Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

447 results about "Reducing substances" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

REDUCING SUBSTANCES DEFINITION. Substances that donate electrons are called reducing agents. Some carbohydrates can reduce other compounds. To be reducing substances, they must contain free aldehyde or ketone group that reduces the blue cupric ions to red cuprous oxide.

High-Potency Sweetener Composition With C-Reactive Protein Reducing Substance and Compositions Sweetened Therewith

InactiveUS20070116839A1Improve flavor profileImproving temporal profile profileSugar food ingredientsMetabolism disorderAdditive ingredientSweetness

The present invention relates generally to functional sweetener compositions comprising non-caloric or low-caloric natural and / or synthetic, high-potency sweeteners and methods for making and using them. In particular, the present invention relates to different functional sweetener compositions comprising at least one non-caloric or low-caloric natural and / or synthetic, high-potency sweetener, at least one sweet taste improving composition, and at least one functional ingredient, such as C-reactive protein reducing substances. The present invention also relates to functional sweetener compositions and methods that can improve the tastes of non-caloric or low-caloric high-potency sweeteners by imparting a more sugar-like taste or characteristic. In particular, the functional sweetener compositions and methods provide a more sugar-like temporal profile, including sweetness onset and sweetness linger, and / or a more sugar-like flavor profile.

Owner:THE COCA-COLA CO

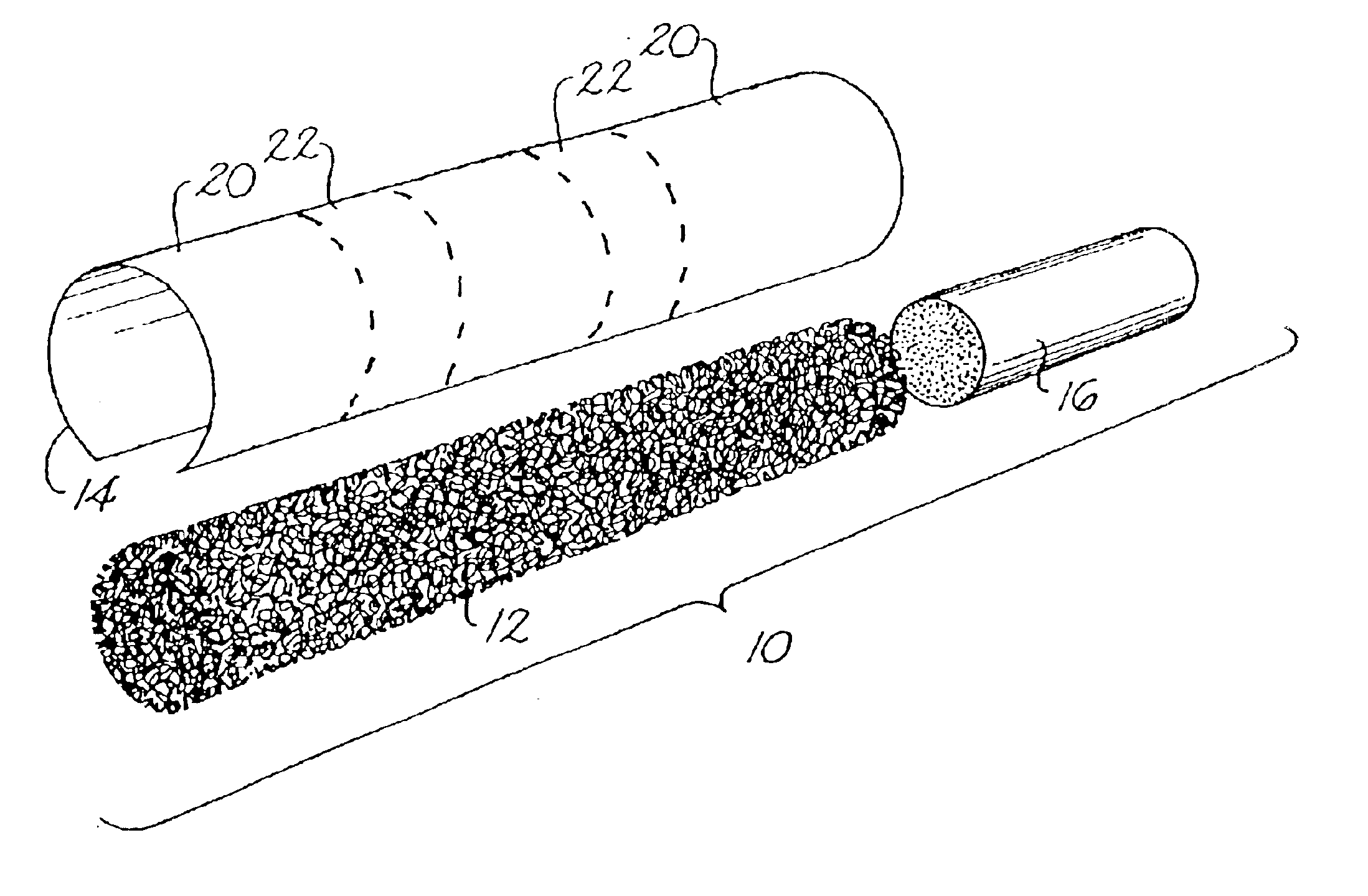

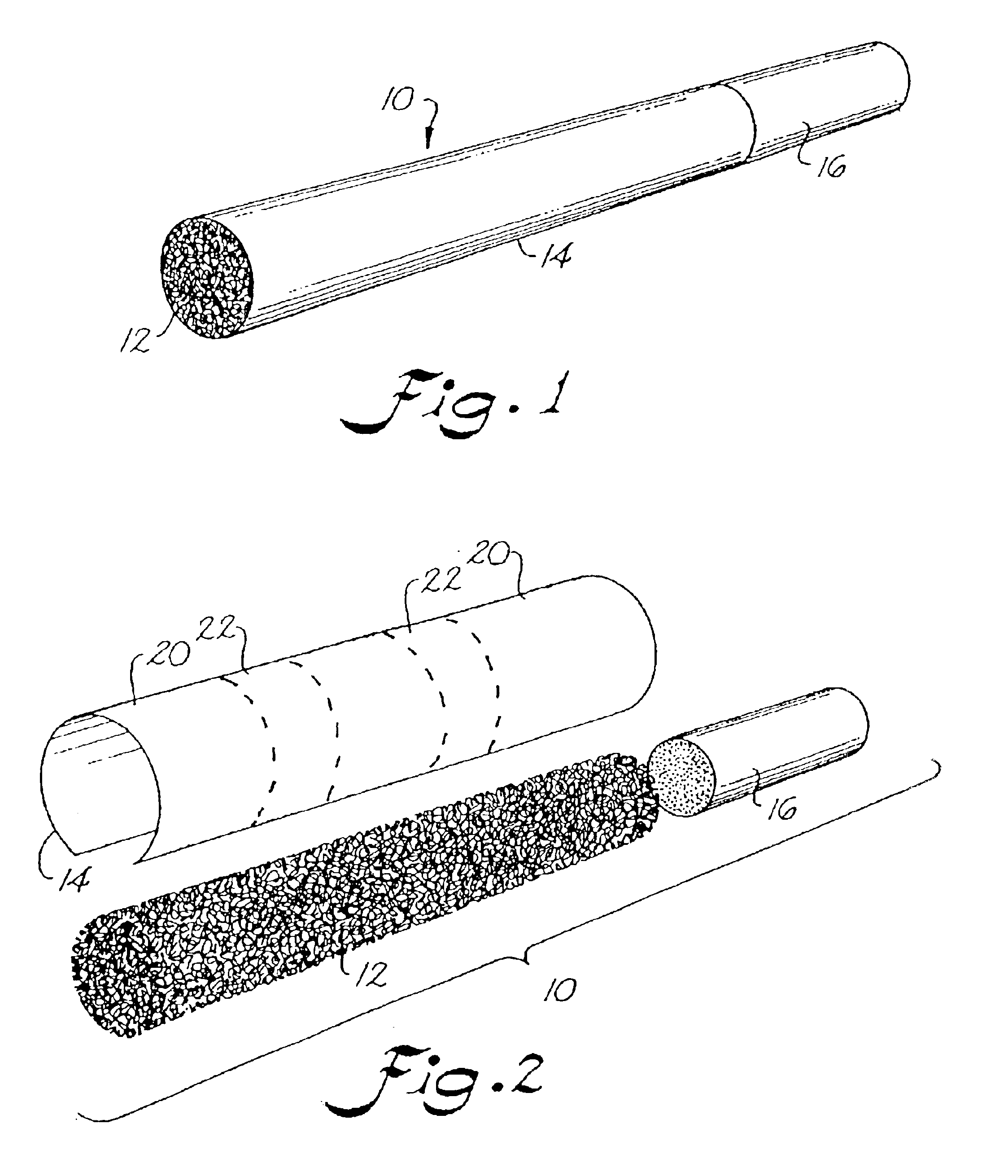

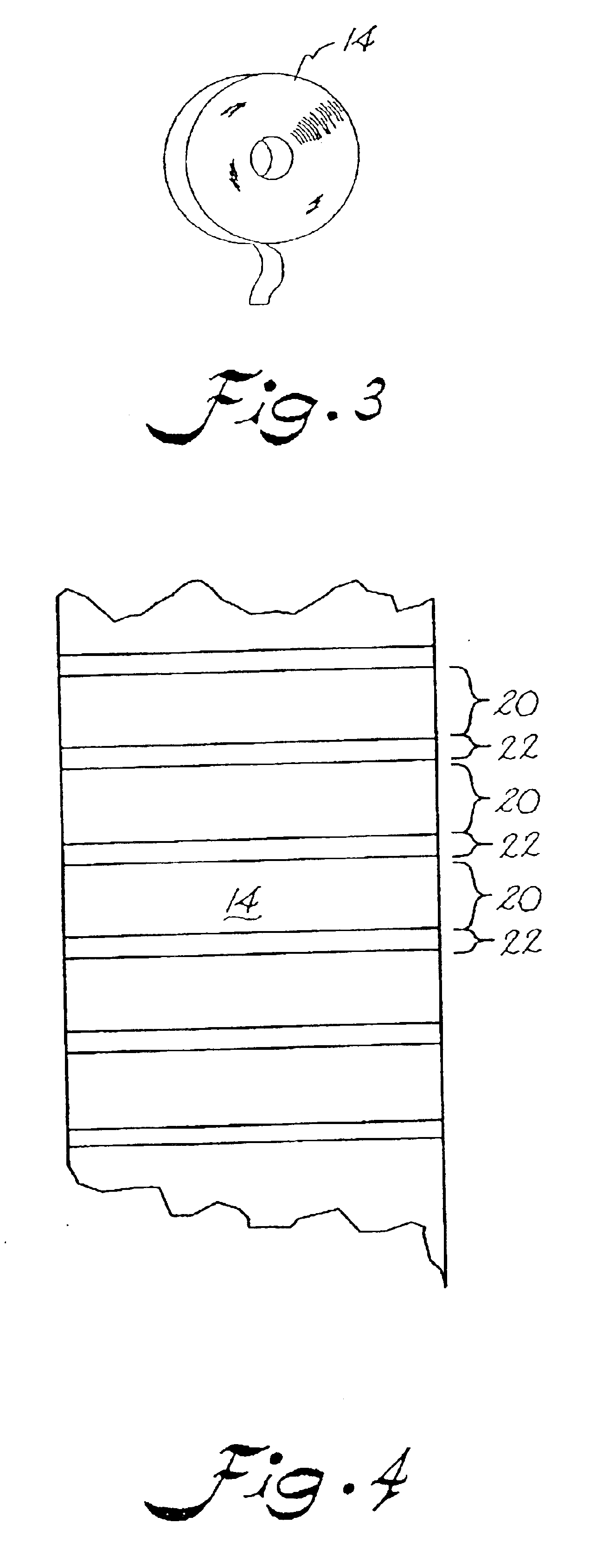

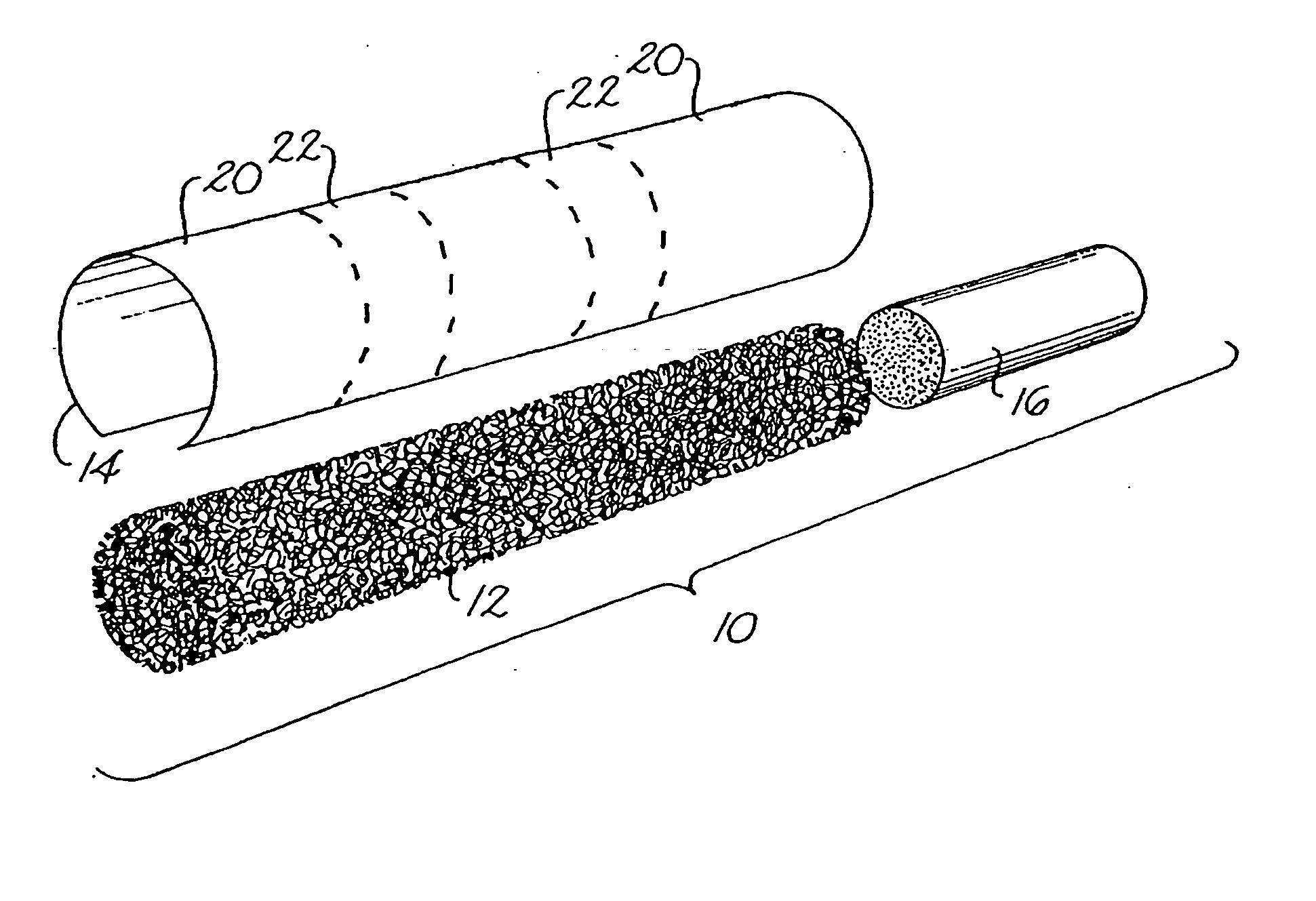

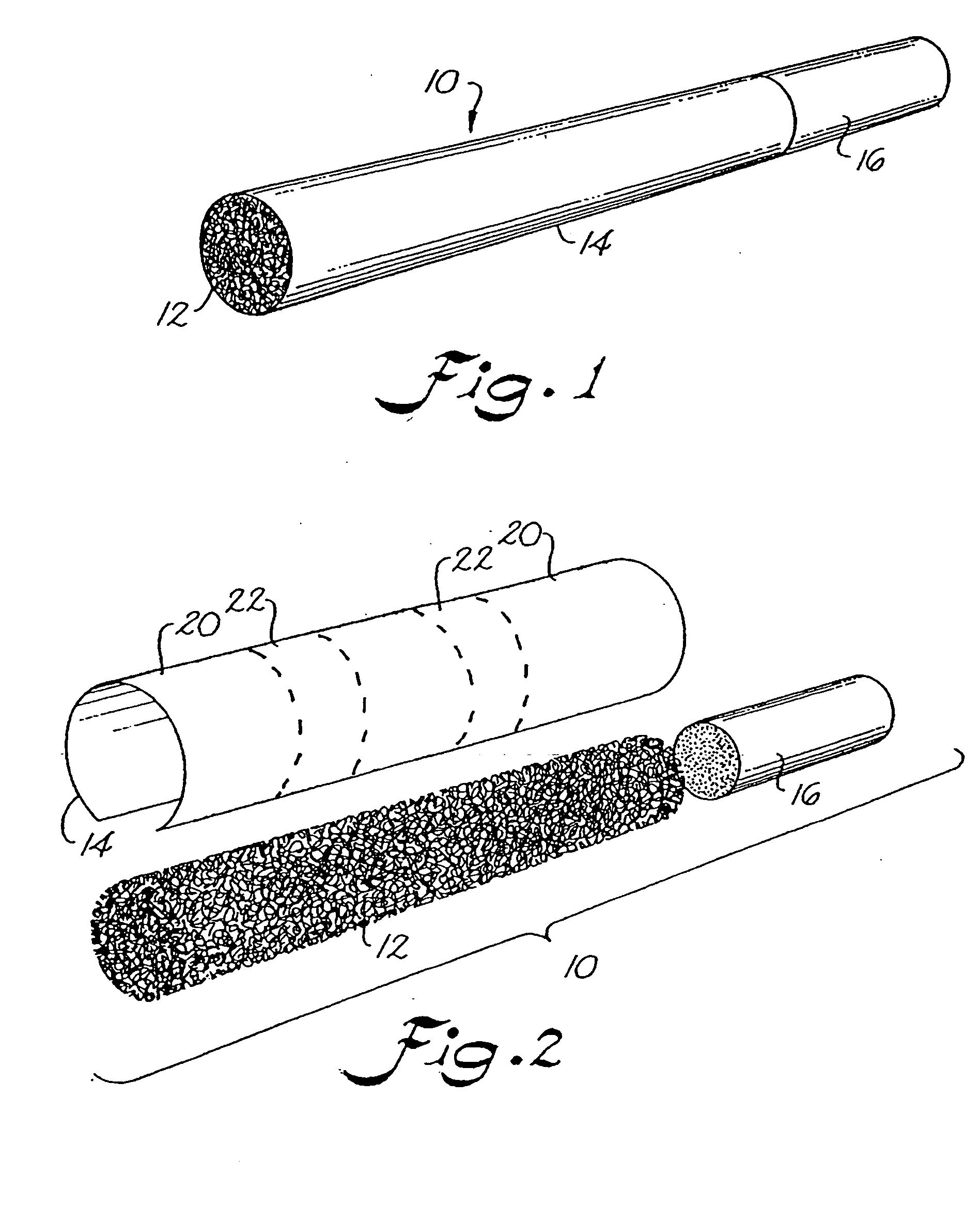

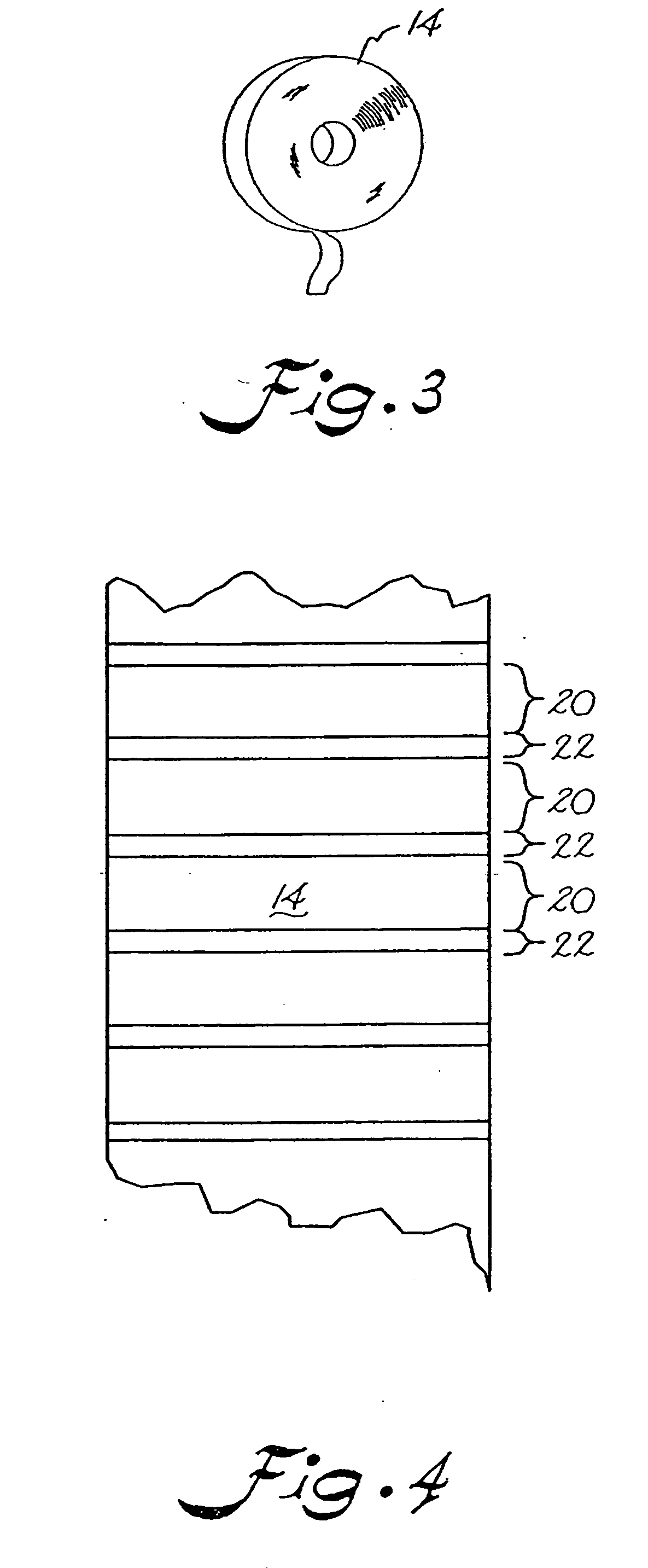

Reduced ignition propensity smoking article

InactiveUS6837248B2Reduced IPReduce penetrationNon-fibrous pulp additionNatural cellulose pulp/paperBurn rateEngineering

A smoking article having reduced ignition propensity is disclosed. The smoking article includes a tobacco column, a wrapper surrounding the tobacco column and a filter element. The wrapper has a base permeability, an untreated area and a least one discrete area treated with a composition to reducing the base permeability. The discretely treated area interacts with a coal of a burning tobacco firecone as it advances to self-extinguish the smoking article. The composition of the treated area includes a permeability reducing substance, a burn rate retarding substance and a burn rate accelerating substance. Either the burn rate retarding substance or the burn rate accelerating substance acts as an organoleptic enhancing substance. In this way a smoker's experience when smoking either the at least one treated area or the untreated area is substantially the same.

Owner:LORILLARD LICENSING

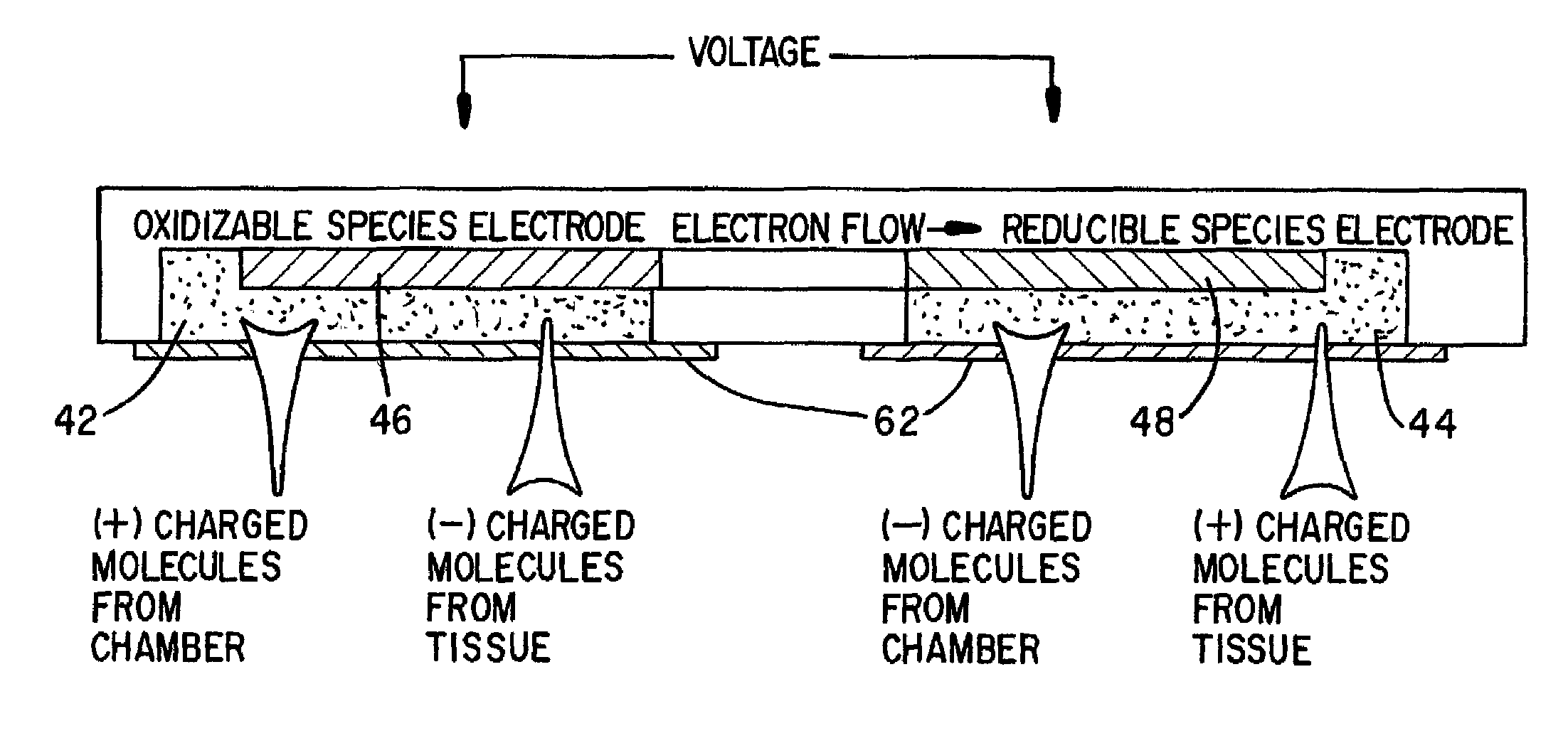

Controlled dosage drug delivery

InactiveUS7031768B2Eliminate oxygen reduction current and associated pH changeAvoid medicationElectrotherapyMedical applicatorsElectricityElectrical conductor

A planar disposable transdermal iontophoretic delivery system is disclosed which includes amounts of an oxidizable species and a reducible species connected by a common conductor forming a galvanic battery for serving as the sole source of power and control for the system, an amount of a therapeutic agent is provided to be driven through the skin of a patient solely through the use of the galvanic battery. The galvanic battery is provided with a lot-tested coulombic capacity rating to predict dosage.

