Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Wide size" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

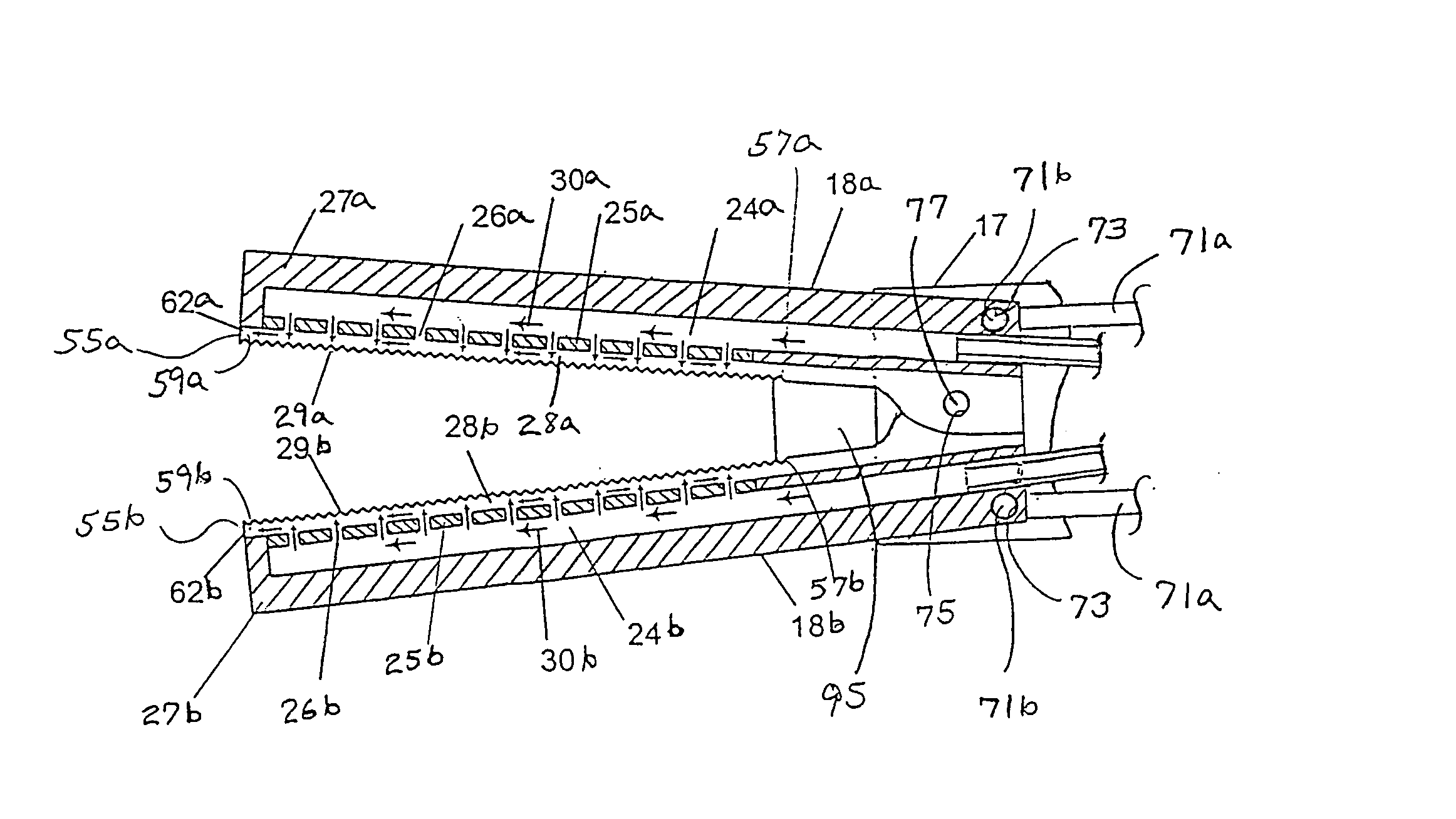

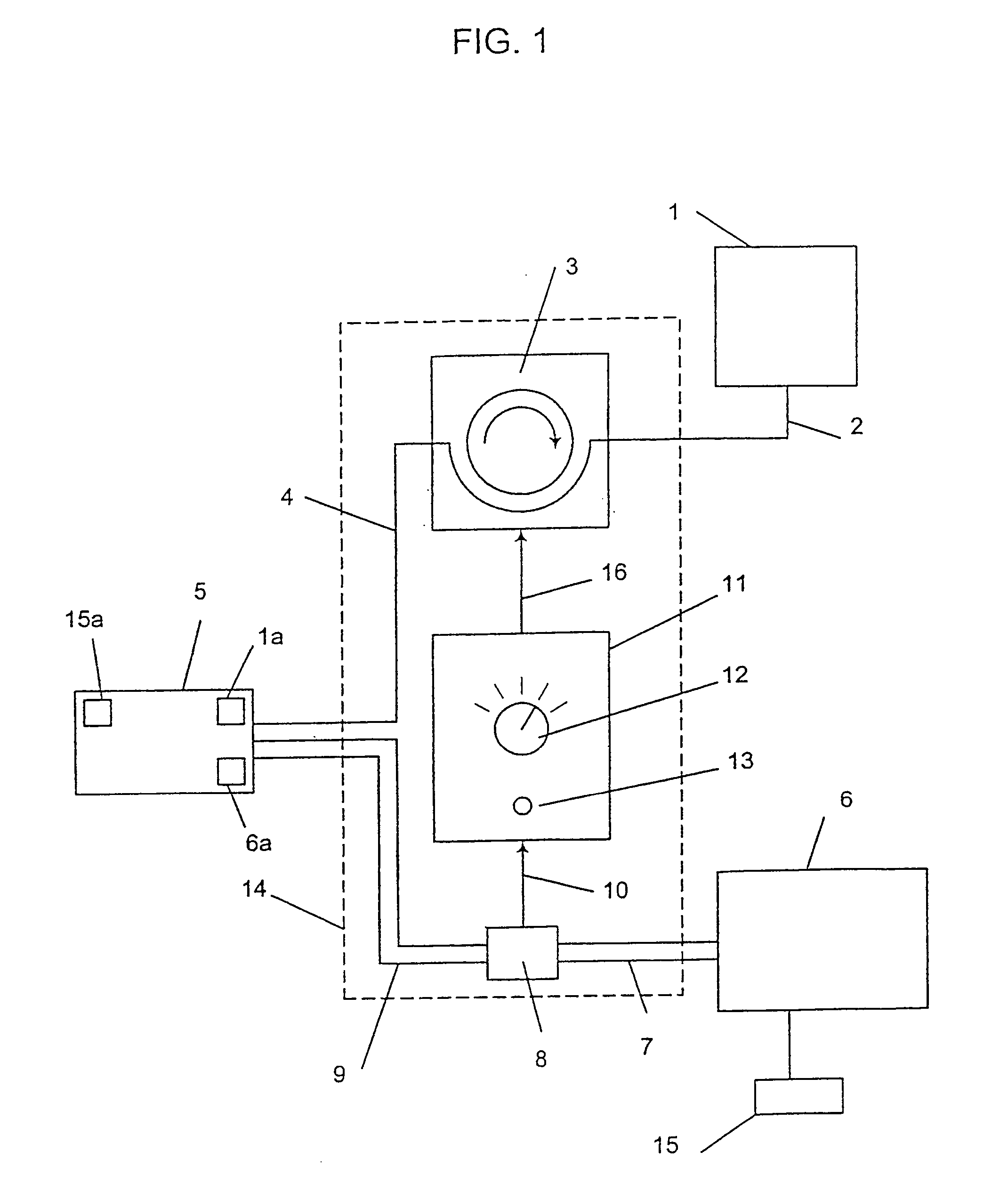

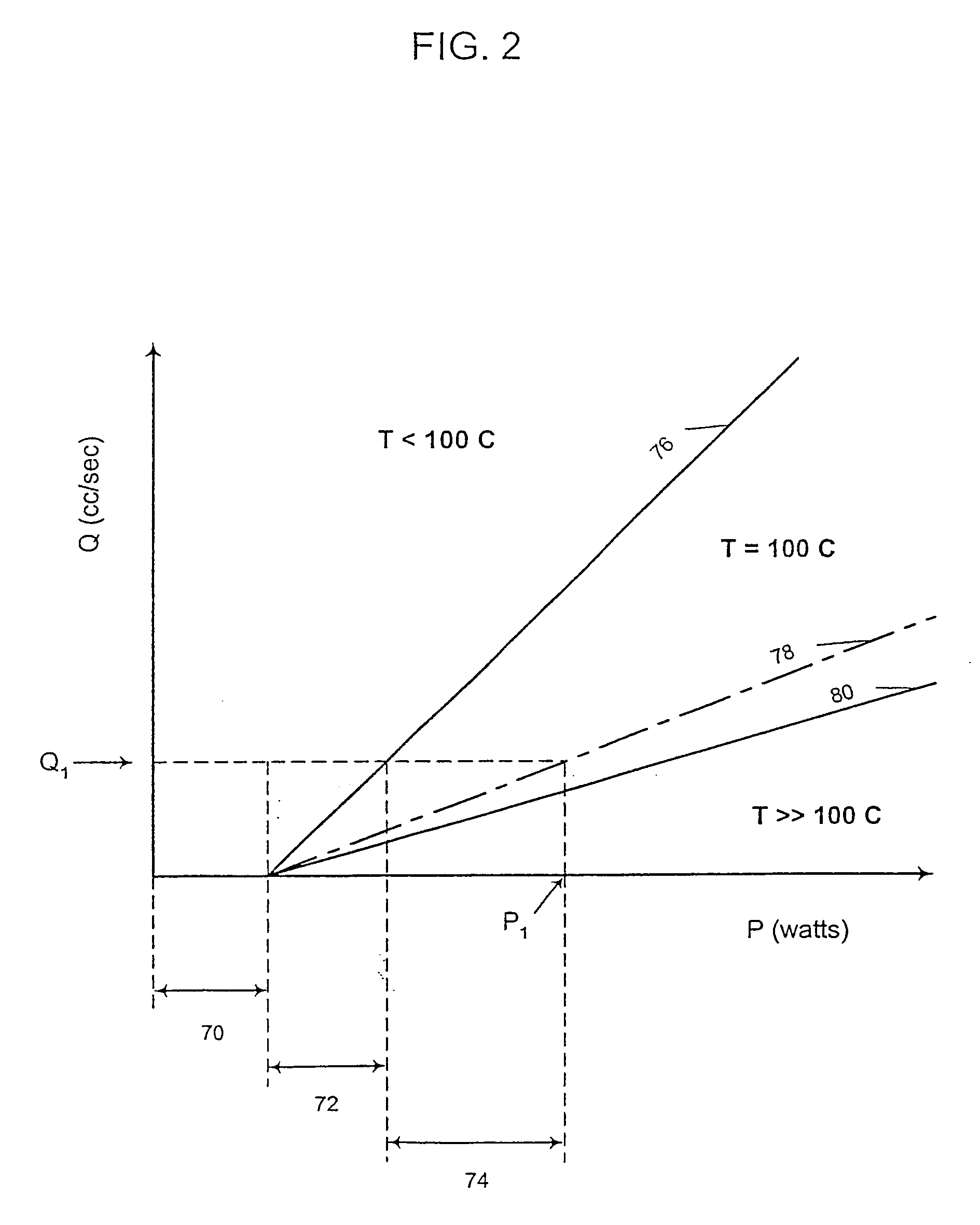

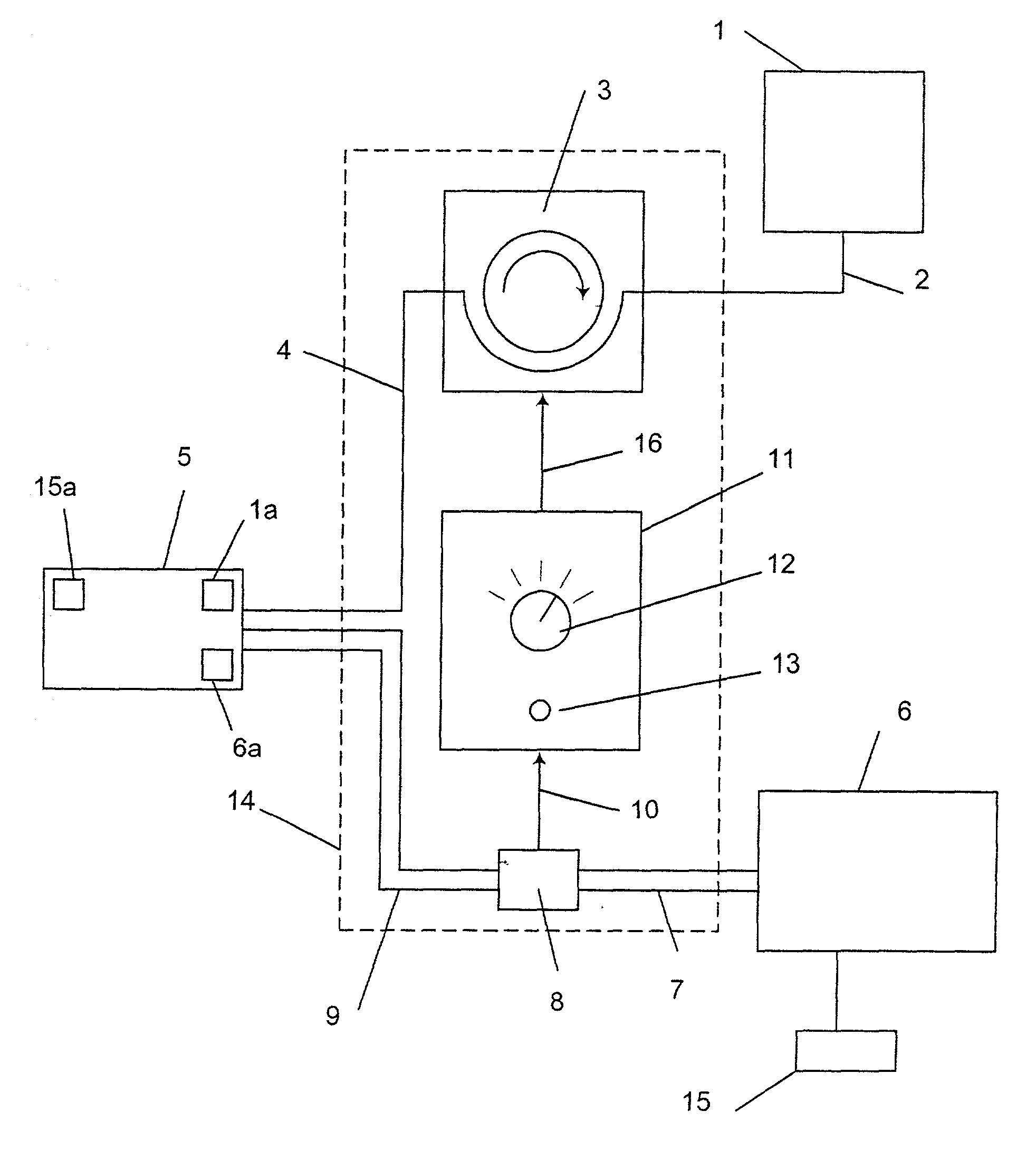

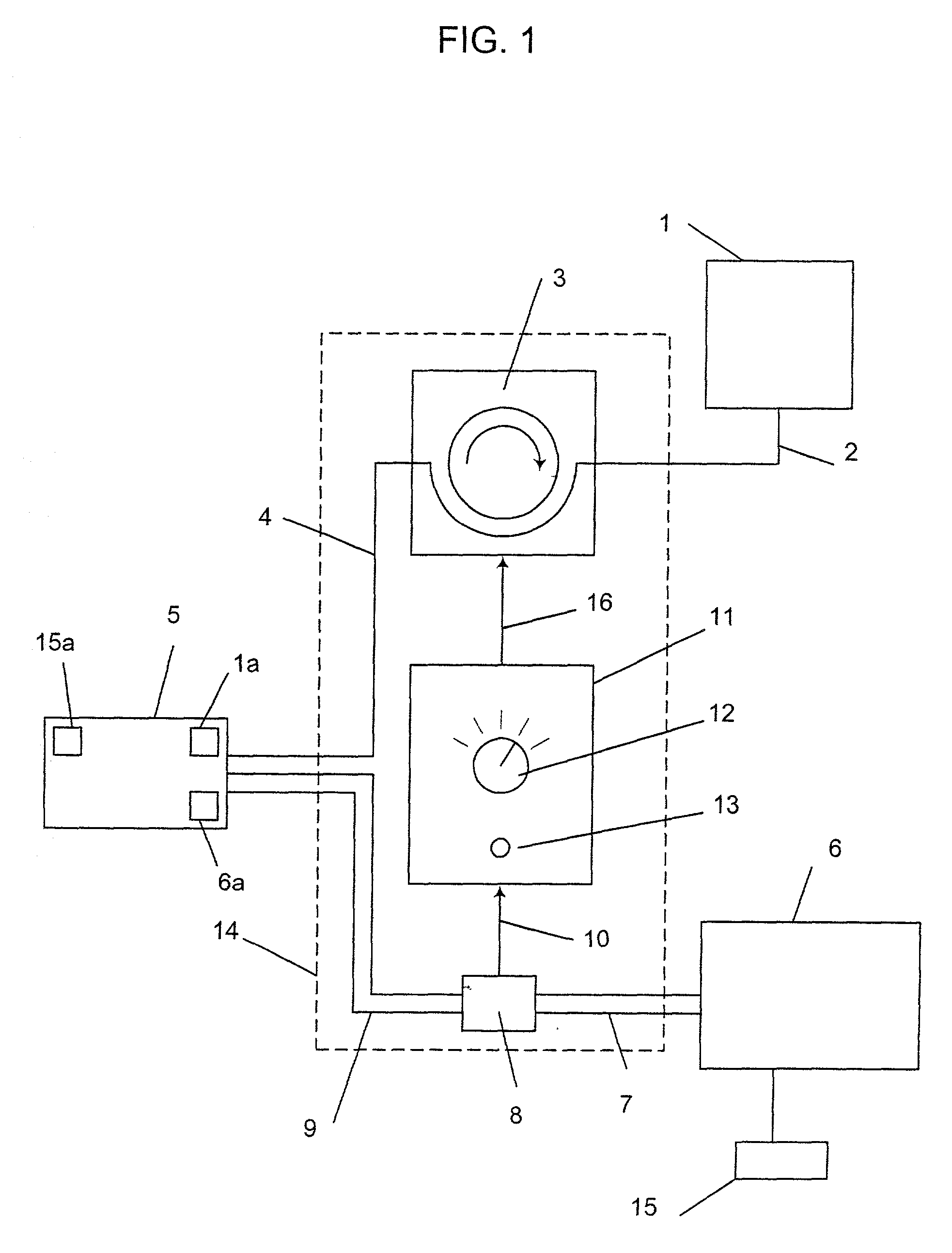

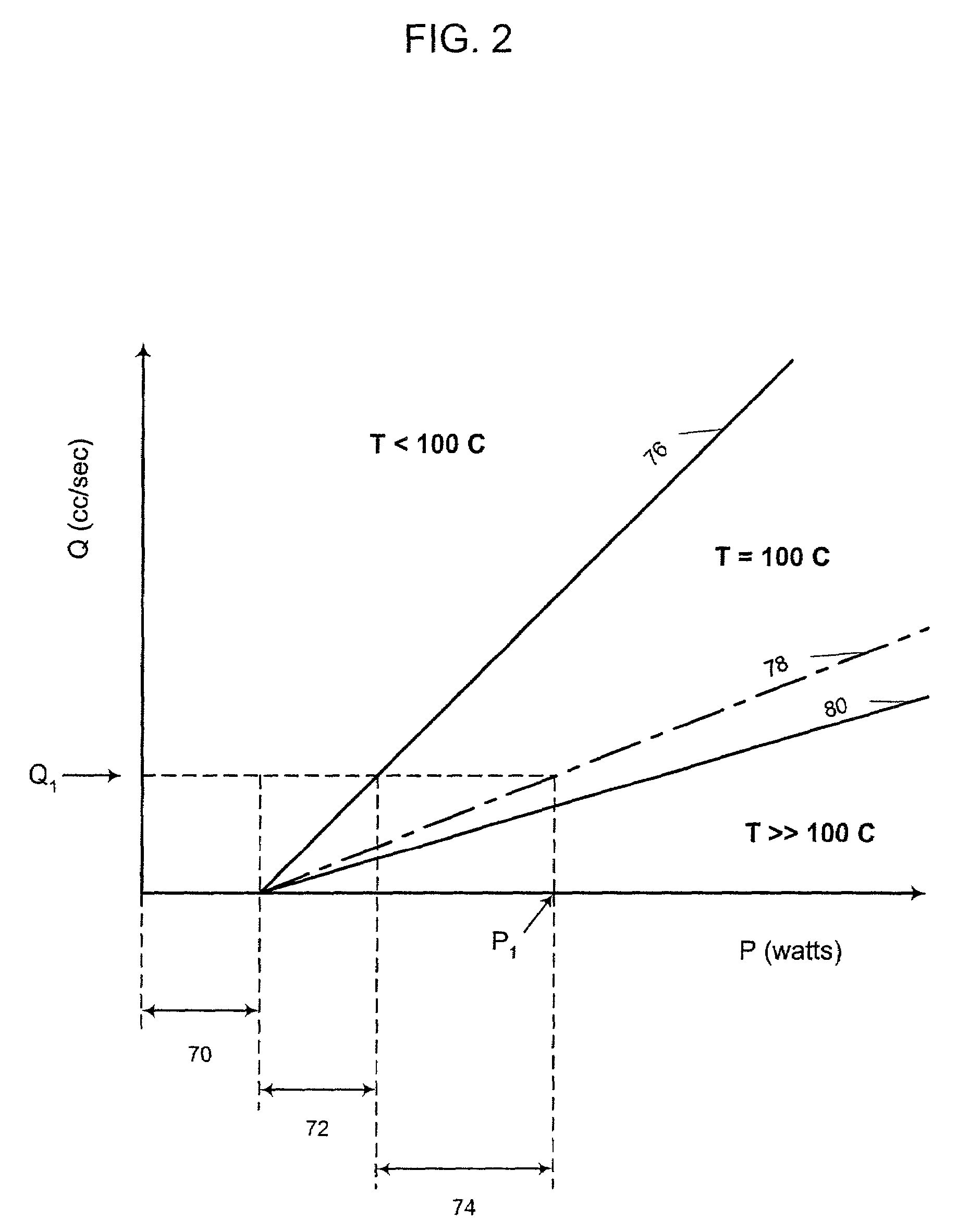

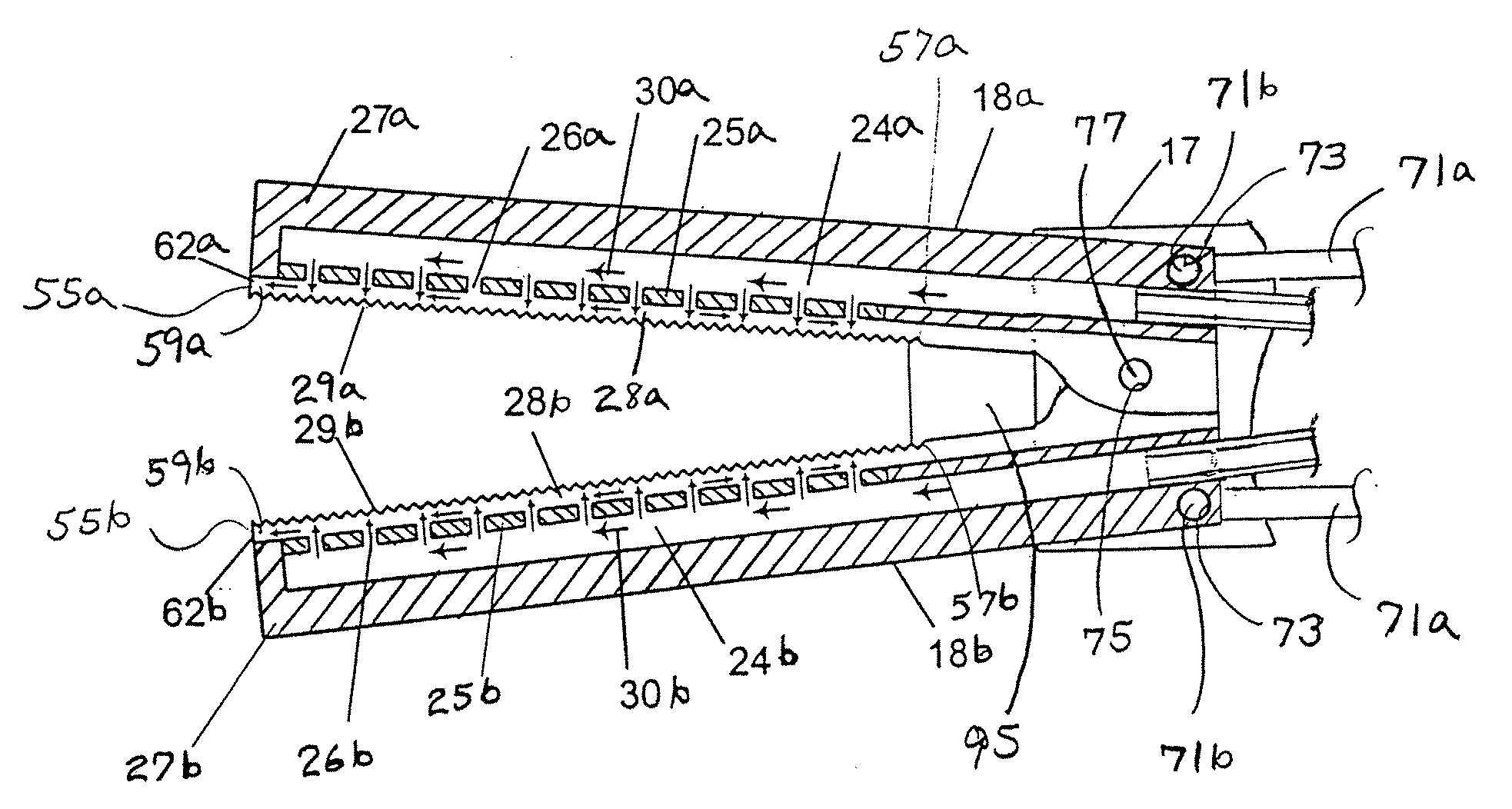

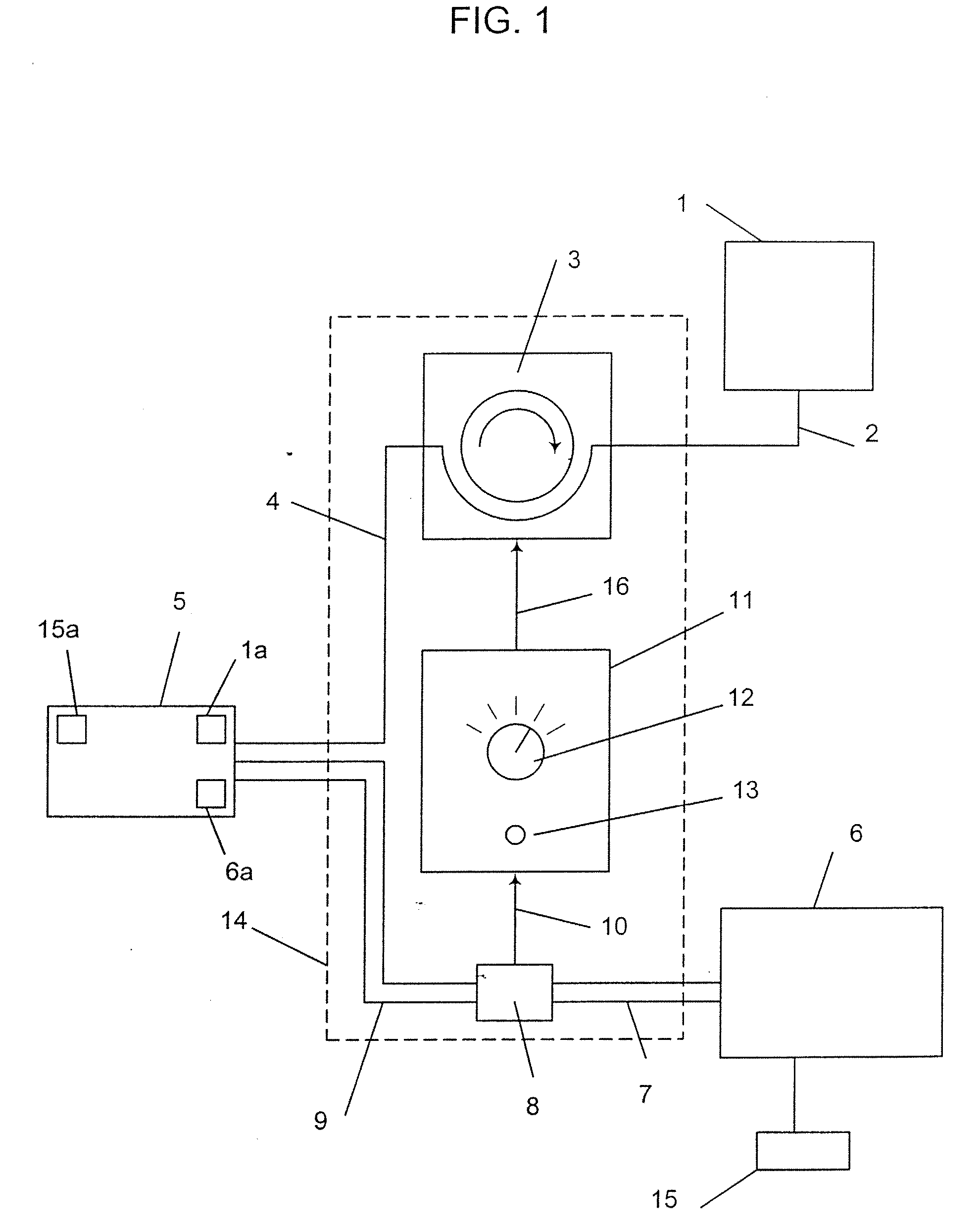

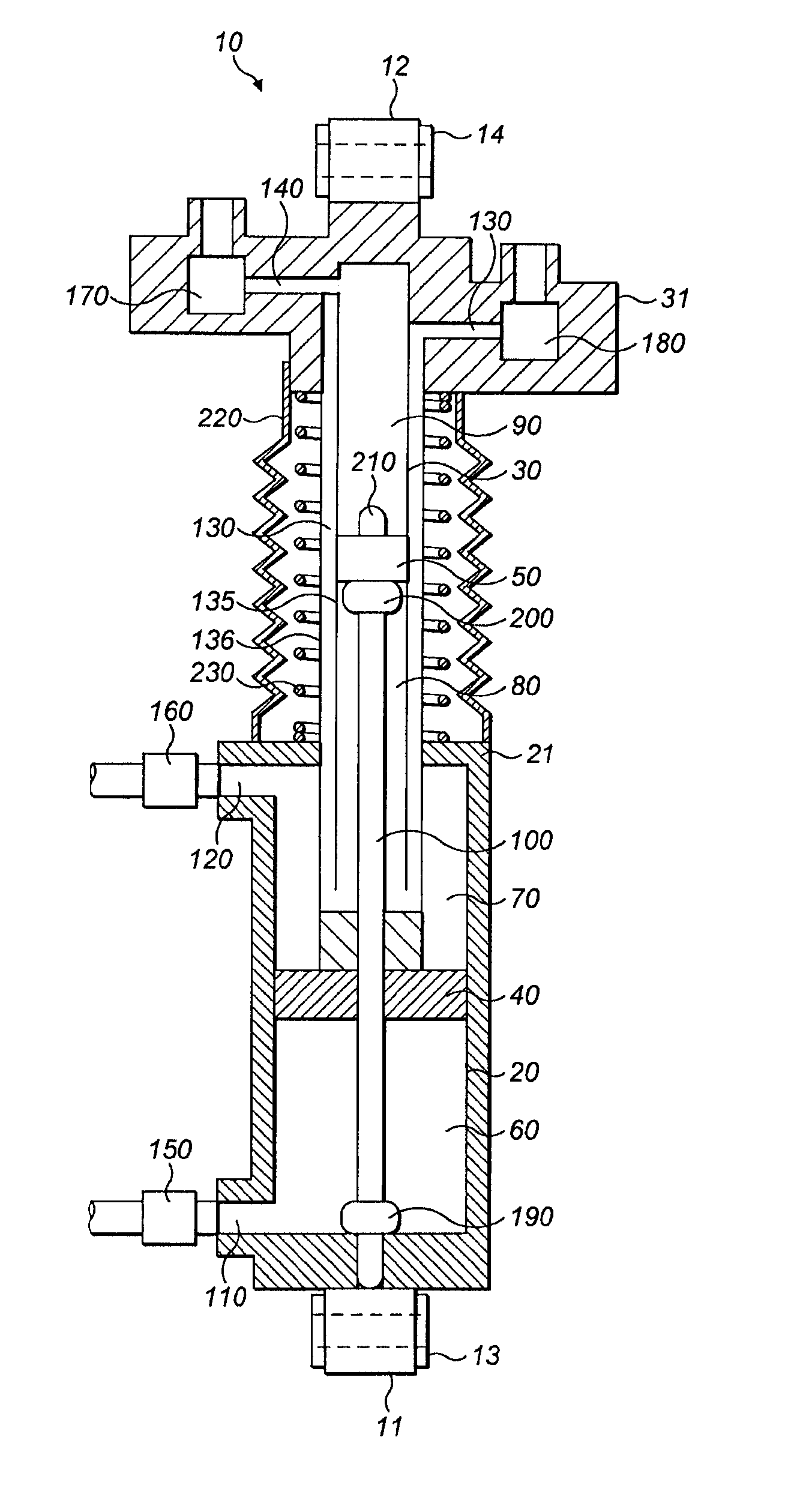

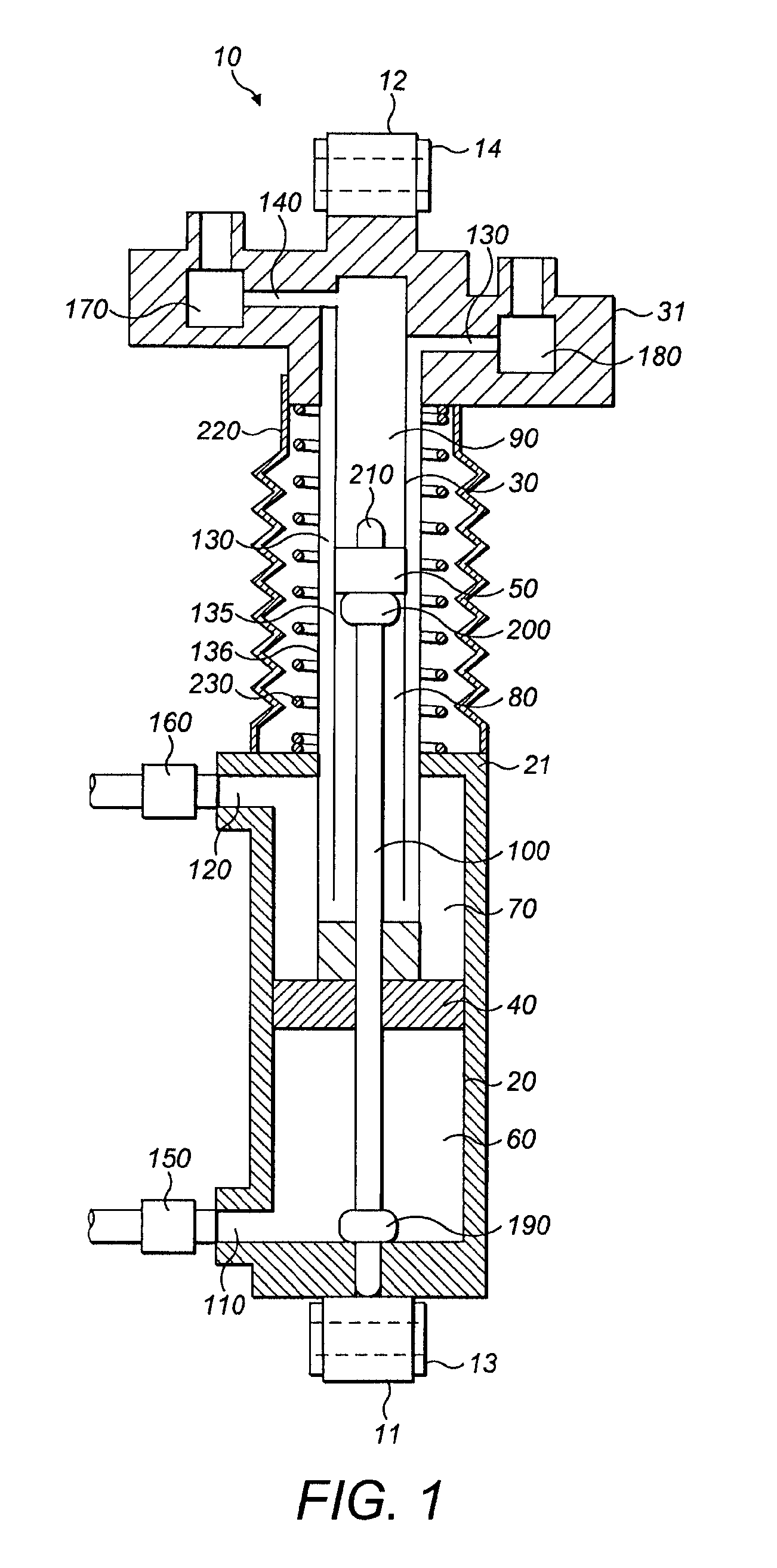

Fluid assisted medical devices, fluid delivery systems and controllers for such devices, and methods

InactiveUS20050033278A1Increase speedWide sizeCatheterSurgical instruments for heatingRate changeMedical device

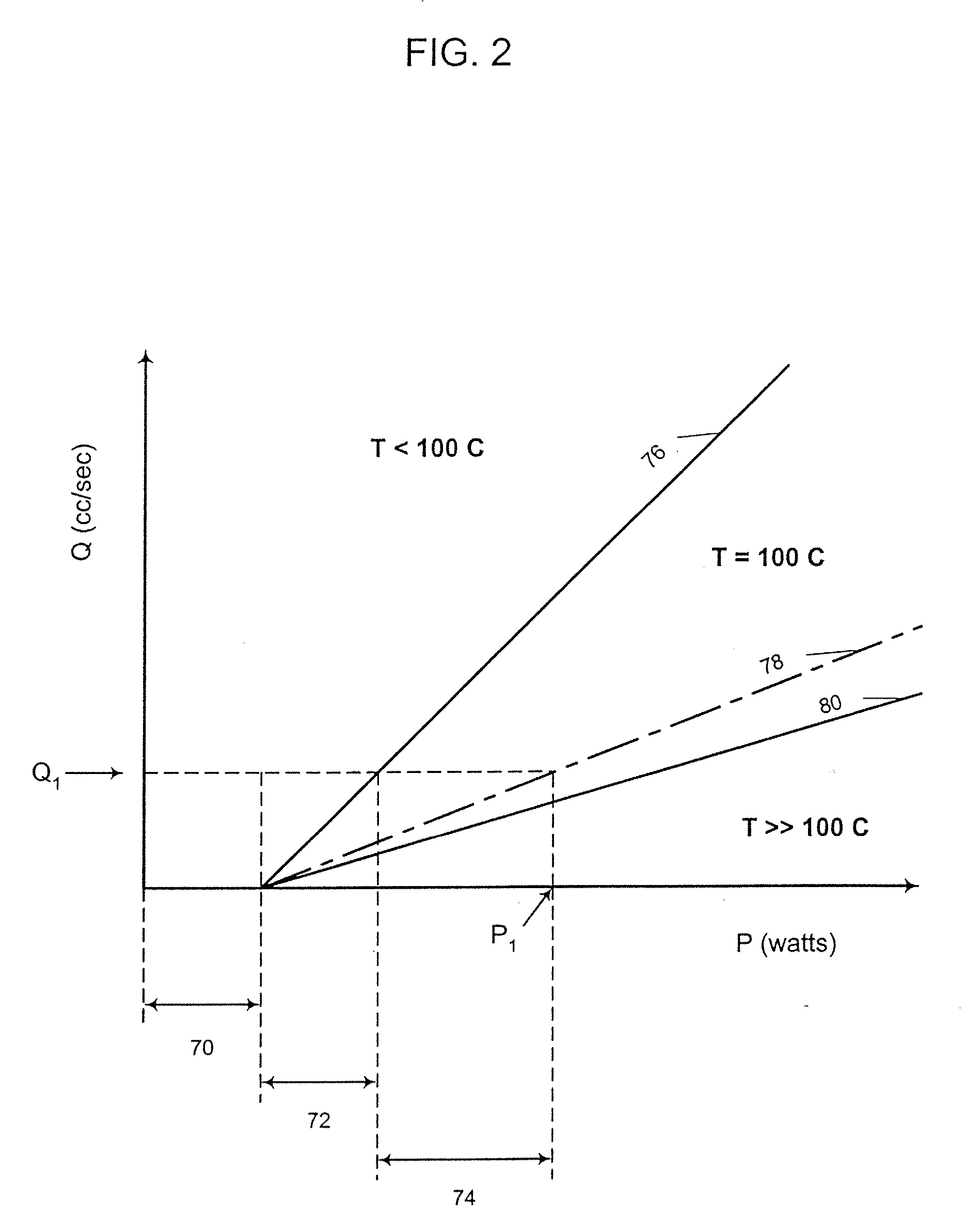

Medical devices, methods and systems for treating tissue are provided. An exemplary system comprises a fluid from a fluid from a fluid source at a fluid flow rate, a surgical device which provides power and the fluid to the tissue and a control mechanism which changes a fluid flow rate provided from the surgical device and changes a power level provided from the surgical device. The fluid flow rate changes between at least two-zero flow rates and the power level changes between at least two non-zero levels. An exemplary method comprises providing a fluid from a fluid source at a fluid flow rate, providing a surgical device which provides power and the fluid to the tissue, and changing the fluid flow rate of fluid provided from the surgical device with a change in power level provided from the surgical device.

Owner:SALIENT SURGICAL TECH

Fluid-assisted medical devices, fluid delivery systems and controllers for such devices, and methods

