Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

130results about How to "Improve flotation recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

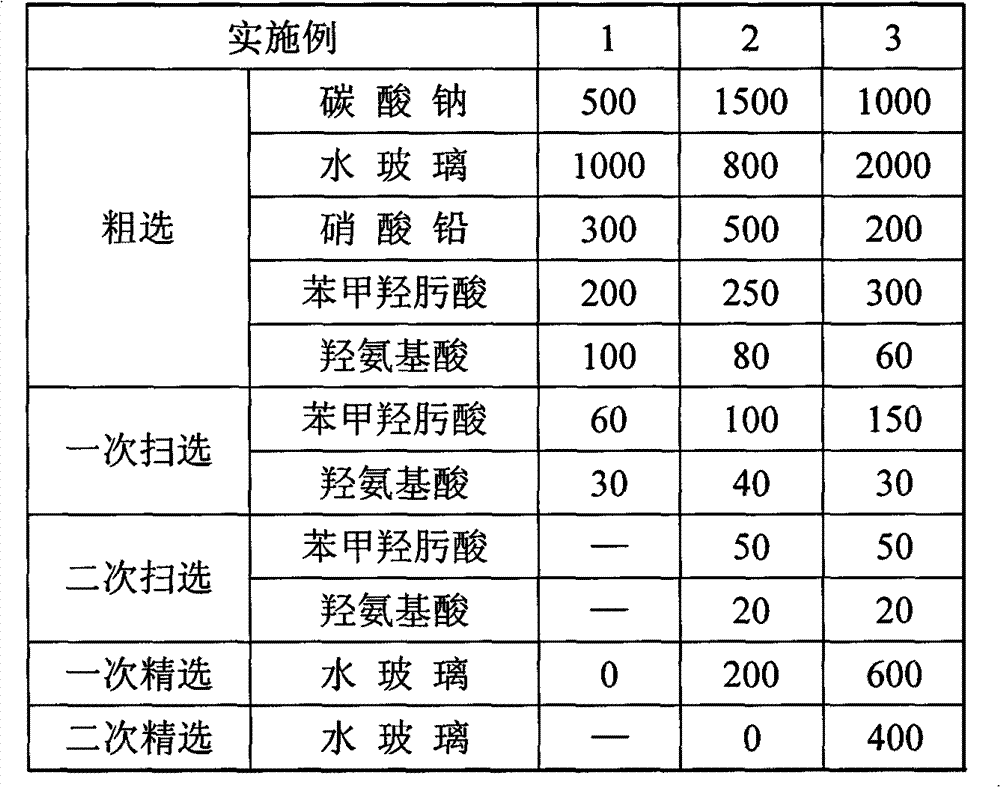

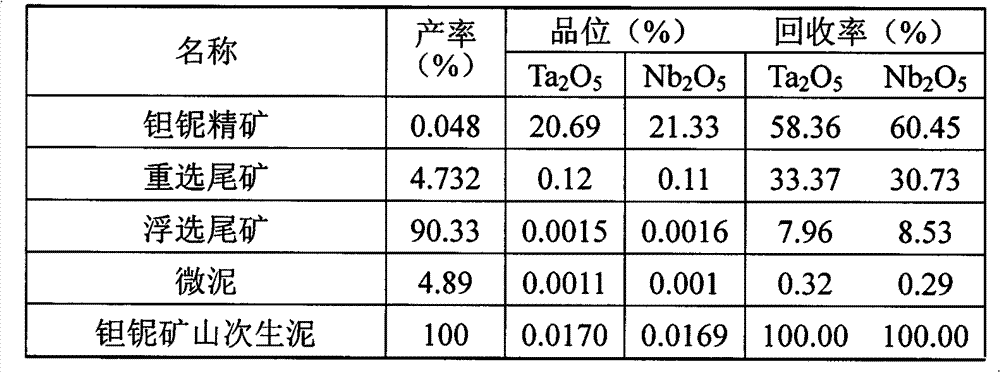

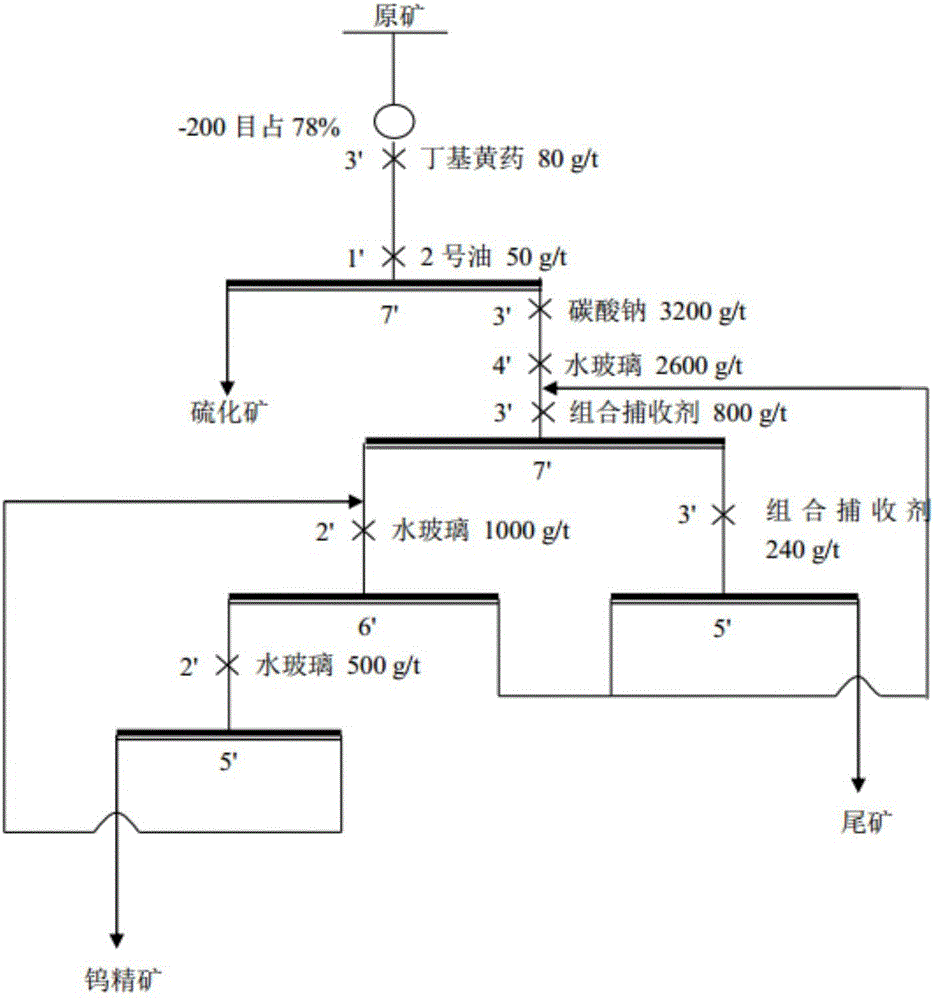

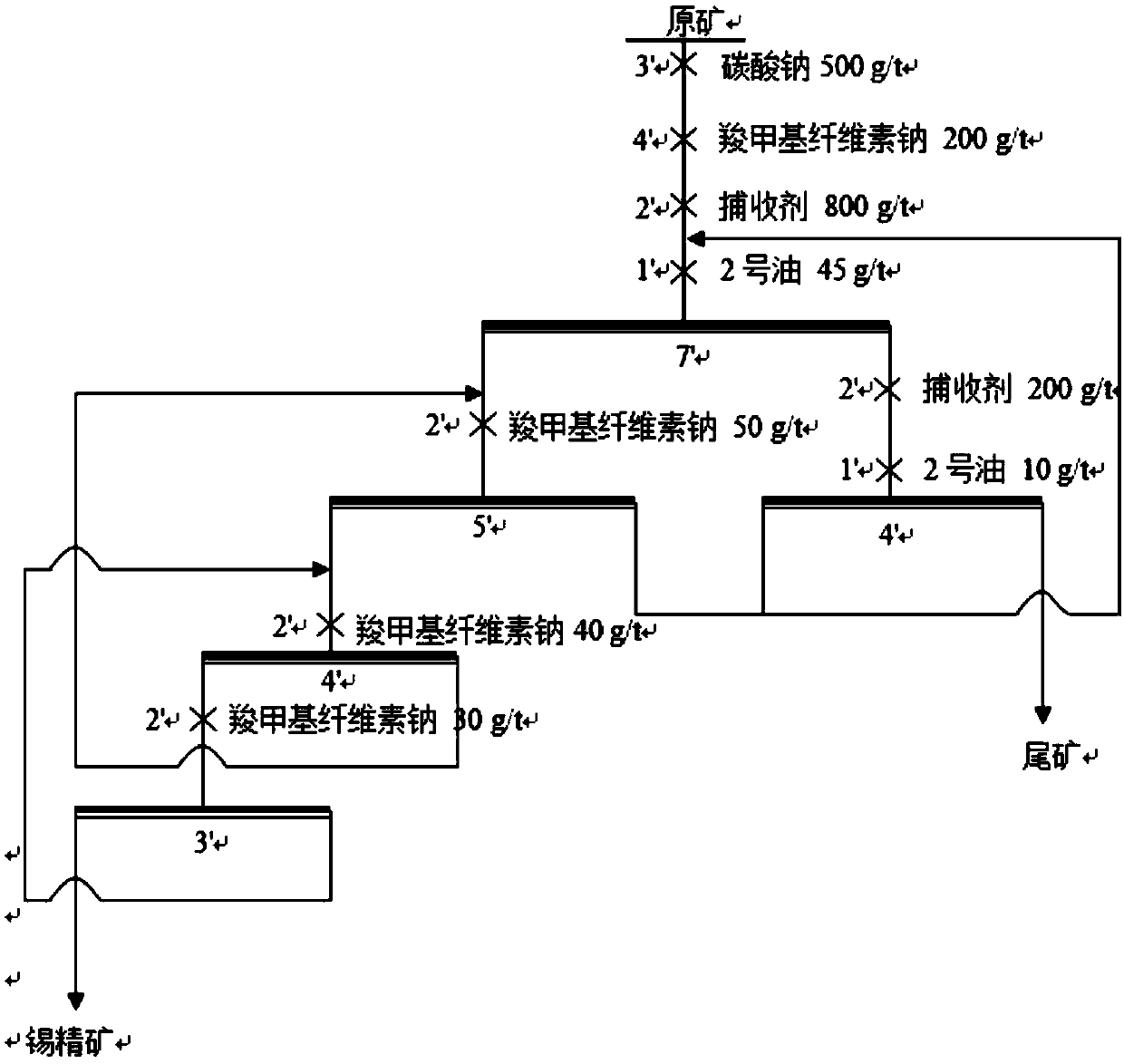

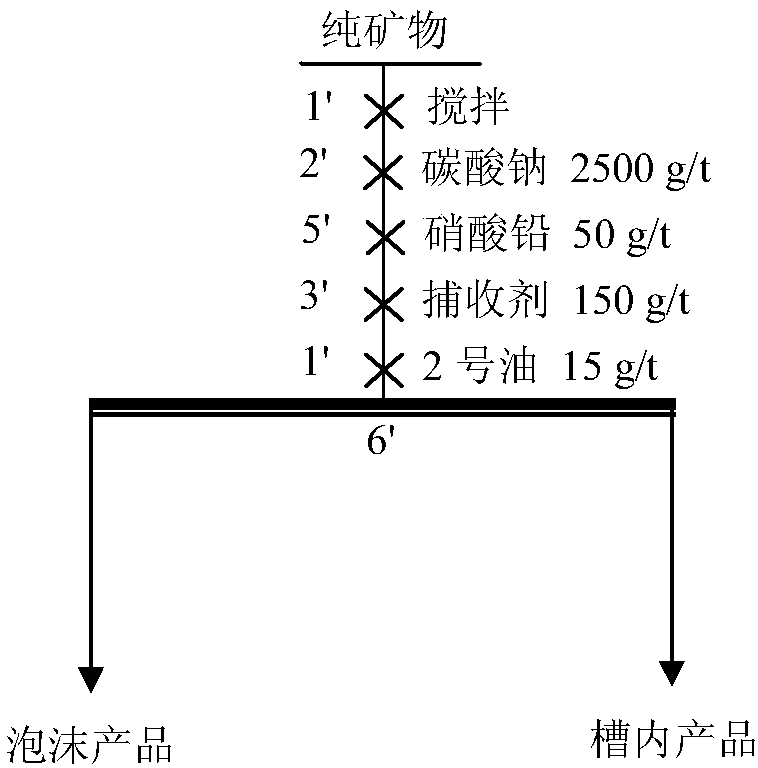

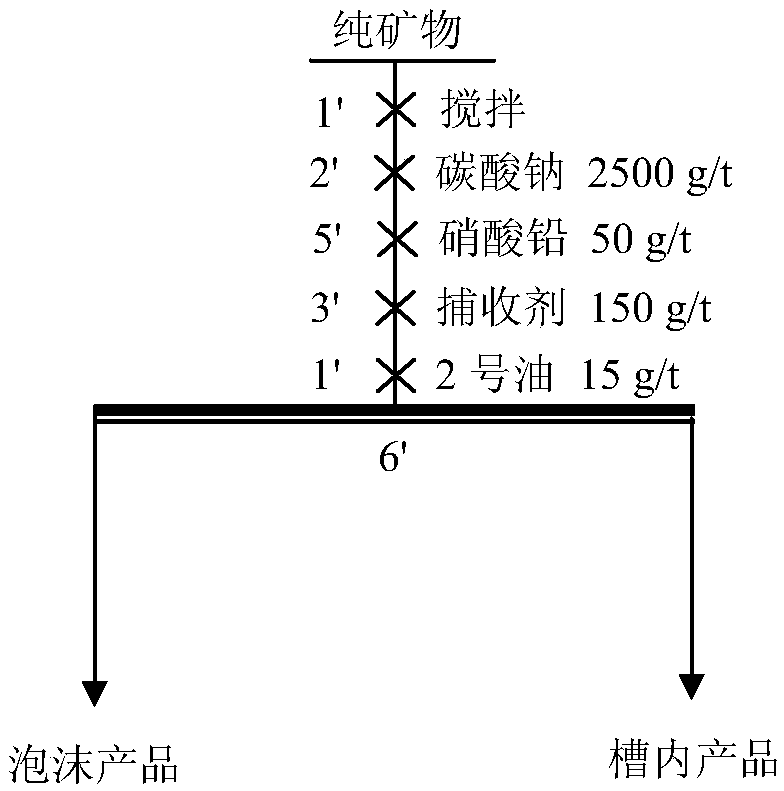

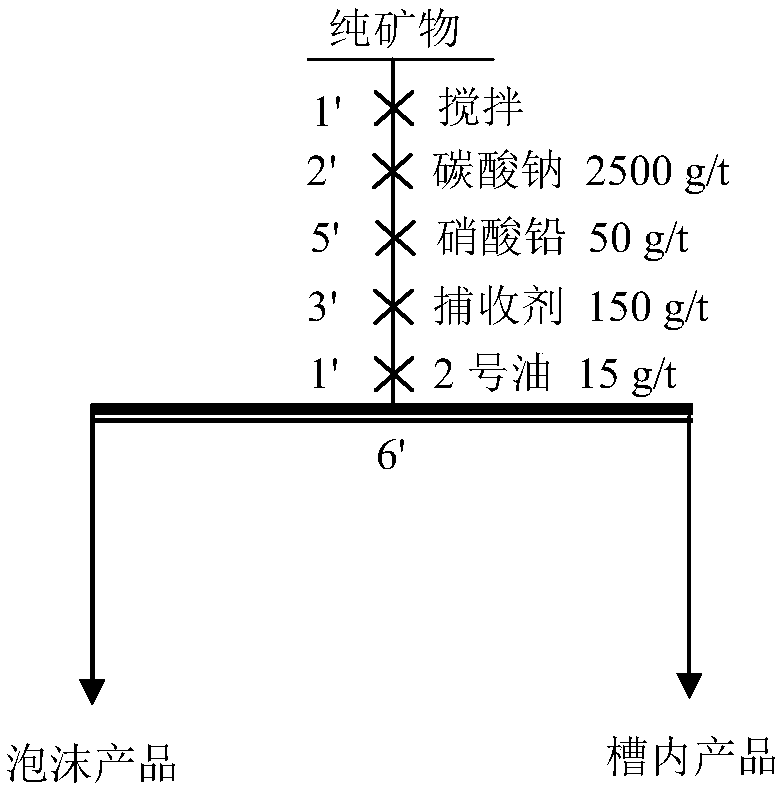

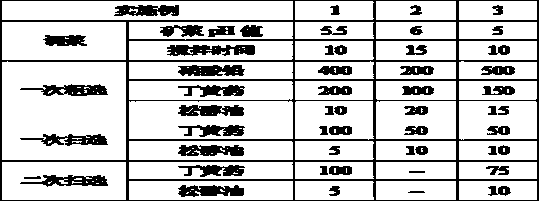

Ore dressing method of micro-fine particle tantalum-niobium ores

InactiveCN102861662AEliminate selection noiseImprove flotation recoveryPlaning/slotting machinesWet separationBenzohydroxamic acidLead nitrate

Disclosed is an ore dressing method of micro-fine particle tantalum-niobium ores. The ore dressing method is characterized by including steps of firstly, performing desliming pre-treatment to obtain set sand and micro-mud; secondly, adding an adjusting agent of sodium carbonate, an inhibiting agent of water glass, an activating agent of lead nitrate and collectors of benzohydroxamic acid and hydroxyamino acid to the set sand for once roughing; adding the benzohydroxamic acid and the hydroxyamino acid for once or twice scavenging; adding the water glass for once or twice concentration or blank concentration to obtain tantalum-niobium rough concentrates and flotation tailings; thirdly, performing de-reagent and de-foaming: adding sulfuric acid to the tantalum-niobium rough concentrates, and stirring the mixture until foams are disappeared; and fourthly, performing gravity concentration: subjecting the tantalum-niobium rough concentrates to de-reagent and de-foaming, and subjecting the tantalum-niobium rough concentrates to gravity concentration to obtain tantalum-niobium concentrates and gravity concentration tailings. According to the ore dressing method of the micro-fine particle tantalum-niobium ores, the recovery rate of the micro-fine particle tantalum-niobium ores is increased by over 30%, and the ore dressing method is applicable to primary mud and secondary mud with sizes of -0.037mm in tantalum-niobium ores.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