Owner:THE TAPEMARK

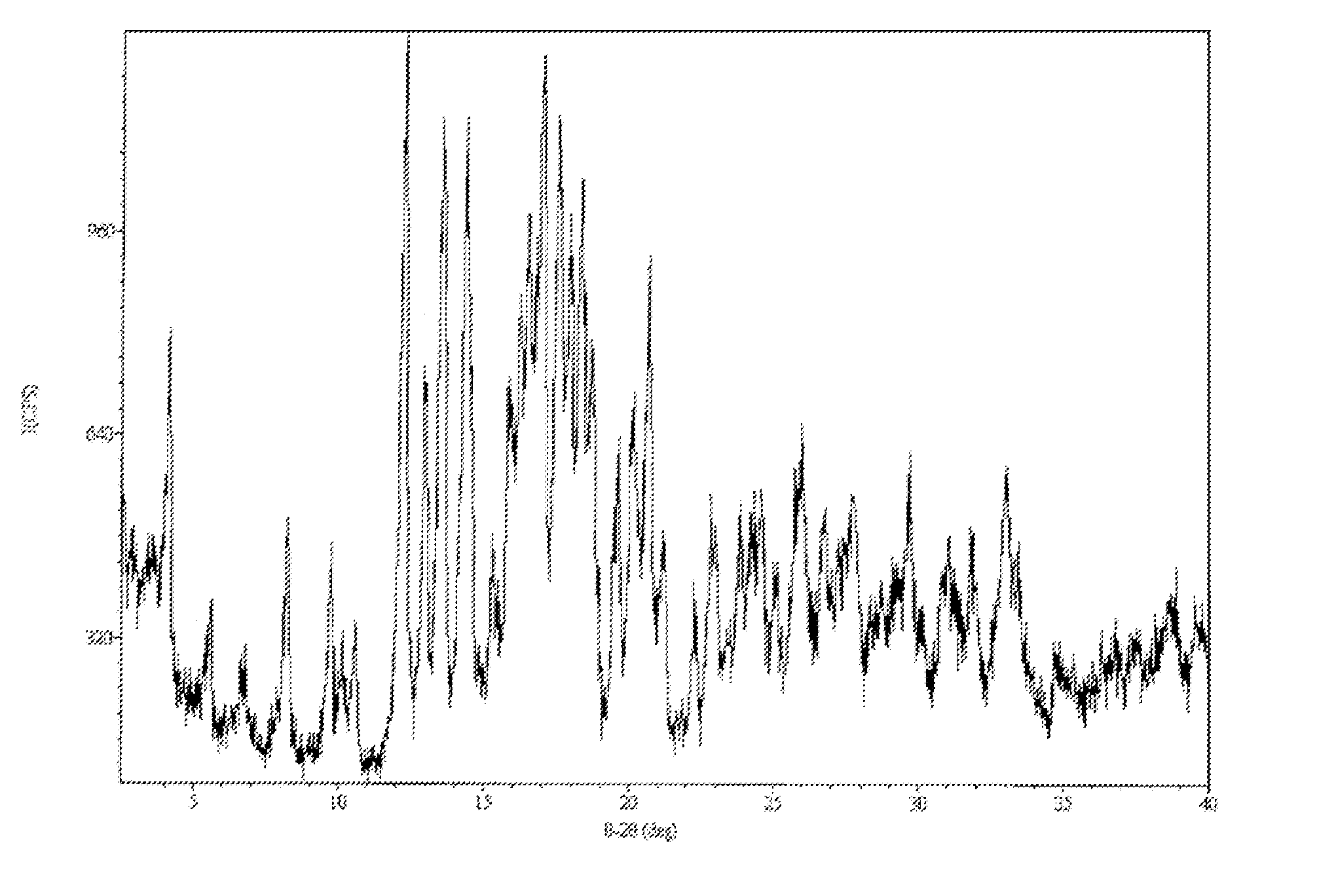

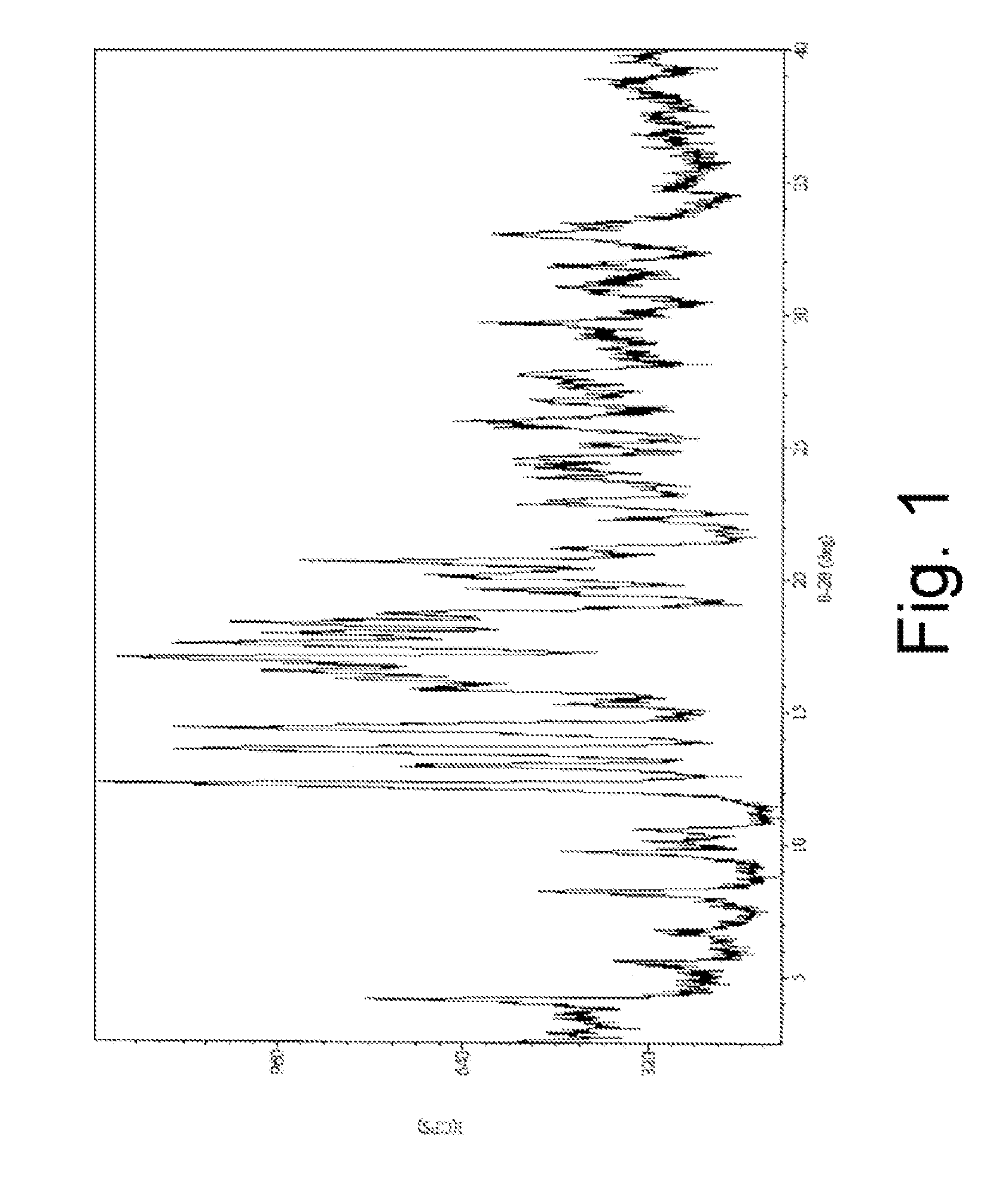

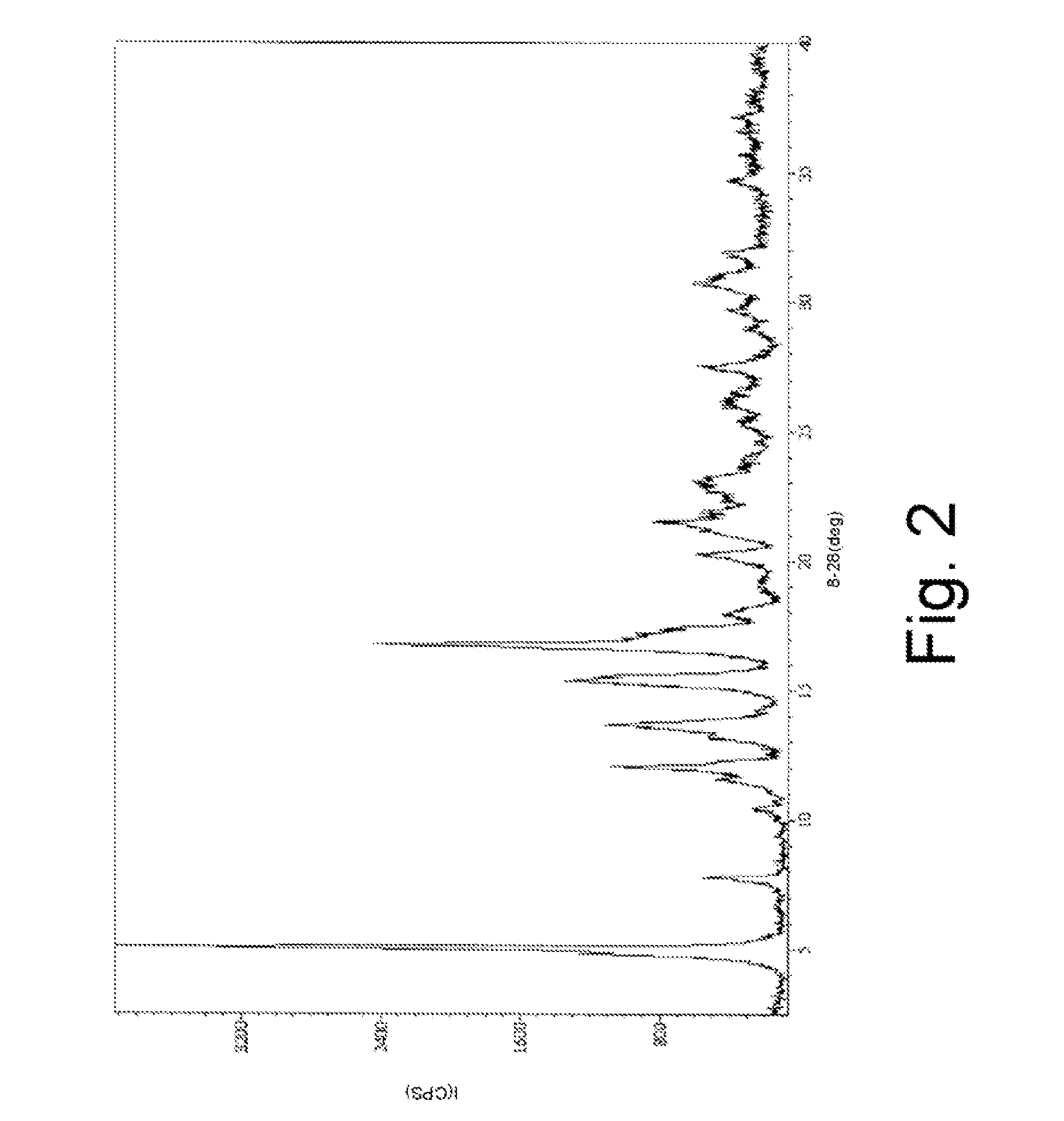

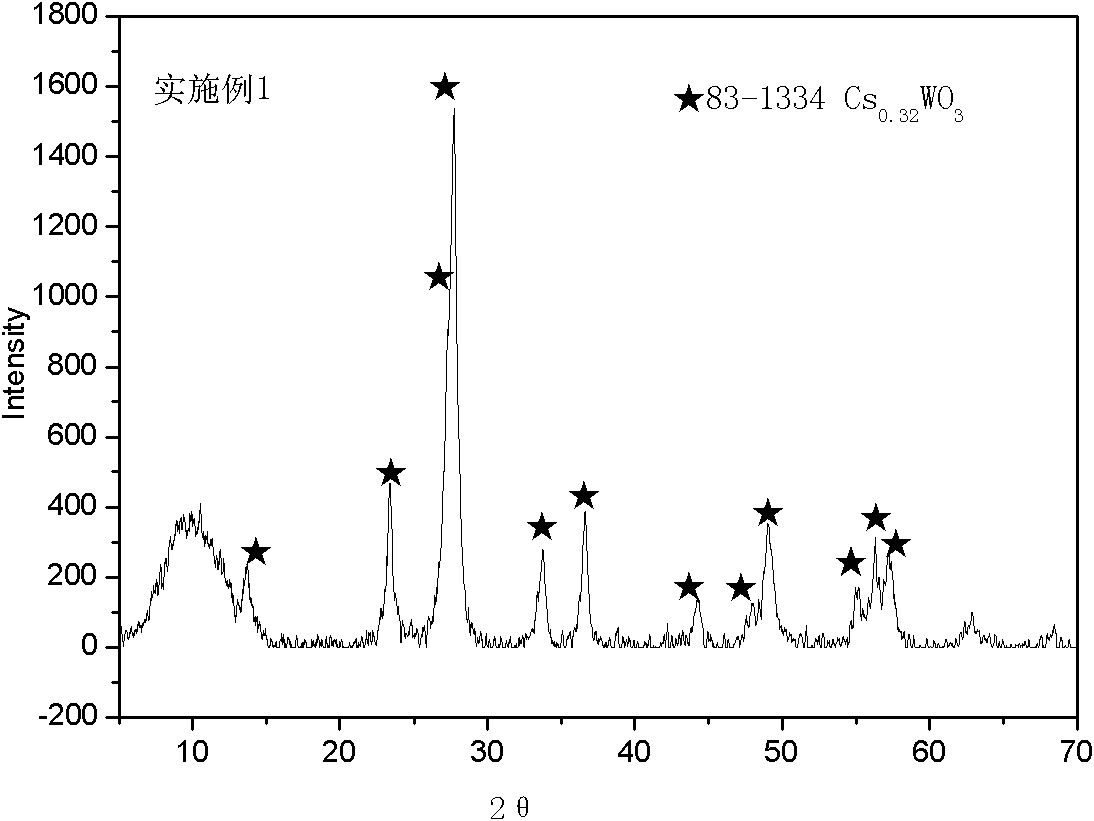

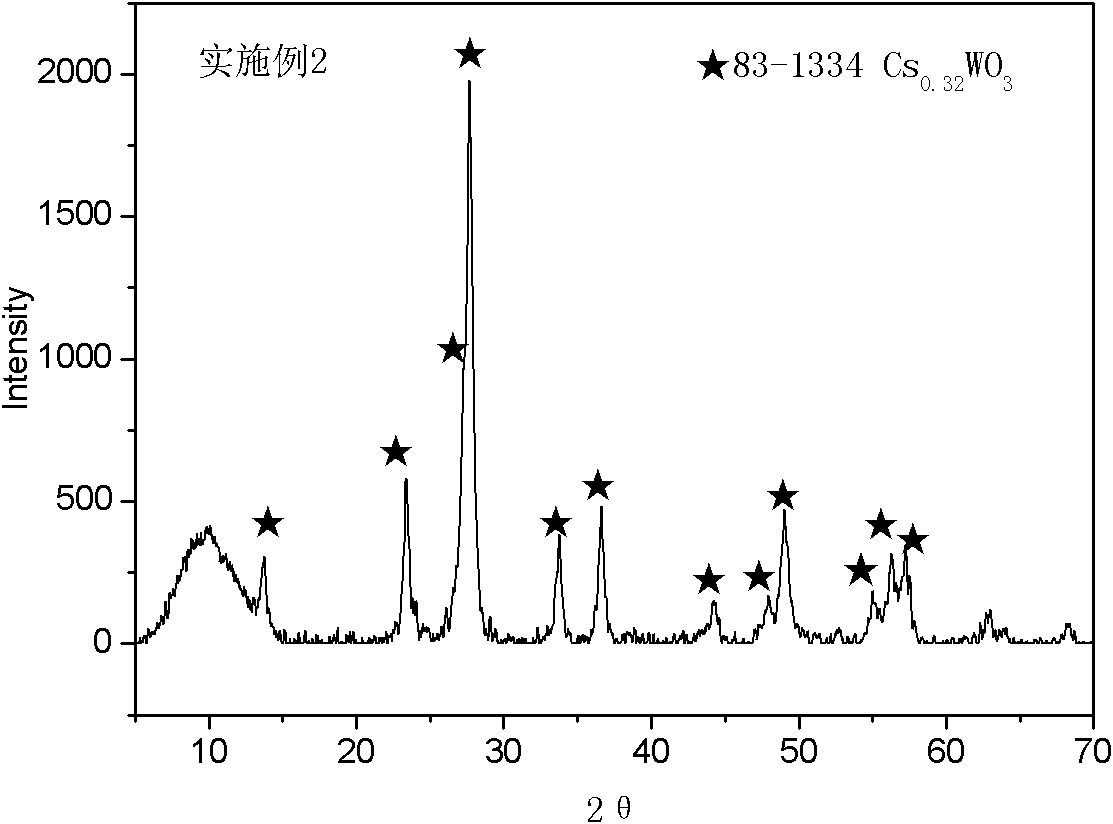

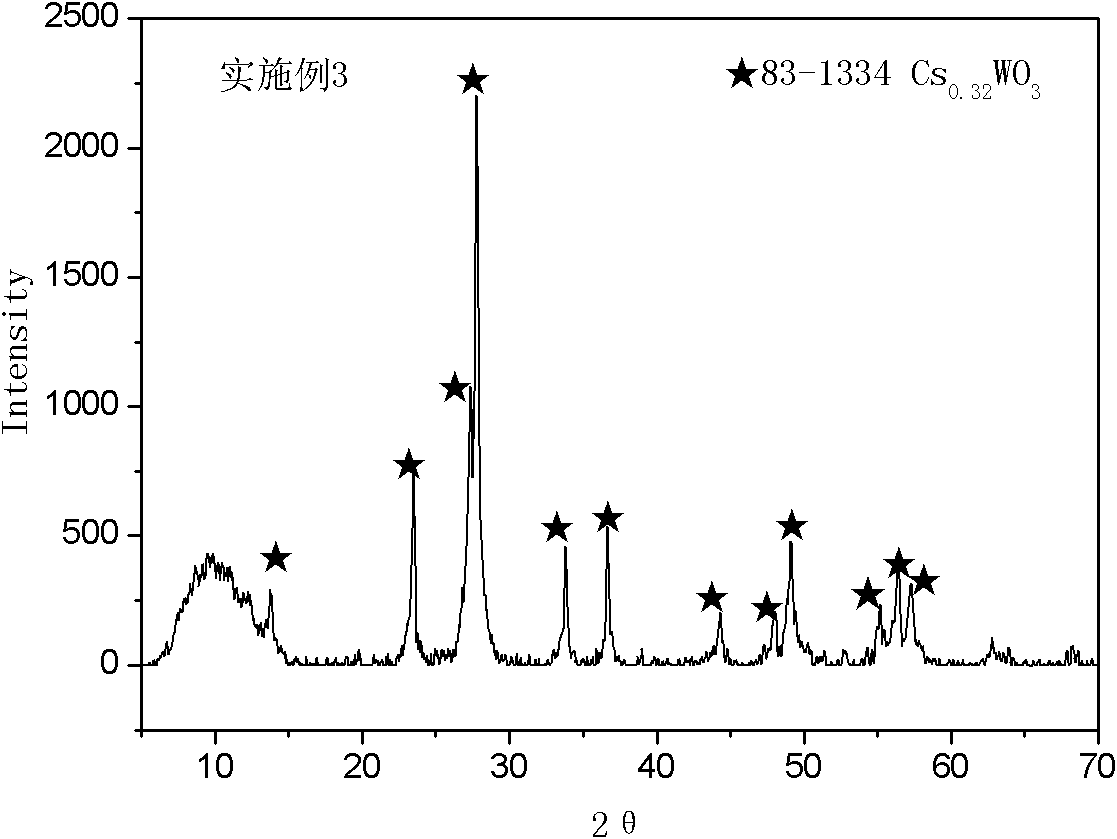

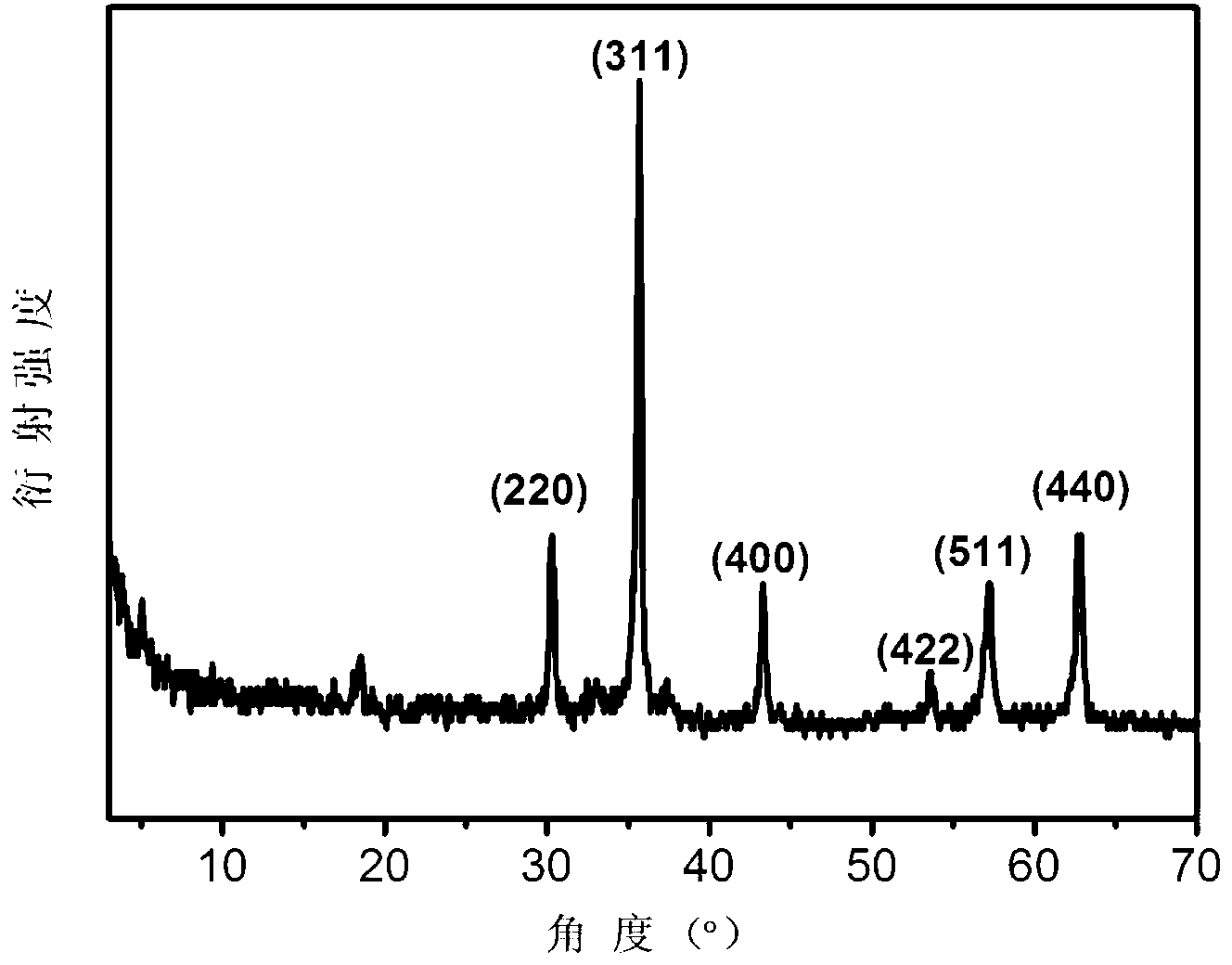

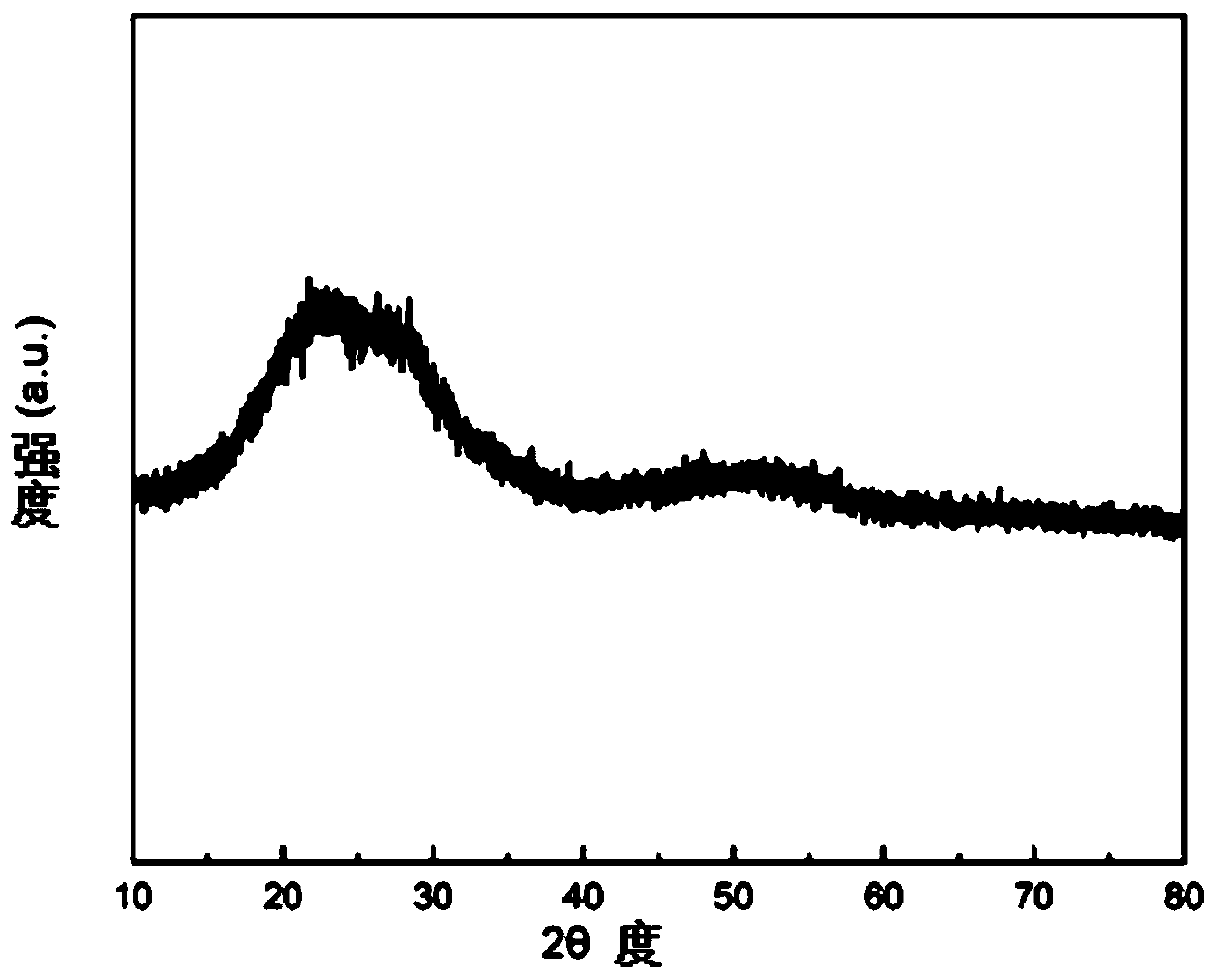

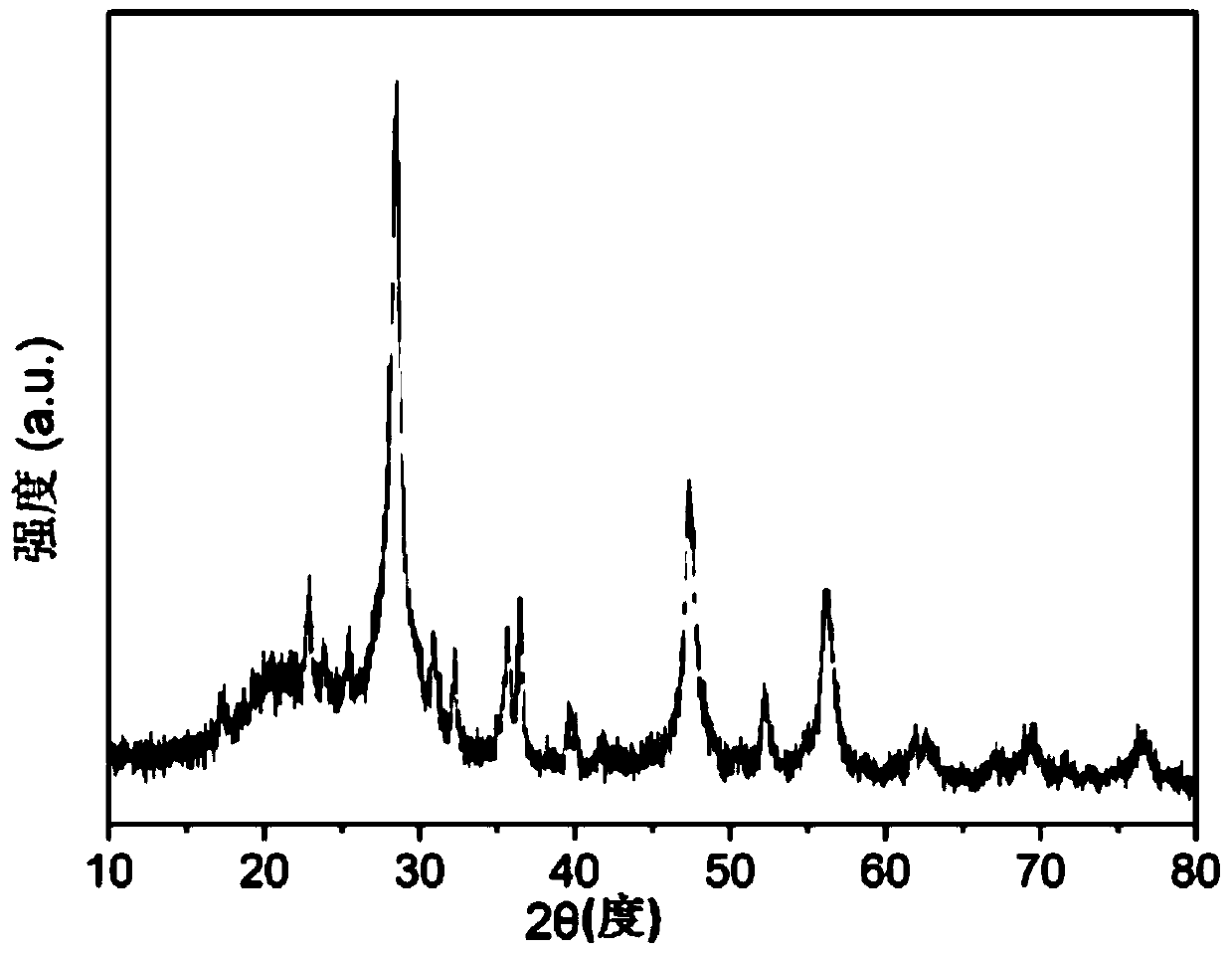

Cesium tungsten bronze powder and preparation method thereof

InactiveCN102320662AOptimal Control StructureReduce manufacturing costTungsten compoundsGranularitySolvent

The invention relates to cesium tungsten bronze powder and a preparation method thereof. The method comprises the following steps that: 1, precursor solution with tungstic acid, cesium carbonate and reducing substances is prepared according to a Cs / W mole ratio of 0.01 to 0.35 / 1, and the solvents are water or a mixture formed by ethanol and the water according to a volume ratio of 1 / 4 to 4 / 1; and 2, the precursor solution takes reaction for 1 to 3d under the condition of 180 to 200 DEG C in an autoclave, and the cesium tungsten bronze powder is obtained after the obtained precipitates are treated. The powder has the crystalline phase composition of Cs0.2WO3 or Cs0.32WO3, the size of the powder particle is 100 to 1300nm, and the specific surface area is 7 to 50m<2> / g. The synthetic process has the advantages that raw materials are cheap and mild, the operation is easy, the production cost can be reduced, in addition, the low-temperature (lower than or equal to 20 DEG C) synthesis is adopted, and the process is suitable for production and practical application. In addition, the product purposes are wide.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Process For Preparing Conductive Material

ActiveUS20090233237A1High transparencyImprove conductivityConductive layers on insulating-supportsConductive materialHalogenPolymer science

It is to provide a process for preparing a conductive material in which transparency and conductivity are both high, and storage stability is high, and further, in a process for preparing a conductive material utilizing ultra fine silver particles, to provide a process for preparing a conductive material having high conductivity without requiring a calcination step which has conventionally been required.A process for preparing a conductive material having a conductive pattern containing silver on a support, which process for preparing a conductive material comprises acting at least one of the following mentioned (I) to (IV) on the pattern portion containing silver provided on the support:(I) a reducing substance,(II) a water-soluble phosphorus oxo acid compound,(III) a water-soluble halogen compound,(IV) warm water of 55° C. or higher.