Medical devices, methods and systems for treating tissue are provided. An exemplary system comprises a fluid from a fluid source, a surgical device which provides energy and the fluid to the tissue and a control mechanism which changes a flow rate of fluid provided from the surgical device and changes a rate of energy provided from the surgical device. The fluid flow rate changes between at least two non-zero flow rates and the energy rate changes between at least two non-zero energy rates. An exemplary method comprises providing a fluid from a fluid source, providing a surgical device which provides energy and the fluid to the tissue, and changing a flow rate of fluid provided from the surgical device with a change in a rate of energy provided from the surgical device. Exemplary devices comprise a tip portion configured to provide energy and a fluid to a tissue.

Owner:MEDTRONIC ADVANCED ENERGY

Fluid-Assisted Medical Devices, Fluid Delivery Systems and Controllers for Such Devices, and Methods

InactiveUS20070049920A1Increase speedWide sizeCatheterSurgical instruments for heatingEnergy rateRate change

Medical devices, methods and systems for treating tissue are provided. An exemplary system comprises a fluid from a fluid source, a surgical device which provides energy and the fluid to the tissue and a control mechanism which changes a flow rate of fluid provided from the surgical device and changes a rate of energy provided from the surgical device. The fluid flow rate changes between at least two non-zero flow rates and the energy rate changes between at least two non-zero energy rates. An exemplary method comprises providing a fluid from a fluid source, providing a surgical device which provides energy and the fluid to the tissue, and changing a flow rate of fluid provided from the surgical device with a change in a rate of energy provided from the surgical device. Exemplary devices comprise a tip portion configured to provide energy and a fluid to a tissue.