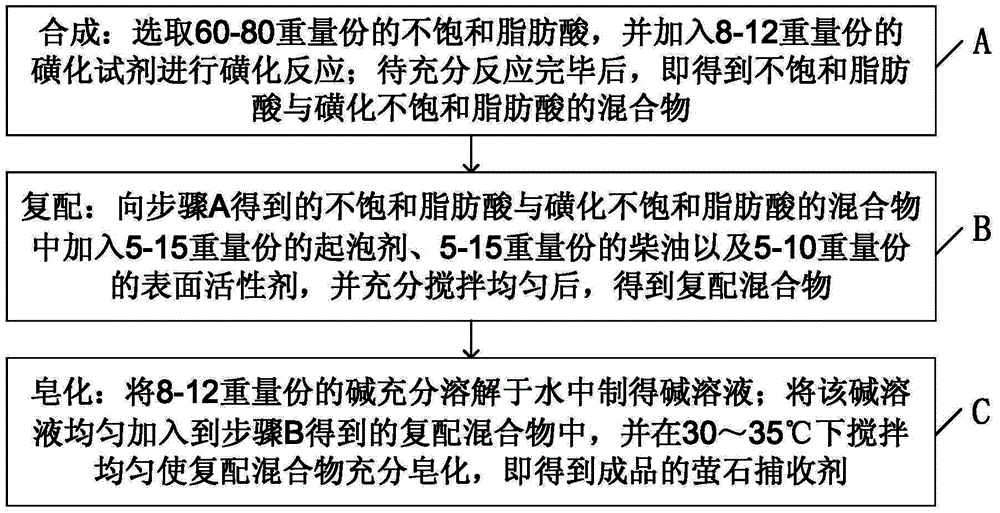

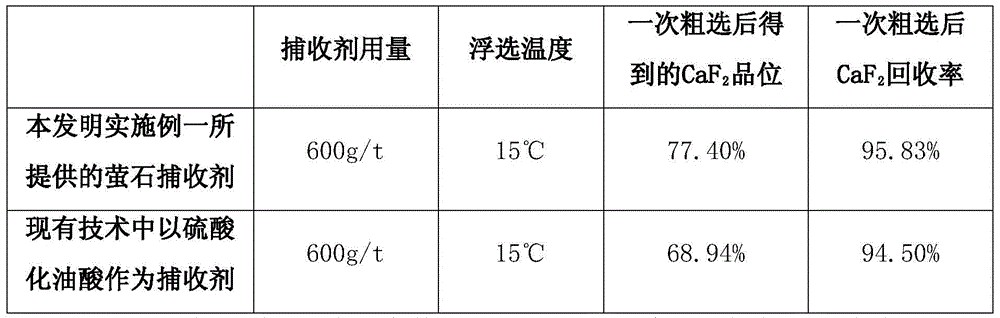

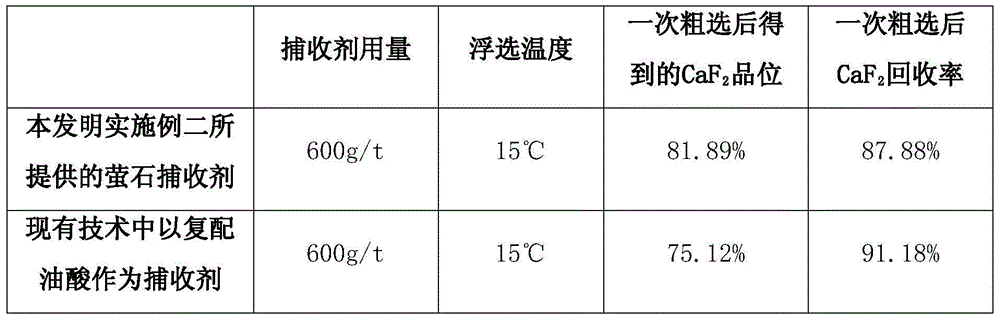

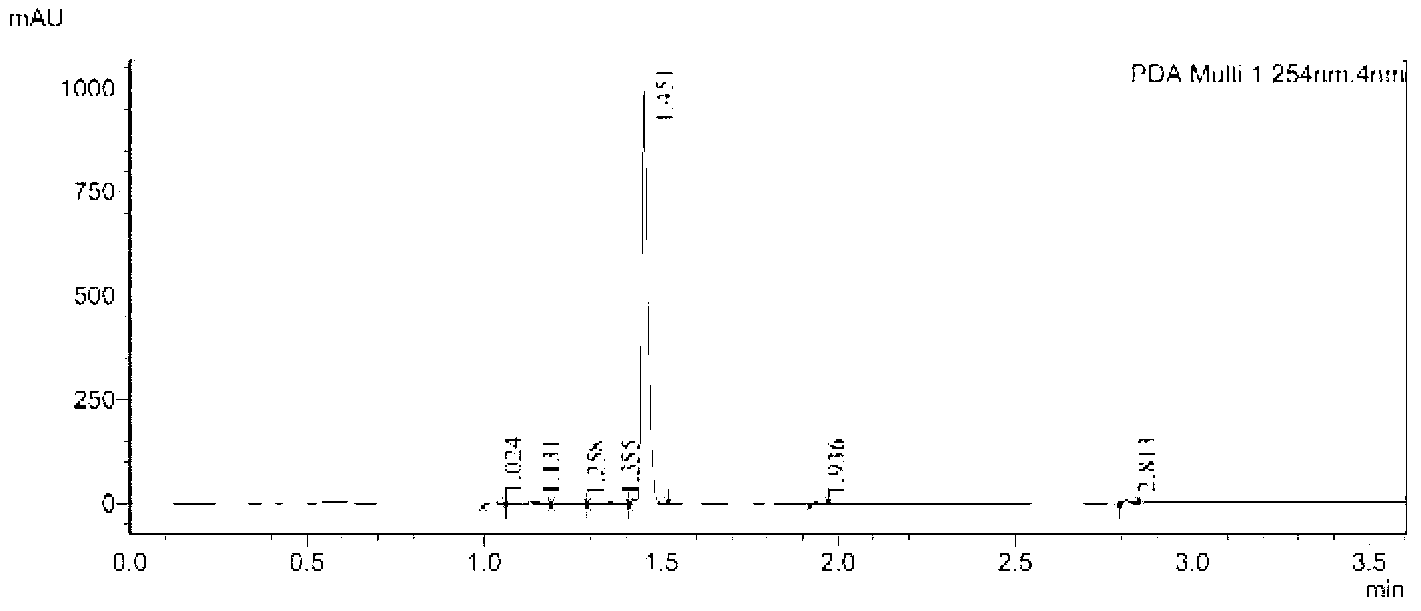

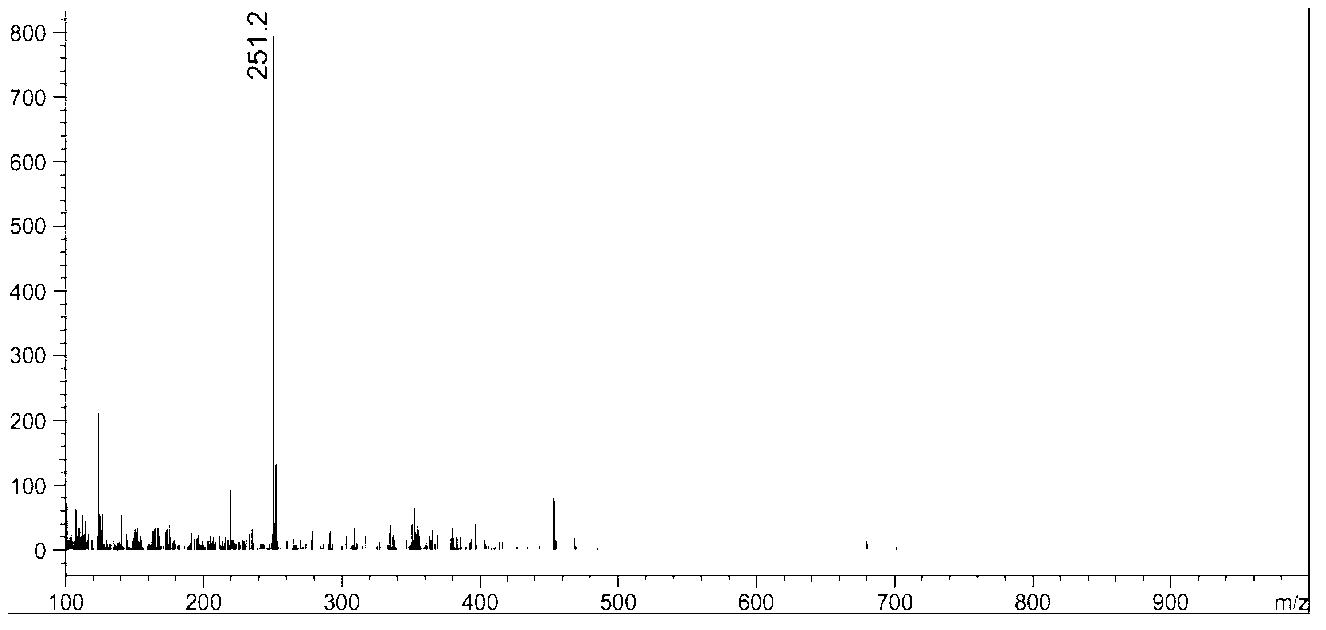

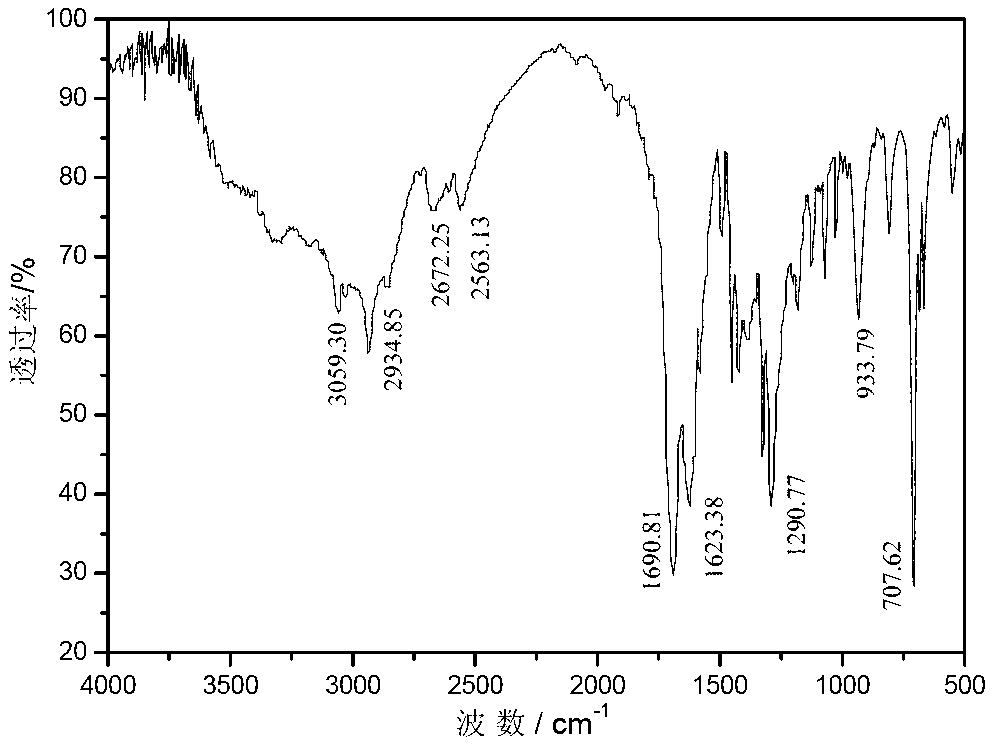

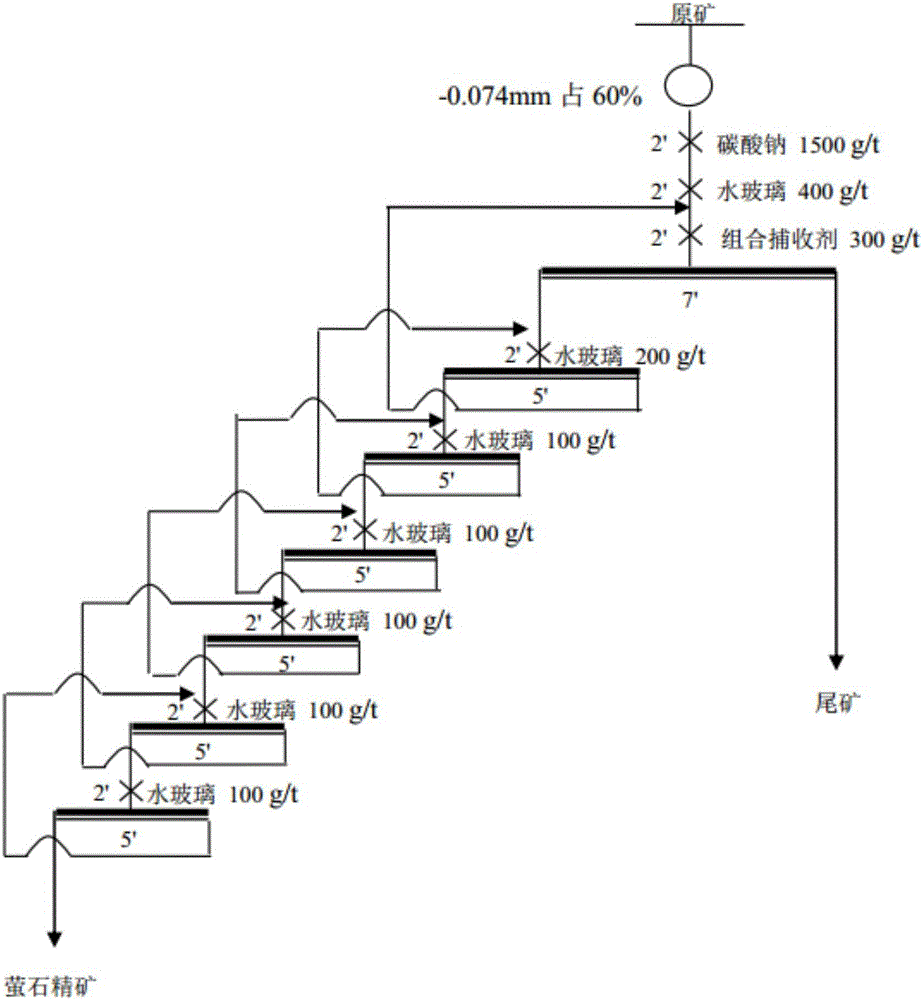

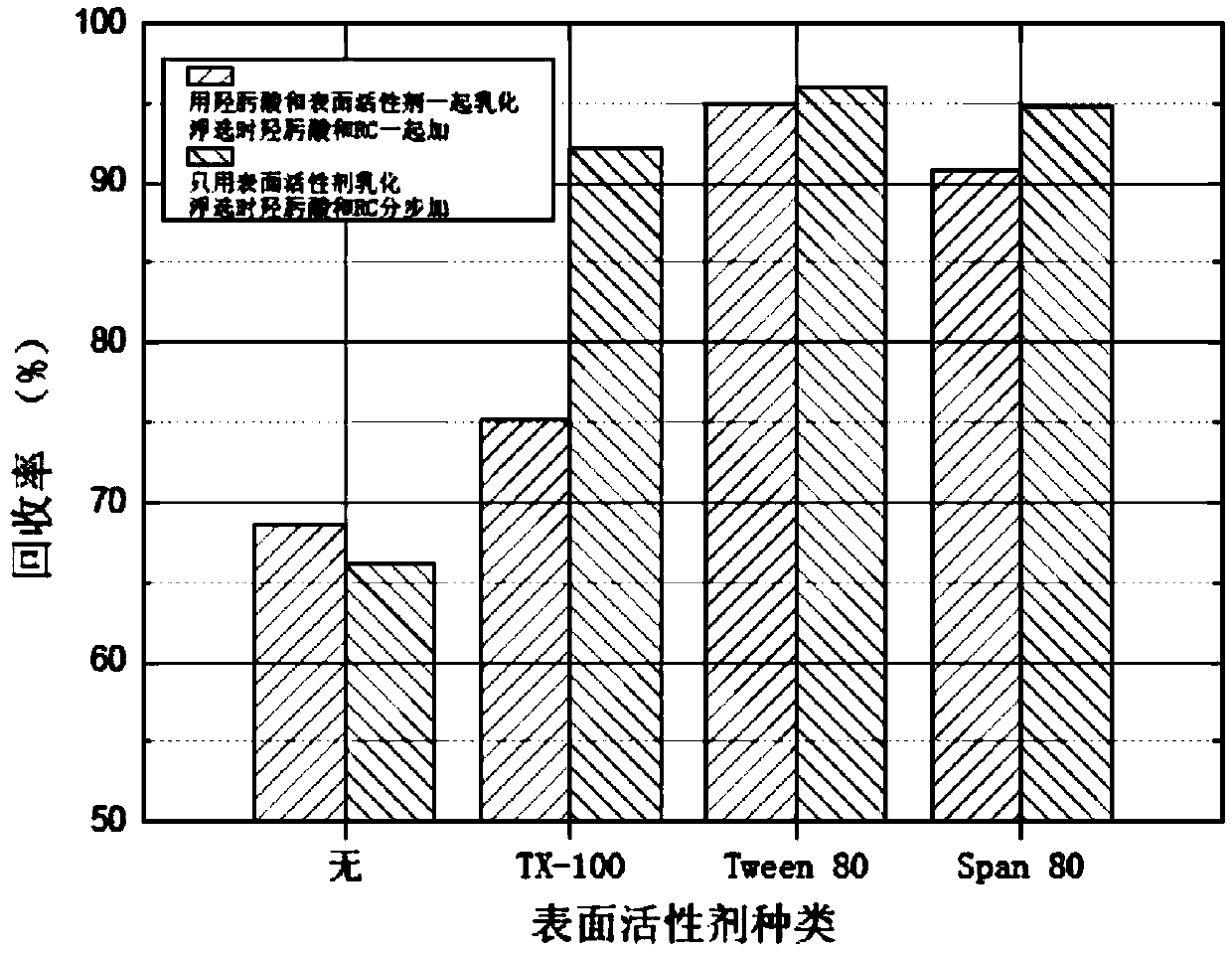

Fluorite collecting agent and preparing method of fluorite collecting agent

ActiveCN104056726AImprove flotation recoveryImprove solubilityFlotationFoaming agentRoom temperature

The invention discloses a fluorite collecting agent and a preparing method of the fluorite collecting agent. The fluorite collecting agent comprises a main agent, an auxiliary agent, alkali and water, wherein the main agent comprises unsaturated fatty acid and sulfonated unsaturated fatty acid, the auxiliary agent comprises a foaming agent, diesel oil and a surface active agent, the ratio of the total weight of the main agent and the auxiliary agent to the weight of the water is 1:(1-10), and the main agent, the auxiliary agent and the alkali have the following proportion in parts by weight: the unsaturated fatty acid accounts for 40 to 50 parts, the sulfonated unsaturated fatty acid accounts for 25 to 30 parts, the foaming agent accounts for 5 to 15 parts, the diesel oil accounts for 5 to 15 parts, the surface active agent accounts for 5 to 10 parts, and the alkali accounts for 8 to 12 parts. The fluorite collecting agent and the preparing method provided by the embodiment of the invention have the advantages that good low-temperature-resistant selectivity and collecting performance are achieved, stable and excellent flotation effects can be obtained both under the normal-temperature conditions and under the low-temperature conditions, the fluorite recovery rate and the quality of fluorite obtained through flotation are improved, in addition, the preparation process is simple, and the production cost is lower than that of the collecting agent in the prior art, so good market popularization values are realized.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

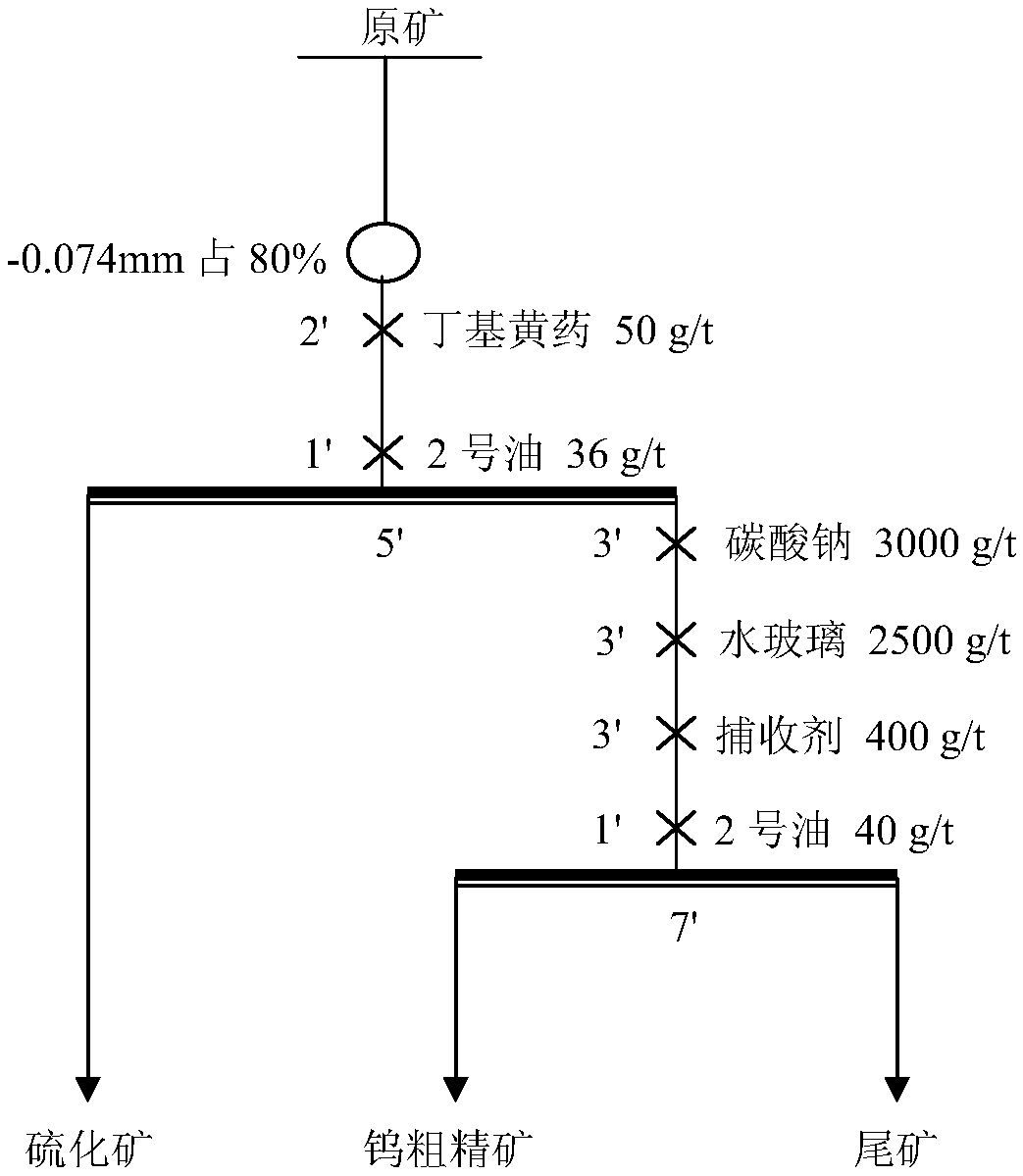

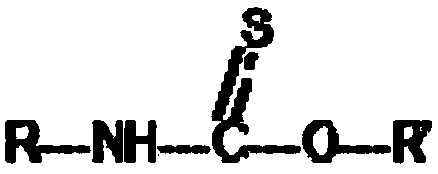

6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof

ActiveCN103301953AStrong harvesting abilityImprove flotation recoveryFlotationPotassium hydroxideSodium hydroxide

