Ship exhaust gas desulfurization wash water treatment process and treatment system based on sodium alkali method

A waste gas desulfurization and treatment process technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage multi-stage treatment, etc., can solve the problems of reduced treatment effect, waste of water treatment chemicals, and large equipment footprint , to achieve the effect of improving processing effect, saving usage and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

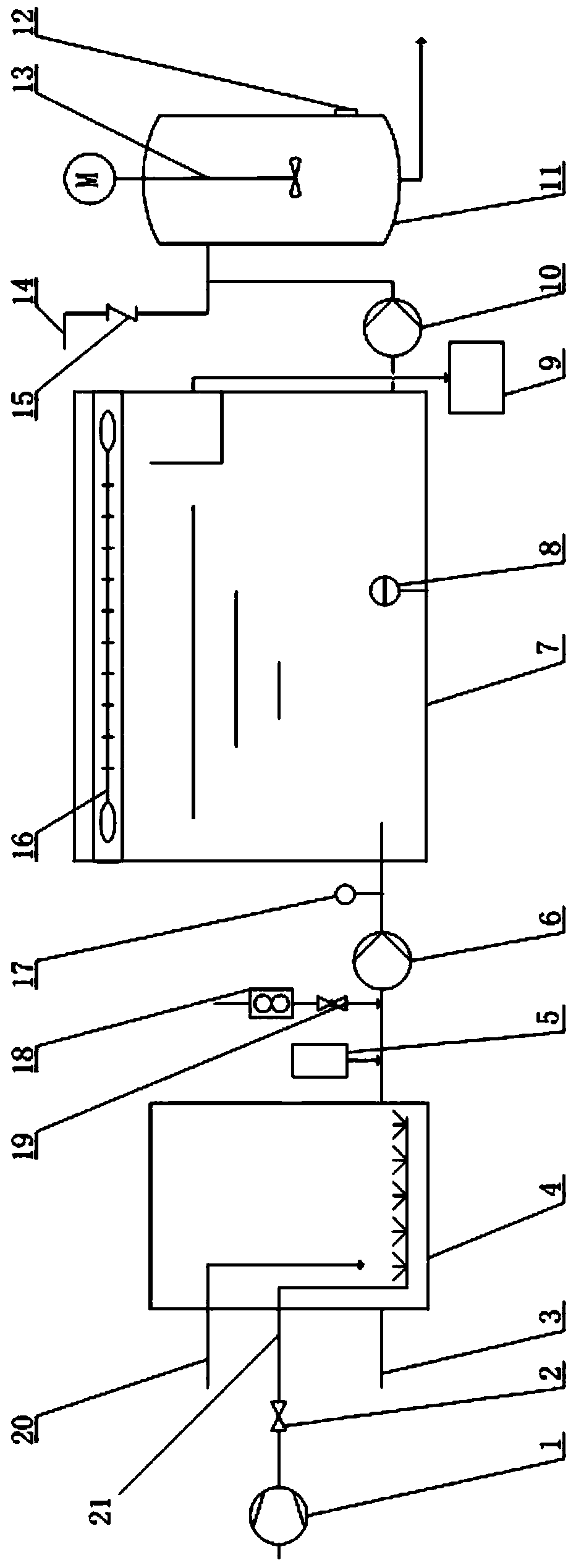

[0028] Please refer to figure 1 . According to an embodiment of the present invention, the ship waste gas desulfurization washing water treatment system based on the sodium-alkali method includes: an aeration fan 1, an integrated neutralization and oxidation tank 4, a flocculation tank 5, an air-water mixing pump 6, an air flotation tank 7, and a lift pump 10 and filter 11.

[0029] The integrated neutralization and oxidation pool 4 is provided with a sewage inlet pipeline 3 , an alkali liquor inlet pipeline 20 , an air inlet 21 and an outlet, and the air inlet 21 is provided with a control valve 2 . The outlet of the aeration fan 1 communicates with the air inlet of the integrated neutralization and oxidation tank 4 through a pipeline. The air-water mixing pump 6 has a liquid inlet, an air inlet and an outlet. The liquid inlet of the air-water mixing pump 6 is respectively connected with the outlet of the neutralization and oxidation integrated tank 4 and the outlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com