Owner:MEDTRONIC ADVANCED ENERGY

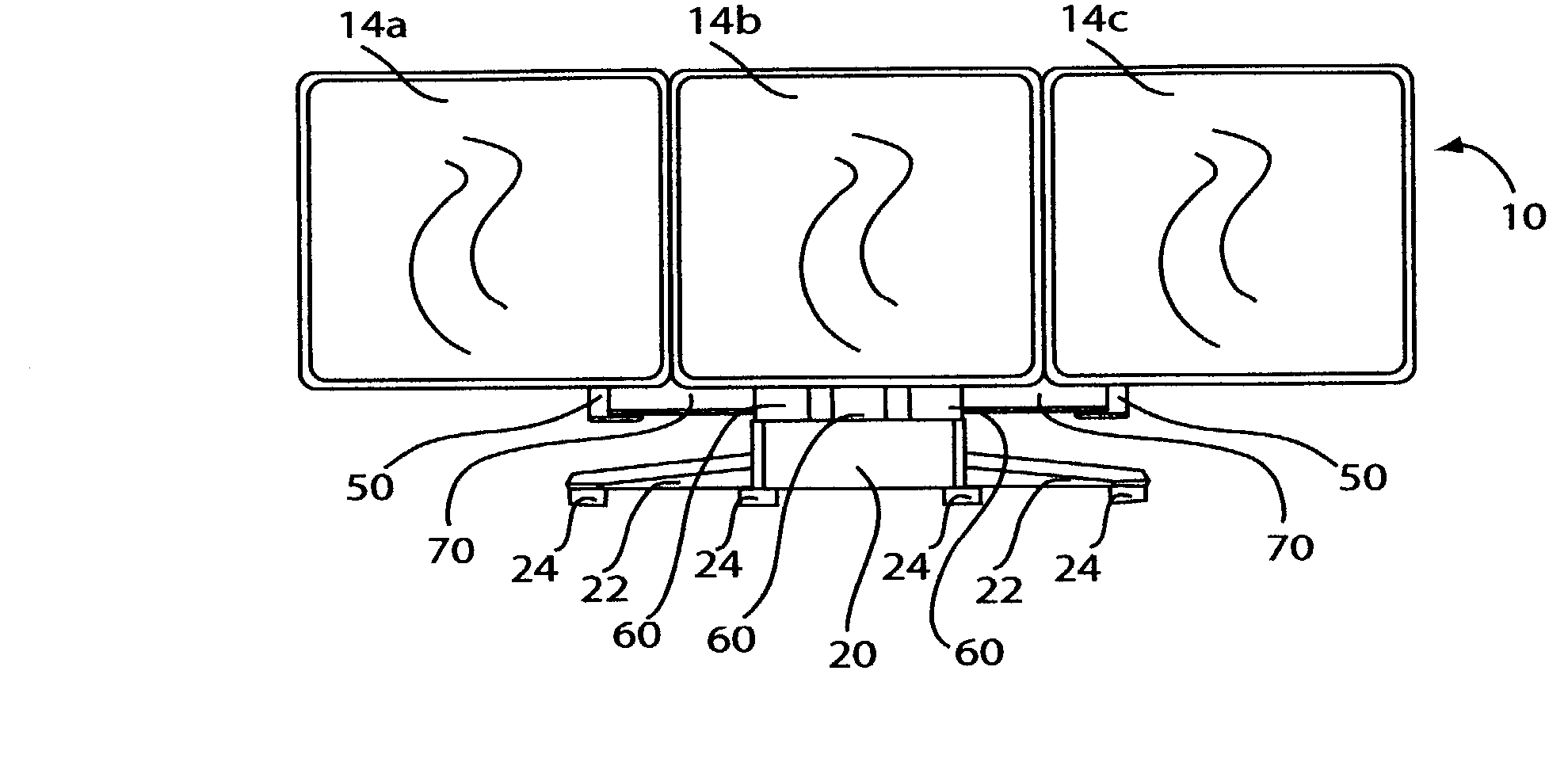

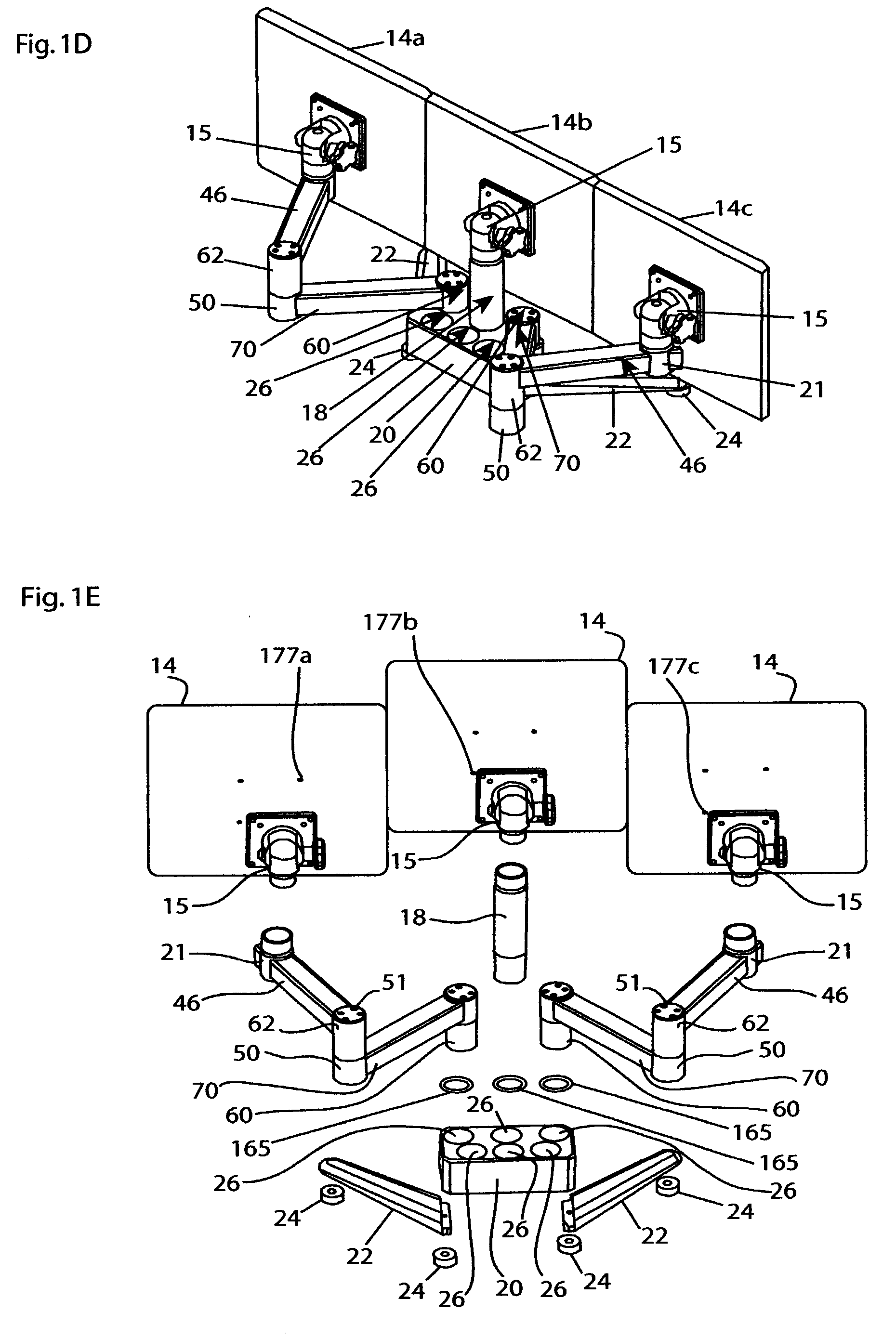

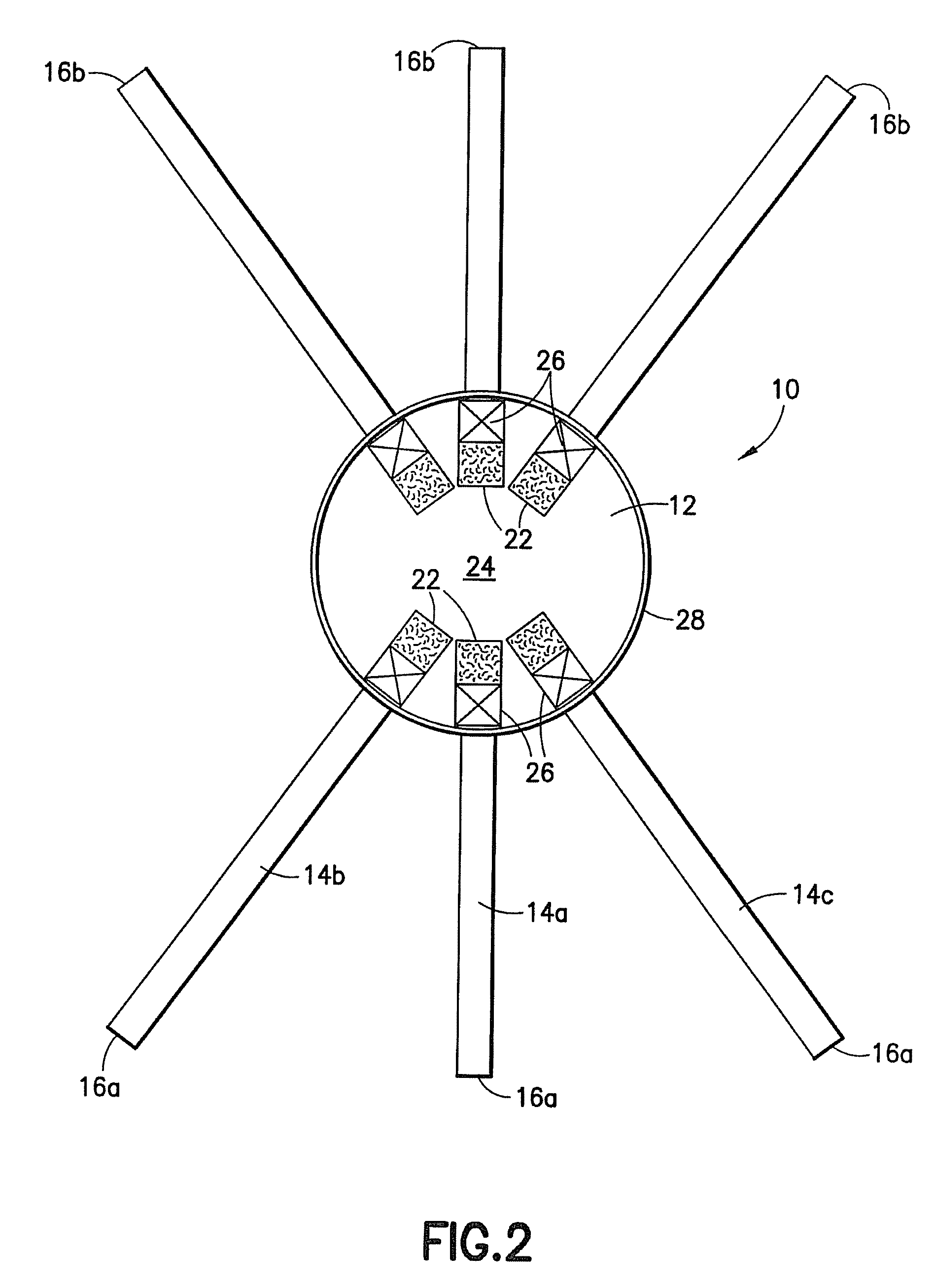

Multiple flat panel display system

InactiveUS20030015632A1Good benefitImprove customizationCabinetsStands/trestlesDisplay deviceEngineering

A multiple display apparatus includes a hub capable of supporting a variable number of display support members and at least two support members coupled to the support hub. The apparatus is expandable to provide a plurality of displays and support members on the hub. Mounting brackets are respectively associated with the members to secure flat panel displays to the apparatus.

Owner:DUNN DANIEL +1

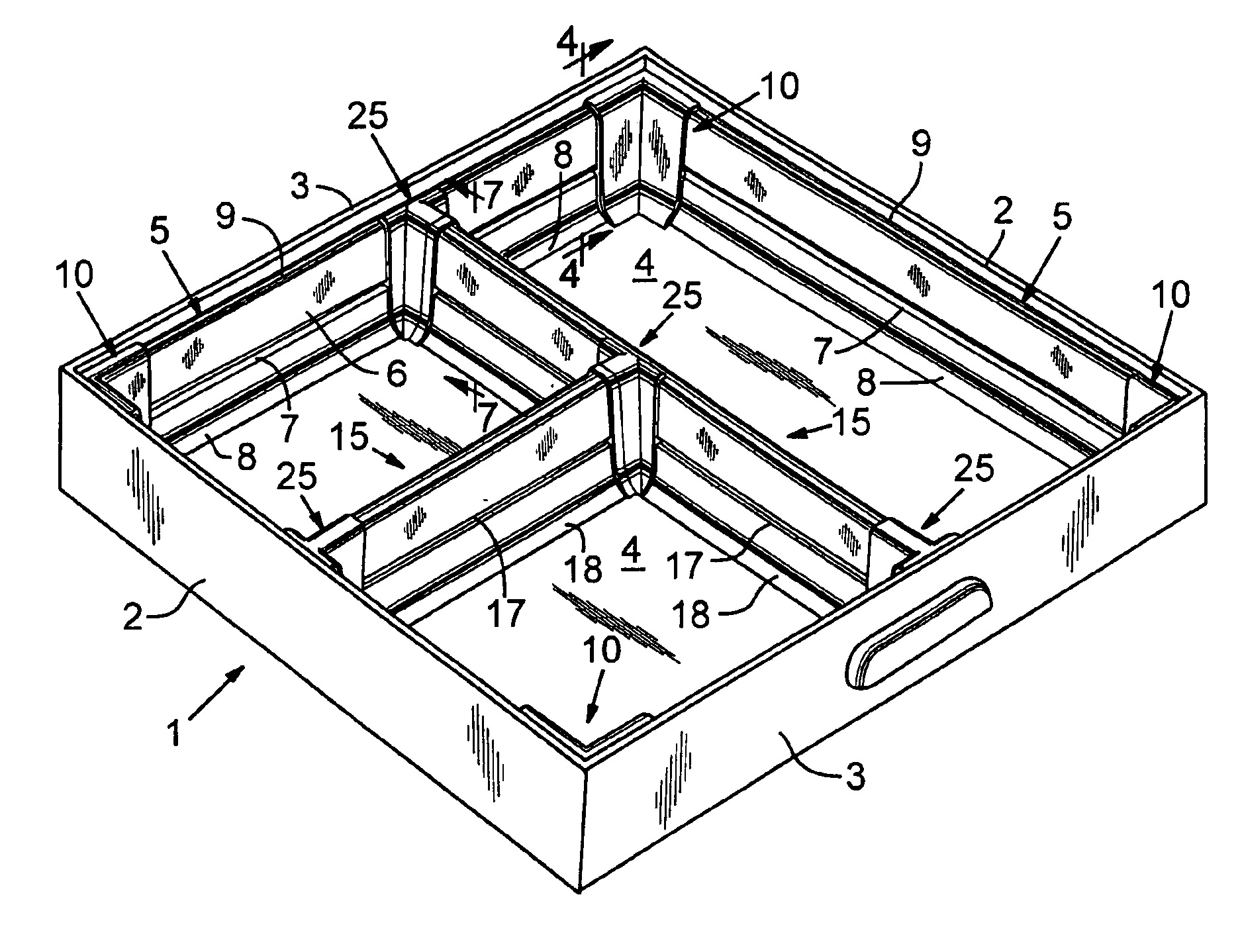

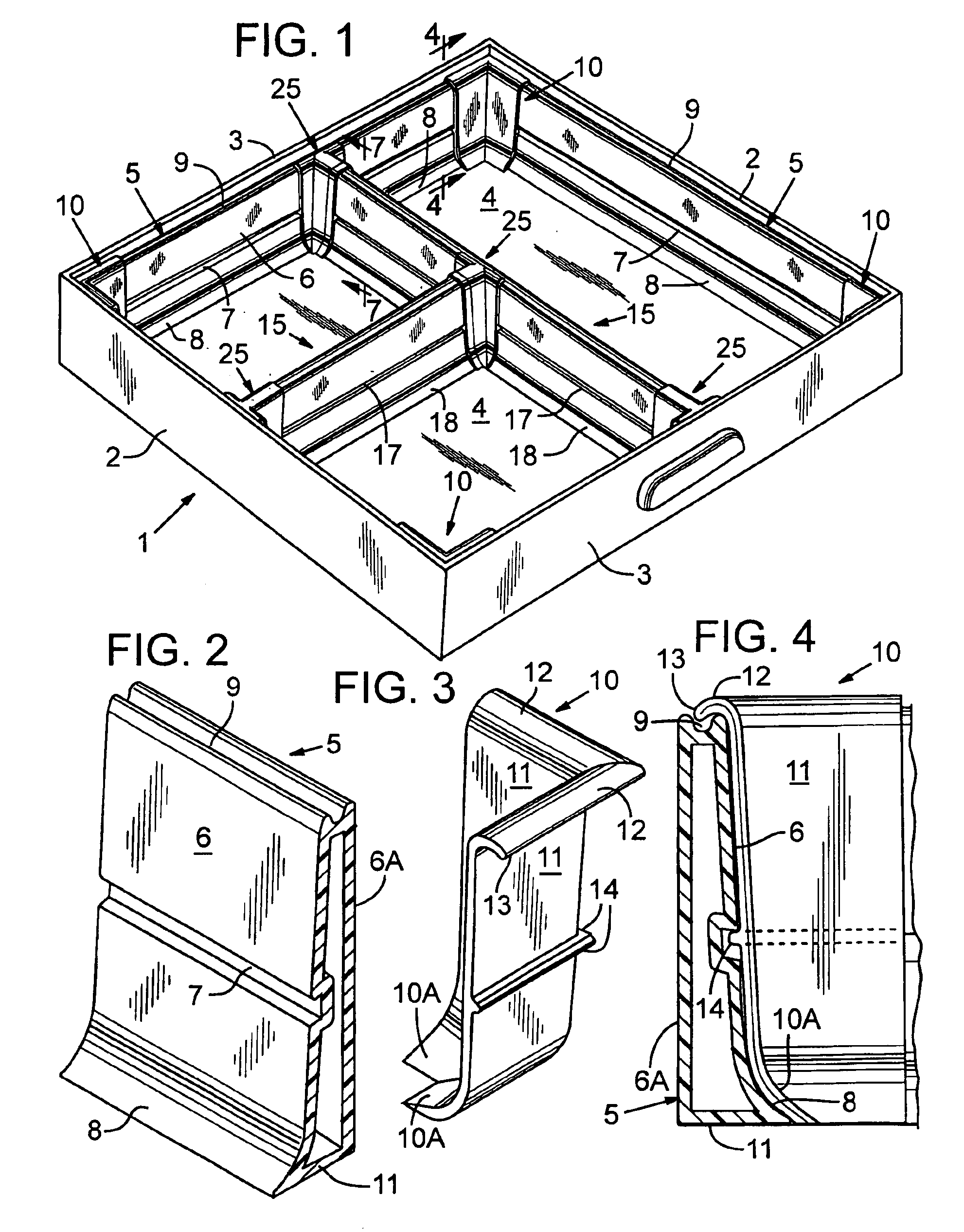

Divider assembly for a drawer

InactiveUS6871921B2Prevent undesired shiftingAvoid separationInternal framesBoxesMechanical engineeringStorage area

A divider assembly for installation in a tool box or chest drawer to provide separate drawer areas for the storage of various grouped articles. Perimeter rails are joined by corner clips to maintain a rectangular shape of the divider assembly. Divider rails extend intermediate perimeter rails to form storage areas of various shapes and sizes. Divider clips receive the divider rail ends. Projections and recesses on the divider clips and the perimeter rail members confine the divider rails against displacement. Flexure of the divider clips permit snapped engagement of the clips with the perimeter rail member.

Owner:ERNST GREGORY R

Variable laminoplasty implant

ActiveUS7264620B2Reducing amount of time and cost to perform operationWide sizeInternal osteosythesisBone implantEngineeringLaminoplasty

A vertebral implant comprising a first base configured for securing to a first cut portion of a vertebra, and second base configured for securing to a second cut portion of the vertebra. A connecting member is configured to associate the first and second bases at a preselected spacing from each other, and the implant is preferable adjustable to select the spacing.

Owner:DEPUY SPINE INC (US)

