Microcapsule and positive electrode material for battery as well as preparation methods and application of microcapsule and positive electrode material

A positive electrode material and microcapsule technology, which is applied in the field of battery microcapsules and positive electrode materials and their preparation, can solve the problems of increasing the valence of transition elements, prone to decomposition reactions, and deteriorating battery safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0074] Generally speaking, the safe positive electrode material and its preparation method of the present invention include the following steps.

[0075] 1) Preparation of microcapsules for batteries;

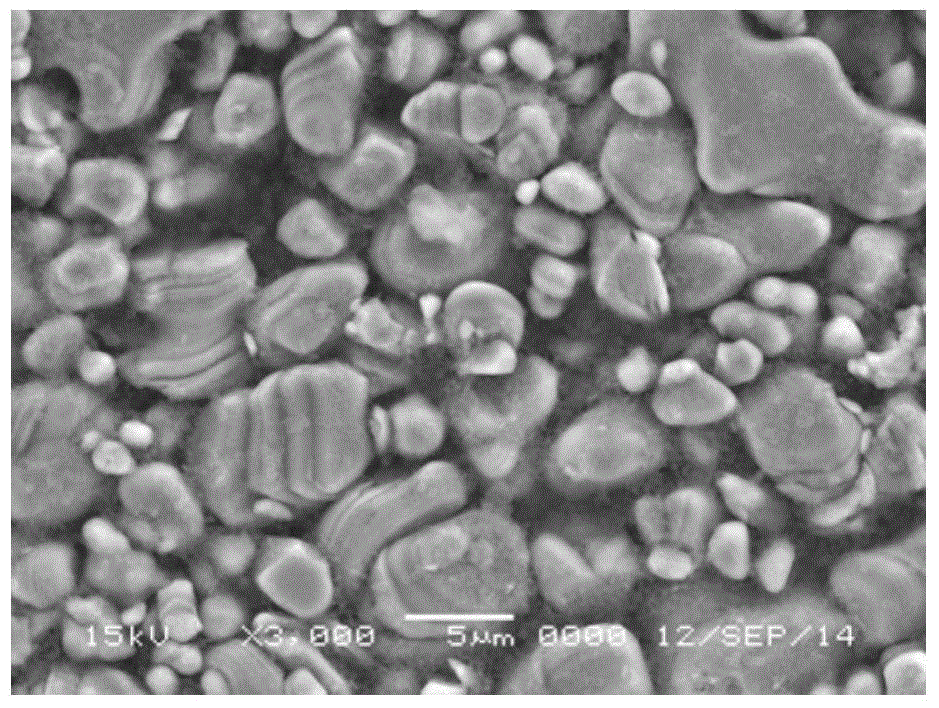

[0076] 2) Preparation of cathode materials for lithium batteries;

[0077] 3) Characterization of microcapsules and preparations;

[0078] 4) The embodiment simulates battery and full battery assembly;

[0079] 5) The safety performance characterization of the full battery of the embodiment;

[0080] 6) Characterization of the electrochemical cycle performance of the full battery of the embodiment.

Embodiment 1

[0090] Microcapsule preparation

Embodiment 1-1

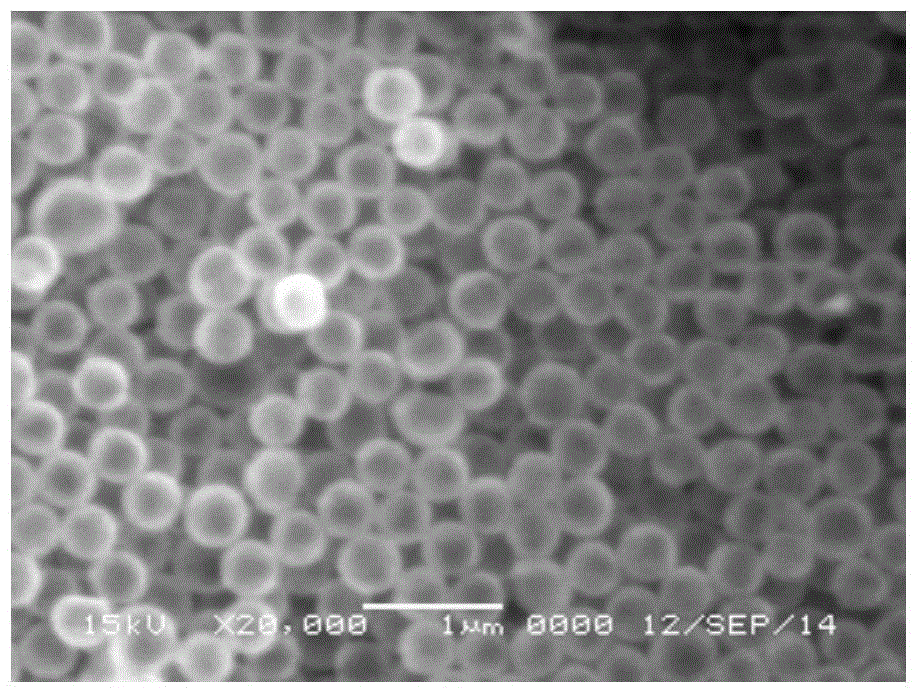

[0092] Weigh 50g of polytetrafluoroethylene emulsion and add a small amount of deionized water to dilute to a solid content of 20%, then start stirring, disperse the mixed liquid evenly, and slowly add 100g of decabromodiphenyl ether to it, at a temperature of 40°C, under the action of an emulsifier Emulsify and disperse for 60 minutes (rotational speed: 1500rpm), then pump the obtained emulsified slurry to the peristaltic airflow nozzle of the spray dryer, and use clean hot air (70°C) to carry out quality and heat treatment with the slurry droplets atomized by the nozzle. Exchange, complete instant evaporation and instant drying, and collect fluffy dry powder particles. The particle size (D 50 ) is about 0.1 μm, and the prepared powder is called Example 1-1. Among them, the particle size (D 50 ) refers to the corresponding particle size when the cumulative particle size distribution percentage reaches 50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com