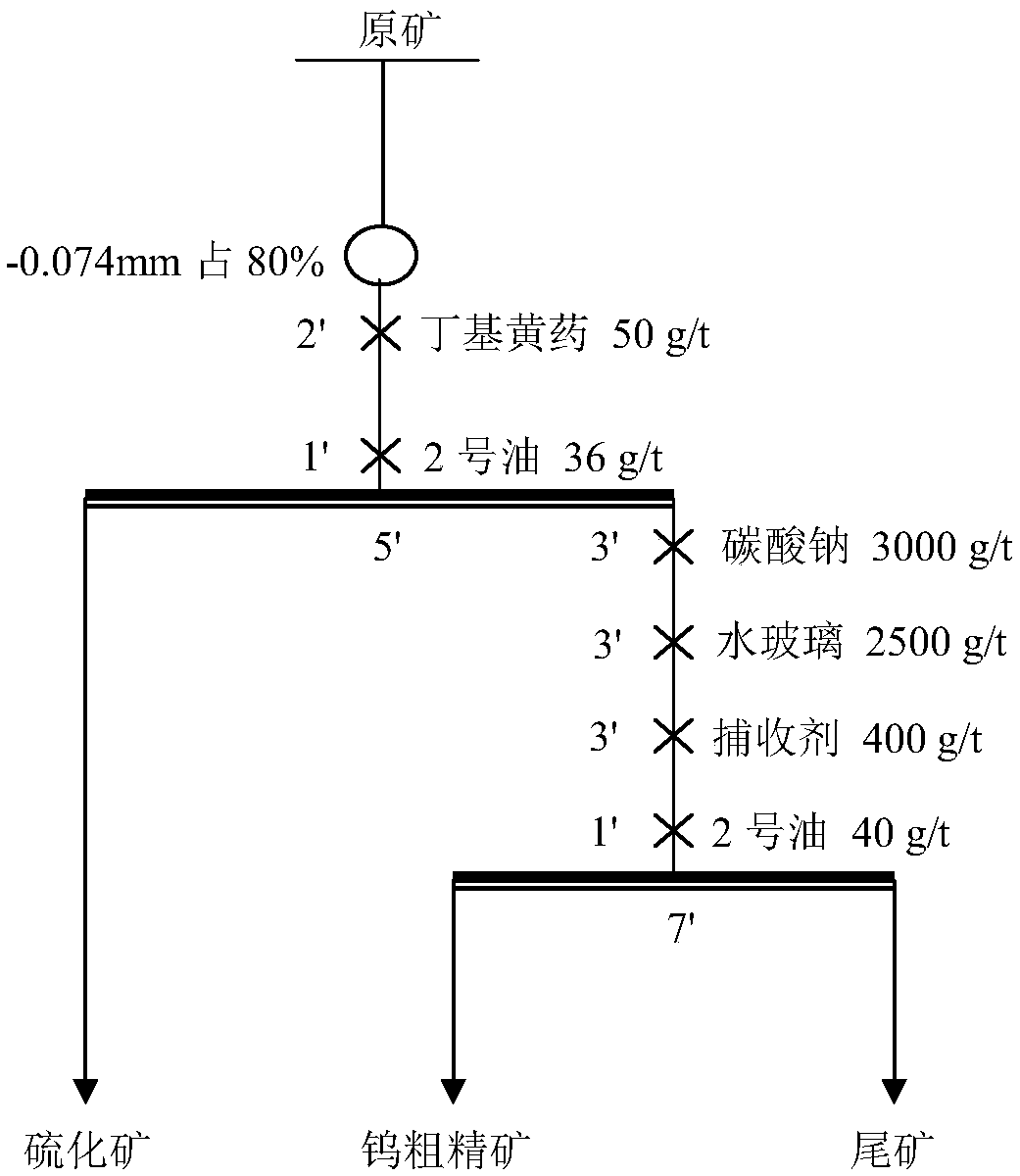

The invention discloses a 6-aryl amido hexyl hydroximic acid collecting agent and preparation and application methods thereof. 6-aryl amido hexyl hydroximic acid represented by a formula (I) is taken as a collecting agent and utilized in flotation of tungsten ore, tombarthite ore, tin ore or bauxite, wherein R represents H or C1-8 alkyl. 6-aryl amido hexyl hydroximic acid and sodium hydroxide, potassium hydroxide or ammonium hydroxide are put into water to prepare an aqueous solution of 6-aryl amido hexyl hydroxyoximate; a flotation reagent is added for size mixing during an ore grinding and / or flotation process, the added reagent at least contains the aqueous solution of 6-aryl amido hexyl hydroxyoximate, and the dosage of 6-aryl amido hexyl hydroximic acid ranges from 100g / t to 3,500g / t; and useful metallic minerals are floated out through a froth flotation method, and the flotation recovery rate can be increased by 2%-5%.

Owner:CENT SOUTH UNIV

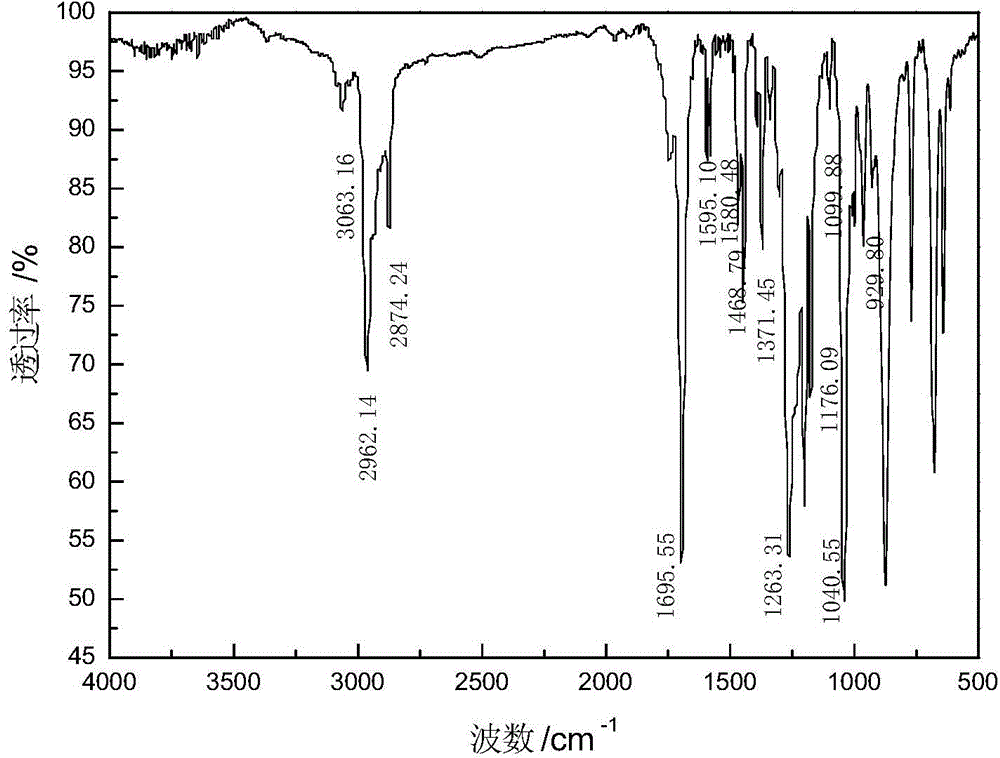

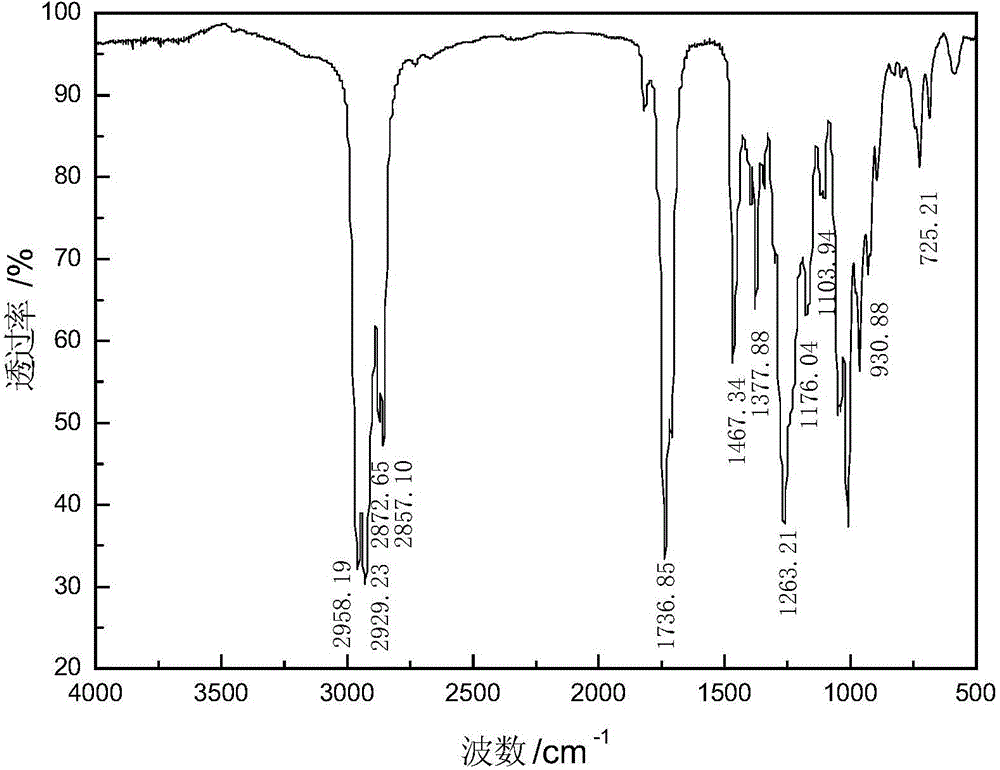

Xanthic acid acyl ester collecting agent and preparation and application methods thereof

ActiveCN103977907AImprove flotation gradeHigh recovery rateOrganic chemistryFlotationReaction temperatureAcyl group

The invention discloses a xanthic acid acyl ester collecting agent and preparation and application methods thereof. The preparation method comprises the steps that alkyl xanthogenate and acyl chloride are taken as raw materials and react for 1-4 h under a reaction temperature 10-50 DEG C to generate xanthic acid acyl ester. According to the preparation method, the reaction operation is simple, no waste water is generated, and the product yield coefficient is high; a xanthic acid acyl ester collecting agent has stronger collecting capacity and selectivity for sulphide ores such as copper sulphide ores, lead zinc ores and copper molybdenum ores precious metal ores as well as associated gold and silver precious metal ores, and better flotation indexes are obtained in the flotation test process.

Owner:CENT SOUTH UNIV

Activating agent for flotation of copper-nickel sulfide ores

InactiveCN105665152ARaw materials are cheap and easy to getApplicable industryFlotationNickel saltPhysical chemistry

The invention discloses an activating agent for flotation of copper-nickel sulfide ores.The activating agent is prepared from a component A and a component B, wherein the component A is copper salt or nickel salt, and the component B is amine, ammonia or ammonium salt.Compared with an existing activating agent for flotation of copper-nickel sulfide ores, the activating agent for flotation of the copper-nickel sulfide ores can remarkably improve the flotation and recovery rate and grade of the nickel-copper the copper-nickel sulfide ores, a good flotation effect can be obtained within the ore pulp pH value range of 7-11, the activating agent adapts to the complicated and volatile ore pulp conditions of industrial flotation, raw materials are cheap and easy to obtain, no harmful gas nor volatile substance is discharged after the activating agent is added into a flotation system, and the activating agent is green, is environmentally friendly, is harmless to the body of an operator and does not corrode flotation equipment.

Owner:LANZHOU UNIVERSITY

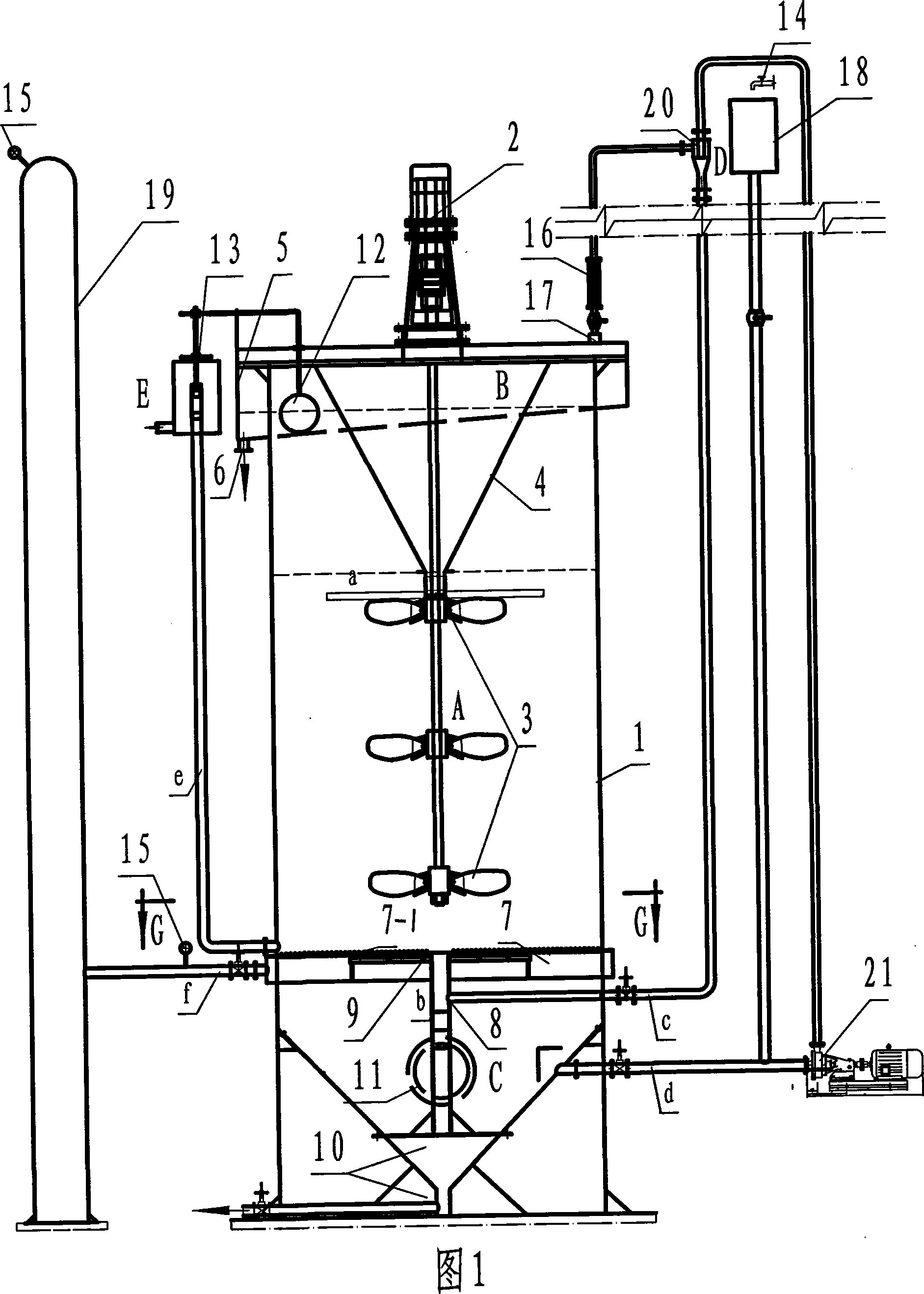

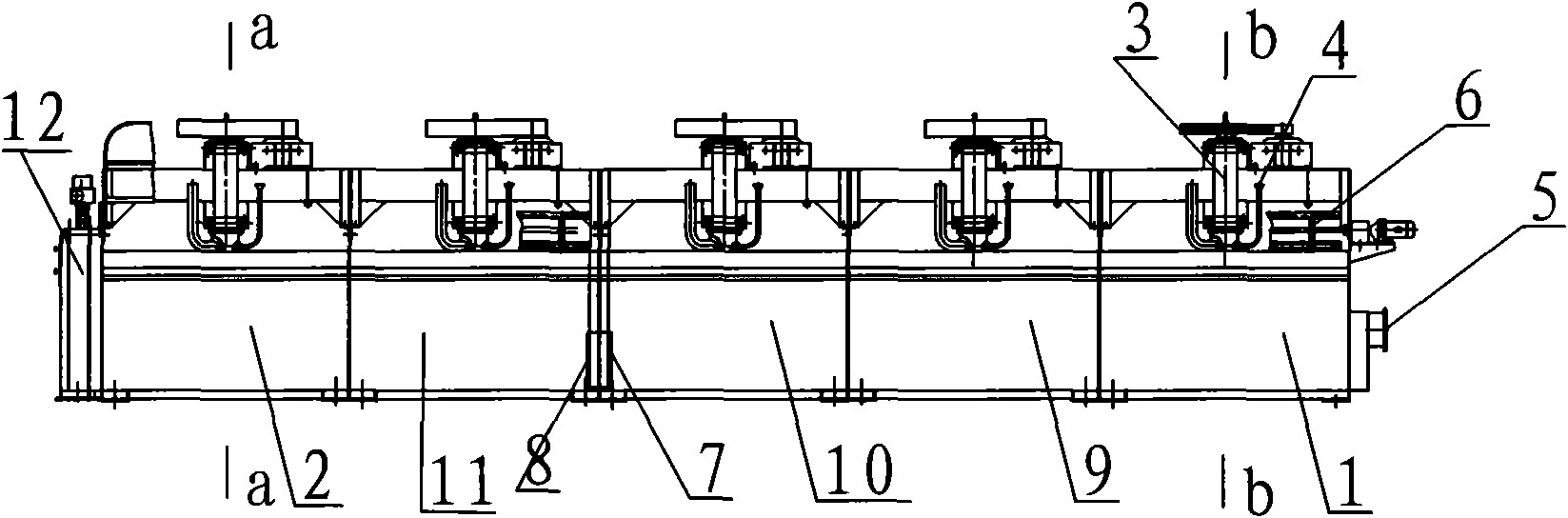

Novel technics of metallurgy mineral dressing flotation air inflation and special equipment

InactiveCN101081379AEnhanced mixing effectImprove flotation recoveryFlotationAutomatic controlMicrobubbles

The present invention discloses inflated metallurgical floatation process and apparatus, and features the completely covered microbubble inflating in the self balanced water separated microbubble generating and inflating mode. The apparatus includes a main machine, a bubble overflowing system, a microbubble generating separator, a microbubble generating system, an automatic mineral slurry regulating mechanism to control the liquid level, etc. Inside the floatation column, leaching tank and oxidation tank, great amount of microbubbles are generated in the bottom and flown in the opposite direction to the falling mineral slurry so as to raise the stirring effect, form stable floating bubble layer, speed oxygen dissolution, increase oxygen utilizing rate, enhance oxidizing leaching and raise floatation recovering rate.