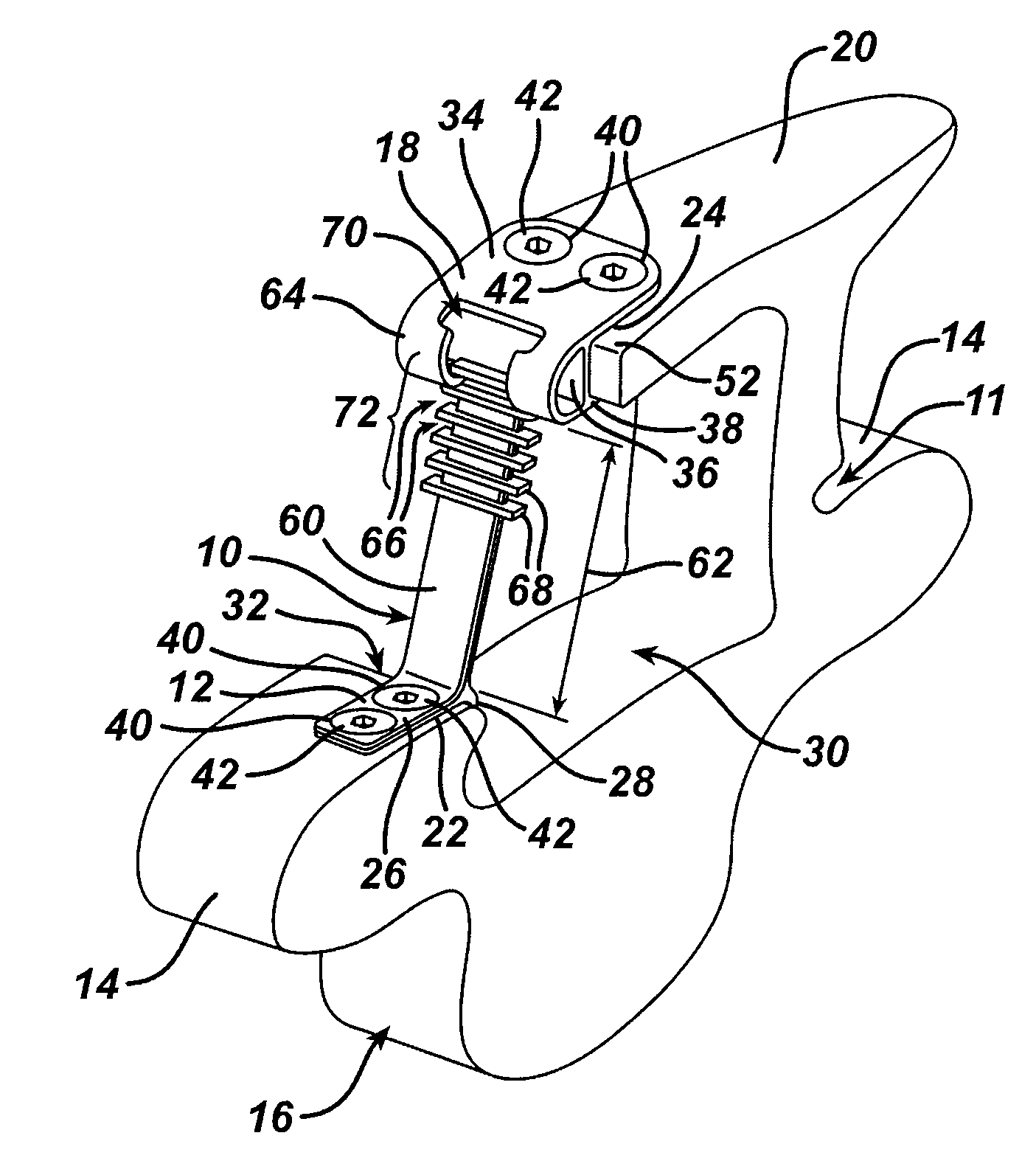

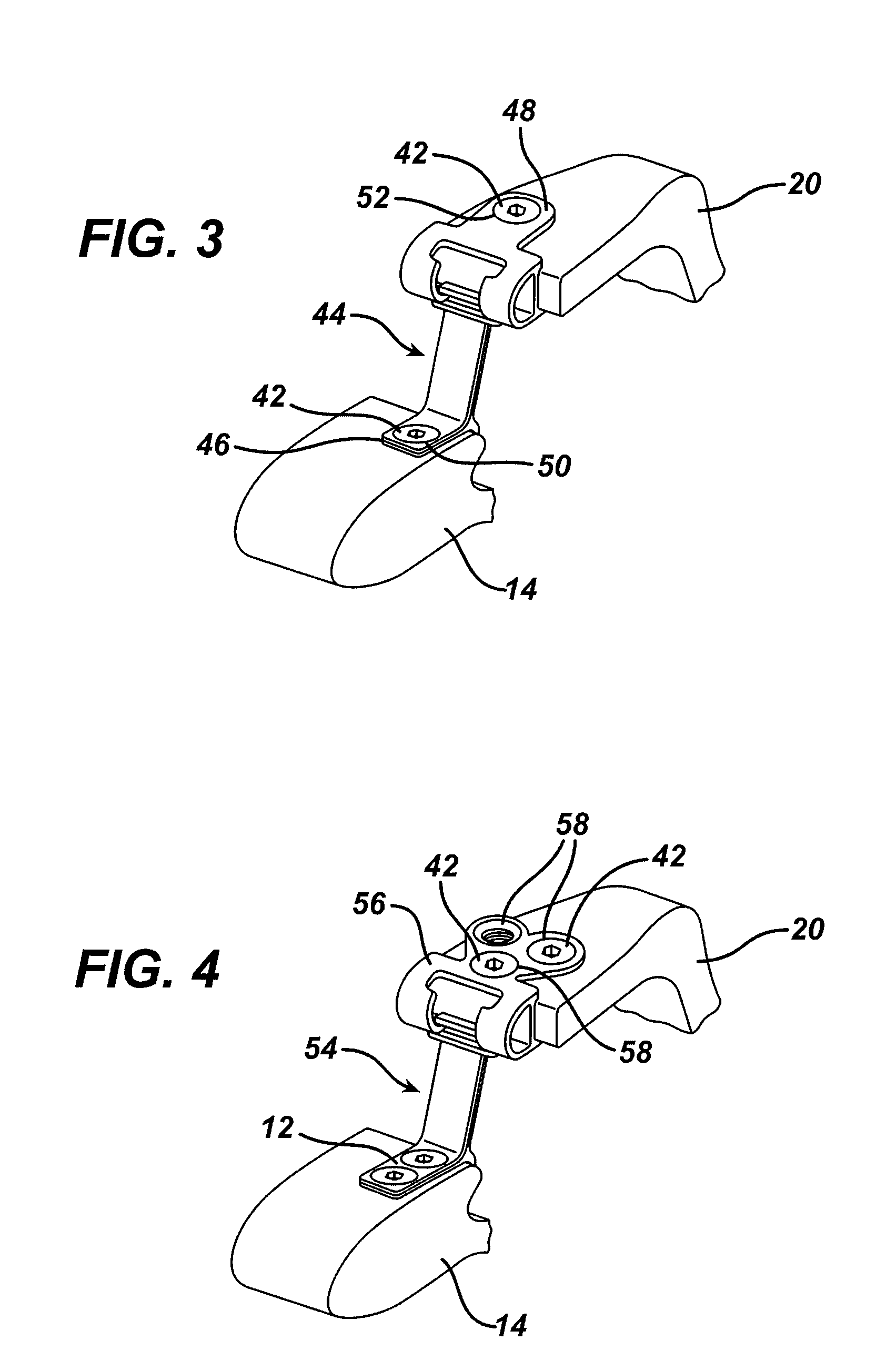

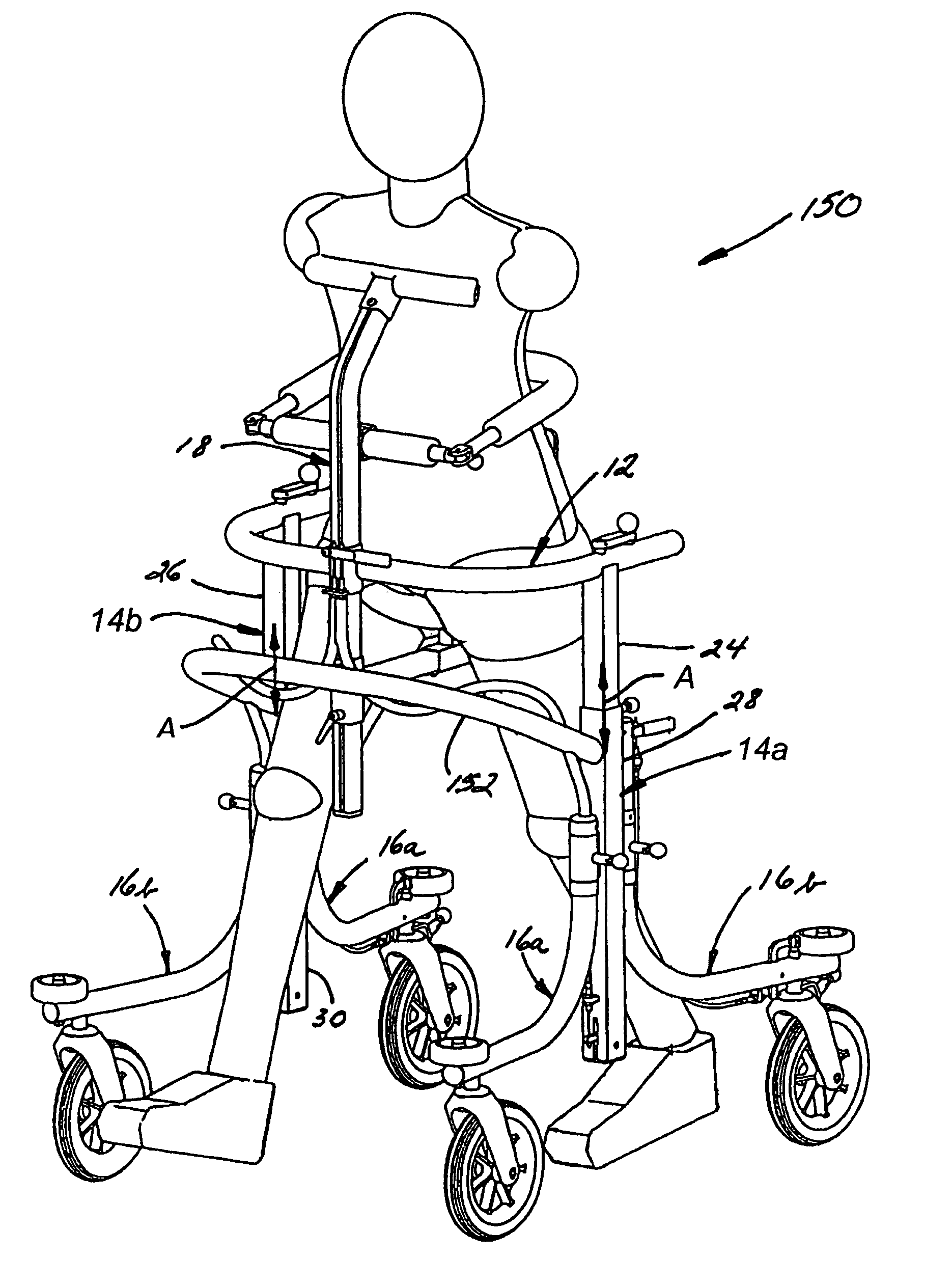

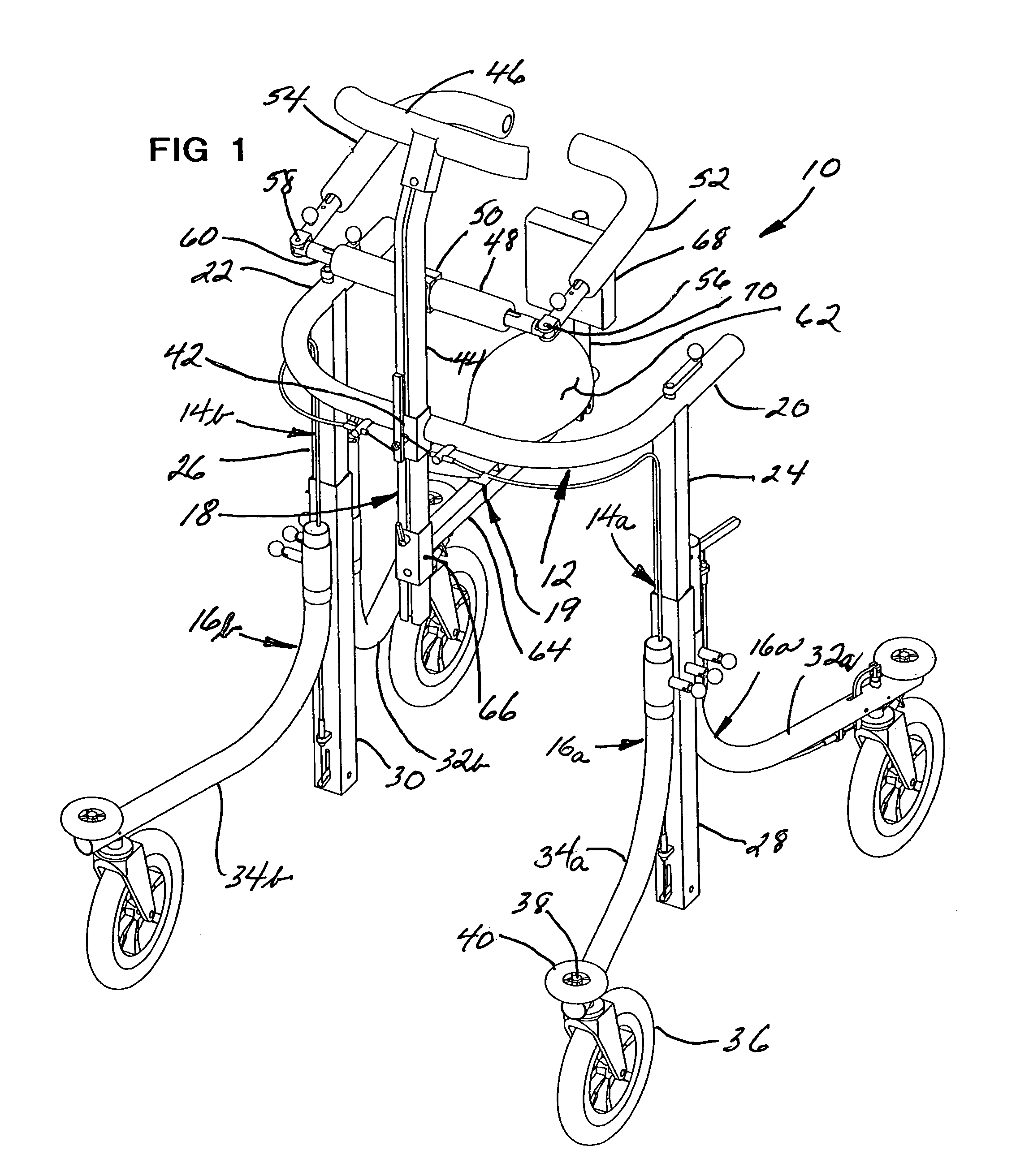

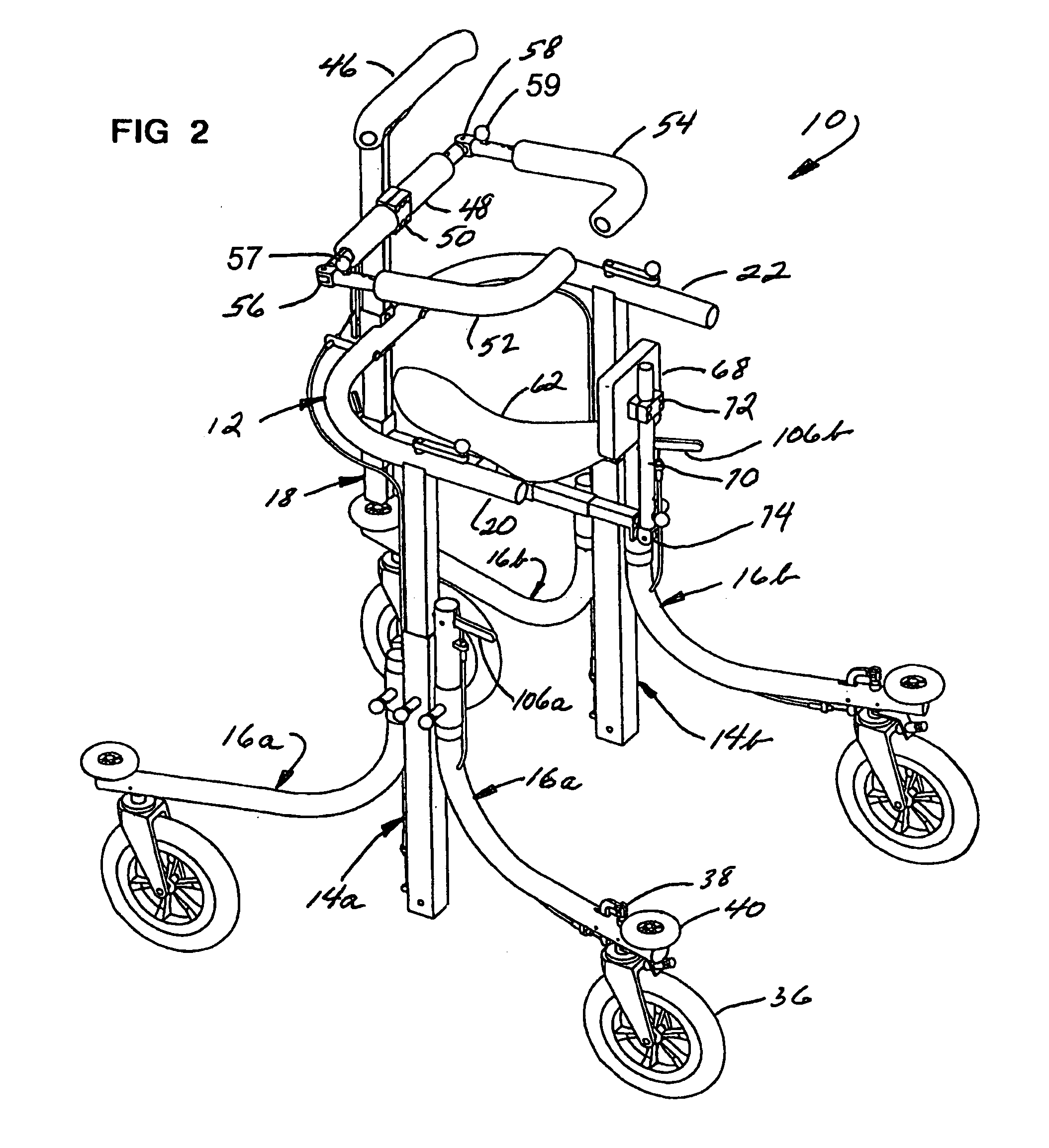

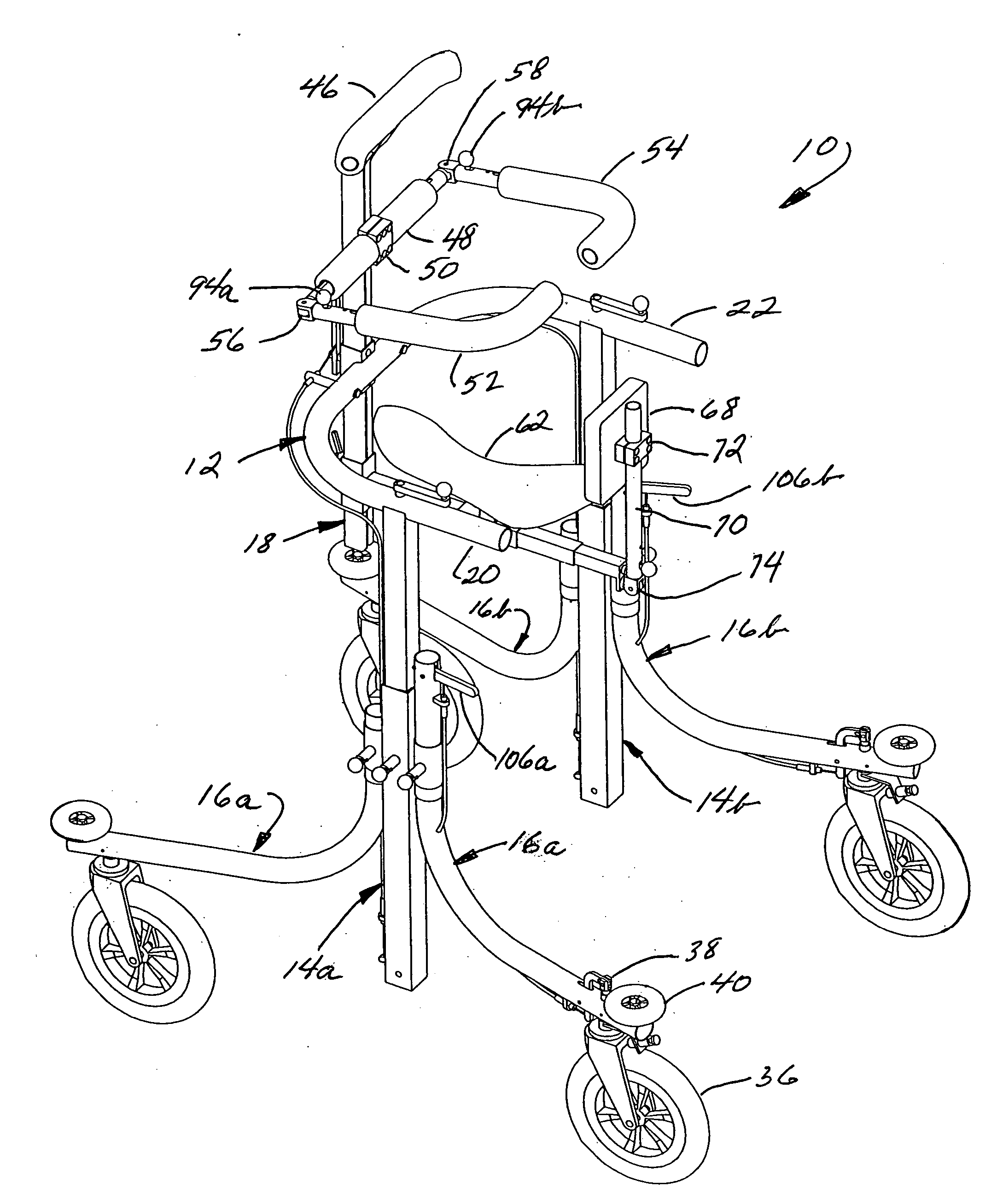

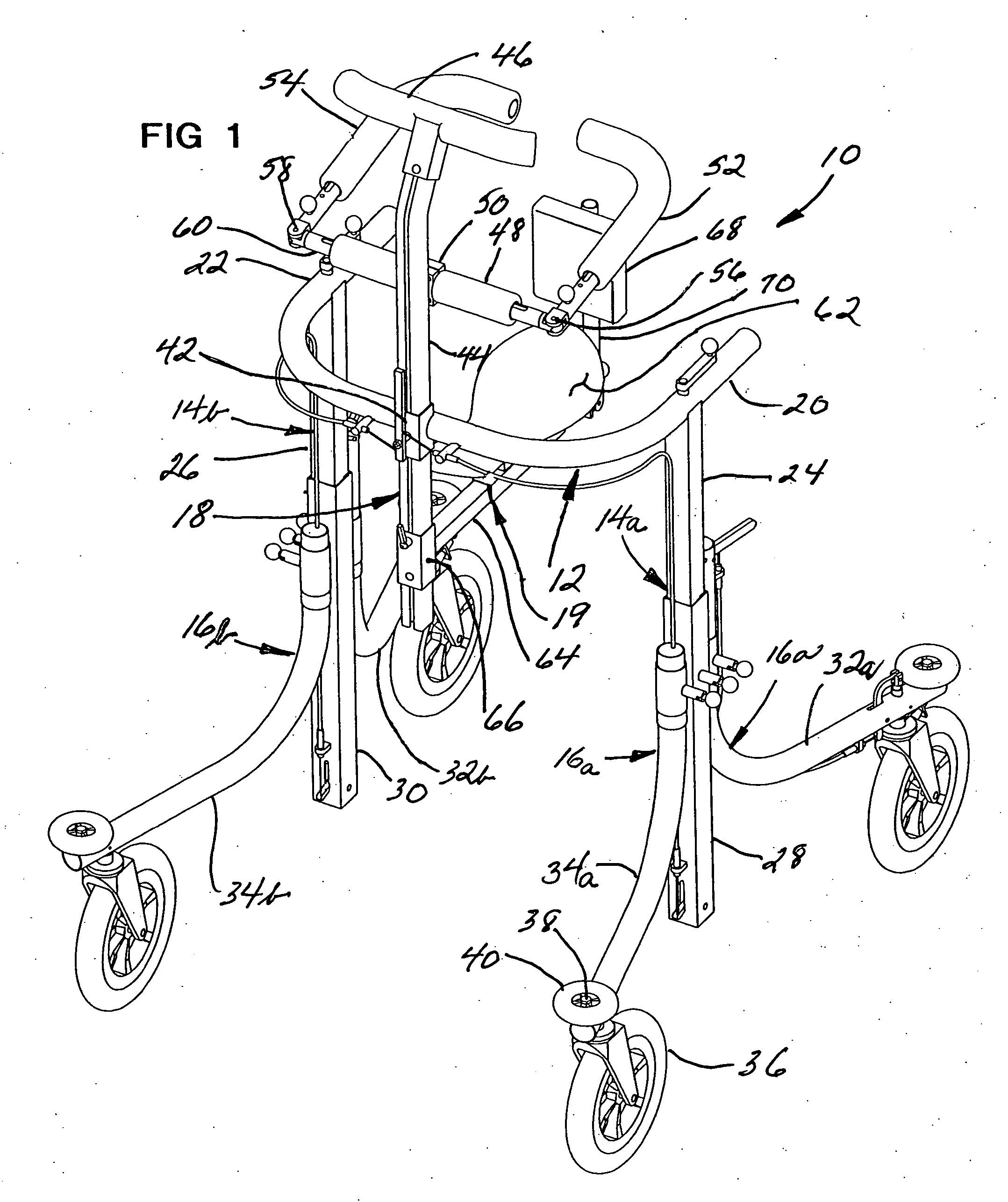

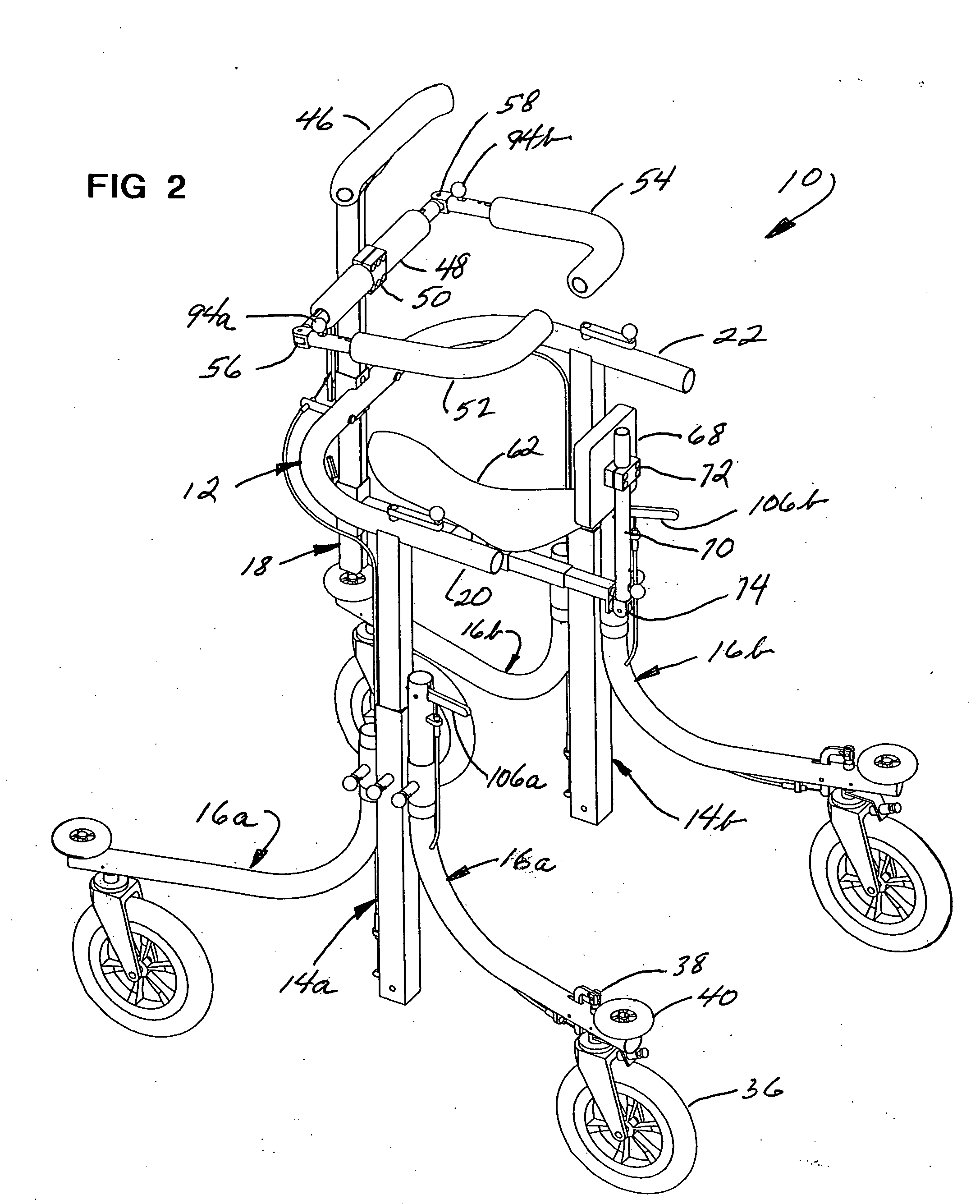

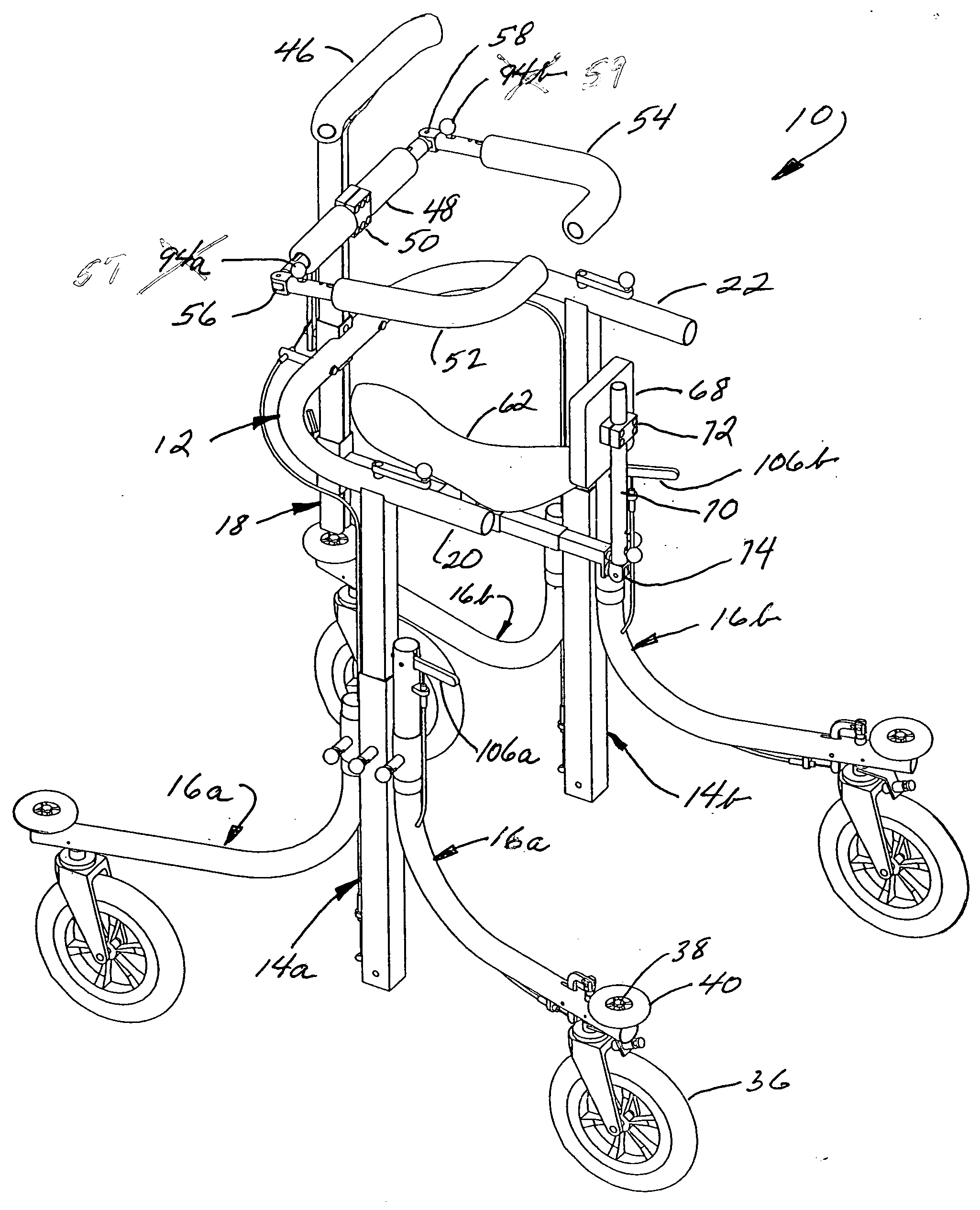

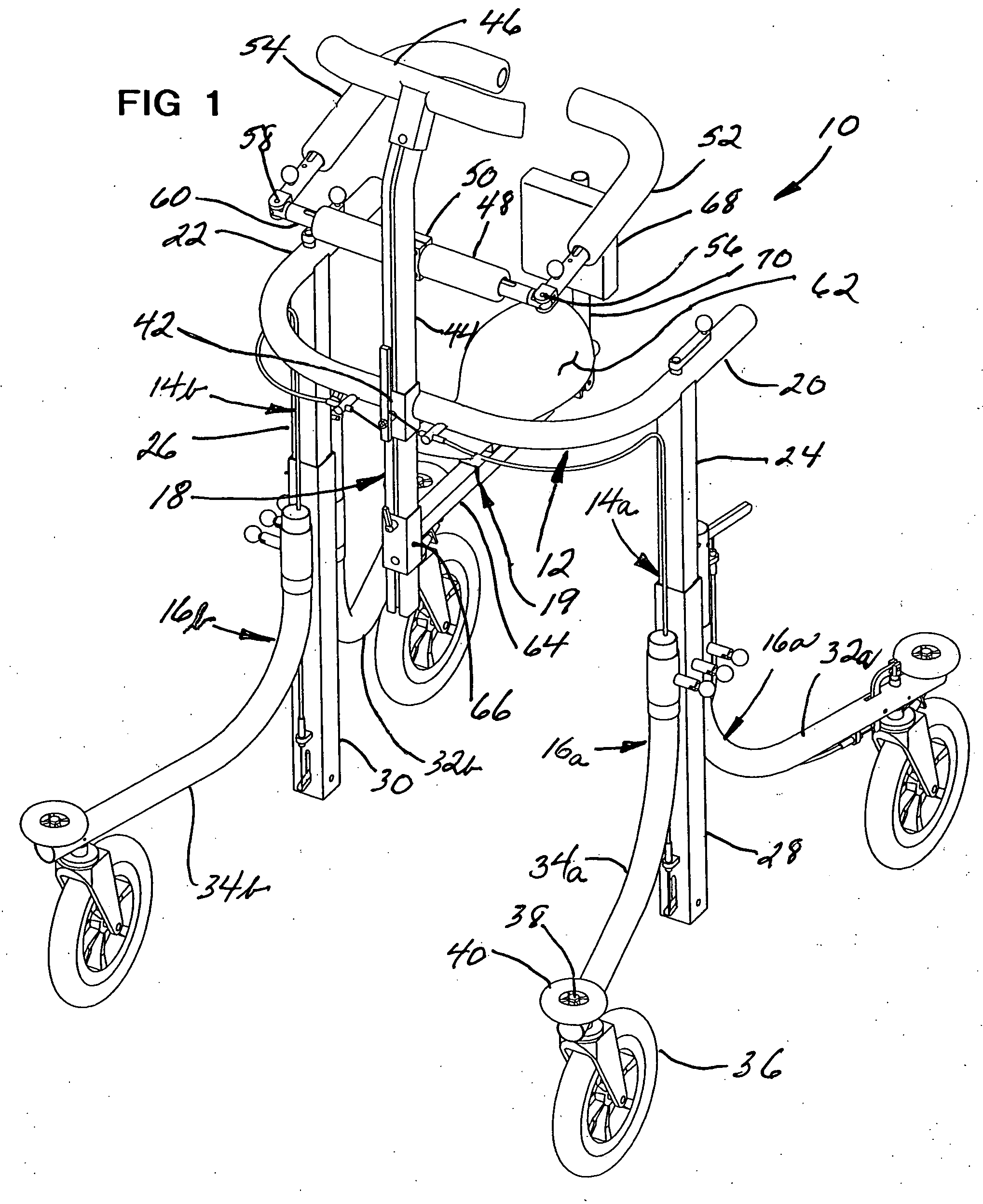

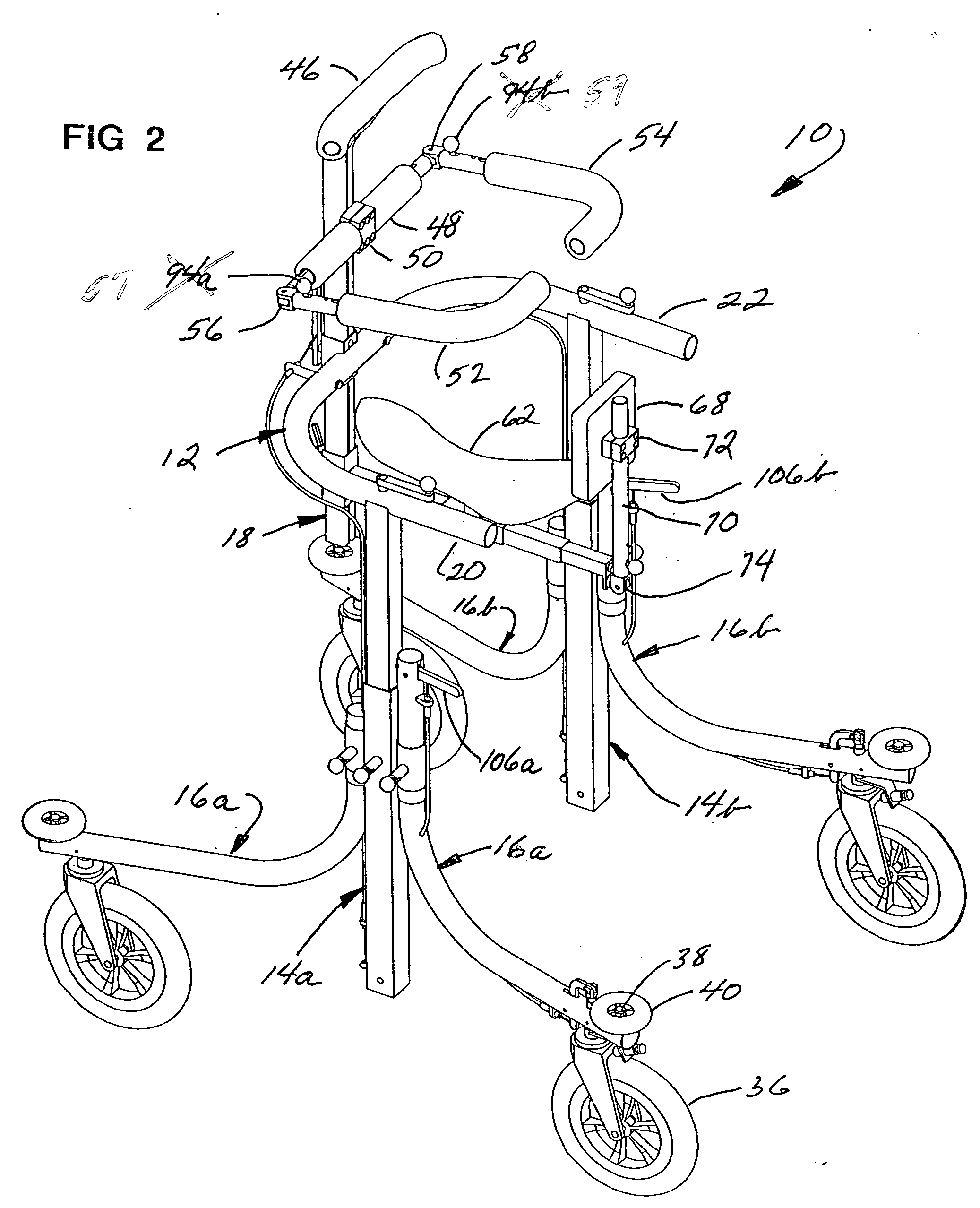

Assistive walking device

An assistive walking rear entry device including a main frame, elongated upright body weight support members connected to each side portion of the main frame and two elongated leg members connected to each body support member one extending forwardly, the other extending rearwardly, each leg member including a rollable member attached to a distal end portion thereof. An elongated seat is attached to and supported on a lower portion of a centerpost, the centerpost being supported on the main frame. Rearwardly opening lateral torso supports are attached to the upper portion of the centerpost and make supporting contact with the thoracic area and for propelling the device during a walking gait. The seat is positioned against the perennial region to support the pelvis and to help propel the device on a “hands free” basis. The body weight support members are preferably multi-function for body weight support during a walking gait and preferably are tied together by a cross member to insure identical side-to-side displacement.

