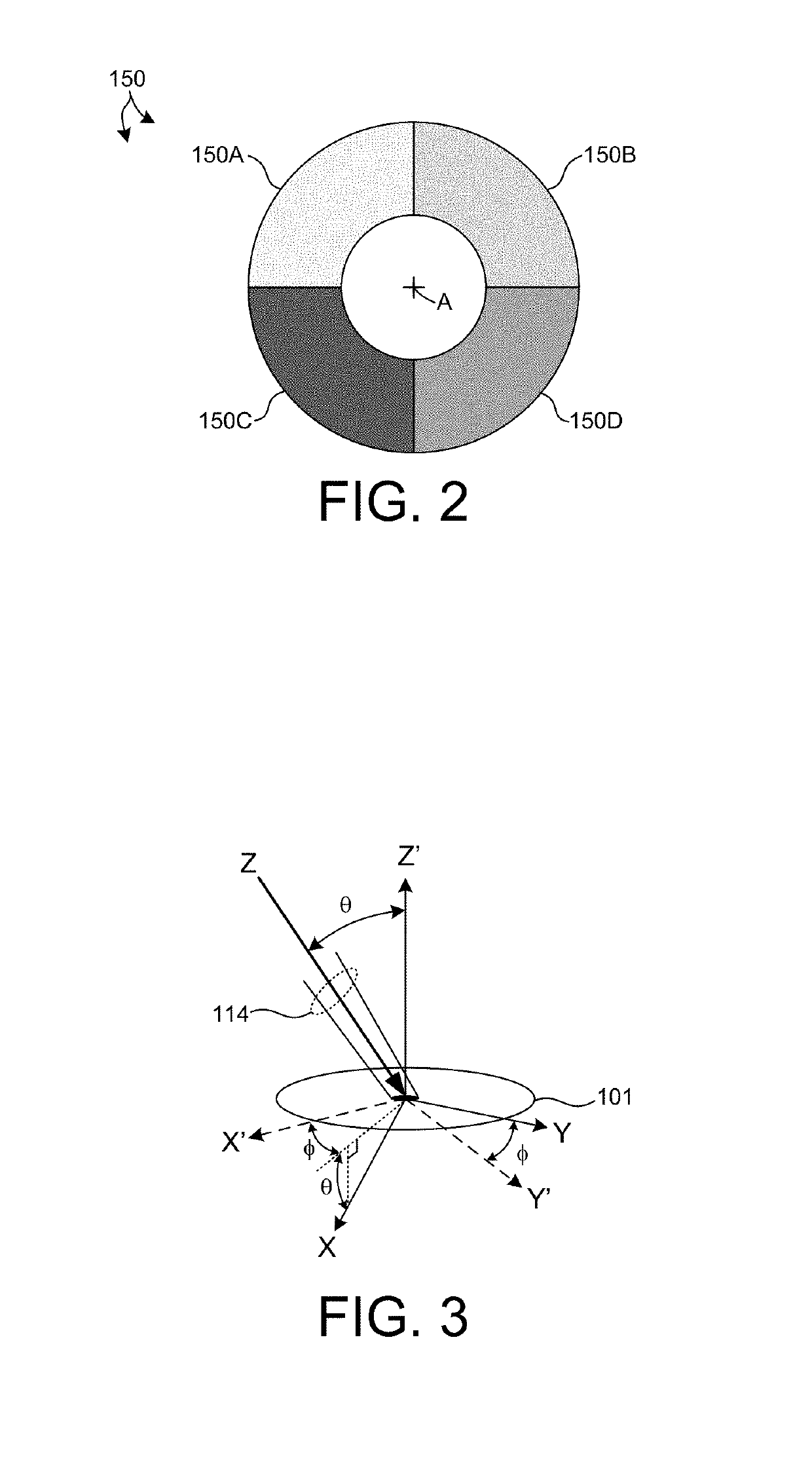

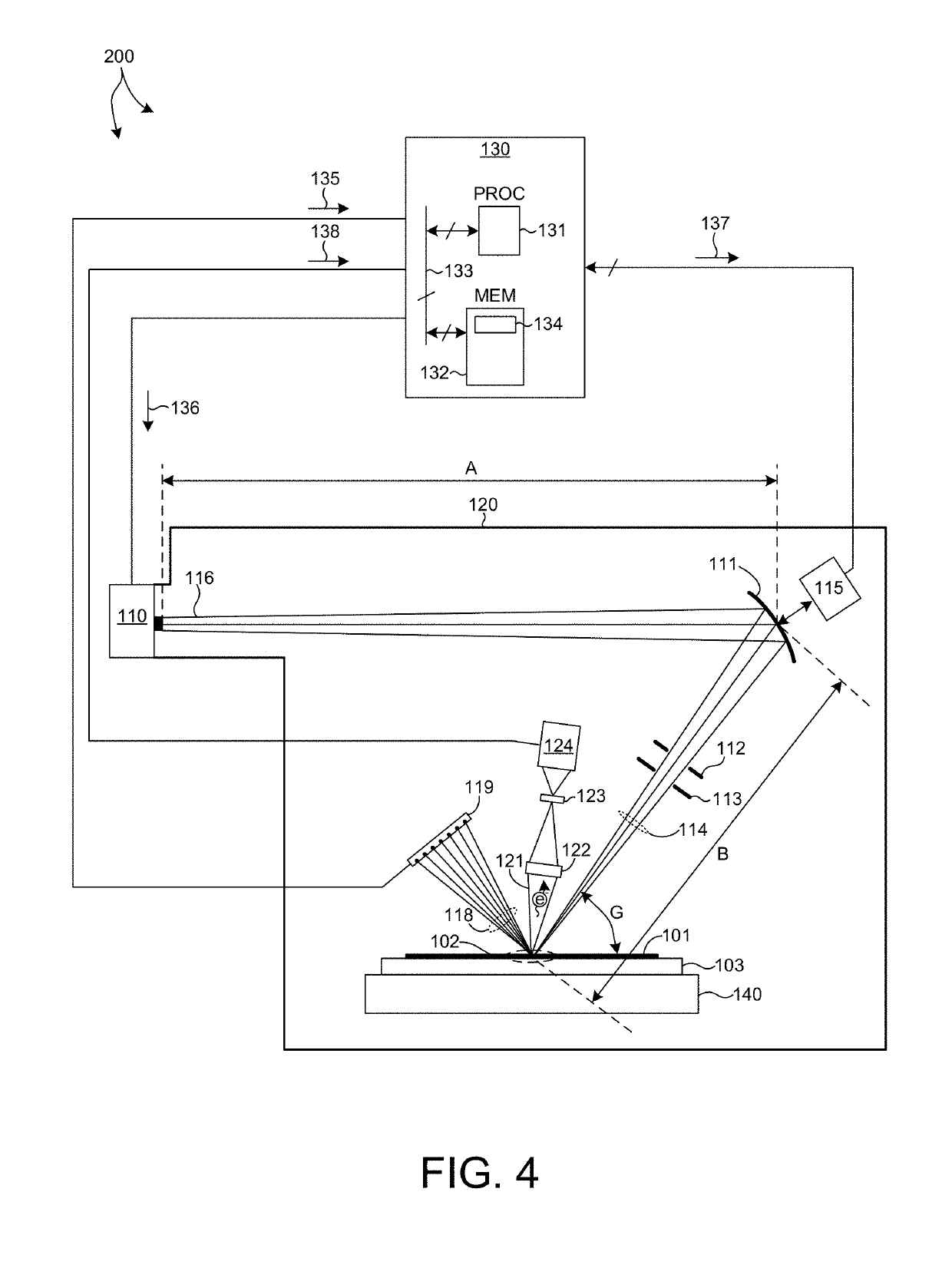

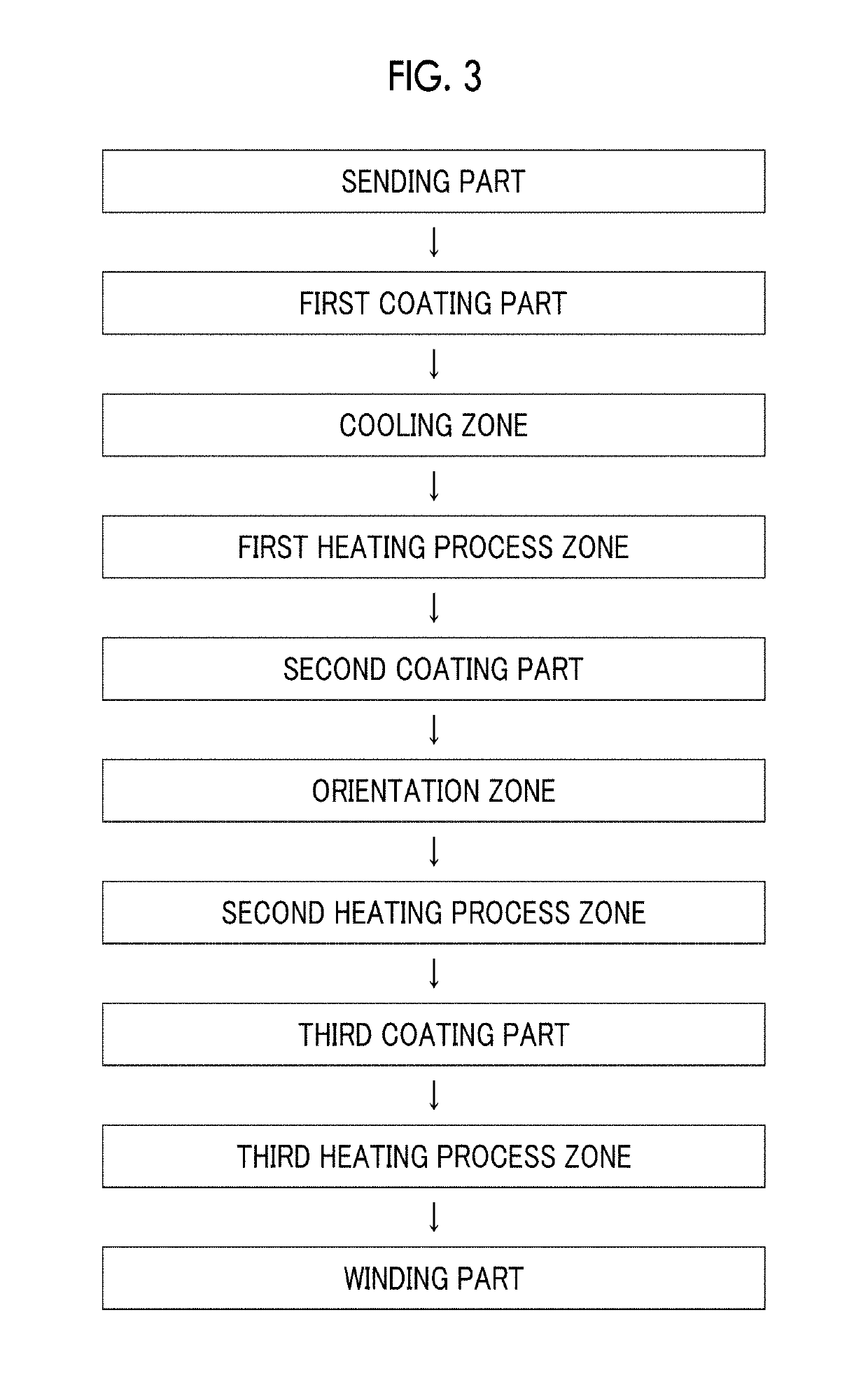

Systems And Methods For Combined X-Ray Reflectometry And Photoelectron Spectroscopy

ActiveUS20190212281A1High measurement accuracyImprove throughputMaterial analysis using wave/particle radiationColor/spectral properties measurementsSemiconductor structureX-ray

Methods and systems for measuring structural and material characteristics of semiconductor structures based on combined x-ray reflectometry (XRR) and x-ray photoelectron spectroscopy (XPS) are presented herein. A combined XRR and XPS system includes an x-ray illumination source and x-ray illumination optics shared by both the XRR and XPS measurement subsystems. This increases throughput and measurement accuracy by simultaneously collecting XRR and XPS measurement data from the same area of the wafer. A combined XRR and XPS system improves measurement accuracy by employing XRR measurement data to improve measurements performed by the XPS subsystem, and vice-versa. In addition, a combined XRR and XPS system enables simultaneous analysis of both XRR and XPS measurement data to more accurately estimate values of one of more parameters of interest. In a further aspect, any of measurement spot size, photon flux, beam shape, beam diameter, and illumination energy are independently controlled.