Owner:王树芳

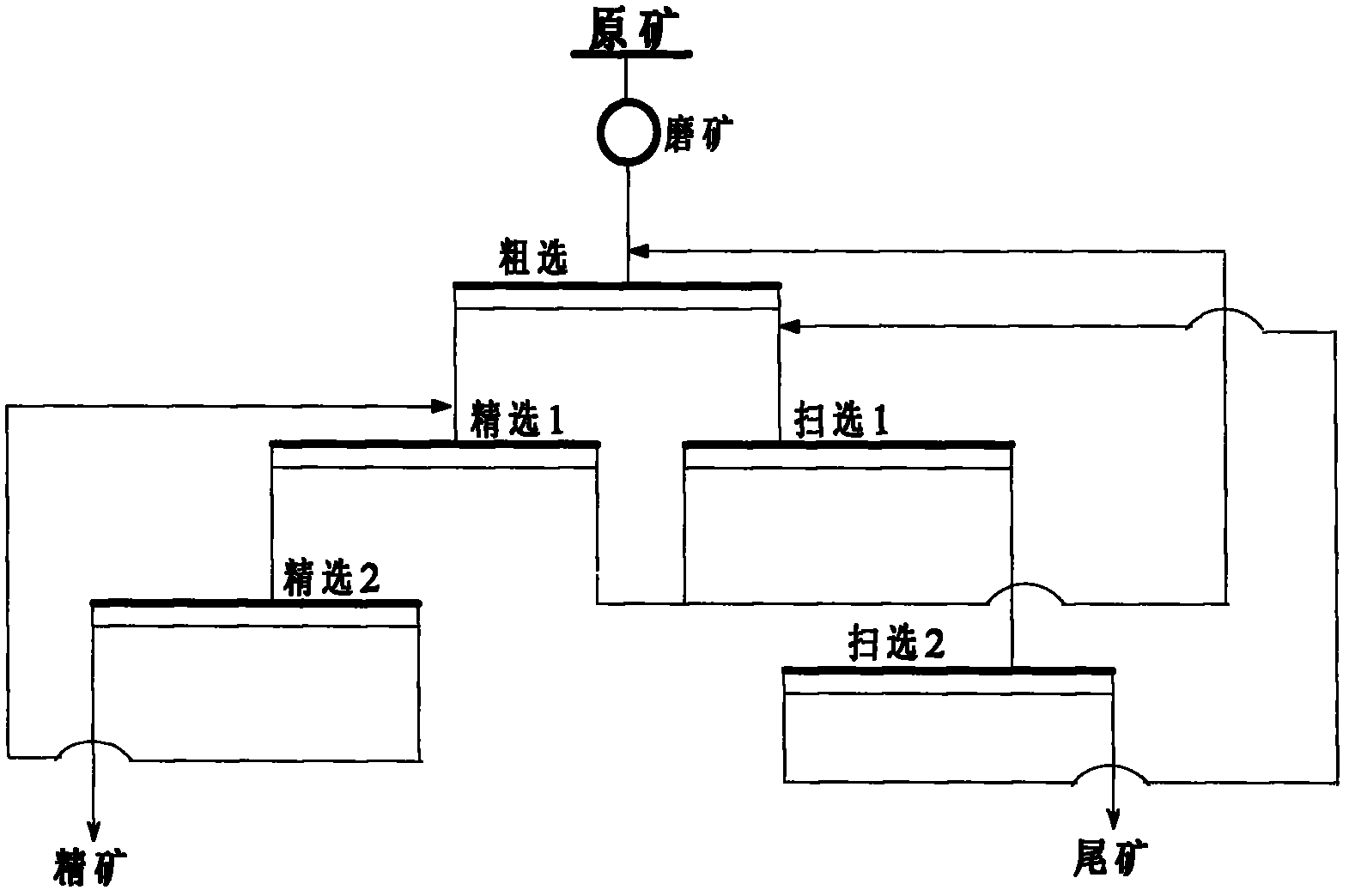

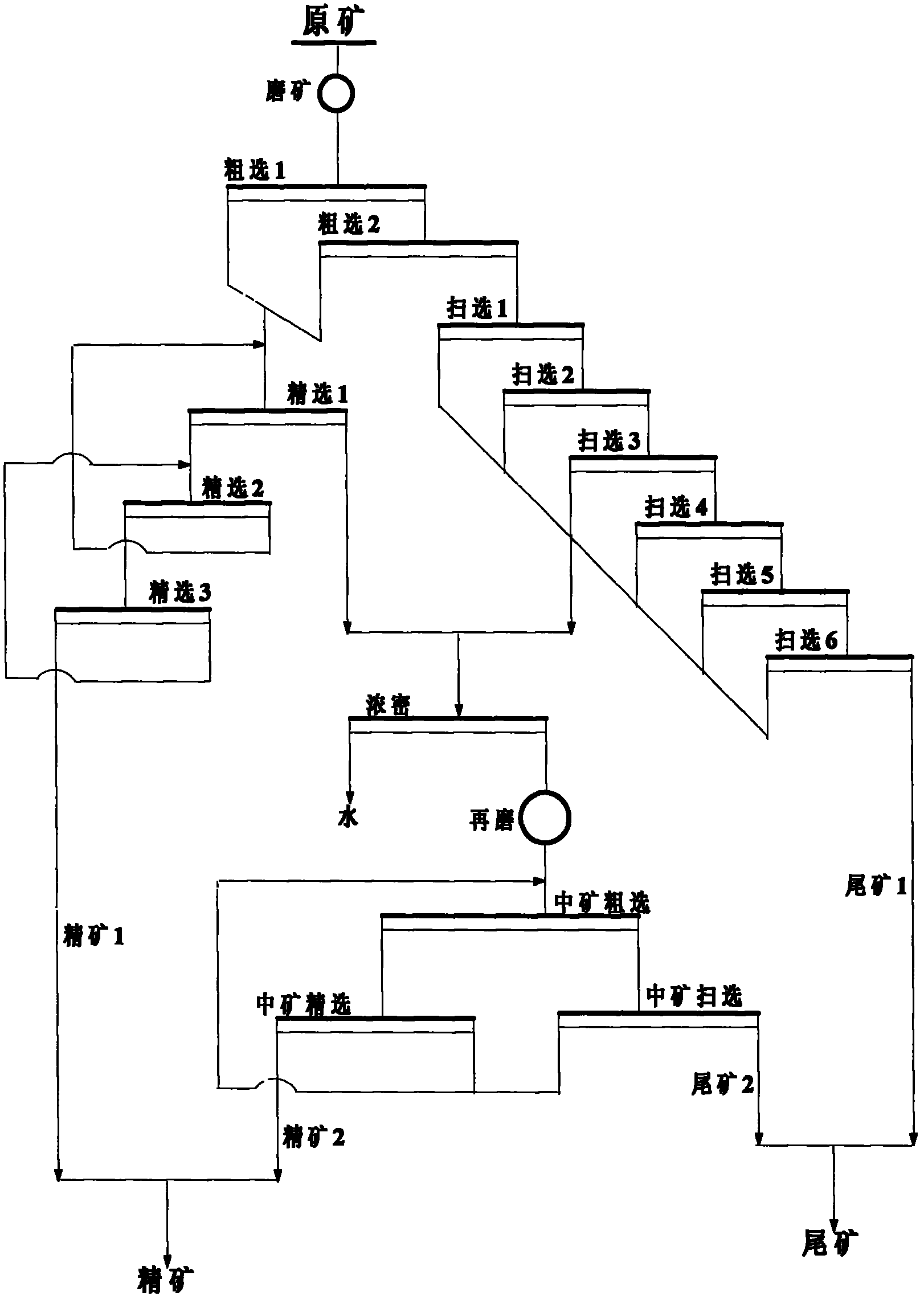

A method of improving flotation recovery rate

The invention relates to a flotation method, in particular to a flotation method for improving the flotation recovery rate of a target mineral in a complex ore. The method comprises the following steps: grinding a target mineral in a raw ore until the target mineral is basically dissociated; producing a concentrate 1 and a tailing 1 through roughing one or twice, cleaning twice or three times, as well as scavenging three to ten times; combining a bottom product of the concentrate 1 and all scavenged foam products to form a middling; concentrating and grinding; returning the grinded ore pulp to a flotation process through an independent sequence to obtain a concentrate 2 and a tailing 2; and combining the concentrate 1 and the concentrate 2 to obtain a final concentrate. According to the flotation method in the invention, the grinding energy consumption can be effectively reduced, partial target mineral with low floating speed is recovered, and the flotation recovery rate of the target mineral is improved by 5 to 20 percent.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

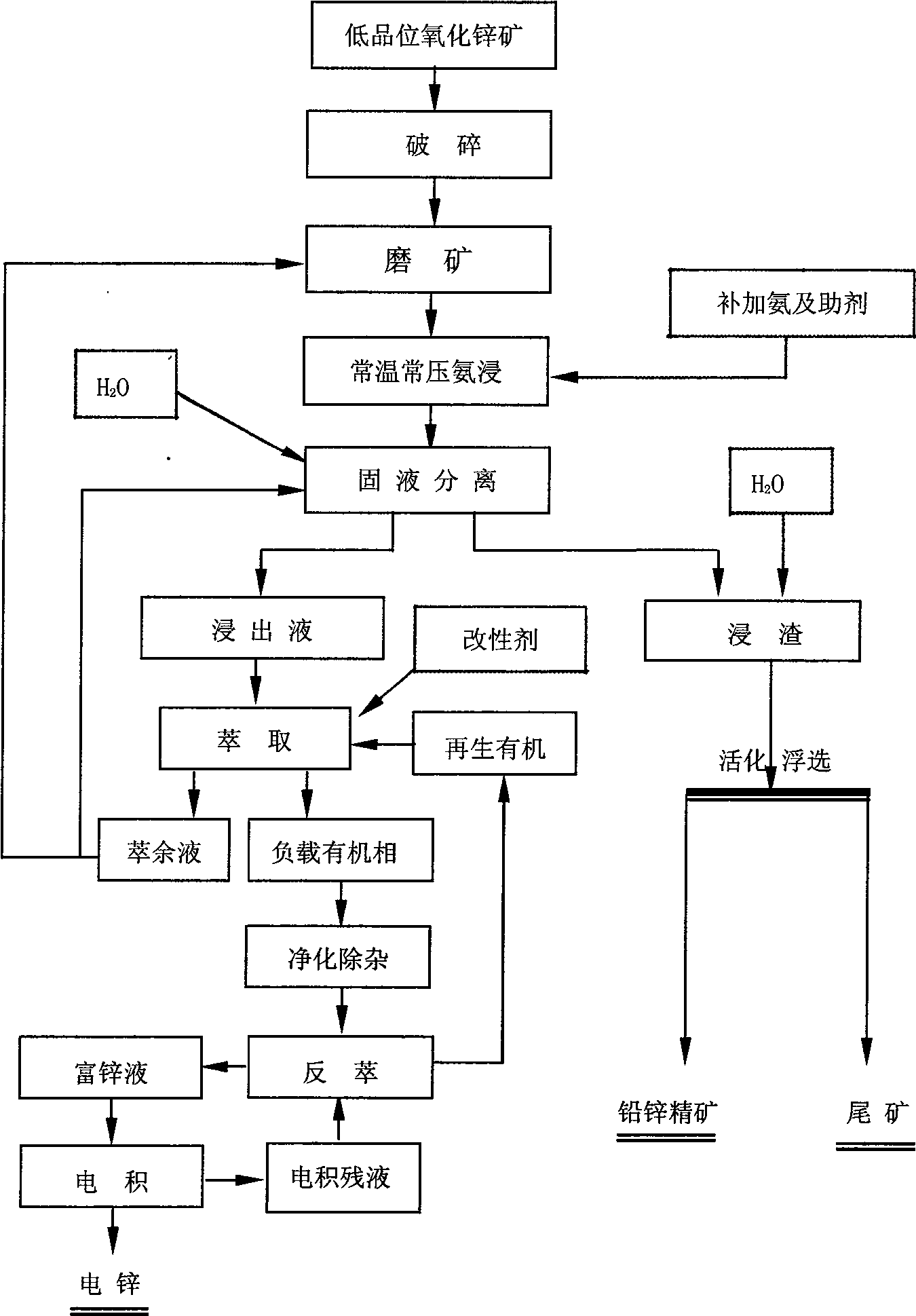

Method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration

InactiveCN101530826AHigh recovery rateReduce the amount of dissolutionWet separationZinc metalResource utilization

The invention provides a method for combined treatment of high calcium and magnesium low-grade oxidized lead zinc ore by means of concentration, comprising the processing techniques of ammonia leaching under normal temperature and pressure-extraction-electrodeposition-leaching floatation, which not only gives full play to the advantage of wet method melting technique in recovering zinc in the oxidized lead zinc ore but also gives full play to the advantage of floatation technique in recovering vulcanized lead zinc; what is more, the advantages in the two aspects are organically combined and have shared complementary advantages, thus realizing integrated optimization of concentration technique, forming a brand-new combined process for concentration of low-grade zinc oxide ore, improving recovery rate of lead and zinc metal and achieving the effect of improving resource utilization rate and saving energy, lowering energy consumption and reducing pollutants discharge on the whole.

Owner:KUNMING UNIV OF SCI & TECH

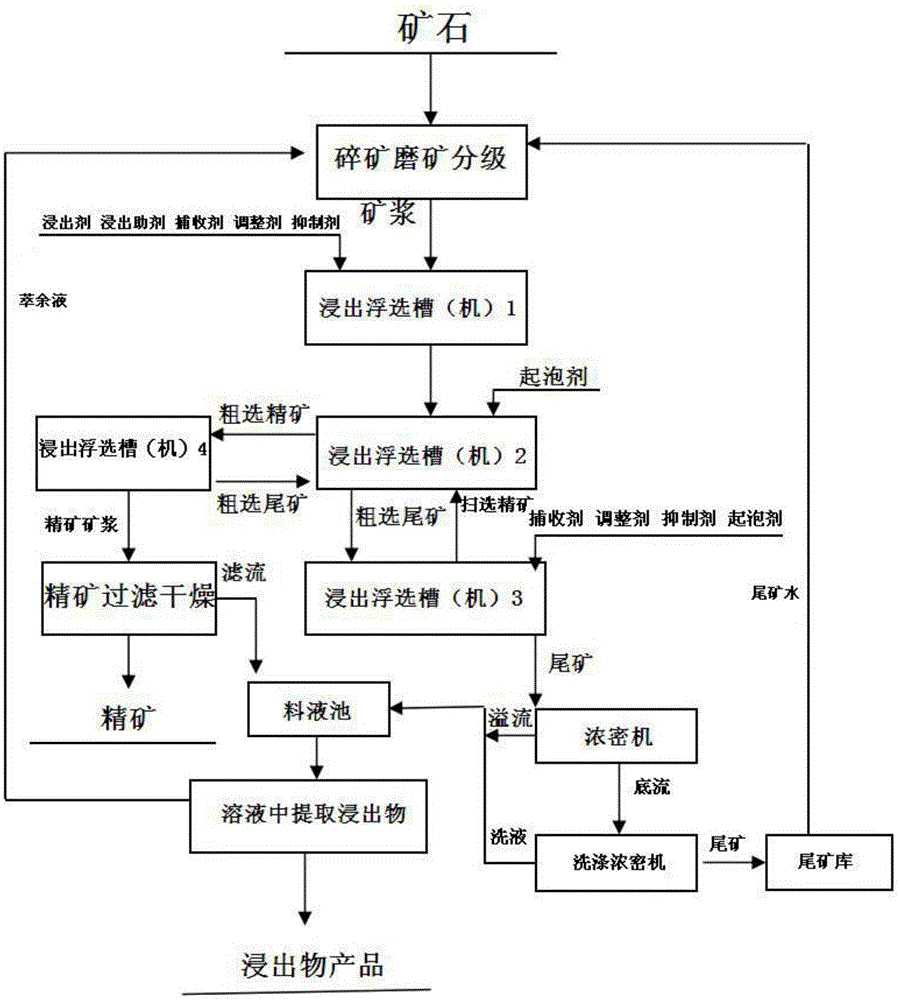

Copper gold silver ore flotation collecting agent and flotation method

InactiveCN107213992AStrong harvesting abilityGood harvesting effectFlotationMineral flotationLow copper

The invention discloses a copper gold silver ore flotation collecting agent and a flotation method, belongs to the technical field of ore flotation, and solves the prominent problems of low copper gold silver ore beneficiation efficiency, high cost and the like. The copper gold silver ore flotation collecting agent ester-205 is prepared from the following raw materials: 30 to 40 parts of N,N-diethyl dithiocarbamate, 20 to 25 parts of diisopropyl dithiophosphate, 10 to 15 parts of black powder acid, 20 to 30 parts of terpenic oil and 2 to 5 parts of ethyl alcohol. The flotation method comprises the following steps: preparation of flotation pulp, flotation preparation and copper gold silver ore flotation. According to the copper gold silver ore flotation collecting agent and the flotation method, multiple circulation times and metal loss of target metal ores in a flotation process are effectively avoided, so that the trunk flotation process is shortened, and the investment and operation cost is reduced; the collecting agent ester-205 is high in collecting capacity; the flotation speed is increased; the copper gold silver recycling rate is increased; the number of the scavenging times is reduced; and the types and the use amounts of flotation agents are reduced.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

