Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88results about How to "Happy to use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composition containing a silicone elastomer and a block silicone copolymer

InactiveUS20050048016A1Good effectHappy to useCosmetic preparationsHair cosmeticsSilicone ElastomersPrimary alcohol

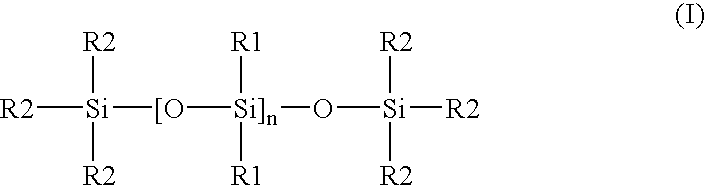

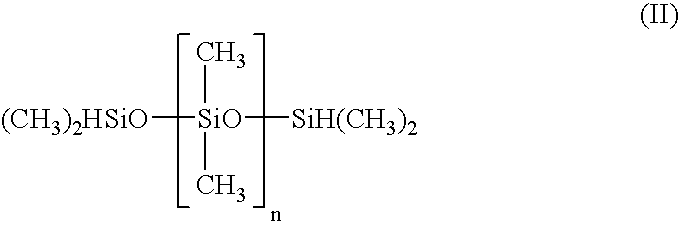

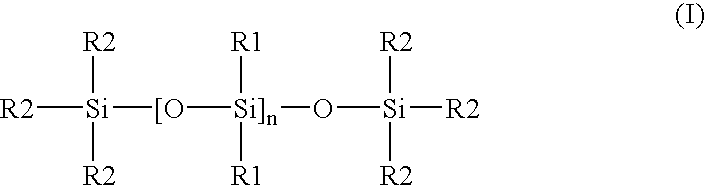

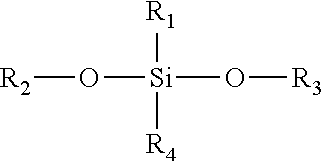

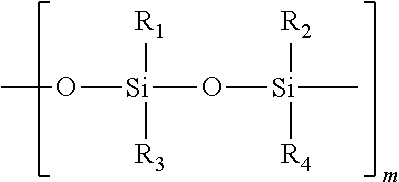

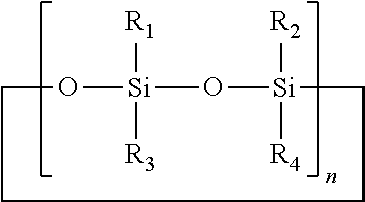

The present patent application relates to a composition containing at least one elastomeric solid organopolysiloxane, at least one filler, at least one C2-C3 primary alcohol and an aqueous dispersion of at least one substantially linear block silicone copolymer.

Owner:LOREAL SA

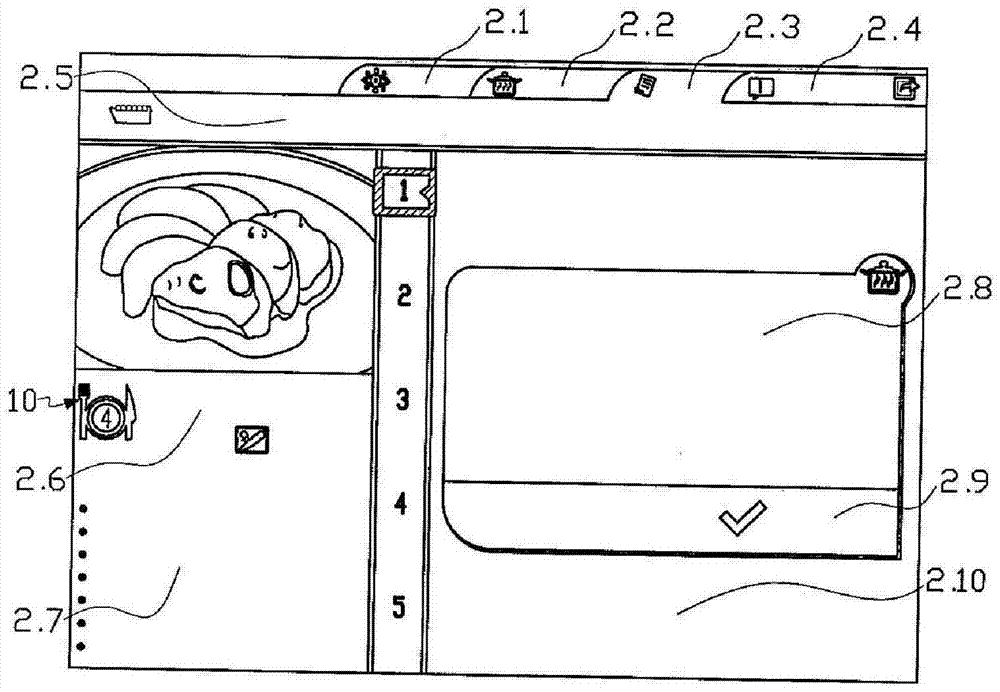

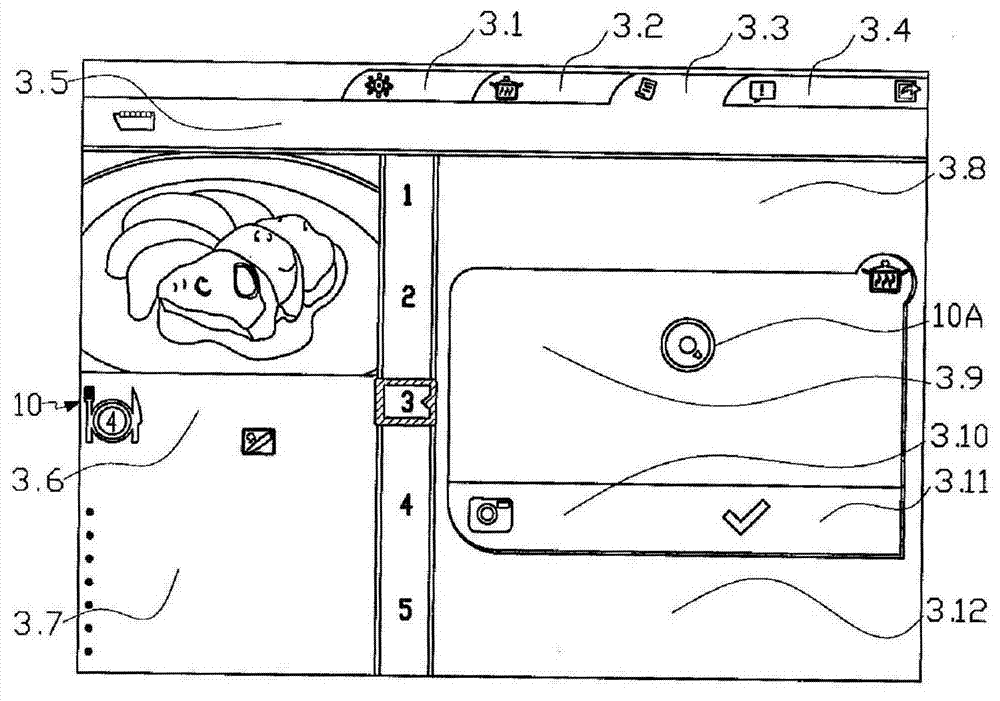

Cooking system with assisted use

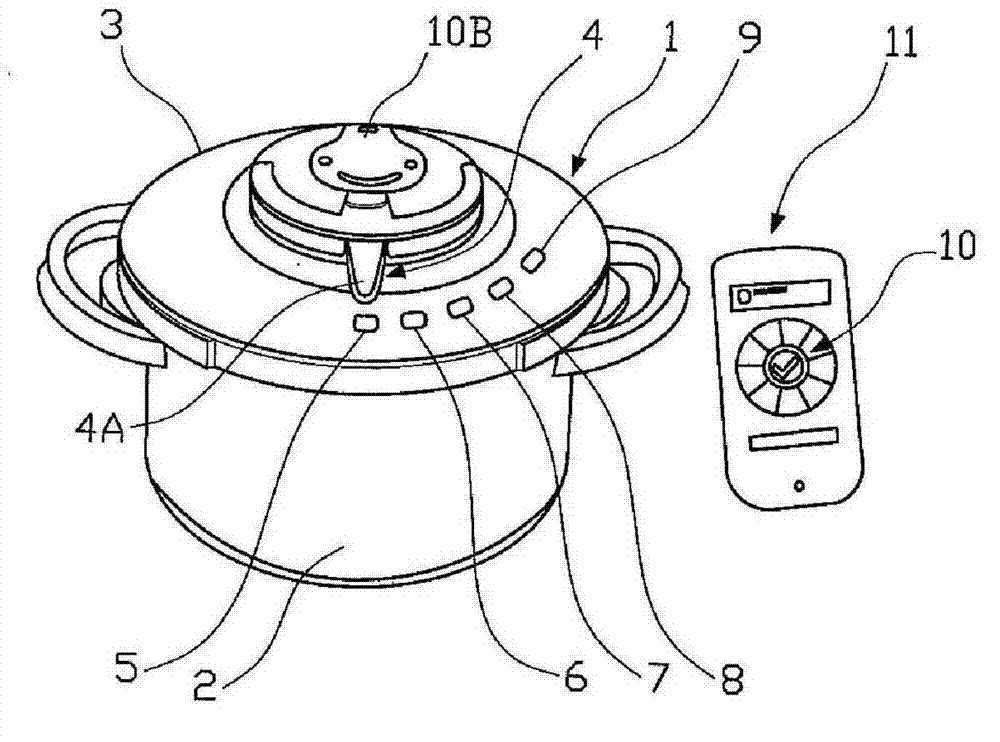

The invention provides a cooking system including a pressure pot (1) provided with a manual control member (4) which is installed movably between a plurality of positions corresponding to a plurality of operating states. The positions are associated with identification marks (5, 6, 7, 8, 9) located in a pre-arrangement. The cooking system is characterized in that the cooking system also includes a graphical user interface or ''GUI''(10) providing help for use of the pressure pot (1), the GUI is operated on a computer terminal (11) provided with a display screen, the GUI (10) is designed to firstly display a pictorial chart located in the arrangement corresponding to a pre-arrangment on the display screen, and secondly display a virtual mouse assigning one pictorial chart in the pictorial charts. The system also includes a radio communication device designed to control the position of the virtual mouse by the position of the manual control member (4).

Owner:SEB SA

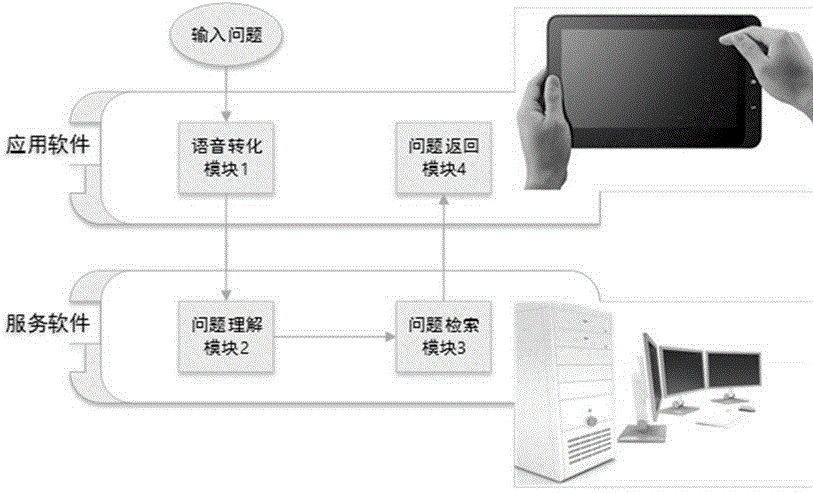

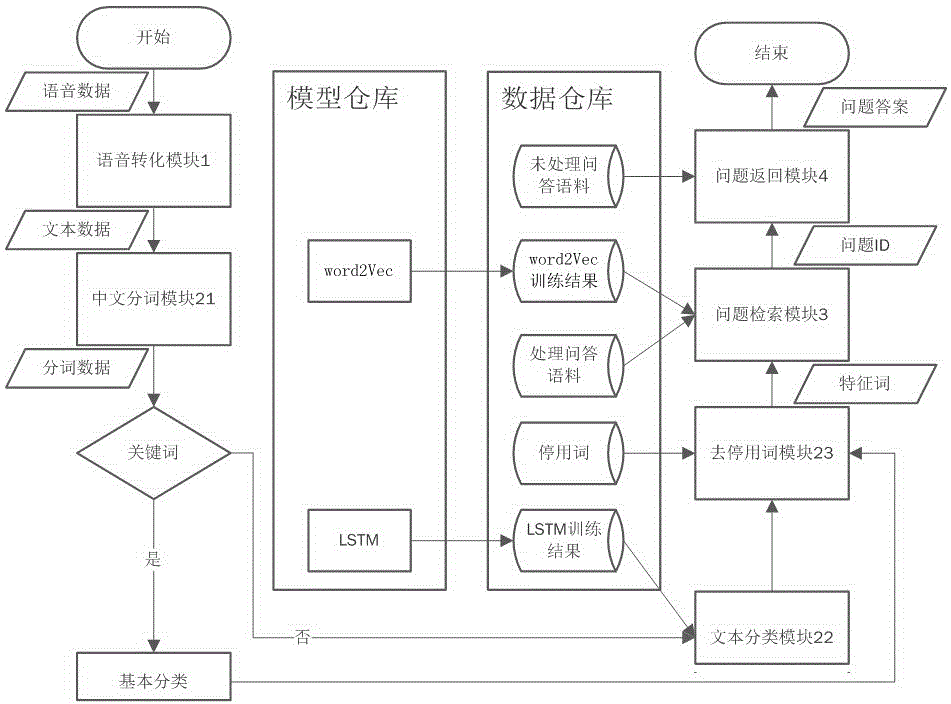

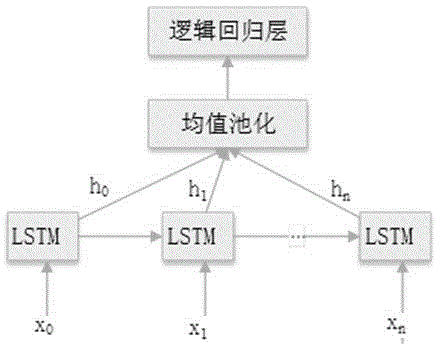

Intelligent question-answering system for tax consultation service

ActiveCN106649561AImprove calculation accuracyReduce computing timeFinanceSpecial data processing applicationsAndroid (operating system)Deep level

The invention belongs to the field of artificial intelligence technology and particularly discloses an intelligent question-answering system for tax consultation service. The system comprises a terminal device where an Android operating system is installed and a computer; an application software program is installed in the terminal, wherein the application software comprises a voice conversion module and a question return module; a service software system is installed on the computer, wherein the service software system comprises a question understanding module and a question retrieval module; when the system operates, the voice conversion module converts voice data output by a user into text data, semantic understanding is performed through the question understanding module, the question retrieval module is used for retrieving answers, and a processing result is transmitted to the terminal user through the question return module. According to the system, voice recognition, text classification, similarity calculation and other technologies are used comprehensively to form a method for performing text similarity matching on an incomplete data set in the area of expertise, profound semantic analysis can be performed on questions raised by taxpayers, and meanwhile ceaseless accurate consultation service is provided for mass users to meet the actual requirement for tax consultation.