Owner:MULLHOLAND LARRY

Assistive walking device

An assistive walking rear entry device including a main frame, elongated upright body weight support members connected to each side portion of the main frame and two elongated leg members connected to each body support member one extending forwardly, the other extending rearwardly, each leg member including a rollable member attached to a distal end portion thereof. An elongated seat is attached to and supported on a lower portion of a centerpost, the centerpost being supported on the main frame. Rearwardly opening lateral torso supports are attached to the upper portion of the centerpost and make supporting contact with the thoracic area and for propelling the device during a walking gait. The seat is positioned against the perennial region to support the pelvis and to help propel the device on a “hands free” basis. The body weight support members are preferably multi-function for body weight support during a walking gait and preferably are tied together by a cross member to insure identical side-to-side displacement.

Owner:MULLHOLAND LARRY

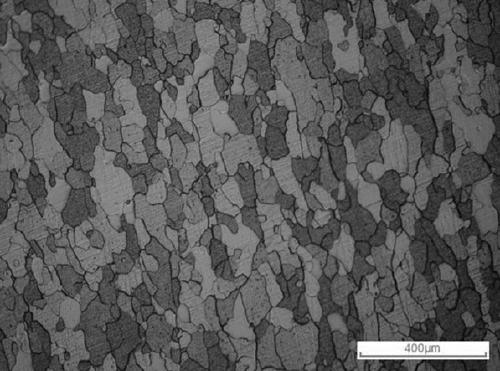

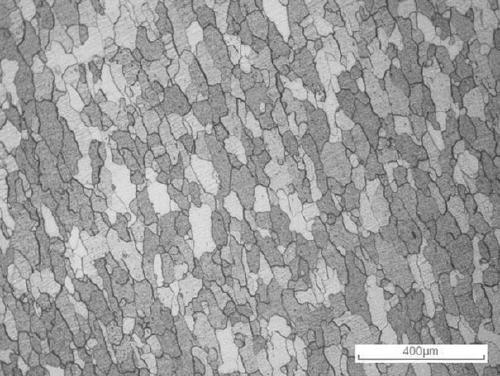

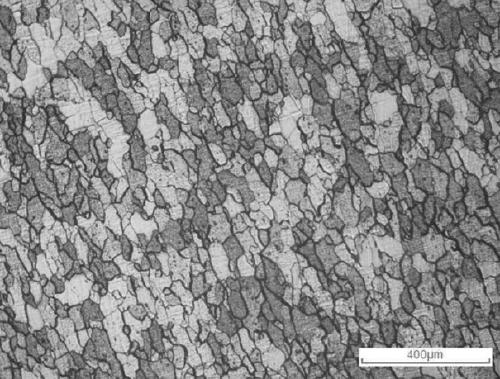

Process for manufacturing high-density molybdenum-niobium alloy sputtering target material

InactiveCN110257784ALow oxygenHigh purityVacuum evaporation coatingSputtering coatingVolumetric Mass DensityMixed materials

The invention belongs to the field of manufacturing high-temperature refractory metal target materials, and particularly relates to a process for manufacturing a high-density molybdenum-niobium alloy sputtering target material. The process comprises the steps of mixing raw materials; loading mixed material powder in a rubber sleeve; performing cold isostatic pressing operation, after the pressure is increased to a certain pressure, maintaining the pressure for a period of time, then depressurizing, and finally taking out a pressed blank from the rubber sleeve; carrying out vacuum sintering or hydrogen protection sintering; carrying out hot isostatic pressing operation directly on the sintered blank; performing hot rolling operation, namely performing metal sleeve rolling on a molybdenum-niobium alloy, and annealing after hot rolling to remove stress; and carrying out machining operations such as grinding to obtain the final required product size. The process is simple in processing steps and convenient to operate, the purity and the relative density of the manufactured molybdenum-niobium alloy sputtering target material all meet the use requirements in the film coating field of high-end electronic products; and the process is low in production cost, wide in production size range, and convenient for industrial batch production.

Owner:LUOYANG SIFON ELECTRONICS

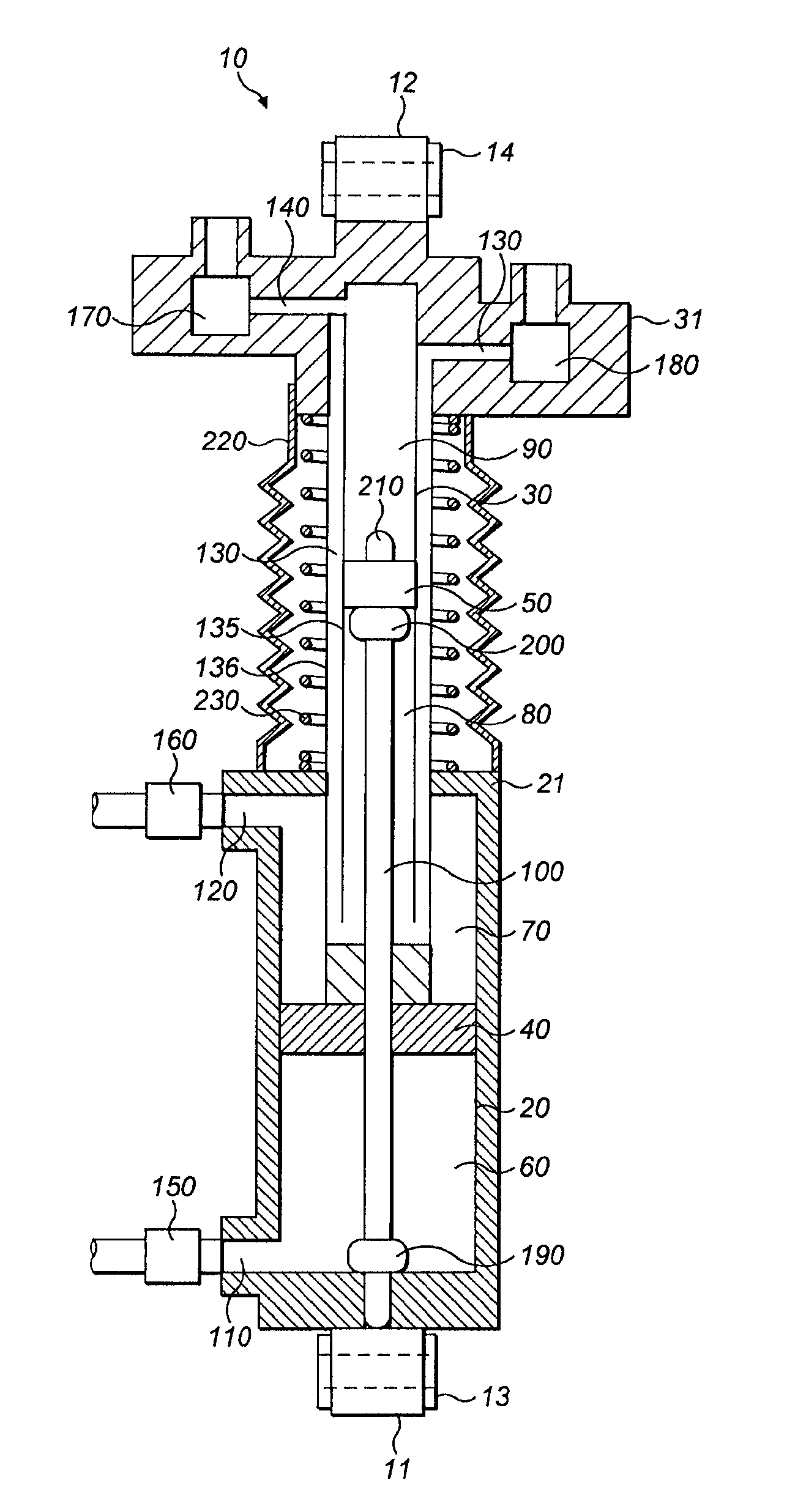

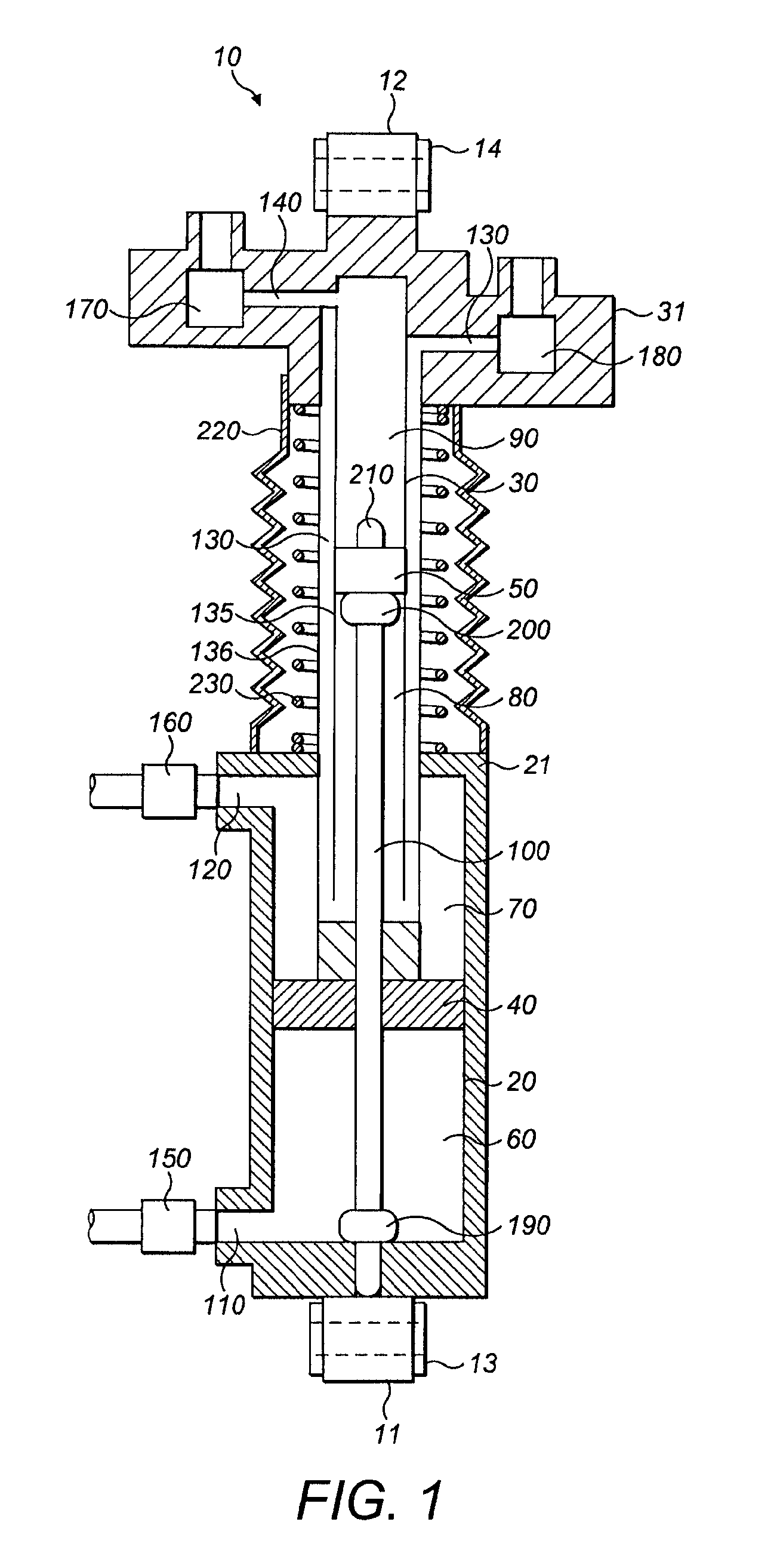

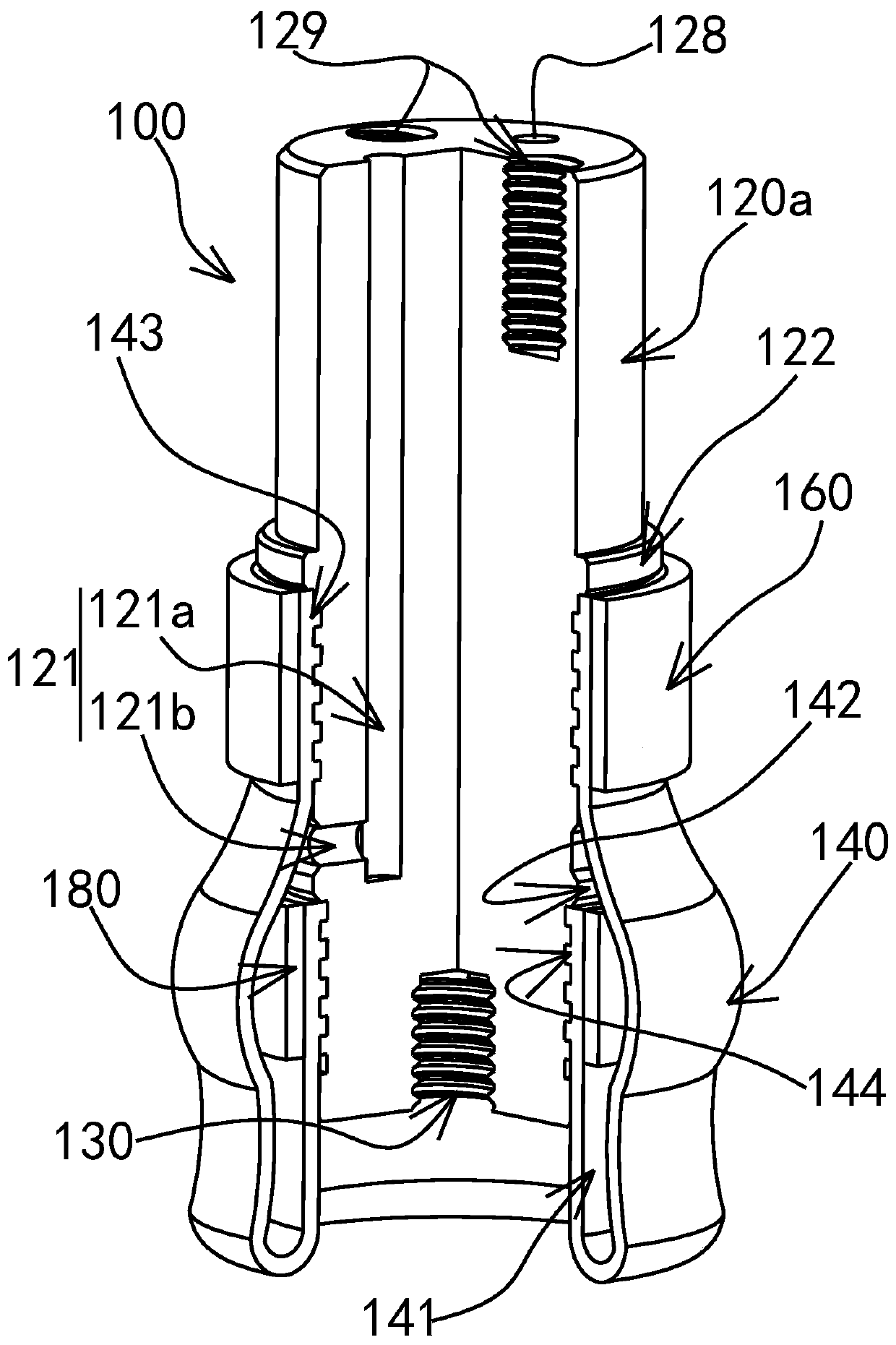

Damper unit

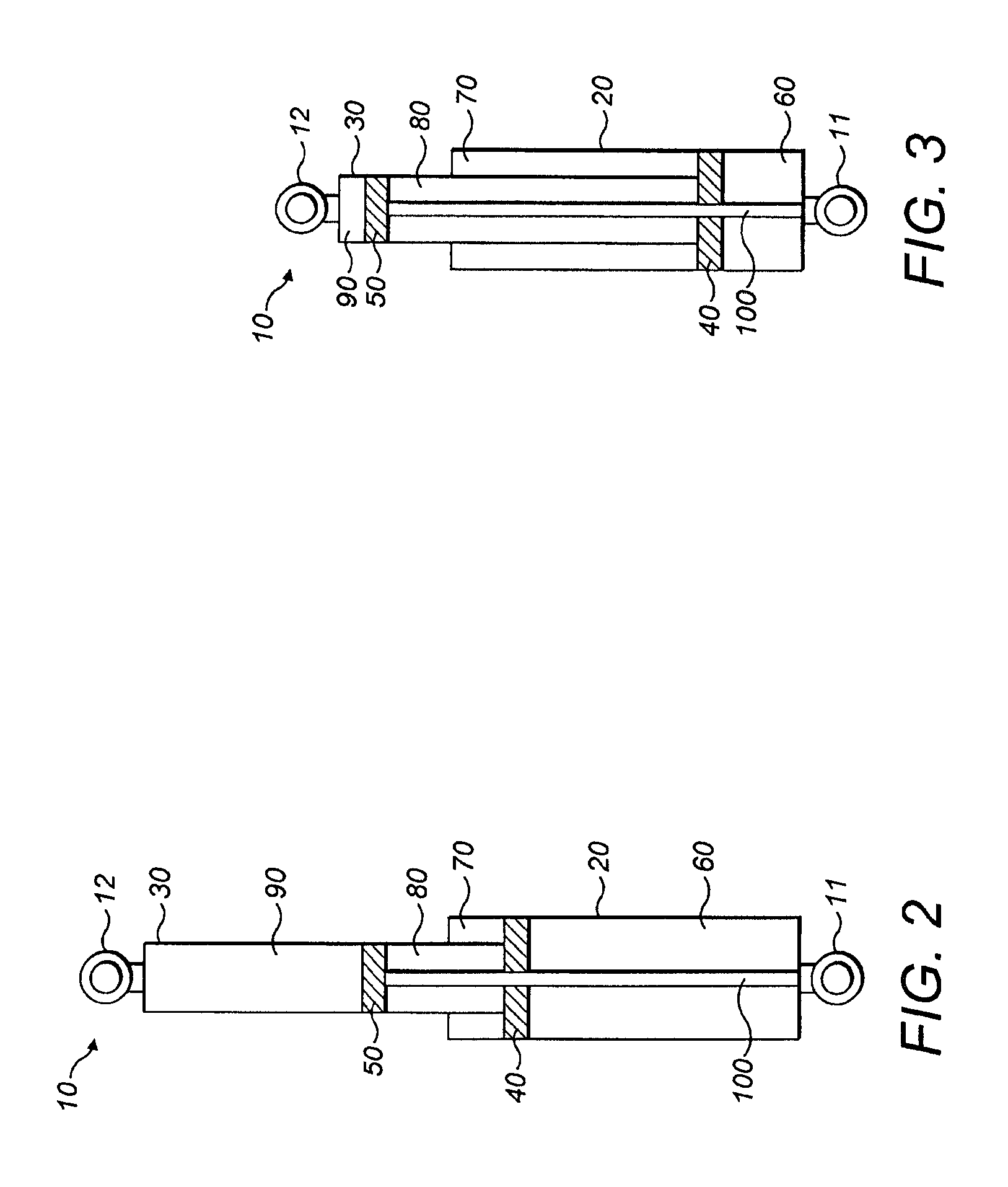

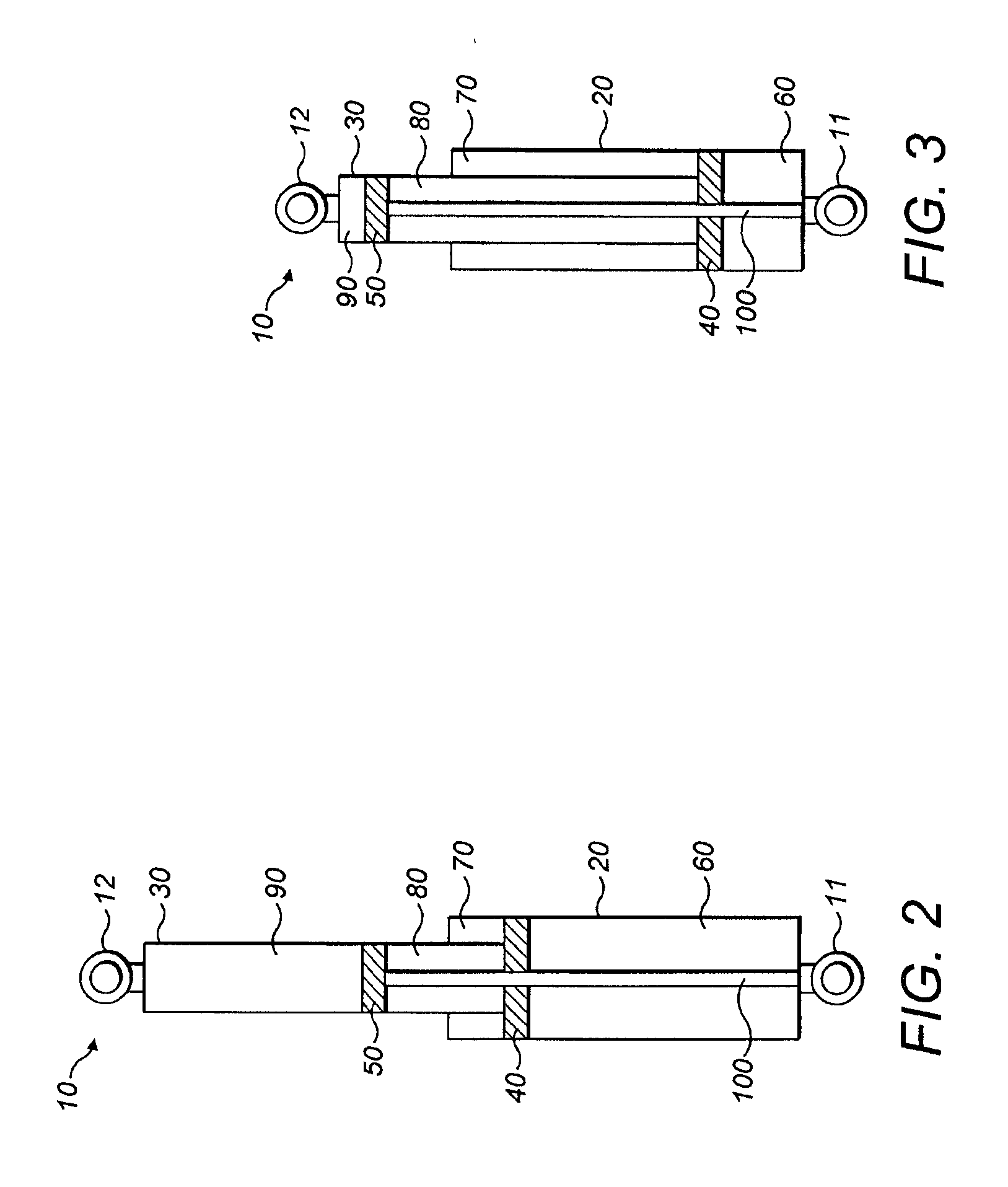

ActiveUS9080631B2Improve vehicle qualitySmooth connectionRace vehiclesLiquid based dampersEngineeringMechanical engineering

A damper unit includes first and second chambers, a first piston dividing the first chamber into first and second volumes, and a second piston dividing the second chamber into third and fourth volumes. Each piston is moveable along the respective chamber. The second chamber has a cross-sectional area that is smaller than the cross-sectional area of the first chamber so that the second chamber at least partially slides inside the first chamber and at least part of the first chamber can be located around the outside of the second chamber. The first piston is attached to the part of the second chamber that slides inside the first chamber. The position of the second piston is fixed relative to the first chamber as the second chamber slides relative to first chamber. The length of the damper unit changes as the second chamber slides relative to the first chamber.