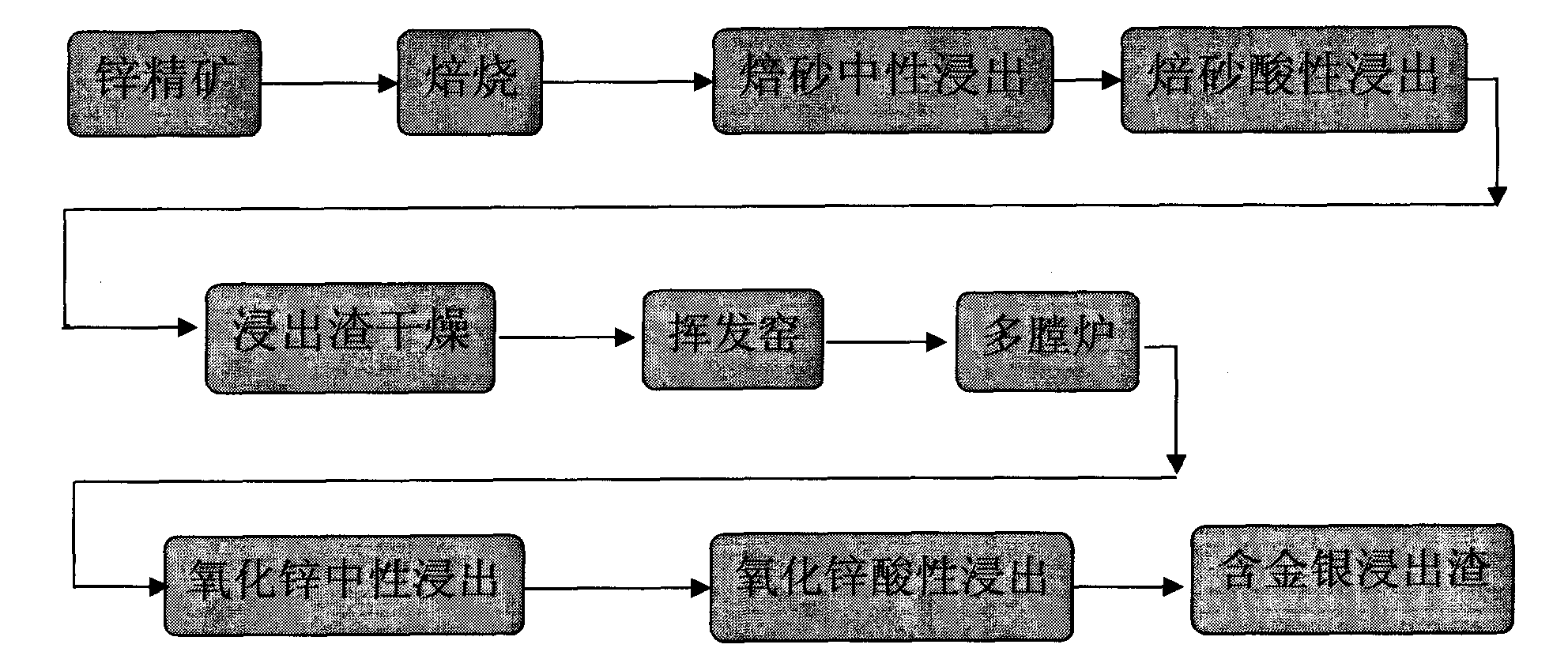

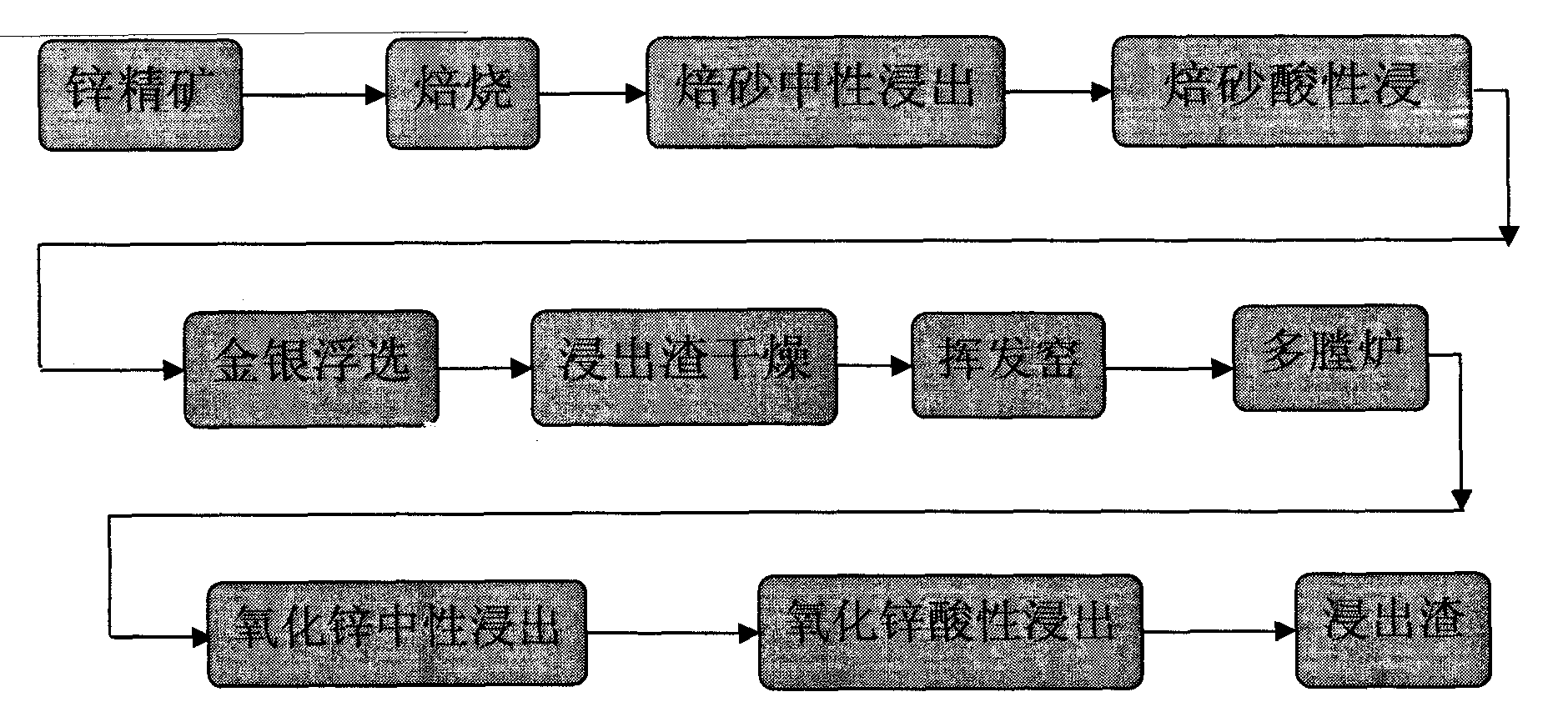

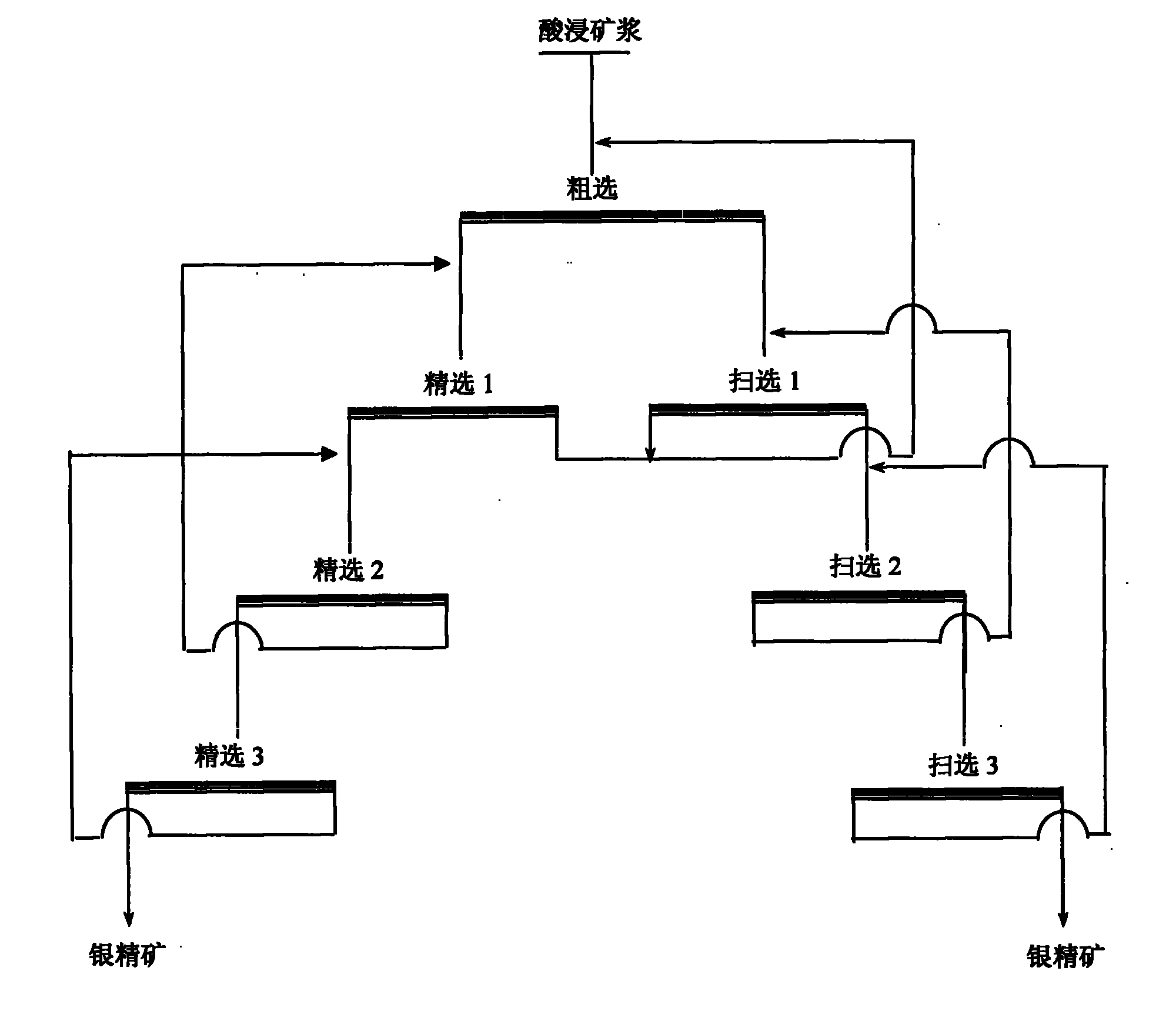

Process for reclaiming gold and silver by floatation from acid leaching ore pulp in wet zinc smelting

InactiveCN101829635AEffective harvesting effectEnhanced harvesting capacityFlotationFoaming agentEconomic benefits

The invention discloses a process for reclaiming gold and silver by floatation from acid leaching ore pulp in wet zinc smelting. The process reclaims the gold and the silver by floatation from the ore pulp after zinc concentrate calcined sand is leached by acid by using a known floatation system under the condition of keeping the primary zinc leaching system. The process comprises the following steps of: extracting the ore pulp after the zinc concentrate calcined sand is leached by acid, adding a collecting agent and a foaming agent for dressing sulfide ores into the ore pulp, fully stirring the ore pulp, then delivering the ore pulp to the flotation system, and adding the collecting agent and the foaming agent into the ore pulp in a flotation tank of each flotation process after the rough flotation process of the flotation system again so as to realize flotation reclamation of the gold and the silver in the ore pulp. The process efficiently reclaims the gold and the silver without affecting the normal operation of a main zinc system, realizes comprehensive utilization of resources, and brings great economic benefit to enterprises.

Owner:JIANGXI UNIV OF SCI & TECH

Method for promoting sulfide floatation of copper oxide ores with amino acid

InactiveCN106824545AImprove flotation efficiencyImprove flotation recoveryFlotationCopper oxideXanthate

The invention discloses a method for promoting sulfide floatation of copper oxide ores with amino acid. The method comprises the following steps: adding an amino acid solution which serves as an activating agent into sulfurized copper oxide ore pulp and floating in a floatation machine with xanthate which serves as a collecting agent. In the method, according to the characteristics of sulfide floatation of the copper oxide ores, the amino acid is added in a floatation process, so that the floatation efficiency of the copper oxide ores is improved. According to the method, firstly, the copper oxide ores are crushed and sieved; then, the amino acid, a sulfide and relevant floatation agents are added into the floatation machine; and floatation is performed by controlling time. Compared with a conventional floatation process with no added amino acid, the method has the advantage that the floatation recovery rate of the copper oxide ores is improved by 10%. The amino acid has an obvious promoting effect in the sulfide floatation process of the copper oxide ores, so that a novel application way is provided for industrial floatation of the copper oxide ores.

Owner:HUNAN RES INST FOR NONFERROUS METALS

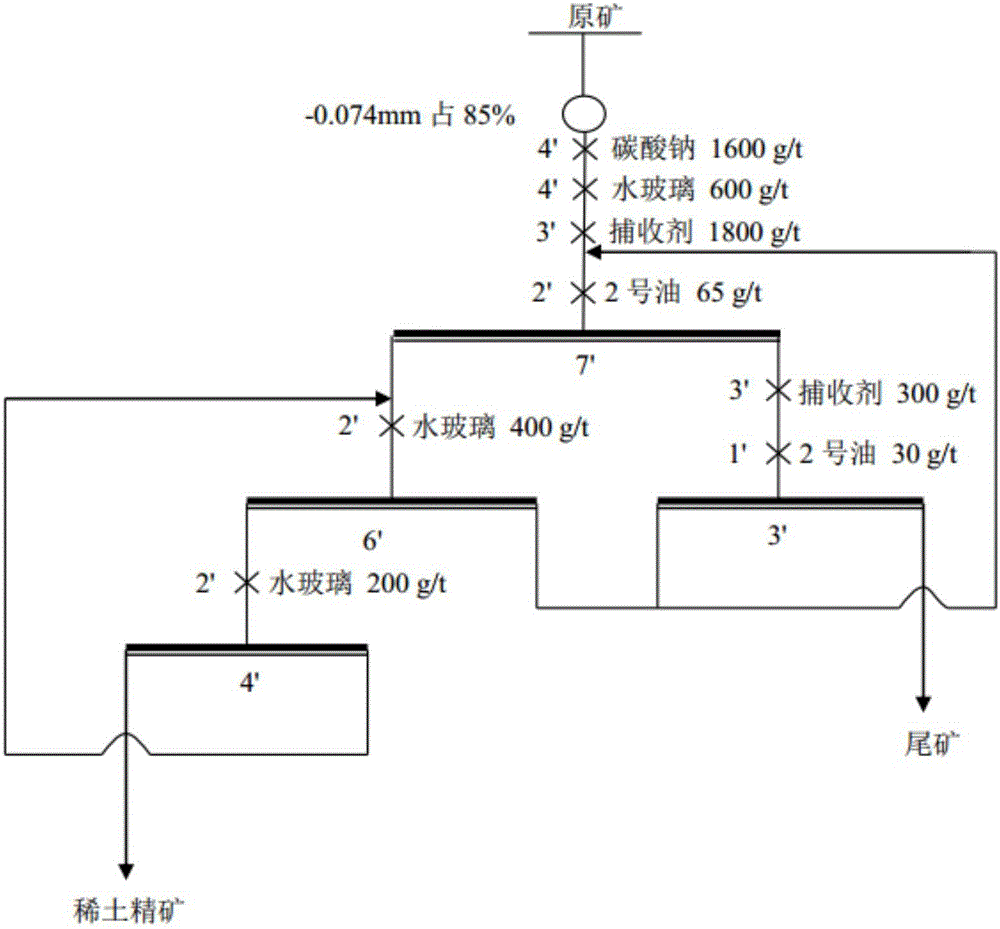

Application method of aromatic dihydroximic acid compound to mineral flotation

The invention provides an application method of an aromatic dihydroximic acid compound to mineral flotation and belongs to the technical field of mineral flotation. The aromatic dihydroximic acid compound as shown in the formula I is used as a collecting agent in flotation of a fluorite ore, a rare earth ore, a tungstite, a wolframite or a tungstite and wolframite mixed ore. A formula I is as shown in the specification, wherein a hydroximic acid group is located on an o-position, a meta-position or a para-position of the hydroximic acid group on a benzene ring. When being used as the collecting agent, the aromatic dihydroximic acid compound is stronger in metal element chelating capacity and better in target mineral selectivity because double hydroximic acid groups, namely two mineral philic groups exist in a molecule of the aromatic dihydroximic acid compound; the two hydroximic acid groups are directly connected with the benzene ring to form a large conjugated structure, so that the electron cloud density is higher, the nucleophilicity of the aromatic dihydroximic acid compound and metal is strong, and the aromatic dihydroximic acid compound more easily undergoes chelation and coordination reactions with the metal as comparison with the hydroximic acid without the conjugated structure; and compared with the common flotation collecting agent in the prior art, the aromatic dihydroximic acid compound has the characteristic of effectively increasing the flotation efficiency, the metal recovery rate and the like.

Owner:JIANGXI UNIV OF SCI & TECH

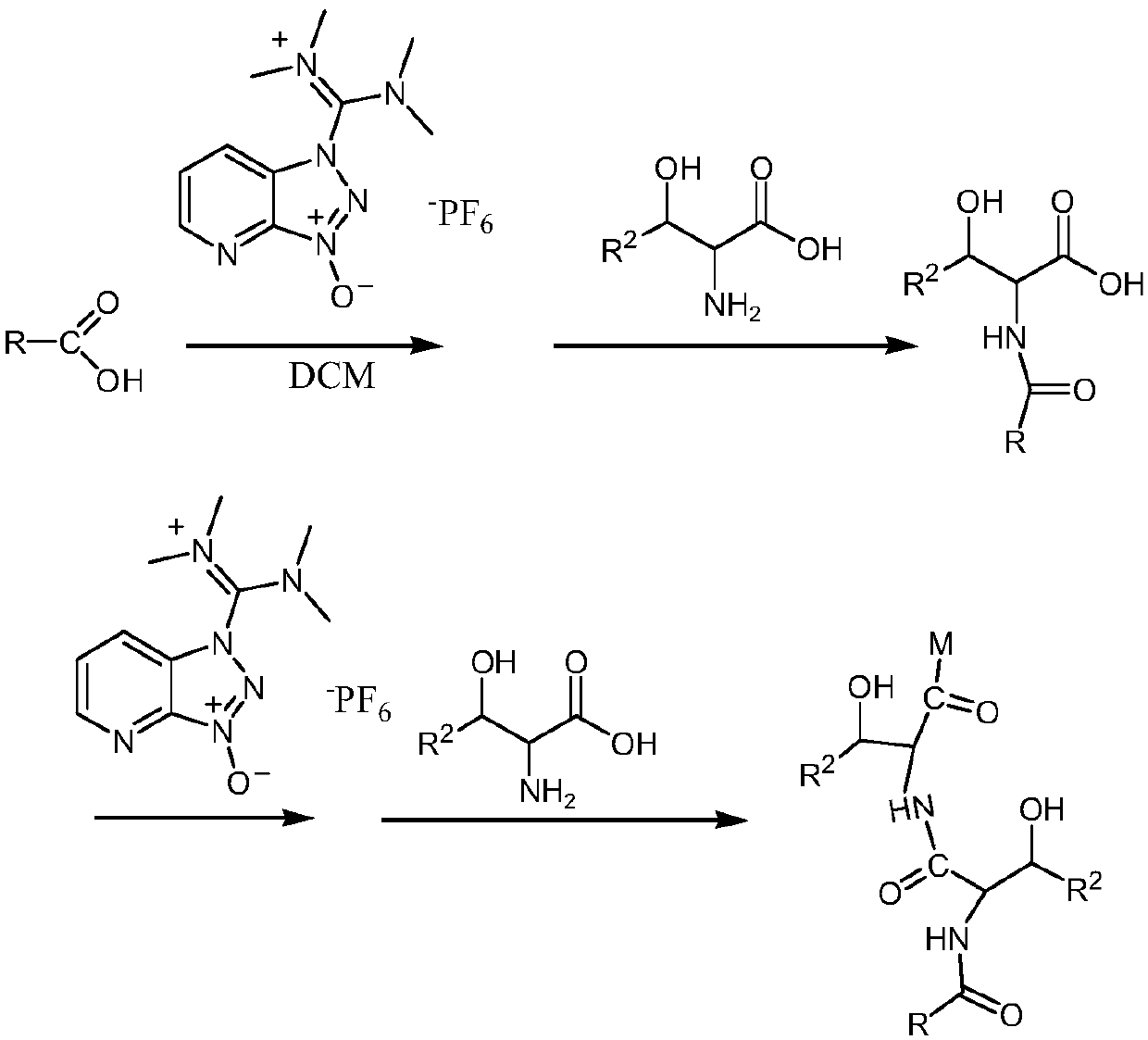

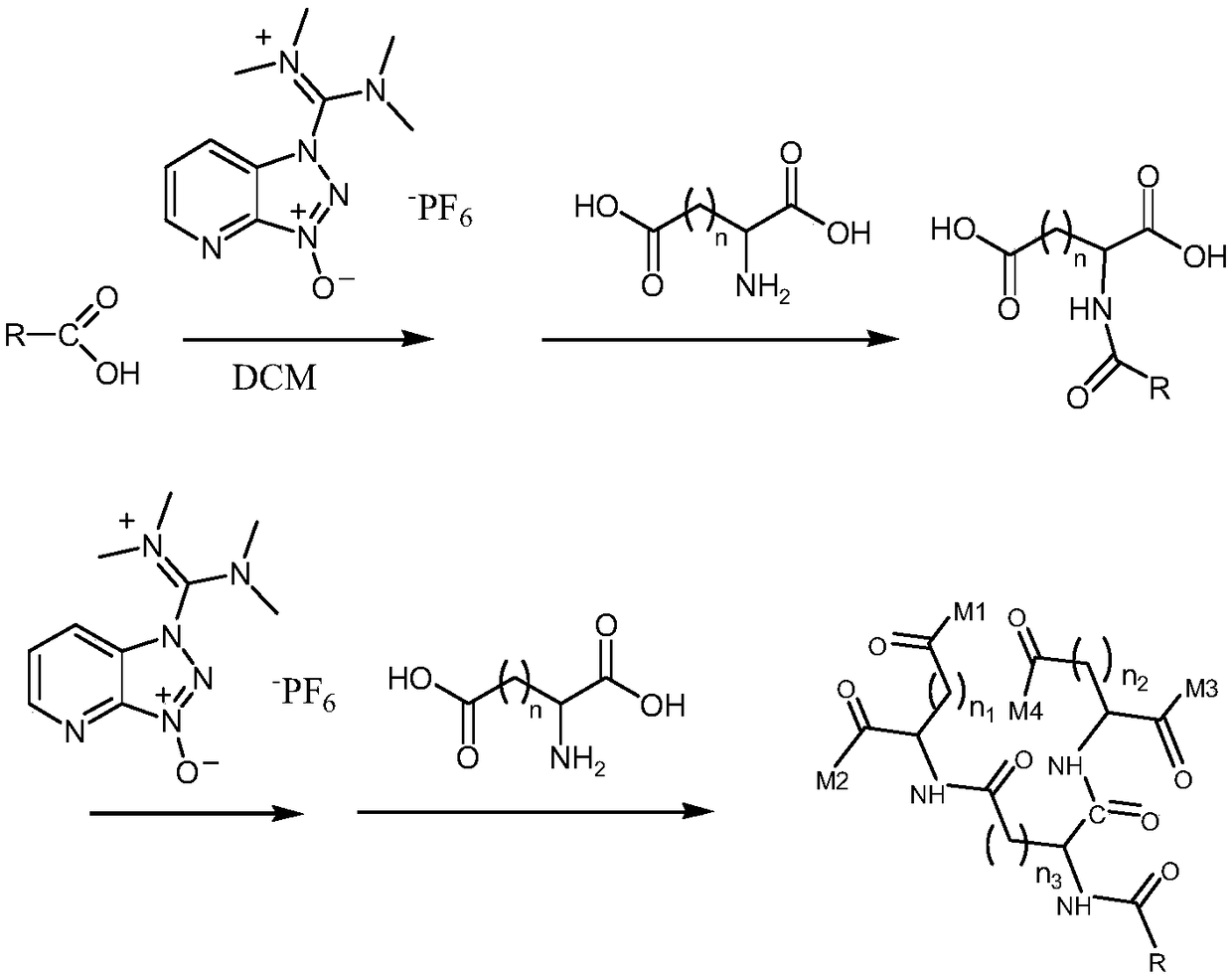

Amidohydroxycarboxylic acid/hydroximic acid compound and application thereof to ore flotation