Owner:KLA TENCOR TECH CORP

Magnetic tape having characterized magnetic layer and magnetic tape device

ActiveUS10431248B2Improve accuracyExact reproductionAlignment for track following on tapesRecord information storageMagnetic tapeSurface roughness

Owner:FUJIFILM CORP

Magnetic tape device with magnetic tape having particular C-H derived C concentration and magnetic reproducing method

ActiveUS10438628B2Avoiding characteristicReduce resistanceMagnetic materials for record carriersBase layers for recording layersMagnetic tapeX-ray

The magnetic tape device includes: a magnetic tape; and a reproducing head, in which a magnetic tape transportation speed of the magnetic tape device is equal to or lower than 18 m / sec, the reproducing head is a magnetic head including a tunnel magnetoresistance effect type element as a reproducing element, the magnetic tape includes a non-magnetic support, and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, the magnetic layer includes one or more components selected from the group consisting of fatty acid and fatty acid amide, and a C—H derived C concentration calculated from a C—H peak area ratio of C1s spectra obtained by X-ray photoelectron spectroscopic analysis performed on the surface of the magnetic layer at a photoelectron take-off angle of 10 degrees is 45 to 65 atom %.

Owner:FUJIFILM CORP

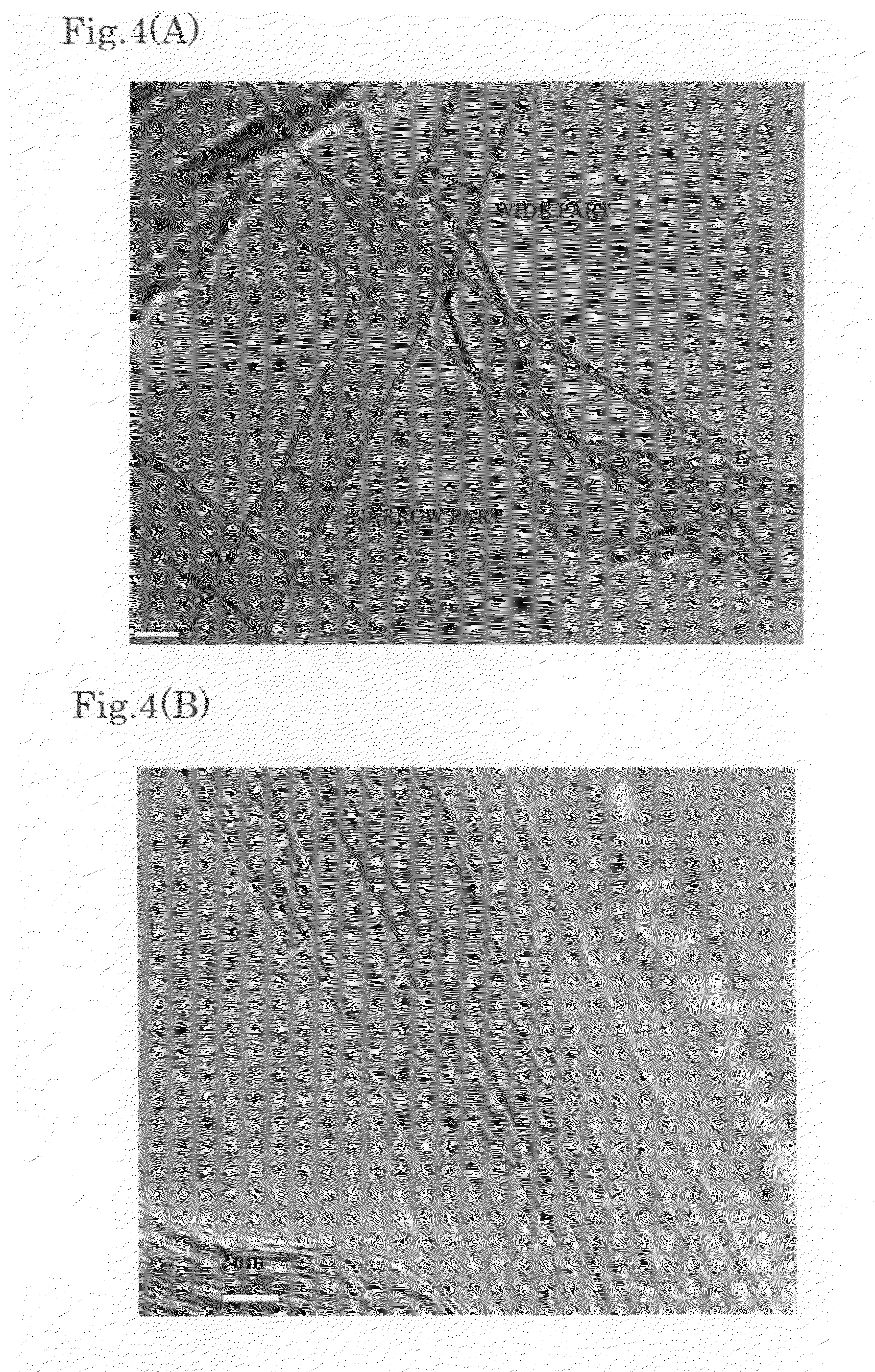

Hollow nanofibers-containing composition

InactiveUS20110027163A1Easy to separateEasy to removeMaterial nanotechnologyMolecular sieve catalystsFiberElectron

