Production method of phosphorus copolymerization flame-retardant regenerated polyester chip and industrial yarn of the polyester chip

A technology of recycled polyester and copolymer flame retardant, which is applied in the field of flame retardant polyester industrial yarn production, can solve problems such as difficulty in increasing melt viscosity, and achieve far-reaching effects of reducing intrinsic viscosity and increasing polyester melt viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

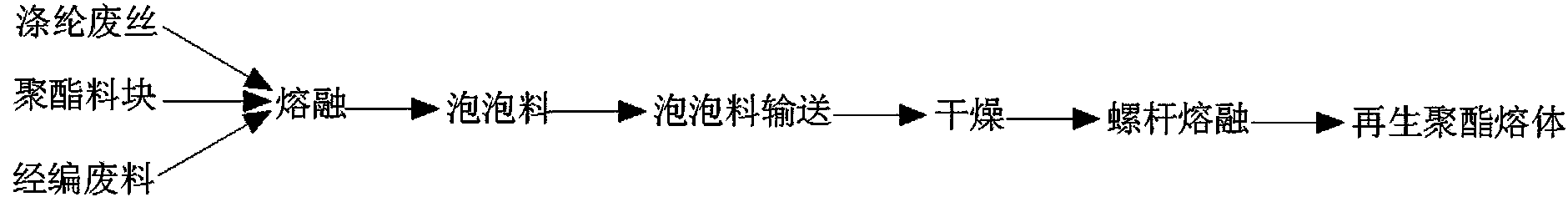

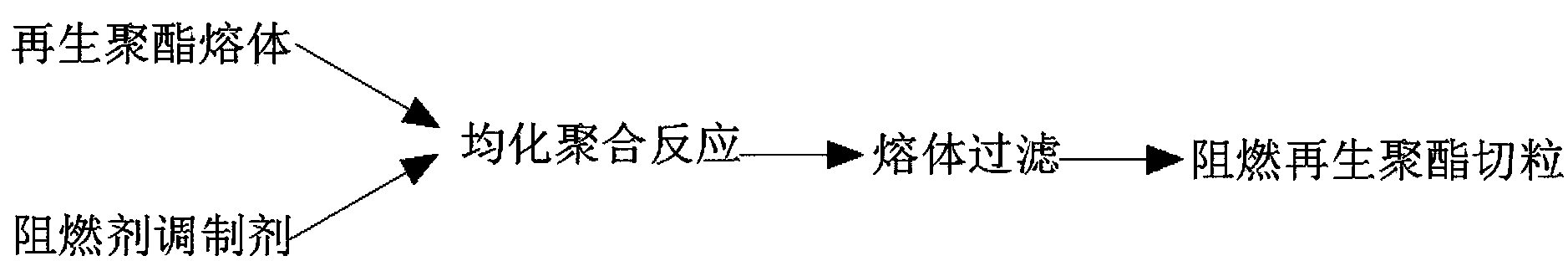

Method used

Image

Examples

Embodiment 1

[0035] Example 1: Production of 1110dtex / 192f flame-retardant recycled polyester industrial yarn

[0036] (1) Solid phase polymerization

[0037] Feed the flame-retardant recycled polyester chips prepared above into the solid-state polymerization system, carry out dry crystallization at 160-180°C, and under the protection of nitrogen with oxygen content ≤ 100ppm, make the molecular chain The polycondensation reaction occurs again at the end to obtain a high molecular weight polymer and increase the viscosity to 0.90-1.10;

[0038] (1) spinning

[0039]The high-viscosity flame-retardant recycled polyester chips obtained after solid-state polymerization are melted into a spinning melt at high temperature in a screw extruder. After static mixing, it is fully mixed during the conveying process, and then sprayed into filaments through the spinning assembly at a pressure of 13-30MPa. The spinning temperature is 275°C, the filament passing temperature is 20±2°C, the humidity is 60±...

Embodiment 2

[0042] Example 2: Production of flame-retardant recycled polyester industrial yarn of 555dtex / 96f

[0043] The process of this example is the same as that of Example 1, the difference is that the high-viscosity flame-retardant recycled polyester chips obtained after solid-state polymerization are melted into a molten spinning melt at a high temperature in a screw extruder, and the temperatures in each zone of the screw are respectively 270°C, 275°C, 270°C, 268°C, 268°C, fully mixed through a static mixer, and then sprayed into filaments through the spinning assembly at a pressure of 13-30MPa, the spinning temperature is 278°C, and the filament passing temperature The temperature is 20±2℃, the humidity is 60±5%, and the constant temperature and humidity air-conditioning wind with a speed of 0.4m / s is used for uniform cooling to form primary fibers; after the primary fibers made in the spinning process are coated with high temperature resistant oil (0.5-1.0%, the meaning is the ...

Embodiment 3

[0044] Example 3: Production of flame-retardant recycled polyester industrial yarn of 2220dtex / 384f

[0045] The process of this example is the same as that of Example 1, the difference is that the high-viscosity flame-retardant recycled polyester chips obtained after solid-state polymerization are melted into a spinning melt at a high temperature in a screw extruder, and the temperature of each zone of the screw is 275°C. , 275°C, 270°C, 270°C, 270°C, fully mixed through a static mixer, and then sprayed into filaments through the spinning assembly at a pressure of 13-30MPa, the spinning temperature is 270°C, and the filament passing temperature is 20± 2°C, humidity 60±5%, constant temperature and humidity air-conditioning wind with a speed of 0.5m / s for uniform cooling to form nascent fibers; 1.0%, the same as above), through 5 pairs of drafting rollers for multi-stage drafting, the speed and corresponding temperature of each pair of drafting rollers are 455m / min, 80°C; 458m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com