Owner:FUDAN UNIV

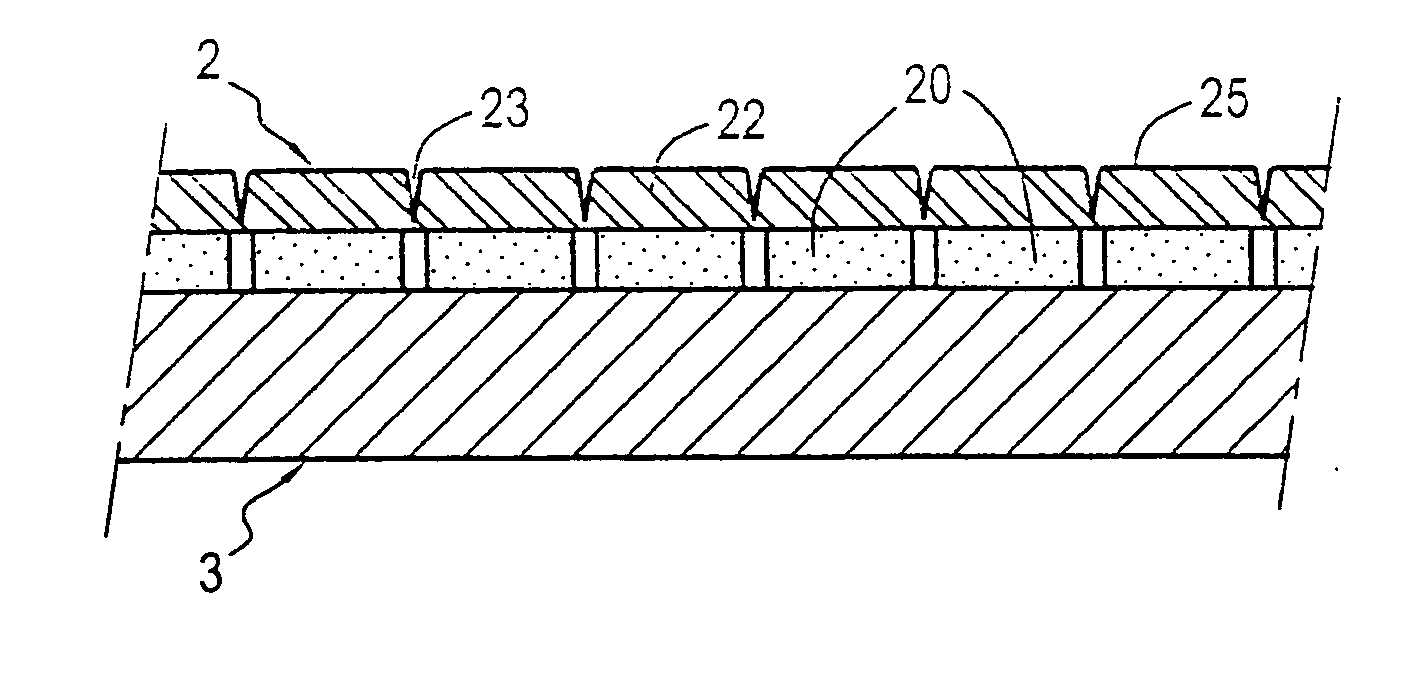

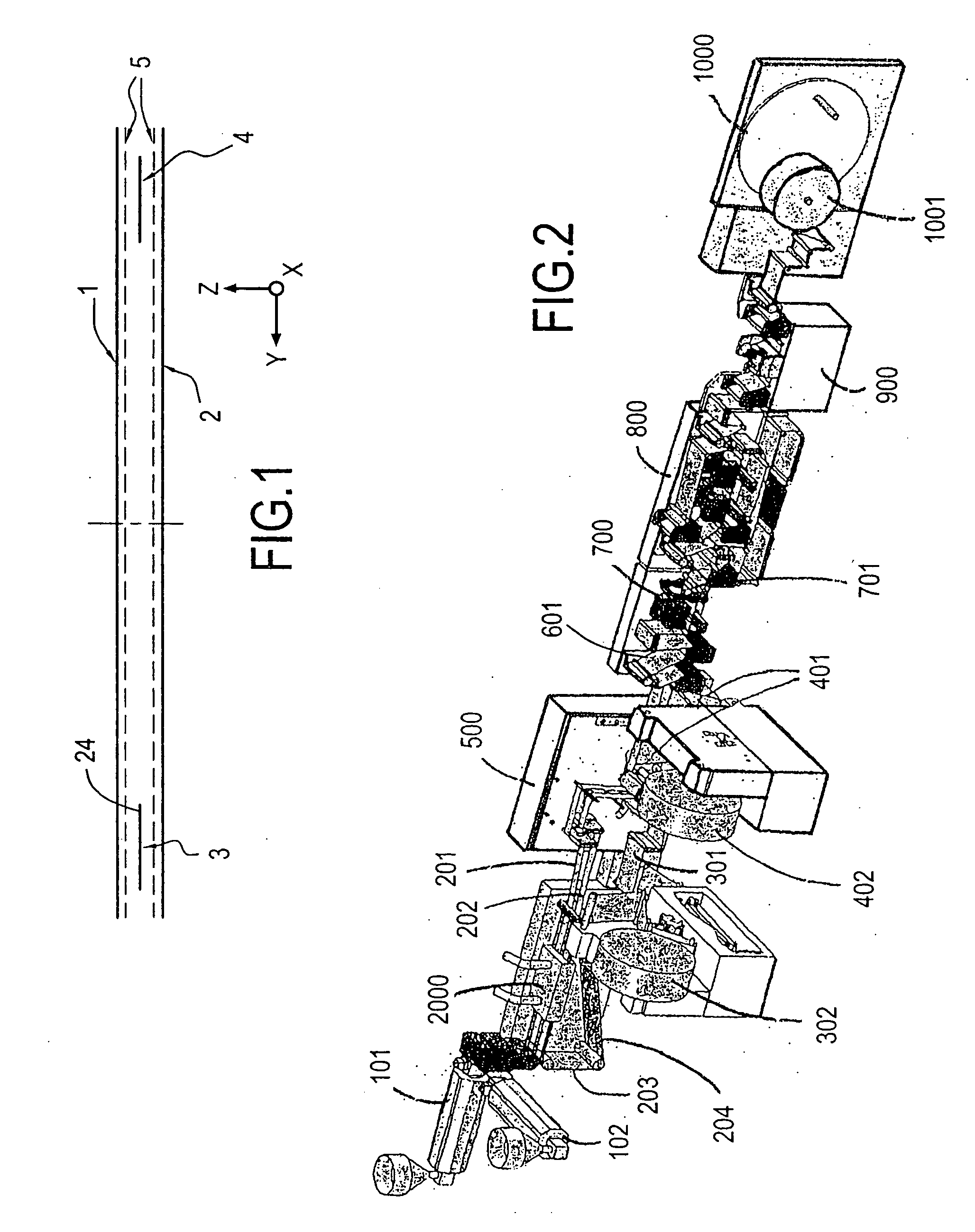

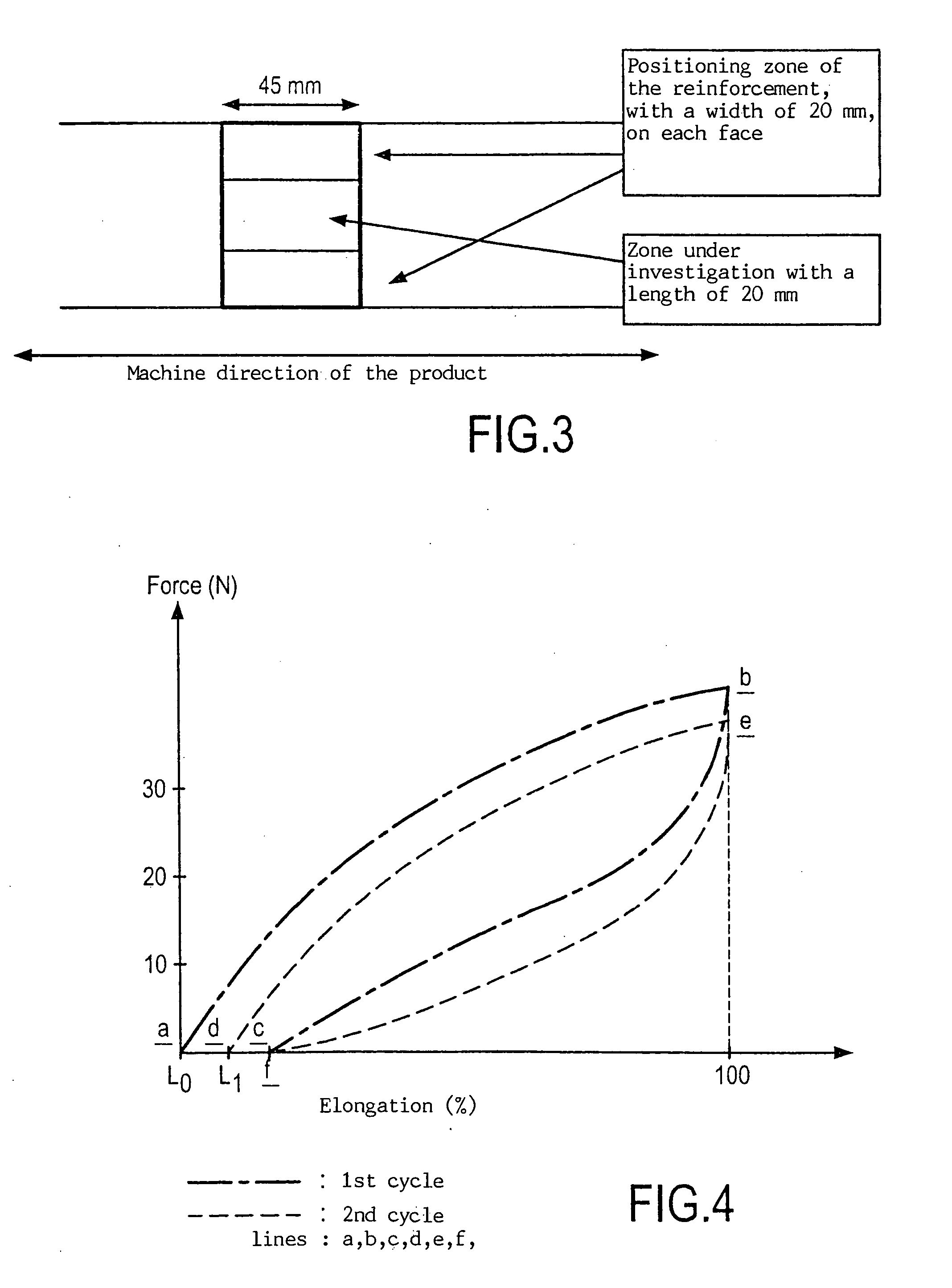

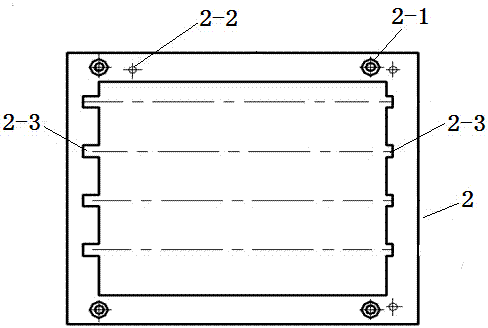

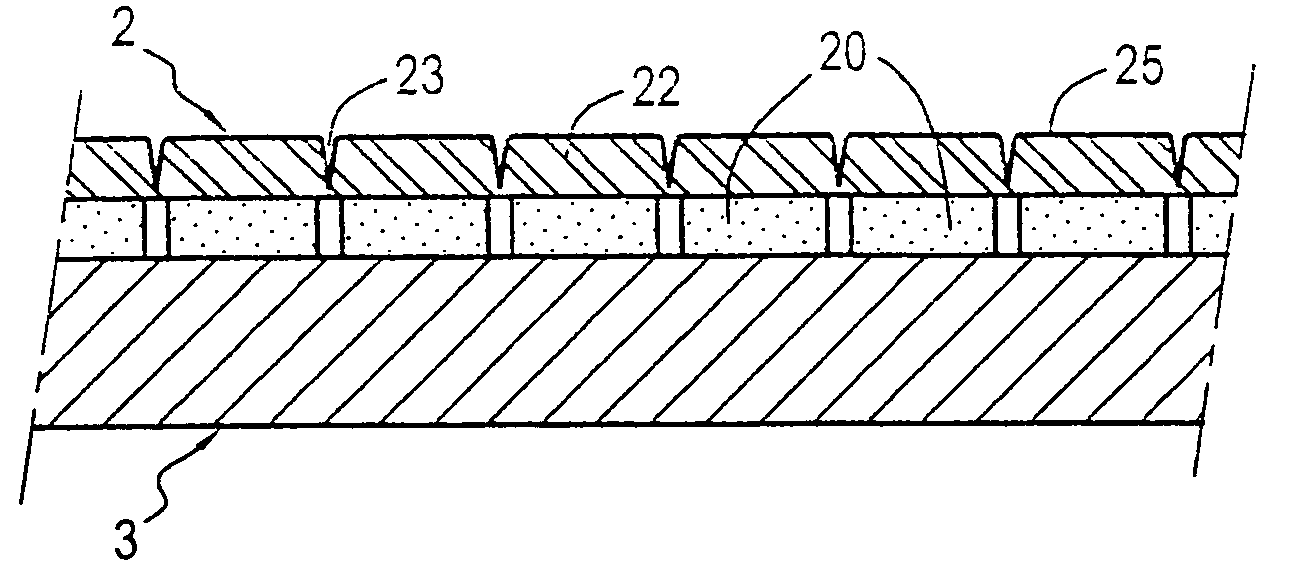

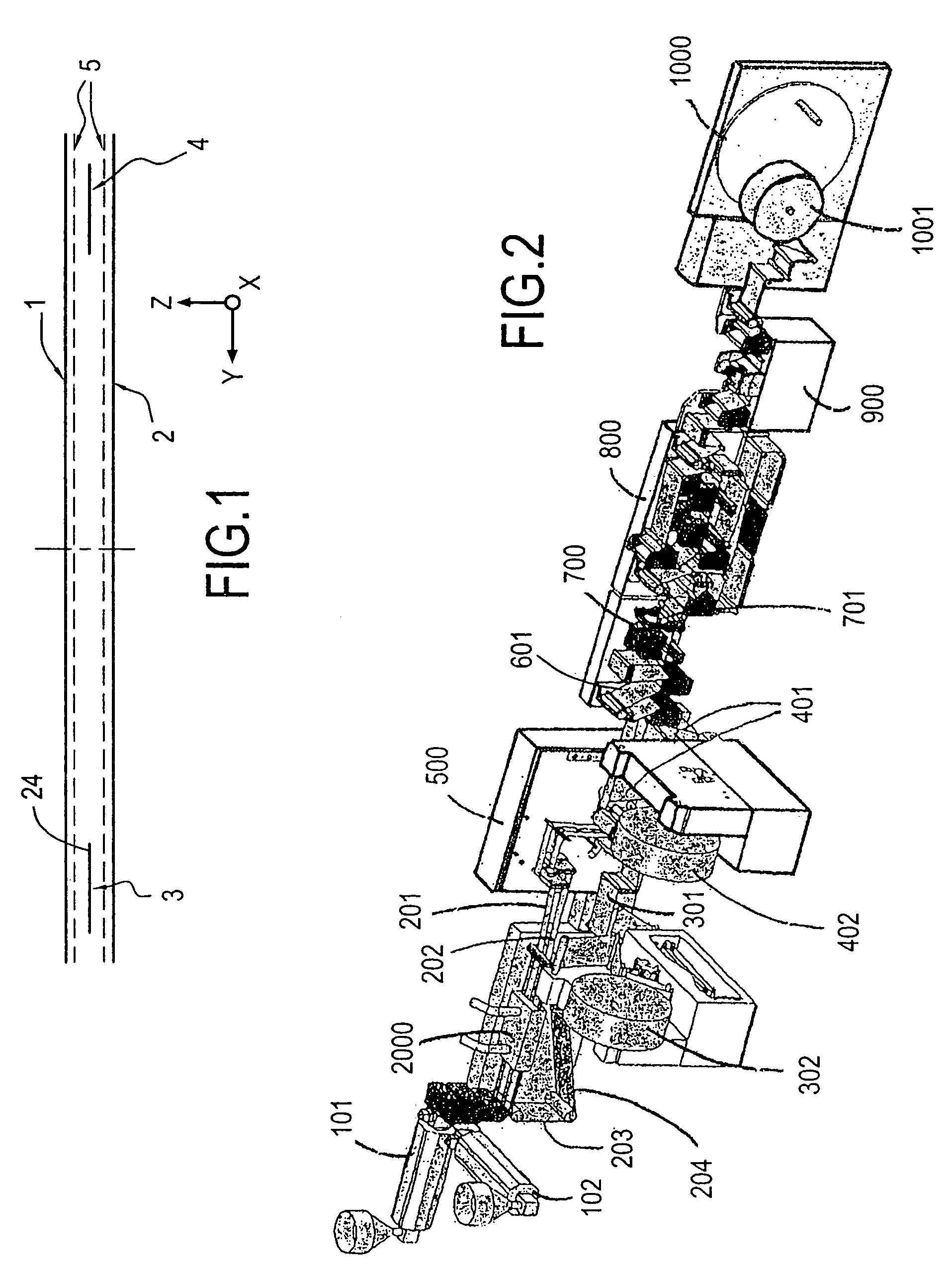

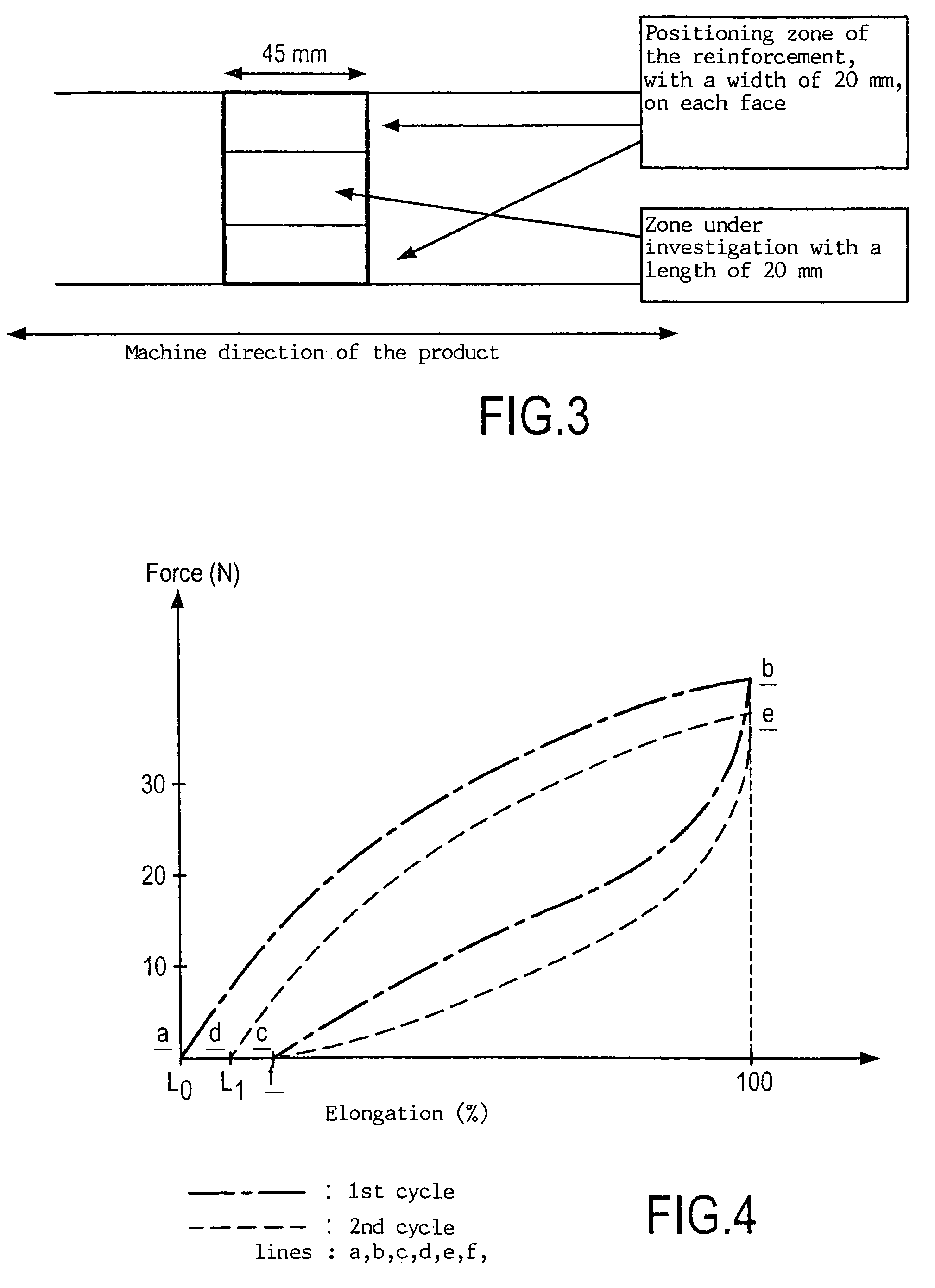

Non-woven fabric laminate/elastomer/non-woven fabric

ActiveUS20070105472A1CharacteristicImprove adhesionLayered product treatmentDecorative surface effectsElastomerAdhesive

A laminate including at least one elastic film having a width and at least one layer of non-woven fabric fixed to the film on at least said width, through interposition of a fixing agent, in particular adhesive, whereby the at least one layer of non-woven fabric has an outer surface at a distance from the film. The outer surface (25) of the at least one layer of non-woven fabric is corrugated in the stretched state of the laminate, having ridge zones (22) and hollow zones (23), whereby fixing agent (20) is provided between the ridge zones and the elastic film.

Owner:APLIX INC

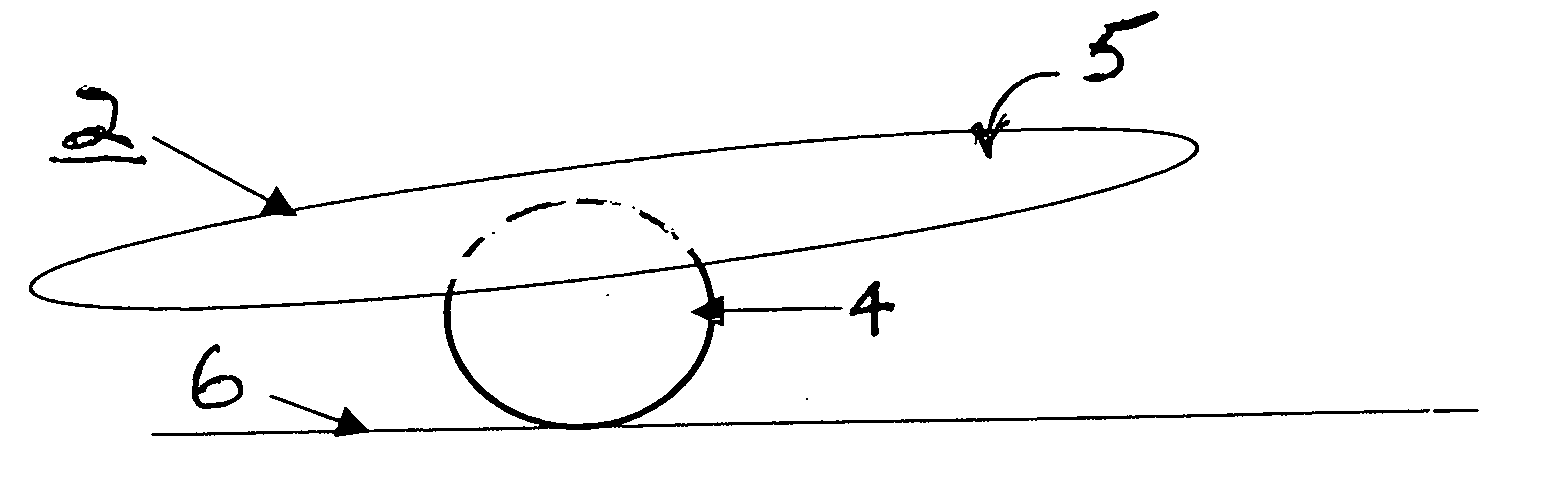

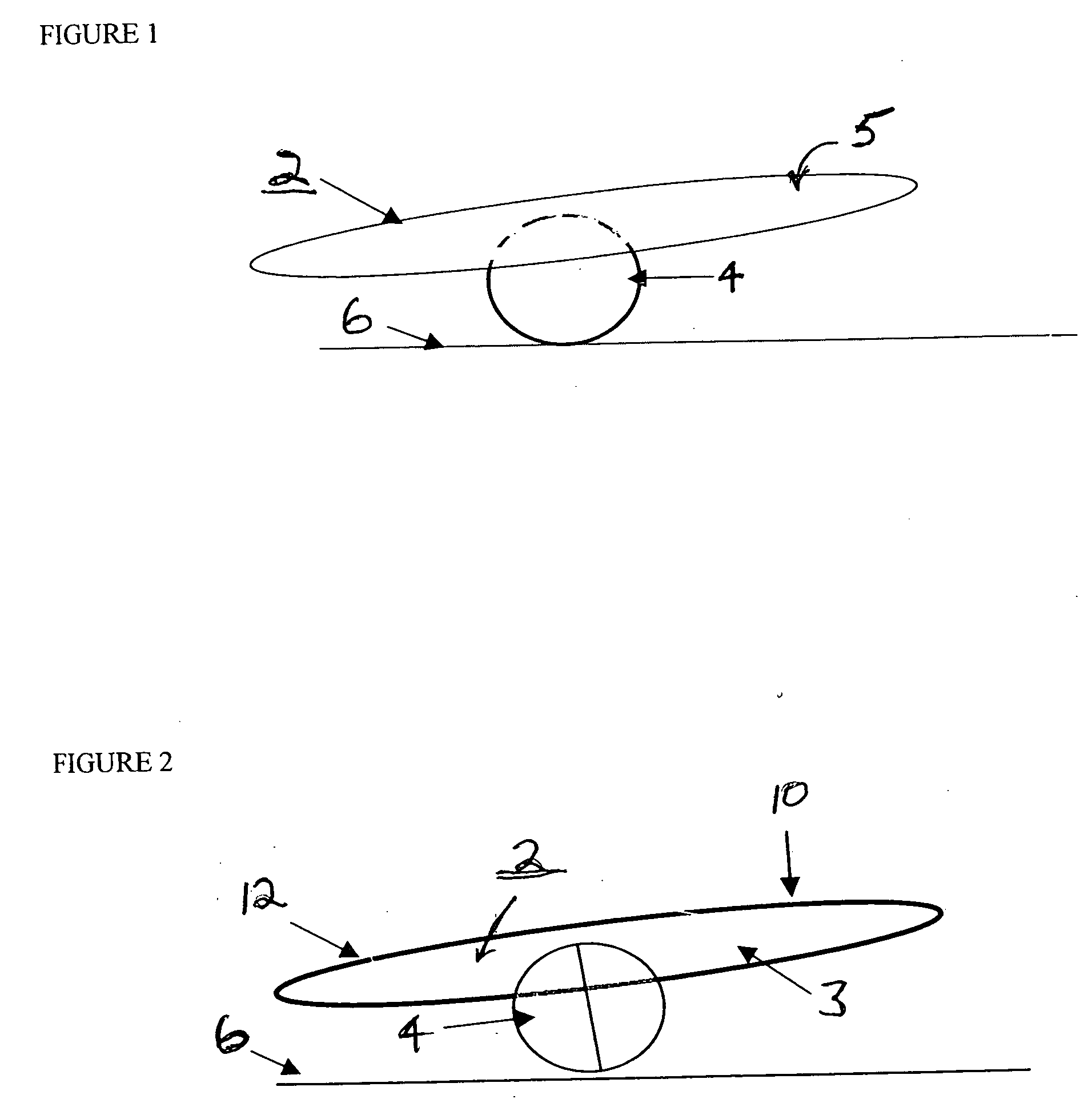

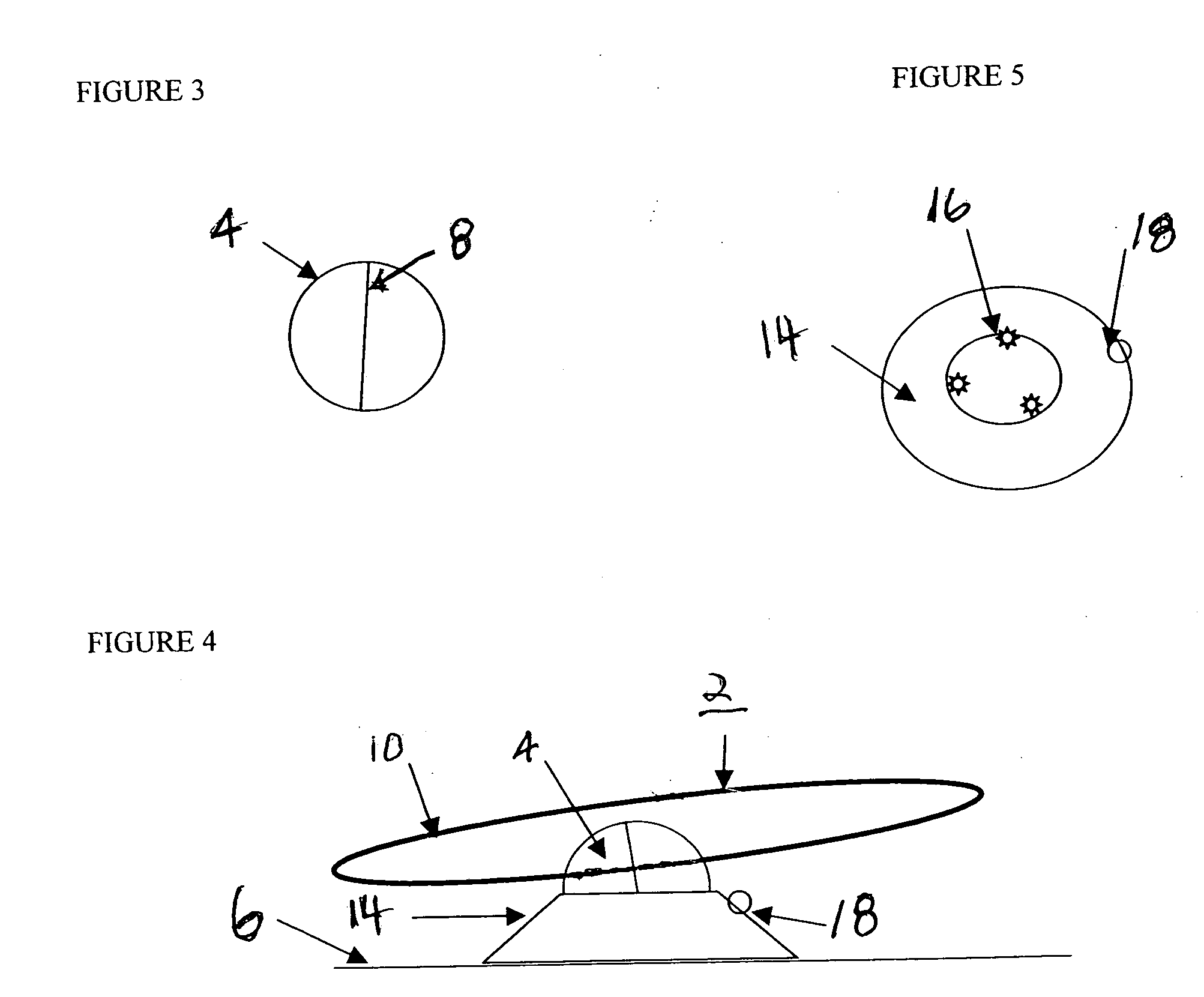

Balance platform method and apparatus

InactiveUS20060211553A1Happy to useInexpensive to manufacturerStiltsMuscle exercising devicesFree rotationEngineering

One embodiment of the present invention comprises a balance platform apparatus, including, a balance platform having upper and lower surfaces, and a freely rotatable ball member. The lower surface of the balance platform includes a rim member which projects in a generally perpendicular direction away from the platform and which encircles an area of the lower surface of the platform. In use, the balance platform is placed upon the ball member, and the user tries to balance platform upon the ball member. During the balancing activity, the rim member tends to confine movement of the ball member to within the area encircled by the rim member. In another embodiment of the invention, the ball member is rotatably supported in a cradle member.

Owner:CANTOR ZACHARY MICHAEL

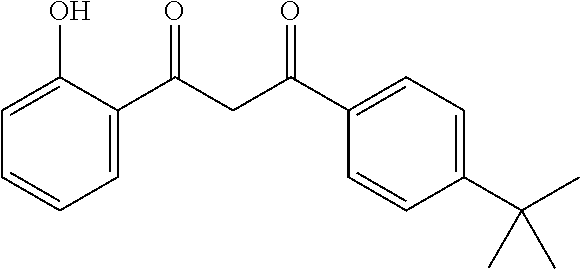

Composition containing a superabsorbent polymer and an organic UV screening agent

InactiveUS20100330018A1Reduce and even eliminateMaintain good propertiesCosmetic preparationsHair cosmeticsSuperabsorbent polymerEmulsion

A composition in the form of an emulsion containing an aqueous phase, a fatty phase, a superabsorbent polymer, and an organic UV screening agent. Method for the treatment of a keratinous substance whereby the composition described is applied to the keratinous substance.

Owner:LOREAL SA

Composition containing a superabsorbent polymer and an organic UV screening agent

InactiveUS20150224046A1Reduce and even eliminateMaintain good propertiesCosmetic preparationsToilet preparationsEmulsionSuperabsorbent polymer

A composition in the form of an emulsion containing an aqueous phase, a fatty phase, a superabsorbent polymer, and an organic UV screening agent. Method for the treatment of a keratinous substance whereby the composition described is applied to the keratinous substance.

