Lubricating oil and additive for lubricating oil

A lubricating oil additive and lubricating oil technology, applied in the field of lubricating oil, can solve the problems of unsatisfactory performance and few types of long-lasting lubricating oil, and achieve the effect of outstanding anti-oxidation performance, increased driving safety and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

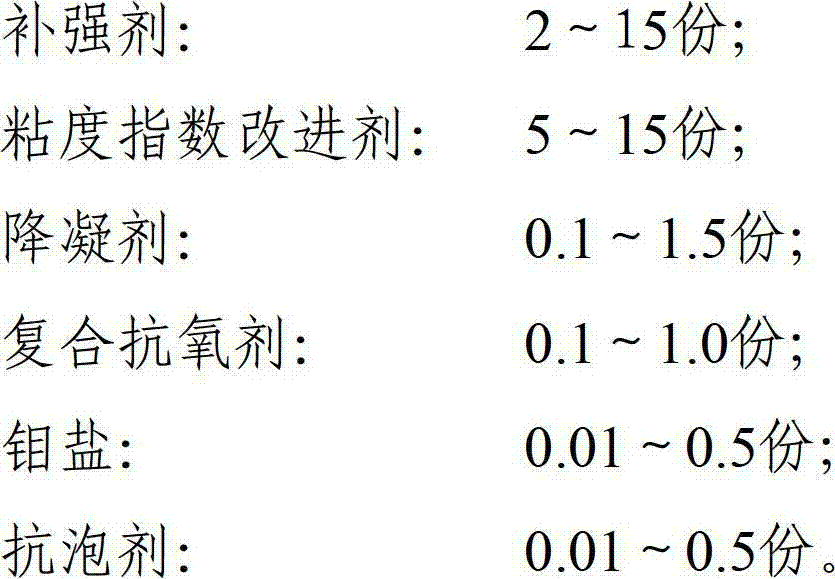

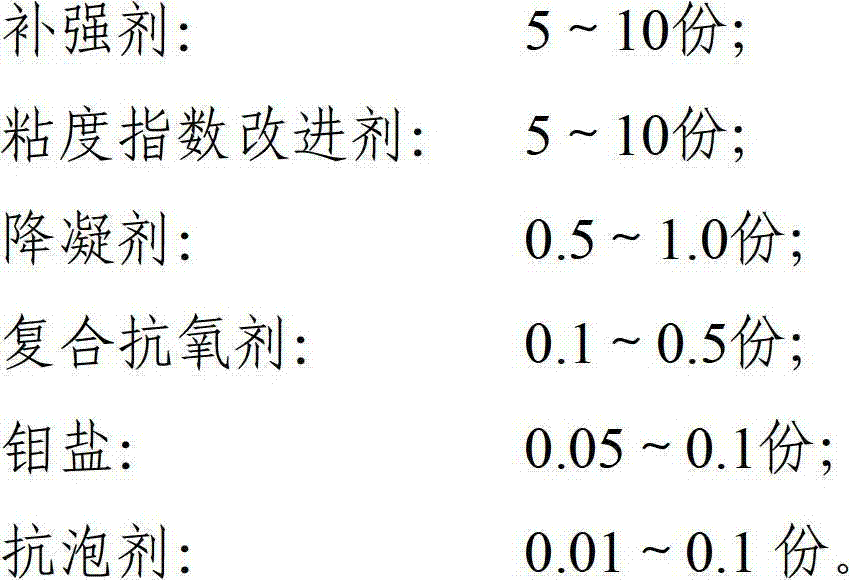

Method used

Image

Examples

Embodiment 1

[0029] The formula of lubricating oil is as follows: the base oil is UHVI 6 and 500SN, accounting for 59.4% and 25.4% of the total weight respectively; the reinforcing agent is H9300 and H9310, accounting for 4.4% and 1.75% of the total weight respectively; the viscosity index improver is T614, It accounts for 8.0% of the total weight; the pour point depressant is T803B, accounting for 0.6% of the total weight; the antioxidant is PKB900, accounting for 0.3% of the total weight; 0.06% by weight; the composite antifoaming agent T921 accounts for 0.09% by weight (the above are all percentages by weight).

[0030] The preparation process is as follows: first add base oil to the container, then add reinforcing agent, viscosity index improver, pour point depressant, antioxidant, molybdenum salt and antifoaming agent, stir until evenly mixed.

Embodiment 2

[0032] The formula of lubricating oil is as follows: the base oil is UHVI 6 and 500SN, accounting for 61.27% and 24.01% of the total weight respectively; the new reinforcing agent is H9300 and H9310, accounting for 4.23% and 1.71% of the total weight respectively; the viscosity index improver is T614 , accounting for 7.8% of the total weight; the pour point depressant is T803B, accounting for 0.61% of the total weight; the antioxidant is PKB900, accounting for 0.3% of the total weight; 0.06% of the total weight; the composite antifoaming agent T921 accounts for 0.01% of the total weight (the above are all percentages by weight).

[0033] The preparation process is the same as in Example 1.

Embodiment 3

[0035] The formula of lubricating oil is as follows: the base oil is UHVI 6 and 500SN, accounting for 55.85% and 28.4% of the total weight respectively; the new reinforcing agent is H9300 and H9310, accounting for 4.82 and 1.78% of the total weight respectively; the viscosity index improver is T614, It accounts for 8.1% of the total weight; the pour point depressant is T803B, accounting for 0.66% of the total weight; the antioxidant is PKB900, accounting for 0.3% of the total weight; the molybdenum salt is molybdenum dialkyl disulfate formate, accounting for 0.07% of the total weight ; Composite antifoaming agent T921 accounts for 0.02% of the total weight (the above are all percentages by weight).

[0036] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com