A method for preparing hollow nanofibers having carbon as a primary component by contacting a carbon-containing compound with a catalyst at 500 to 1200° C., wherein the catalyst is one of a zeolite exhibiting thermal resistance at 900° C. and, supported thereon, a metal; a metallosilicate zeolite containing a heteroatom except aluminum and silicon and a metal; a supporting material and fine cobalt particles exhibiting a binding energy of a cobalt 2P3 / 2 electron of 779.3 to 781.0 eV; a supporting material and fine cobalt particles exhibiting a cobalt atom ratio in the surface of the supporting material of 0.1 to 1.5%, as measured by the X-ray photoelectron spectroscopy at 10 kV and 18 mA; a supporting material and fine cobalt particles exhibiting a weight ratio of cobalt to a second metal component of 2.5 or more; and a zeolite having a film form and a metal.

Owner:SHINOHARA HISANORI +4

Toner

Provided is a toner including toner particle, the toner particle having a core-shell structure having: a core containing a core resin, a colorant, and a wax; and a shell layer containing a resin “A” on a surface of the core, in which: the resin “A” contains a segment having an organopolysiloxane structure; the toner particle has an amount of Si derived from the organopolysiloxane structure of 6.0 or more and 10.0 or less, the amount of Si being measured by X-ray photoelectron spectroscopy; the resin “A” is a polymer of a monomer composition containing a monomer “a” having two or more polymerizable unsaturated groups in one molecule thereof; and the monomer “a” satisfies the following formula (1).(Xa−1.0)×Ya≧3.0×10−5 (1)