Owner:LOREAL SA

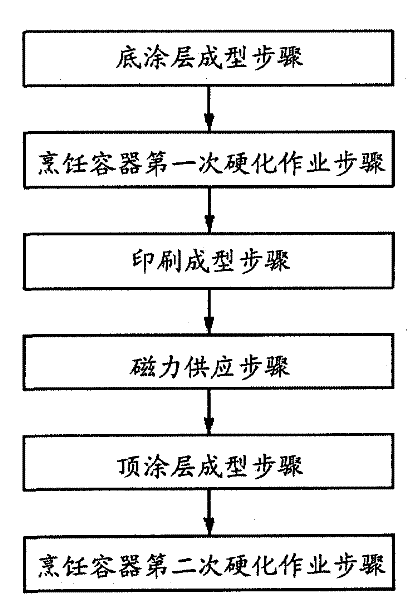

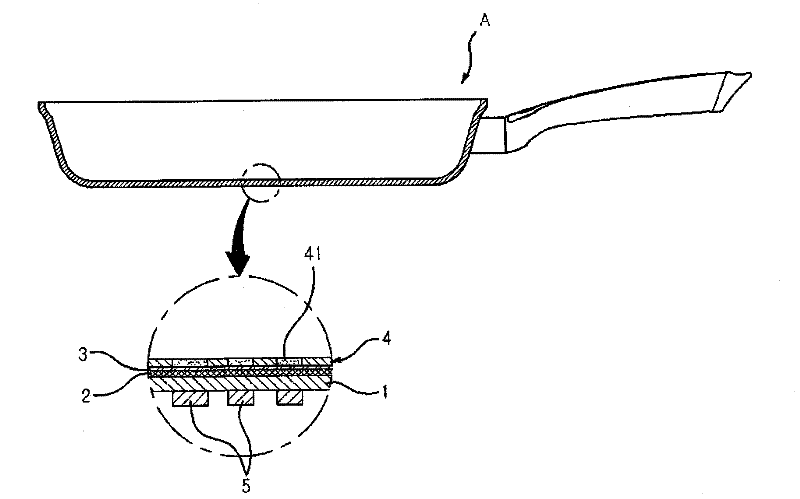

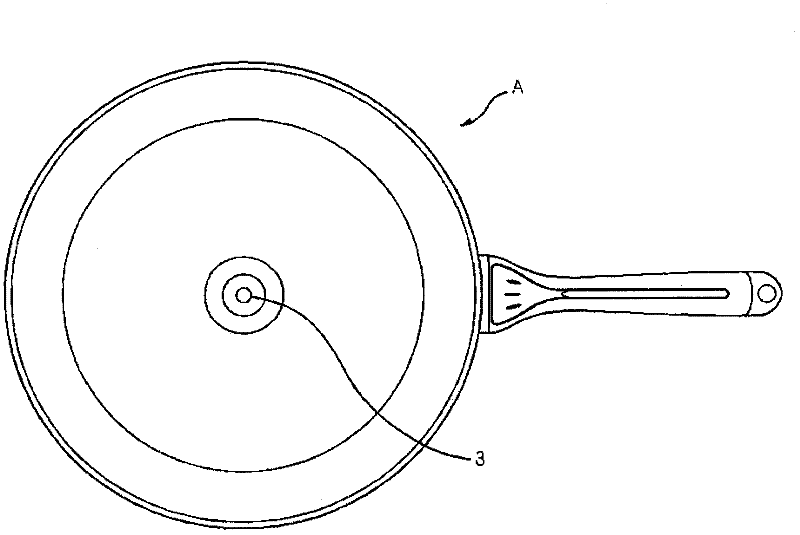

Cooking vessel processing method and cooking vessel provided thereby

InactiveCN102186388AMeet needsWon't fall offCooking-vessel materialsPretreated surfacesCeramic coatingHigh surface

The present invention relates to a cooking vessel processing method and a cooking vessel provided thereby, and more specifically, to a cooking vessel processing method, which involves forming a base-coating layer over a base that is formed at the bottom of the cooking vessel; forming a printing layer over the base-coating layer by pad printing or screen printing; and forming a top-coating layer over the printing layer, and to a cooking vessel provided by the processing method. Conventional cooking vessels commonly use fluorine resin based materials as a non-stick coating material, but they have a weak surface strength (H 2~3) and the coating comes off during use or can be plasticized at high temperature (400? or above), thereby deforming the base materials.; However, a ceramic coating method using a sol-gel technique provides a high surface strength (H 8~9) and a coating provided thereby does not come off even when cleaned with a scrubbing sponge or pad or scraped down by a metal spatula such that a cooking vessel having such a coating can be washed with water and used continuously in a hygienic manner. Further, the coating provided by the sol-gel technique gets plasticized at a low temperature (200? or below), thereby preventing the base materials from being deformed, and the coating is possible over a variety of materials.; In the cooking vessel thus configured according to the present invention, the printing layer formed over the base-coating layer has various patterns, and the color of the printing layer changes depending on a heating temperature being transferred to the cooking vessel, which in turn helps a user determine the temperature being transferred to the cooking vessel with the naked eye. In addition, the top-coating layer formed over the base-coating layer contains a blend of magnetic elements such as iron, magnesium, cobalt and the like, and displays various patterns on the top of the cooking vessel depending on the angle of view and attracts the interest of users.

Owner:河相薰

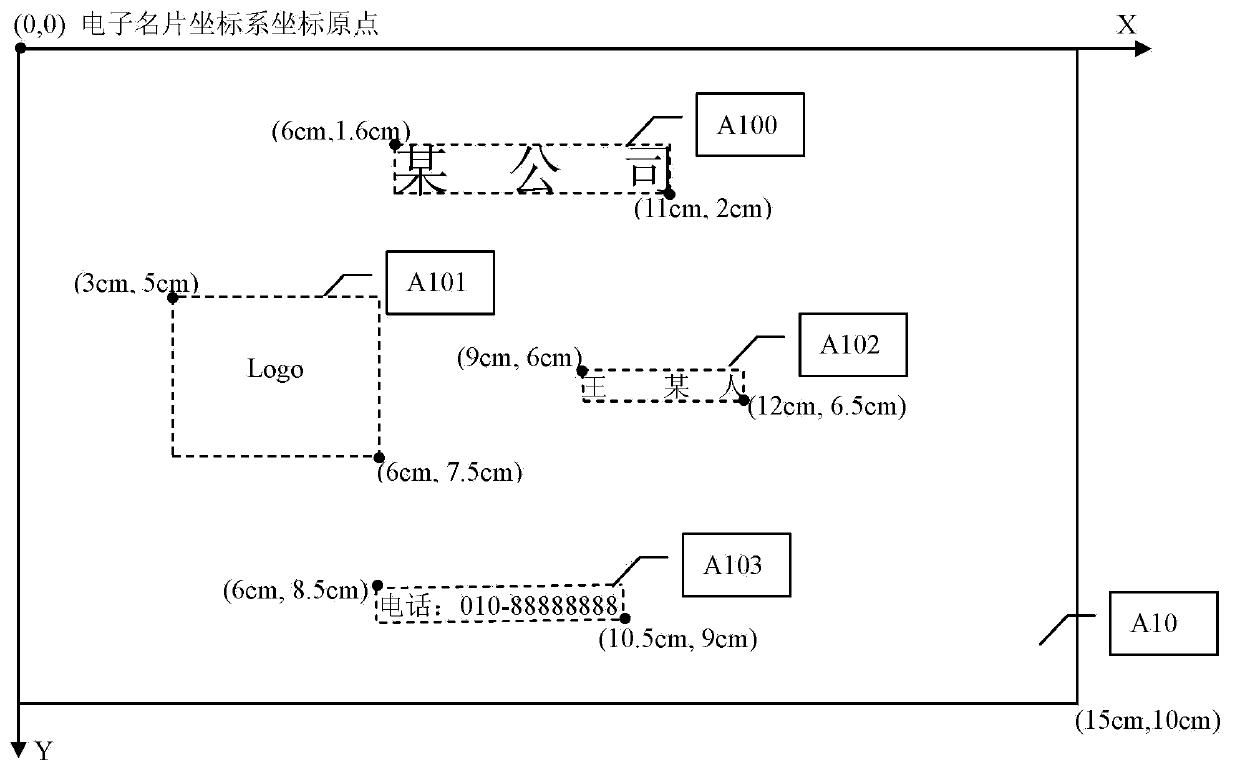

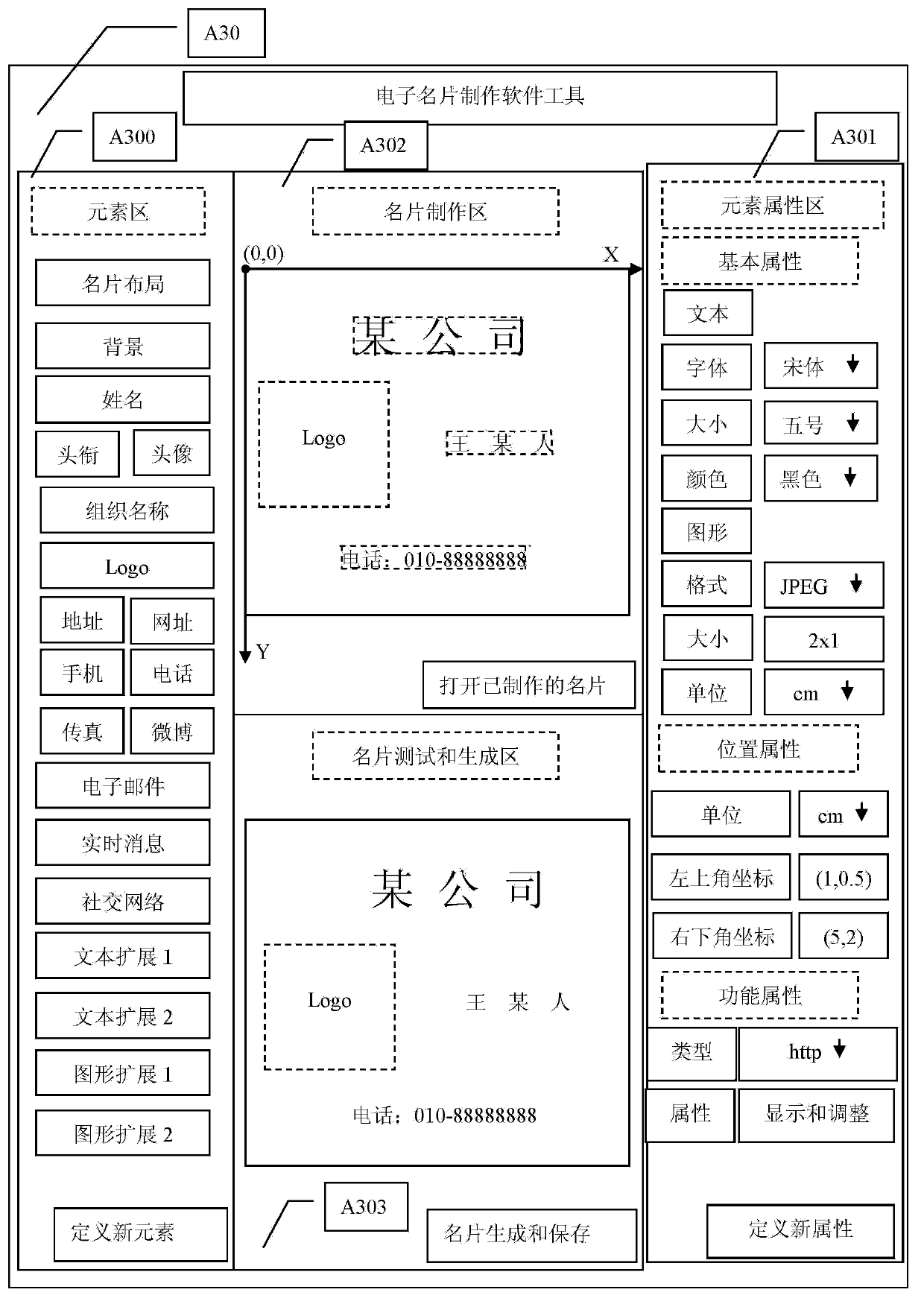

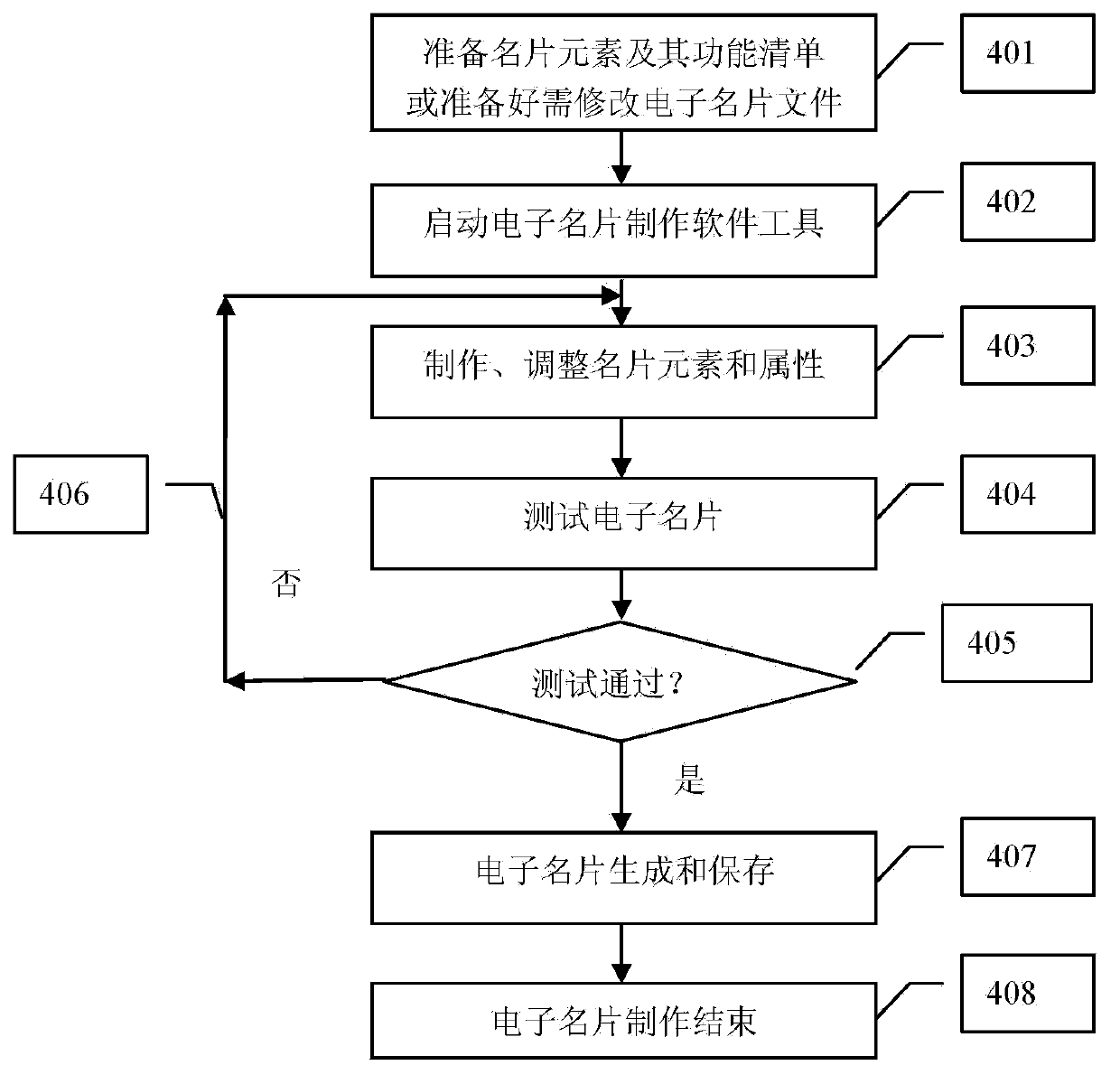

Novel electronic business card manufacture, display and use method

InactiveCN103870265APromote conversionElement function activationSpecific program execution arrangementsInput/output processes for data processingBusiness cardSoftware engineering

The invention discloses a novel electronic business card manufacture, display and use method. The electronic business card comprises the content of a rich, integral and an expandable business card element as well as the attributes, such as the position and the function of the business card element. The novel electronic business card manufacture is that an electronic business card which approaches to the effect of a true paper business card can be precisely and vividly manufactured by a manufacture software tool operated on a smart device; the regional position of each business card element is precisely identified by leading in a coordinate system; the element function corresponding to each regional position is defined and is finally stored as electronic business card data; the novel electronic business card display is that the visible element content and layout of the electronic business card can be precisely and vividly displayed after electronic business card data is read by a display and use software tool operated on the smart device, and attributes, such as invisible but activatable element positions and functions, are hidden; the electronic business card use is that a specific element area is trigged by a man-machine interaction event to immediately activate a corresponding element function when the electronic business card is displayed on the smart device.

Owner:北京米时科技股份有限公司

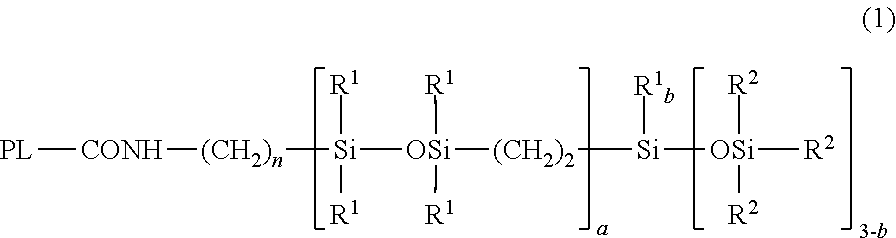

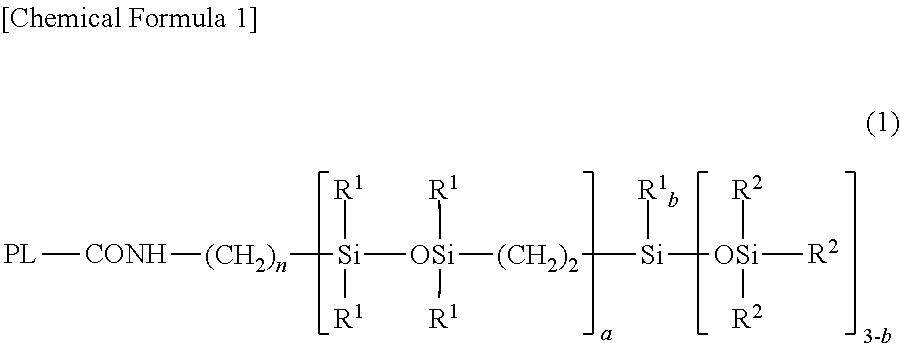

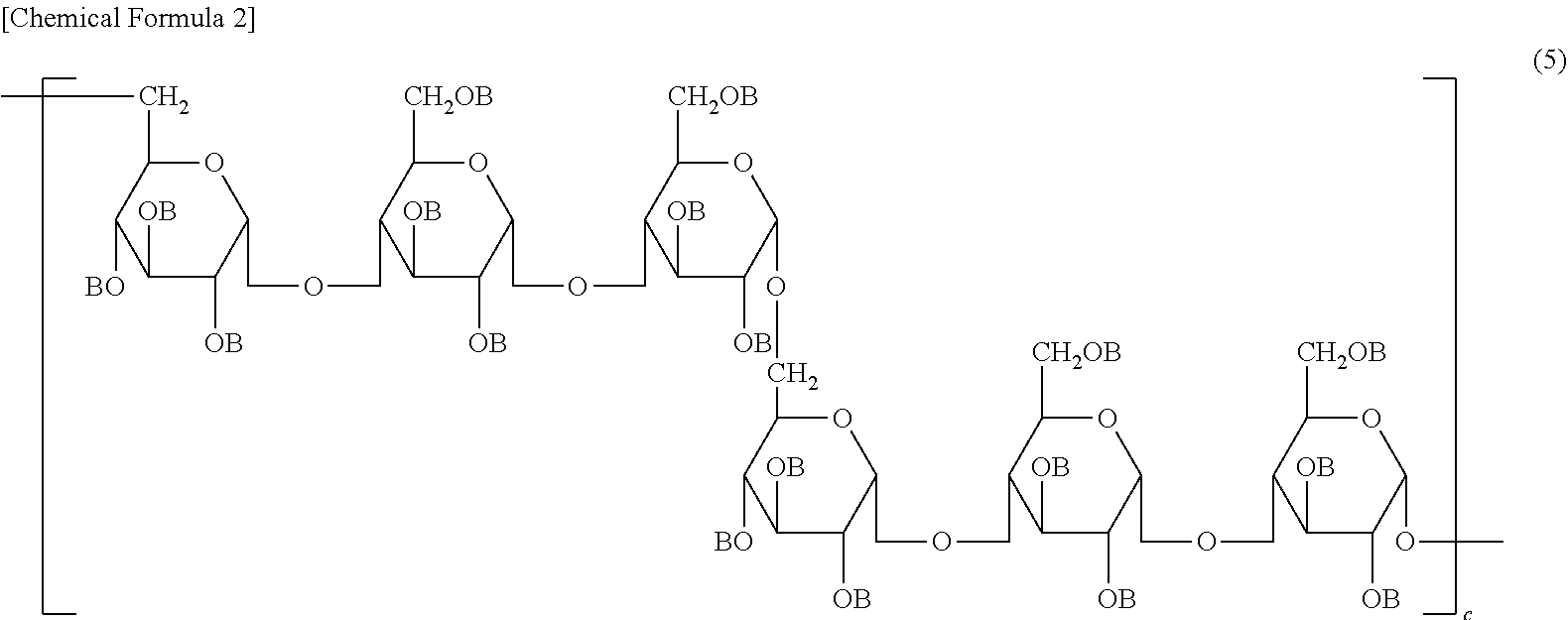

Oil-based thickening agent, oil-based thickening composition, and cosmetic preparation

InactiveUS20160113860A1Good thickening effectInadequate tackinessCosmetic preparationsHair cosmeticsPullulanGlucose polymers

Provided are: an oil-based thickening agent which is capable of providing an oil-based composition that has a high thickening effect on an oil component such as a silicone oil, while achieving excellent feeling of use; an oil-based thickening composition which contains this oil-based thickening agent and a liquid oil component; and a cosmetic preparation in which this oil-based thickening agent or oil-based thickening composition is blended. An oil-based thickening agent which is composed of a silicone-modified polysaccharide compound represented by formula (1) and a silicone emulsifying agent.(In the formula, PL represents a glucose residue of pullulan; R1 represents a monovalent hydrocarbon group having 1-10 carbon atoms; R2 represents a monovalent hydrocarbon group having 1-10 carbon atoms or a siloxy group represented by —OSi(R3)3; R3 represents a monovalent hydrocarbon group having 1-8 carbon atoms; n is an integer of 1-10; a is 0 or 1; and b is 0, 1 or 2. The average number of bonded silicone compounds (substitution degree of silicone compounds) per one constituent sugar unit of the polysaccharide compound is 0.5-2.5; and the average molecular weight of the silicone-modified polysaccharide compound is 50,000-10,000,000.)