Owner:MITSUBISHI PAPER MILLS LTD

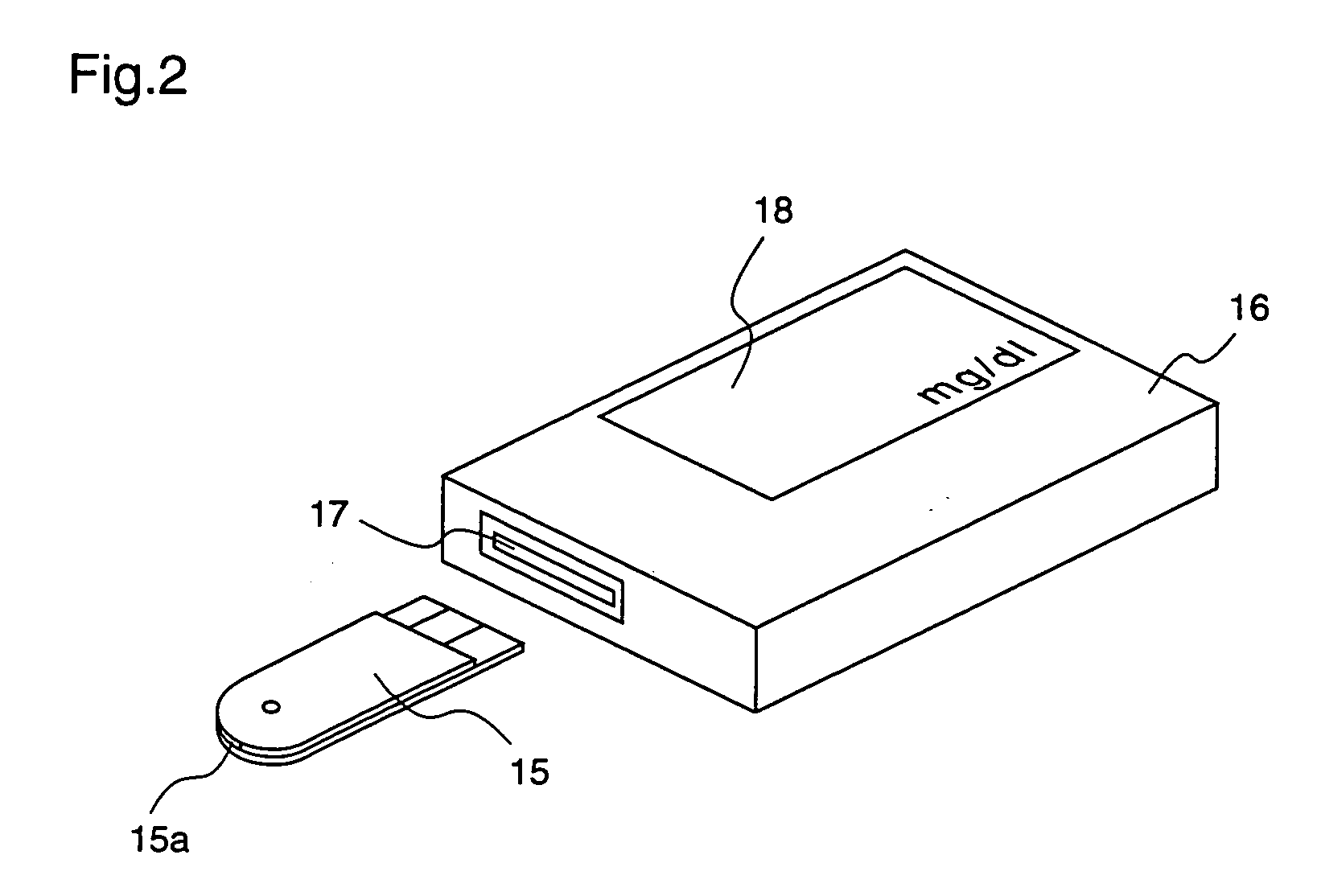

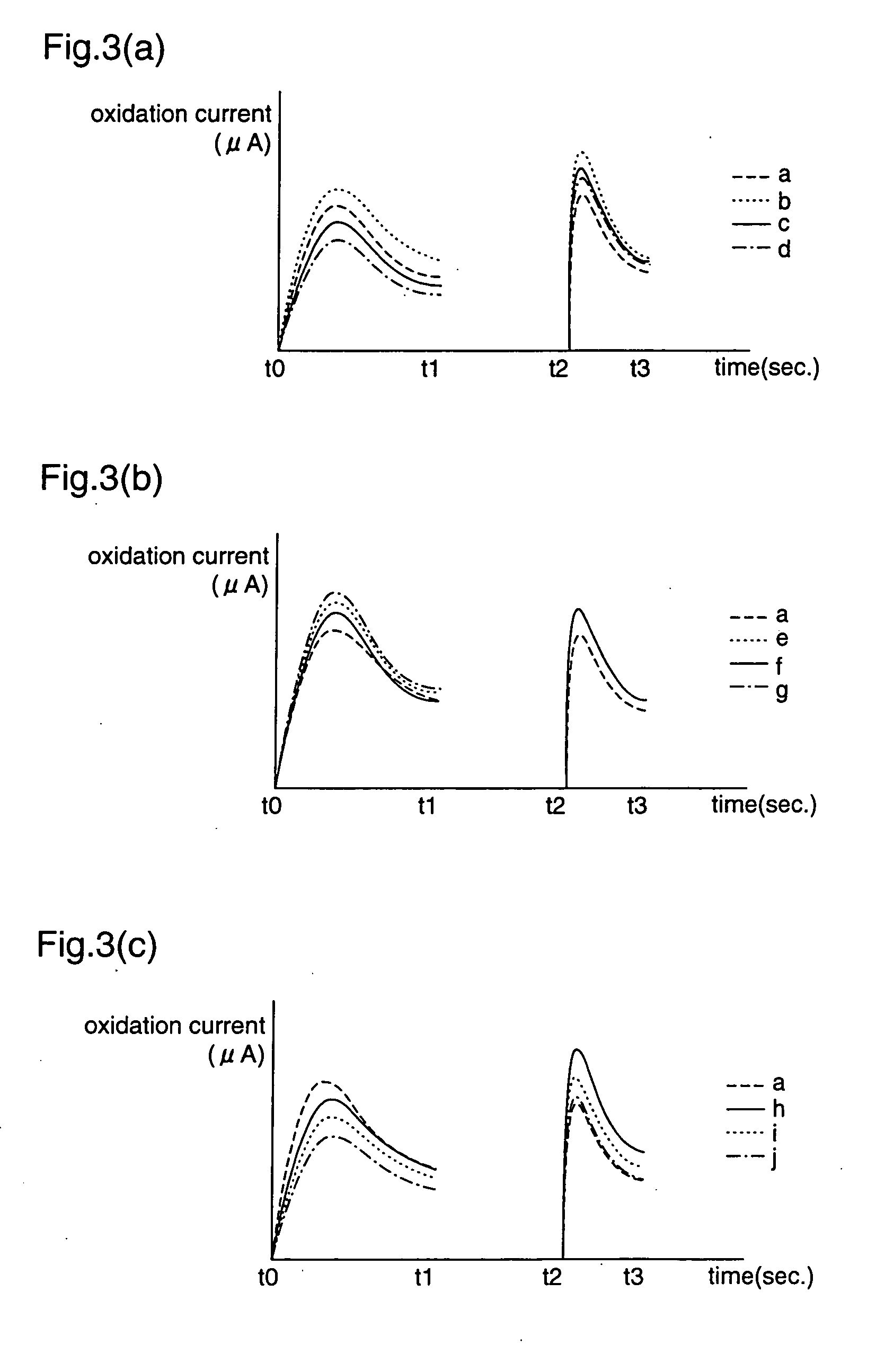

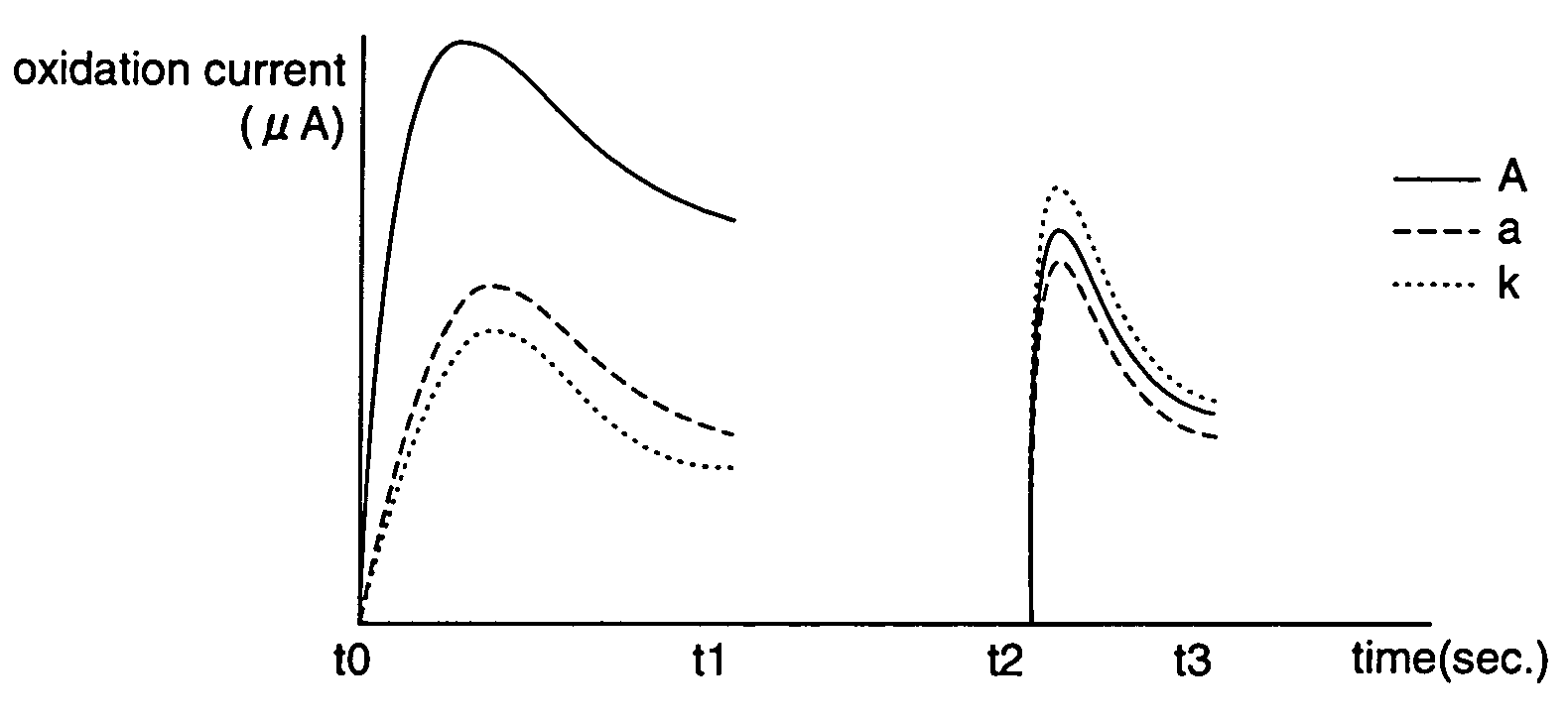

Determination method for automatically identifying analyte liquid and standard solution for biosensor

ActiveUS20050247562A1Improve accuracyHigh-precision identificationElectrolysis componentsWeather/light/corrosion resistanceAnalyteMeasuring instrument

According to the standard solution and the determination method of the present invention, in a case where a voltage is applied by a drive voltage of a measurement apparatus to an electrode portion of a biosensor comprising an electrode portion including a counter electrode and a measuring electrode formed on an insulating substrate, and a reagent layer which reacts with a sample solution supplied to the electrode portion, and a current value which flows at the application is measured, thereby determining a substrate contained in the sample solution, a reducing substance is contained in the standard solution used for controlling a precision of measurement of the measurement apparatus. Therefore, when the standard solution is measured, a large change occurs in a current waveform between time t0 and t1 shown in FIG. 6 due to the reducing substance, thereby discriminating whether the analyte liquid being measured is the standard solution or the sample solution and easily identifying the kind of analyte liquid.

Owner:PHC HLDG CORP

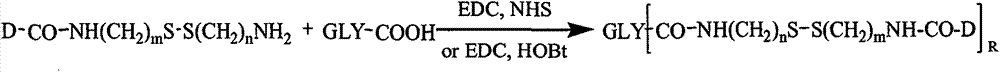

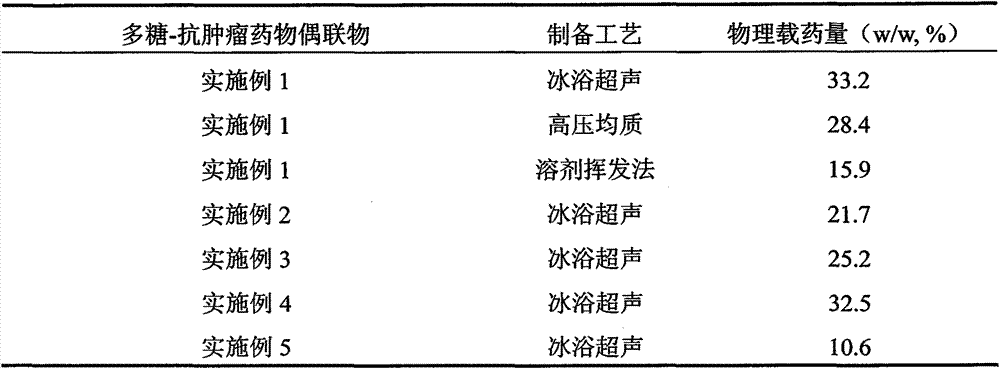

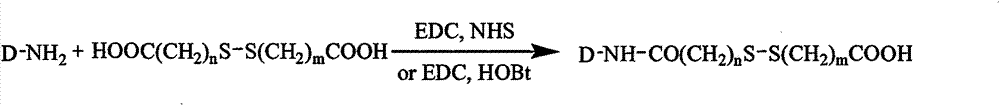

Amphiphilic polysaccharide-anti-tumor medicament conjugate capable of releasing medicines specifically at lesion site of living body, as well as preparation method and application of medicinal composition of amphiphilic polysaccharide-anti-tumor medicament conjugate

InactiveCN103301472AImprove stabilityQuick releaseSolution deliveryPharmaceutical non-active ingredientsHigh concentrationTreatment effect

The invention relates an amphiphilic polysaccharide-anti-tumor medicament conjugate capable of releasing medicines specifically at a lesion site of a living body, as well as a preparation method and application of a medicinal composition of the amphiphilic polysaccharide-anti-tumor medicament conjugate. In the conjugates, hydrophobic anti-tumor medicaments are introduced into a polysaccharide skeleton through a connecting arm which contains a disulfide bond, so that the polysaccharide-anti-tumor medicament conjugate has amphipathic characteristics and can be self-assembled into nano-micelles; the nano-micelles can load anti-tumor medicaments additionally and also can be directly used as conjugate pre-drug micelles. The amphiphilic polysaccharide-anti-tumor medicament conjugate is mainly characterized in that 1) after the nano-micelles reach the lesion site, the disulfide bond connecting arm of the conjugate can be specifically degraded by high-concentration reducing substances in lesion cells, so that the micelles are depolymerized and the medicament is released quickly, and therefore, the treatment effect is improved; 2) the anti-tumor medicament is chemically conjugated and physically coated to achieve a common treatment effect. The polysaccharide conjugate and the medicinal composition thereof can be used for injection, oral administration or external use administration; the anti-tumor activity can be improved remarkably; new ideas are provided for the development of anti-tumor medicaments.