Owner:MCLAREN AUTOMOTIVE

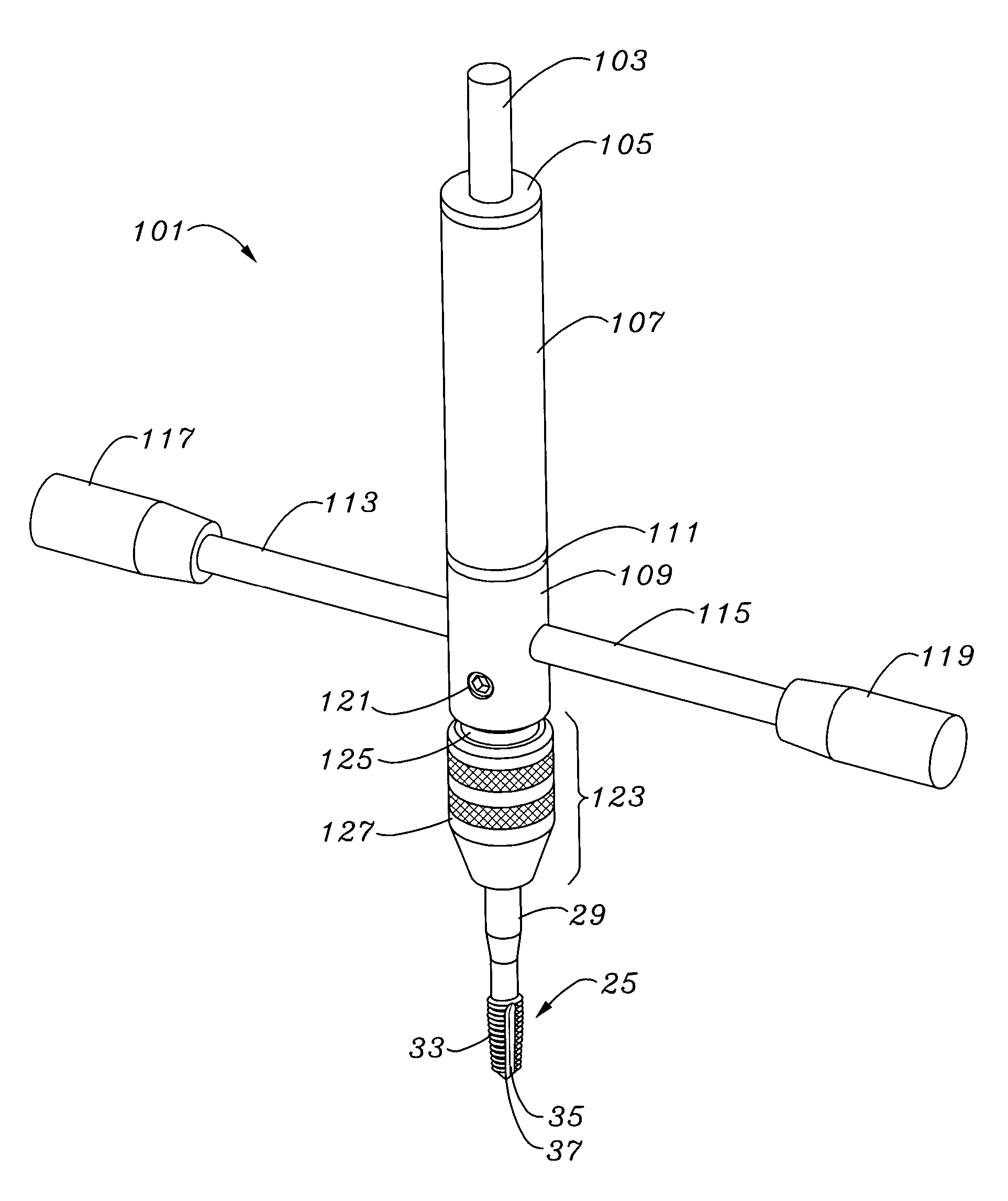

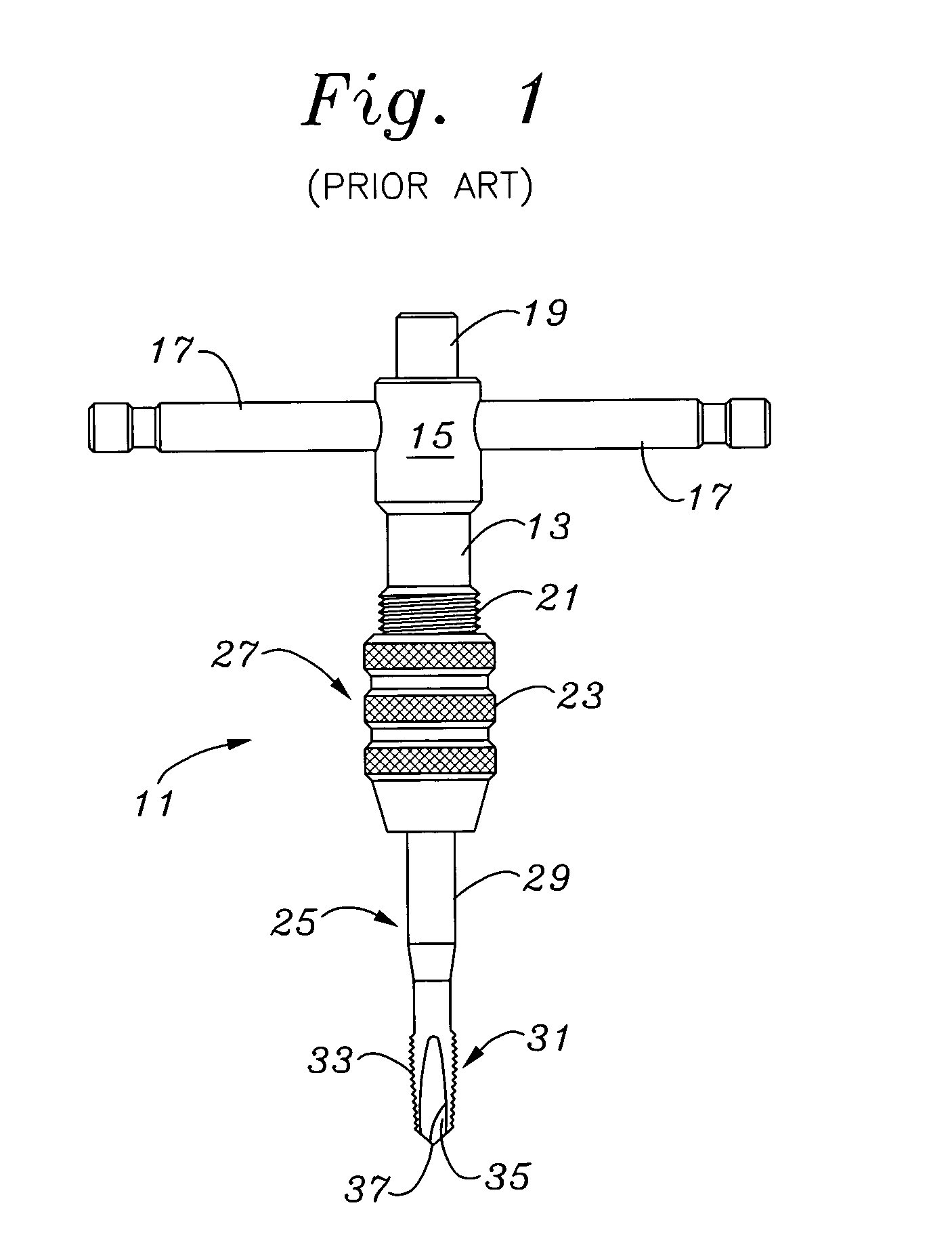

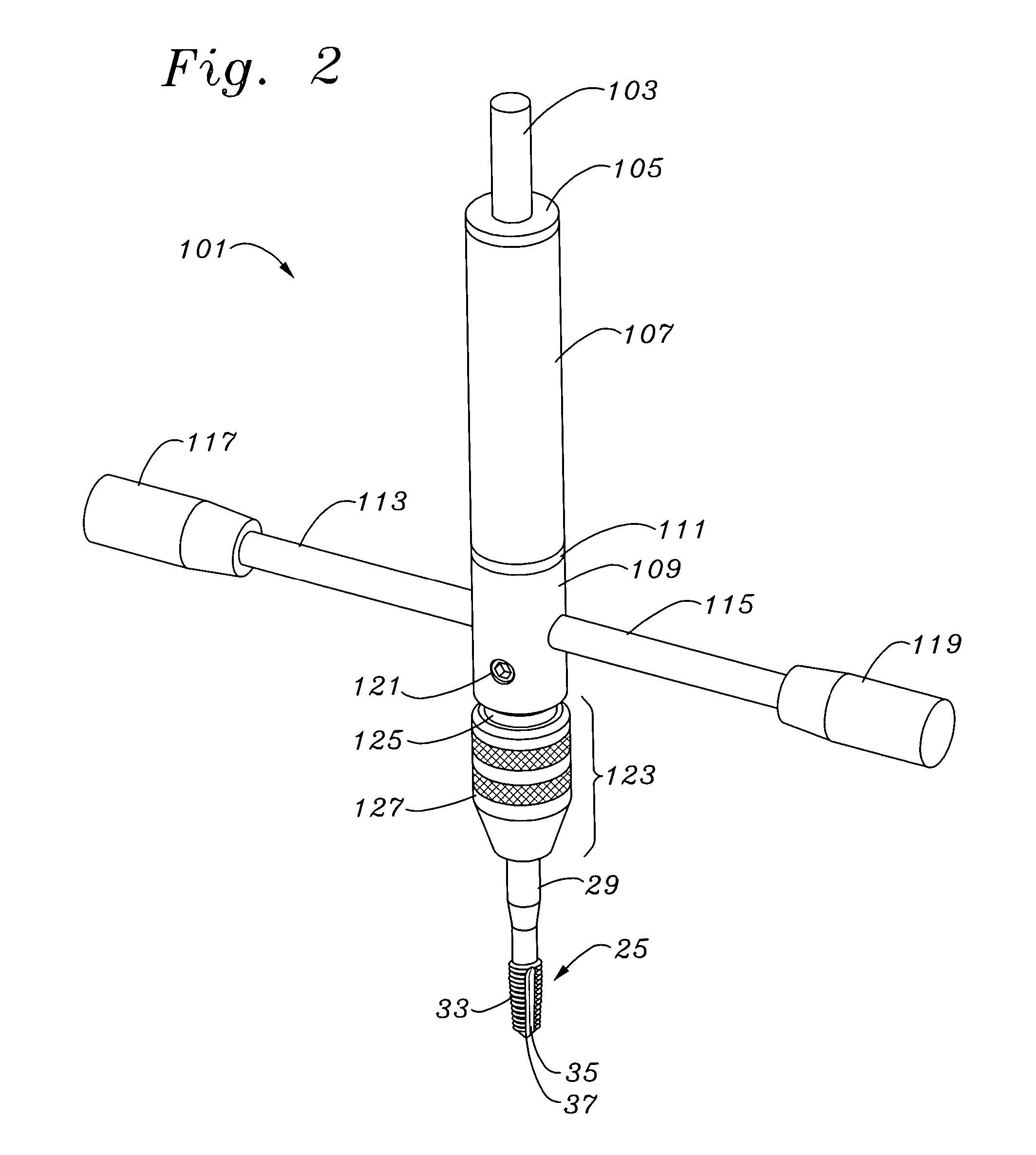

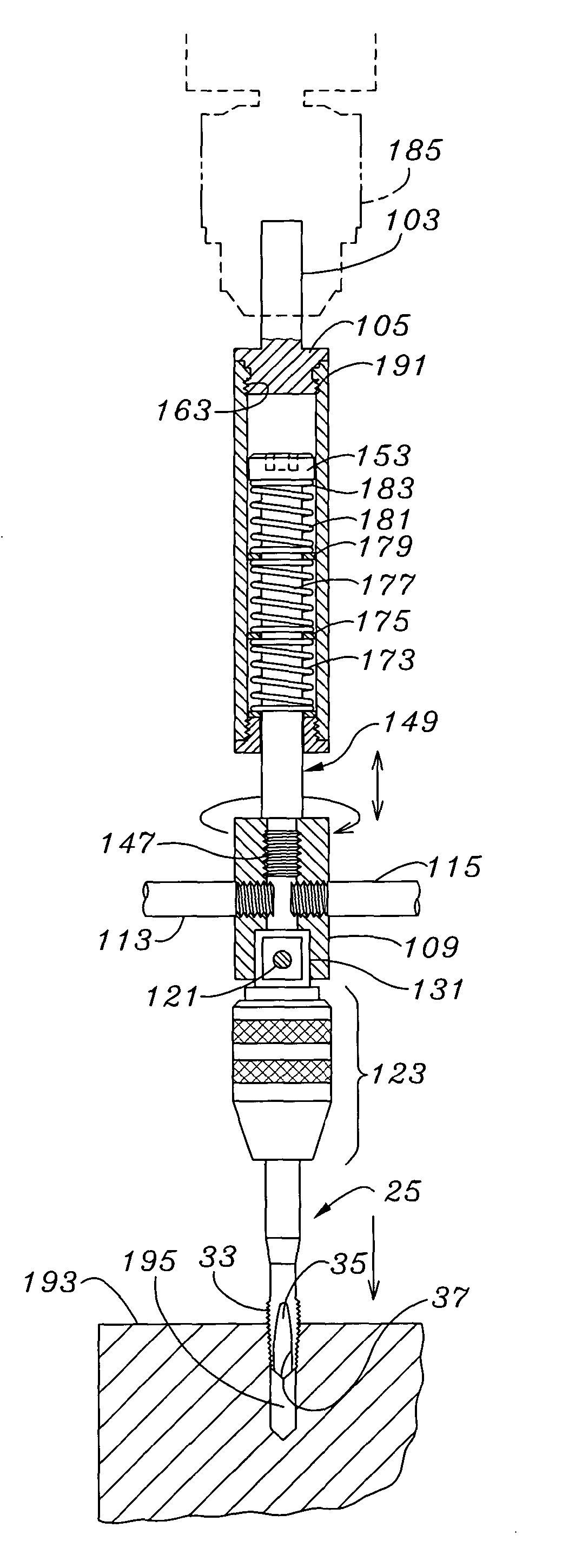

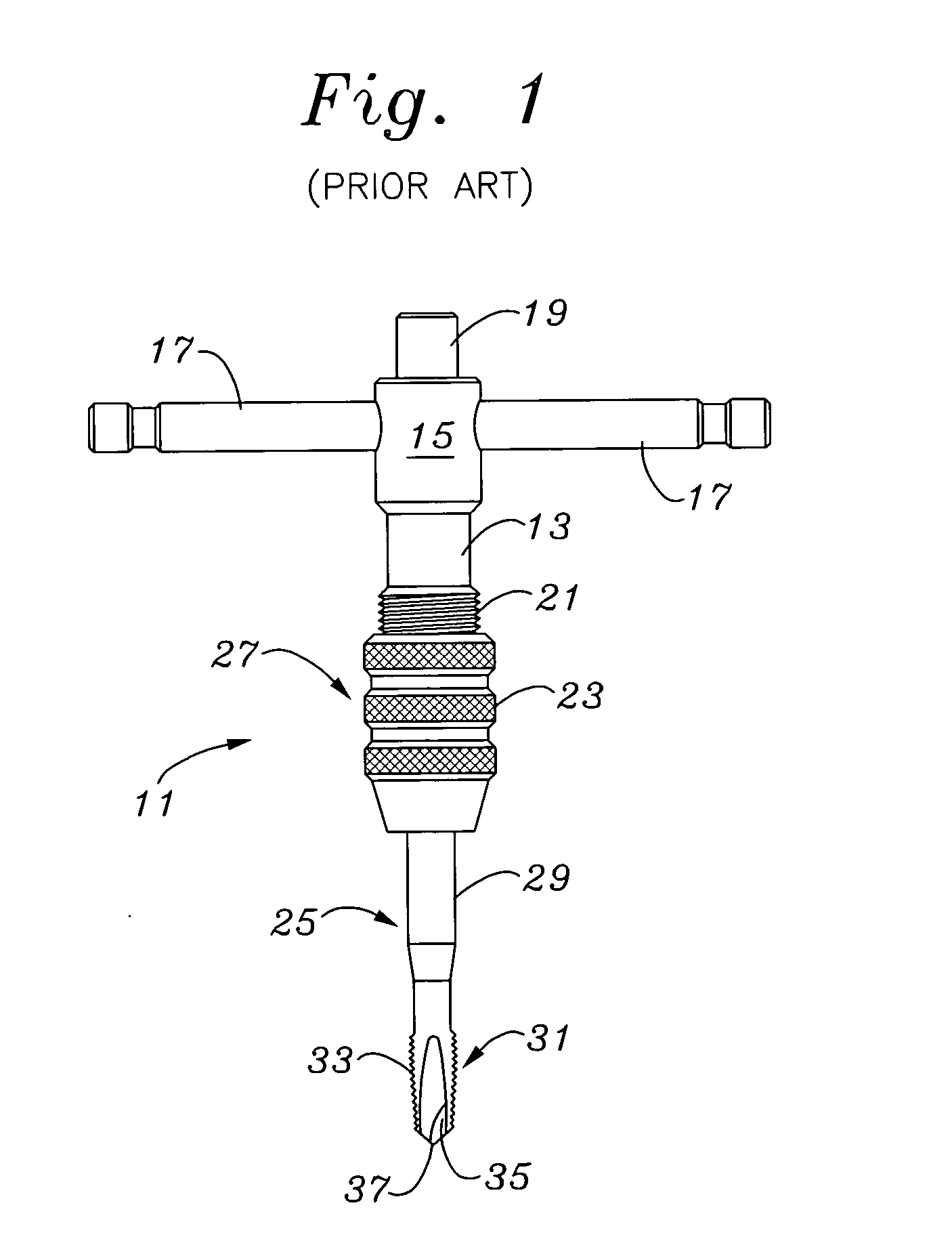

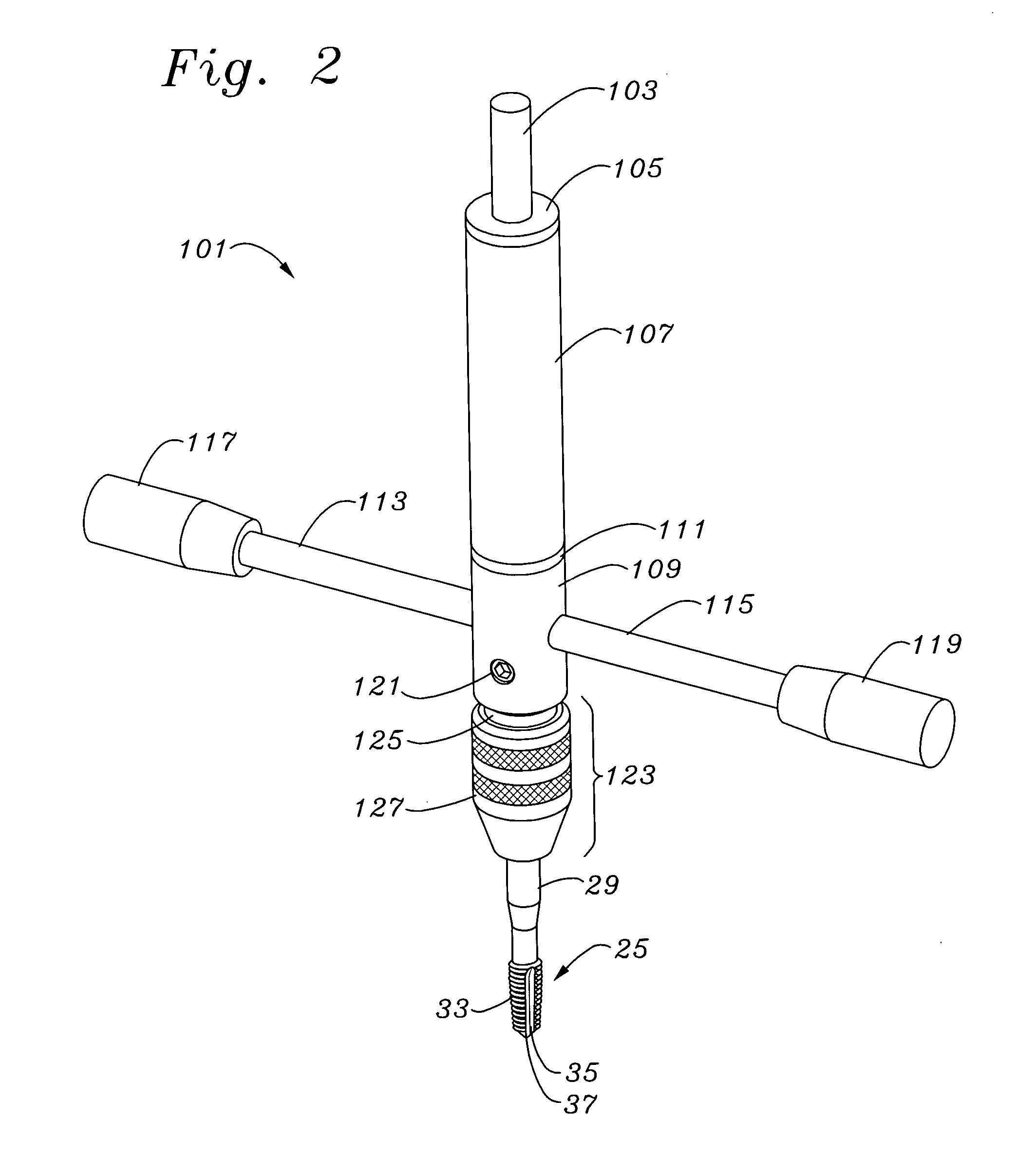

Tapping tool for use with drill press

InactiveUS6997654B2Easy to useWide sizeThread cutting machinesTransportation and packagingMechanical advantageDrilling machines

Owner:BLICK JOHN

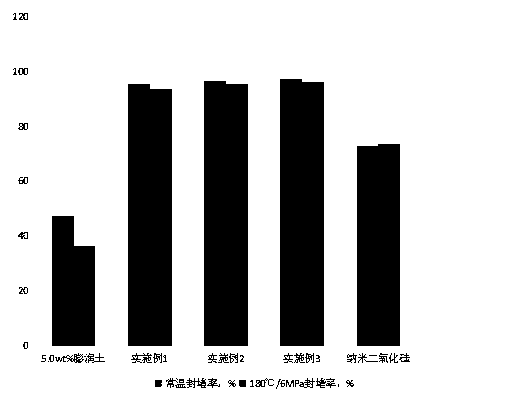

Nanofiber compound-based shale formation blocking agent for drilling fluid and preparation method

ActiveCN109810678AEffective blockingSimple methodDrilling compositionMicro nanoAcute toxicity testing

The invention relates to a nanofiber compound-based shale formation blocking agent for drilling fluid and a preparation method. The blocking agent is prepared from the following raw materials: bagasse, a dispersant, nano silica, nano graphite and deionized water. A nanofiber compound method is adopted to form the efficient blocking agent for effectively blocking nano pores and micro-nano cracks bycompounding various types of nano particles, the method is simple and reliable, and the prepared shale blocking agent has little influence on the performance of the drilling liquid, but has an obvious shale blocking effect. The blocking rate of base mud added with the amount of 3.0 percent by weight of a nanofiber compound in a shale core exceeds 96%, while under the conditions of high temperature and high pressure (180 DEG C / 6MPa), the blocking capacity remains basically unchanged (higher than 93%), and the treatment agent is non-toxic, has no adverse effects on environment, has acute toxicity EC50 which is greater than 60000, and is an efficient shale blocking agent.