Owner:SHIN ETSU CHEM IND CO LTD

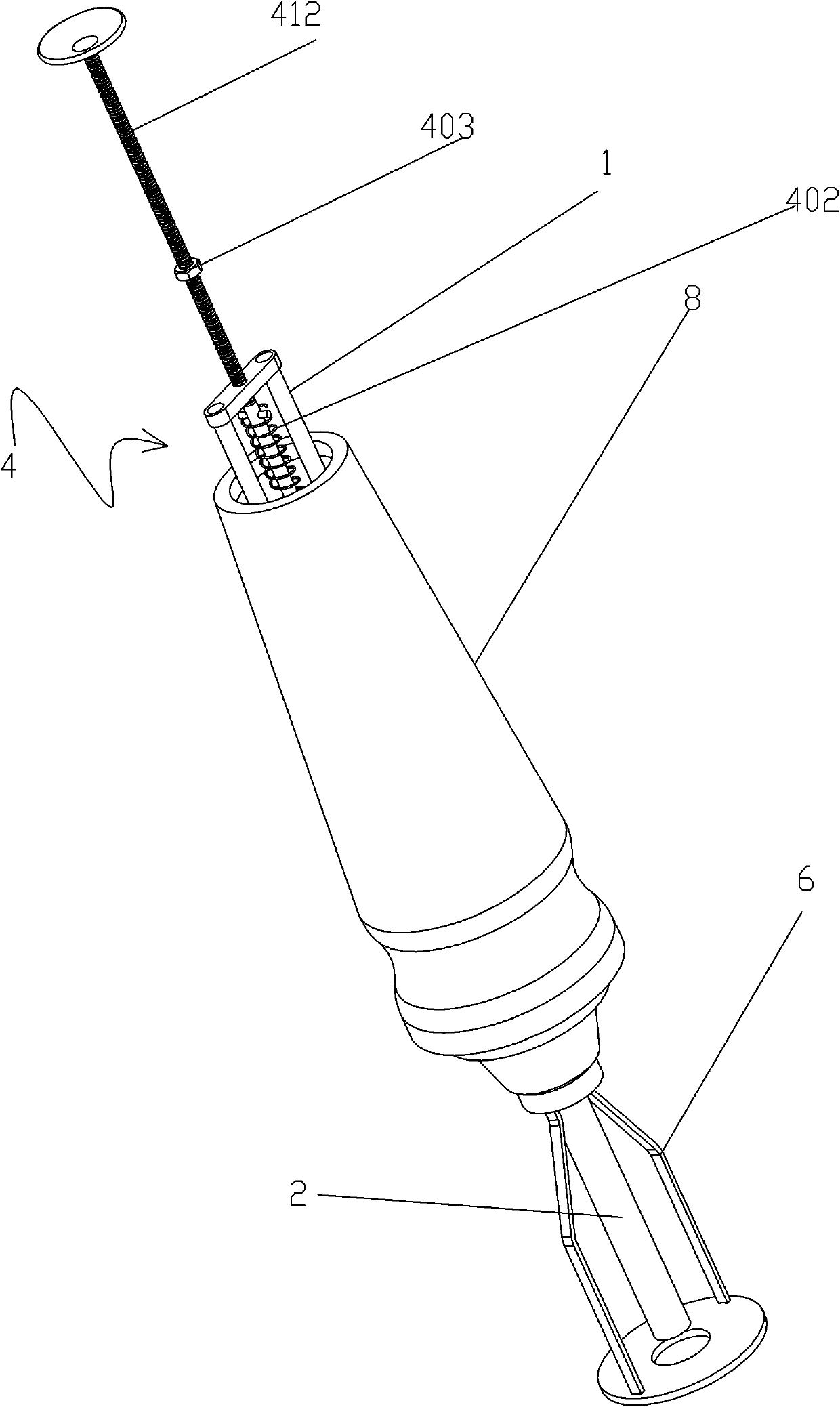

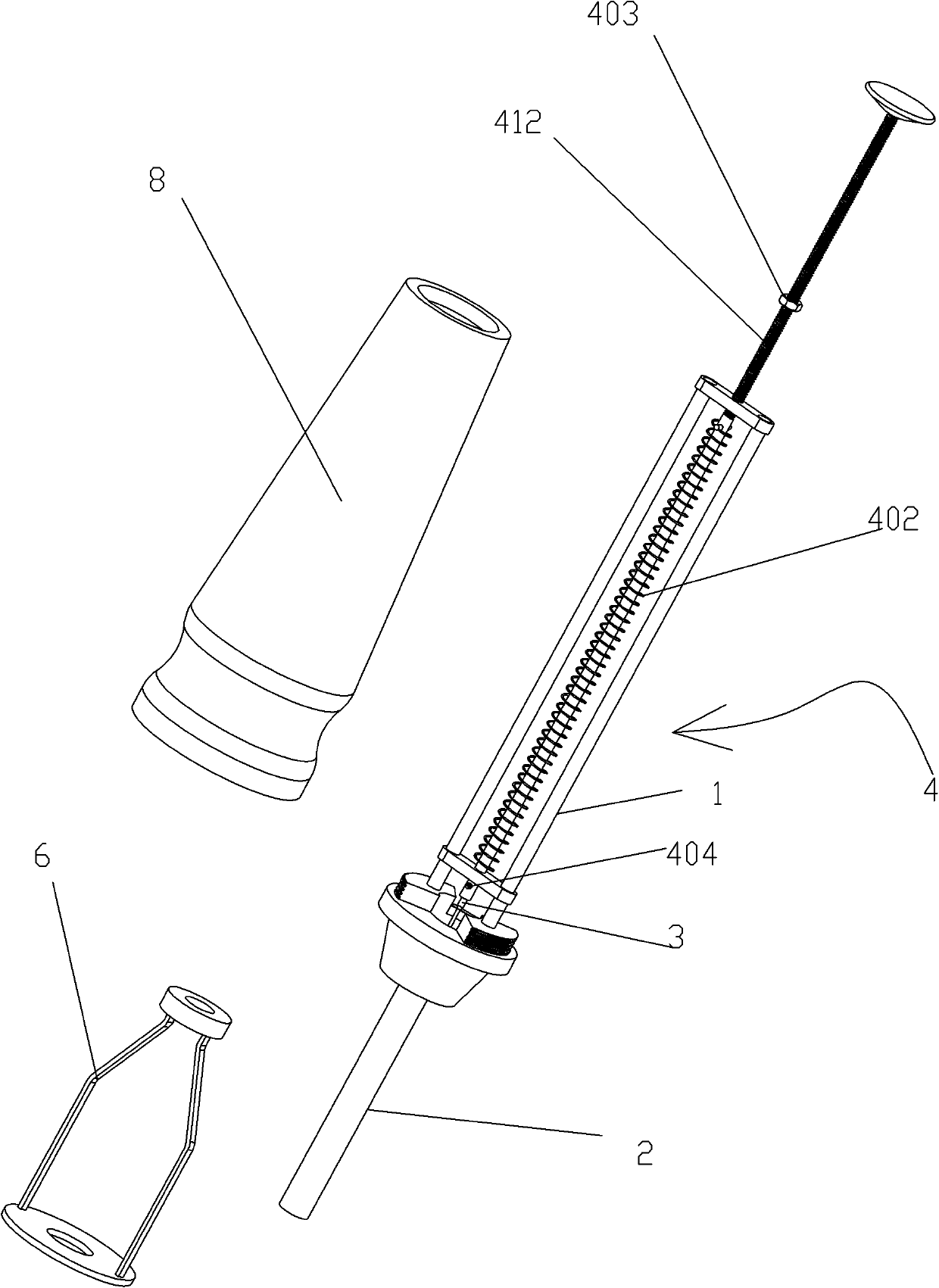

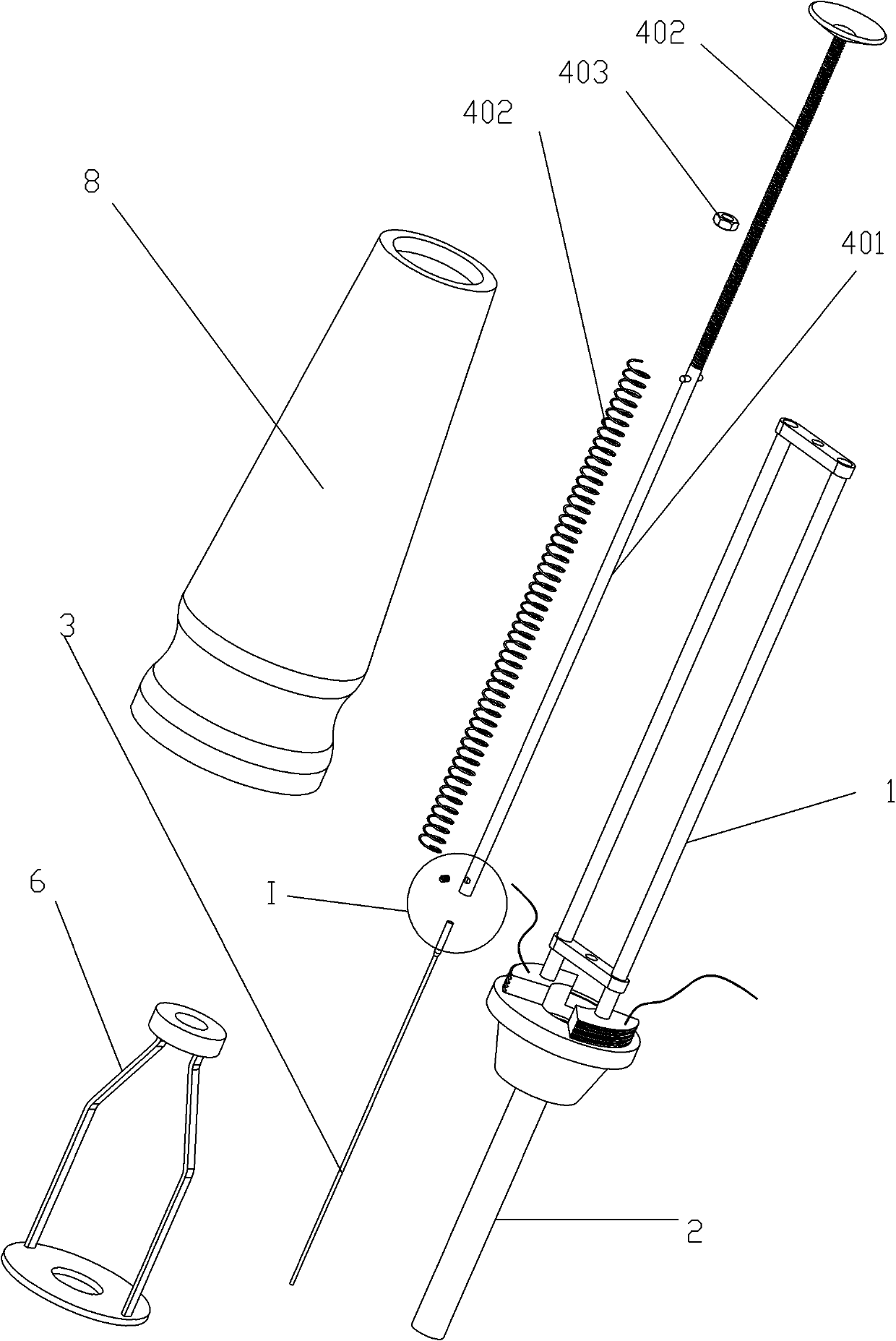

Electric fire needle

InactiveCN102178599ACompact structureSuperior performance, stable and reliableDevices for heating/cooling reflex pointsAcupunctureEngineeringNeedle insertion

The invention discloses an electric fire needle that is characterized by comprising a support. The front end of the support is provided with a heating sleeve, the heating sleeve is internally provided with a fire needle hole and an electric heating device; the fire needle is inserted in the fire needle hole, and the support is provided with a pushing device for pushing the fire needle to extend out of the front end of the heating sleeve. The aims of the invention are to overcome the defects of the prior art and provide an electric fire needle that is simple in structure, convenient to use andcapable of retaining stable temperature, and facilitates exactly finding the position of needle insertion and controlling the depth of needle insertion.

Owner:广东恒一电子科技有限公司

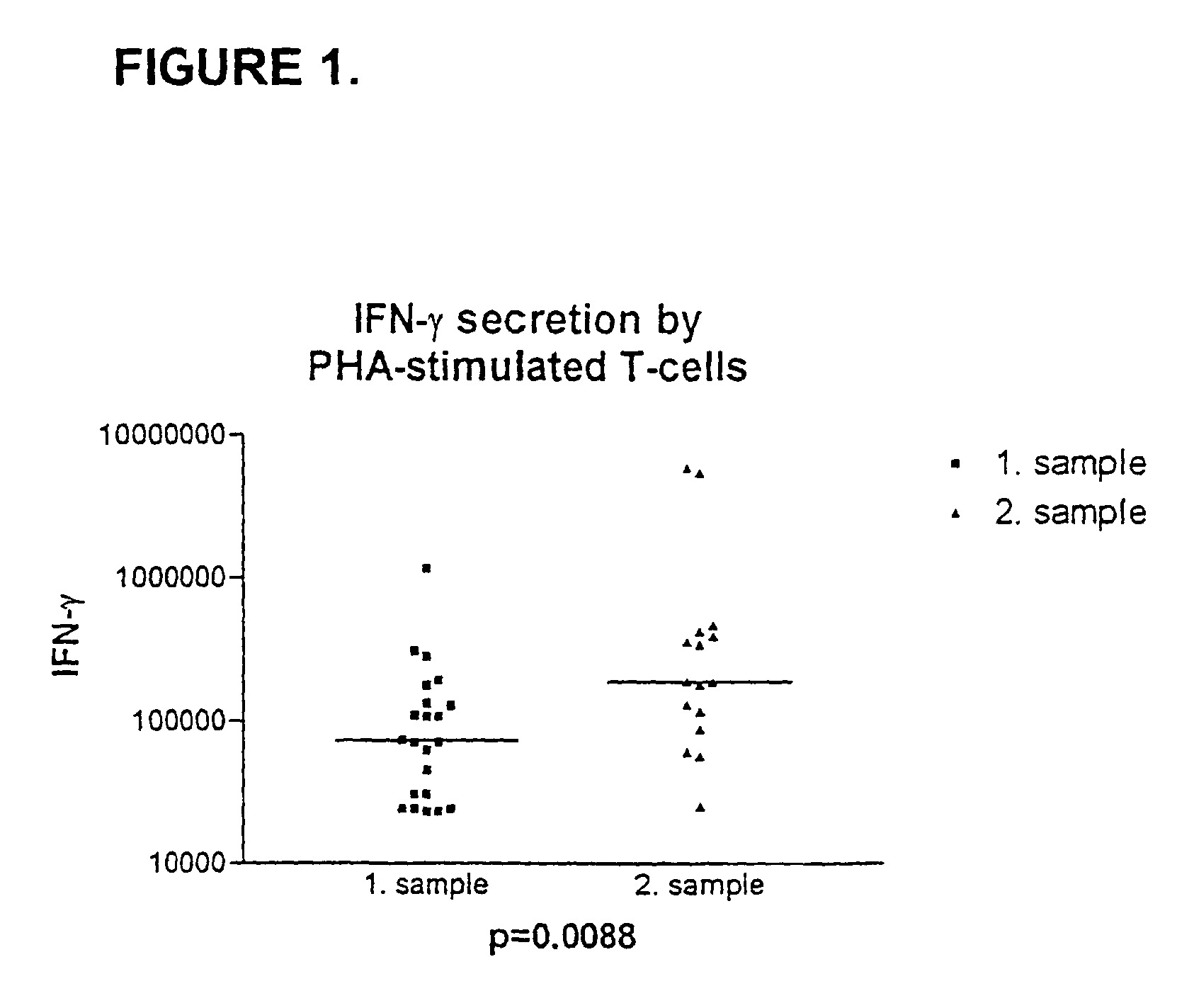

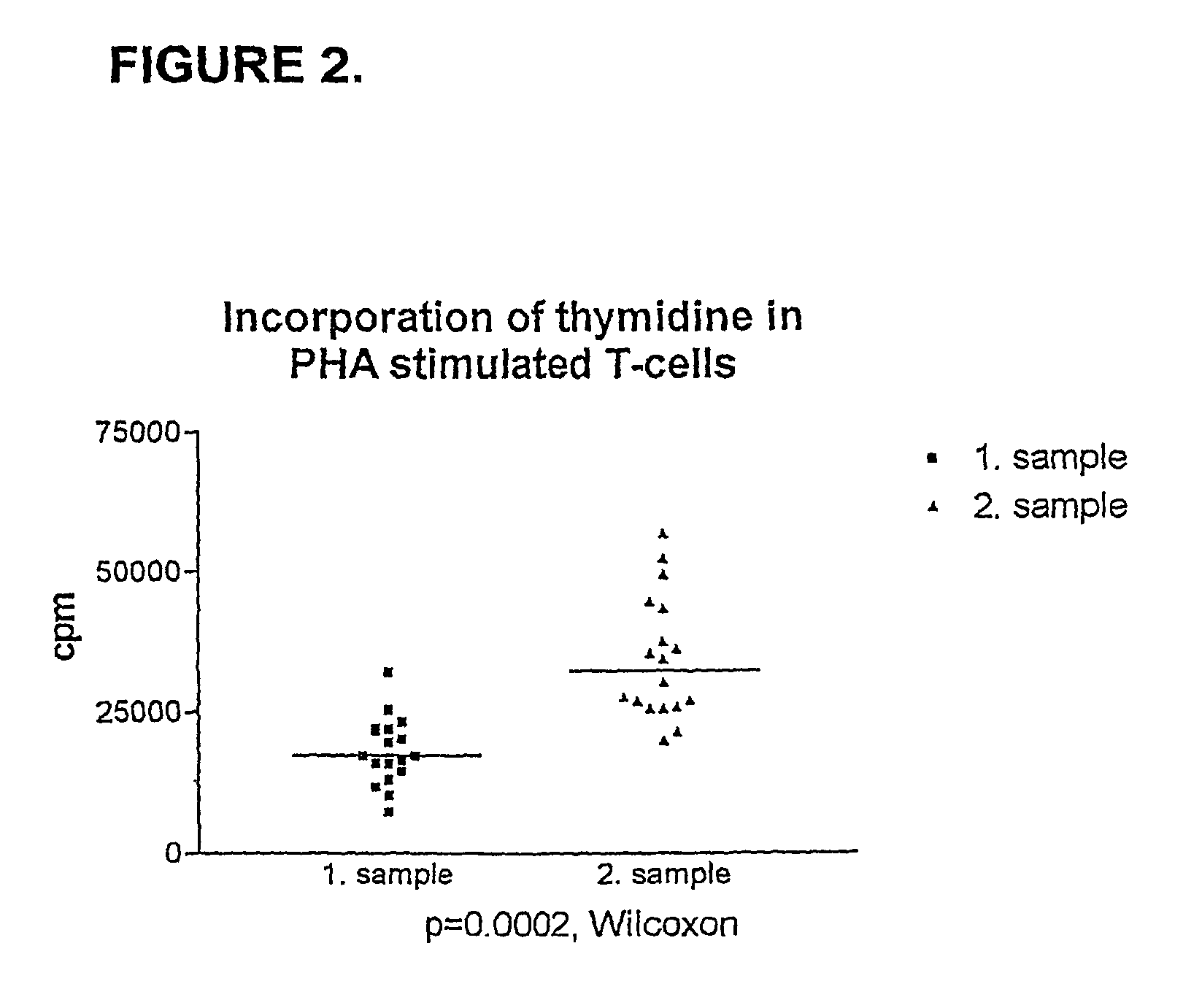

Combination of probiotics

ActiveUS8309073B2Happy to useHealthy for consumerAntibacterial agentsBiocideBiotechnologyBifidobacterium

The invention relates to a probiotic combination comprising different combinations of lactobacilli, propionic acid bacteria and / or bifidobacteria. The probiotics are preferably combined with a suitable prebiotic to form a synbiotic. The combination of the invention can be consumed as such or combined with a suitable foodstuff or pharmaceutical product, and it is therapeutically useful for example for stimulating the immune system and for general health improvement.