Owner:CHINA PHARM UNIV

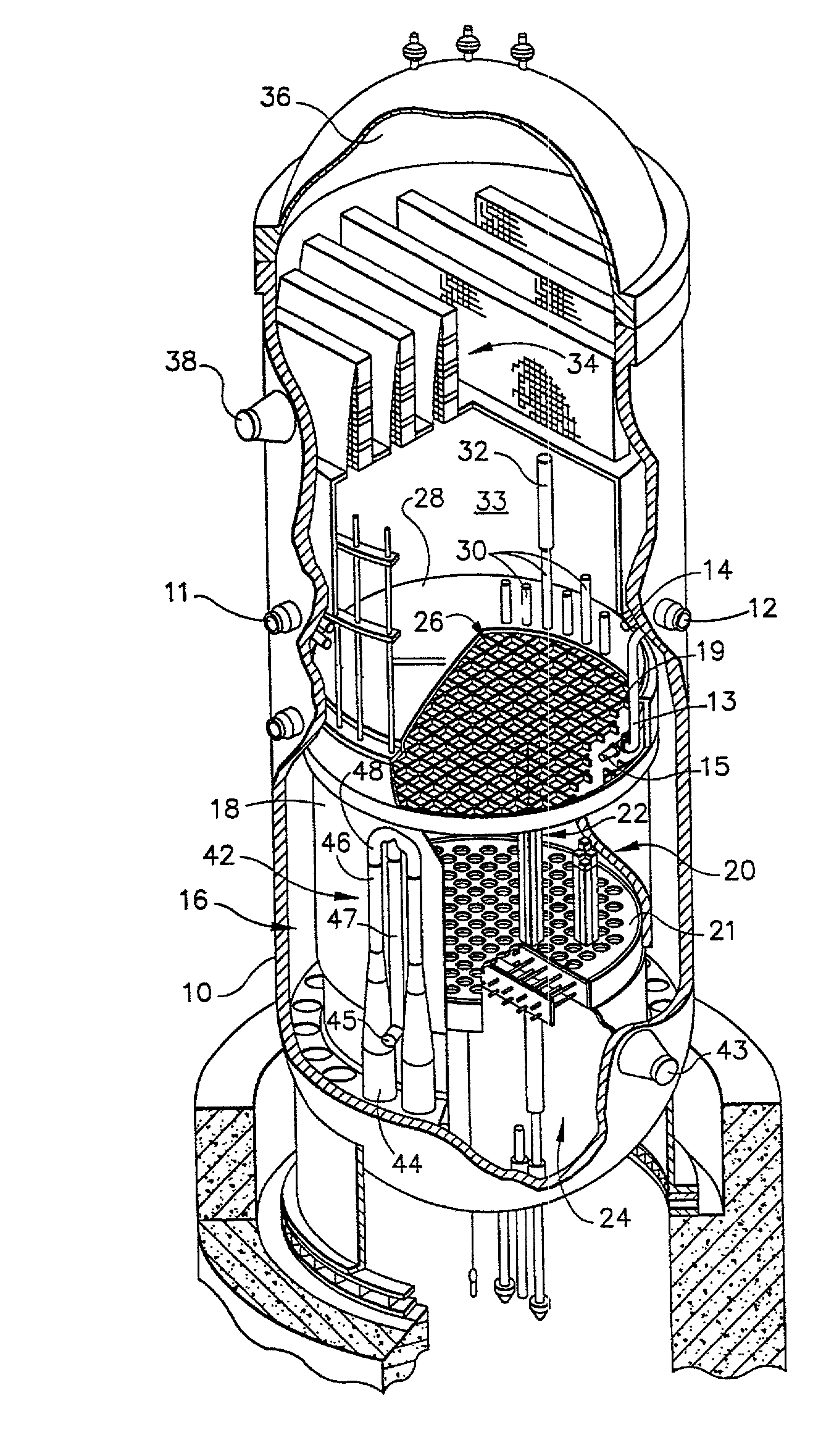

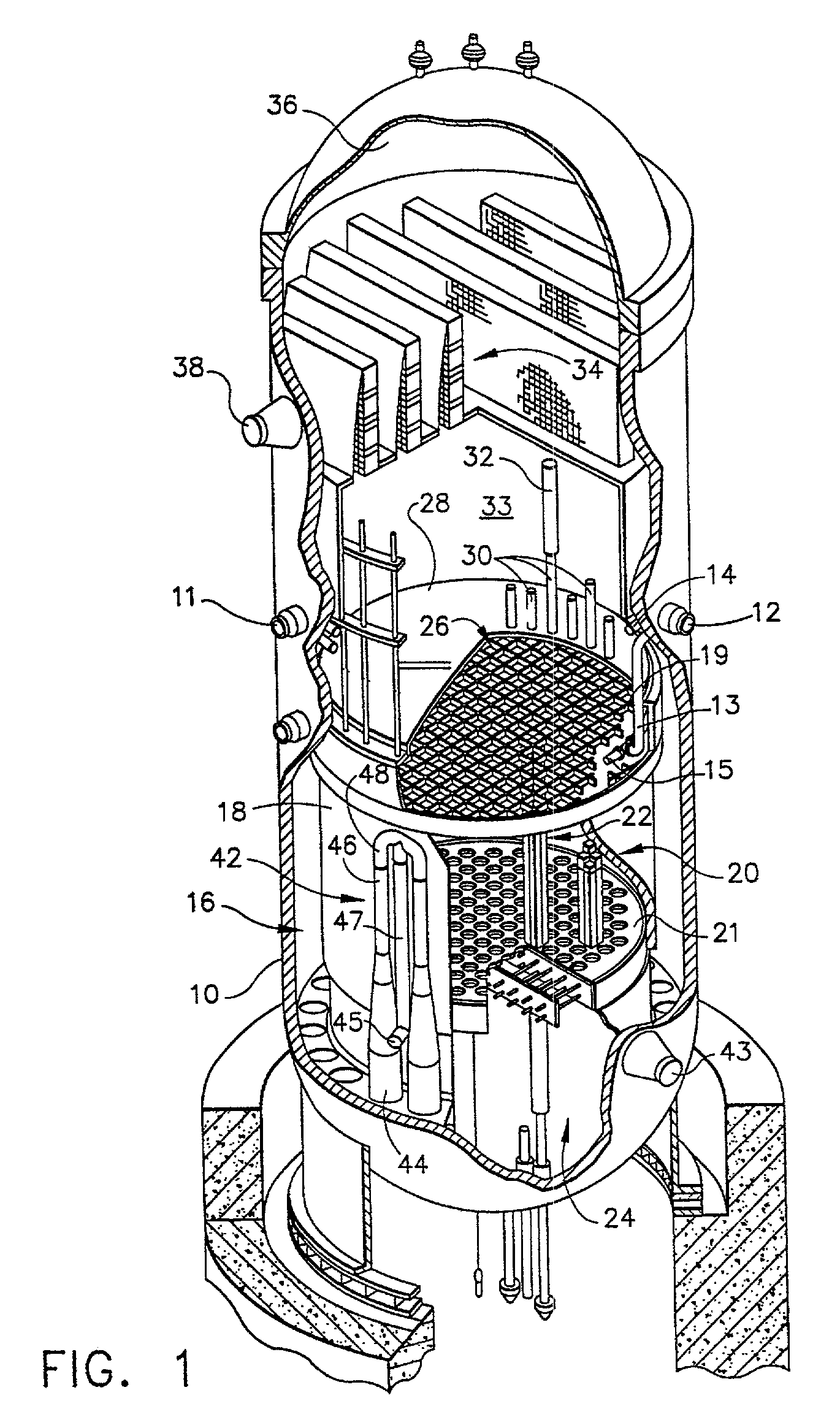

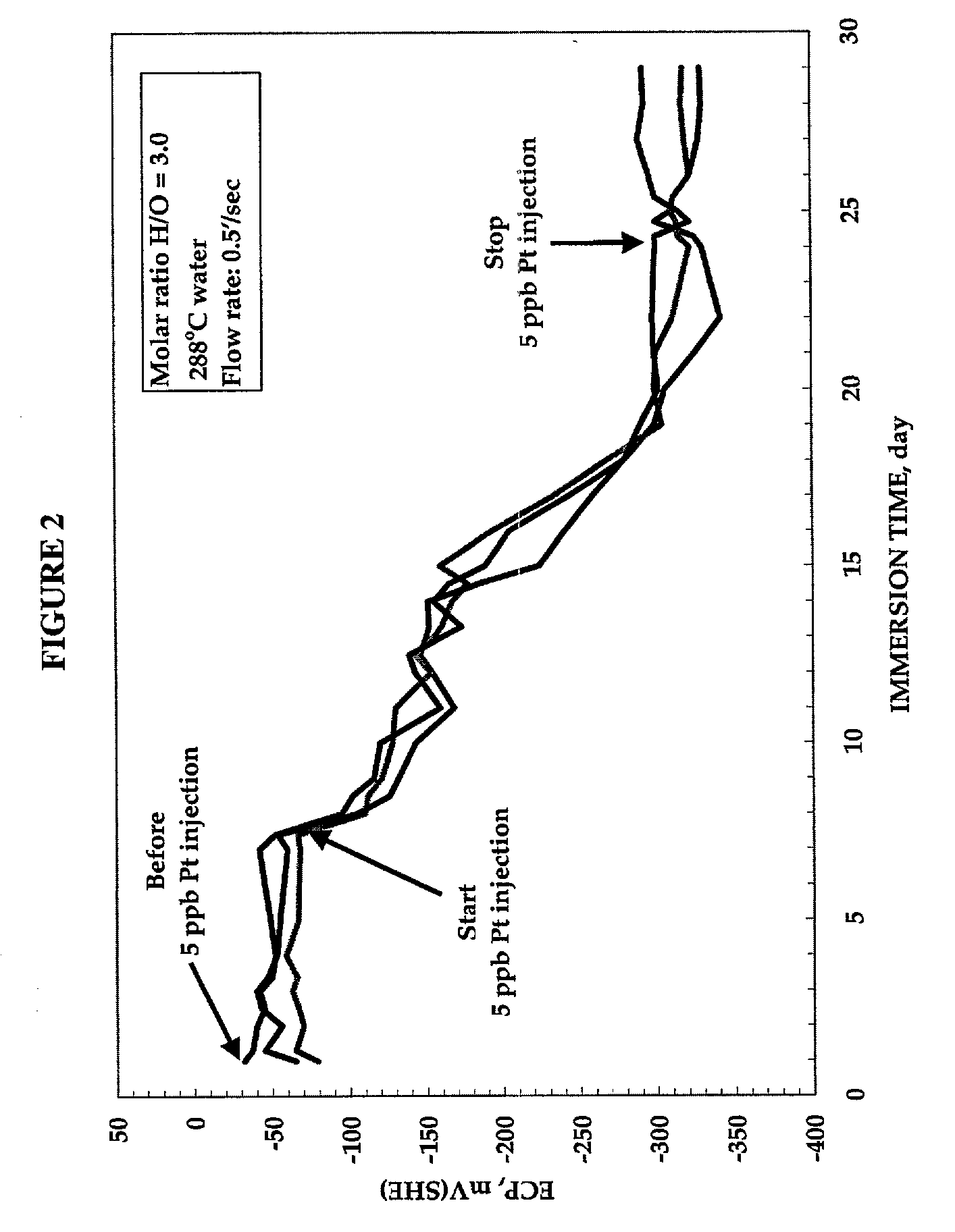

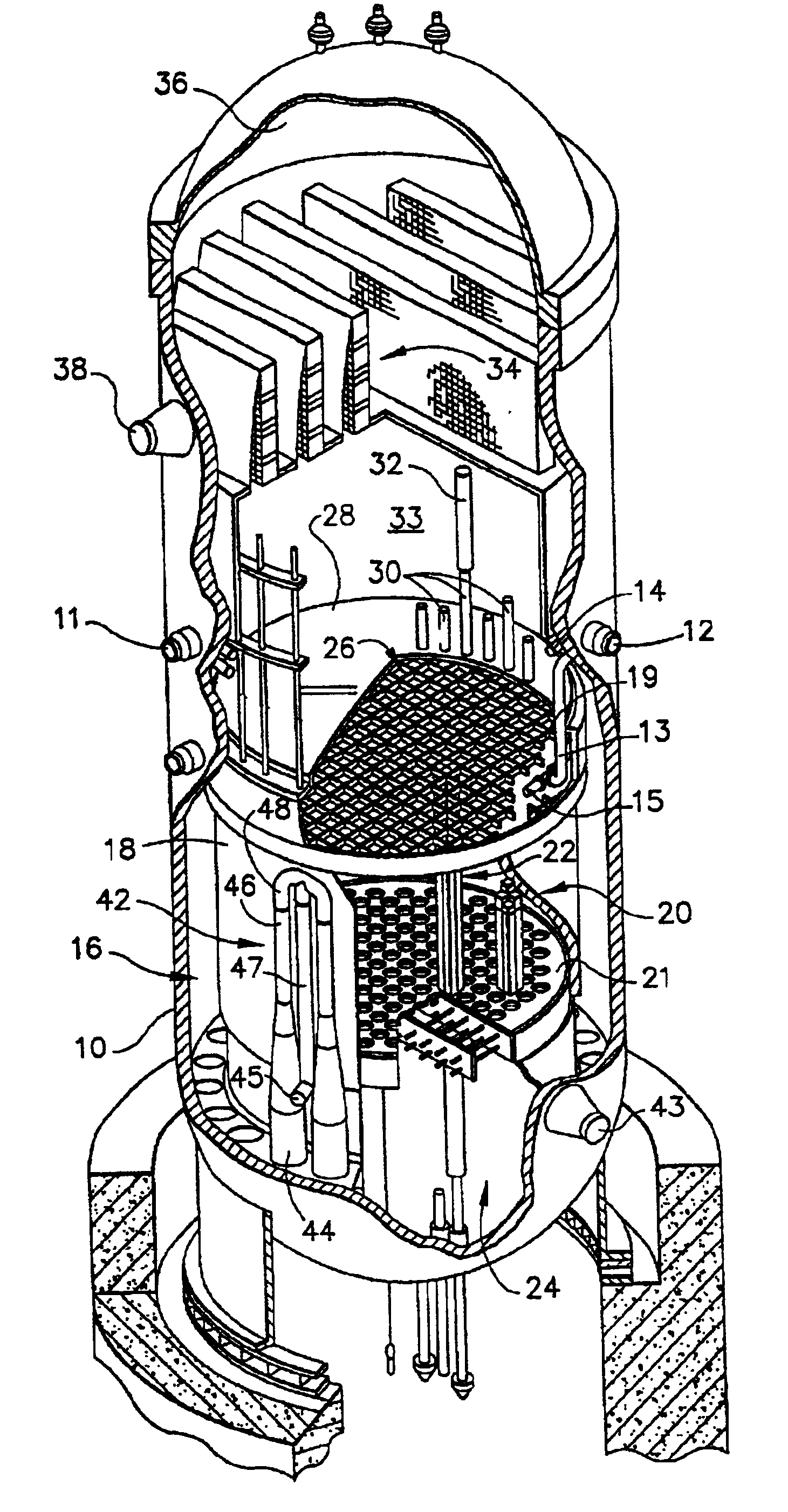

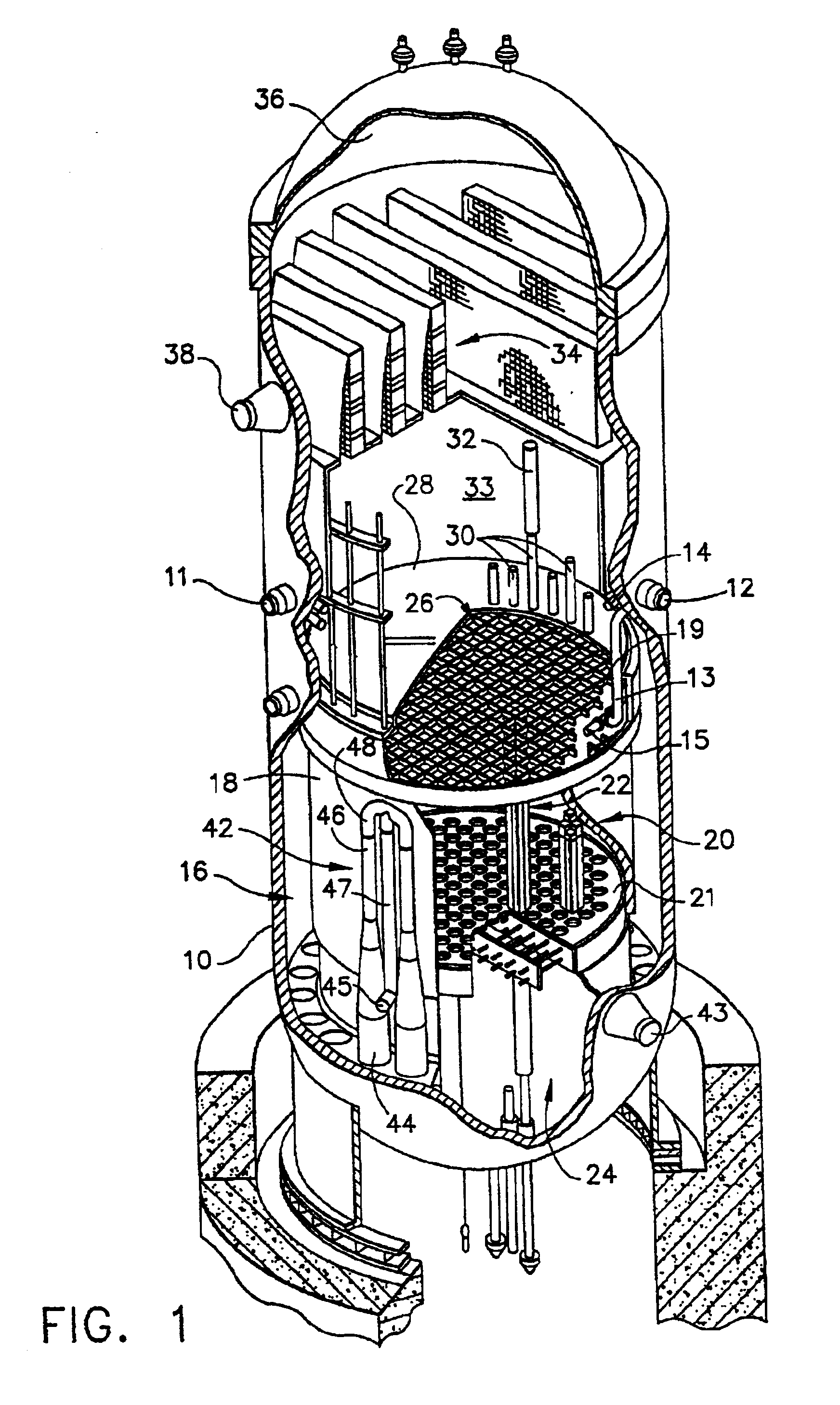

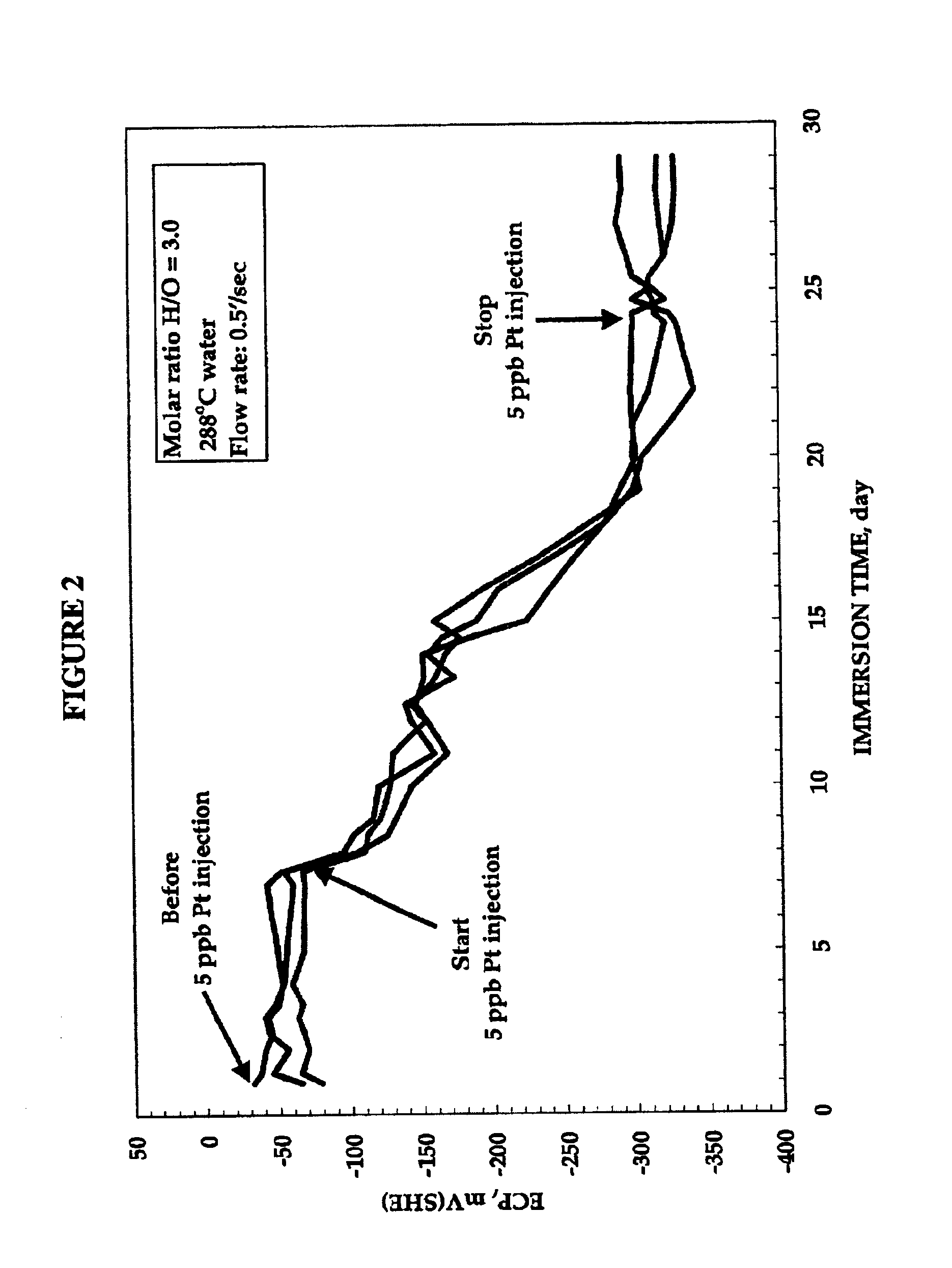

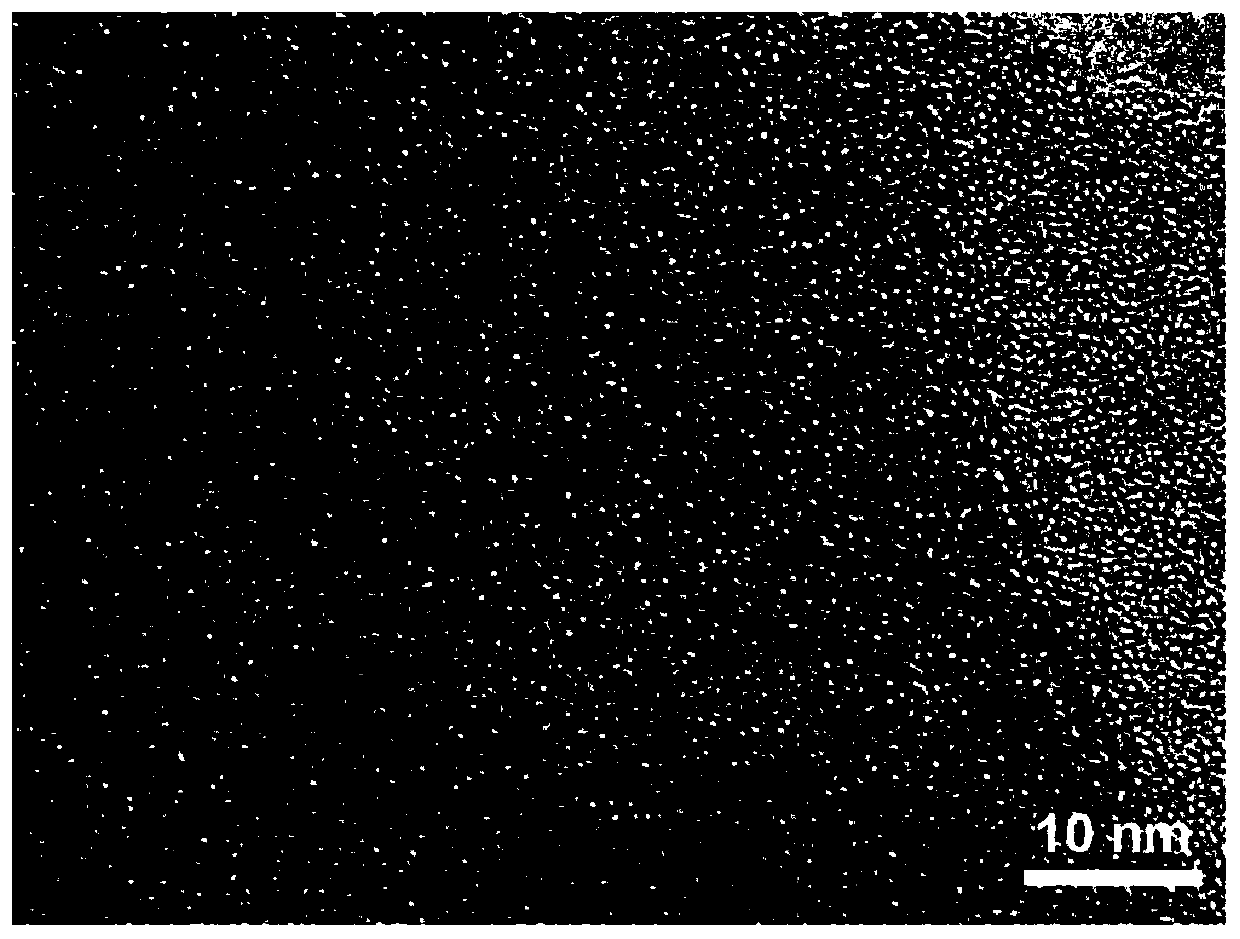

Application of catalytic nanoparticles to high temperature water systems to reduce stress corrosion cracking

InactiveUS20030012686A1Reducing electrochemical corrosion potentialReduce componentsNuclear energy generationNuclear monitoringNuclear reactorNanoparticle

A method and system for reducing stress corrosion cracking in a hot water system, such as a nuclear reactor, by reducing the electrochemical corrosion potential of components exposed to high temperature water within the structure. The method comprises the steps of: providing a reducing species to the high temperature water; and providing a plurality of noble metal nanoparticles having a mean particle size of up to about 100 nm to the high temperature water during operation of the hot water system. The catalytic nanoparticles, which may comprise at least one noble metal, form a colloidal suspension in the high temperature water and provide a catalytic surface on which a reducing species reacts with least one oxidizing species present in the high temperature water. The concentration of the oxidizing species is reduced by reaction with the reducing species on the catalytic surface, thereby reducing the electrochemical corrosion potential of the component.

Owner:GENERAL ELECTRIC CO

Microcapsule and positive electrode material for battery as well as preparation methods and application of microcapsule and positive electrode material

ActiveCN104466186AReduce security risksImprove securityCell electrodesCell/batteries leak testingLithiumPhysical chemistry

The invention relates to the field of lithium ion secondary batteries, specifically relates to a microcapsule and a positive electrode material for a battery as well as preparation methods and application of the microcapsule and the positive electrode material. The microcapsule comprises 30-100 parts by weight of a core part and 10-110 parts by weight of a shell part, wherein the core part comprises a reducing substance and / or a flame retardant compound, the shell part is a macromolecule substance, the particle size of the microcapsule is 0.01-20 mum; the positive electrode material is prepared by blending and compounding the microcapsule and the basis positive electrode material. In a situation that internal temperature increase is out of control when the battery meets conditions such as acupuncture, over-charge, extrusion and fire, the microcapsule is molten and covers the surface of the positive electrode material, so that the volume resistivity of the material is enlarged; furthermore a reducing compound or a fire retardant compound is released, so that occurrence of the burning or explosion phenomenon caused by high temperature of the battery is reduced.

Owner:GUIZHOU ZHENHUA E CHEM INC

Application of catalytic nanoparticles to high temperature water systems to reduce stress corrosion cracking

InactiveUS6793883B2Reducing electrochemical corrosion potentialReduced dose rateNuclear energy generationNuclear monitoringNuclear reactorNanoparticle

A method and system for reducing stress corrosion cracking in a hot water system, such as a nuclear reactor, by reducing the electrochemical corrosion potential of components exposed to high temperature water within the structure. The method includes the steps of: providing a reducing species to the high temperature water; and providing a plurality of noble metal nanoparticles having a mean particle size of up to about 100 nm to the high temperature water during operation of the hot water system. The catalytic nanoparticles, which may contain at least one noble metal, form a colloidal suspension in the high temperature water and provide a catalytic surface on which a reducing species reacts with least one oxidizing species present in the high temperature water. The concentration of the oxidizing species is reduced by reaction with the reducing species on the catalytic surface, thereby reducing the electrochemical corrosion potential of the component.

Owner:GENERAL ELECTRIC CO

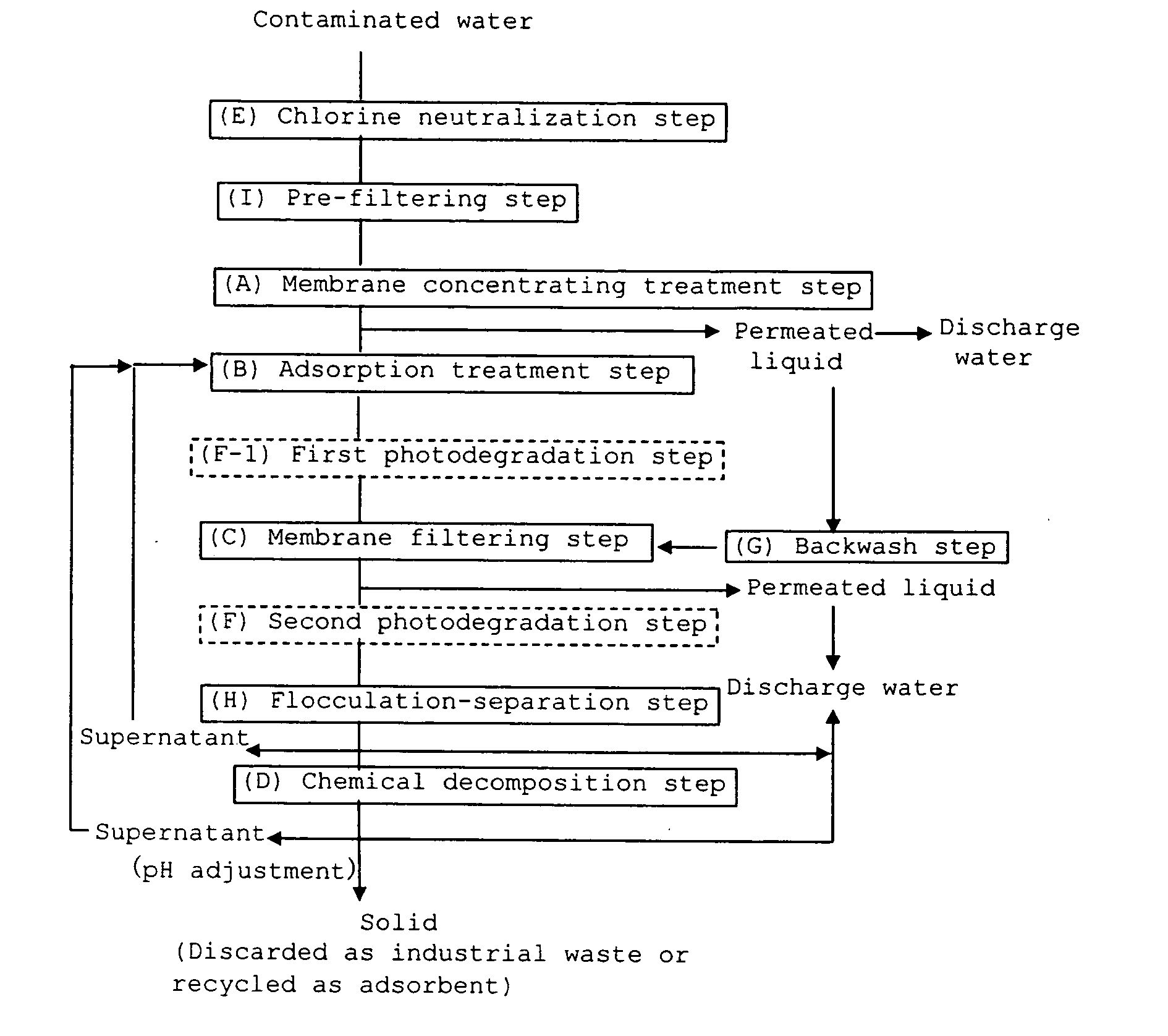

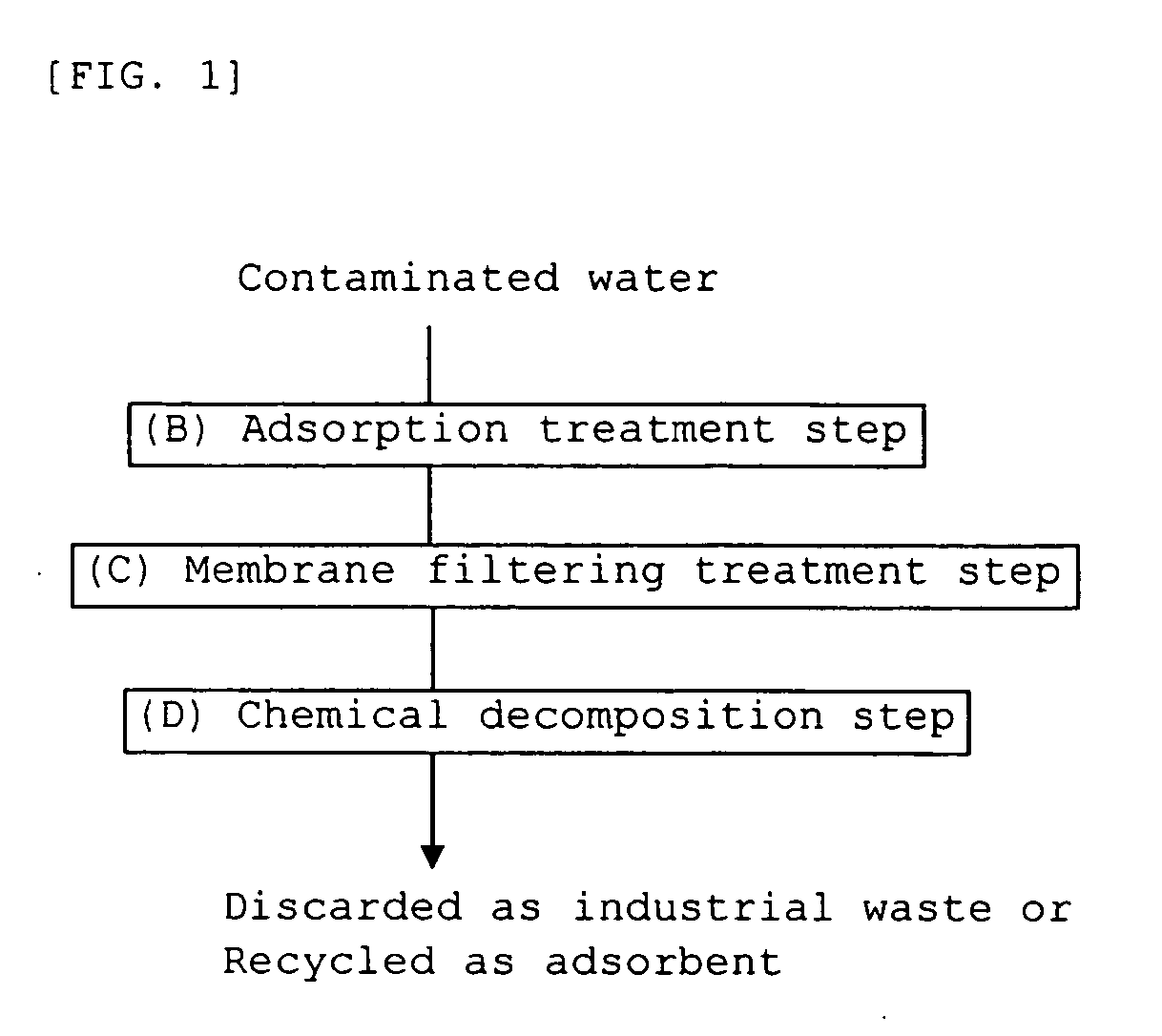

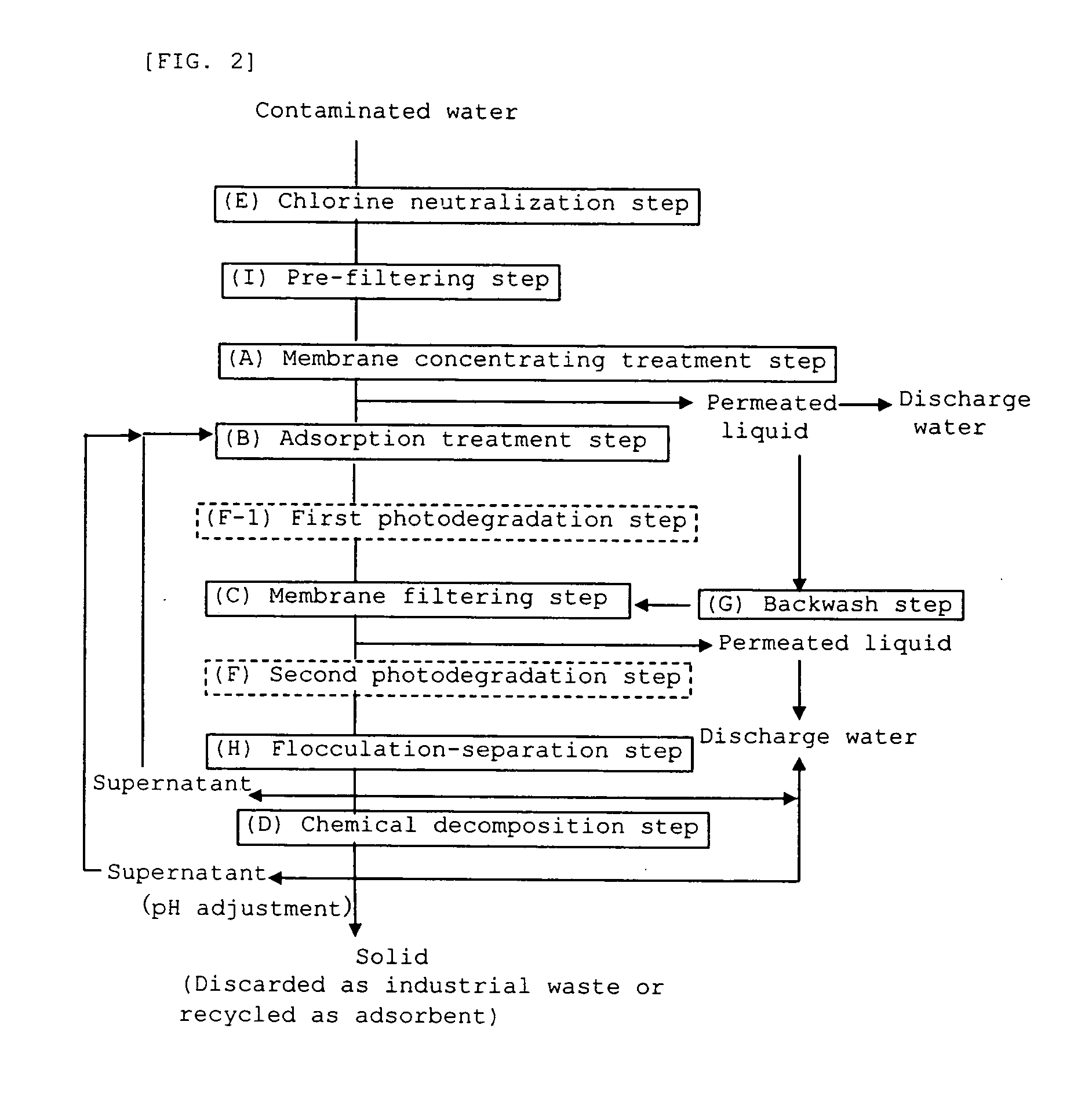

Method for treating raw water containing hardly decomposable substance

InactiveUS20070119779A1Efficient decompositionReduce concentrationUltrafiltrationSolid sorbent liquid separationDesorptionSorbent

Provided a method for treating hardly-decomposable-substance-containing water, in which hardly decomposable substances such as dioxins, contained in contaminated water (treatment raw water) are concentrated and rendered harmless by providing the steps of (B) adding an adsorbent to water containing a hardly decomposable substance (treatment raw water) to cause the hardly decomposable substance to be adsorbed on the adsorbent (adsorption treatment step), (C) separating a permeated liquid through a filter membrane to concentrate the adsorbent adsorbing the hardly decomposable substance (membrane filtering treatment step), and (D) chemically decomposing the hardly decomposable substance adsorbed on the concentrated adsorbent with a peroxide without any operation of desorption from the adsorbent (chemical decomposition step), and the method can be applied to water containing a reducing substance such as bisulfate that neutralize free chlorine and can render the hardly decomposable substances harmless efficiently at a low cost without being limited by properties of the hardly decomposable substances contained.

Owner:IDEMITSU KOSAN CO LTD

Process for preparing conductive material

InactiveUS8012676B2High transparencyImprove conductivityConductive layers on insulating-supportsConductive materialPolymer scienceWarm water

It is to provide a process for preparing a conductive material in which transparency and conductivity are both high, and storage stability is high, and further, in a process for preparing a conductive material utilizing ultra fine silver particles, to provide a process for preparing a conductive material having high conductivity without requiring a calcination step which has conventionally been required.A process for preparing a conductive material having a conductive pattern containing silver on a support, which process for preparing a conductive material comprises acting at least one of the following mentioned (I) to (IV) on the pattern portion containing silver provided on the support:(I) a reducing substance,(II) a water-soluble phosphorus oxo acid compound,(III) a water-soluble halogen compound,(IV) warm water of 55° C. or higher.