Owner:CHINA PETROCHEMICAL CORP +3

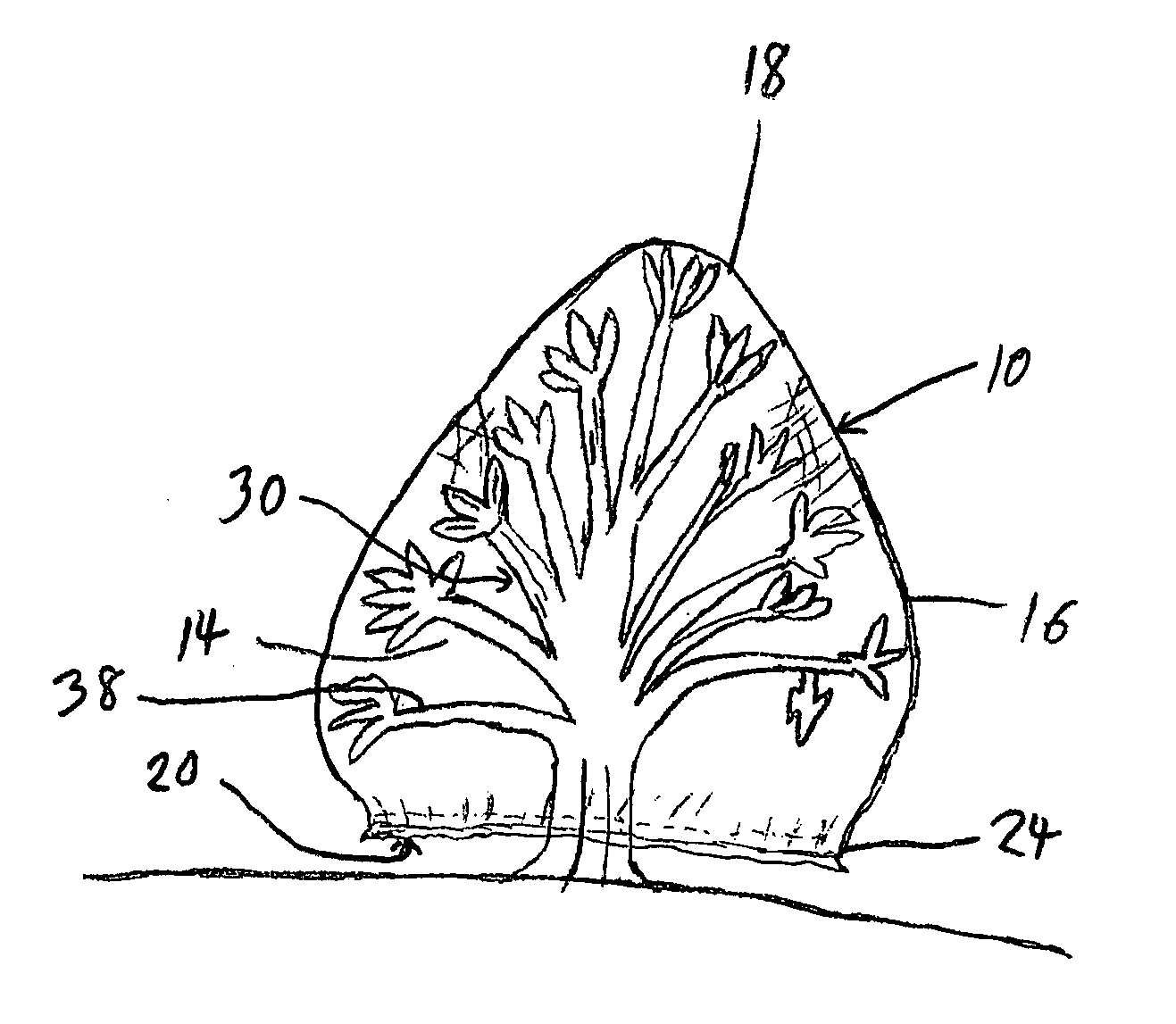

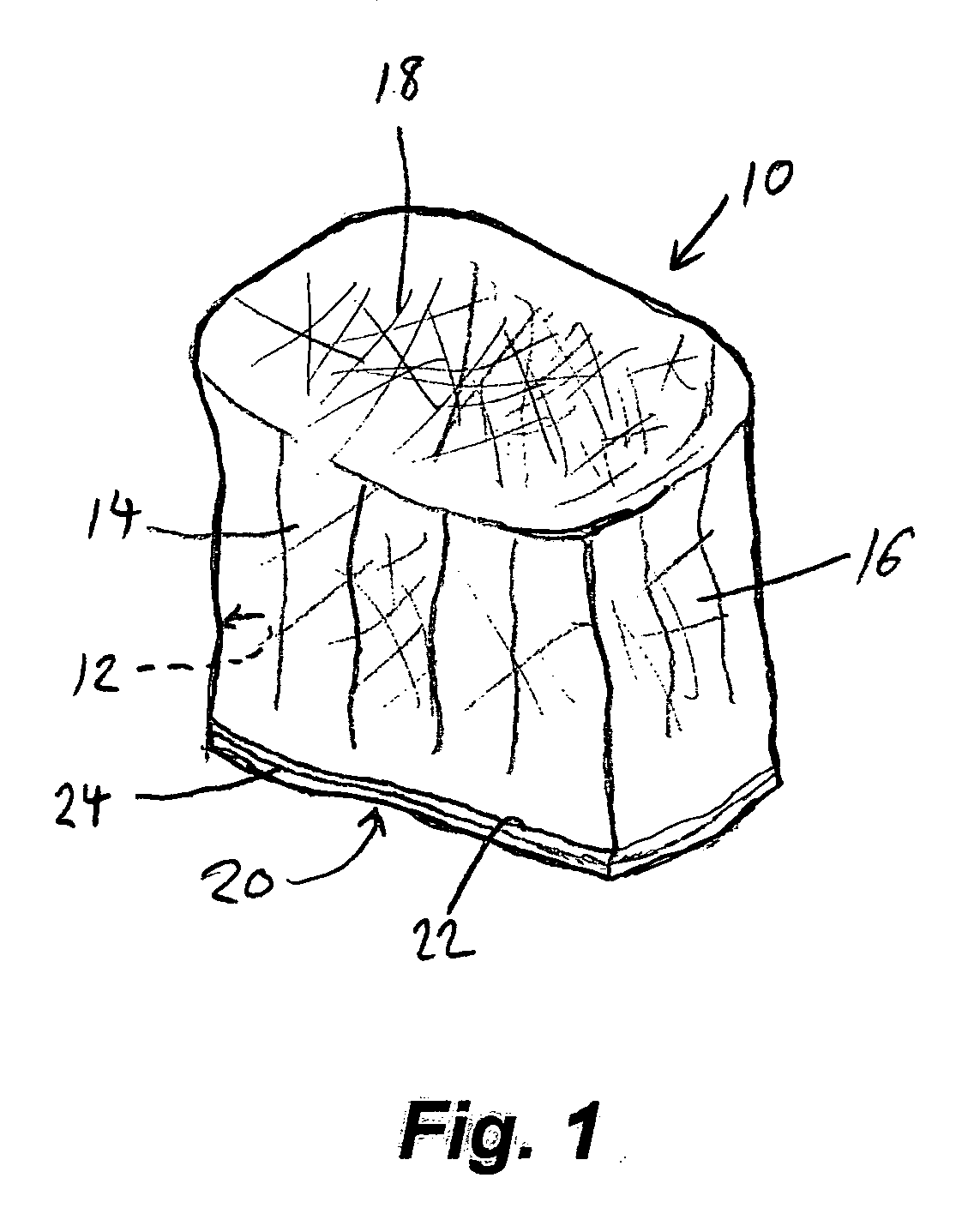

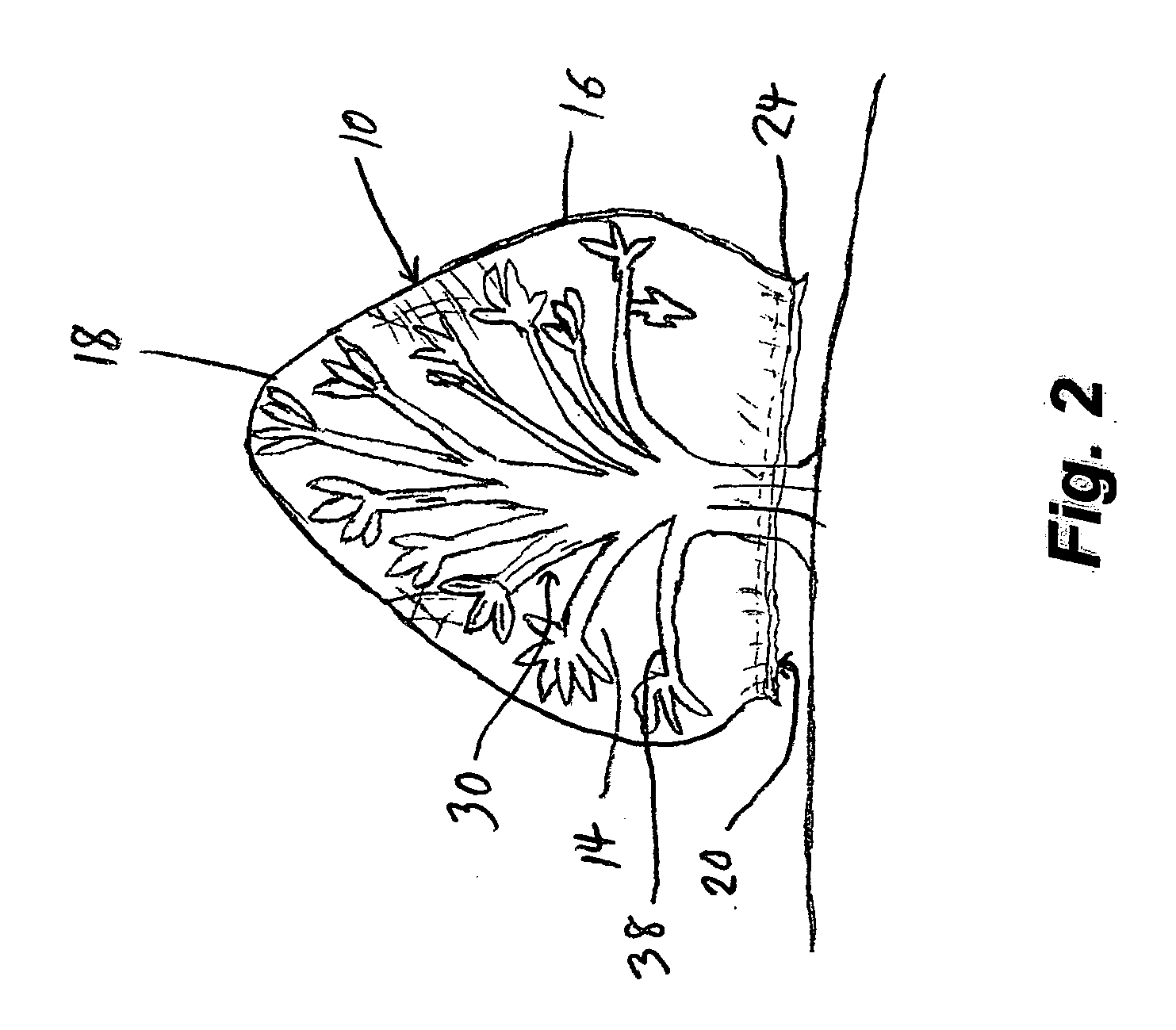

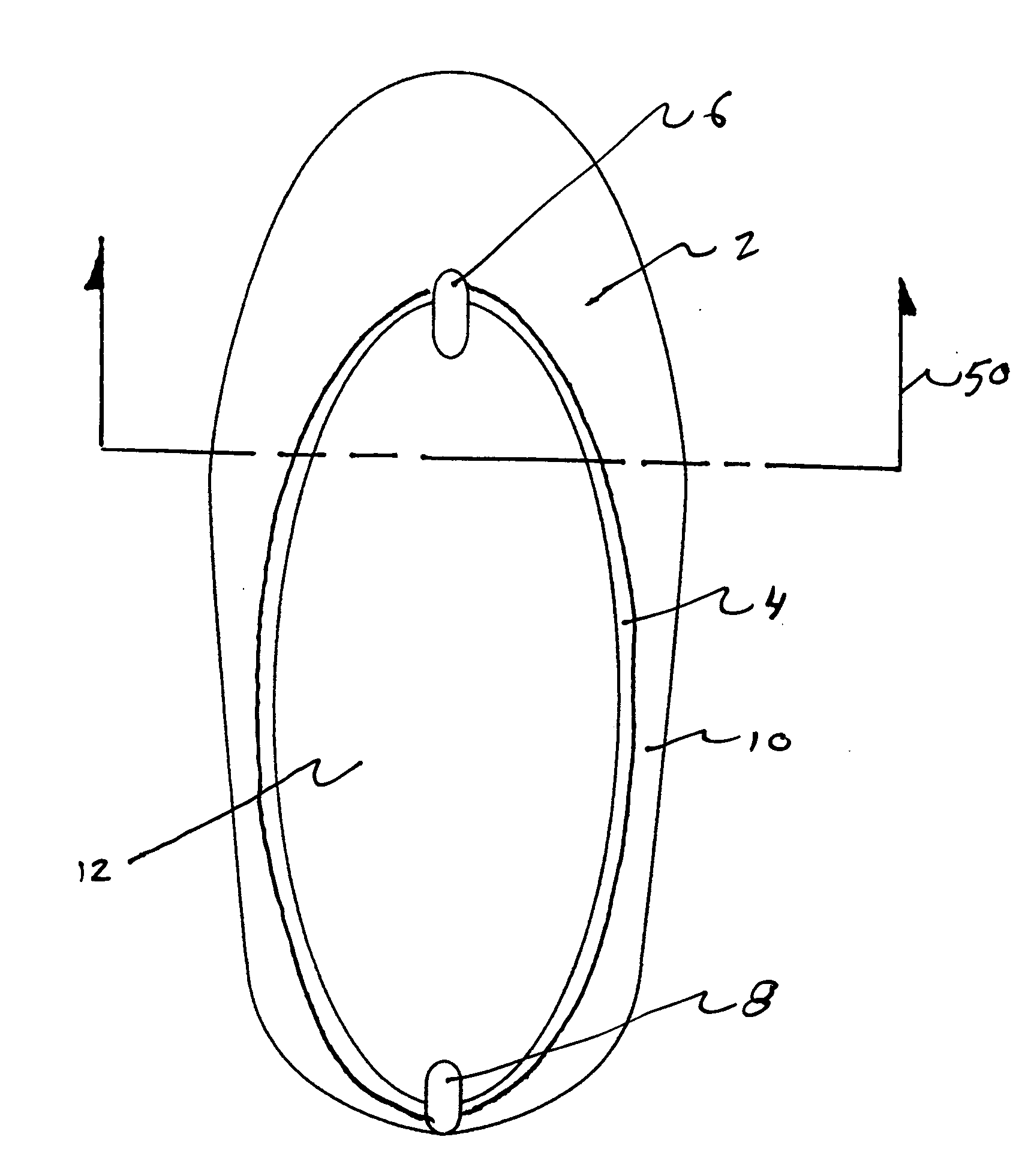

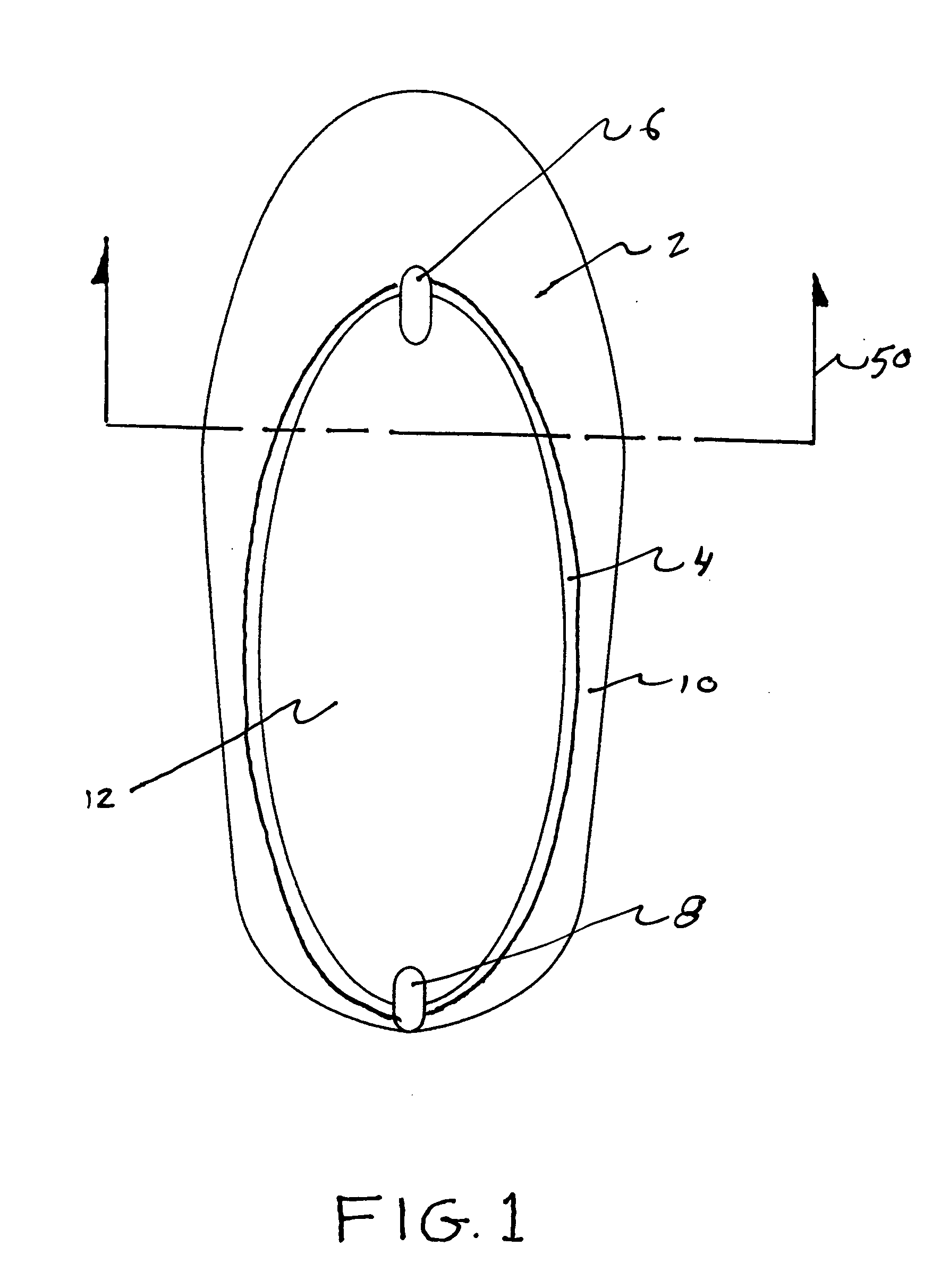

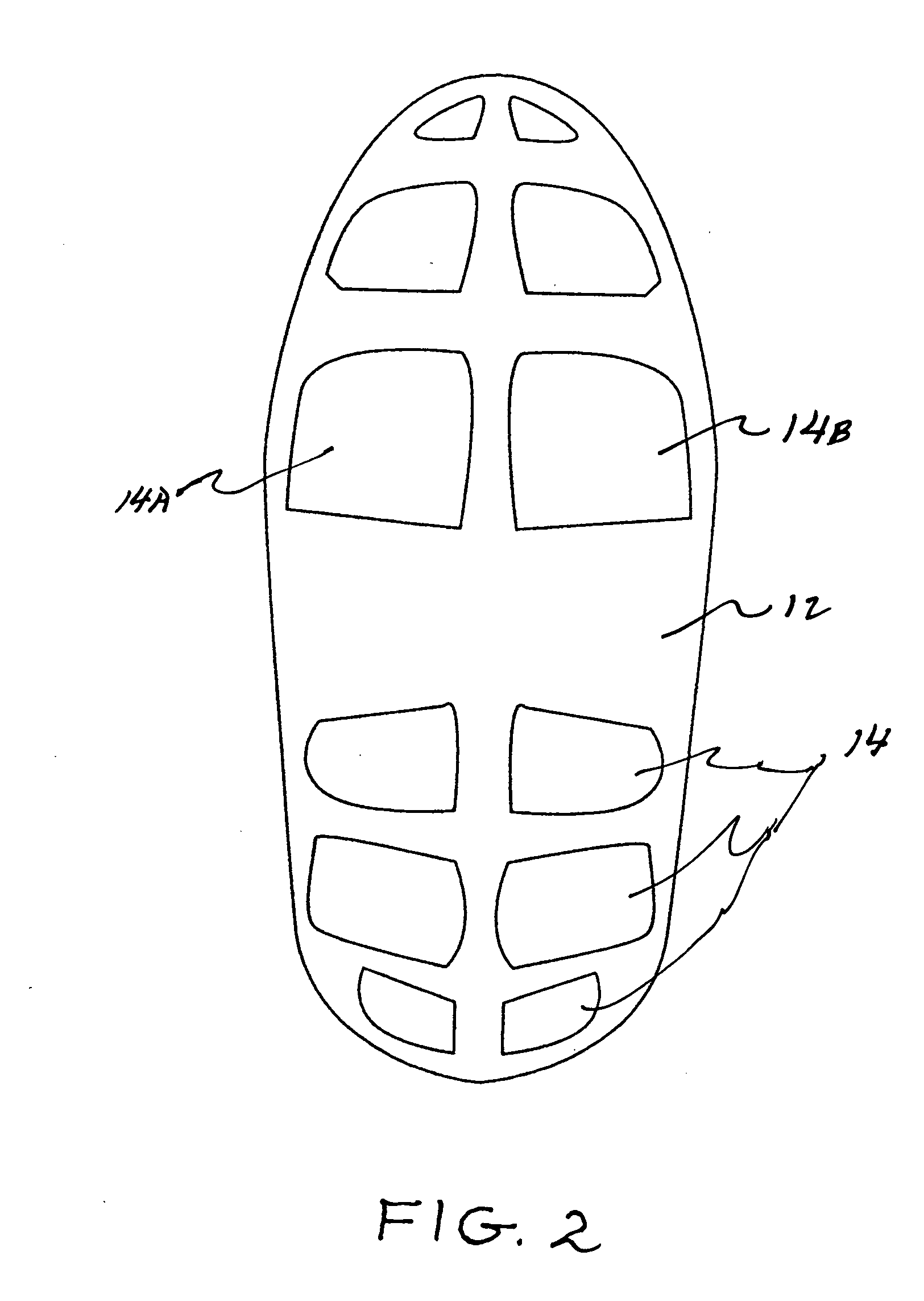

Frost protection for plants

InactiveUS20050172548A1Easy to disassembleImprove protectionPlant protective coveringsFrostEngineering

Frost covers are described that define an enclosure for an individual plant or group of plants to protect the sides and lower portions of the plants as well as their tops from frost damage. Each cover is shaped to envelop a single plant or group of plants and is provided with a retaining mechanism, such as an elastic band or drawstring, which allows the frost cover to be secured to the plant or group of plants against winds. The covers are inexpensive, reusable, disposable, and may be formed into a variety of shapes and sizes to accommodate a wide variety of sizes of plants and groups of plants. The frost covers are fashioned from a semi-transparent, air-permeable and moisture permeable membrane that permits some sunlight and water to pass through the membrane while causing frost to form atop the membrane rather than on the covered plant.

