Special nano-modified impregnating compound for basalt continuous fiber and preparation method of special nano-modified impregnating compound

A continuous fiber, nano-modified technology, applied in the field of textile materials, can solve the problems of inability to meet the requirements of weaving into fiber cloth, poor textile properties of basalt fibers, etc., to improve spinnability, mechanical properties, mechanical properties and aging resistance. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

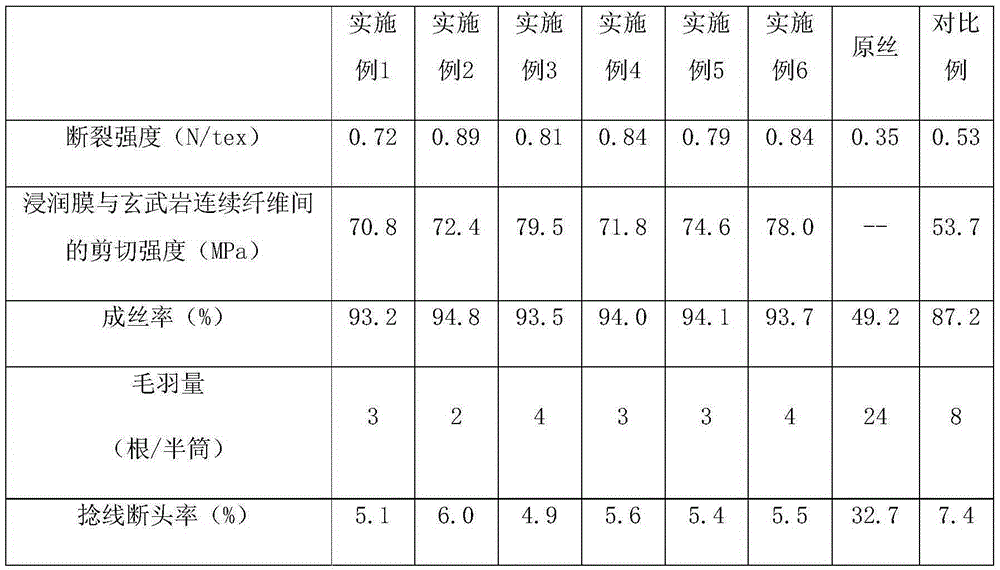

Examples

Embodiment 1

[0037] Components of a nano-modified sizing agent for continuous basalt fibers, in parts by weight, comprising:

[0038] 25 parts of silicone modified acrylate and polyester resin emulsion;

[0039] 15 parts of fatty acid amide acetate and fatty acid ester sulfate;

[0040] 5 parts of quaternary ammonium salt cationic antistatic agent;

[0041] 5 parts of nano silicon dioxide and titanium dioxide particles;

[0042] 15 parts of silane coupling agent;

[0043] 20 parts of citric acid;

[0044] 5 parts of sodium lactate;

[0045] 50 parts of deionized water.

[0046] Specifically include the following steps:

[0047] (1) Add citric acid to the deionized aqueous solution, adjust the pH value of the citric acid aqueous solution to 3, stir at a high speed of 2000rpm / min for 5min, and add 40 parts of citric acid aqueous solution at 15 drops / min Slowly add 1 part of silane coupling agent dropwise, and continue to stir for 2 hours until the hydrolysis is complete to obtain a cl...

Embodiment 2

[0051] Components of a nano-modified sizing agent for continuous basalt fibers, in parts by weight, comprising:

[0052] 35 parts of silicone modified acrylate and polyester resin emulsion;

[0053] 20 parts of fatty acid amide acetate and fatty acid ester sulfate;

[0054] 10 parts of quaternary ammonium salt cationic antistatic agent;

[0055] 15 parts of nano silicon dioxide and titanium dioxide particles;

[0056] 25 parts of silane coupling agent;

[0057] 30 parts of citric acid;

[0058] 10 parts of sodium lactate;

[0059] 100 parts of deionized water.

[0060] Specifically include the following steps:

[0061] (1) Add citric acid to the deionized aqueous solution, adjust the pH value of the citric acid aqueous solution to 4, stir at a high speed of 2000rpm / min for 10min, and add 50 parts of citric acid aqueous solution at 20 drops / min Slowly add 1 part of silane coupling agent dropwise, and continue to stir for 3 hours until the hydrolysis is complete to obtain...

Embodiment 3

[0065] Components of a nano-modified sizing agent for continuous basalt fibers, in parts by weight, comprising:

[0066] 30 parts of silicone modified acrylate and polyester resin emulsion;

[0067] 17 parts of fatty acid amide acetate and fatty acid ester sulfate;

[0068] 8 parts of quaternary ammonium salt cationic antistatic agent;

[0069] 10 parts of nano silicon dioxide and titanium dioxide particles;

[0070] 20 parts of silane coupling agent;

[0071] 25 parts of citric acid;

[0072] 7 parts of sodium lactate;

[0073] 80 parts of deionized water.

[0074] Specifically include the following steps:

[0075] (1) Add citric acid to the deionized aqueous solution, adjust the pH value of the citric acid aqueous solution to 3.5, stir at a high speed of 2000rpm / min for 8min, and add 45 parts of citric acid aqueous solution at 17 drops / min Slowly add 1 part of silane coupling agent dropwise, and continue to stir for 2.5 hours until the hydrolysis is complete to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com