Owner:MITSUBISHI PAPER MILLS LTD

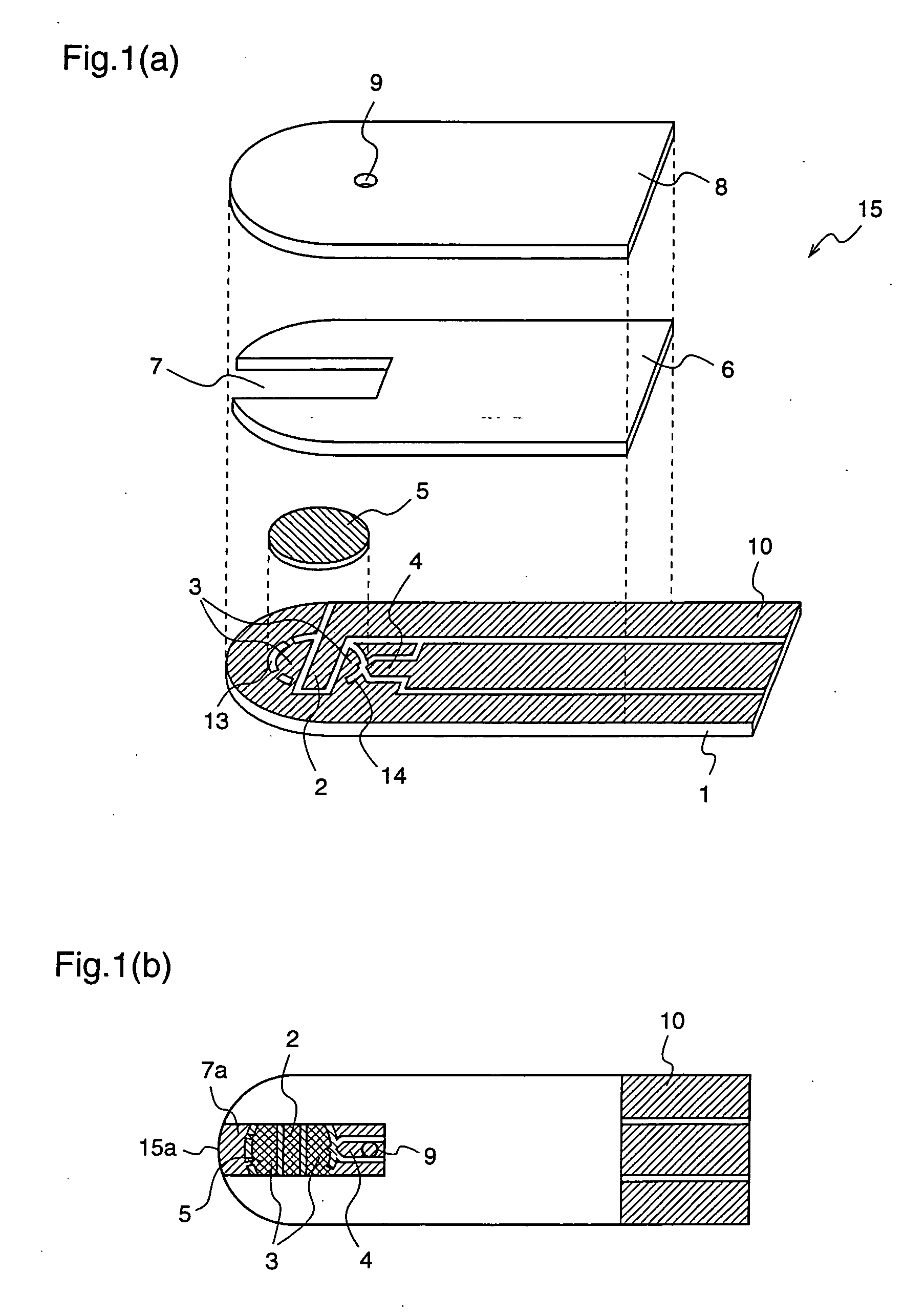

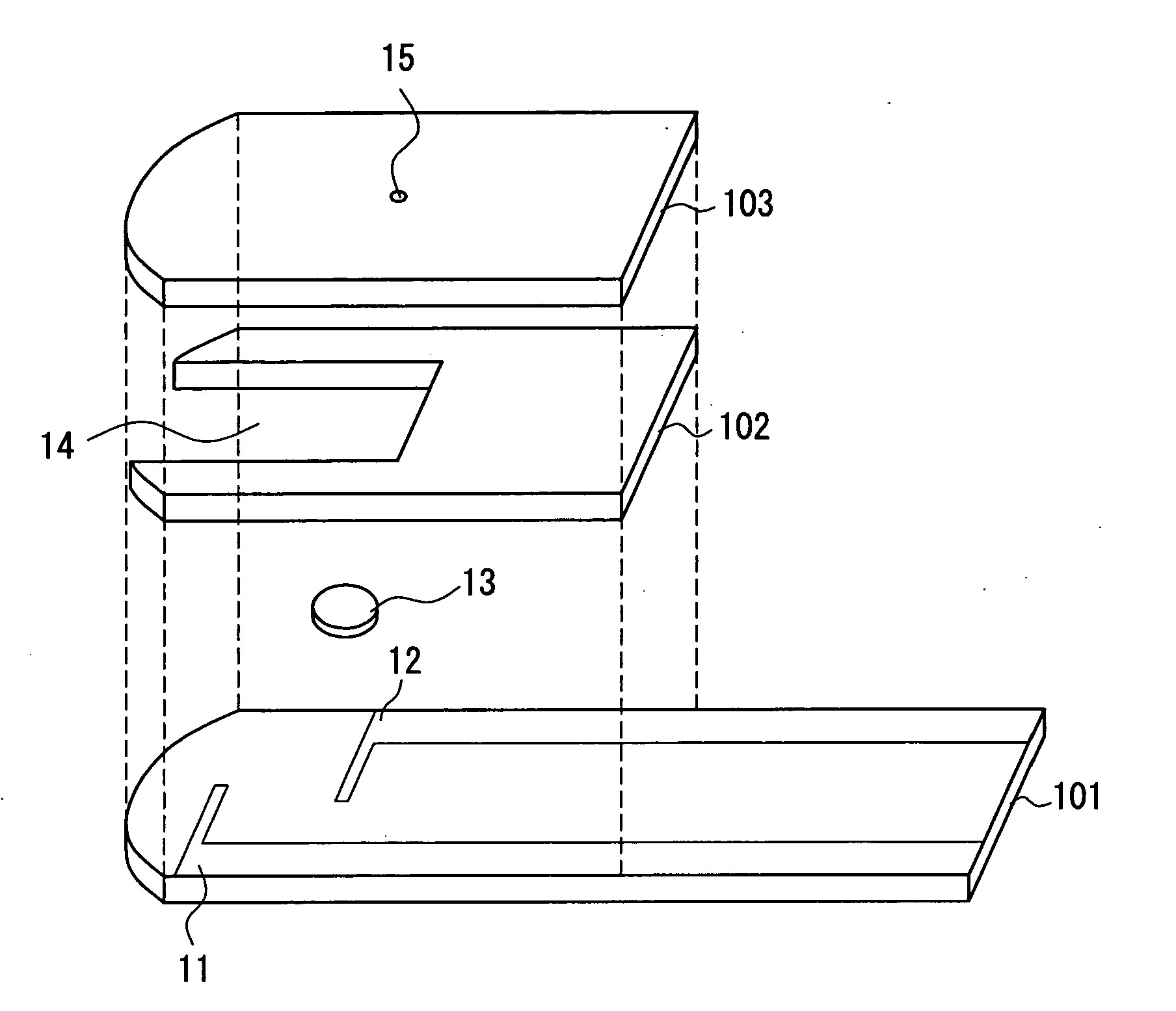

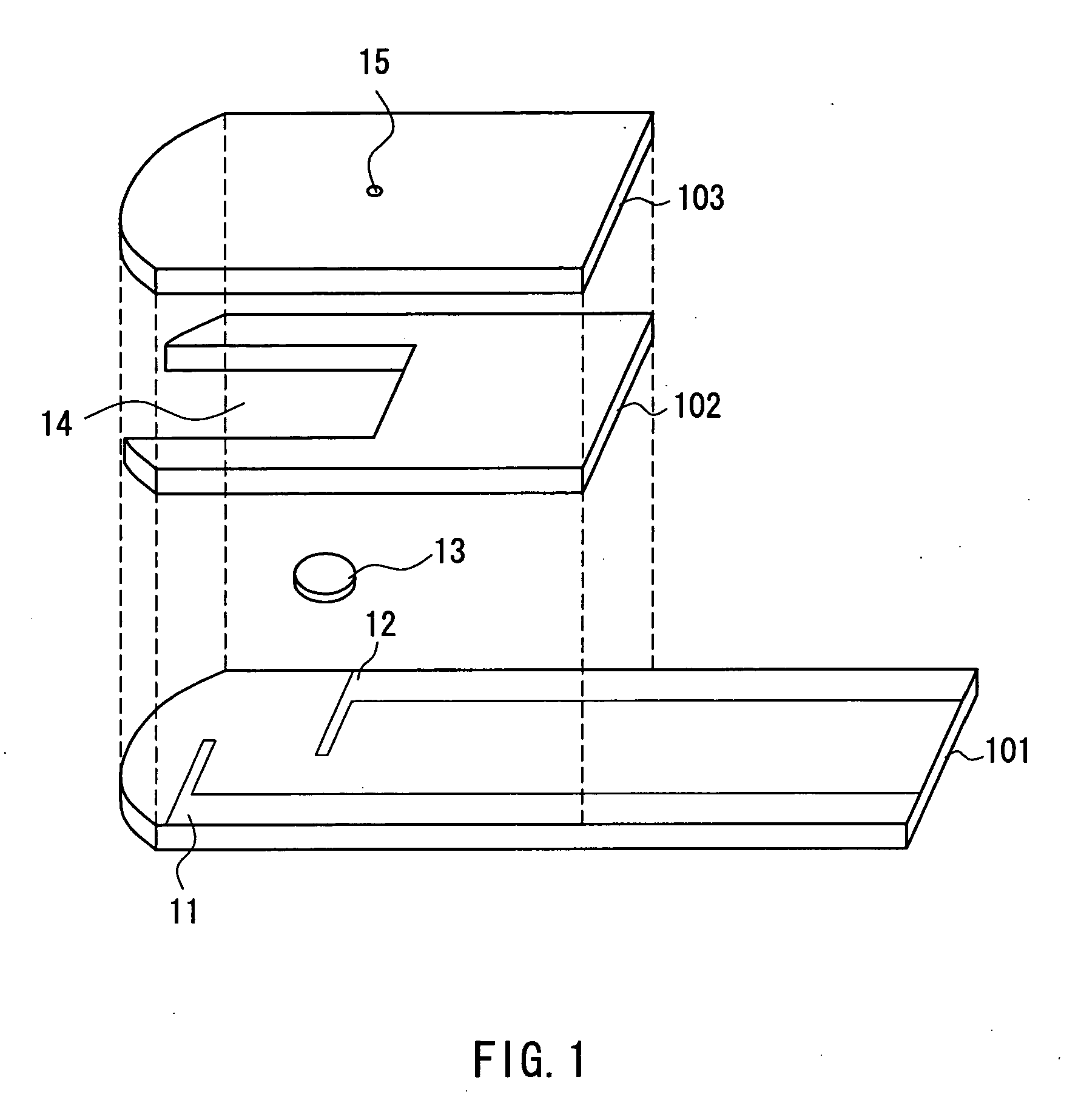

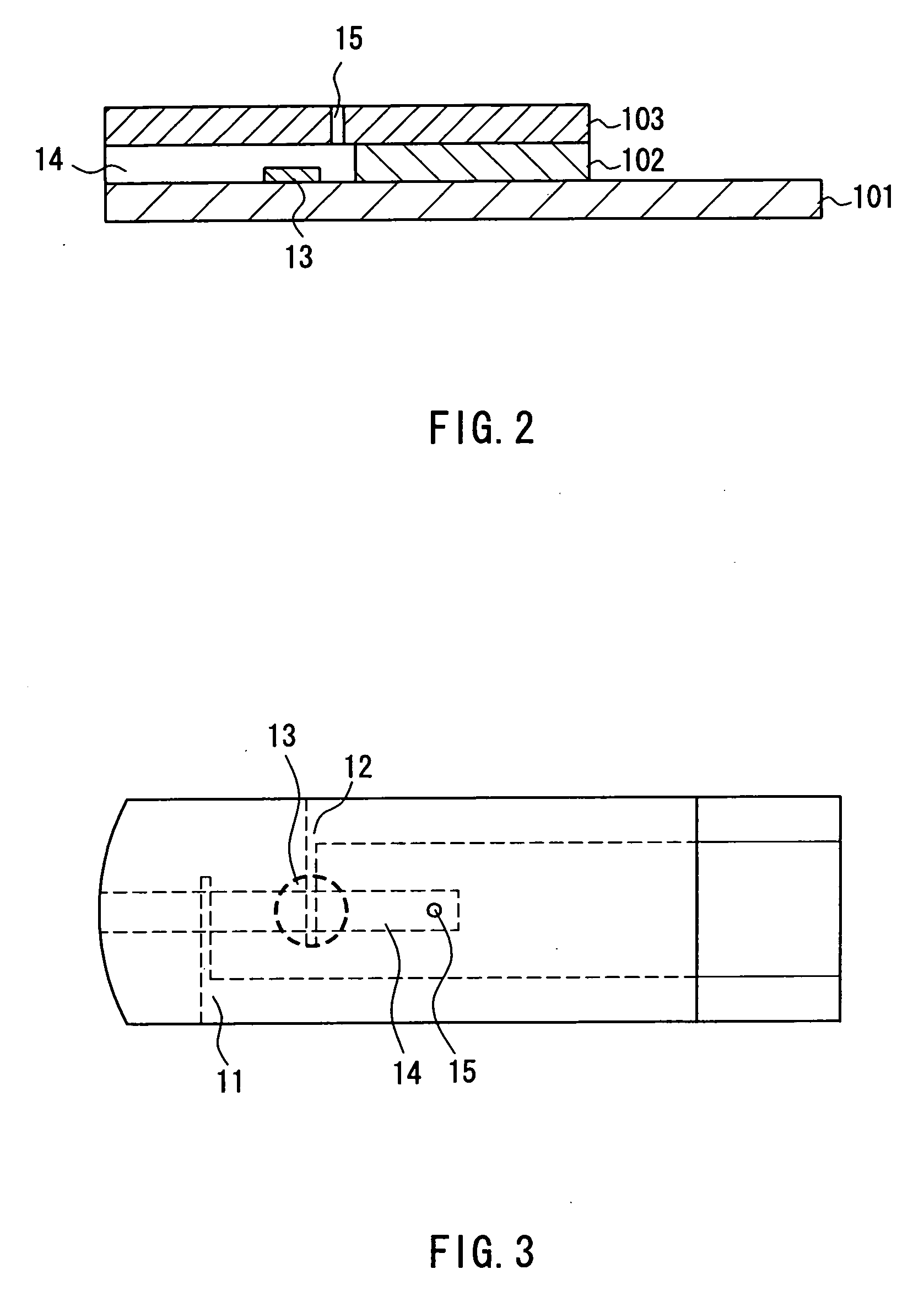

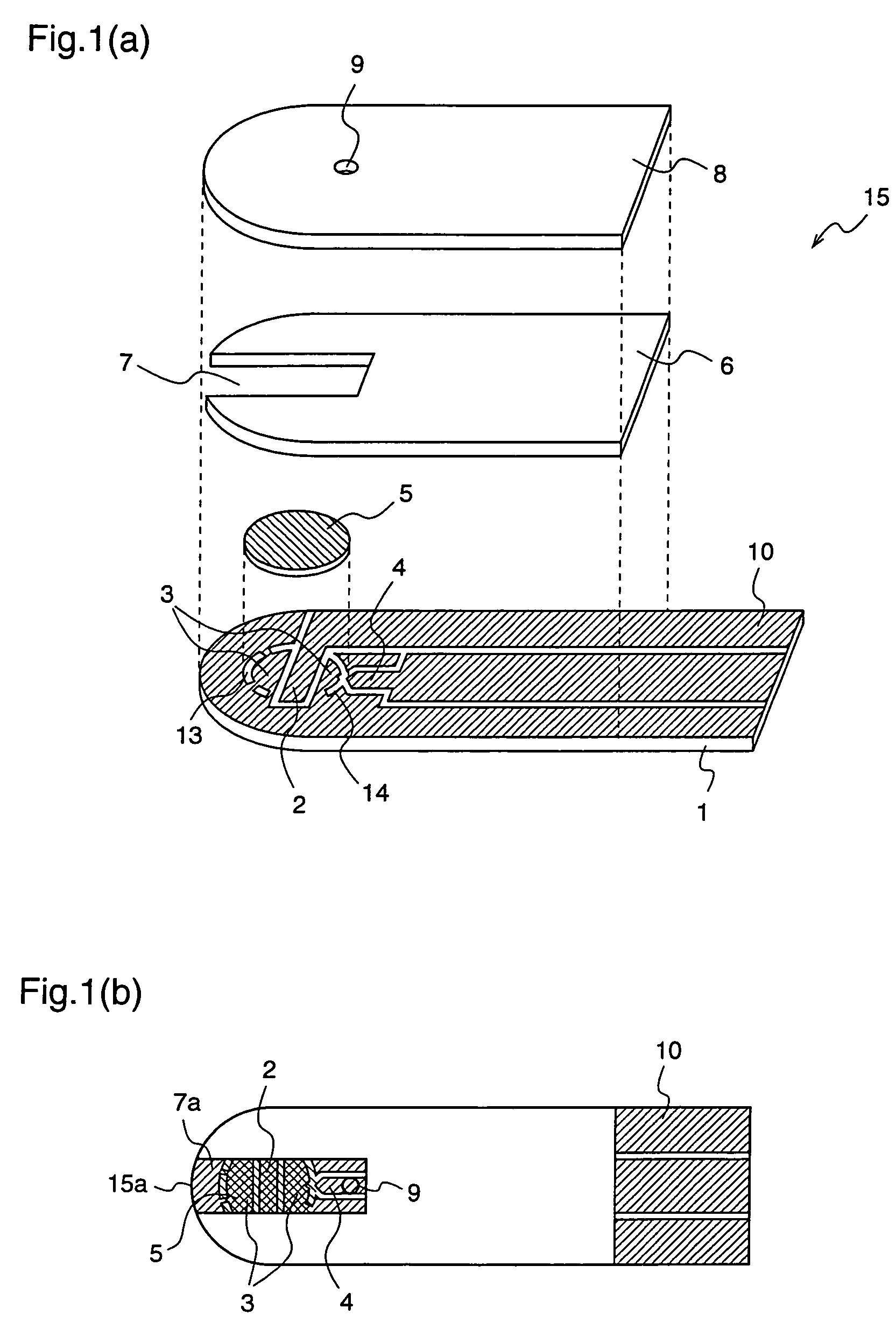

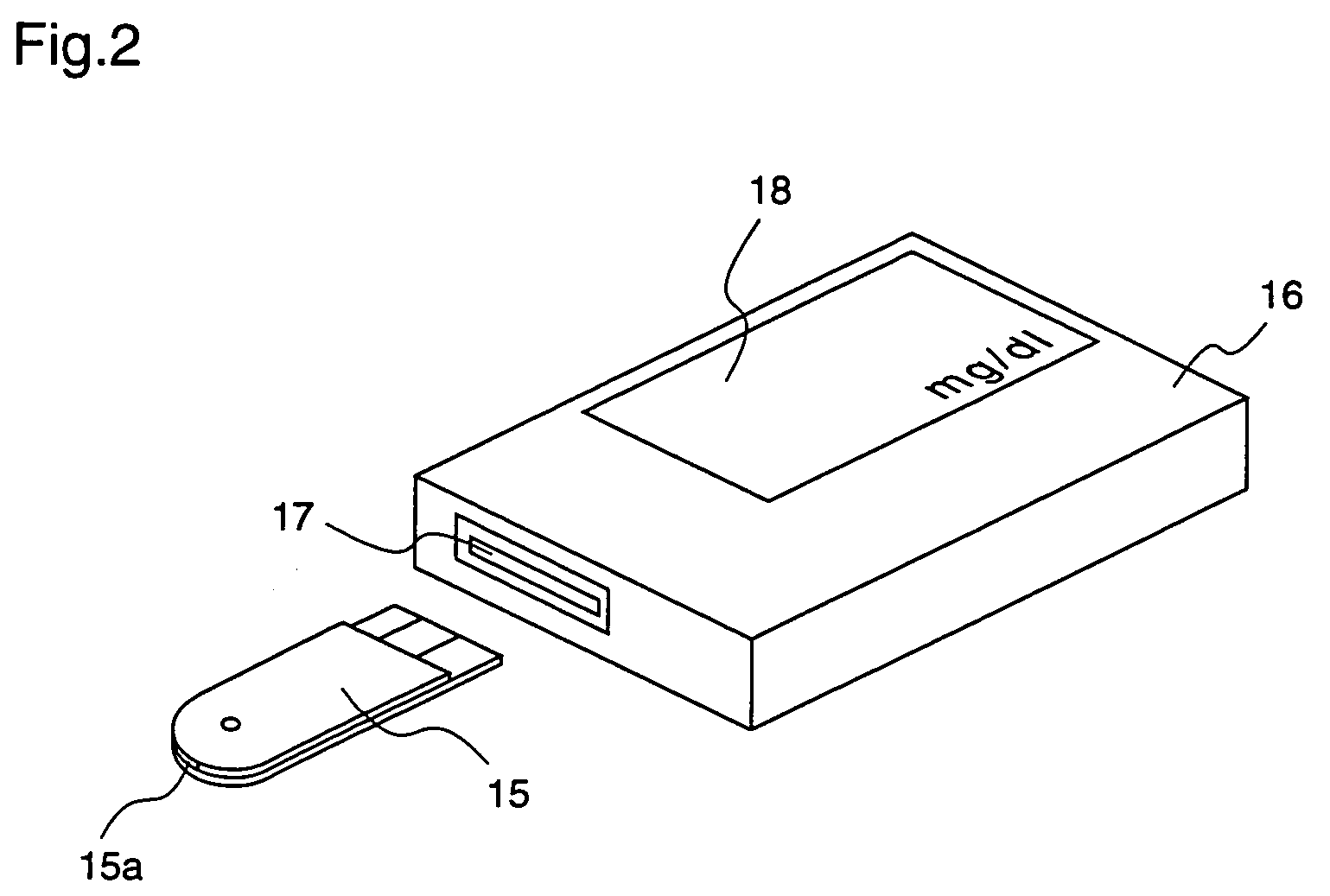

Method of measuring hematocrit (hct), sensor used in the method, and measuring device

ActiveUS20070062822A1High sensitivityHigh measurement accuracyImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceRedox

The present invention provides a method of electrochemically measuring a hematocrit (Hct) value using a sensor, capable of achieving excellent measurement accuracy and reliability and also provides a sensor used in the method. The method of electrochemically measuring a hematocrit (Hct) value of blood include: providing an electrode system having a working electrode (11) and a counter electrode (12), in which a redox substance is provided on the counter electrode (12) but not on the working electrode (11); supplying blood to the electrode system; applying a voltage to the electrode system in this state to cause an oxidation current or a reduction current to flow between the working electrode (11) and the counter electrode (12); detecting the oxidation current or the reduction current; and determining a Hct value based on a value of the detected current.

Owner:PHC HLDG CORP

Powder molding additive and application thereof in preparing various shaping products

InactiveCN101168651AHigh mechanical strengthImprove water resistanceBiocideBituminous material adhesivesUltimate tensile strengthTackifier

The powder molding additive belongs to a compound additive mainly composed of inorganic substances. It is composed of dimensioning agent 1-99% (weight), forming agent (1-99% (weight) and reinforcing agent, tackifier, toughening agent, and combustion agent. The present invention can be used for carbon-containing powder .Using carbon-containing substances to reduce substances, or mixing powders of the two, can also be used in fertilizers, chemicals, daily chemicals and other industries. It has no smoke caused by starch and has certain water resistance. No matter at low temperature or high temperature, the produced The products have the required strength and their cost is low.

Owner:张弥问

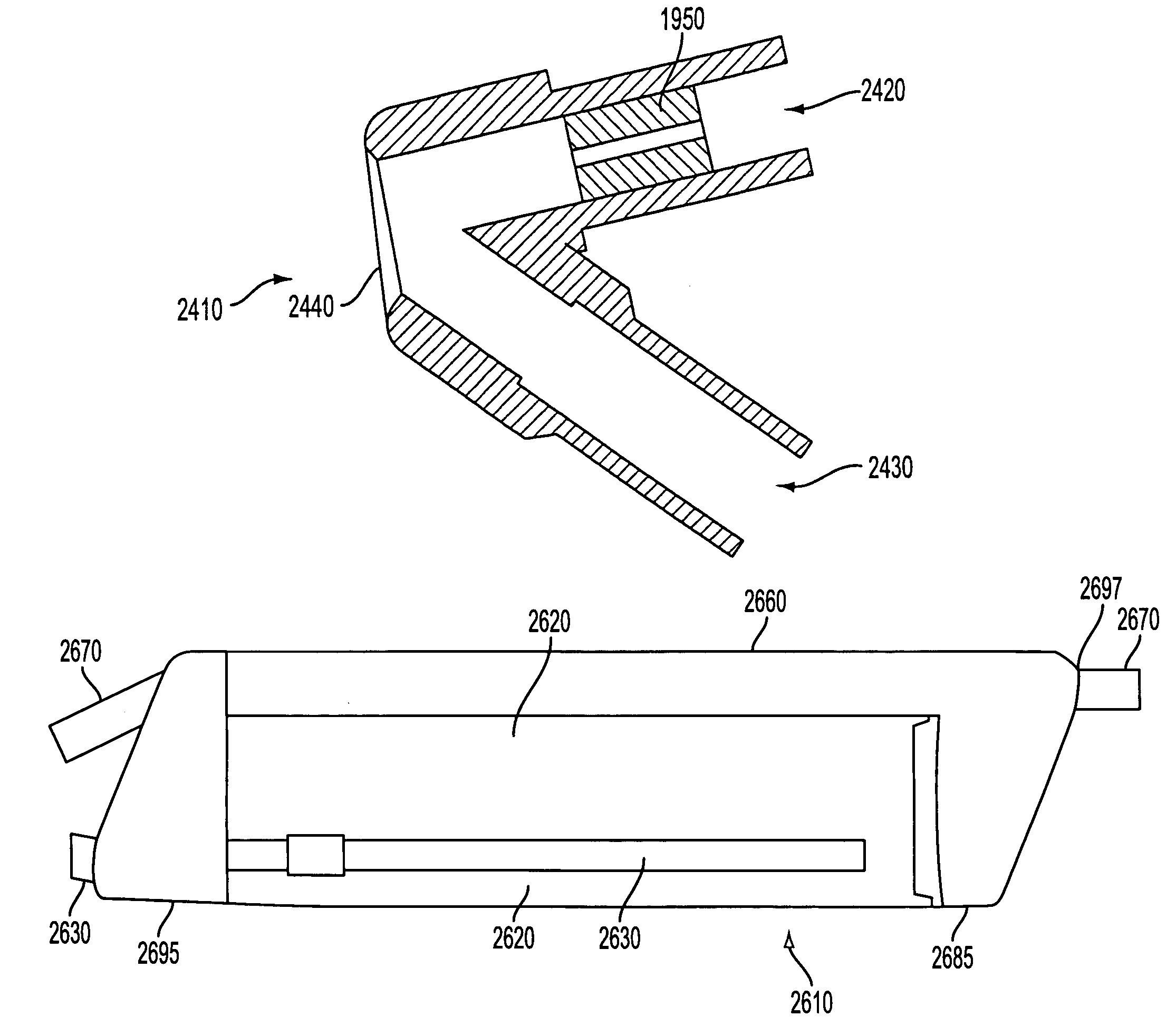

Dermabrasion apparatus and method having oval-shaped mixing bottle

A dermabrasion apparatus operates by a flow of air and reducing substances conveyed to a patient through a handpiece. The apparatus includes an oval-shaped mixing bottle that has a first enclosed region for holding reducing substances. The mixing bottle includes a cap that has two tubes extending therefrom, for coupling to respective input and output legs of the handpiece. The mixing bottle also includes a second enclosed region for holding one of the two tubes that provides an air-tight coupling between the output leg of the handpiece and a collecting bottle. The mixing bottle is oval-shaped so that a user can readily manipulate the handpiece so as to move the handpiece coupled to the mixing bottle in a desired direction. This is especially useful for small handpieces that are hard to hold onto by themselves.

Owner:MATTIOLI ENG

Functional composition with functions of controlling blood sugar and enhancing nutrition

InactiveCN101829160AEasy to useGreat tasteMetabolism disorderAnhydride/acid/halide active ingredientsMultivitaminL-Arabinose

The invention discloses a functional composition with functions of controlling blood sugar and enhancing nutrition, which is prepared from main materials and a common carrier, wherein the main materials consist of functional sugars, composite vitamins, mineral substance, dietary fiber and high sweetener; and the functional sugars comprise L-arabinose and trehalose, the weight content of the L-arabinose is 10 to 80 percent, and the weight content of the trehalose is 10 to 50 percent. The functional composition uses two functional sugars as main sugar-reducing substances and is added with multiple composite vitamins, the mineral substance, the dietary fiber and the high sweetener, so the invention provides the functional composition with convenient use, good mouthfeel, safety, effectiveness and practicability of controlling blood sugar and enhancing nutrition for diabetes patients. The functional composition can well supplement nutrient substances required for the human body when the diabetes patients can feel relieved to enjoy a proper amount of sweet food.

Owner:GUANGDONG FOOD IND INST

Reduced ignition propensity smoking article

A smoking article having reduced ignition propensity is disclosed. The smoking article includes a tobacco column, a wrapper surrounding the tobacco column and a filter element. The wrapper has a base permeability, an untreated area and a least one discrete area treated with a composition to reducing the base permeability. The discretely treated area interacts with a coal of a burning tobacco firecone as it advances to self-extinguish the smoking article. The composition of the treated area includes a permeability reducing substance, a burn rate retarding substance and a burn rate accelerating substance. Either the burn rate retarding substance or the burn rate accelerating substance acts as an organoleptic enhancing substance. In this way a smoker's experience when smoking either the at least one treated area or the untreated area is substantially the same.

Owner:LORILLARD LICENSING

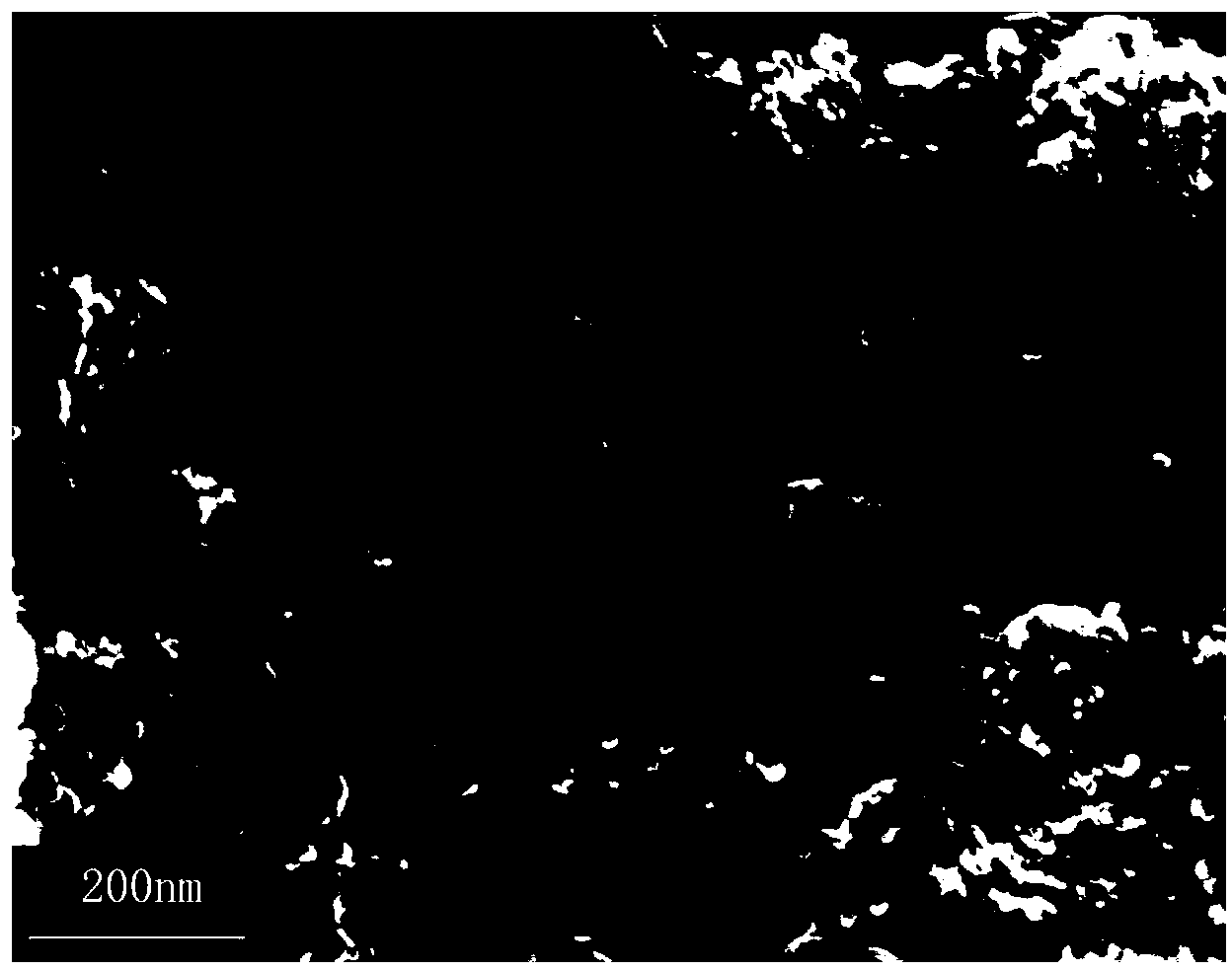

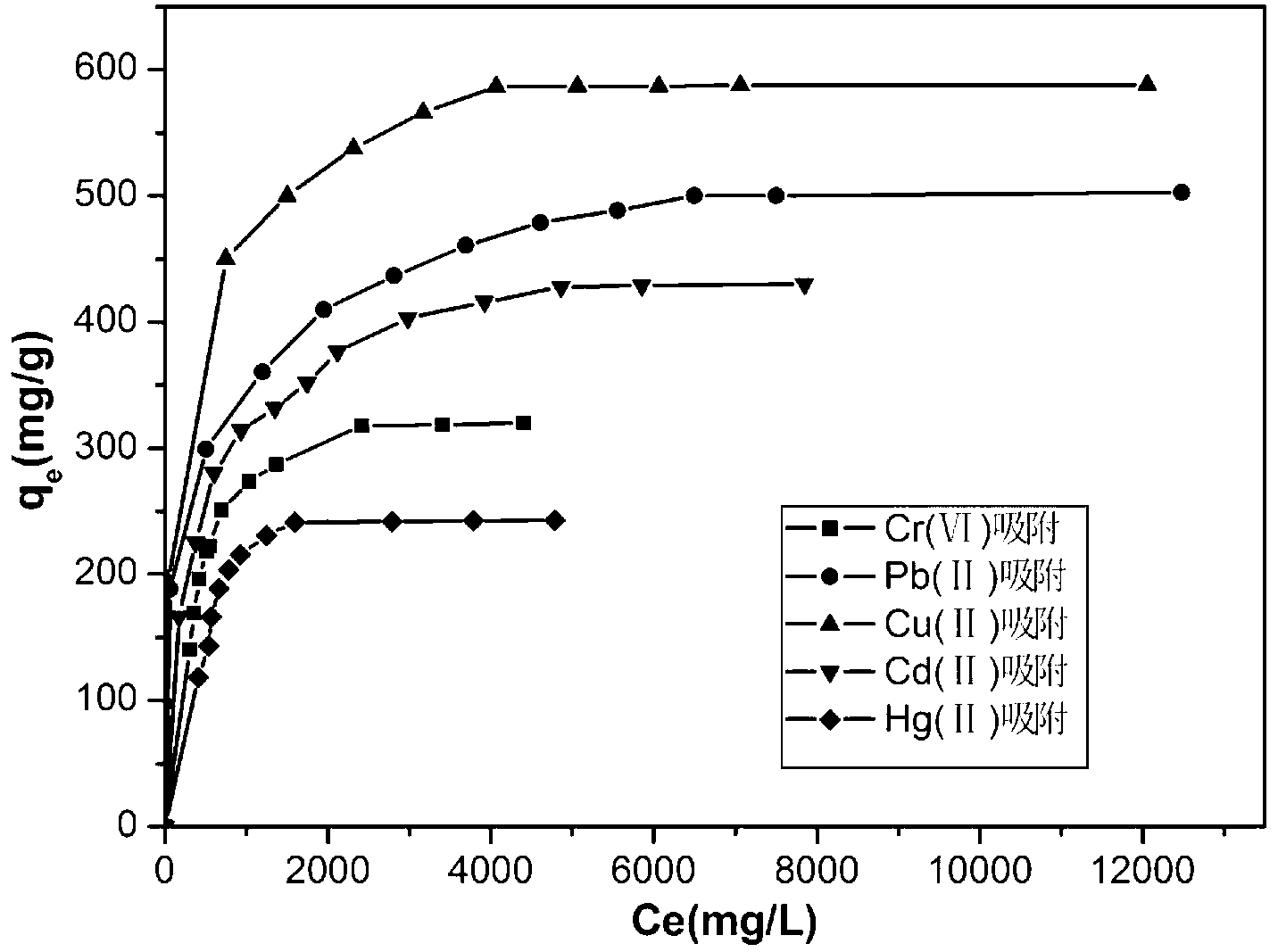

Ferrite/graphene composite adsorbent and preparation and using methods thereof

InactiveCN103191699AMagneticHighly uniform dispersionOther chemical processesWater/sewage treatment by sorptionSorbentHexamethylenetetramine

The invention discloses a ferrite / graphene composite adsorbent and preparation and using methods thereof, and belongs to the technical field of adsorbents. The ferrite MFe2O4 / graphene composite adsorbent is prepared by taking hexamethylenetetramine as a precipitator and a reducing agent and decomposing the hexamethylenetetramine under a hydrothermal condition to generate alkaline and reducing substances by one step. M is Mn, Ni, Co and Zn; the mass percentage of the ferrite is 40-70 percent; ferrite nano particles are dispersed on the sheet type graphene surface; the particle sizes of the ferrite nano particles are 5-30 nanometers; and the specific surface area of the ferrite / graphene composite adsorbent is 60-300 m<2> / g. The ferrite / graphene composite adsorbent has the advantages that the shortcomings of high reaction temperature, non-uniform reactants and low product structure and composition uniformity of the conventional ferrite composite metal oxide prepared by solid phase reaction are overcome; an effect of adsorbing heavy metal ions Cr<6+>, Pb<2+>, Cu<2+>, Cd<2+> and Hg<2+> in water is achieved; and a wide application prospect is realized.