Owner:CHR HANSEN AS

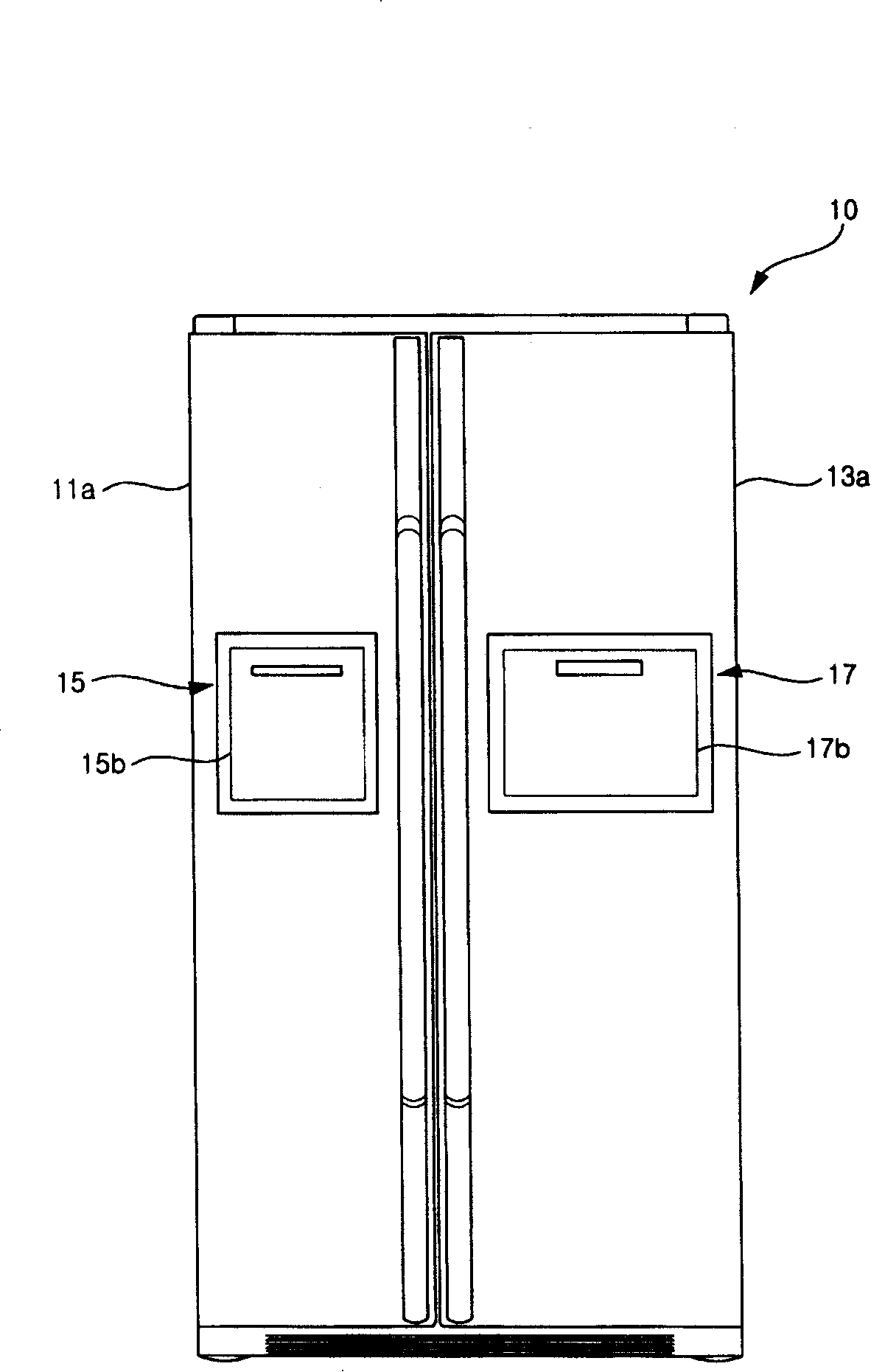

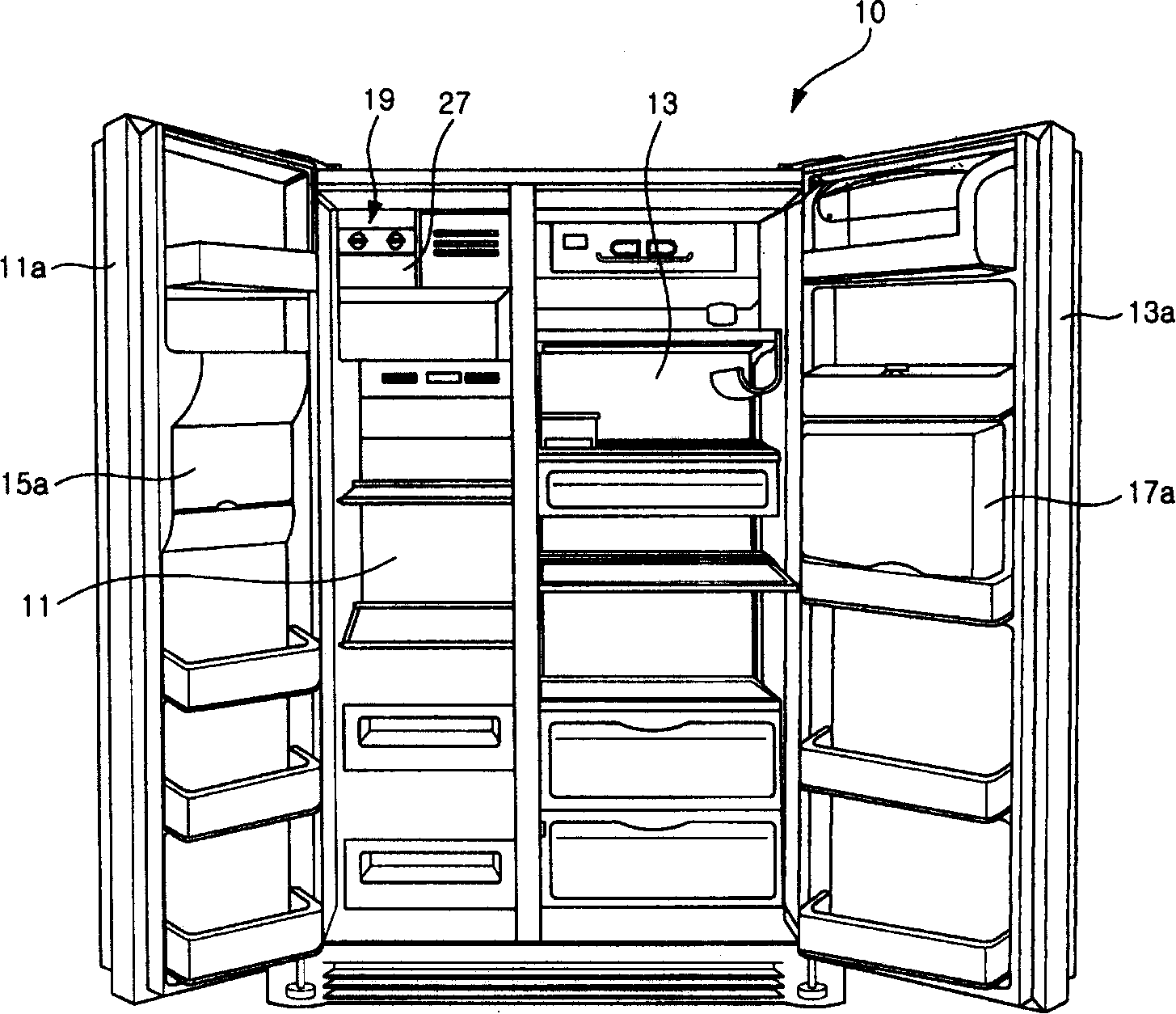

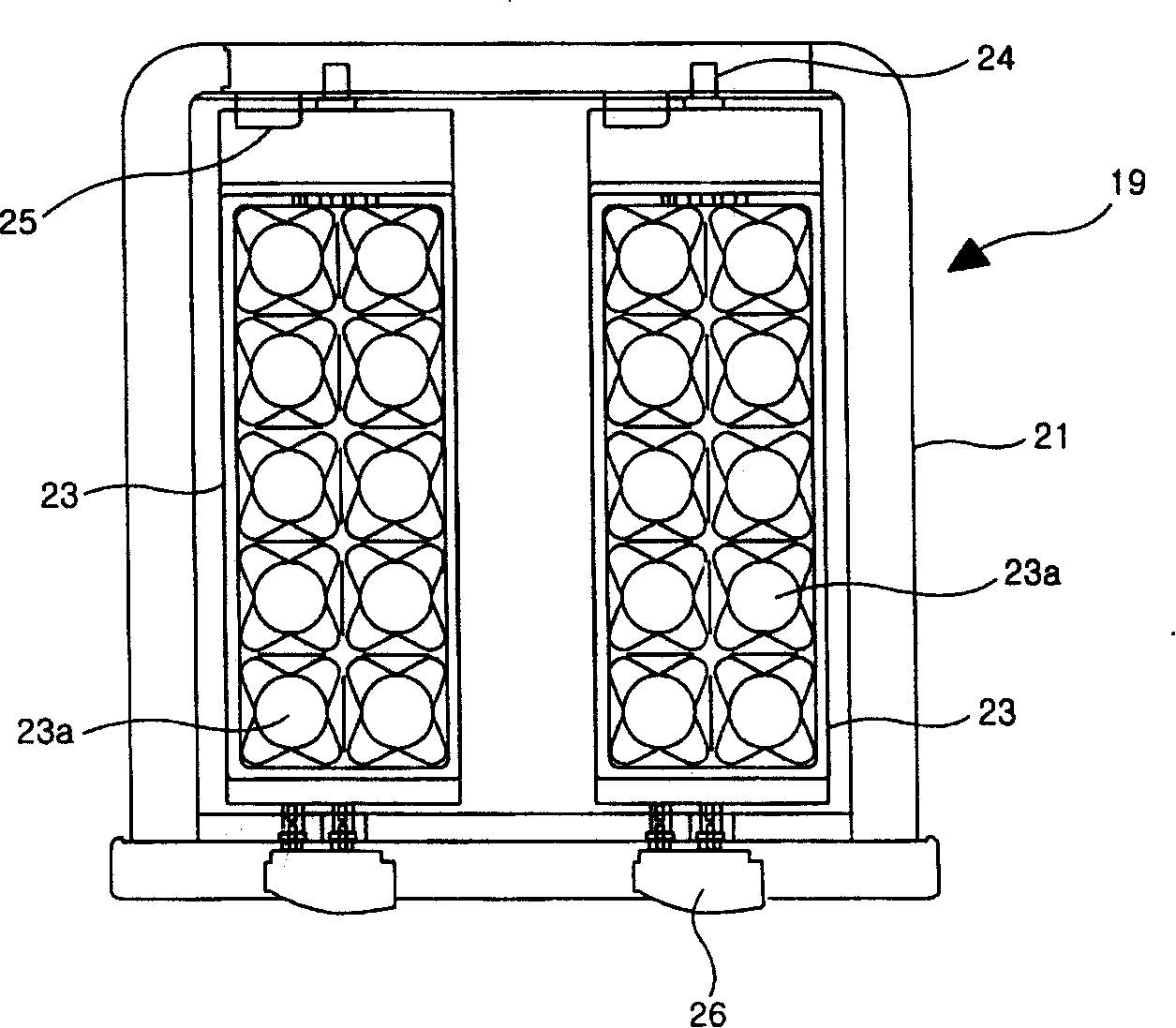

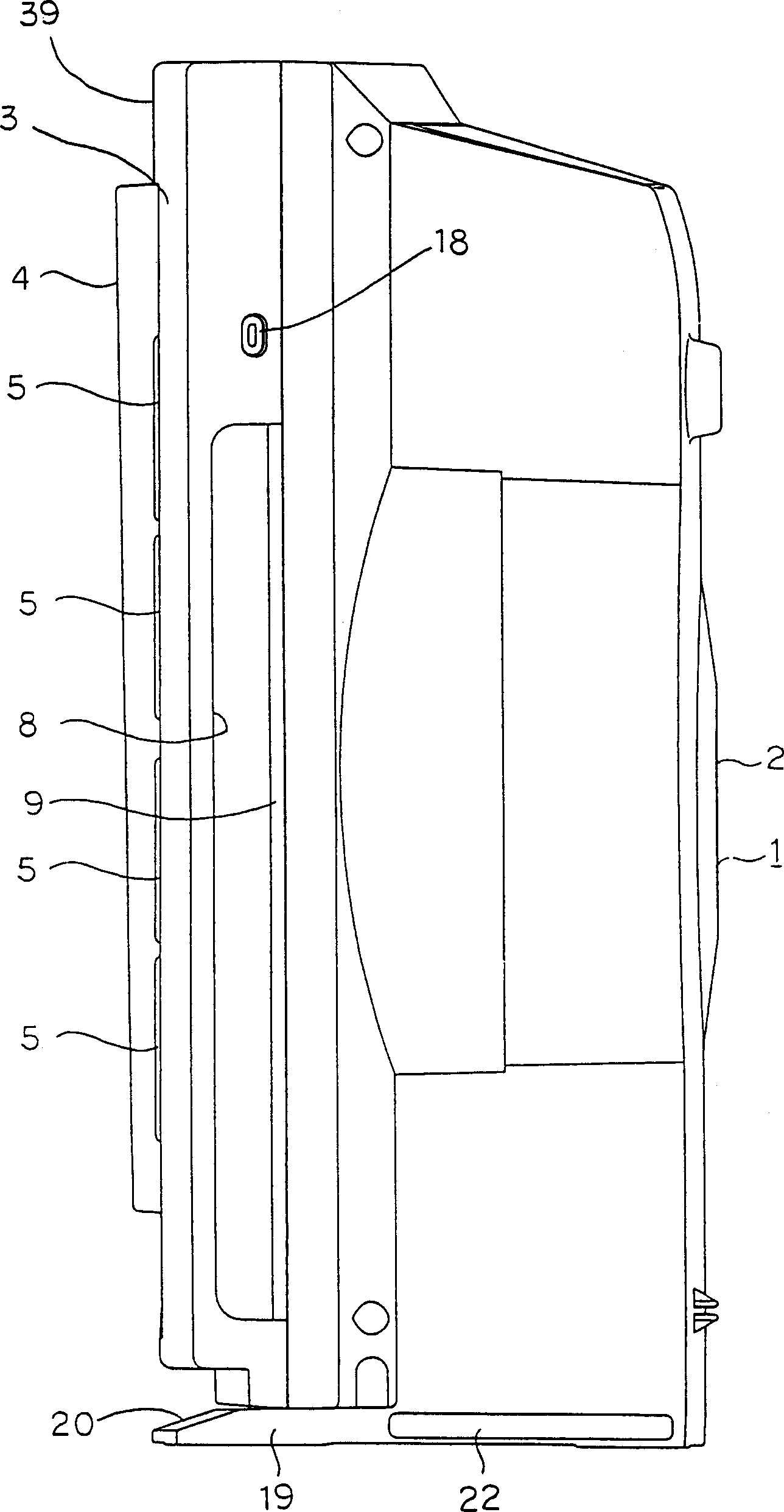

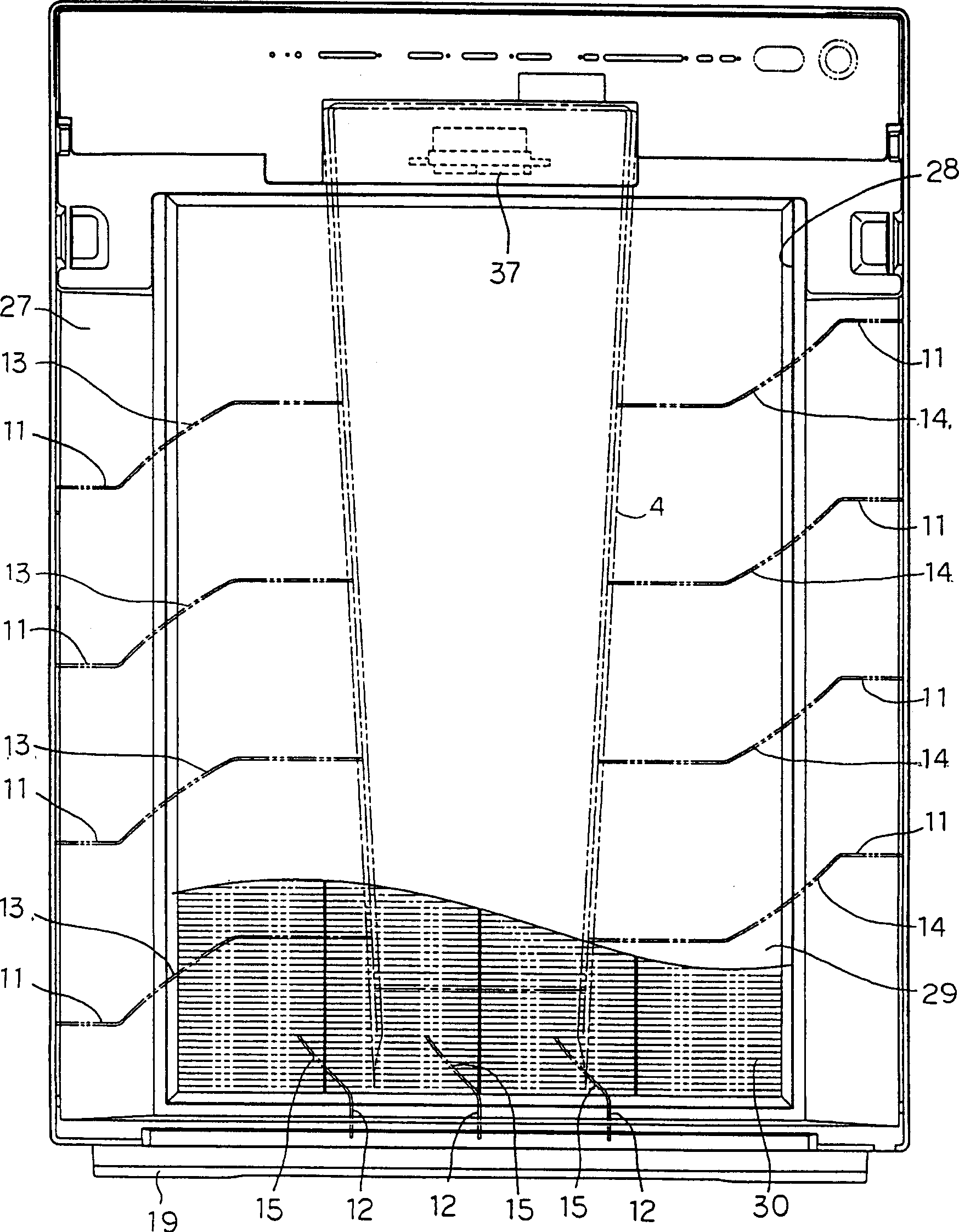

Ice-making apparatus for refrigerator

InactiveCN101231090APrevent water flowPrevent outflowDomestic cooling apparatusLighting and heating apparatusRefrigerated temperatureFreezing chamber

The invention relates to an ice-making device of a refrigerator. In the invention, a first ice-making device casing and a second ice-making device casing are arranged inside a freezing chamber door for opening and closing the main freezing chamber of the refrigerator, mounting space is formed between a door frame inside the freezing chamber door and the top surface of the first ice-making device. A water tank is disassembly arranged inside mounting space, and water storage space of the water tank stores water. The water which is stored in the water storage space is selectively supplied into an ice-making plate which is positioned in the arrangement space of the casing of the first ice-making device under the effect of a valve arranged on the bottom surface of the water tank and used for making ice. Moreover, the ice blocks which are produced by the ice-making plate are stored in an ice block storage device which is arranged in the second ice-making device casing. The invention can cause the ice-making to be cleaner and more hygienic.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

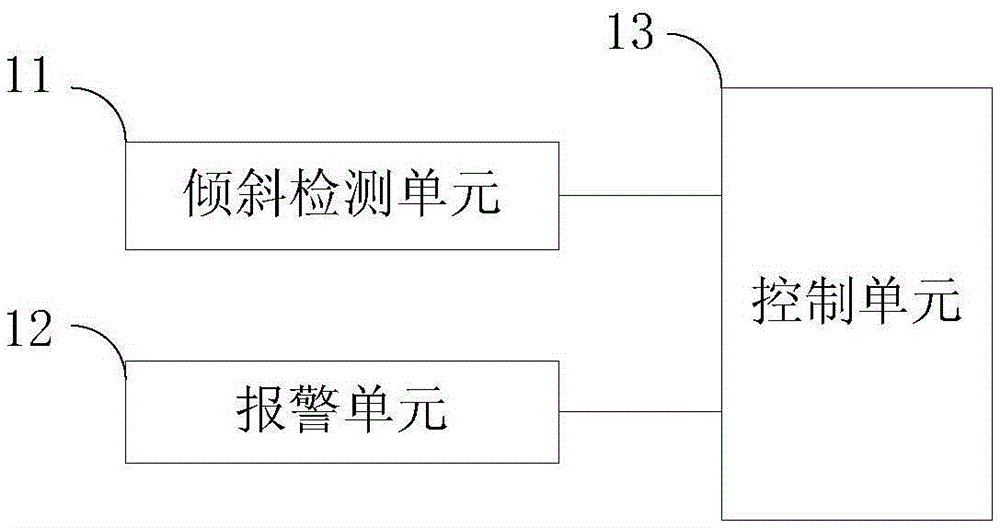

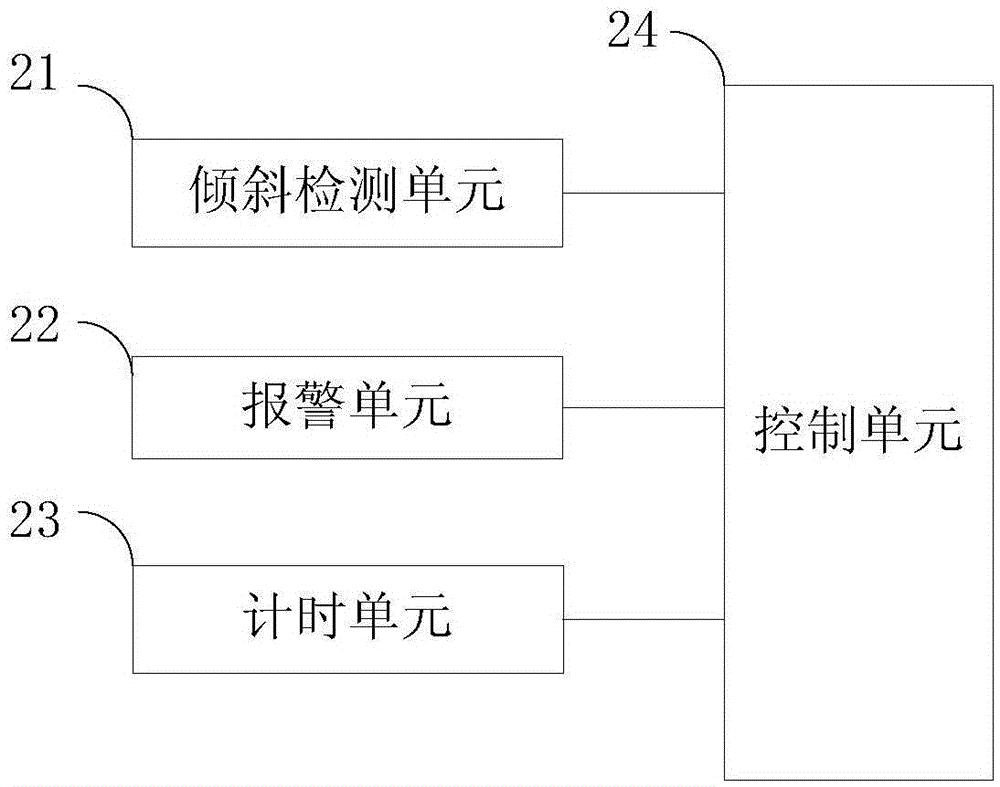

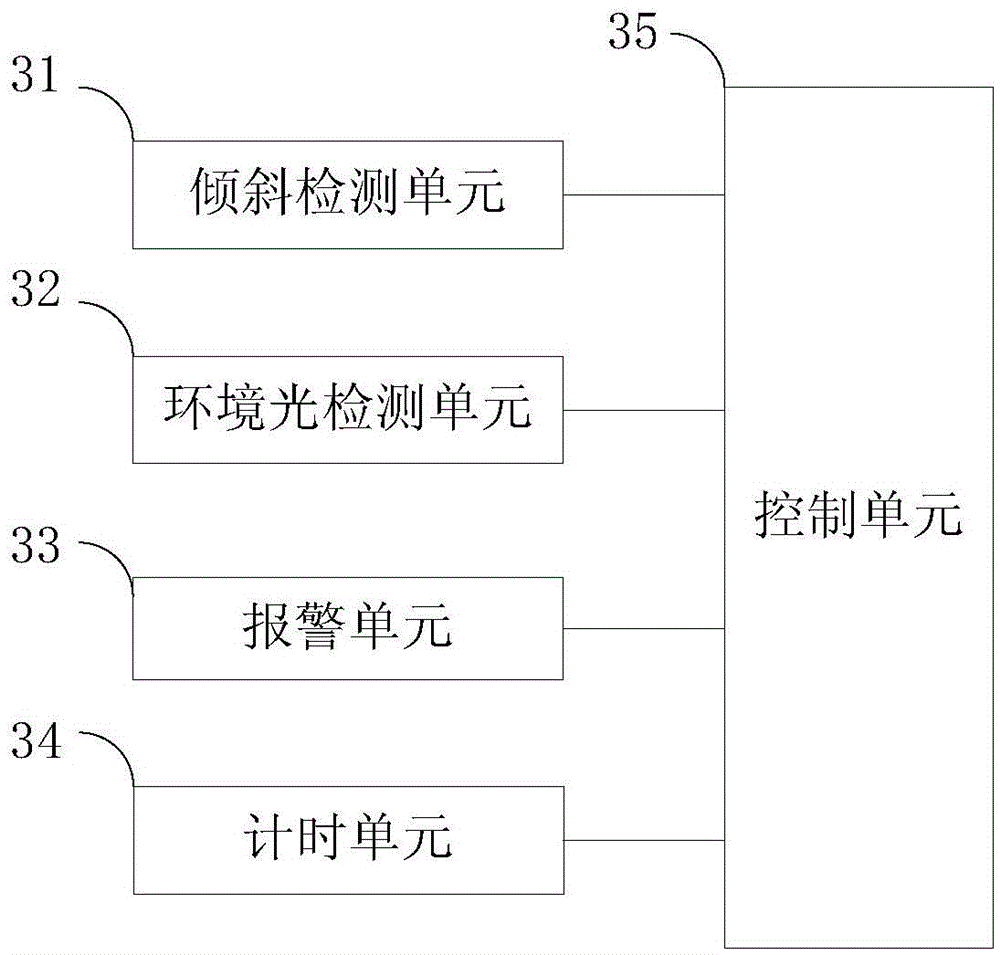

Intelligent glasses

The invention discloses intelligent glasses. The intelligent glasses comprise an inclination detection unit, an alarm unit and a control unit, wherein the inclination detection unit is used for detecting the inclination degree of the intelligent glasses so that an inclination angle can be obtained; the alarm unit is used for giving out an alarm signal; the control unit is connected with the inclination detection unit and the alarm unit and used for judging whether the inclination angle is greater than a preset angle threshold value or not, and when the inclination angle is greater than the preset angle threshold value, the control unit controls the alarm unit to give out the alarm signal. The intelligent glasses can be directly worn on the head of a student, the space of a desk or a chair does not need to be occupied, and the intelligent glasses are not limited by the height of the desk or the chair and are convenient to use; in addition, the inclination detection unit is adopted, therefore the precise inclination angle can be detected, the intelligent glasses are not limited to only height detection, and thus the intelligent glasses have the advantages of being wide in detection range and high in alarm accuracy; in addition, the intelligent glasses further have the advantages of being simple in structure, convenient to carry, low in cost and easy to apply and popularize.

Owner:LE SHI ZHI ZIN ELECTRONIC TECHNOLOGY (TIANJIN) LTD

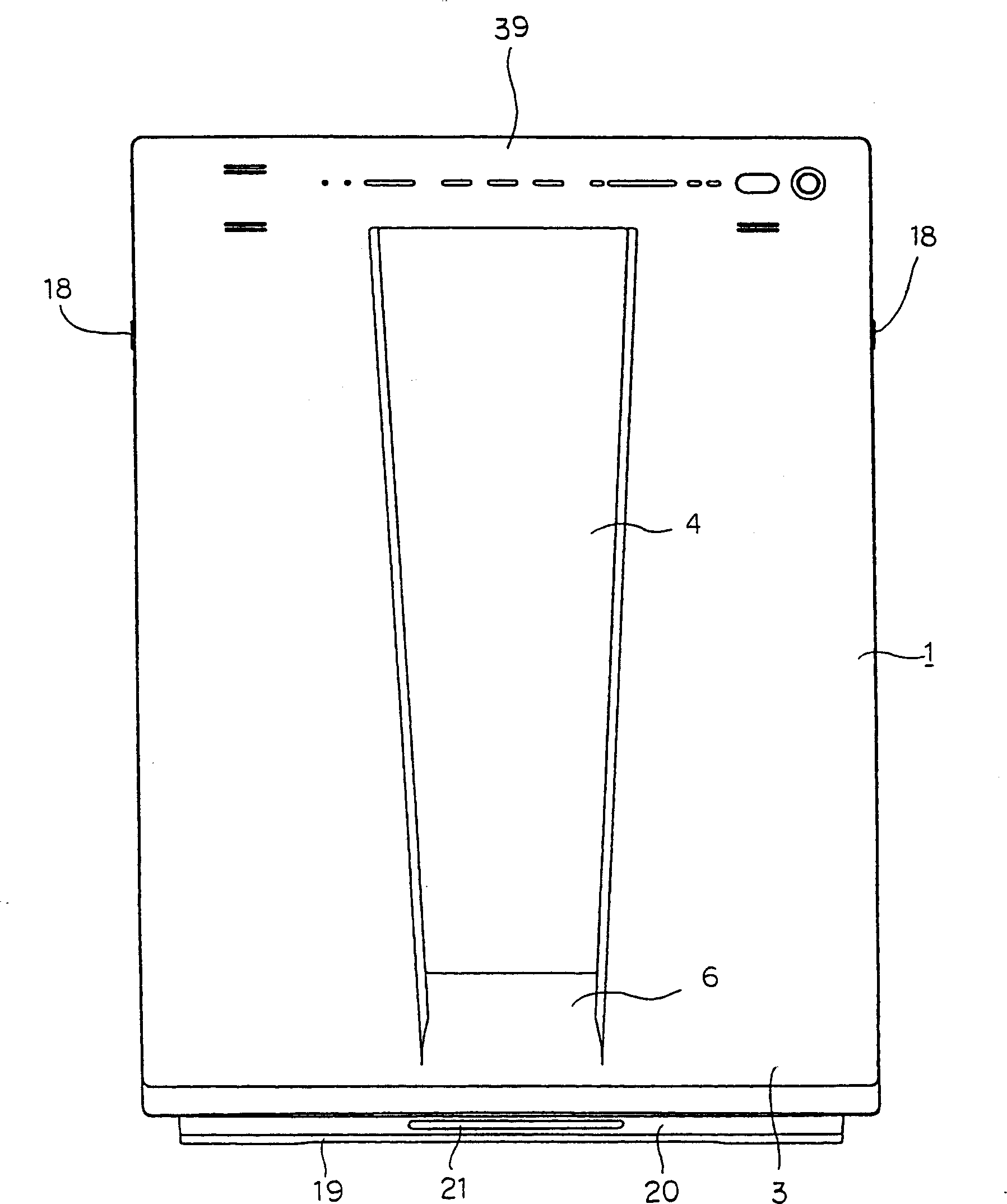

Air cleaner

InactiveCN1480223AHappy to useLarge-scale removalDispersed particle filtrationLighting and heating apparatusEngineeringAir cleaners

In this air cleaner, air sucked into a body case 1 is purified by a prefilter 29, the dust collecting filter 30 and a deodorizing filter 31, and is blown outside the body case 1. In the air cleaner, ozone is generated by an ozonizer 37 provided on the windward side of the prefilter 29, and is diffused on the windward side of the prefilter 29. The air sucked into the body case 1 is guided upward on the windward side of the prefilter 29 by a first guidance part 13, and is guided downward on the windward side of the prefilter 29 by a second guidance part 14 provided opposite to the first guidance part 13. Thereby, by diffusing ozone all over the whole face on the windward side of the filter, the miscellaneous germs adhering to the filter can be extensively sterilized, and adsorbed bad smell components can be extensively removed.