ActiveCN109530094AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides an amidohydroxycarboxylic acid / hydroximic acid compound and application thereof to ore flotation. The compound has a structural formula shown as a formula (I) in the description, wherein in the formula (I), R1 represents C6-C18 aliphatic groups; R2 represents C1-C4 aliphatic groups; M represents -OH, -ONa, -OK, -NHOH, -NHONa or -NHOK. The amidohydroxycarboxylic acid / hydroximic acid compound provided by the invention is used as a collecting agent, and can reinforce the chelation and recognition effects of the collecting agent on metal oxidized ore; the ordered arrangementof the collecting agent on the surface of the ore is promoted; tungsten ore, rare earth ore, tin ore, lithium mineral, phosphorite, manganese oxide roe, copper oxide ore, fluorite or ilmenite can beeffectively recovered through floatation; the advantages of high collecting capability, high selectivity, low ton ore dosage and the like are realized; the compound is particularly suitable for beingused for treating refractory fine particle ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

Application of acyl amino polycarboxylic acid/hydroximic acid like compound in mineral flotation

ActiveCN109499773AImprove flotation recoveryHigh flotation separationFlotationRare earthMineral flotation

The invention provides application of acyl amino polycarboxylic acid / hydroximic acid like compound in mineral flotation. A structural formula of the acyl amino polycarboxylic acid / hydroximic acid likecompound is shown as a formula (I); (shown in the description) wherein R in the formula (I) represents aliphatic hydrocarbyl of C<6>-C<18>, n=1-3, and M1, M2, M3 and M4 are separately selected from one or several of -OH, -ON, -OK, -NHOH, -NHON or -NHOK. And n<1>=1-3, n<2>=1-3, and n<3>=1-3. The acyl amino polycarboxylic acid / hydroximic acid like compound is used as a collecting agent to enhance the chelation and recognition action on metal oxidized ores, facilitate ordered arrangement of the collecting agent on the mineral surface, effective flotation recovery is carried out on tungstenores, rare earth ores, tin ores, lithium ores, phosphorus ores, manganese oxide ores, cooper oxide ores, fluorites or titanium iron ores, the acyl amino polycarboxylic acid / hydroximic acid collectingagent has the advantages of high collecting capacity, high selectivity, low ton ore use amounts and the like, and is especially suitable for processing difficultly selected fine grain ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE +1

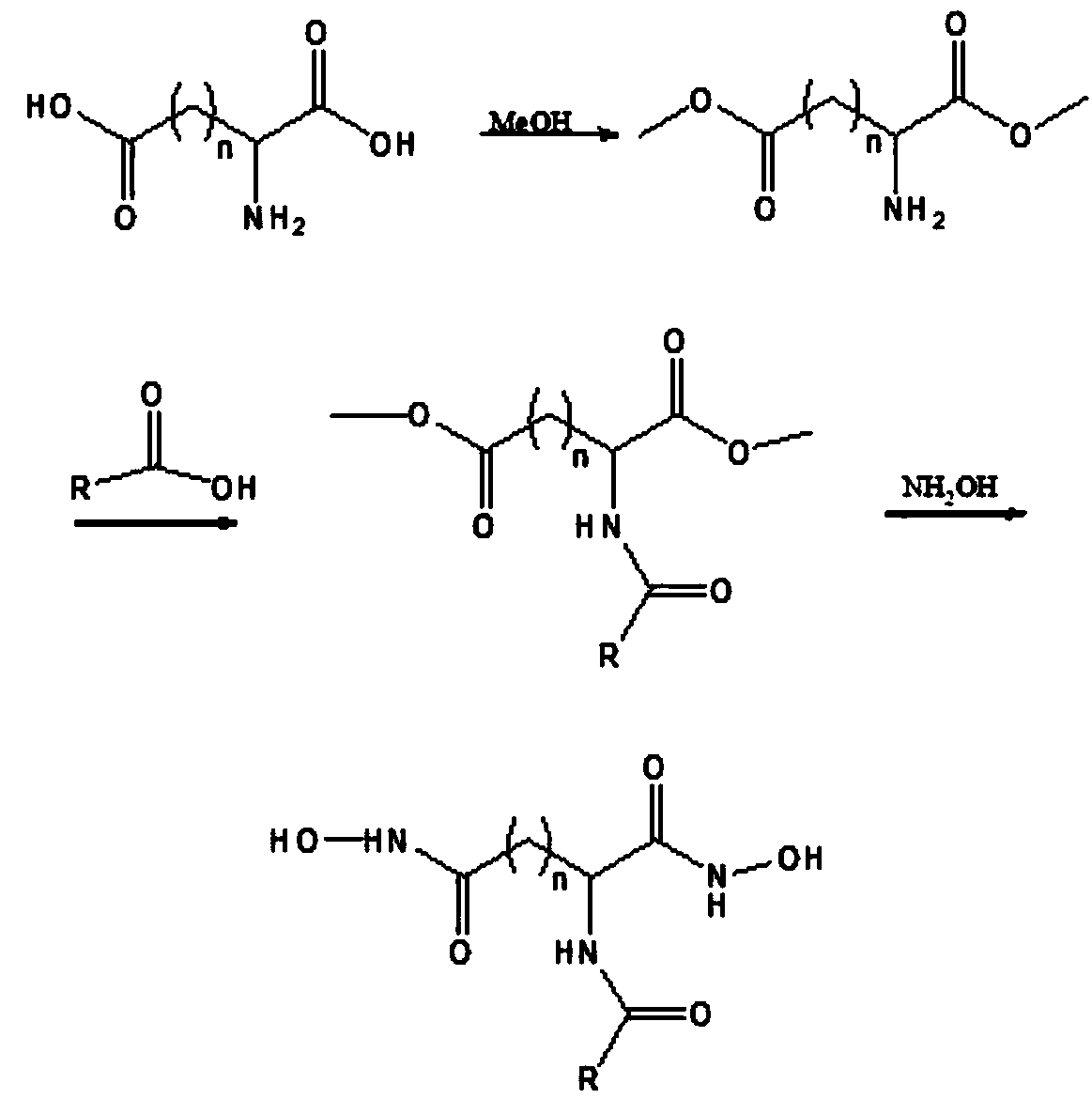

Hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation

ActiveCN108906331AStrong harvesting abilityImprove flotation recoveryFlotationHydroxamic acidRare earth

The invention provides a hydrocarbon amide-bi-hydroxamic acid compound and application thereof in mineral flotation. The structural formula of the hydrocarbon amide-bi-hydroxamic acid compound is as shown in the description, wherein R represents an aliphatic hydrocarbon group of C2 to C18, and n ranges from 1 to 10. The hydrocarbon amide-bi-hydroxamic acid compound serving as a collector can enhance the chelation and recognition to metal oxidized ores, promote the ordered arrangement of the collector on a mineral surface and effectively recover tungsten ores, rare earth ores, tin ores or ilmenite by flotation, has the advantages of strong collecting capacity, high selectivity, low consumption of tons of ores, etc., and is especially suitable for processing hard dressing fine grained ores.

Owner:HUNAN UNIV OF CHINESE MEDICINE

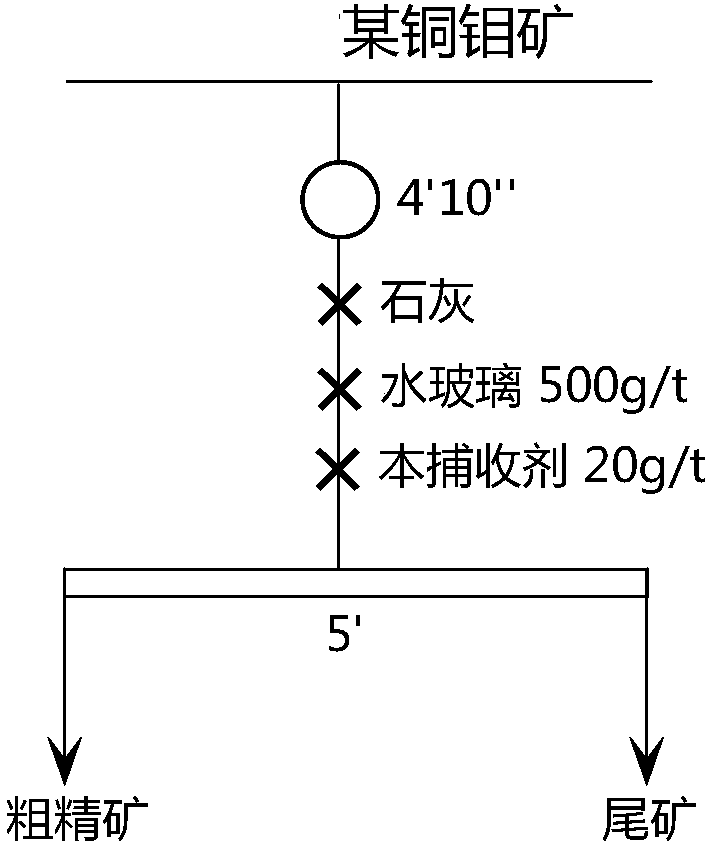

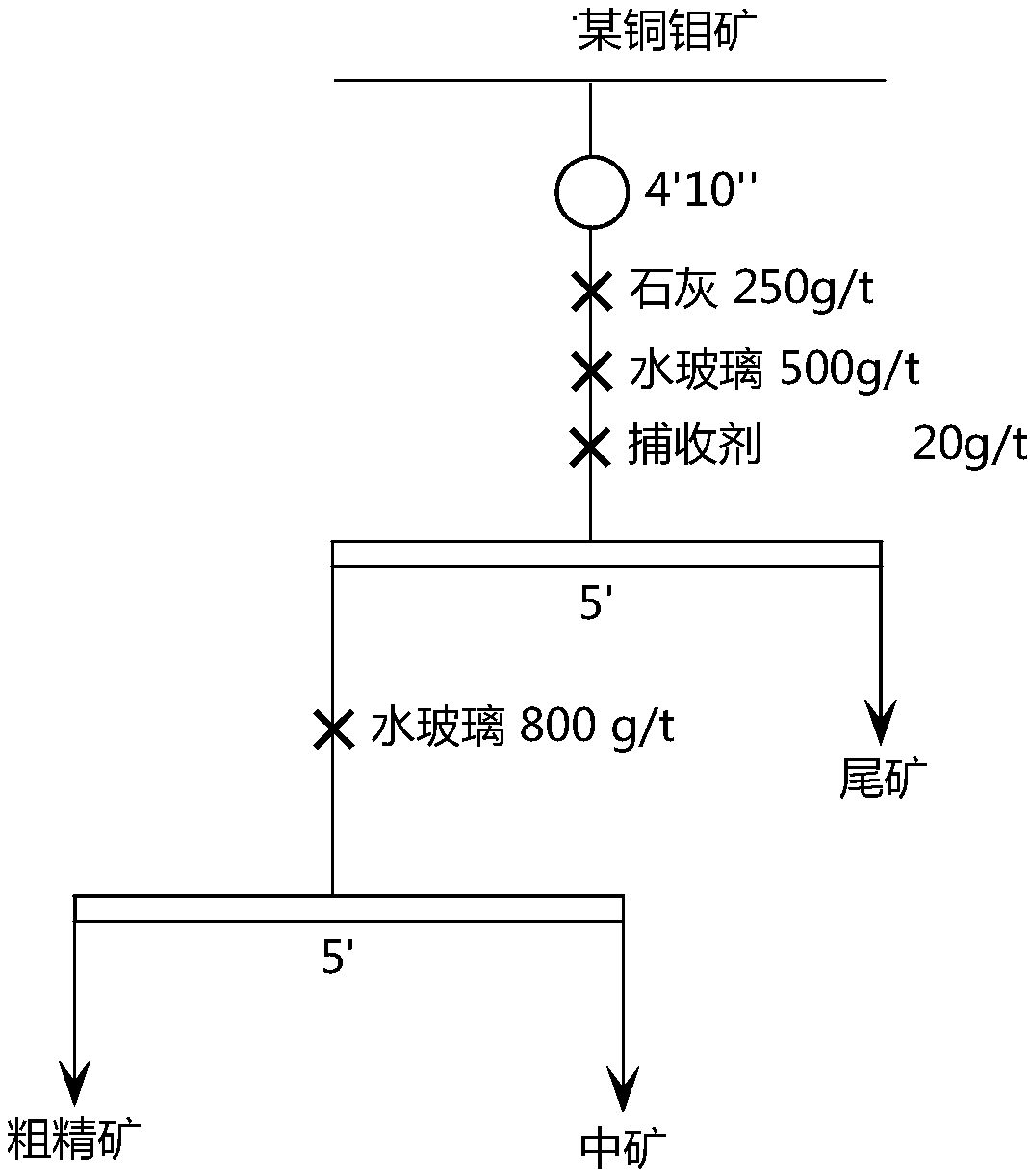

Low alkalinity and high selectivity copper-molybdenum flotation collector and preparation method thereof

The invention discloses a low alkalinity and high selectivity copper-molybdenum flotation collector and a preparation method thereof. Effective components of the copper-molybdenum flotation collectorcomprise, by weight, 22-28 parts of heavy oil, 8-12 parts of thiocarbamate, 22-28 parts of hydrocarbon oil mixtures and 35-45 parts of diesel. The preparation method of the collector comprises the following steps that 22-28 parts of the hydrocarbon oil mixtures are added into 22-28 parts of the heavy oil and full stir is carried out; 8-12 parts of the thiocarbamate is added and fully stirred, 35-45 parts of the diesel is added and fully stirred, and the low alkalinity and high selectivity copper-molybdenum flotation collector is obtained. According to the low alkalinity and high selectivity copper-molybdenum flotation collector and the preparation method thereof, efficient collection of copper mineral and molybdenum mineral can be achieved in low alkalinity environment with a PH value of 7-9; the concentrate grade is high, separation is convenient, recovery is high, and selectivity is high; equipment is not liable to corrode, and promotion value and application prospect are high.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Ore grinding flotation silicon-removing method of bauxite

The invention relates to a process for removing impurities from bauxite, in particular to an ore grinding flotation silicon-removing method of bauxite, which comprises the steps of: carrying out primary floatation on the bauxite after rough grinding, wherein the floated foam is used as a concentrate product; carrying out secondary ore grinding on floating underflow; and carrying out secondary floatation after secondary ore grinding, wherein the floated foam is used as a concentrate product and the underflow is used as tailings to be discharged. The invention has the characteristics of proper granularity of flotation pulp, reasonable fraction distribution, shortened process flow, reduced mineral dressing cost and improved floatation recycling rate due to the adoption of reasonable configuration of ore grinding and floating and equipment selection.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

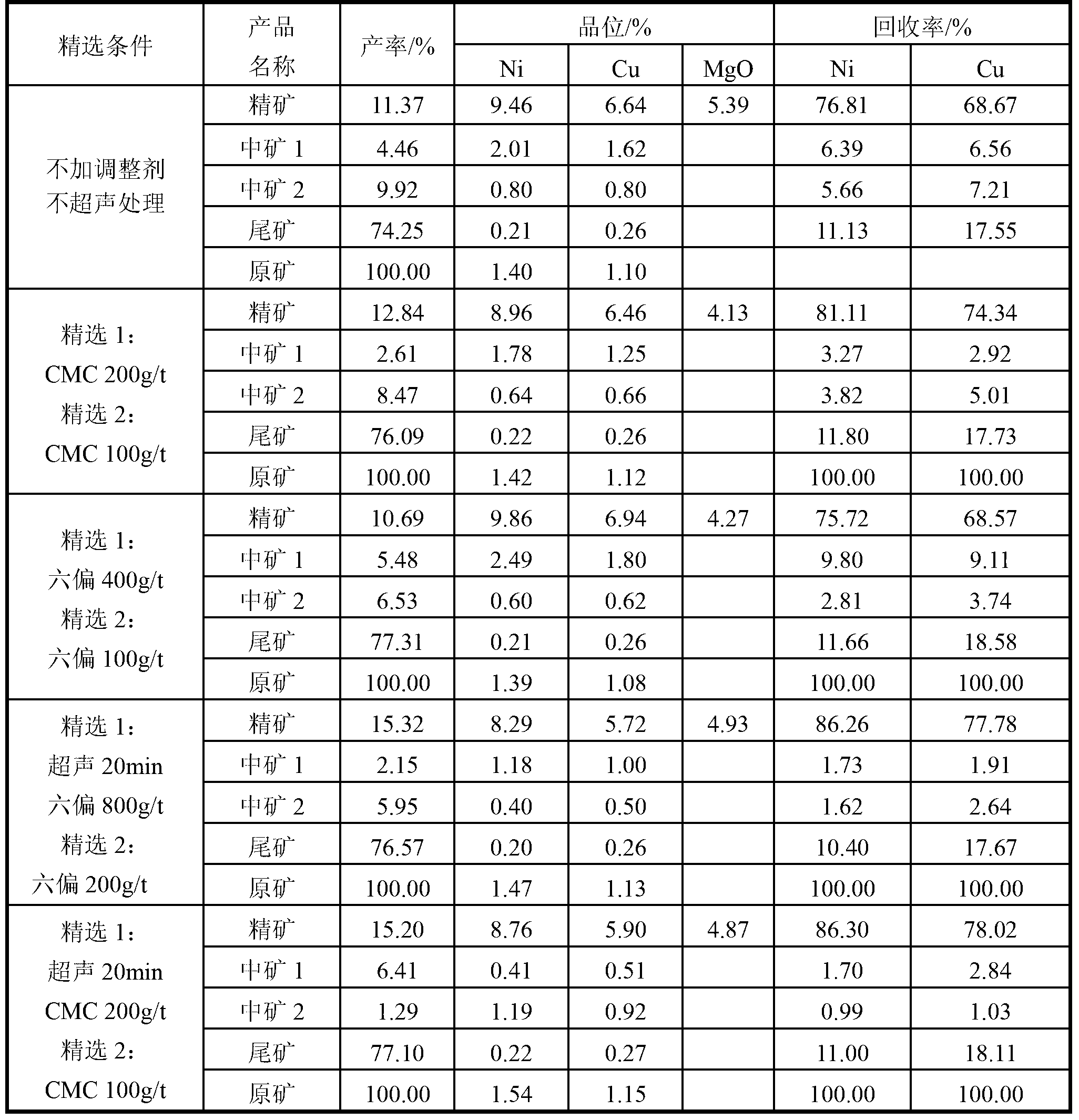

Method for improving flotation recovery rate of copper and nickel and reducing content of magnesium oxide in concentrates of copper-nickel sulfide ores

InactiveCN103301948AImprove adsorption capacityElimination of heterogeneous condensationFlotationUltrasound - actionNickel sulfide

The invention relates to a method for improving the flotation recovery rate of copper and nickel and reducing content of magnesium oxide in concentrates of copper-nickel sulfide ores. According to the method, before the copper-nickel sulfide ores are subjected to flotation, ultrasonic waves are used for carrying out dispersion treatment on ore pulp. The ore pulp can be crude ore pulp added with a collecting agent, or ore pulp which comprises the collecting agent and enters a random flotation operation; the ultrasonication can be carried out before flotation and also can be simultaneously carried out with flotation. According to the invention, supersonic jet generated in the ultrasonic treatment and cavatition are utilized to desorb serpentine pulp covering the surface of sulphide mineral, the flotation recovery rate of the sulphide mineral is improved, the quantity of the serpentine pulp entering the concentrates is reduced and the content of magnesium oxide in the concentrates of the copper-nickel sulfide ores is reduced, so that a sorting index is improved.