Owner:BEIJING UNIV OF CHEM TECH

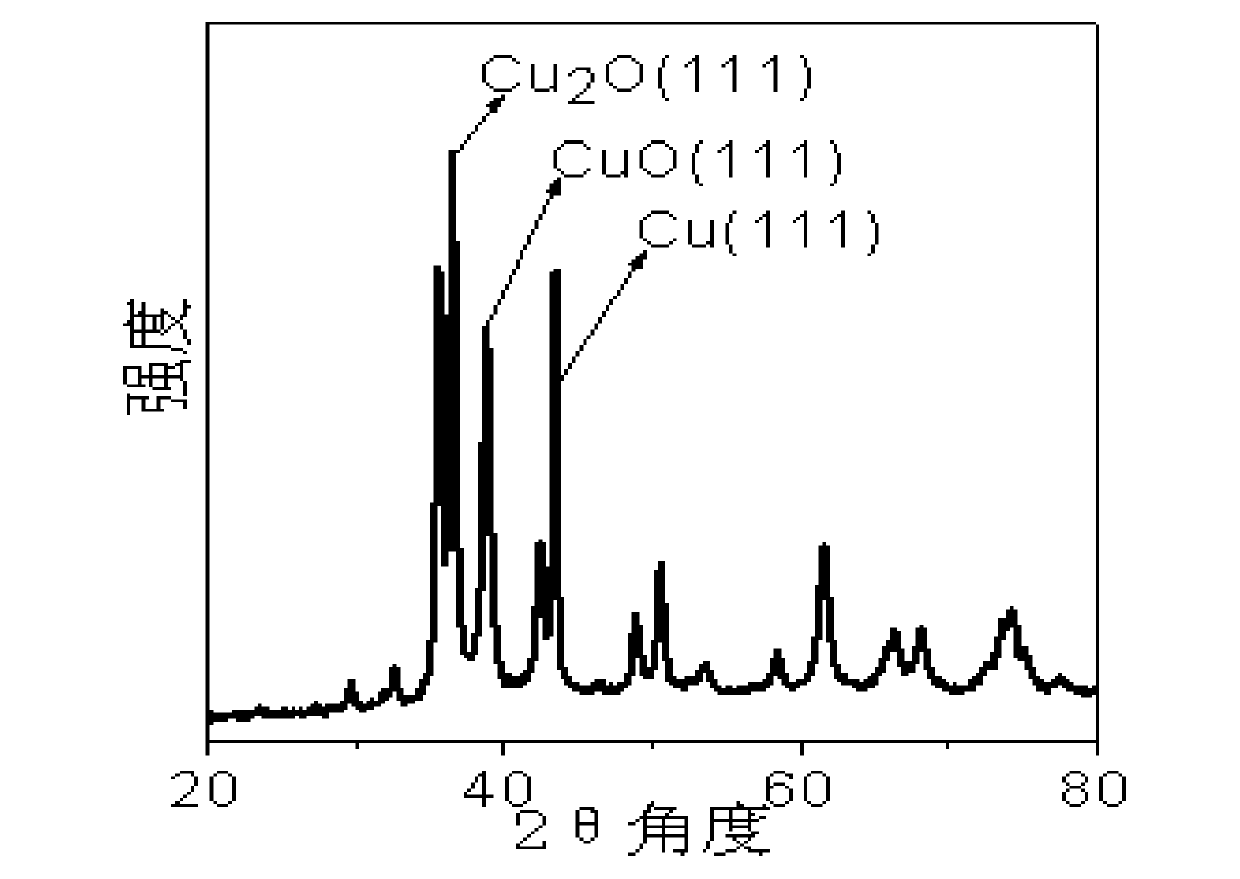

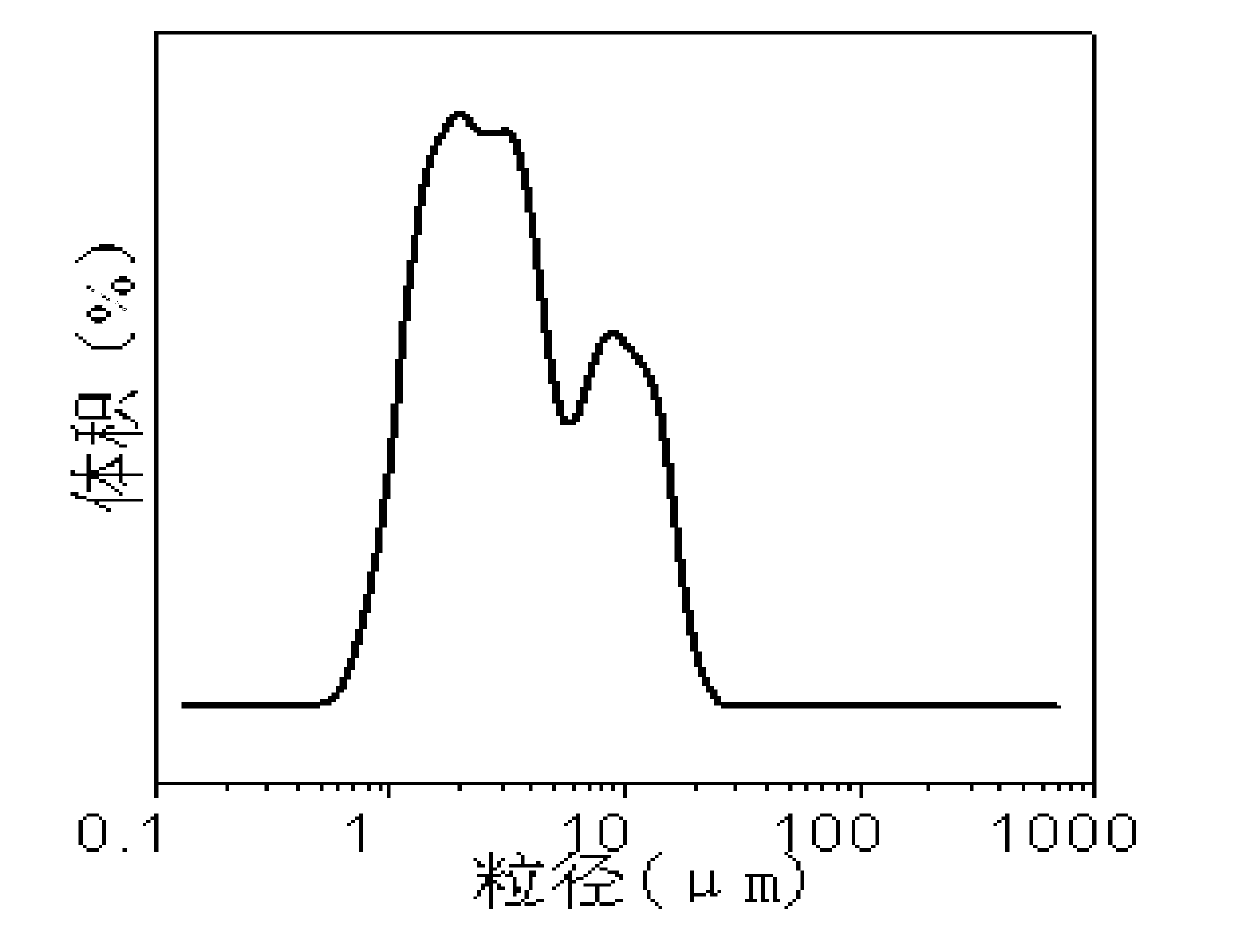

Method preparing catalyzer through liquid phase ball-milling partial reduction method and ternary copper catalyzer

ActiveCN103127936AEnhanced ability to participate in reduction reactionsEnhanced interactionGroup 4/14 element organic compoundsCatalyst activation/preparationFiltrationCopper oxide

The invention relates to a method preparing a copper catalyzer used for dimethyldichlorosilance synthetic reaction through a liquid phase ball-milling partial reduction method. The method includes the steps of taking copper oxide as raw material, adding solvent media containing reducing substances, enabling copper oxide particles to become small and achieve partial reduction through mechanical ball-milling, obtaining the copper-based catalyzer containing the ternary components of copper, cuprous oxide, copper oxide after suction filtration, drying and smashing, and obtaining the ternary copper catalyzer with adjustable components and controllable particles through adjusting the parameters of reducing agent types, concentration and ball-milling conditions. In catalytic reaction of organosilicone monomer synthesis, the catalyzer is high in catalytic activity and selectivity and helpful for improving the processing ability of an existing organosilicone monomer device, reduces production cost, and improves the yield of target products. The method preparing the catalyzer through the liquid phase ball-milling partial reduction method is simple in process, mild in condition and convenient to operate, and brings convenience to achieve large scale production.

Owner:JIANGXI INST OF RARE EARTHS CHINESE ACAD OF SCI

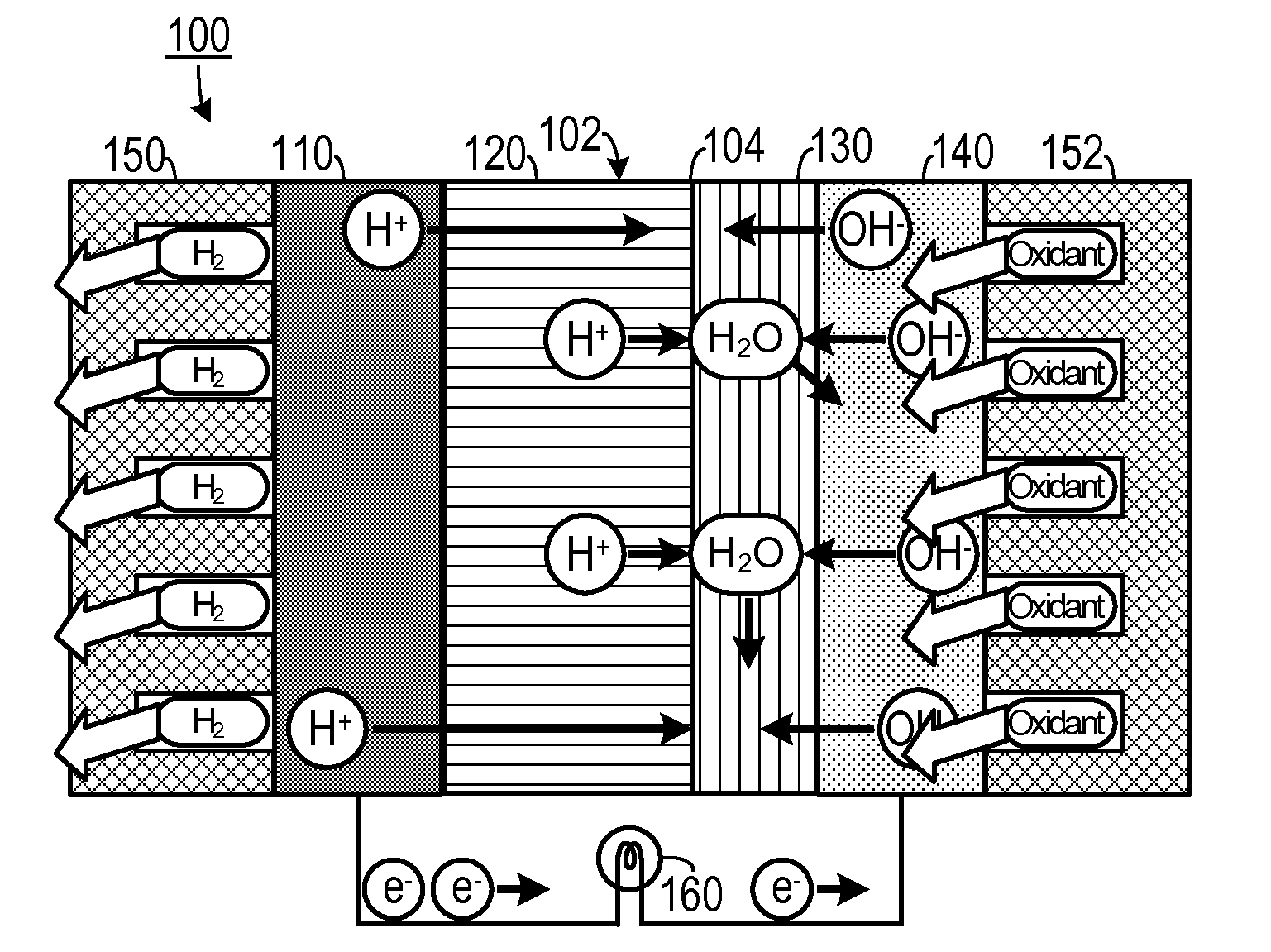

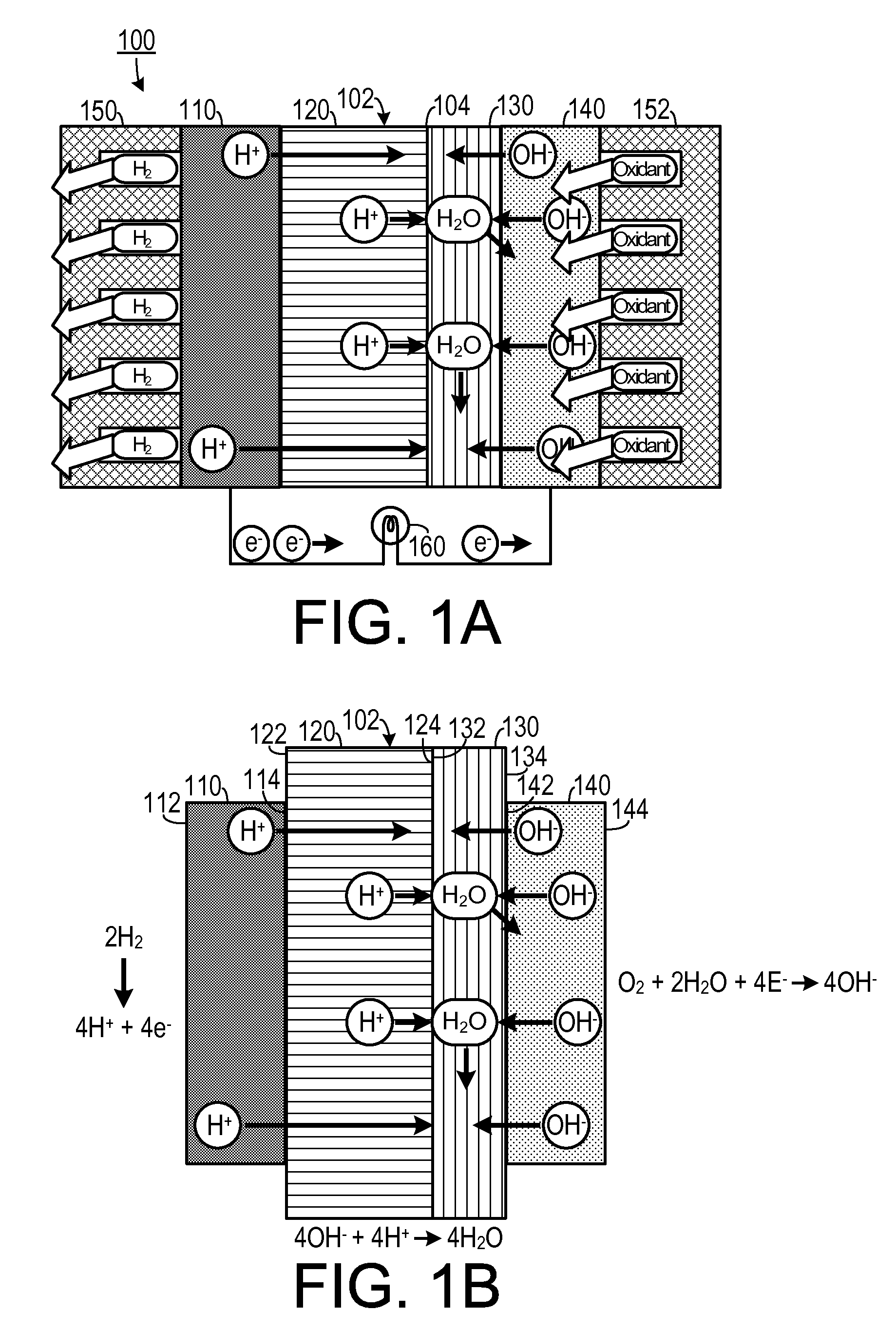

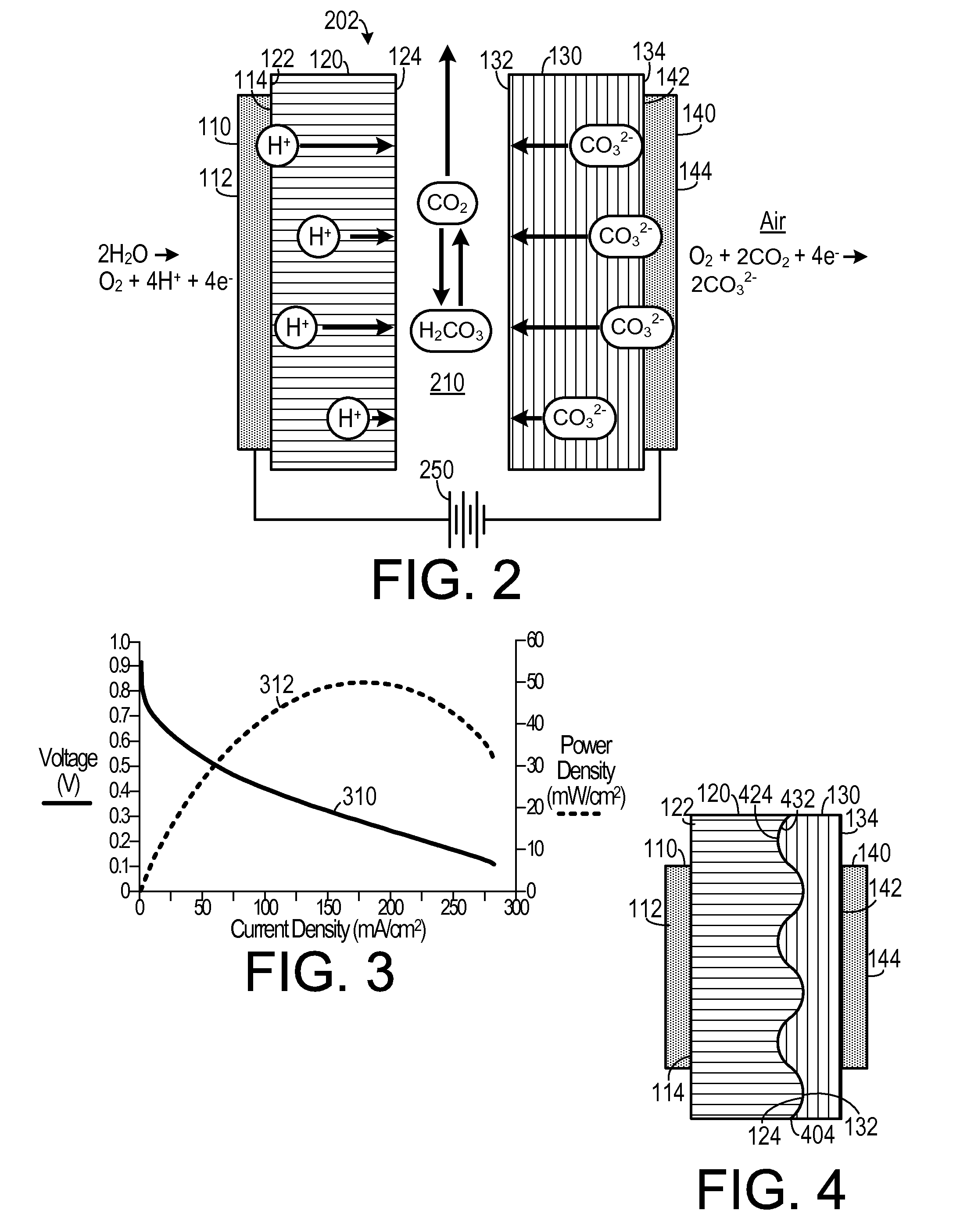

Hybrid Ionomer Electrochemical Devices

A membrane electrode assembly for use in a fuel cell includes an anode electrode, a cation exchange membrane, an anion exchange membrane and a cathode electrode. The anode electrode includes a first catalyst. The first catalyst separates a reducing agent into a plurality of positively charged ions and negative charges. The cation exchange membrane is configured to favor transport of positively charged ions therethrough and is also configured to inhibit transport of negatively charged particles therethrough. The anion exchange membrane is configured to favor transport of negatively charged ions therethrough and is also configured to inhibit transport of positively charged ions therethrough. The cathode electrode includes a second catalyst and is disposed adjacent to a second side of the anion exchange membrane. The second catalyst reacts electrons with the at least one oxidizing agent so as to create reduced species.