Owner:SANYO ELECTRIC CO LTD

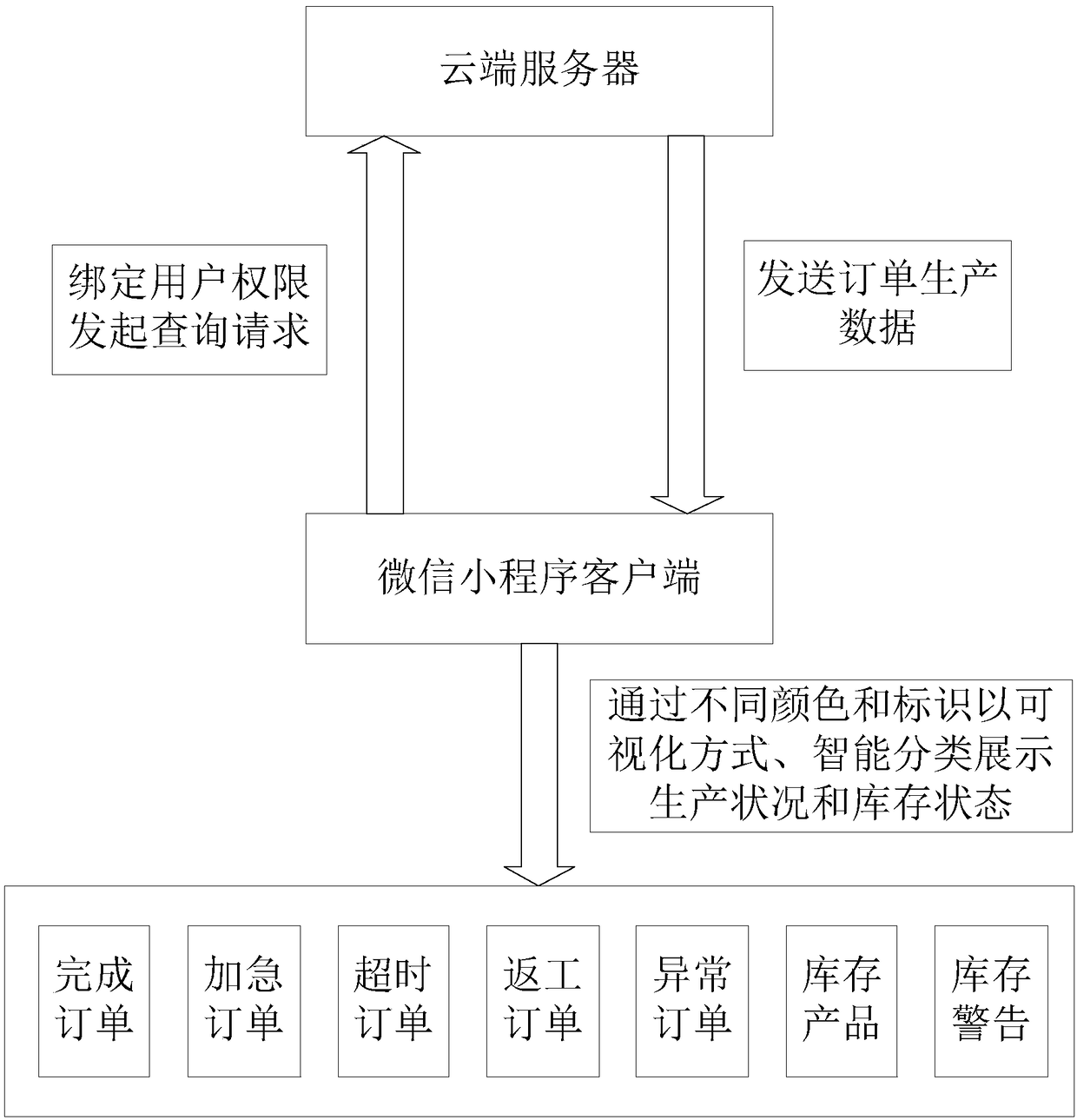

Intelligent classification display order production management board based on WeChat

InactiveCN108346018AHappy to useDynamically understand the order production progressLogisticsOther databases browsing/visualisationDisplay OrderClient-side

The invention discloses an intelligent classification display order production management board based on WeChat. The board comprises a WeChat applet client and a cloud server. The WeChat applet clientbinds a WeChat software user and a corresponding production management authority through a WeChat code scanning mode and responds to the login request and the order production data query request of the WeChat software user to the cloud server, acquires order production data from the cloud server and intelligently classifies and displays all production states and inventory states through differentcolors and identifications by a visualization mode. The cloud server receives the order production data query request forwarded by the WeChat applet client, confirms a production management authoritycorresponding to a user identity by using the order production data query request and outputs order production data corresponding to the production management authority to the WeChat applet client.

Owner:吴展

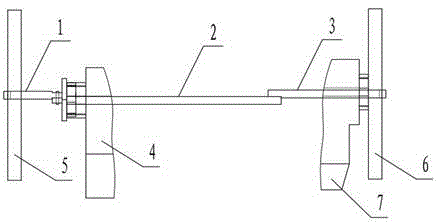

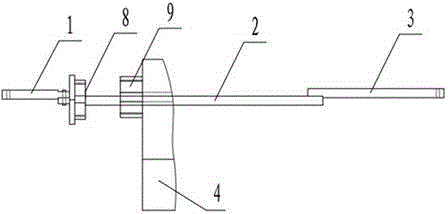

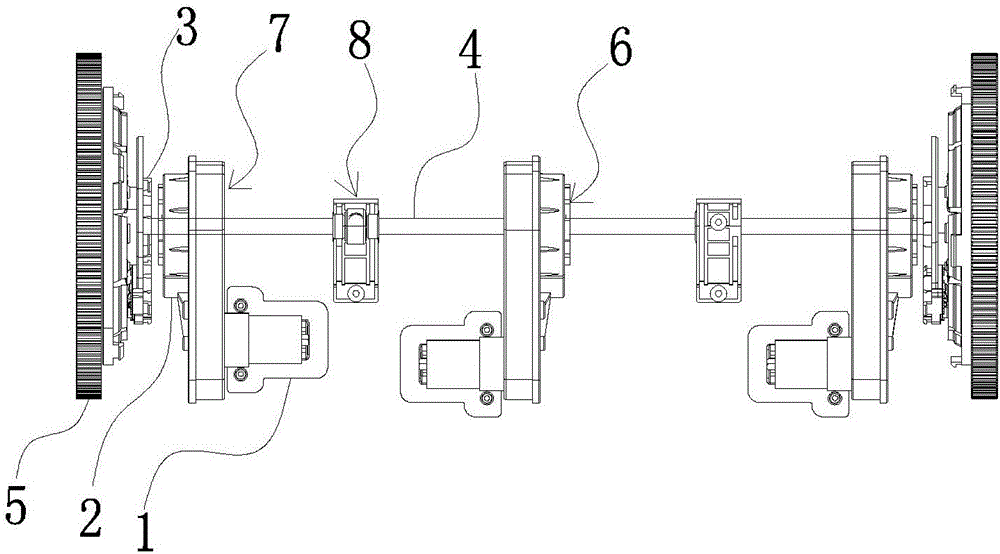

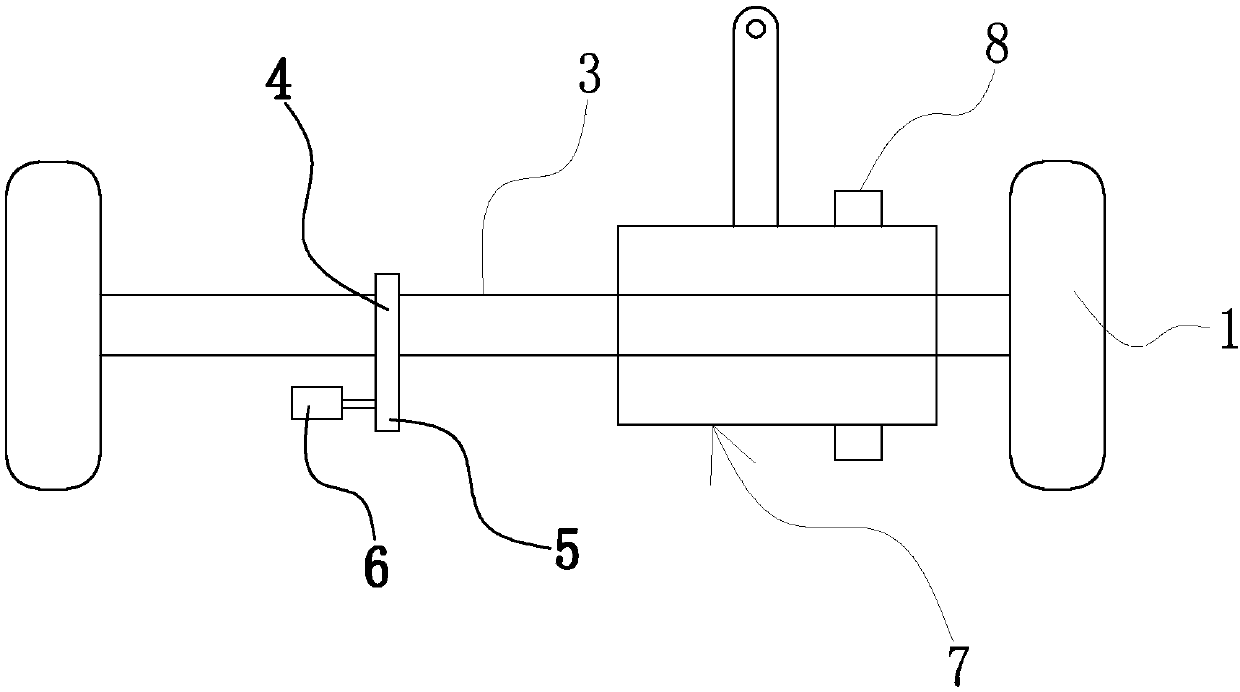

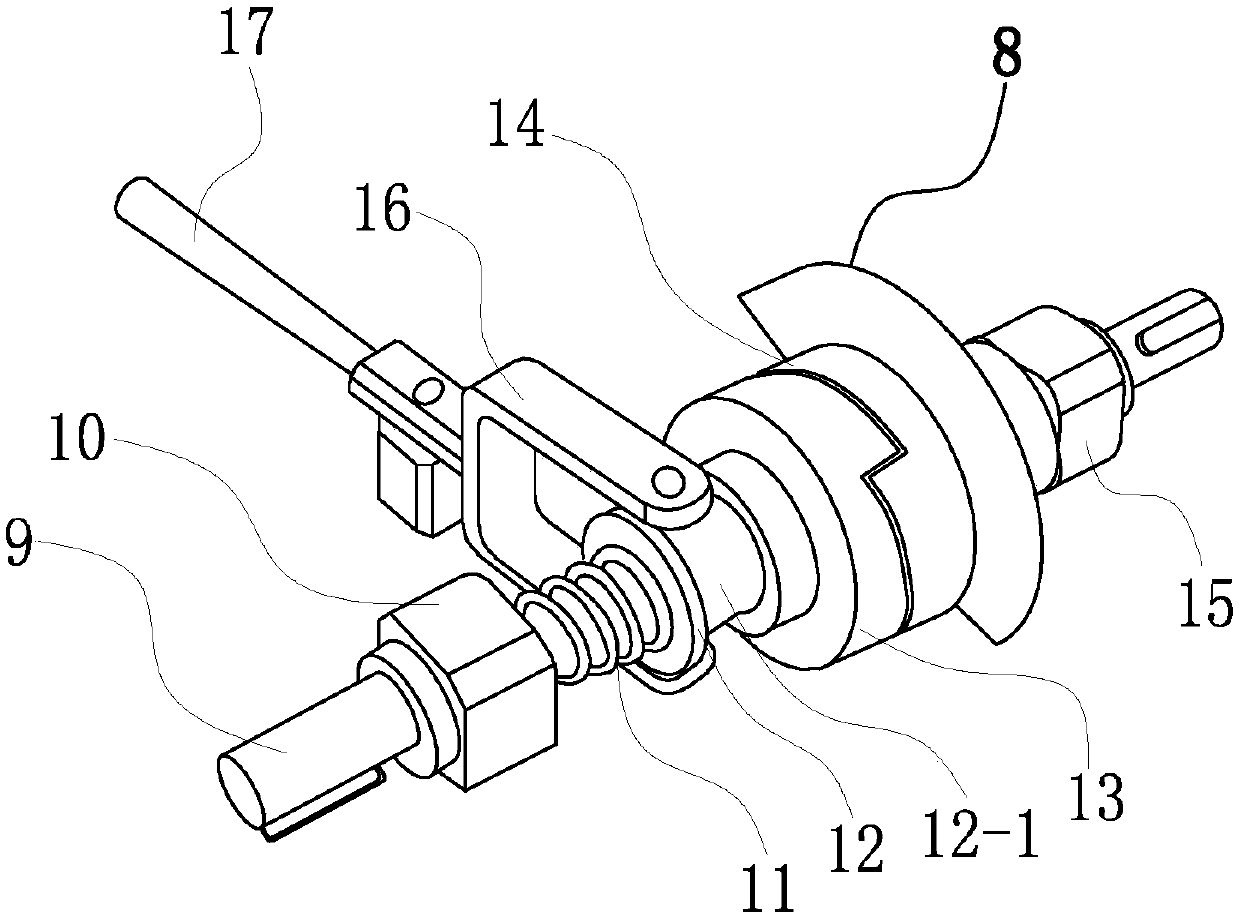

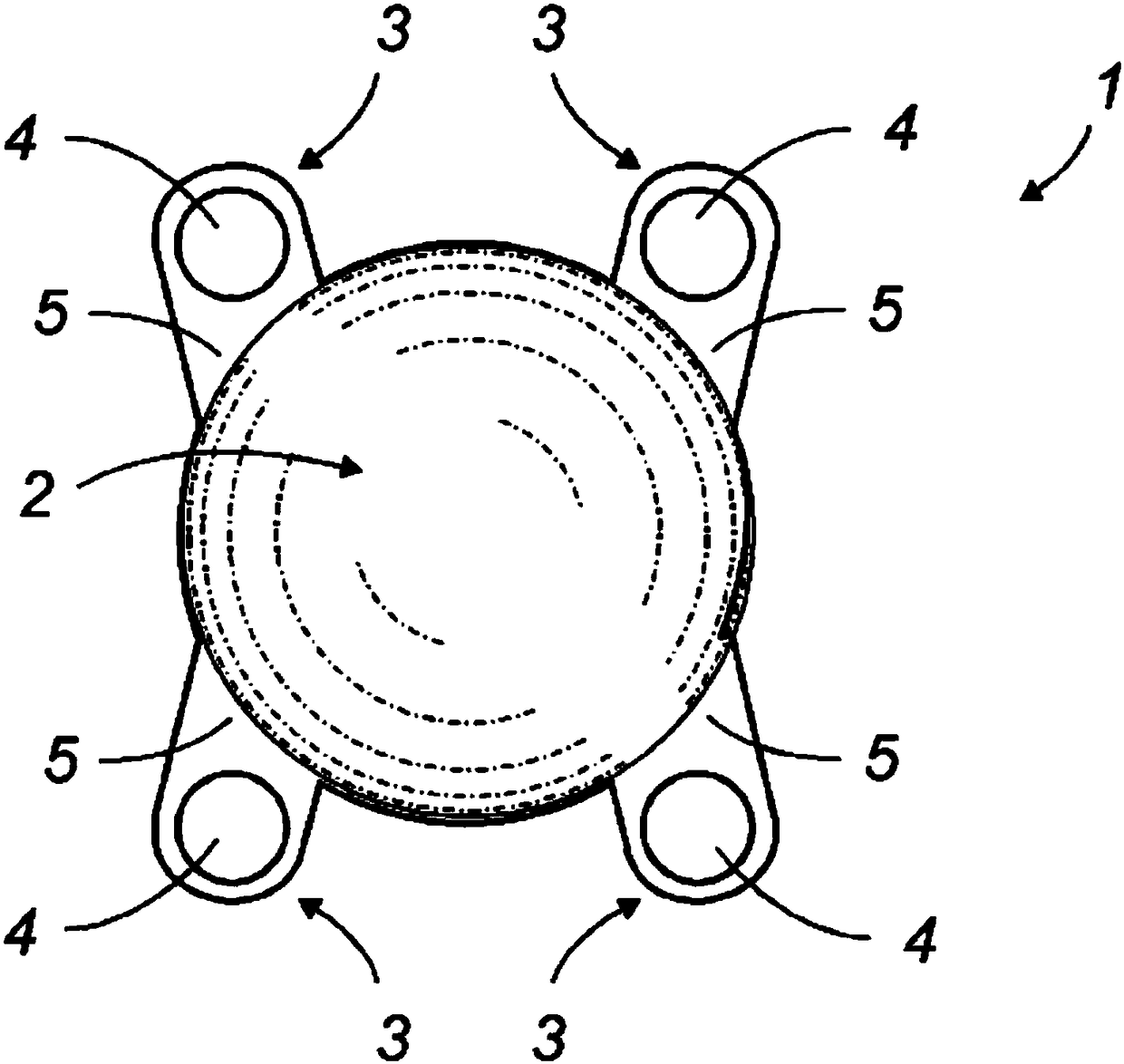

Mechanism for allowing electric baby carriage to have swinging function

ActiveCN104802845AWith swing functionHappy to useCarriage/perambulator accessoriesWheel and axleMechanical engineering

The invention discloses a mechanism for allowing an electric baby carriage to have a swinging function. The mechanism comprises carriage wheel rotation axles on which eccentric mechanisms and a driving mechanism are arranged; wheels of the baby carriage are sleeved on the eccentric mechanisms. The eccentric mechanisms are a first eccentric axle and a second eccentric axle which are respectively fixed at two ends of each carriage wheel rotation axle and positioned at the same axis; the wheels of the baby carriage are respectively sleeved on the first eccentric axle and the second eccentric axle. Or the eccentric mechanisms are a first eccentric wheel and the second eccentric wheel which are respectively fixed at two ends of the carriage wheel rotation axle, and the centers of the first eccentric wheel and the second eccentric wheel are positioned at the same axis and the eccentric directions are the same, a first wheel axle and a second wheel axle are arranged outside the first eccentric wheel and the second eccentric wheel, and the wheels of the baby carriage are respectively sleeved on the first eccentric wheel and the second eccentric wheel. The mechanism is applied to the electric baby carriage.

Owner:林耸霓

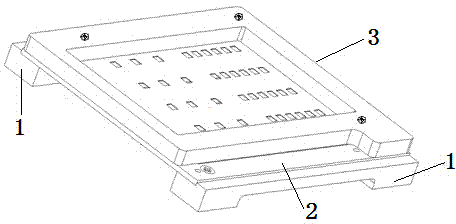

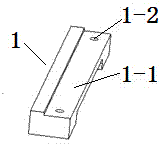

Fixture for welding patch component to heat dissipation metal strip

ActiveCN104722879AEnsure consistencyAvoid potential damageWelding/cutting auxillary devicesAuxillary welding devicesMetal stripsEngineering

The invention relates to a fixture for welding a patch component to a heat dissipation metal strip. Two supports are arranged correspondingly, two end faces of a locating frame are fixed in concave surfaces of the two correspondingly arranged supports respectively, and a tin cream printing jig is located on the locating frame. The fixture for welding the patch component to the heat dissipation metal strip has the advantages that the biggest improvement compared with a former manual welding is that the component consistency of the product after welded is guaranteed, the welding quality is guaranteed, the hidden danger of component damage due to multi-pass operations is avoided, and the damage degree of the component is reduced. The requirement for the welding level of operational personnel is not high, only does the component need to be placed in a corresponding position, the working efficiency is improved, and the operational personnel and production managers are pleased to use.

Owner:TIANJIN 712 COMM & BROADCASTING CO LTD

Non-woven fabric laminate/elastomer/non-woven fabric

ActiveUS7655583B2Feel goodNot to damageLayered product treatmentDecorative surface effectsElastomerAdhesive

A laminate including at least one elastic film having a width and at least one layer of non-woven fabric fixed to the film on at least said width, through interposition of a fixing agent, in particular adhesive, whereby the at least one layer of non-woven fabric has an outer surface at a distance from the film. The outer surface (25) of the at least one layer of non-woven fabric is corrugated in the stretched state of the laminate, having ridge zones (22) and hollow zones (23), whereby fixing agent (20) is provided between the ridge zones and the elastic film.

Owner:APLIX INC

Topical pharmaceutical compositions

InactiveUS20140200203A1Easily applied to skinEasy to spreadOrganic active ingredientsAntipyreticDiseaseAtopic dermatitis

Topical pharmaceutical compositions are described comprising, based on the total weight of the composition: a) 0.01 to 0.2 wt. % of mometasone furoate, b) 5 to 18 wt. % of hexylene glycol, c) 20 to 40 wt. % of water, and d) 25 to 70 wt. % of an oil phase. Said compositions are stable and can be safely and easily applied over large surface areas of the skin in an acceptable way by the general patient population for the treatment or prevention of psoriasis, atopic dermatitis (atopic eczema) and other skin disorders or diseases.

Owner:ALMIRALL

Traditional Chinese medicine ointment used for treating keratosis pilaris, and preparation method thereof

InactiveCN105012688AOvercome the deficiency in the treatment of keratosis pilarisSuitable for long-term useAnthropod material medical ingredientsAerosol deliverySide effectKeratosis Pilaris

The invention discloses a traditional Chinese medicine ointment used for treating keratosis pilaris, and a preparation method thereof. The traditional Chinese medicine ointment is prepared from following raw materials, aloe, spirulina platensis powder, sea silt, herba portulacae, rhizoma bletillae, chamomile, Trillium tschonoskii Maxim., raw radix astragalis, jack fruit, pineberry, periostracum cicada, fresh rose flower, tuna oil, and camellia oil. The traditional Chinese medicine ointment for external use is used for treating keratosis pilaris, is capable of solving problems of conventional therapeutic approaches on keratosis pilaris, is safe, is suitable for long-term application, is fragrant, is capable of improving symptoms of keratosis pilaris rapidly, nourishing and protecting skin, and eliminating symptoms of keratosis pilaris; and no side effect is caused.

Owner:QINGDAO HAIZHIXING BIOLOGICAL SCI & TECH

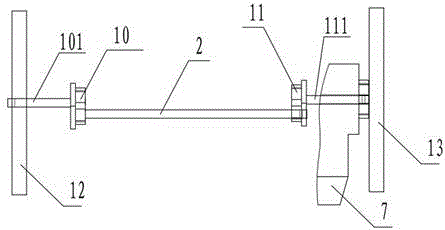

Mechanism enabling electric baby carriage to have swinging function

PendingCN107521546AWith swing functionHappy to useCarriage/perambulator accessoriesMotor driveEngineering

The invention relates to a mechanism enabling an electric baby carriage to have a swinging function. The mechanism comprises an axle for loading a carriage body and wheels mounted at the two ends of the axle, and a swinging mechanism and a driving mechanism are arranged on the axle. The driving mechanism comprises a motor and a driving gear, and the driving gear is connected with the motor. Driven gears are arranged on the wheels, and the driven gears are engaged with the driving gear of the motor. The swinging mechanism comprises a swinging motor and a swinging device, the swinging device is fixedly arranged on the axle, the swinging motor drives the axle to rotate, and thus the swinging device is driven to rotate and swing. The electric baby carriage has the swinging function besides the running function, so that children are provided with joys when using the baby carriage. By arranging the swinging device, the swinging motion track of the baby carriage can be adjusted according to structures of a sliding device and a swinging rod, the electric baby carriage can swing front and back and up and down, or front and back and up and down, and the application range is wide.

Owner:平湖市飞驰童车有限公司

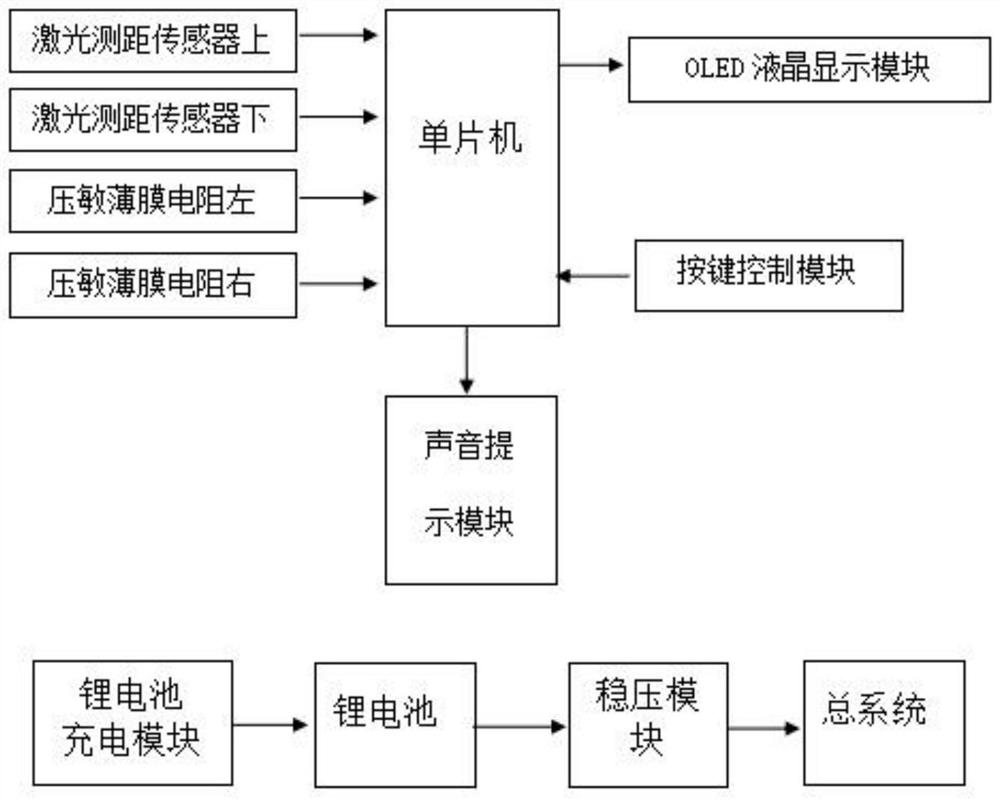

Control system of intelligent reminding device for incorrect sitting posture

InactiveCN112137292AVersatileEasy to installStuffed mattressesMeasurement devicesLiquid-crystal displayLaser ranging

The invention provides a control system of an intelligent reminding device for incorrect sitting posture, and relates to the field of incorrect sitting postures. The control system is composed of a main control single-chip microcomputer, an OLED liquid crystal display module, a laser ranging module, a pressure monitoring module, a sound prompt module, a key control module and a power supply module. According to the invention, the system realizes multi-dimensional comprehensive monitoring, and is humanized in design. Different wrong sitting postures such as humpback sitting, prone sitting and inclined sitting are monitored in an up-and-down and left-and-right multi-dimensional mode, and reminding threshold values such as pressure and distance difference are customized by the user accordingto the actual situations such as different heights and weights of students and different sizes of chairs. According to the set parameters, the device intelligently judges the sitting posture of the student, and once the sitting posture is incorrect, correction is reminded in time. The device also has the functions of sedentariness duration reminding and winter heating. The device is good in expansibility, a WIFI module can be added in the later period, and parents can check the sitting posture condition of the child on a mobile phone.