Owner:CENT SOUTH UNIV

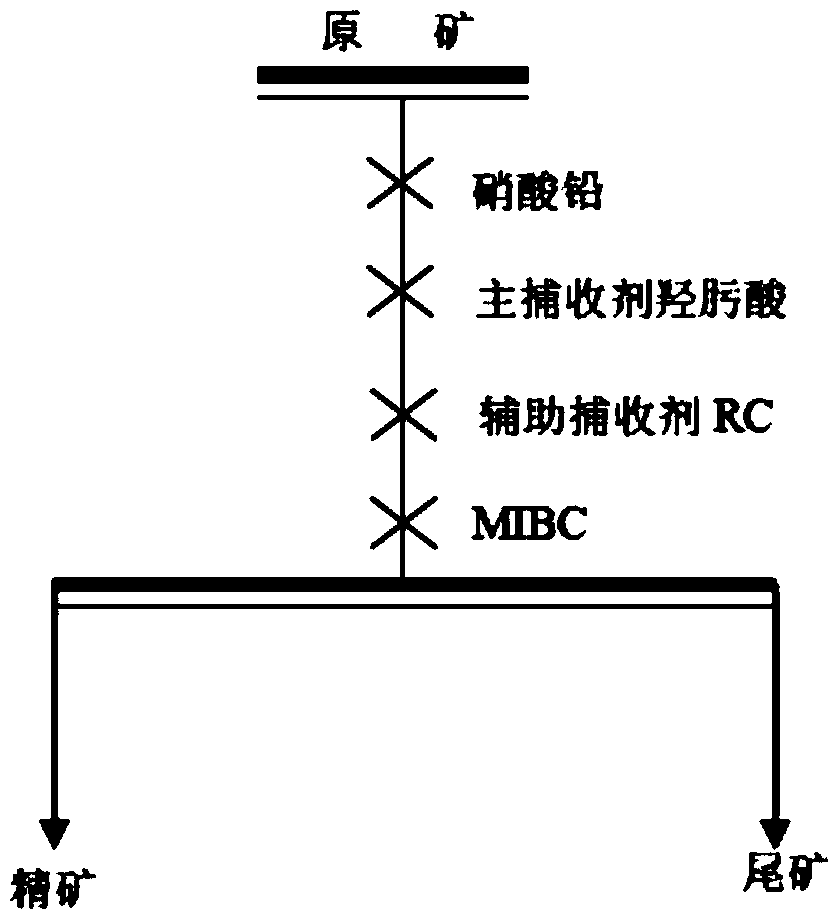

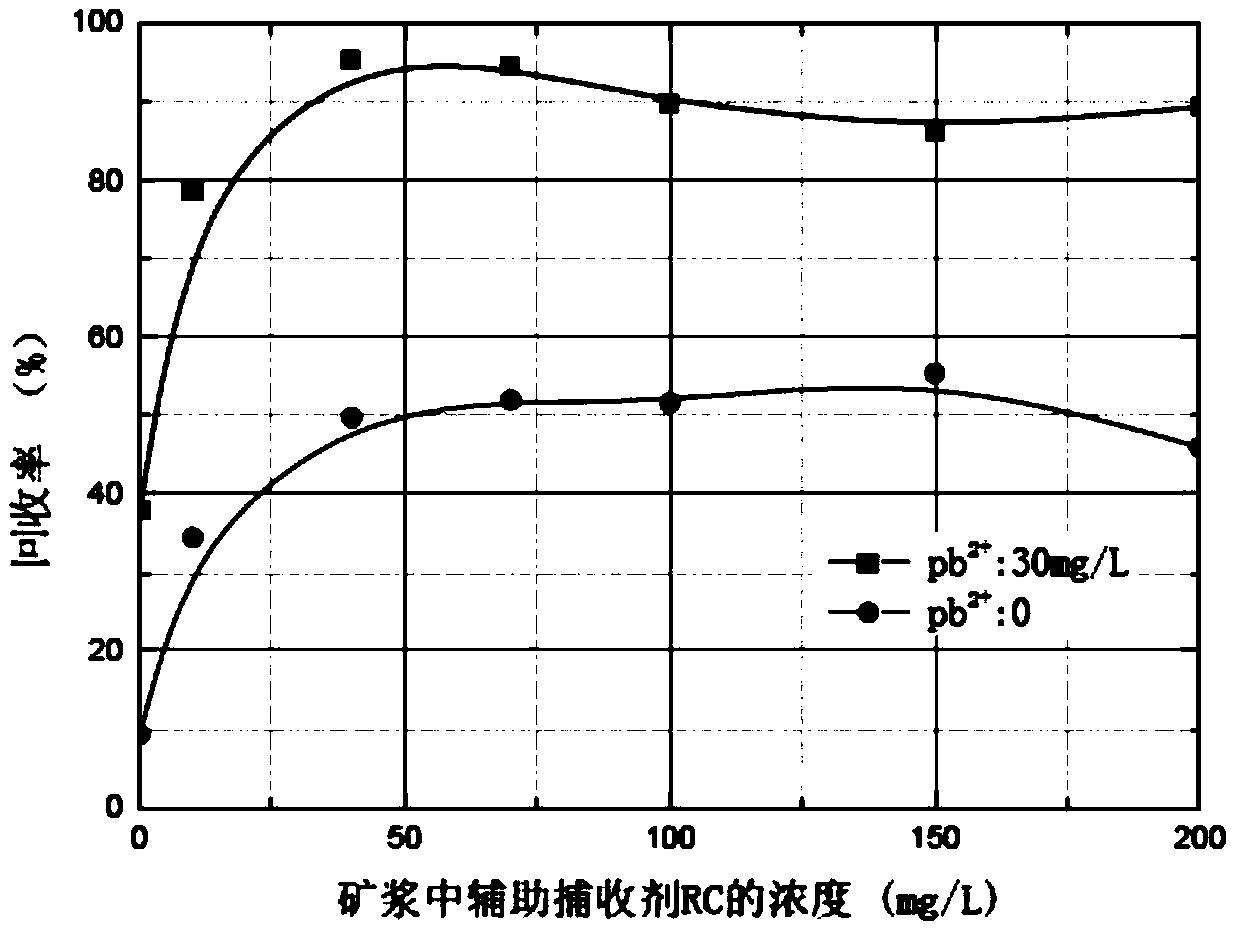

Rutile flotation collector composition and application thereof

The invention belongs to the technical field of rutile flotation, and particularly relates to a rutile flotation collector composition and application thereof. The rutile flotation collector composition is composed of a main hydroximic acid collector and an assistant RC collector. According to the application, a lead nitrate activator, the main hydroximic acid collector, the assistant RC collector and an MIBC frother are sequentially added in rutile flotation pulp, wherein before the next agent is added, stirring is carried out for 3 min every time after each agent is added; after all the agents are added, ventilated flotation is carried out; after flotation is finished, an obtained froth product and tailings in a flotation tank are respectively filtered, dried and weighed finally. According to the rutile flotation collector composition and the application thereof, on the basis of the hydroximic acid collector with good selectivity, the assistant RC collector capable of achieving a synergistic effect with hydroximic acid is added, so that the collecting capability of the agents is substantially improved, and the flotation recovery rate of rutile is effectively improved; meanwhile, the use amount of hydroximic acid is reduced, so that the agent cost for rutile flotation is greatly reduced.

Owner:WUHAN UNIV OF TECH

Turbulent flow regulating and controlling external particle fluidized bed mineralizing and floating device uniform in turbulence degree

ActiveCN106944264ASize balanceHigh kinetic energy utilization efficiencyFlotationFluidized bedEngineering

The invention discloses a turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree and belongs to a mineral separation device. The device comprises a column floating area, a concentrate overflow groove in the upper portion of the column floating area and a middling ore circulating port outside the column floating area; the lower portion of the column floating area is provided with a gas and liquid mixing area; a fluidized bed mineralizing and floating area is arranged between the column floating area and the gas and liquid mixing area; the fluidized bed mineralizing and floating area is provided with a mineralizing area 1, a mineralizing area 2,... and a mineralizing area n; and the interiors of the mineralizing area 1, the mineralizing area 2,...and the mineralizing area n are filled with turbulent flow regulating and controlling particles. According to the turbulent flow regulating and controlling external particle fluidized bed uniform in turbulence degree, mineralizing and floating are totally separated, and are different from current integration of mineralizing and floating; the mineralizing time can be achieved by adjusting the mineralizing area segment number of the fluidized bed mineralizing and floating area, and therefore the kinetic energy utilizing efficiency is very high; the energy dissipating rate is high, the bubble size balance and stable retention of high-pressure gas are guaranteed, and the floating recovery rate is increased; and upper, middle and lower mineralizing fluidized bed layers are provided with different turbulence degrees, and the mineralizing efficiency is high.

Owner:CHINA UNIV OF MINING & TECH

Co-production method of thionocarbamate and benzyl thioether acetic acid and application of the method

ActiveCN110483352AEasy to achieve joint productionHigh yieldFlotationSulfide preparationSodium acetateSodium chloroacetate

The invention discloses a co-production method of thionocarbamate and benzyl thioether acetic acid and application of the method. The method comprises the following steps: with xanthate and benzyl chloride as initial raw materials, and performing esterification reaction to obtain benzyl xanthate; carrying out ammonolysis on benzyl xanthate by using primary amine to obtain thionocarbamate and benzyl mercaptan; further adding sodium chloroacetate into the mixture for reaction, thus generating benzyl thioether sodium acetate; finally, performing liquid separation to obtain the thionocarbamate collecting agent and a water phase containing benzyl thioether sodium acetate. The benzyl thioether sodium acetate-containing water phase can further react with benzyl chloride to obtain benzyl thioetherbenzyl acetate or be acidified and esterified with fatty alcohol to generate benzyl thioether alkyl acetate, and the two ester compounds can be subjected to hydroximation to synthesize benzyl thioether ethyl hydroximic acid. The method solves the problems of difficult recovery, difficult utilization and unpleasant smell of the byproduct sulfhydryl compound in the traditional thionocarbamate process, realizes co-production of benzyl thioether acetic acid and derivatives thereof, and improves the reaction efficiency.

Owner:CENT SOUTH UNIV

Flotation collector solvent for recovering tantalum-niobium from granitic pegmatite tantalum-niobium ore and application thereof

The invention discloses a flotation collector solvent for recovering tantalum-niobium from granite pegmatite tantalum-niobium ore and application thereof. The flotation collector solvent comprises a main collector solvent hydroxamic acid compound and an auxiliary collector solvent TB, The mass ratio of the main collector solvent hydroxamic acid compound (in terms of the mass of the hydroxamic acid) to the auxiliary collector solvent TB (in terms of the mass of the fatty acid) is 1: (0.2-2). In the flotation collector solvent, the hydroxamic acid compound formed by the hydroxamic acid and the inorganic metal ion compound is used for replacing the traditional form of activating the inorganic metal ion and then adding the hydroxamic acid collector solvent, and the selectivity of the hydroxamic acid compound is better than that of the traditional form of activating the inorganic metal ion; the auxiliary collecting solvent TB which can generate synergistic action with the hydroxamic acid compound is added auxiliary, so that the flotation collector solvent can greatly improve the collecting capacity of the medicament and improve the flotation recovery rate of tantalum-niobium; Meanwhile,the auxiliary collector solvent TB with lower cost is added, so that the dosage of the hydroxamic acid can be greatly reduced, and the cost of the flotation reagent for recovering the tantalum -niobium from the granitic pegmatite tantalum -niobium ore is greatly reduced.

Owner:淄博特斯博新材料科技有限公司

Three-product coal slurry flotation machine and system

The invention discloses a three-product coal slurry flotation machine and a three-product coal slurry flotation system. The three-product coal slurry flotation machine is characterized in that raw coal slurry is divided into three products, i.e. flotation clean coal, flotation middling coal and waste coal slurry through arranging a primary concentration device and a secondary middle flotation device. During work, the ash content of the flotation clean coal can be adjusted at any time according to needs, and the ash content of the waste coal slurry is adjusted at any time according to needs through adjusting the ash content of the flotation middling coal in the secondary middle flotation device. After the three-product coal slurry flotation machine and the three-product coal slurry flotation system are applied to the flotation of the coal slurry, the ash content of flotation waste coal is improved to be higher while the ash content of the flotation clean coal is reduced to be lower. The three-product coal slurry flotation machine and the three-product coal slurry flotation system have the advantages of high recovery rate, less total investment, simpler system and lower operating cost, and the improvement of the resource utilization is greatly facilitated.

Owner:JINYITONG SCI ANDTECH BEIJING CO LTD

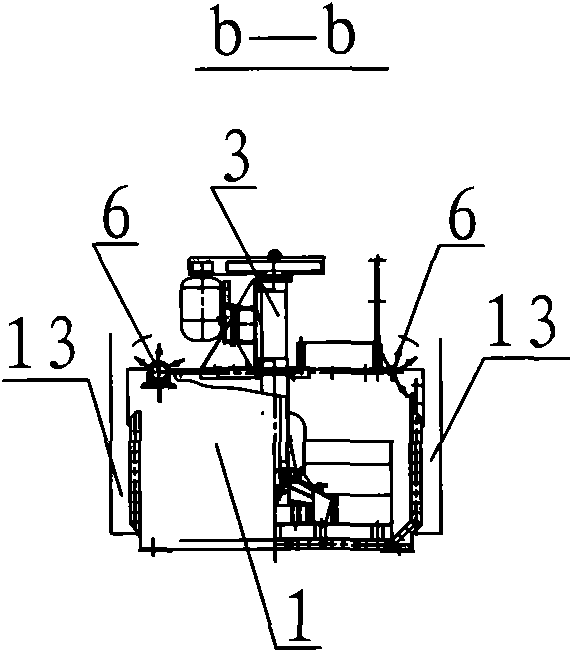

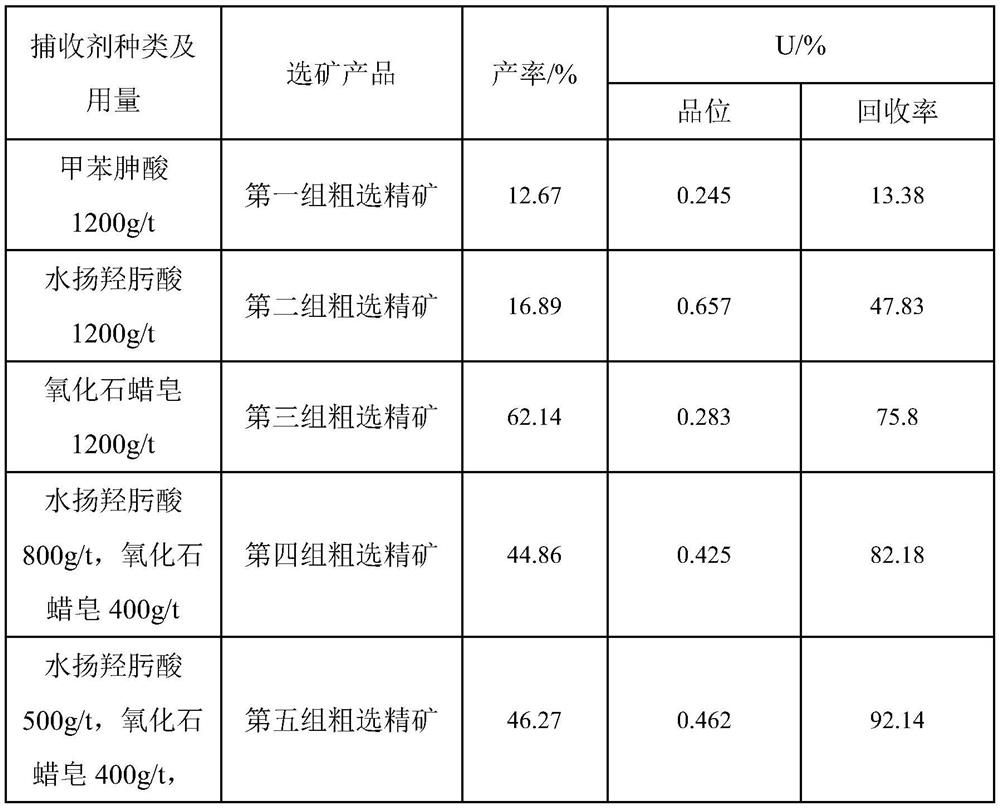

Method for flotation of uranium minerals from volcanic rock type uranium ores

ActiveCN112156894ARealize separation and enrichmentImprove flotation recoveryFlotationHydroxamic acidSodium phosphates

The invention discloses a method for flotation of uranium minerals from volcanic rock type uranium ores. The method comprises the following steps: crushing volcanic rock type uranium ores, adding an acid, performing ore grinding, and carrying out size mixing treatment to obtain ore pulp; and adjusting the ore pulp through sodium carbonate, and by taking sodium silicate and sodium hexametaphosphateas inhibitors, hydroxamic acid compounds and fatty acid compounds as collecting agents and P507 as an auxiliary collecting agent, performing froth flotation under the action of a foaming agent to obtain uranium concentrate. According to the method, sodium silicate and sodium hexametaphosphate are used as the inhibitors, and hydroxamic acid and fatty acid collecting agents and the P507 auxiliary collecting agent are used in cooperation, so that the yield of the flotation concentrate is greatly reduced, the content of carbonate minerals in the flotation concentrate is reduced, and reagent consumption and hydrometallurgy ore treatment capacity in the subsequent leaching process can be reduced; and meanwhile, separation and enrichment of uranium minerals are achieved, the flotation concentrate yield is 19.06%, the uranium grade is 1.073%, and the recovery rate is 86.63%.

Owner:BEIJING RESEARCH INSTITUTE OF CHEMICAL ENGINEERING AND METALLURGY

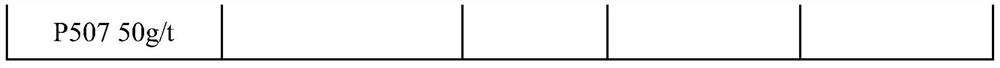

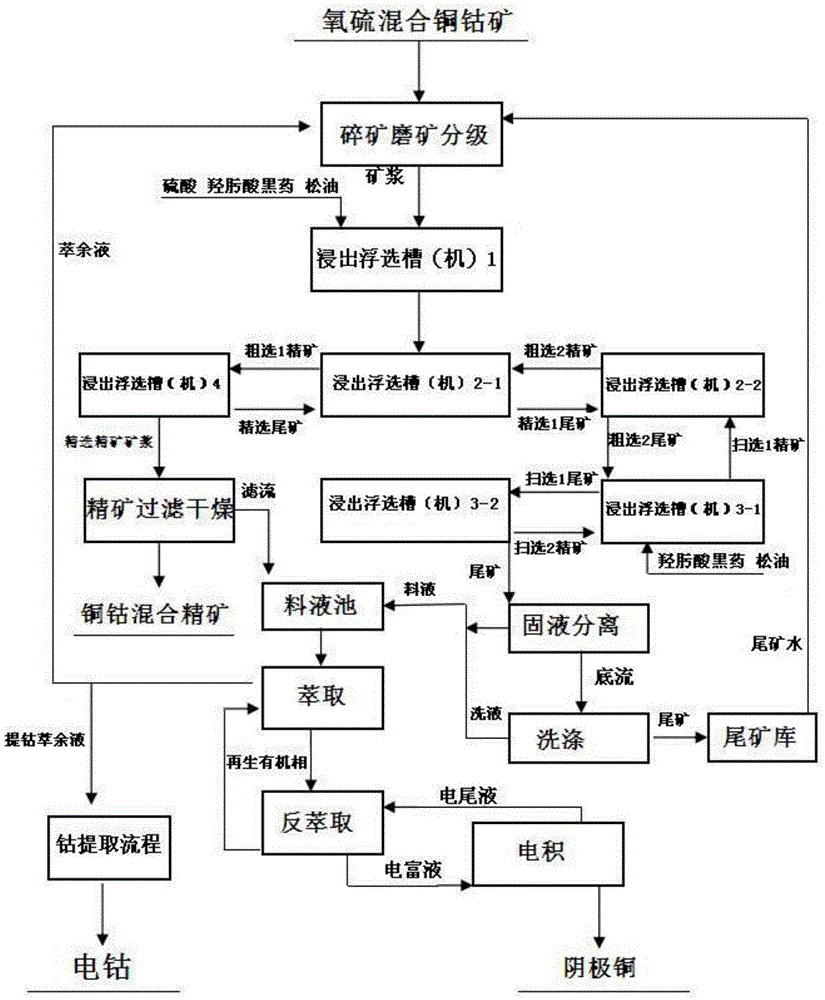

Method for conducting leaching and flotation on ores in same leaching and flotation cells

ActiveCN105483374AOptimum drug conditionSimple process conditionsFlotationEnergy consumptionMaterials science

The invention provides a method for conducting leaching and flotation on ores in the same leaching and flotation cells. The method is characterized in that the ores are leached and floated in the same leaching and flotation cells; and the leaching and flotation cells are divided into two or more sections according to the chemical mixing, roughing, scavenging and fine selecting functions required by the flotation procedure in the procedure, and each section is provided with at least one leaching and flotation cell. The method has the beneficial effects that leaching and flotation are performed in the same cells, so that the leaching process, the flotation process, a leaching system, a flotation system, a leaching agent, a floating agent and leaching liquid are coordinated, and the recovery rate index and the concentrate quality index are increased. The leaching process and the flotation process are better combined. The procedure of the method is shorter than the procedure in which the ores are leached firstly and then floated or floated firstly and then leached in the prior art, equipment investment is saved, energy consumption is low, used labor is small, and production cost is low.