Owner:GEORGIA TECH RES CORP

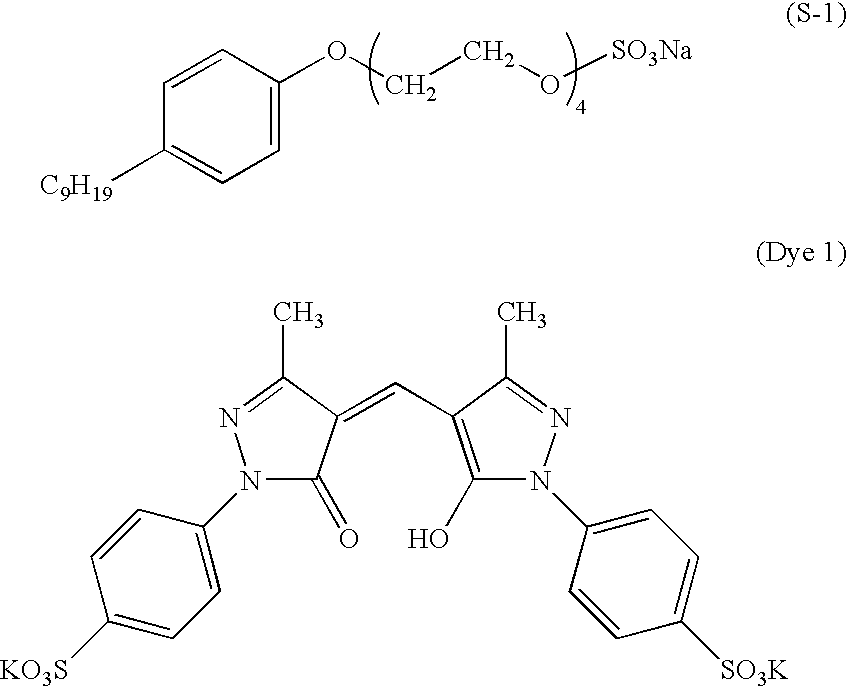

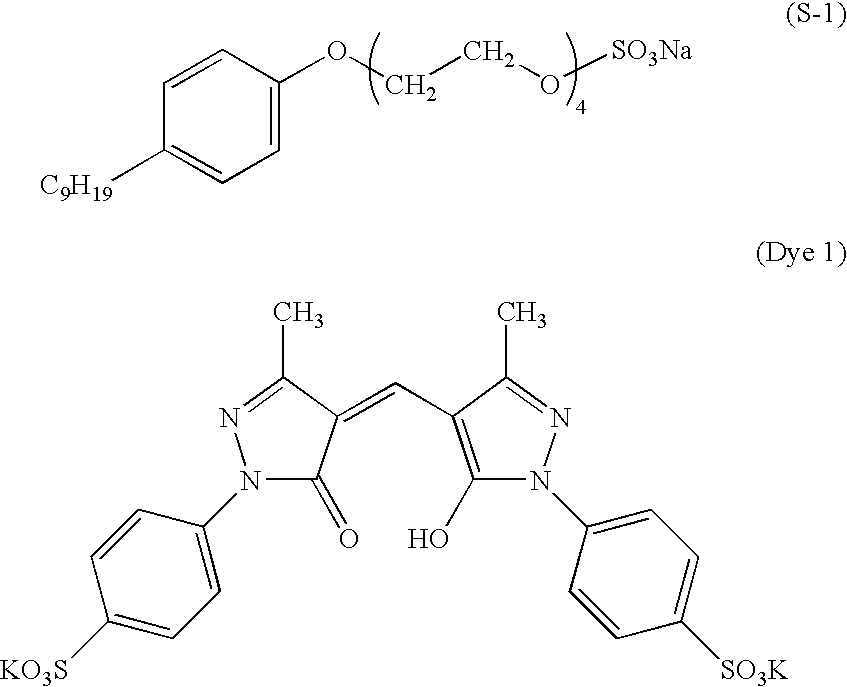

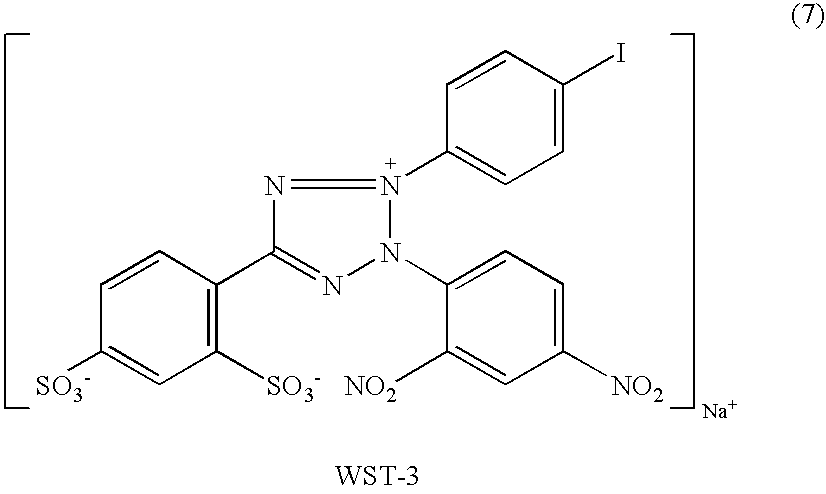

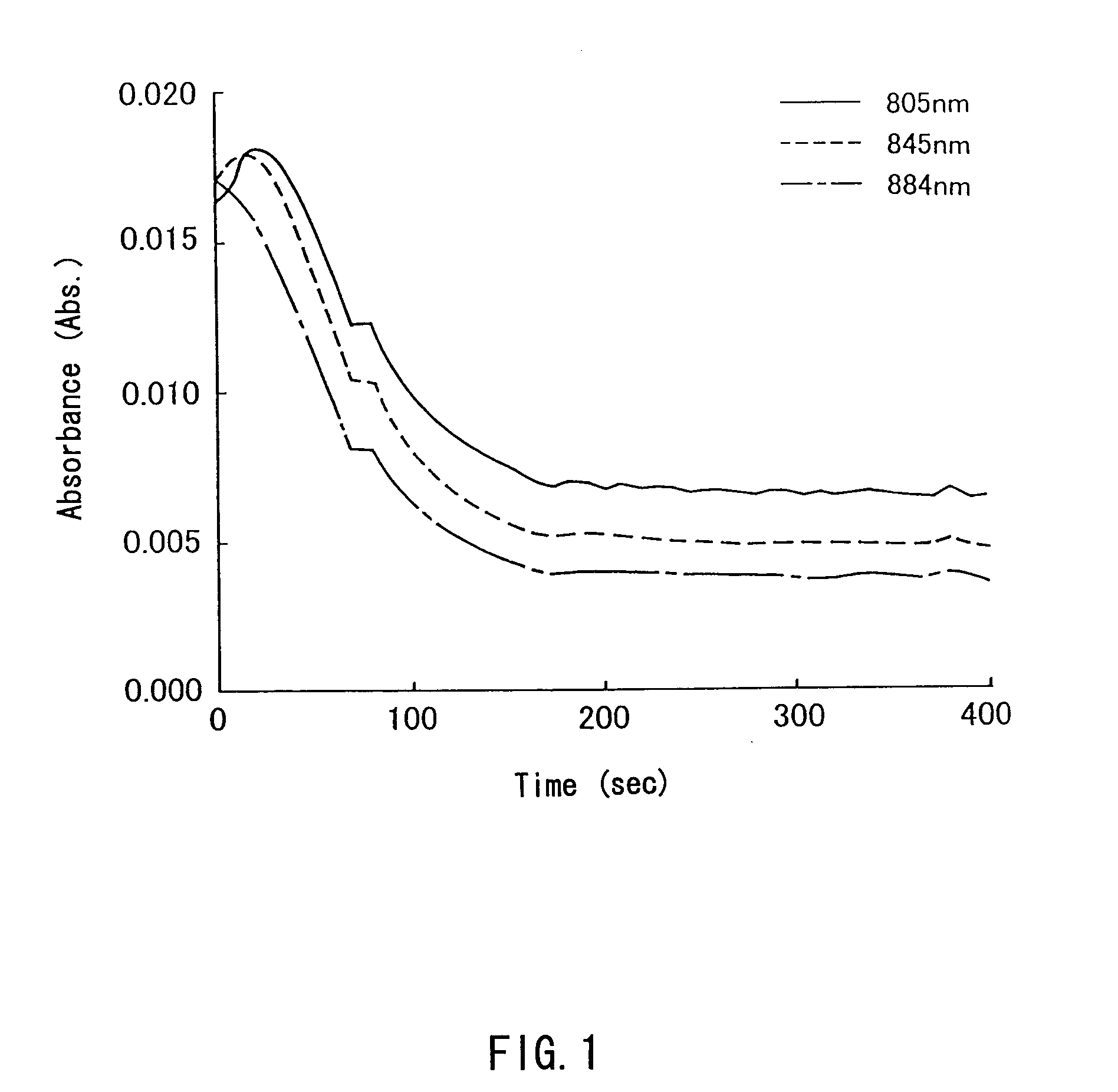

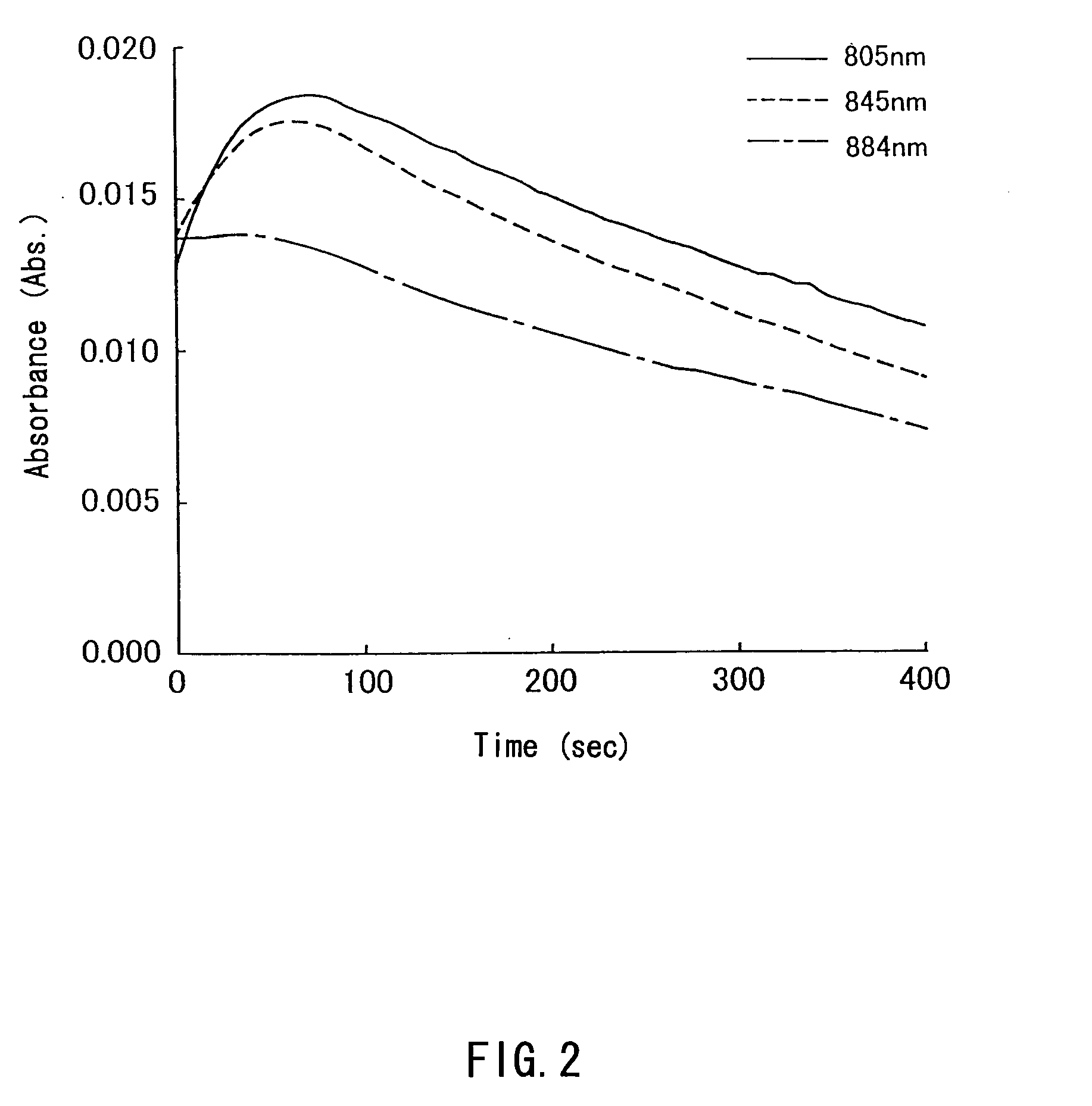

Assay method with the use of redox reaction

InactiveUS20040063213A1Improve reliabilityReliable valueMicrobiological testing/measurementBiological testingAnalyteRedox

A method of determining an analyte in a sample utilizing a redox reaction is provided, by which a highly reliable determined value can be obtained. In this method, a tetrazolium compound is added to a sample in the presence of a surfactant prior to a redox reaction so as to eliminate an effect of hemoglobin and a hemoglobin degradation product as reducing substances in the sample. Thereafter, a reducing or oxidizing substance derived from an analyte is produced and the amount thereof is determined by the redox reaction. Then, the amount of the analyte in the sample is determined based on the amount of the reducing or oxidizing substance thus determined. According to this method, cloudiness due to the coexistence with the hemoglobin can be prevented by the surfactant and thus an increase in the absorbance due to the cloudiness can be inhibited as shown in FIG. 1. As the surfactant, polyoxyethylene ether and the like can be used.

Owner:ARKRAY INC

Enzyme-catalyzed metal deposition for the enhanced detection of analytes of interest

ActiveUS7642064B2Rapidly and accurately determinedHigh detection sensitivitySugar derivativesMicrobiological testing/measurementAnalyteRedox

The invention is directed to enhanced methods for detecting an analyte of interest in situ, by immunoassay, or by hybridization comprising binding an enzyme-labeled conjugate molecule to an analyte of interest in the presence of a redox-inactive reductive species and a soluble metal ion. The enzyme catalyzes the conversion of the inactive reductive species to an active reducing agent, which in turn reduces the metal ion to a metal atom thereby providing an enhanced means of detecting the analyte via metal deposition.

Owner:VENTANA MEDICAL SYST INC

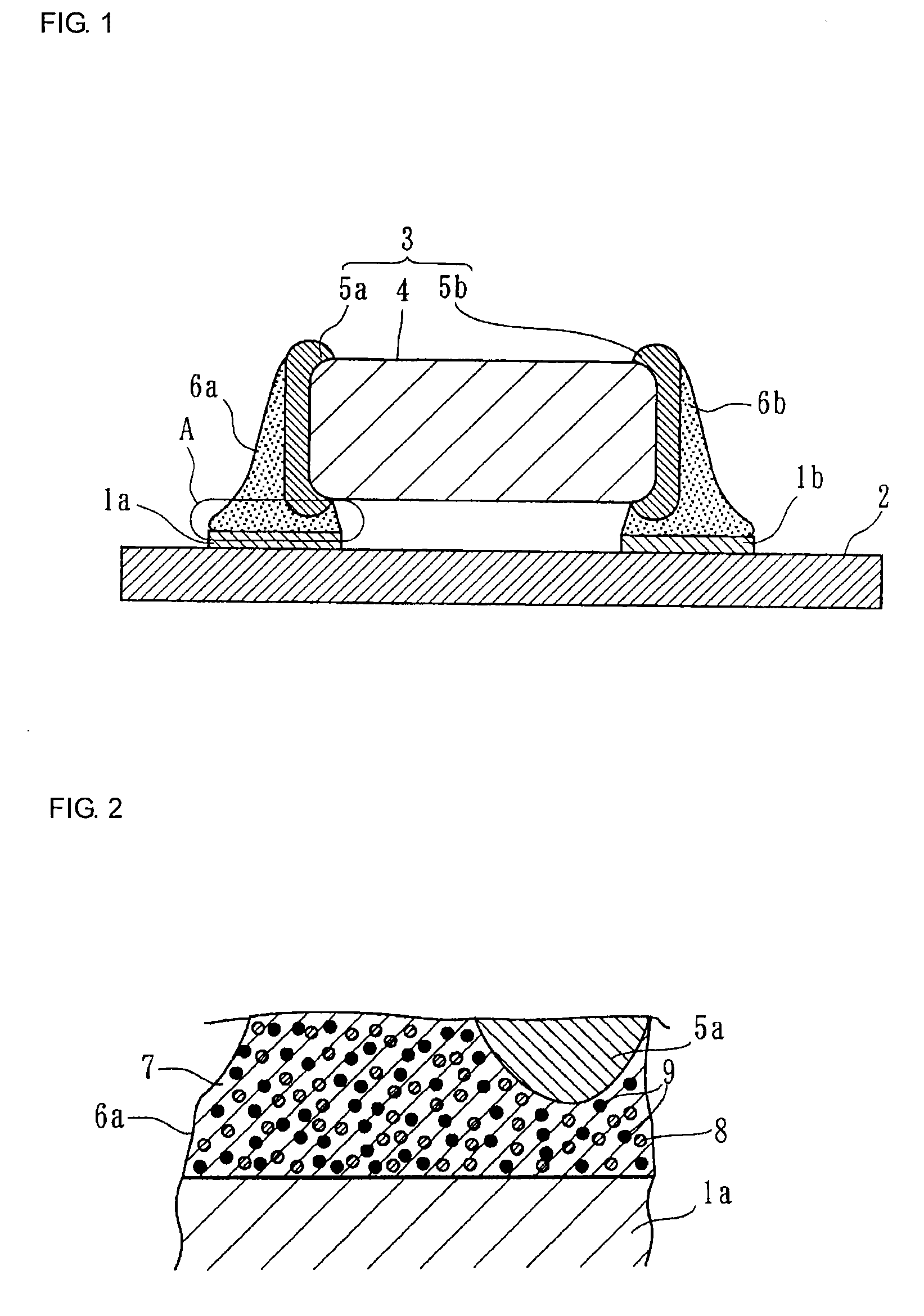

Electroconductive Bonding Material and Electronic Apparatus

ActiveUS20090155608A1High bonding strengthWell formedNon-macromolecular adhesive additivesFinal product manufactureUltimate tensile strengthMetal powder

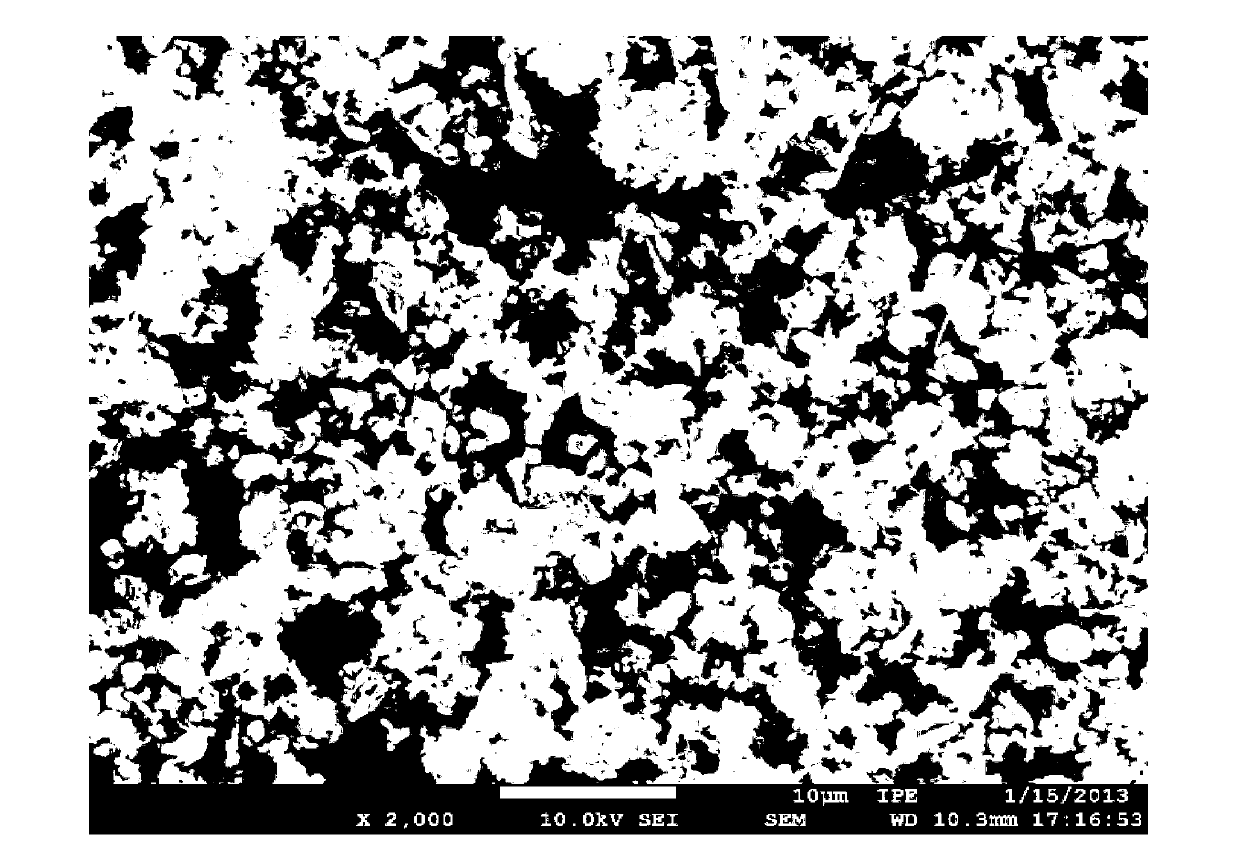

An electroconductive bonding material contains a thermosetting resin, a low-melting-point metal powder which is melted at a temperature equal to or lower than the thermosetting temperature of the thermosetting resin, a high-melting-point metal powder which is not melted at a temperature equal to or lower than the thermosetting temperature of the thermosetting resin and which reacts with the low-melting-point metal powder to form a reaction product having a high melting point of 300° C. or higher during heat-hardening of the thermosetting resin, and a reducing substance which removes an oxide formed on the surface of the high-melting-point metal powder. The total content of the low-melting-point metal powder and the high-melting-point metal powder is 75% to 88% by weight, and the particle size ratio D1 / D2 of the average particle size D1 of the low-melting-point metal powder to the average particle size D2 of the high-melting-point metal powder is 0.5 to 6.0. Thereby, an electroconductive bonding material is provided which has good conduction properties and high connection strength even when reflow heat treatment is repeatedly carried out or thermal shock accompanied with a rapid temperature change is applied to the electroconductive bonding material, and an electronic apparatus using such an electroconductive bonding material.

Owner:MURATA MFG CO LTD

Photophobic medical soft polyvinyl chloride plastic and preparation method thereof

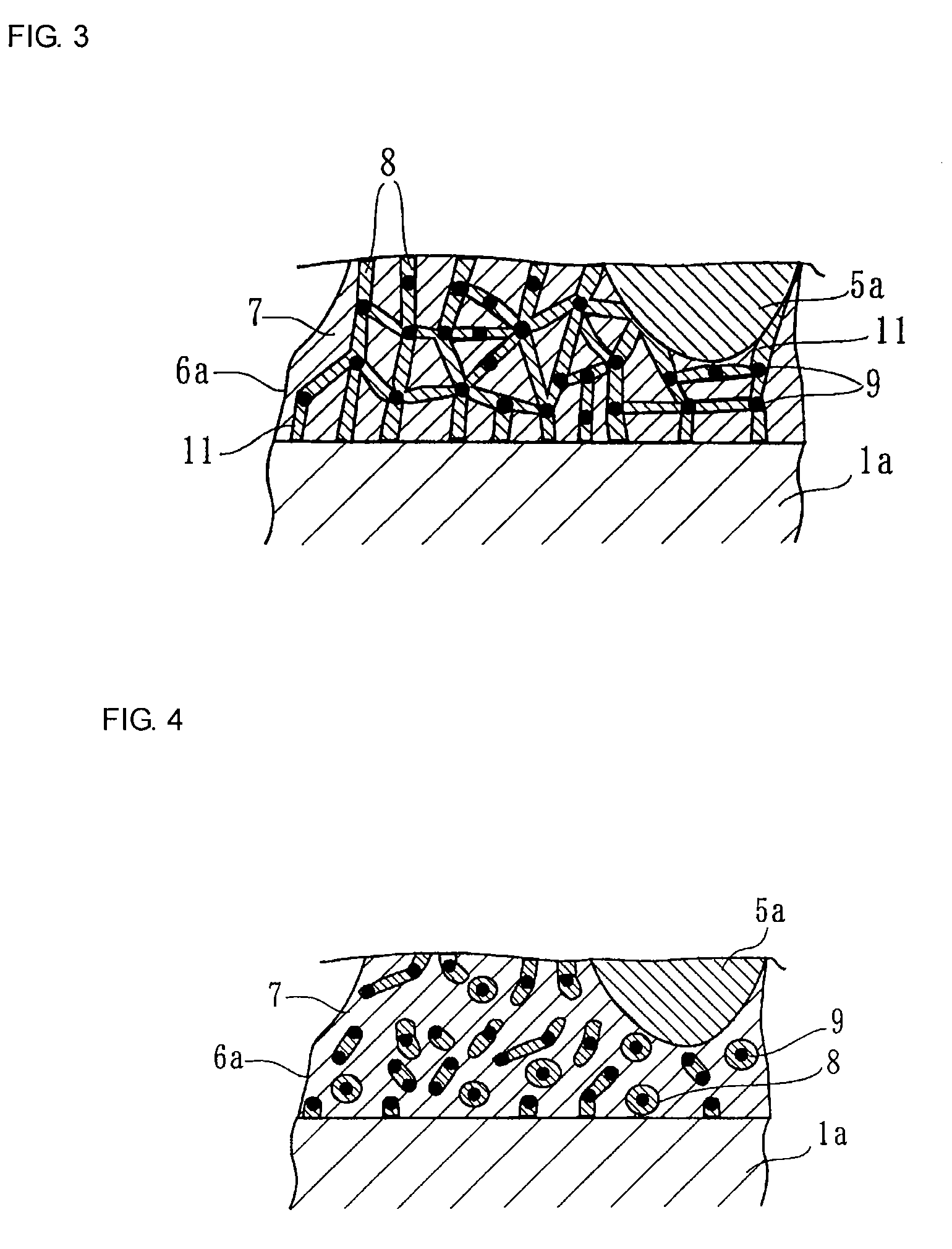

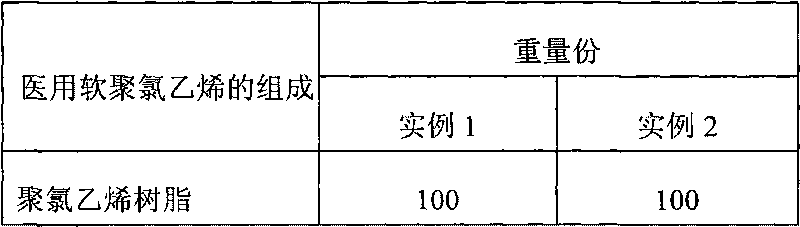

The invention provides a photophobic medical soft polyvinyl chloride plastic and a preparation method thereof. The photophobic medical soft polyvinyl chloride plastic comprises the following compositions in part by weight: 100 parts of polyvinyl chloride resin, 10 to 90 parts of plasticizer, 1 to 10 parts of stabilizer, 1 to 10 parts of auxiliary stabilizer, 0.1 to 2.0 parts of ultraviolet absorber, 0.1 to 0.5 part of auxiliary antioxidant and 0.1 to 6 parts of surfactant. In the photophobic medical soft polyvinyl chloride plastic, a proper opacifier and the surfactant are selected, pohydrophilic and oleophilic property of the surfactant are utilized, the photophobic medical soft polyvinyl chloride plastic is dispersed more evenly and combined more firmly in a system containing a lipoid plasticizer, the use amount of the opacifier is reduced, and a pigment is difficult to separate out; and the photophobic medical soft polyvinyl chloride plastic has good dissolution resistance, and is suitable for producing special liquid bags, conduits, medical accessories, drip chambers and various disposable medical products. Various indexes of a reduction material and the like of a finished product meet the requirement of GB18458.3-2005 standard; and the photophobic range can meet the special requirement and is even expanded to all wave bands.

Owner:上海新上化高分子材料有限公司

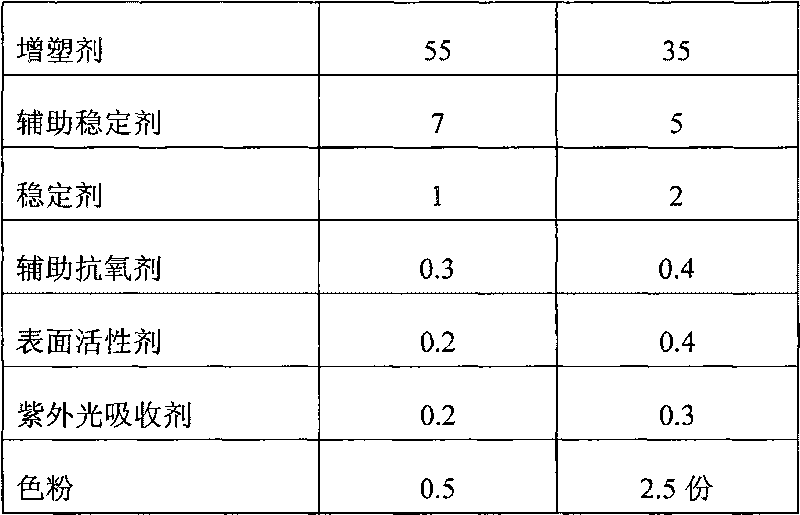

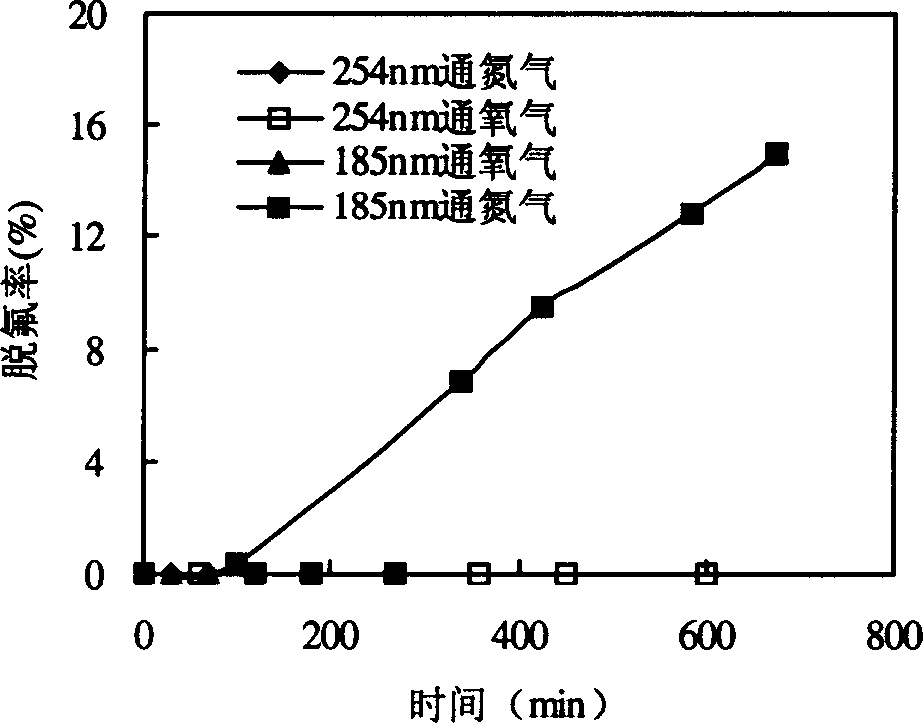

Method for defluorinating and degrading complete fluorine substituted compounds

InactiveCN1680219ALow toxicityEasy to handleSolid waste disposalOrganic decompositionUltravioletLaser light

A defluorinating and degrading method of fluorine substituted compound is characterized by vacuum ultraviolet irradiating PFOS and PFOA etc. fluorine substituted compound at anaerobic condition, defluorinating reacting fluorine substituted compound at irradiation of 185nm ultraviolet mercury vapour light or 172nm xenon quasi molecule laser light, inducing protective inert gas or reducing gas for realizing anaerobic condition, or adding reducing substance or semiconductor catalyst with high conducting band energy level during reacting process to improve defluorinating and decomposing ratio. It achieves simple operation and non-toxic.

Owner:TSINGHUA UNIV

Determination method for automatically identifying analyte liquid and standard solution for biosensor

ActiveUS7504020B2Easy to identifyImprove accuracyImmobilised enzymesBioreactor/fermenter combinationsMeasurement deviceAnalyte

Owner:PHC HLDG CORP

Preparation method of silicon-based composite negative electrode material of lithium battery

ActiveCN110615423AImprove the first Coulombic efficiencyImprove cycle performanceElectrode thermal treatmentNegative electrodesCarbon coatingAlloy

The invention provides a preparation method of a silicon-based composite negative electrode material of a lithium battery, which comprises the following steps: forming steam from a Si-containing raw material A and a reducing substance raw material B capable of reacting to generate silicate under a vacuum heating condition, condensing and depositing the reactants in a deposition system after reaction, and carrying out carbon coating to obtain a silicon-based composite material. In the invention, it is unexpectedly found that when a certain amount of alloy is added into the raw material B, the proportion of a crystal region in the silicon-based composite material can be reduced, and the initial coulombic efficiency and the cycling stability of the negative electrode material are further improved. The preparation method also has the advantages of simple process, cheap and easily available raw materials, suitability for large-scale production, high practical degree and the like.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