Owner:方翊霖

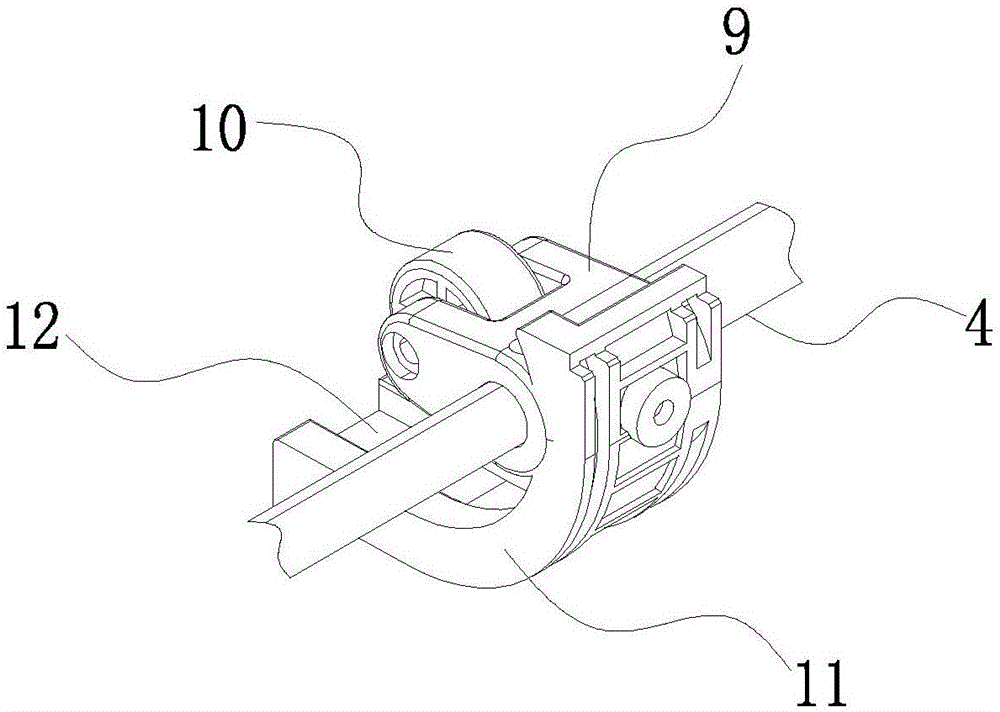

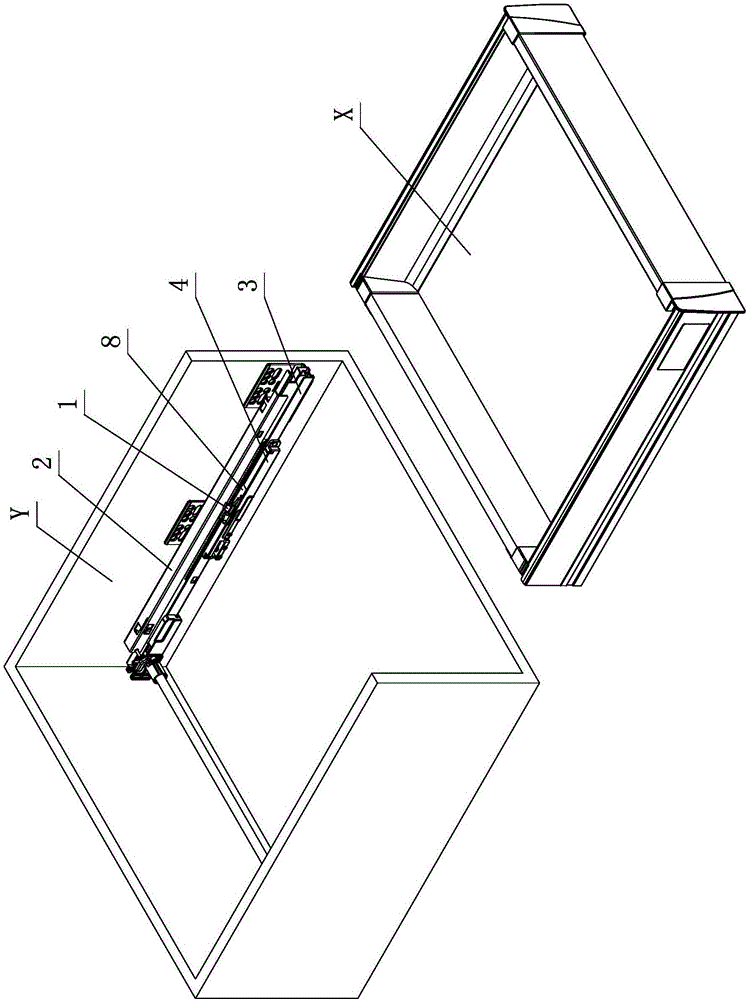

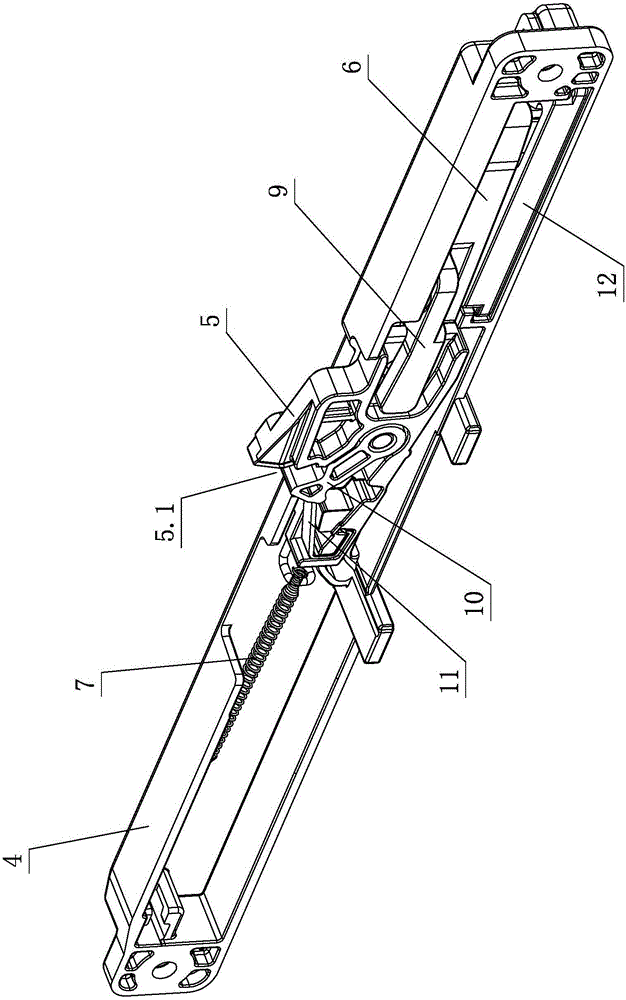

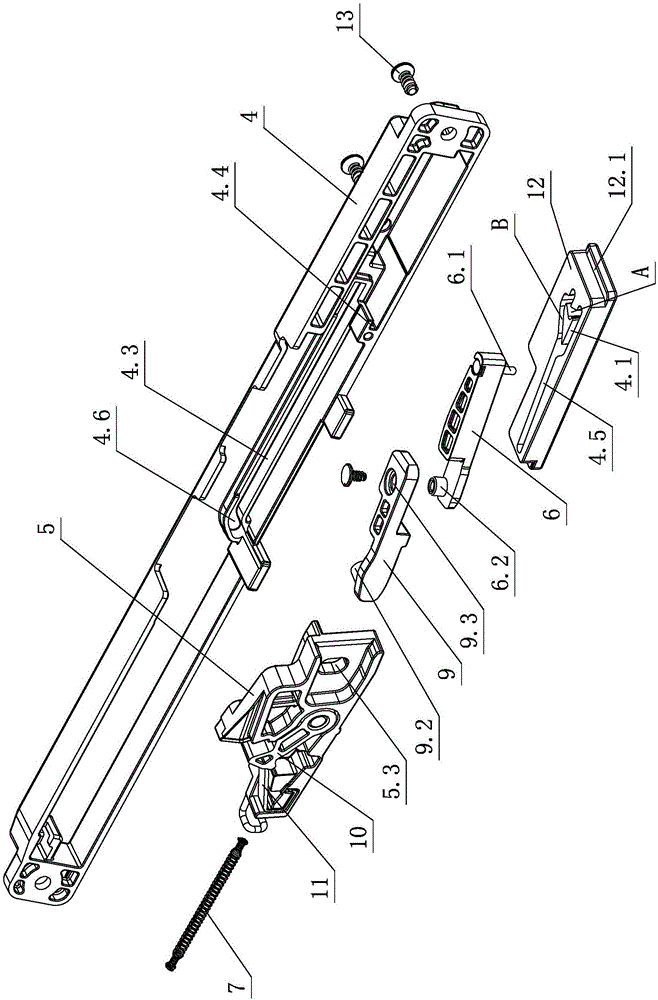

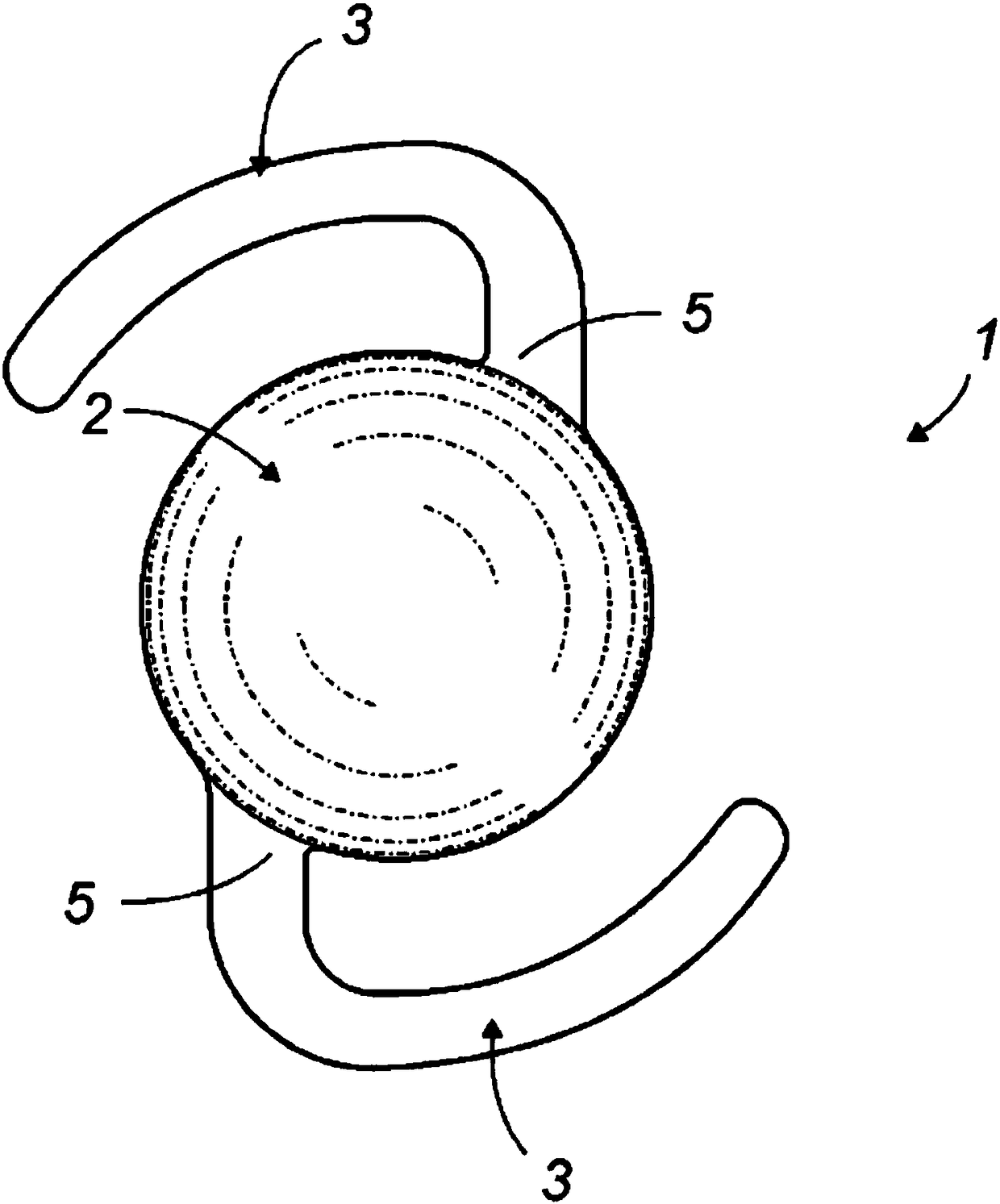

Integrated optimized rebound mechanism of furniture slide rail

The invention discloses an integrated optimized rebound mechanism of a furniture slide rail. The integrated optimized rebound mechanism comprises a slide rail assembly, a striking unit and a rebound device, wherein the slide rail assembly comprises a movable slide rail and a fixed slide rail; the movable slide rail is opened and closed on the fixed slide rail in a sliding mode; the striking unit is arranged on the movable slide rail; the rebound device is arranged on the fixed slide rail; the striking unit interacts with the rebound device at least when the movable slide rail is closed by a certain distance relative to the fixed slide rail in a sliding mode; the rebound device comprises a fixed bracket, a swing bolt, a pushing element, an adapter element and a heart-shaped sliding groove piece; the fixed bracket and the heart-shaped sliding groove piece are in matched connection by virtue of a locating matching portion; a vertical sliding groove is formed in the fixed bracket or between the fixed bracket and the slide rail assembly; a heart-shaped sliding groove is formed in the heart-shaped sliding groove piece; a notching direction of the heart-shaped sliding groove is parallel with the sidewall of the movable slide rail or the fixed slide rail; the swing bolt is arranged on the vertical sliding groove in a sliding mode; one end of the pushing element is in matched connection to the swing bolt by virtue of the adapter element; and the other end of the pushing element is arranged on the heart-shaped sliding groove in a sliding mode. The rebound mechanism provided by the invention, through the structure improvement, is strong in practicability.

Owner:伍志勇

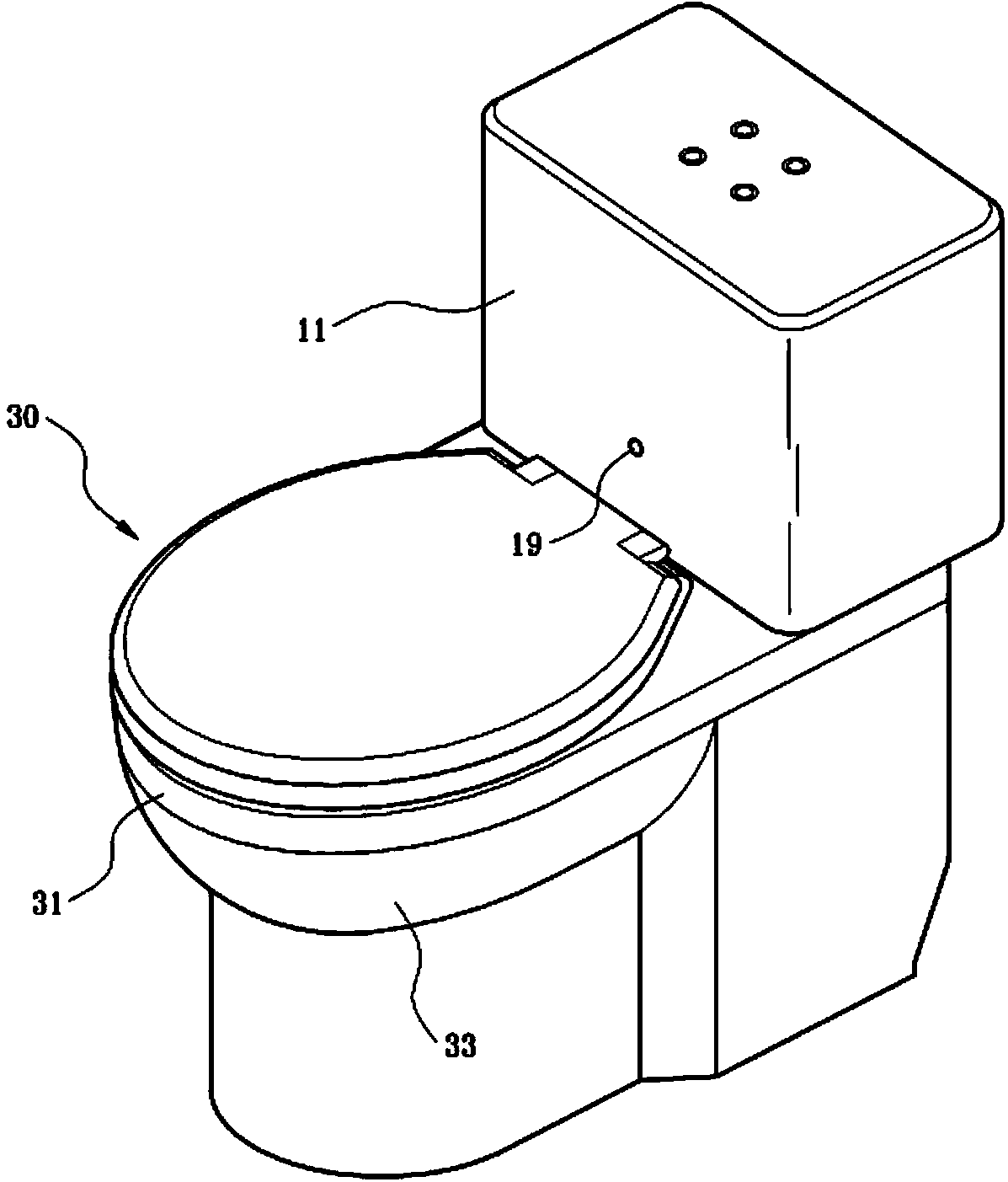

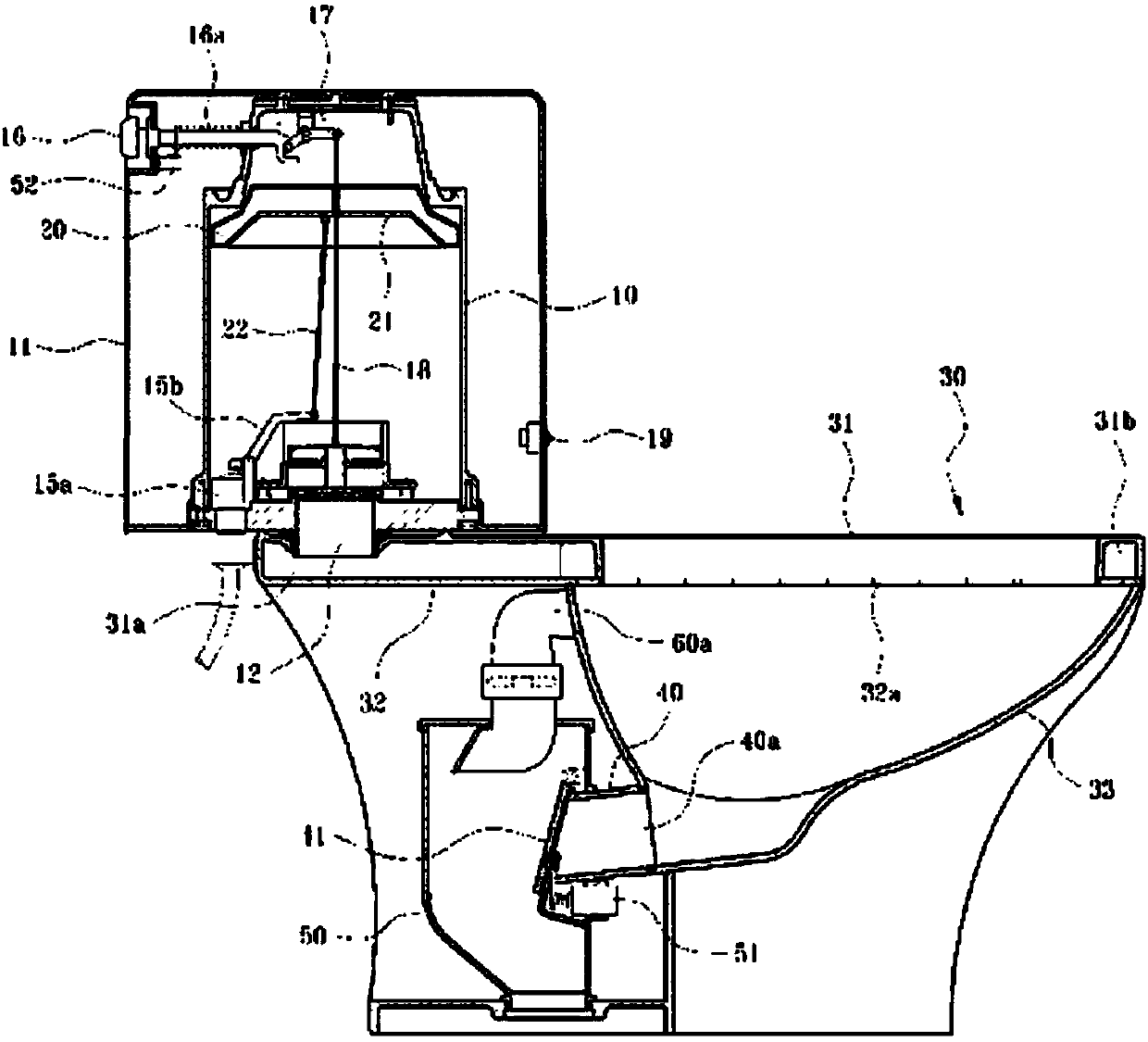

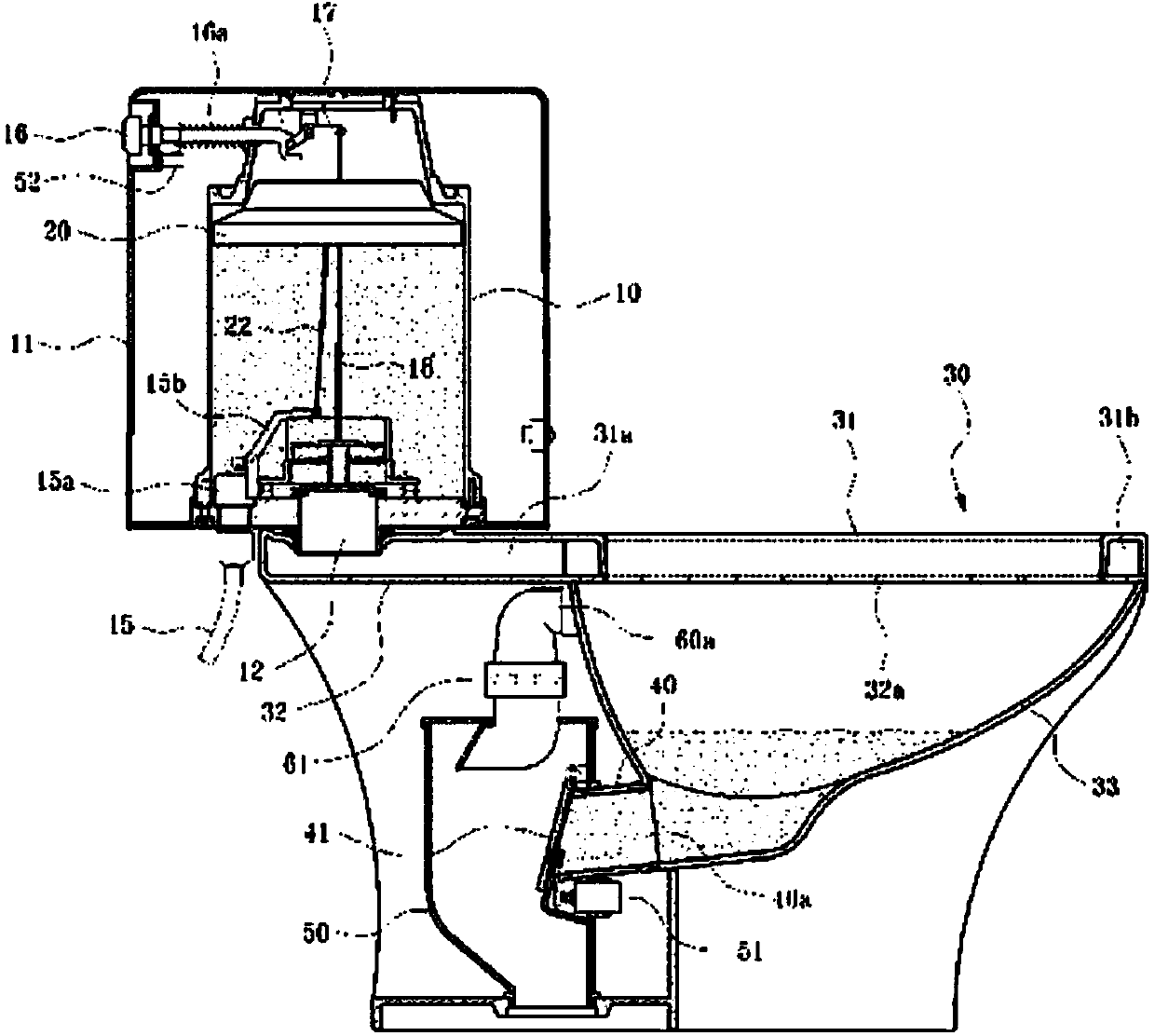

Water-saving toilet

ActiveCN104093918AIncrease water pressureUnhappy to useWater resource protectionWater closetsWater savingEngineering

The invention relates to a technology relating to a sit-down toilet wherein the toilet is flushed by using a dramatically reduced amount of flushing water, and to a water-saving sit-down toilet wherein the pressure of flushing water discharged from a cistern into the toilet is raised and a straight discharge pipe is used so that the toilet is flushed clean using a small amount of water, and excreta is smoothly discharged as the direct discharge tube is opened and closed automatically by means of the water pressure and a permanent magnet and an electromagnet, and an appropriate amount of residual water is supplied to the toilet bowl such that odours are blocked from rising from a foul-water port into the toilet, and an odour removing unit sucks in odours emanating from the excreta and discharges same through the foul-water port such that the user can use the sit-down toilet without feeling any embarrassment. The sit-down toilet essentially comprises: a cistern provided with a discharge valve for opening and closing a drainage port, and is provided with a water-supply lever and a water-supply valve for opening and closing a water-supply pipe, and provided with a button for operating the discharge valve; a pressure tube inserted into the cistern, holdsing flushing water and linked by a rope to the water-supply lever of the water-supply valve; a main toilet body which is formed so as to have a drainage path and a water path for discharging the flushing water via the drainage port of the cistern, and which is formed so as to have a plurality of drainage holes around the bottom end and have a discharge port below the rear end of the drainage path; a straight discharge pipe which is joined to the discharge port of the main toilet body and is provided with an opening and closing port which is automatically opened and closed by means of the pressure of the flushing water and a permanent magnet, and discharges flushing water and excreta from the main toilet body; a discharge box for discharging the excreta through the foul water port, which box is disposed to the rear of the straight discharge pipe, and is provided with an electromagnet on a side surface on one side on the inside and of which the lower part is joined to the foul-water port; and an odour removing unit which is provided with a suction pipe linked to the main toilet body and discharge box, and sucks in odours emanating from the excreta and eliminates same by discharging same through the discharge box.