Owner:CANON KK

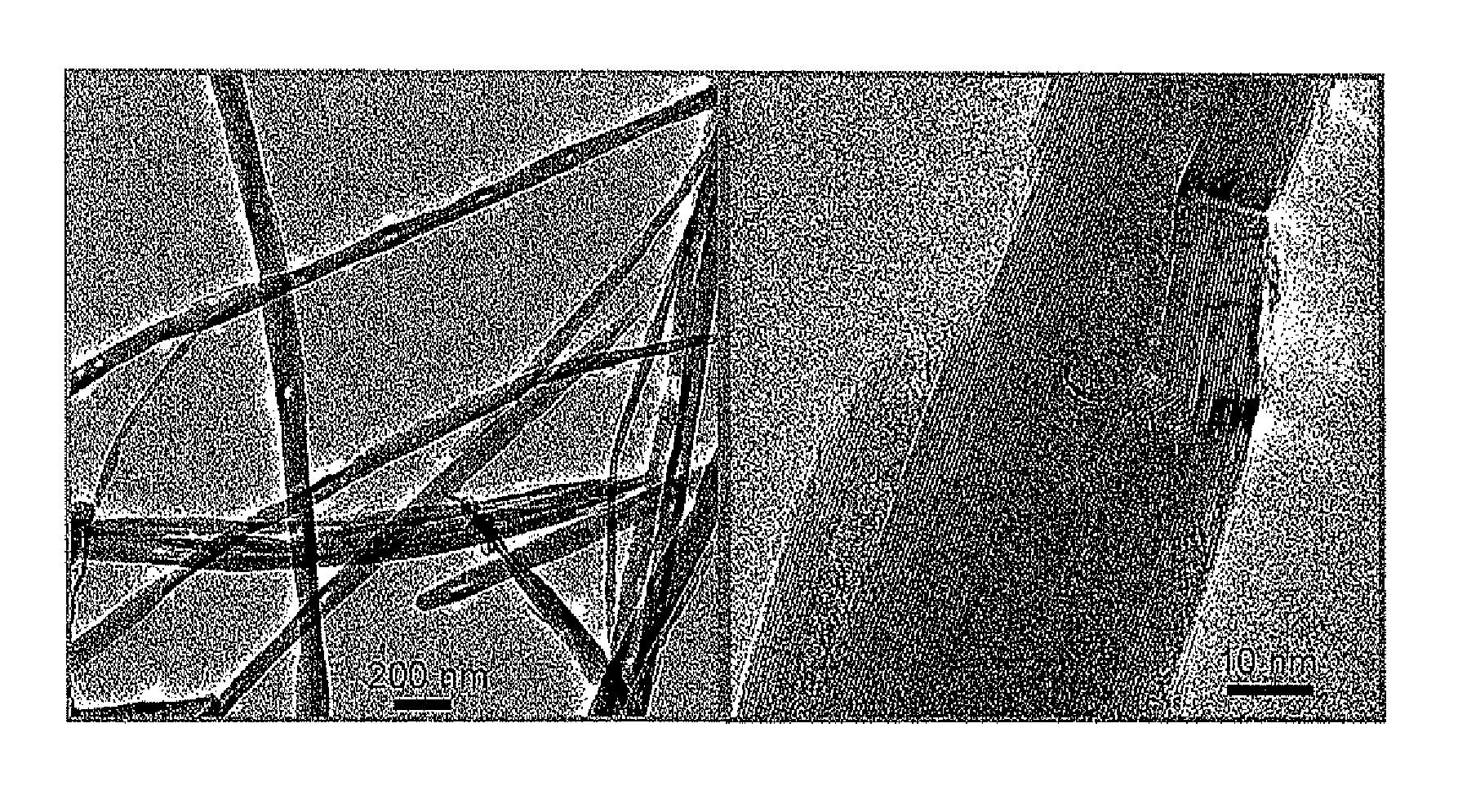

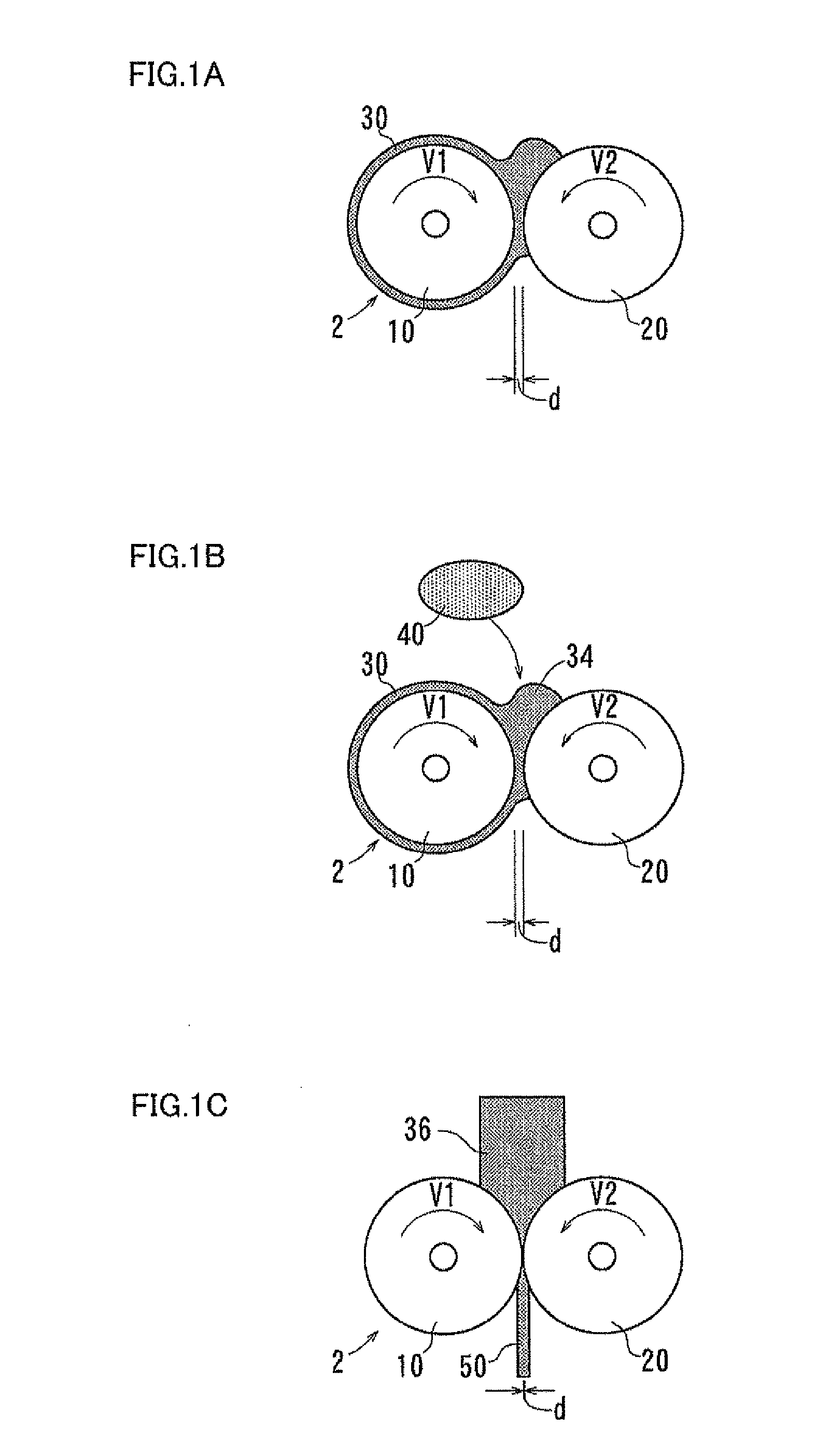

Carbon nanofiber, method for production thereof, method for production of carbon fiber composite material using carbon nanofiber, and carbon fiber composite material

ActiveUS20110060087A1Improve surface reactivityImprove wettabilityMaterial nanotechnologySpecial tyresElastomerFiber

A method of producing a carbon fiber composite material includes a first step and a second step. The first step includes oxidizing first carbon nanofibers produced by a vapor growth method to obtain second carbon nanofibers having an oxidized surface. The second step includes mixing the second carbon nanofibers into an elastomer, and uniformly dispersing the carbon nanofibers in the elastomer by applying a shear force to obtain the carbon fiber composite material. The second carbon nanofibers obtained by the first step have a surface oxygen concentration measured by X-ray photoelectron spectroscopy (XPS) of 2.6 to 4.6 atm %.

Owner:HITACHI ASTEMO LTD +1

Toner and image forming method

InactiveUS6447969B1Improve charging effectHigh image densityDevelopersElectrographic process apparatusElectron microscopeFerric

A toner is formed of toner particles each comprising a binder resin and iron oxide particles dispersed therein. The toner particles are characterized by uniform but non-surface-exposed dispersion of the iron oxide particles within the toner particles as represented by (i) a carbon content (A) and an iron content (B) giving a ratio B / A<0.001 at surfaces of the toner particles as measured by X-ray photoelectron spectroscopy, (ii) an average circularity of at least 0.970, and (iii) at least 50% by number of toner particles satisfying D / C<=0.02, wherein C denotes a projection area-equivalent circular diameter of each toner particle and D denotes a minimum distance of iron oxide particles from a surface of the toner particle, based on a sectional view of the toner particle as observed through a transmission electron microscope (TEM).

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com