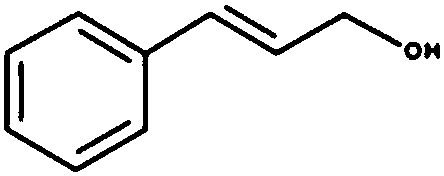

Acrylic copolymer, which is hydrophobic, cross-linked and based on cinnamic alcohol, for intraocular lenses

A technology of intraocular lens and acrylic polymer, which is applied in the field of manufacturing the polymer material, intraocular lens, and production of intraocular lens, can solve the problems of difficult production cycle, strong, unpleasant smell, etc., and achieve the effect of improving comfort and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0163]

[0164] Polymerization was initiated by addition of 0.5% TAEC. After polymerization, an acrylic polymer material was obtained having an optical index equal to 1.5381, a glass transition temperature equal to 7.5° C., and a modulus of elasticity at 25° C. after 1 minute of relaxation of 0.658 MPa.

example 2

[0166]

[0167]

[0168] Polymerization was initiated by addition of 0.5% TAEC. After polymerization, an acrylic polymer material is obtained having an obtained optical index equal to 1.540, a glass transition temperature equal to 12.4° C. and a modulus of elasticity at 25° C. after 1 minute of relaxation of 0.51 MPa.

example 3

[0170]

[0171] Polymerization was initiated by addition of 0.5% TAEC. After polymerization, an acrylic polymer material is obtained having an obtained optical index equal to 1.5390, a glass transition temperature equal to 6.3° C., and a modulus of elasticity at 25° C. after 1 minute of relaxation of 0.495 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com