Owner:李 载 谟

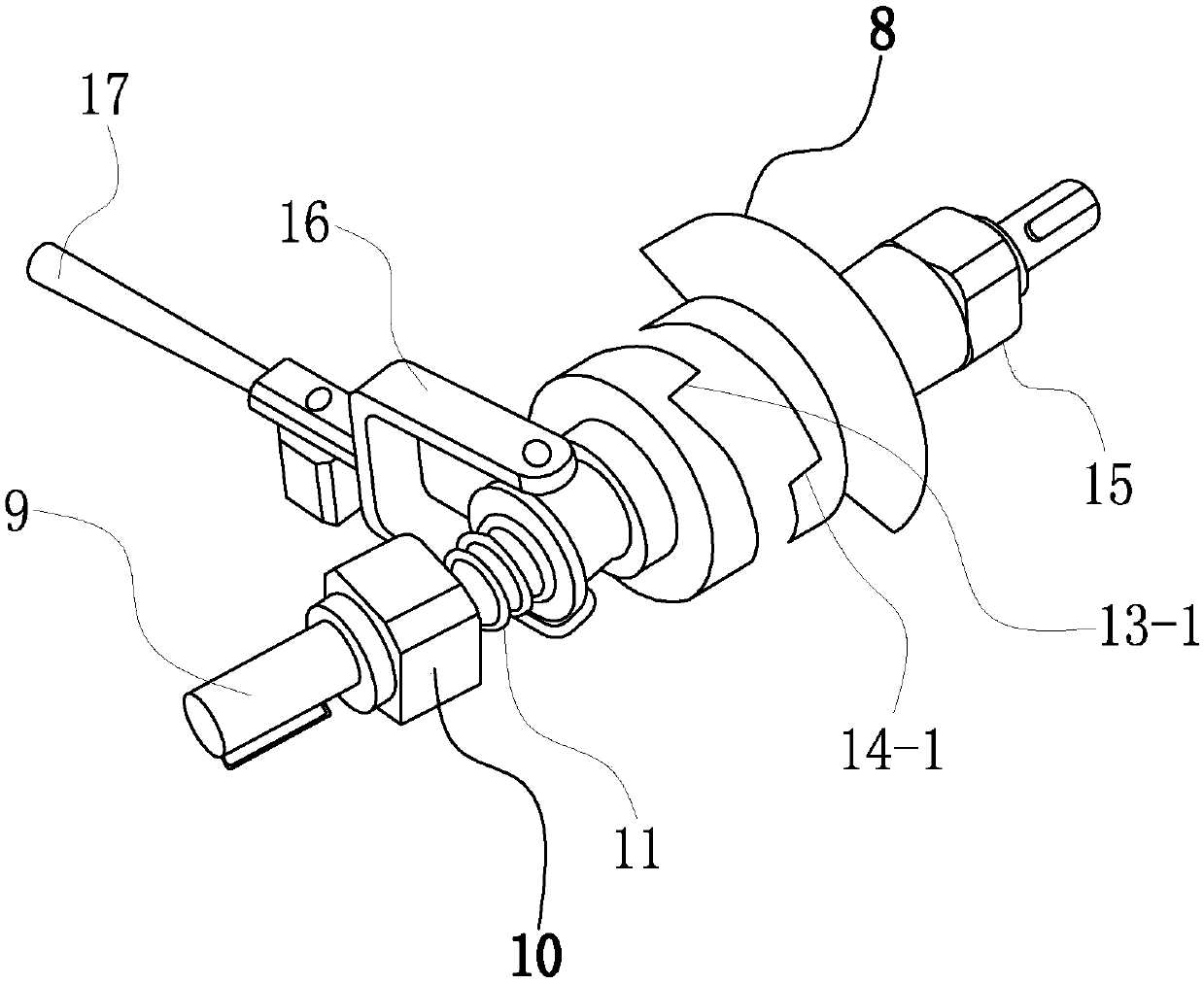

Mechanism for driving electric car for children to swing

PendingCN107600262AWith swing functionHappy to useChildren cyclesVehicle transmissionElectric carsClutch

The invention relates to a mechanism for driving an electric car for children to swing. The electric car for children comprises an axle which is used for bearing a car body and wheels which are installed at two ends of the axle; the axle is driven by a power device to rotate; the axle is sleeved by a clutch mechanism which is connected with an eccentric mechanism; when the clutch mechanism is in astate of separating, the clutch mechanism drives the axle to rotate so that the electric car for children is driven forward; when the clutch mechanism is in a state of closing, the clutch mechanism drives the axle to rotate so that the electric car for children is driven forward and the eccentric mechanism is also driven by the clutch mechanism to make the electric car for children swing up and down. According to the invention, the electric car for children has the function of running and the swing as well; besides, the running and swing can be carried out at the same time, which brings joy for children; besides, the electric car for children of the invention has simple structure and is low in production cost and is not liable to break.

Owner:PINGHU KEYUAN TECH SERVICE

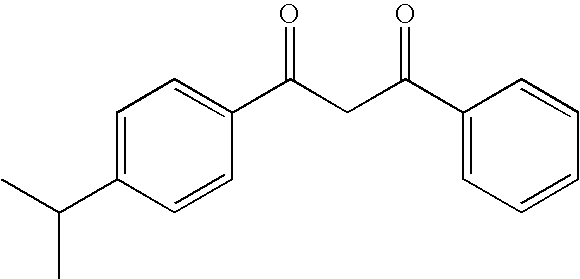

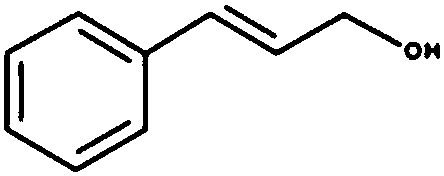

Acrylic copolymer, which is hydrophobic, cross-linked and based on cinnamic alcohol, for intraocular lenses

ActiveCN108348642AImprove productivityHappy to useTissue regenerationIntraocular lensCross-linkPolymer science

The material according to the invention is an acrylic copolymer, which is cross-linked, viscoelastic, flexible and deformable at room temperature and hydrophobic, with at least 50 wt % of acrylic or methacrylic monomers and cinnamic alcohol. The mixture of monomers preferably includes: at least one arylalkoxy-acrylate or one arylalkoxy-methacrylate; at least one hydroxylated acrylate and one hydroxylated methacrylate; at least one ethoxylated diol diacrylate and one ethoxylated diol dimethacrylate; and cinnamic alcohol. Said material is obtained in a single step of radical polymerisation and is presented in the form of a three-dimensional macromolecular network including a cinnamic alcohol unit. Said material is used for manufacturing intraocular lenses (1).

Owner:ACRYLIAN

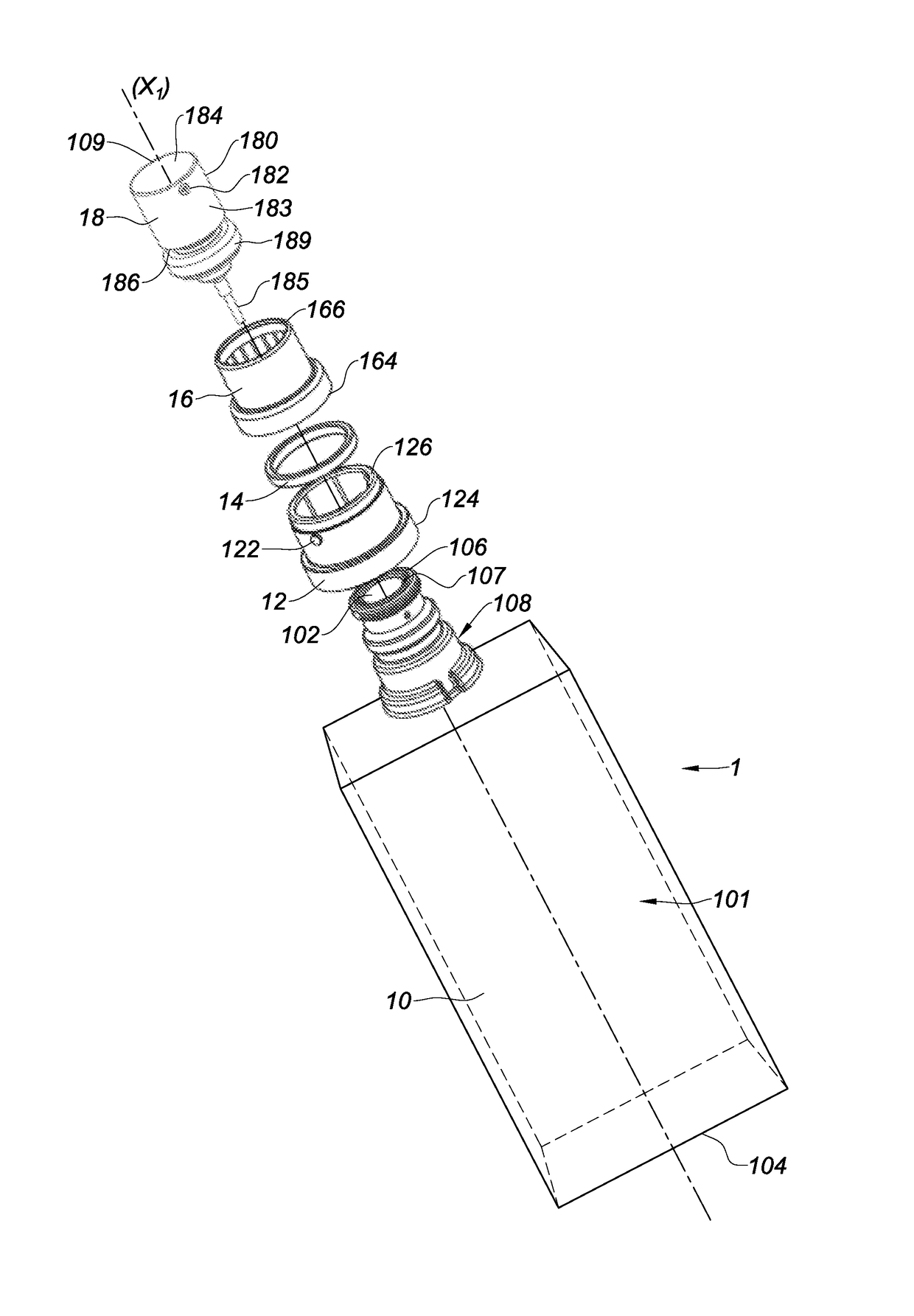

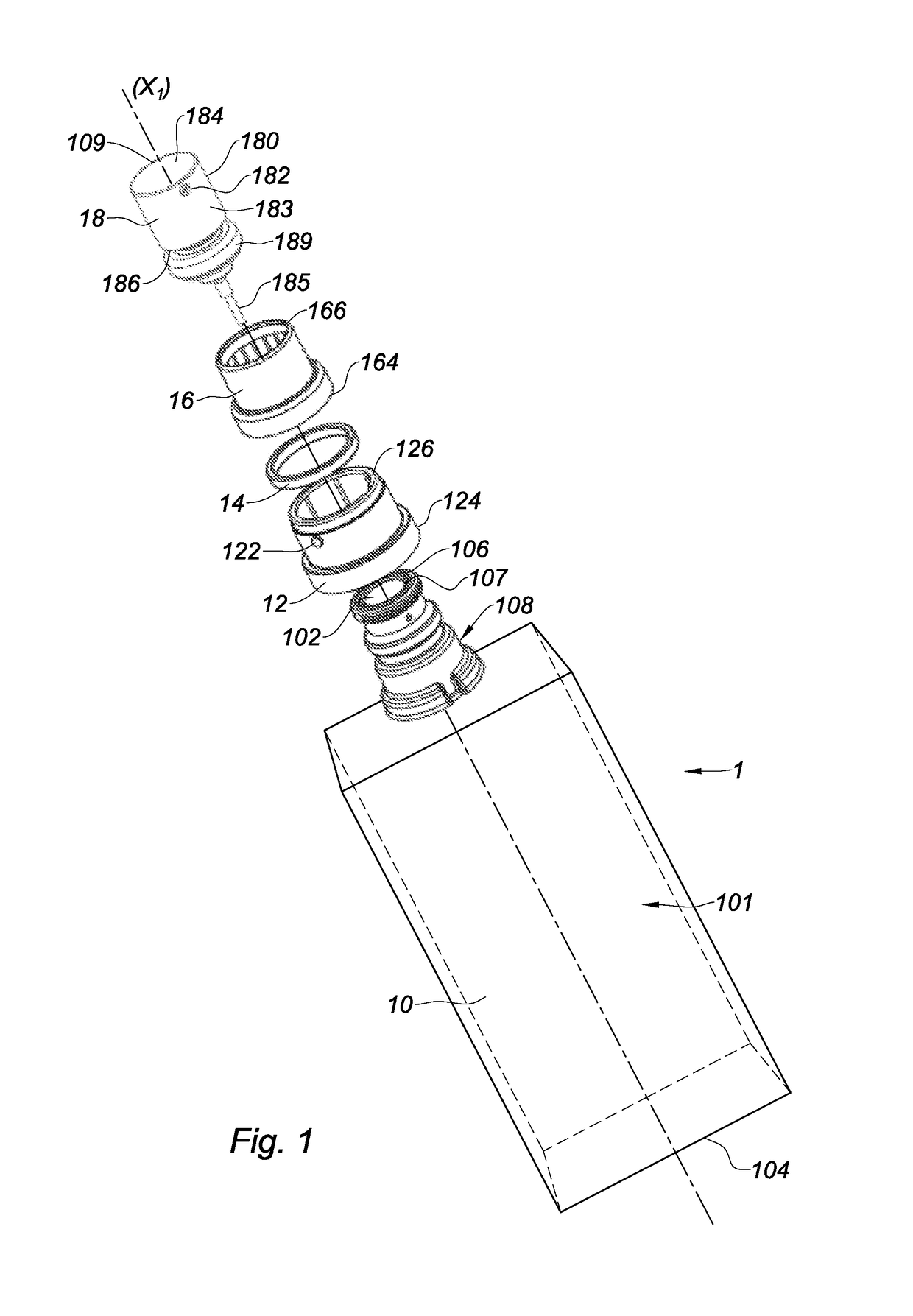

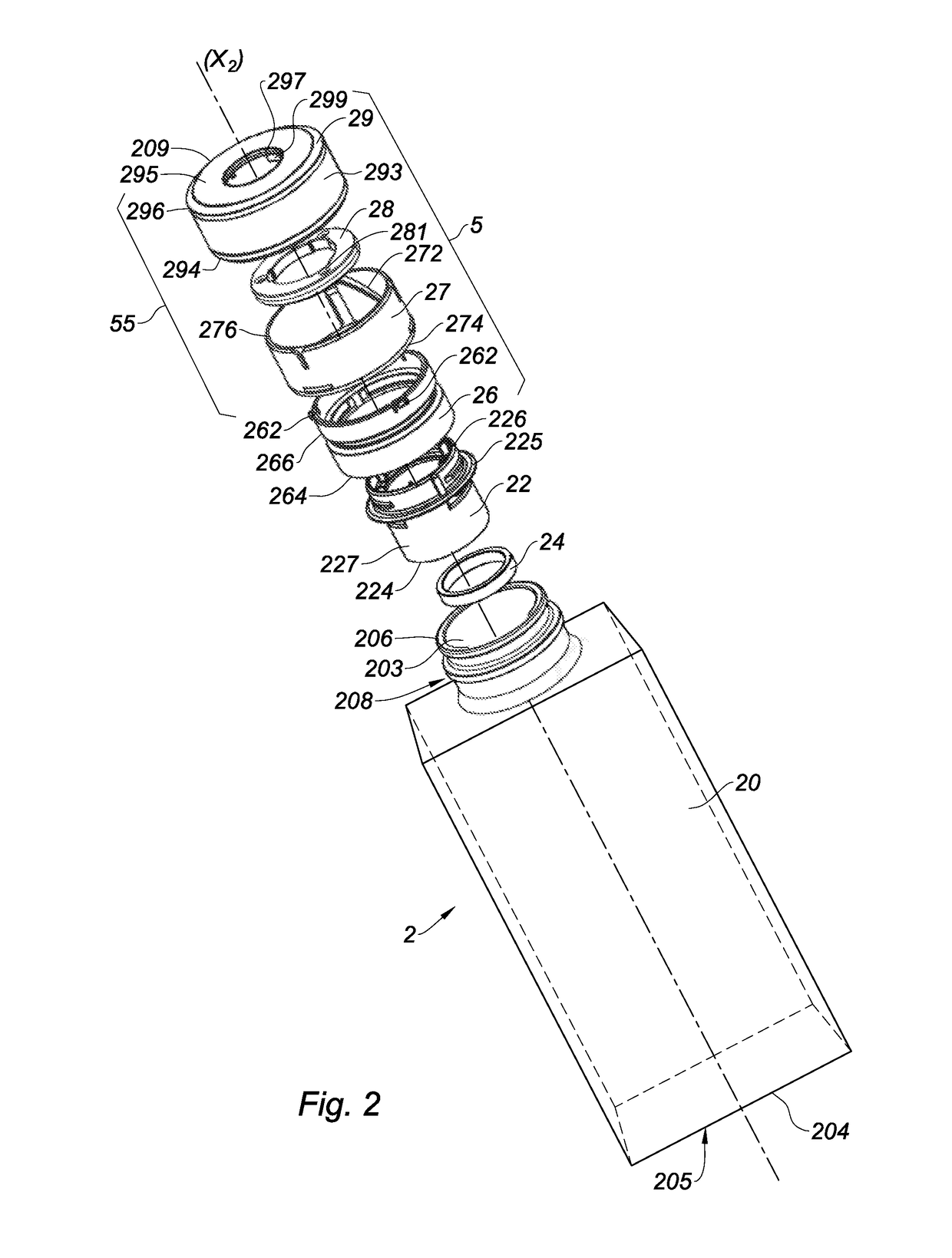

Device for distributing a liquid particularly a cosmetic liquid

ActiveUS20170341096A1Increase inertiaHappy to usePackaging toiletriesSingle-unit apparatusEngineeringBottle

A device for distributing a liquid. The device includes a bottle including a reservoir designed to store liquid, and a distribution element, and a concealment assembly. The distribution element allows the liquid to be distributed from the inside to the outside of the reservoir. The concealment assembly includes a base and a concealment ring that is movable along a main displacement axis from a first, operating position, to a second, locking position. The displacement of the concealment ring occurs through a helical movement of the concealment ring relative to the base in relation to the main displacement axis. As well, the displacement of the concealment ring from the operating position to the locking position allows at least part of the distribution element to be concealed. Finally, the concealment element further includes a ballast rigidly connected to the concealment ring.

Owner:ALBEA SERVICES SAS

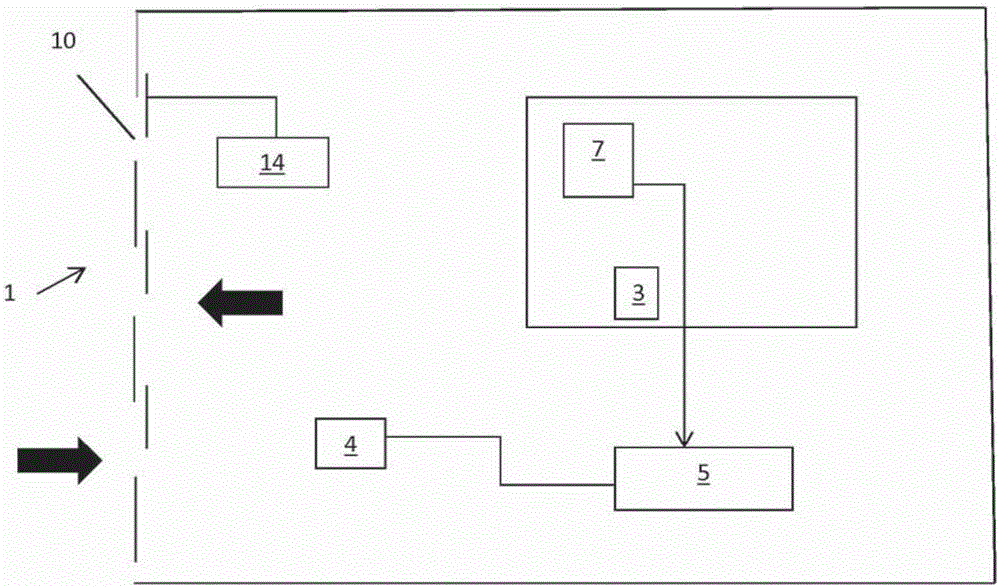

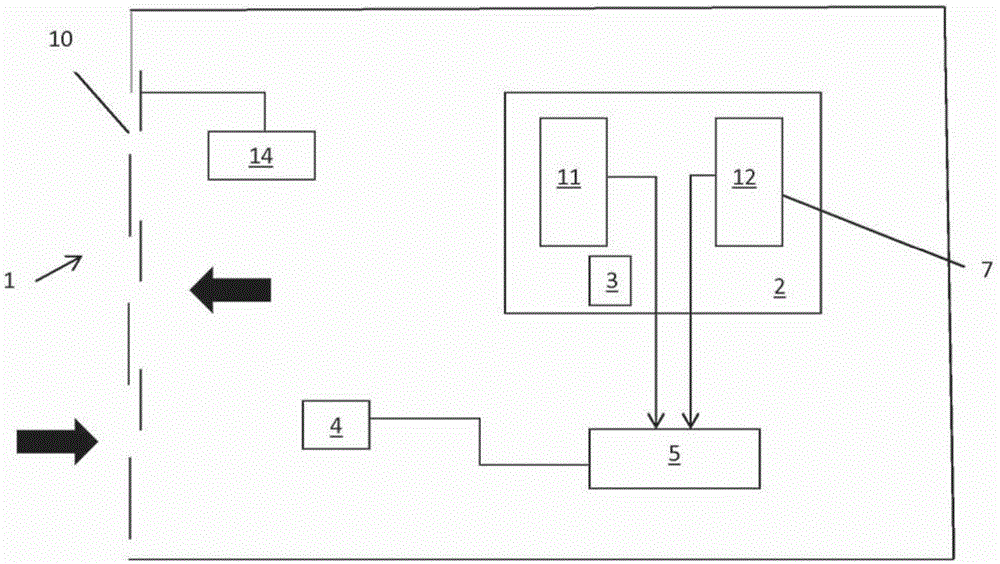

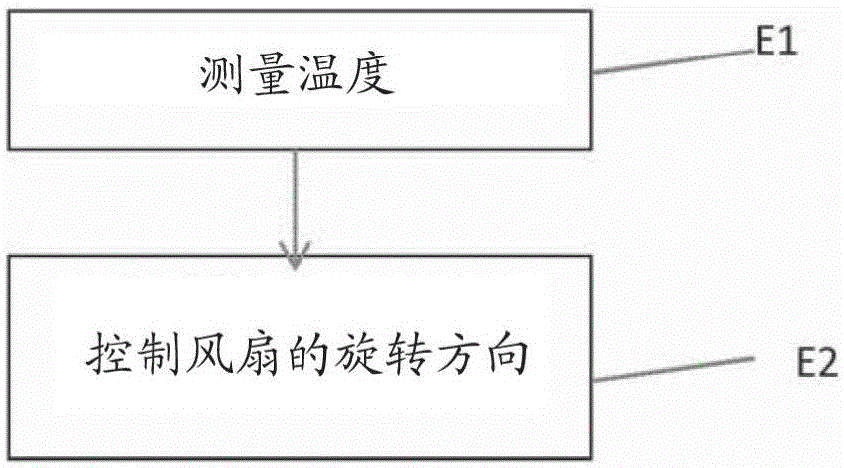

Optimisation of heat regulation in device comprising fan

InactiveCN105103078AImprove performanceReduce noiseDigital data processing detailsProjectorsEngineeringHeat regulation

The invention concerns a device (1) comprising: at least one component (7), at least one fan (4) for regulating the temperature of the component (7), a processor (5), and at least one temperature sensor (3), characterised in that the processor (5) is configured to control the direction of rotation of the fan (4) on the basis of the temperature of the component (7) measured by the temperature sensor (3), so as to regulate the temperature of the component (7) and the noise generated by the fan (4). The invention also concerns a method for regulating the temperature in this device.

Owner:艾科斯杰姆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com