Owner:罗光臣

Carbonate-type collecting agent reverse flotation drug and preparation method thereof

ActiveCN104998761ANo emission issuesThere is no problem with the use of cooking oilFlotationAlcoholFoaming agent

The invention relates to a carbonate-type collecting agent reverse flotation drug and a preparation method thereof. The preparation method comprises the following steps: (1) taking low erucic acid rapeseed oil alkali refining and deacidification niger and short carbon chain fatty acids (6-14 carbon) as collecting agent raw materials; (2) taking mixed alcohols and 1,1,3-triethyl orthobutyrate as foaming agents; (3) mixing the collecting agent raw materials with excessive amounts of alkalies and a certain amount of water, reacting for 1.5 h in a reaction kettle at 80-100 DEG C, reducing the temperature of a reaction liquid to be 40-70 DEG C, adding the foaming agents, and continuously stirring for 30 min, so as to obtain the finished product, namely the collophanite reverse flotation drug, wherein the mass ratio of the collecting agents to the foaming agents in the finished product, namely the reverse flotation drug, is (7-9):1. The carbonate-type collecting agent reverse flotation drug and the preparation method have the advantages that the flotation performance of the low erucic acid rapeseed oil alkali refining and deacidification niger and the short carbon chain fatty acids in the carbonate-type collophanite reverse flotation operation can be improved remarkably, the flotation recovery rate and the concentrate grade are improved remarkably, and low-cost industrial greasy leftovers are sufficiently utilized.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

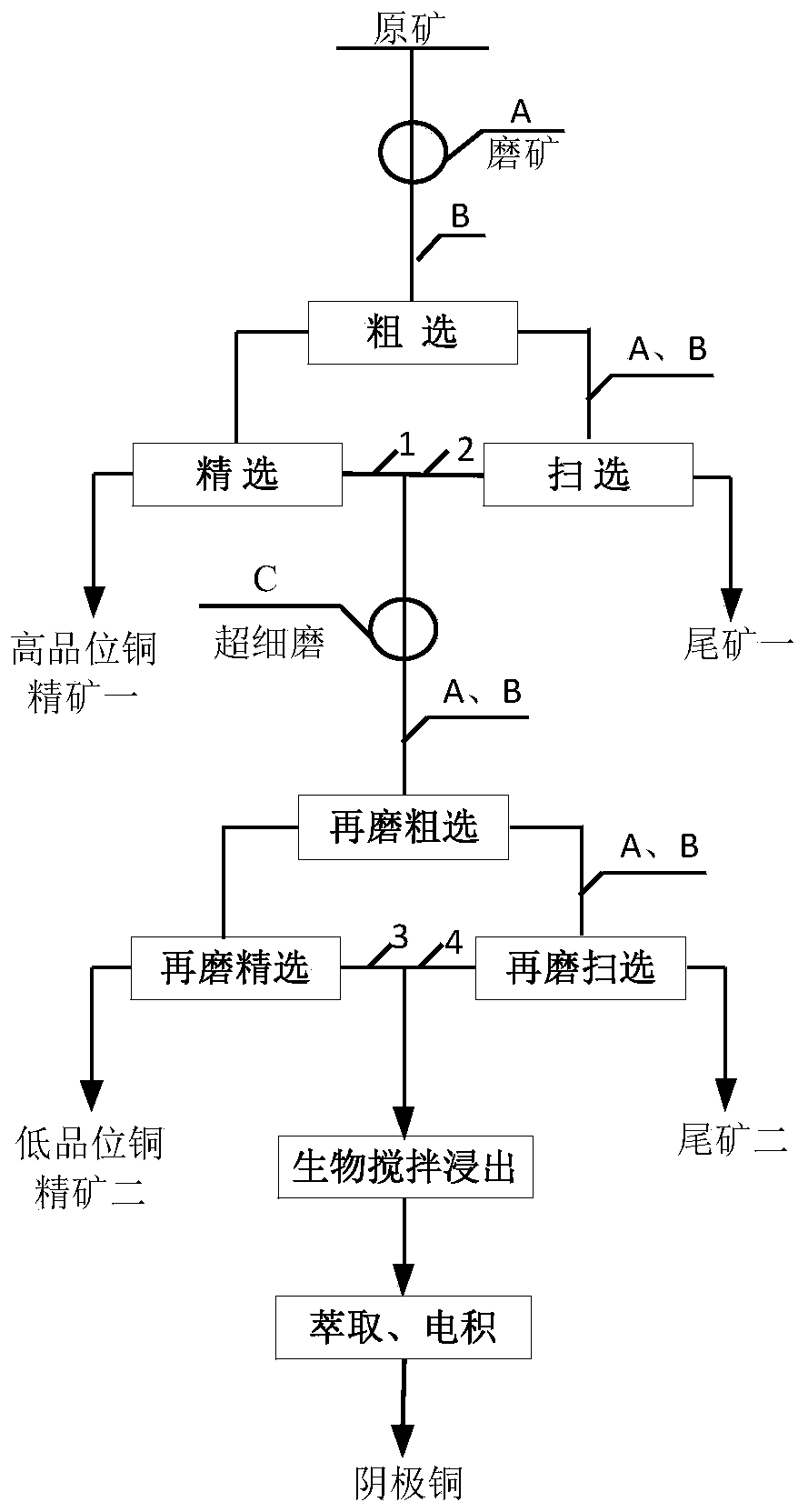

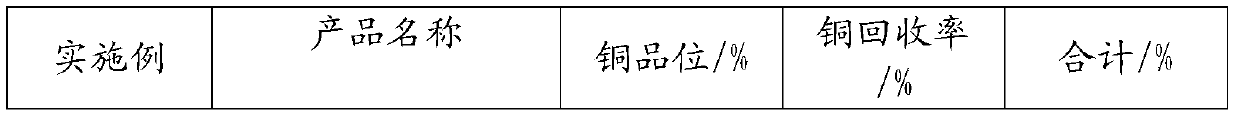

Dressing-metallurgy combined method for treating ultra-fine copper sulfide ore

InactiveCN110449270AAchieve stepwise dissociationAchieve step-by-step mineralizationFlotationProcess efficiency improvementCombined methodUltra fine

The invention discloses a dressing-metallurgy combined method for treating ultra-fine copper sulfide ore. The method comprises the following steps: performing ore grinding on crude ore, adding a collecting agent, adding a foaming agent, performing rough sizing, performing a section of blank quick fine sizing operation on the copper rough concentrate obtained through rough sizing so as to obtain high-grade copper concentrate No. 1 and middling No. 1, perform scavenging operation on the rough tailings obtained through rough sizing so as to obtain tailings No. 1 and middling No. 2, merging the middling No. 1 and middling No. 2, performing ultra-fine grinding so as to obtain an ultra-fine ground product, adding a gangue inhibitor in the ultra-fine grinding process, adding the collecting agentand foaming agent to the ultra-fine ground product, performing ultra-fine grinding rough sizing operation, performing blank and fine sizing on the obtained ultra-fine ground rough-sized concentrate soas to obtain low-grade copper concentrate No. 2 and middling No. 3, performing scavenging operation on the ultra-fine ground rough-sized tailings so as to to obtain tailings No. 2 and middling No. 4,merging the middling No. 3 and the middling No. 4, performing biological stirring leaching, and performing extraction electrodeposition on the leachate so as to obtain a cathode copper. The comprehensive utilization rate of resources can be improved effectively.

Owner:厦门紫金矿冶技术有限公司

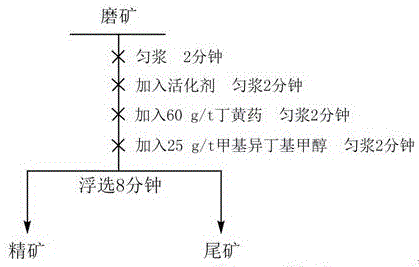

Beneficiation method for recycling bismuth from molybdenum selecting tailings

A beneficiation method for recycling bismuth from molybdenum selecting tailings is characterized by including the following steps that grout is mixed, in the step, concentrated sulfuric acid is added into the molybdenum selecting tailings; flotation roughing is performed, in the step, activator lead nitrate, collecting agent butyl xanthate and foaming agent terpenic oil are added to perform primary roughing to obtain roughed concentrate and roughed tailings; floating scavenging is performed, in the step, the butyl xanthate and the foaming agent terpenic oil are added in the primary scavenging of the roughed tailings, and the butyl xanthate and the foaming agent terpenic oil are added in the secondary scavenging or blank scavenging is performed to obtain scavenged concentrate and flotation tailings; flotation fine selection is performed, in the step, three to four times of blank fine selection is performed on the roughed concentrate to obtain bismuth concentrate and fine selected tailings; the fine selected tailings and the scavenged concentrate are made to return to the flotation roughing operation. According to the beneficiation method, bismuth is recycled from the molybdenum selecting tailings under the faintly acid condition in order to solve the problems that under the alkaline condition, activation of bismuthinite is poor and the recycling efficiency is low. According to the method, the recycling rate of the bismuth is larger than 85%, the Bi content in the bismuth concentrate is larger than 20%, and the method is applicable to molybdenum ore mines containing bismuth.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

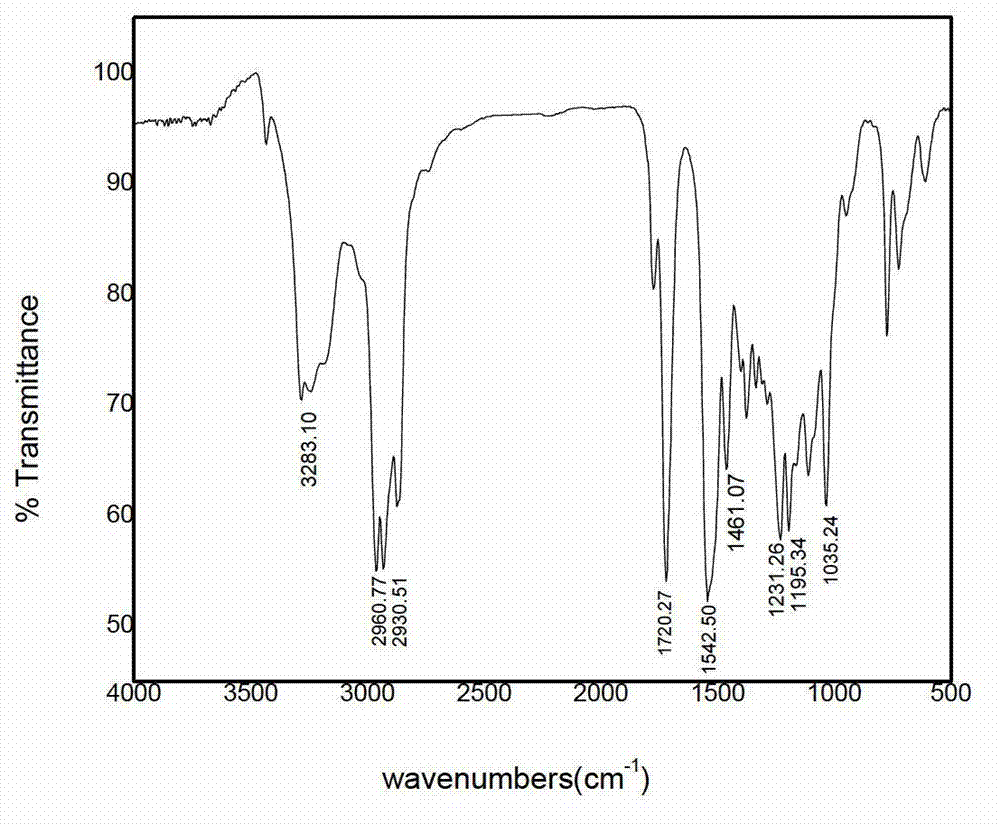

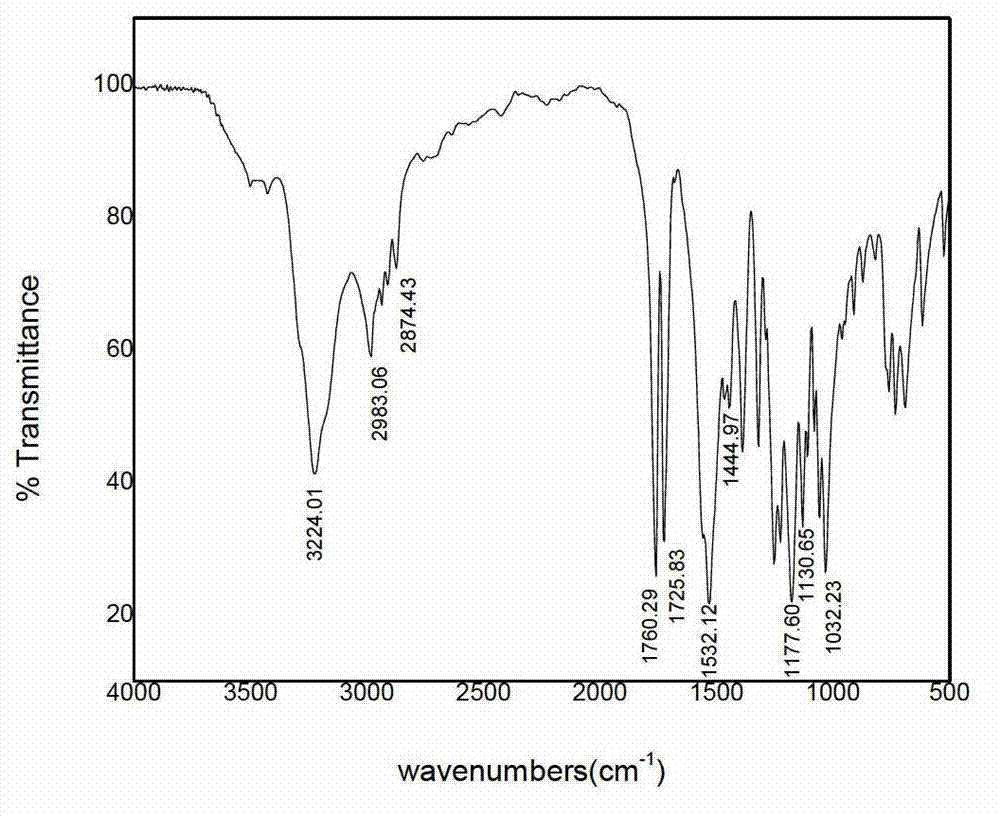

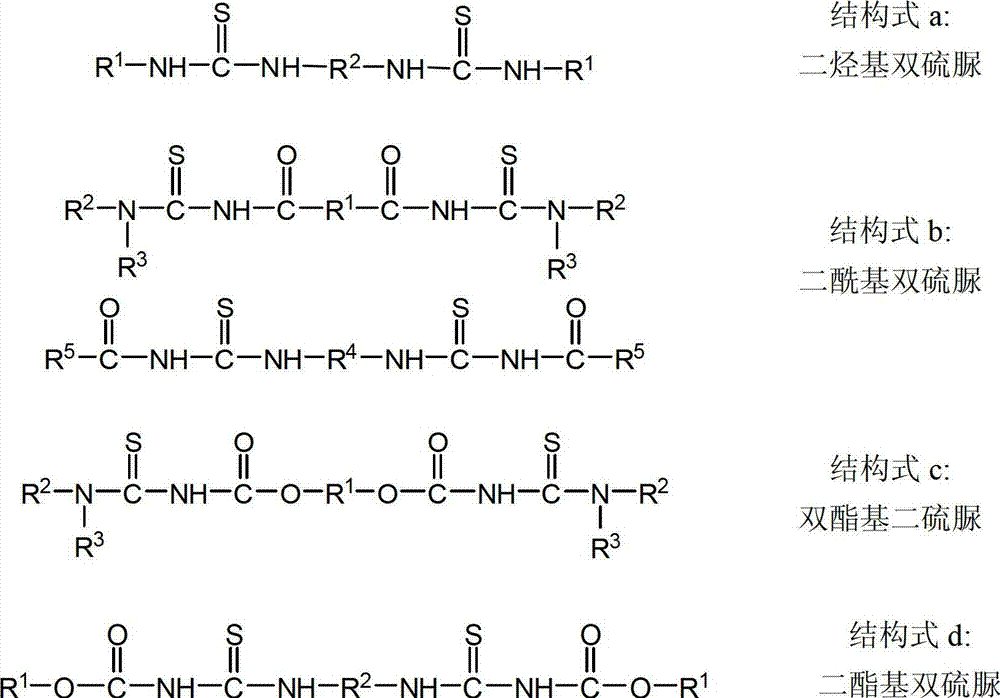

Double-ligand collecting agent and preparation and application thereof

The invention discloses a double-ligand collecting agent-ether double thiourea or ethionine ester thiourea composite-radical compound and preparation and application thereof. The ether double thiourea or ethionine ester thiourea composite-radical compound shown as a formula (I) is used as a collecting agent for metal ore flotation, wherein R1 refers to an acyl radical with the general formula of R3-C(=O)- or an ester group with the general formula of R4O-C(=O)-, R3 and R4 respectively refer to C1-C8 alkyl radicals, R2 refers to hydrogen or methyl, X refers to O or NH, and n refers to 1-6. The compound with the structure shown as the formula (I) is used as the flotation collecting agent to efficiently recover value metal from nonferrous metal ores and precious metal ores. Flotation separation and extraction of the nonferrous metal ores and precious metal ores can be enhanced by the ether double thiourea or ethionine ester thiourea composite-radical compound. The melting point of the collecting agent can be lowered, dispersity of the collecting agent in aqueous solution is improved, adsorption of the collecting agent on the surfaces of ores is promoted, and flotation efficiency is improved while metal recovery rate is increased.

Owner:CENT SOUTH UNIV

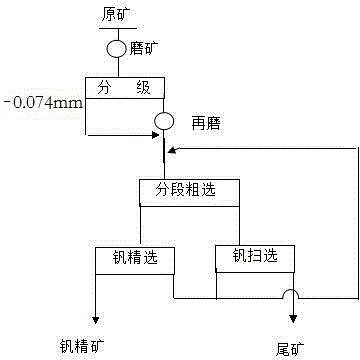

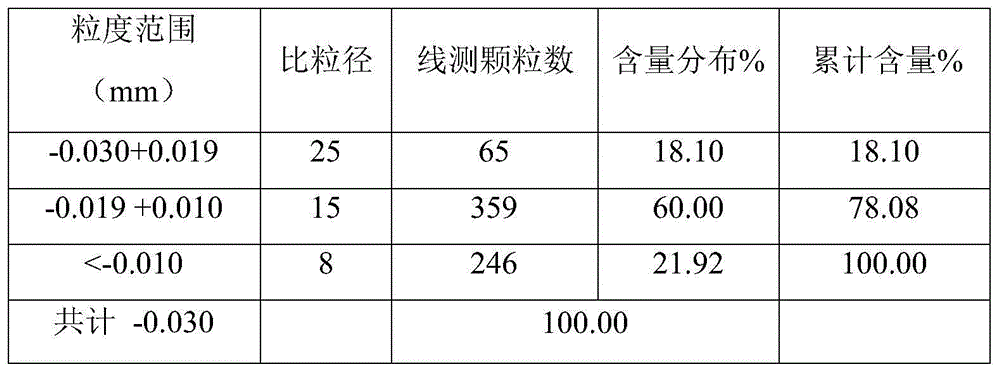

Mineral separation method of finely disseminated vanadium contained carbonaceous shale

InactiveCN104907163AImprove beneficiation indexImprove flotation recoveryFlotationWet separationRoscoeliteMineral collecting

The invention discloses a mineral separation method of finely disseminated vanadium contained carbonaceous shale. The amount of roscoelite with the disseminated grain size less than 0.019mm is larger than 50% of the total amount of roscoelite in the finely disseminated vanadium contained carbonaceous shale. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale includes following steps: (a) performing rough grinding on raw ore after being crushed so as to obtain roughly ground minerals; (b) performing screening classification on the roughly ground minerals, obtaining coarse grain minerals +0.074mm in size and fine grain minerals -0.074mm in size after the screening classification, and combining the coarse grain minerals after being ground twice with the fine grain minerals -0.074mm in size; (c) adding PH (power of hydrogen) regulators into the combined minerals, adjusting PH value to 5-6, adding gangue mineral inhibitor and vanadium mineral collecting agents into ore pulp for 6-12 times, and obtaining concentrated vanadium ore through segmenting rough concentration, vanadium concentration and vanadium scavenging after obtaining flotation pulp by adding flotation reagents once. The mineral separation method of the finely disseminated vanadium contained carbonaceous shale can perform mineral separation on the finely disseminated vanadium contained carbonaceous shale, can effectively improve a mineral separation index, and further can reduce mineral separation cost.

Owner:HUNAN RES INST FOR NONFERROUS METALS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com