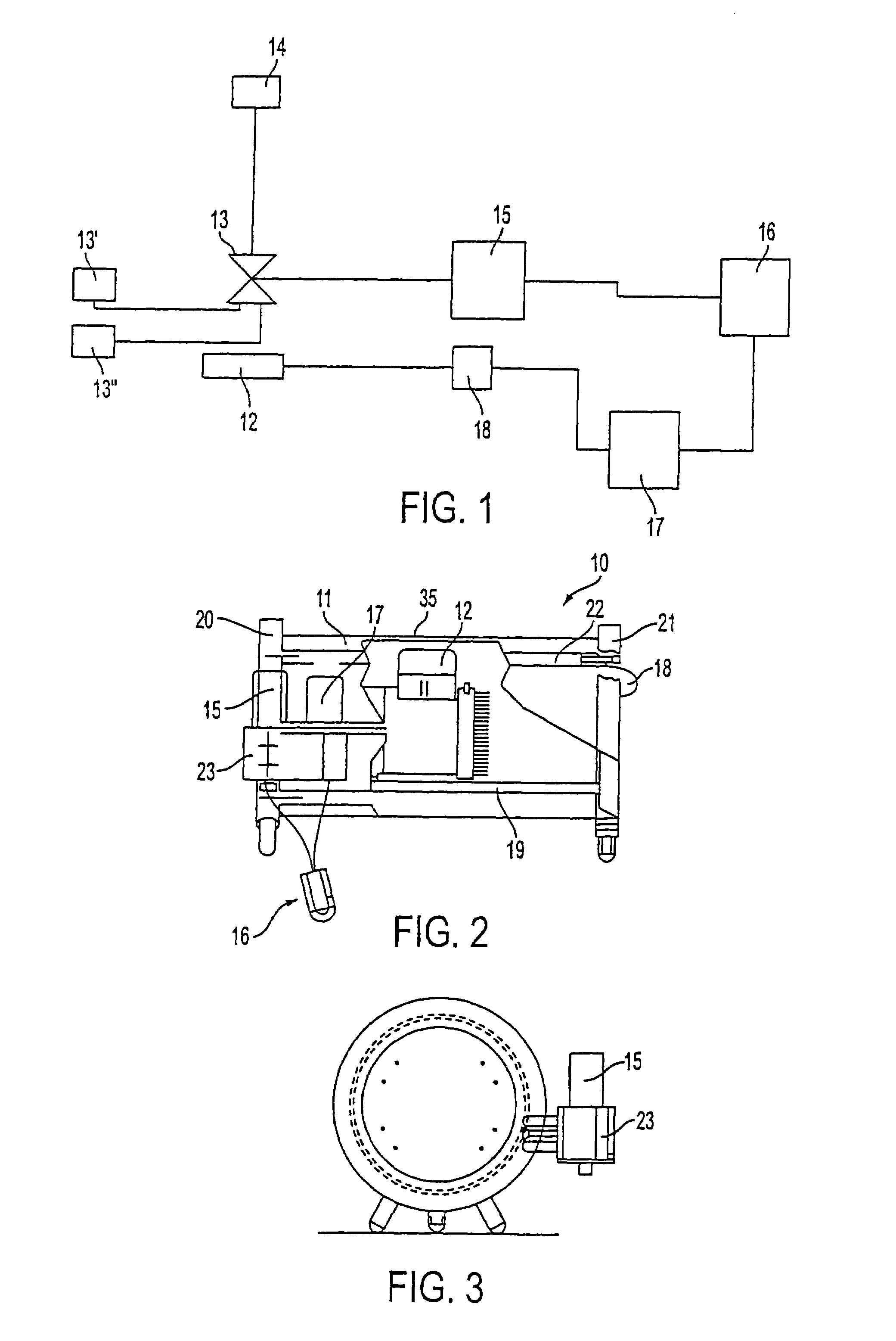

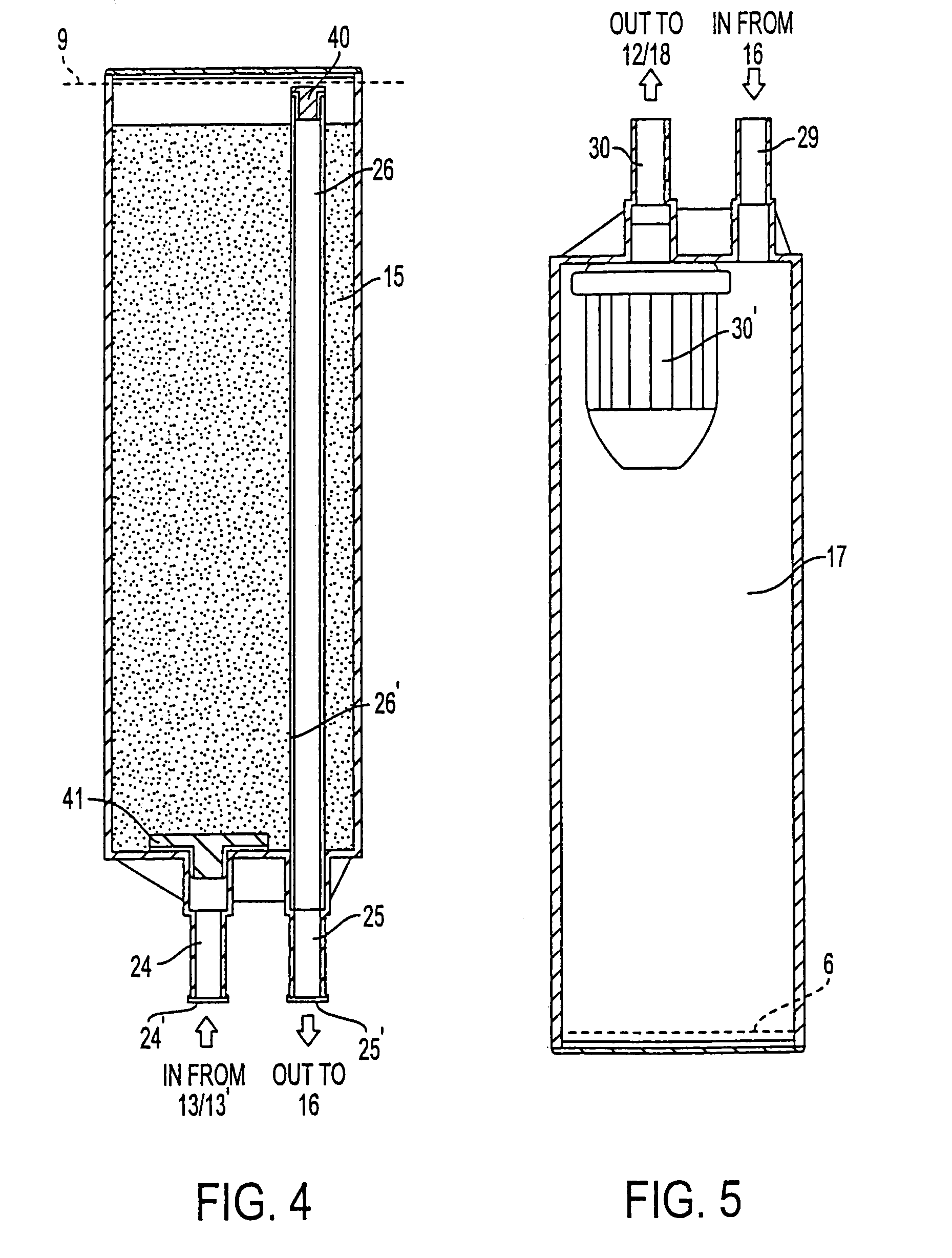

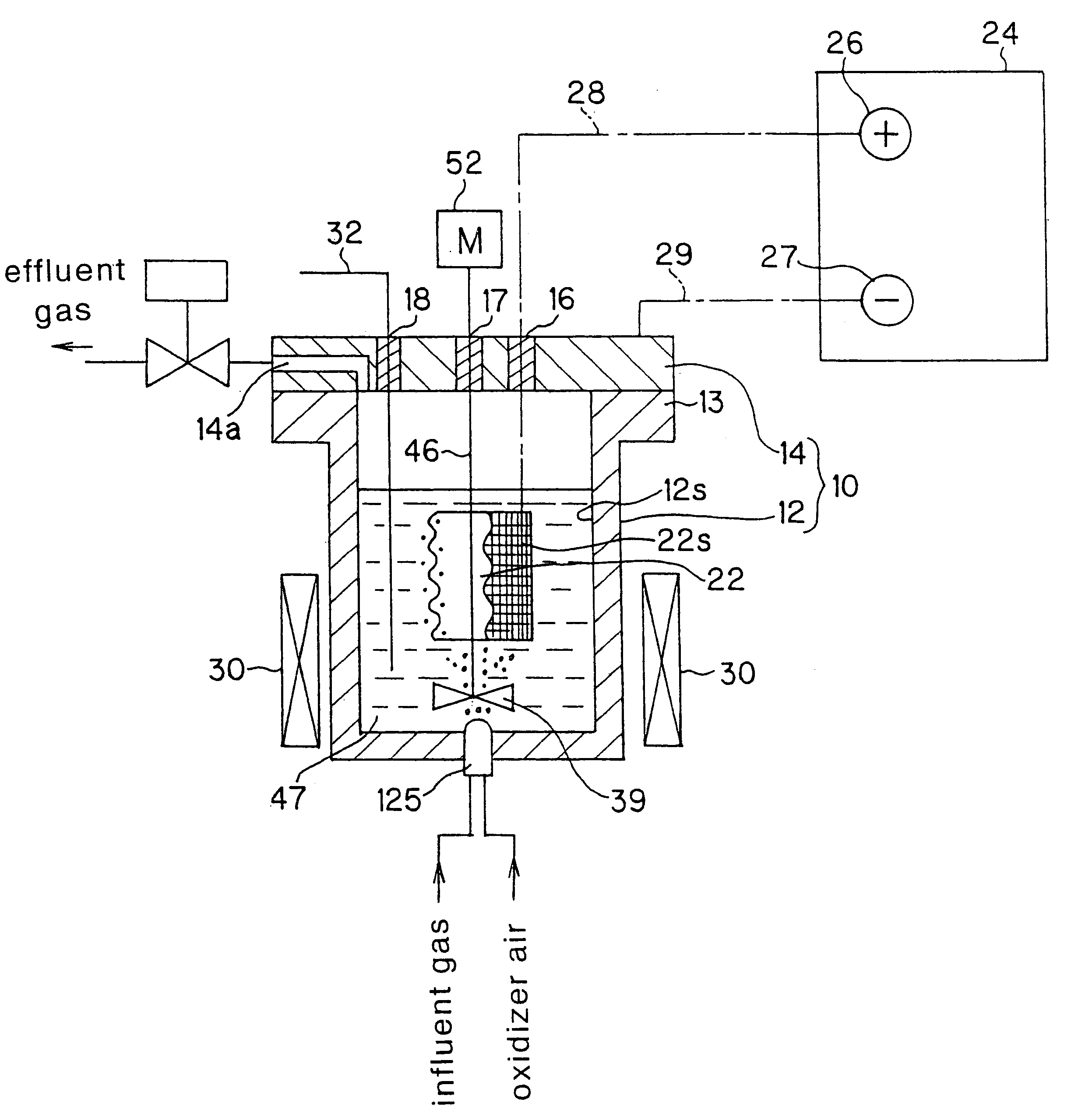

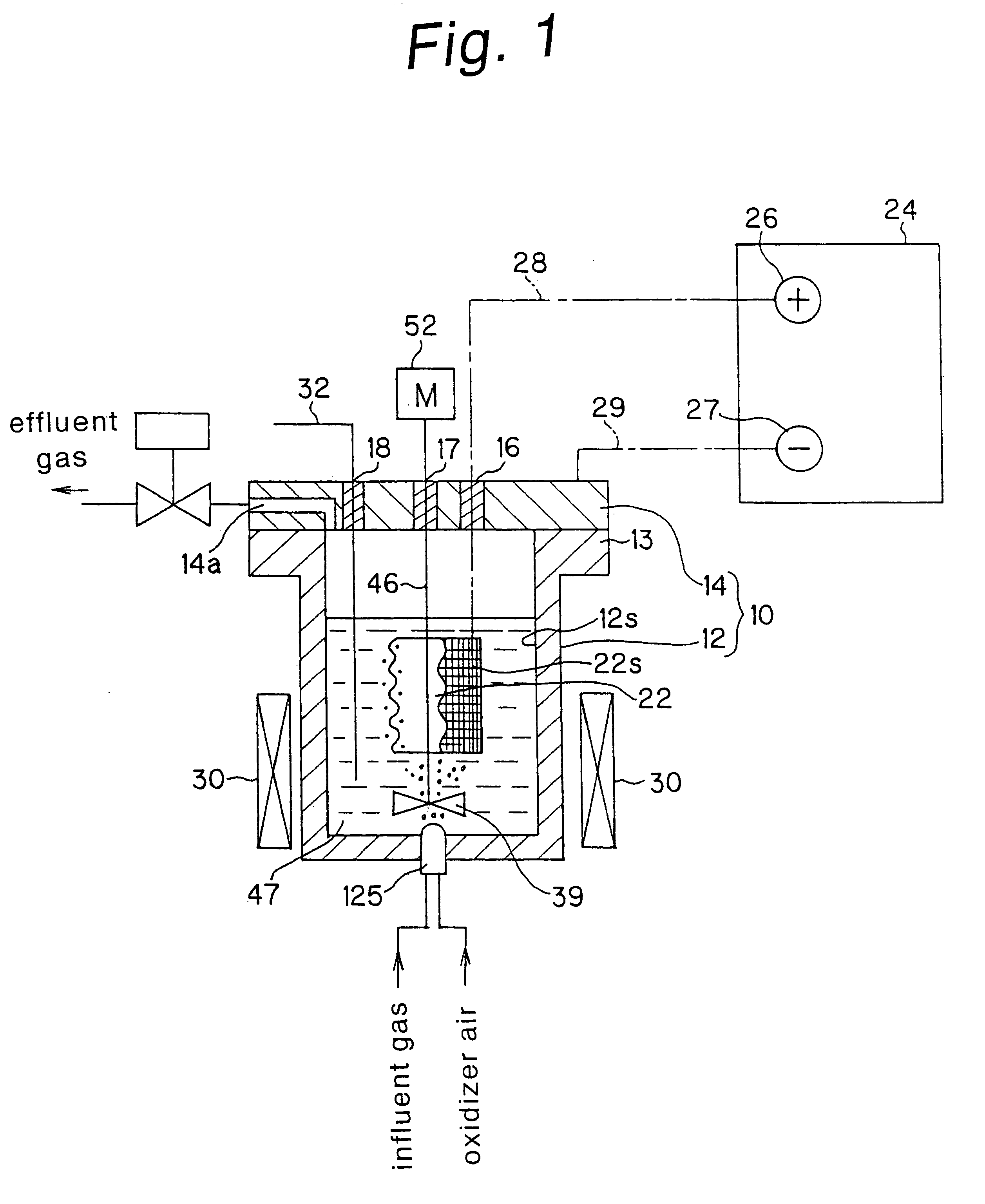

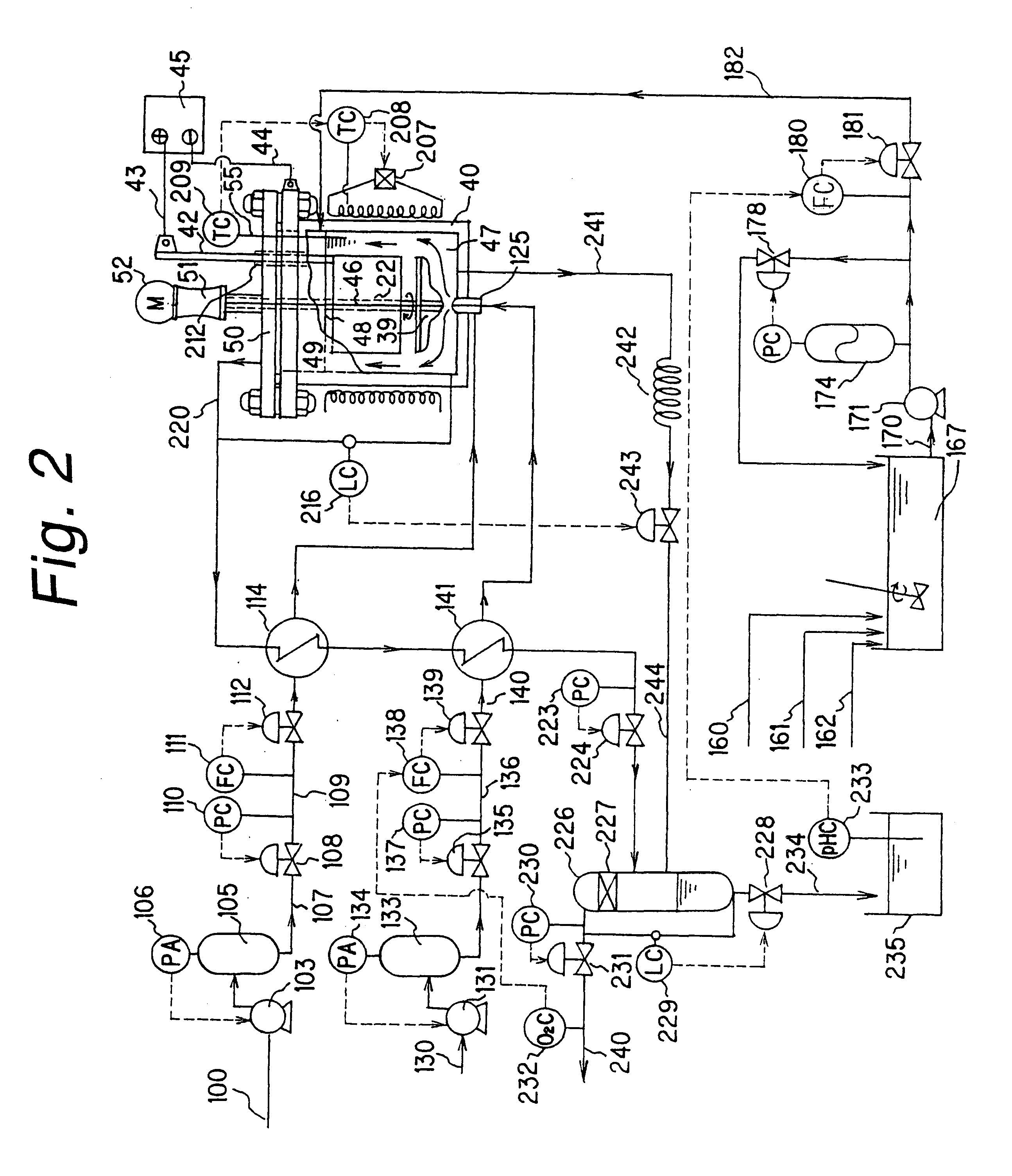

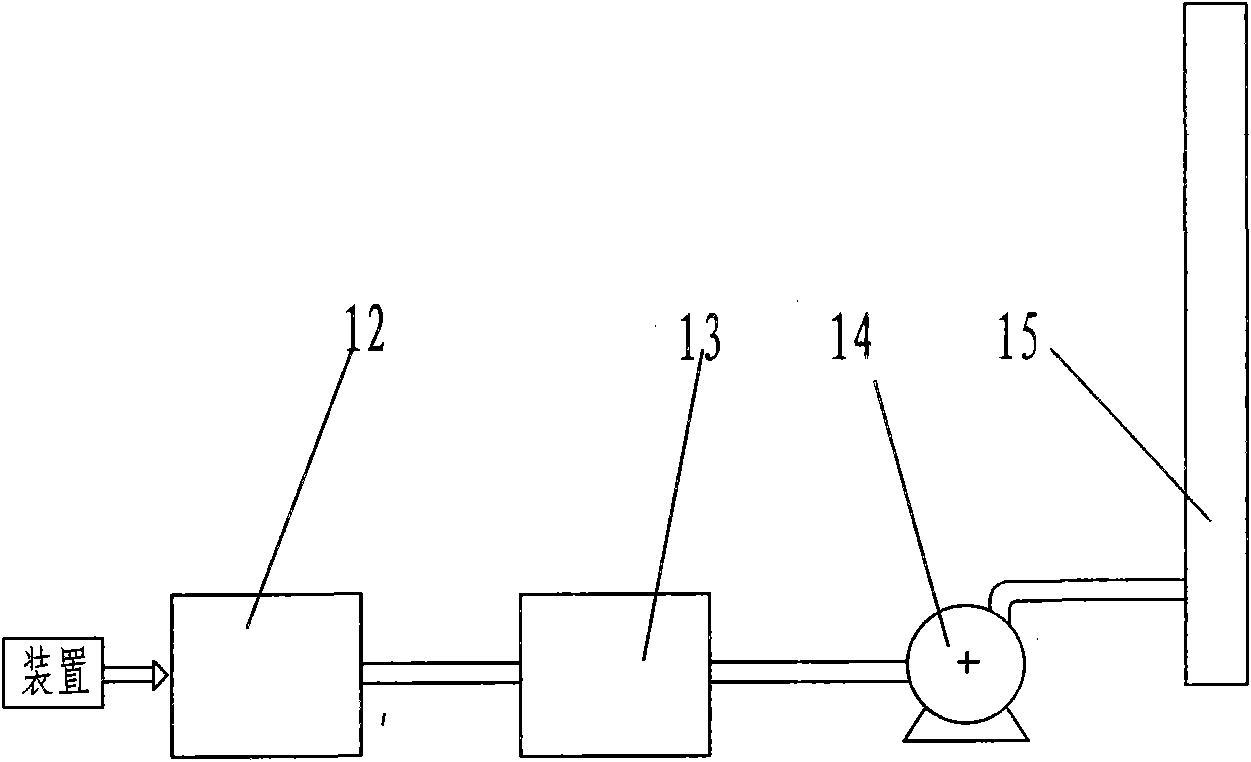

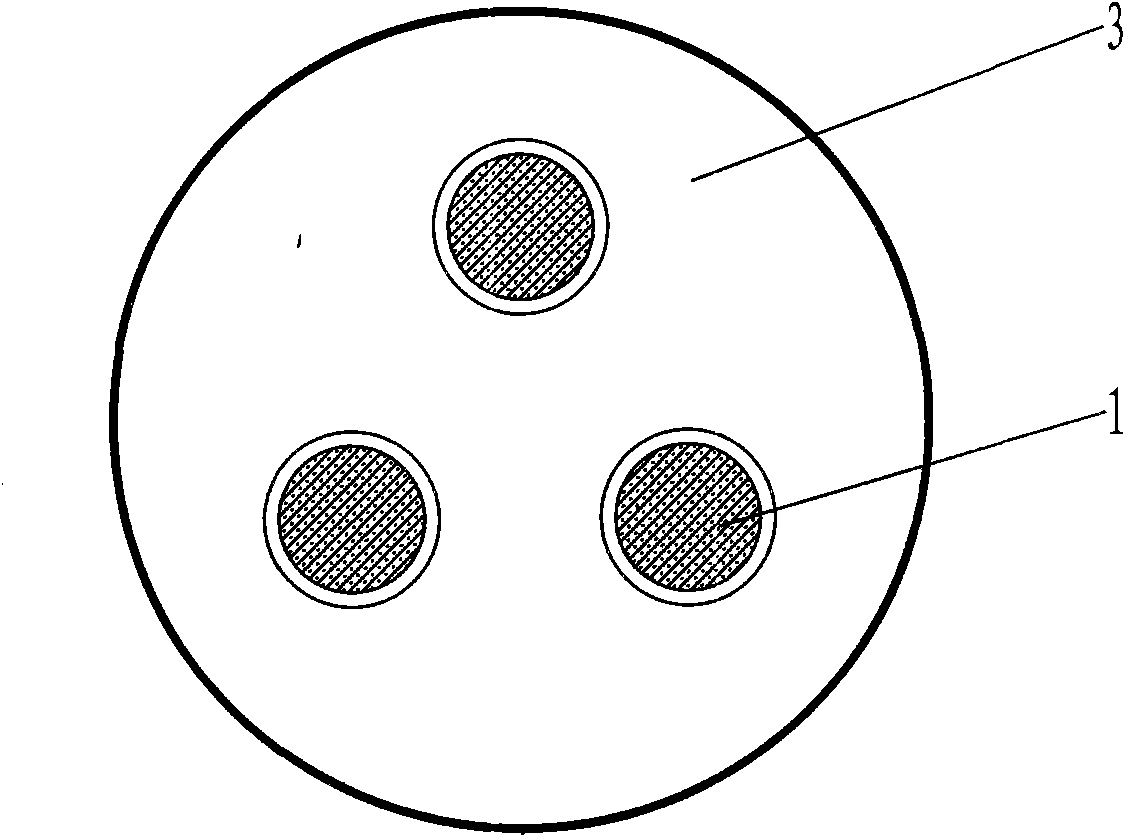

Method and apparatus for treatment of gas by hydrothermal electrolysis

InactiveUS6585882B1Effectively oxidatively degradedFrom normal temperature solutionsLiquid separation by electricityElectrolysisAqueous medium

An object of the present invention is to provide a process and an apparatus for treating a gas containing reducing substances to efficiently degrade and remove the reducing substances. As a means to achieve this object, the present invention provides a process for treating a gas containing reducing substances by hydrothermal electrolysis, comprising supplying a gas containing reducing substances into a reactor charged with an aqueous medium containing a halide ion under application of a direct current at a temperature of 100° C. or more but the critical temperature of said aqueous medium or less and at a pressure that allows said aqueous medium to be kept in the liquid phase.

Owner:EBARA CORP

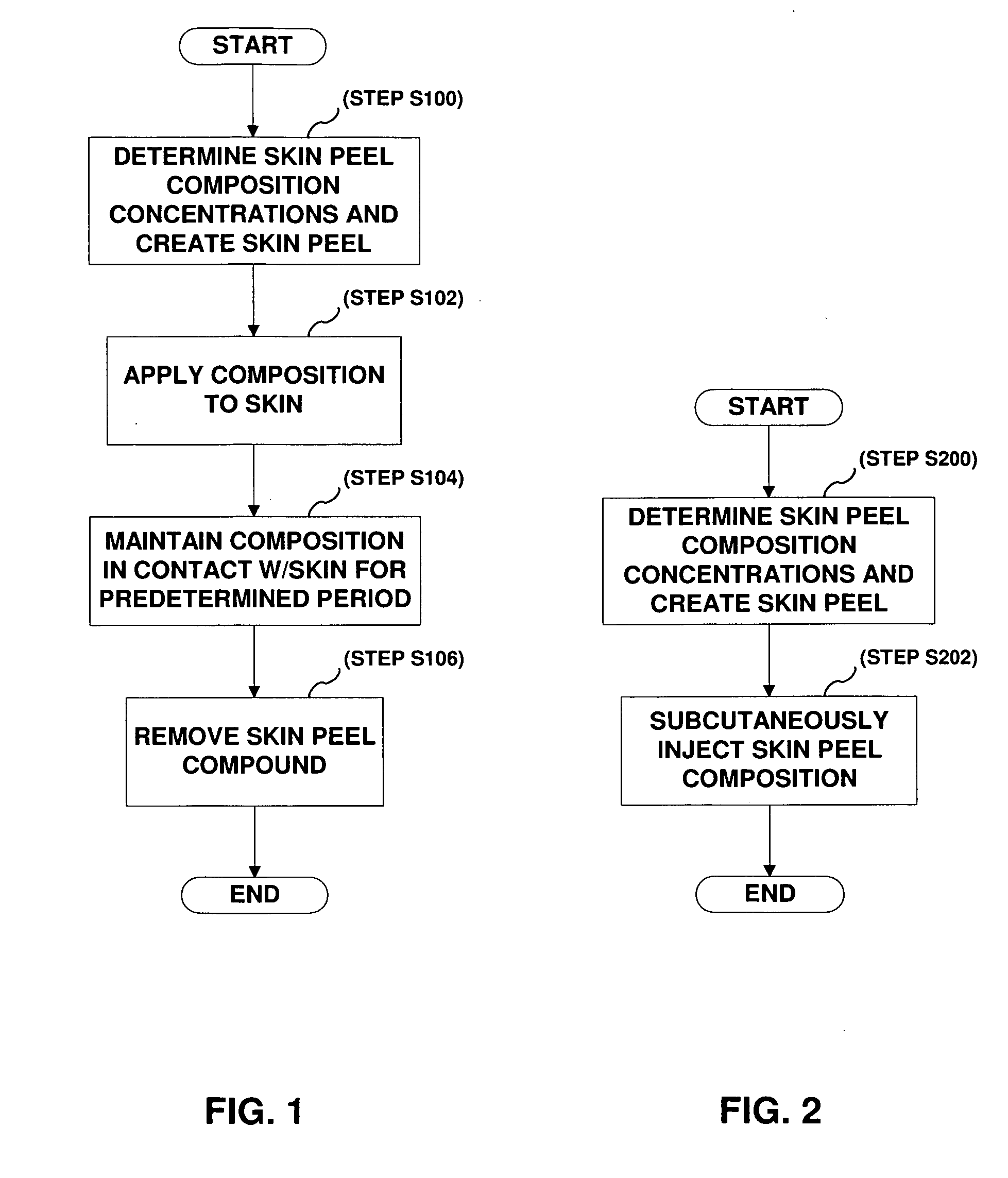

Method and compound for skin chemical peel

The present invention provides a skin peel composition including a plurality of keratolytic substances, such as trichloroacetic acid and salicylic, and a post inflammatory hyper pigmentation reducing substance such as retinoic acid. In addition, the skin peel composition may further include ascorbic acid (vitamin C), as well as vitamins A and E. Application of the skin peel composition may be either topically in the form of a cream or gel, and may further be injected subcutaneously into the skin to achieve deeper penetration of the composition within the skin layers of the area to be treated.

Owner:KALIL ENTERPRISES

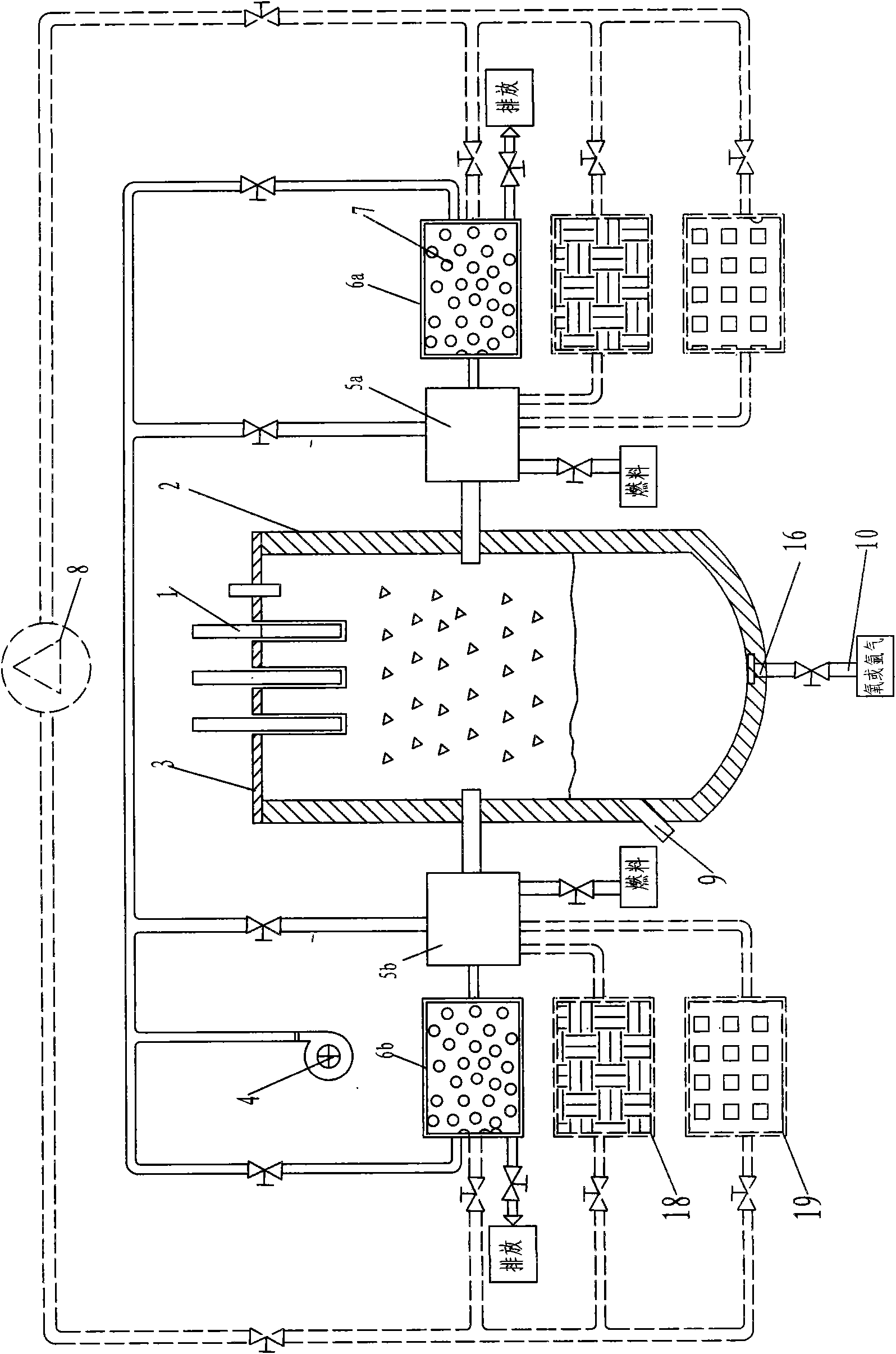

Method and device for making iron by smelting reduction

ActiveCN101649366ALess investmentReduce pre-restore timeCalcium carbideManufacturing convertersElectric arc furnaceSlag

The invention relates to a method and a device for making iron by smelting reduction. The method for making iron by smelting reduction comprises the following steps: putting raw material forming matters into a smelting ironmaking device; heating and reducing the raw material forming matters into metallic iron; after the reduced metalation rate of various oxides of iron reaches 40-95 percent in rawmaterials, heating and melting products of a reducing furnace; and producing direct reduction molten steel or molten iron produced by the similar blast furnace. The raw materials comprise a breath shell or a half-breath shell or an opening shell or the combination of the raw materials, a coating shells of the breath shell, the half-breath shell and the opening shell is prepared by adding an adhesive in calcium oxide or calcium carbonate or calcium carbide or the combination of the materials. The device for making iron by smelting reduction comprises an arc furnace, a buried arc furnace, a converter, an induction furnace, and the like. After reduction products are heated and melted, and oxygen or inert gas is blown into the arc furnace in order to remove slag. Due to the adoption of a shell coating technology, the method and the device effectively prevent from oxidizing reduced matters in the process, avoid bonding formed matters for contact and are combined with blowing gas and are good for making slag. Slag iron has good separation effect, and the produced iron and steel products have good quality.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com