Mineral oil defoaming agent and preparation method thereof

A technology of mineral oil and defoamer, which is applied in the direction of foam dispersion/prevention, and can solve the problems of gel state destruction, poor product stability, and low viscosity of defoamer products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

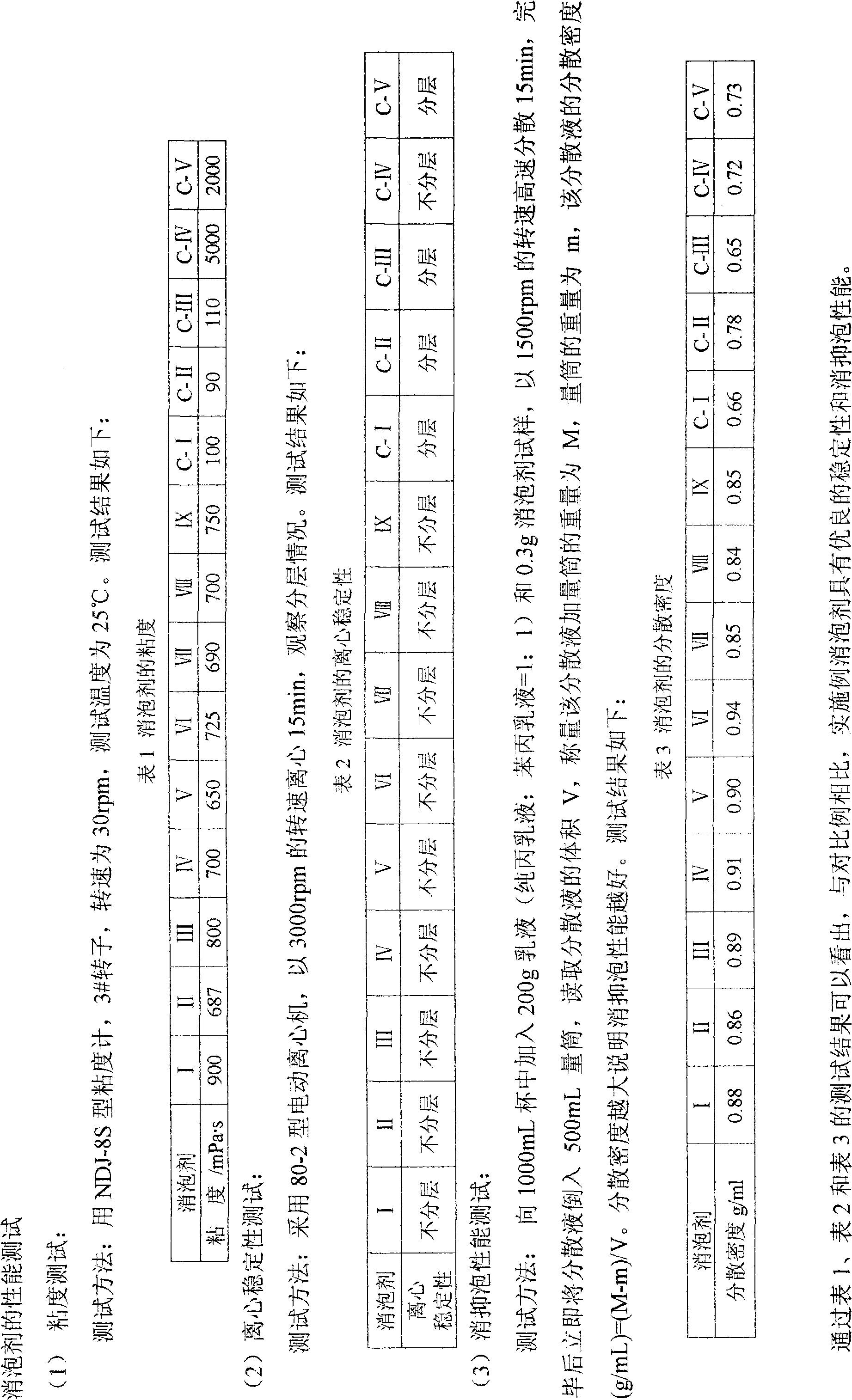

Examples

Embodiment 1

[0038] 52g white oil (5#), 10g aluminum di(octadecanoate) and 15g structural formula are C 16 h 33 O(EO) 18 (PO) 29 Add the defoaming aid of H into the reaction flask, start stirring, and slowly raise the temperature. When the temperature rises to 140°C, keep it warm for 1 hour, and then lower the temperature to 40°C. Add 5g of EBS and 10g of white oil (5#) into the beaker, start stirring, slowly raise the temperature to 125°C, keep it warm for 0.5h, and immediately add it to the stirring aluminum di(octadecanoate) / white oil gel In the system, lower the temperature to below 70°C, add 8g of oleic acid polyoxyethylene (6) ether and mix well to obtain defoamer I.

Embodiment 2

[0040] 66g of kerosene, 6g of aluminum hexadecanoate, and 15g of structural formula C 10 h 21 O(EO)10 (PO) 50 H's defoaming aid and 4g specific surface area is 200m 2 / g Vapor-phase hydrophobic silica was added to the reaction flask, stirring was started, and the temperature was raised slowly until the temperature was raised to 140°C, kept for 1 hour, and then cooled to 50°C. In addition, add 1g of ethylene bispalmitic acid amide and 10g of white oil (15#) into the beaker, start stirring, slowly raise the temperature to 125°C, keep it warm for 0.5h, and immediately add it to the stirring aluminum hexadecanoate / kerosene gel In the glue system, lower the temperature to below 70°C and mix evenly to obtain the defoamer II.

Embodiment 3

[0042] 70g of alkylbenzene, 3g of aluminum dibutyrate, and 10g of structural formula C 12 h 25 O(EO) 15 (PO) 45 The defoaming aid of H and the specific surface area of 5g is 230m 2 / g of vapor-phase hydrophobic silica was added to the reaction flask, stirring was started, and the temperature was raised slowly until the temperature was raised to 130°C, kept for 2 hours, and then cooled to 50°C. Add 0.5g of ethylene bis-myristic acid amide and 6g of liquid wax (300#) into the beaker, start stirring, slowly raise the temperature to 125°C, keep it warm for 0.5h, and immediately add it to the stirring aluminum / alkane dibutyrate In the benzene gel system, lower the temperature to below 70°C, add 5.5g of oleic acid polyoxyethylene (9) ether and stir evenly to obtain the defoamer III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com