Owner:BEMENT RONALD A

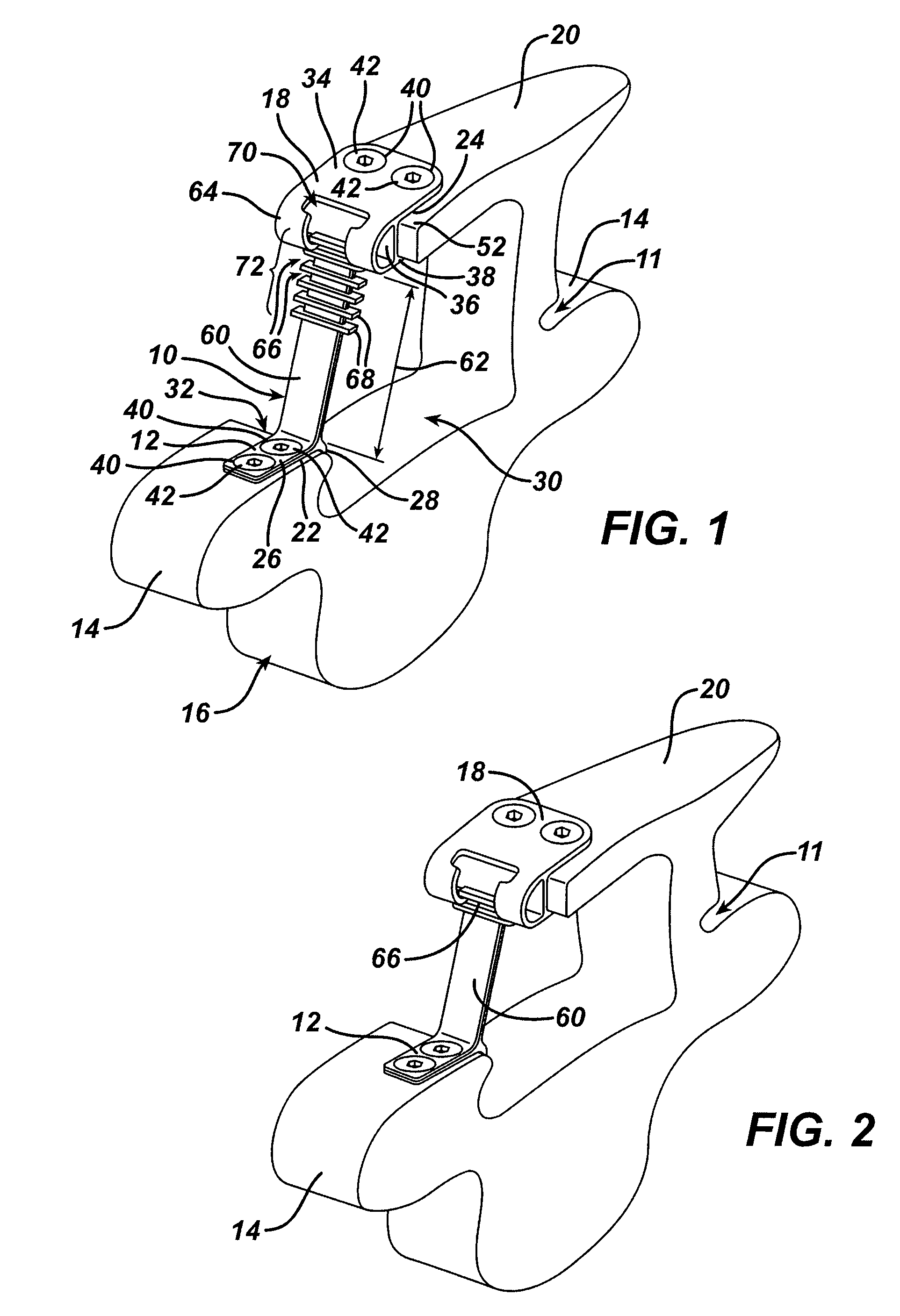

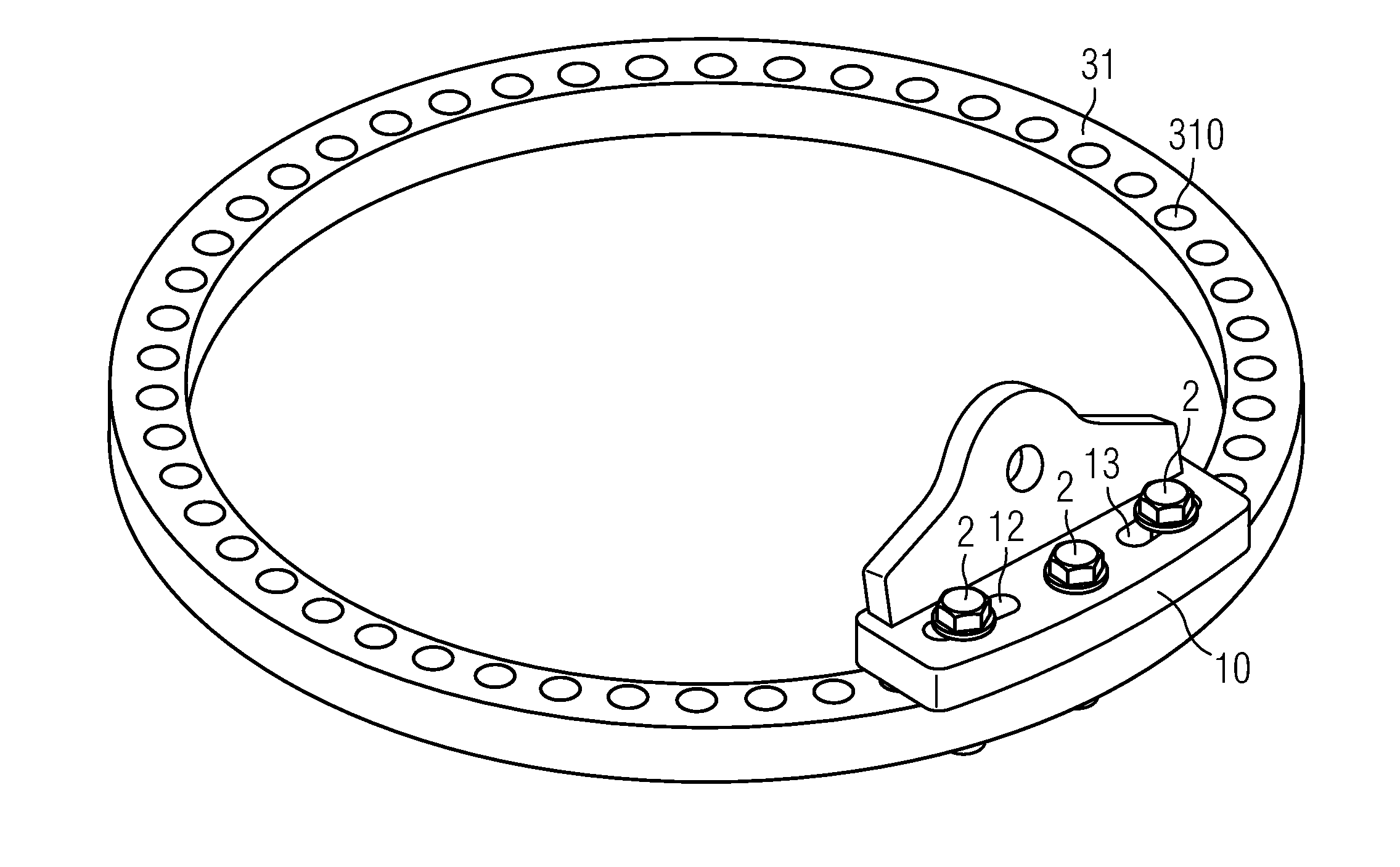

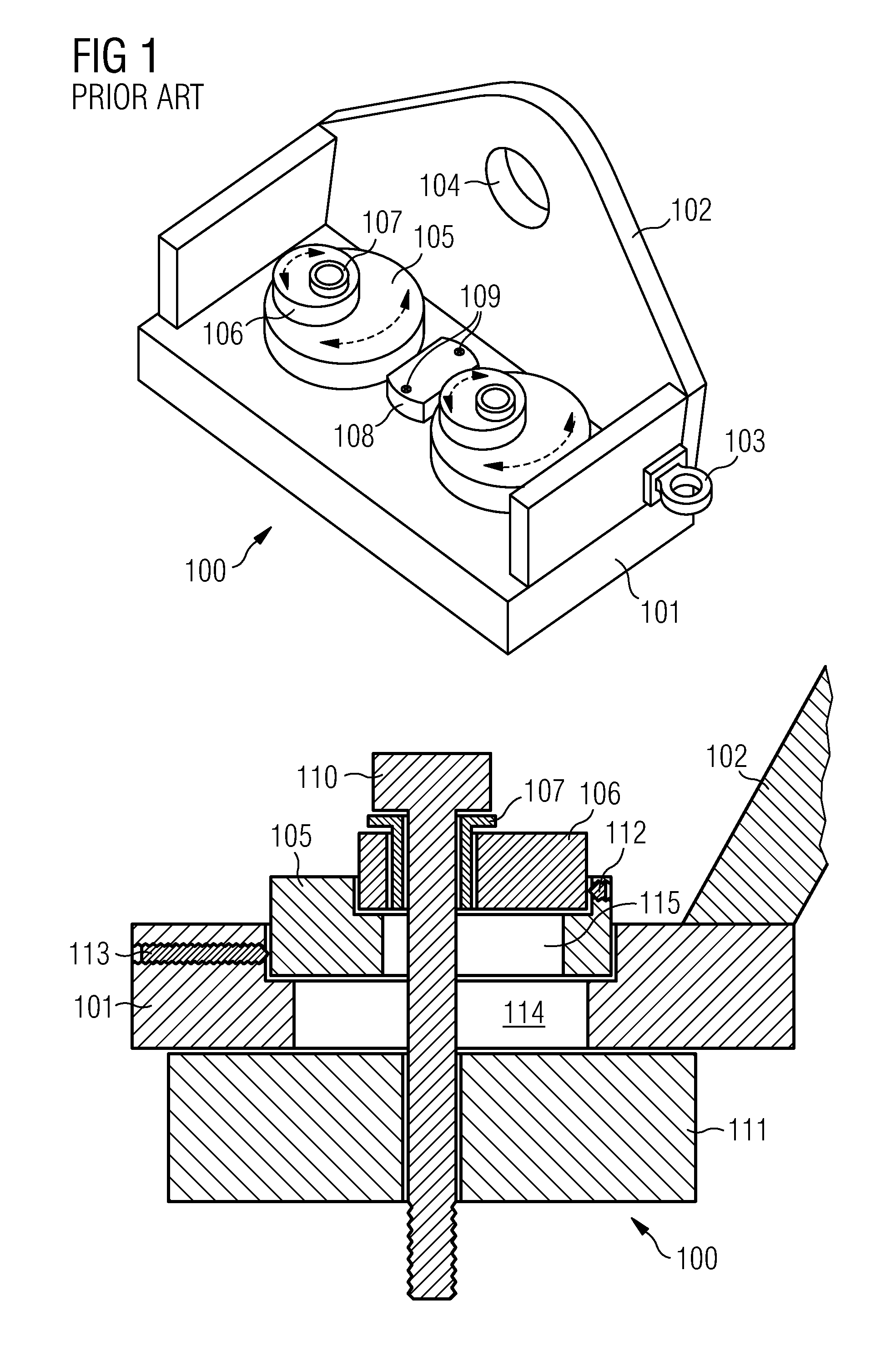

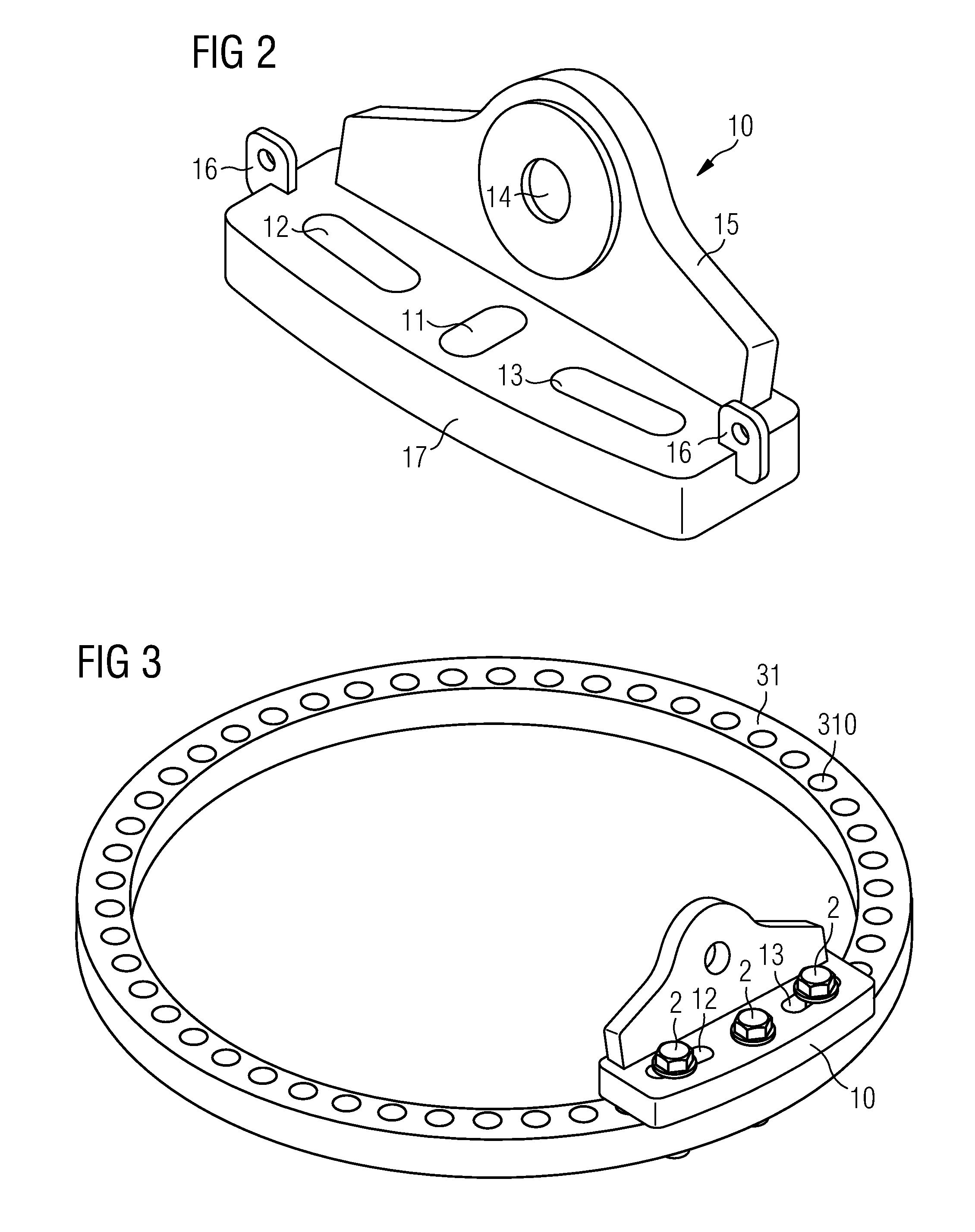

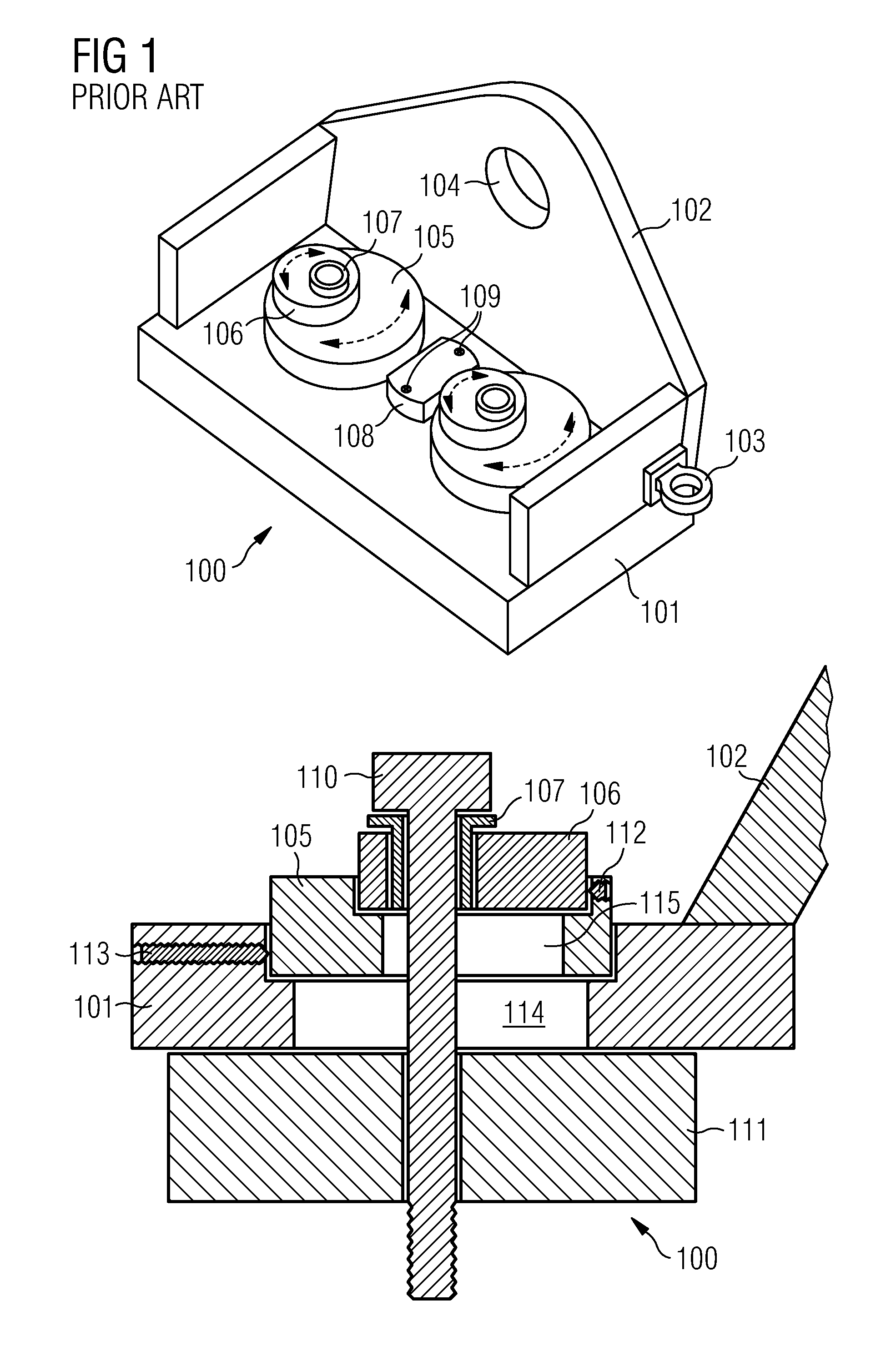

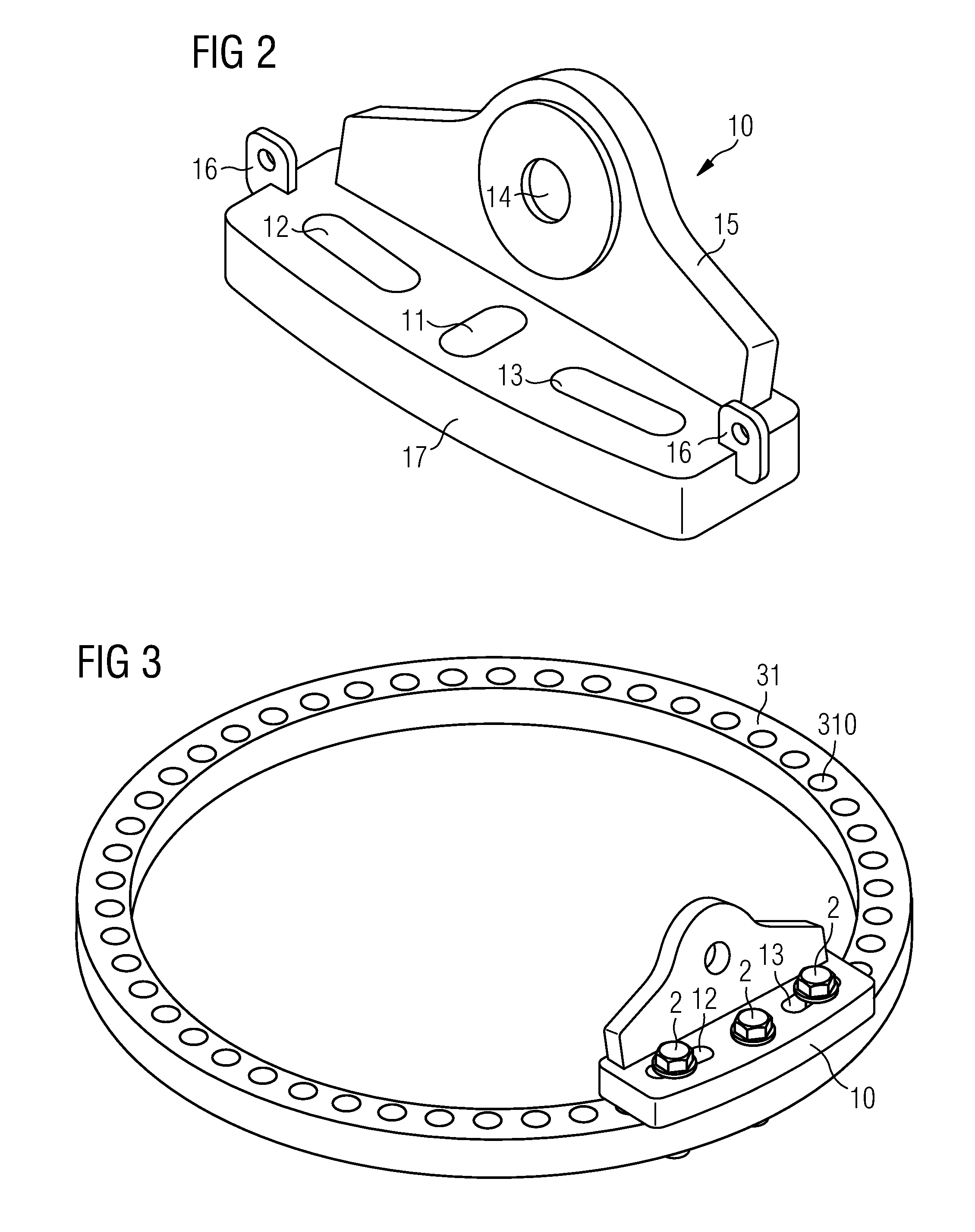

Lifting fitting

ActiveUS20120107084A1Quick assemblyManufacture is particularly economical and straightforwardWind motor assemblySemiconductor/solid-state device manufacturingFastenerIndustrial engineering

A lifting fitting for lifting a series of elements of different sizes in a wind turbine is proposed. The lifting fitting has a base plate having at least one central slotted hole shaped to accommodate a fastener for fastening the lifting fitting to an element to be lifted, at least two outer slotted holes each shaped to accommodate a further fastener for fastening the lifting fitting to an element to be lifted. The outer slotted holes are arranged transverse to the central slotted hole. The lifting fitting is connected to a lifting apparatus for lifting the element. A method of assembling the series of elements is proposed. The elements are successively lifted into place. The lifting fitting can be used in the assembly of a wind turbine tower having individually liftable tower sections for lifting the tower sections into place.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

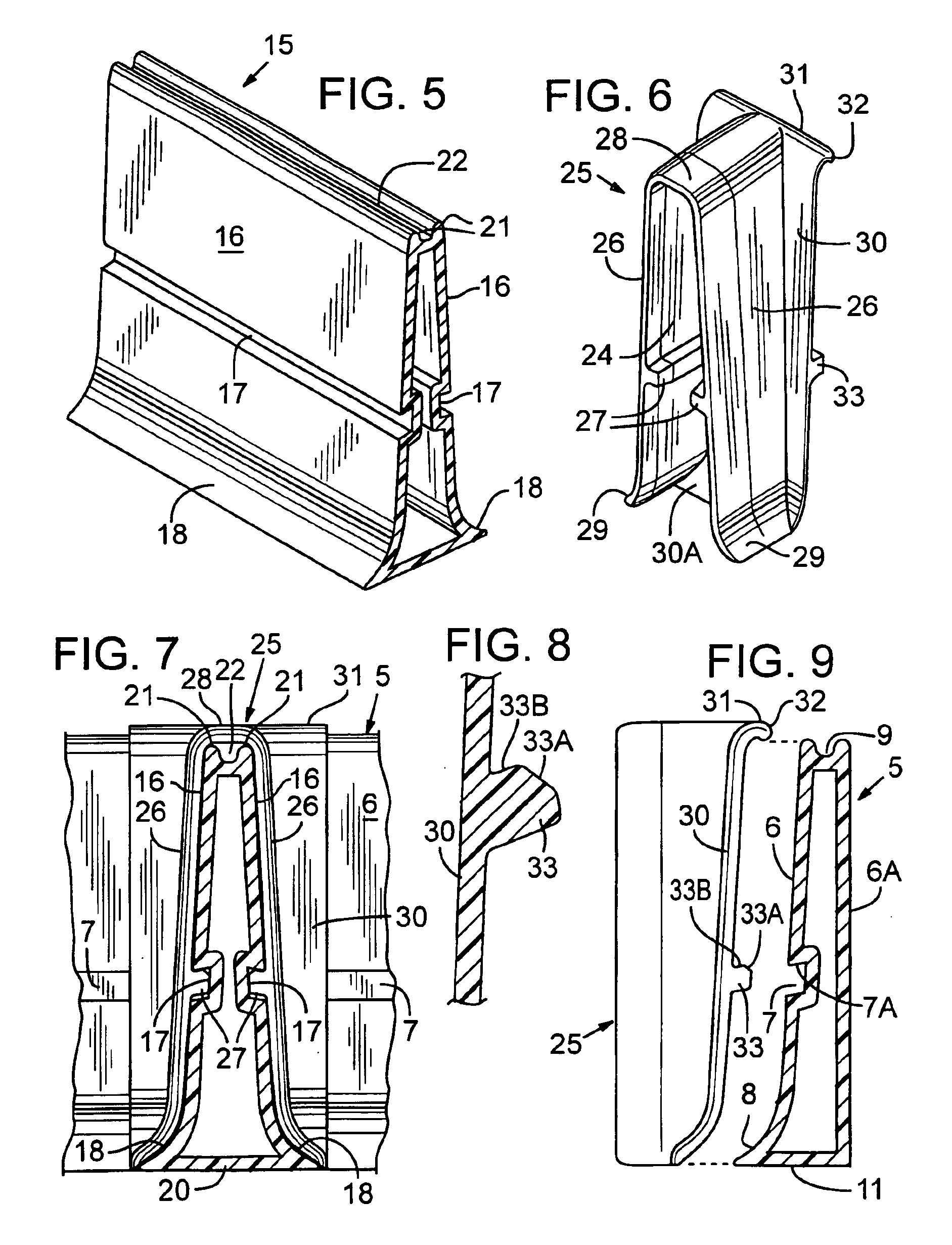

Tapping tool for use with drill press

ActiveUS20050042045A1Easy to useWide sizeThread cutting machinesTransportation and packagingEngineeringMechanical advantage

A tapping device is configured to be used within a drill press or lathe or other device capable of holding a cylindrical object. The tapping device has an upper projection for being axially fixed in, for example, a drill press. The remainder of the body of the tapping device is rotatable with respect to the upper projection and includes side handles for providing handy mechanical advantage to the turning of the tapping device body. The end of the body opposite the upper projection includes a chuck for holding a typical tapping tool. The projection is connected to an internal shaft which engages the body of the tapping tool and is spring biased to draw the projection and internal shaft within the body of the tapping tool. Conversely, when the tapping tool is supported in, as an example, a drill press chuck, such spring urging acts to lift the body of the tapping tool in the direction of the projection. The number and nature of the springs which act between the internal shaft and the body of the tapping tool, as well as the dimensions noted can be widely varied to accommodate a variety of force versus displacement characteristics especially taking into account the mass of both the body of the tapping tool and its tap chuck. An adapter is provided for quick change of socket supported taps.

Owner:BLICK JOHN

Damper unit

ActiveUS20140238795A1Improve vehicle qualitySmooth connectionSpringsRace vehiclesPistonShock absorber

A damper unit includes first and second chambers, a first piston dividing the first chamber into first and second volumes, and a second piston dividing the second chamber into third and fourth volumes. Each piston is moveable along the respective chamber. The second chamber has a cross-sectional area that is smaller than the cross-sectional area of the first chamber so that the second chamber at least partially slides inside the first chamber and at least part of the first chamber can be located around the outside of the second chamber. The first piston is attached to the part of the second chamber that slides inside the first chamber. The position of the second piston is fixed relative to the first chamber as the second chamber slides relative to first chamber. The length of the damper unit changes as the second chamber slides relative to the first chamber.

Owner:MCLAREN AUTOMOTIVE

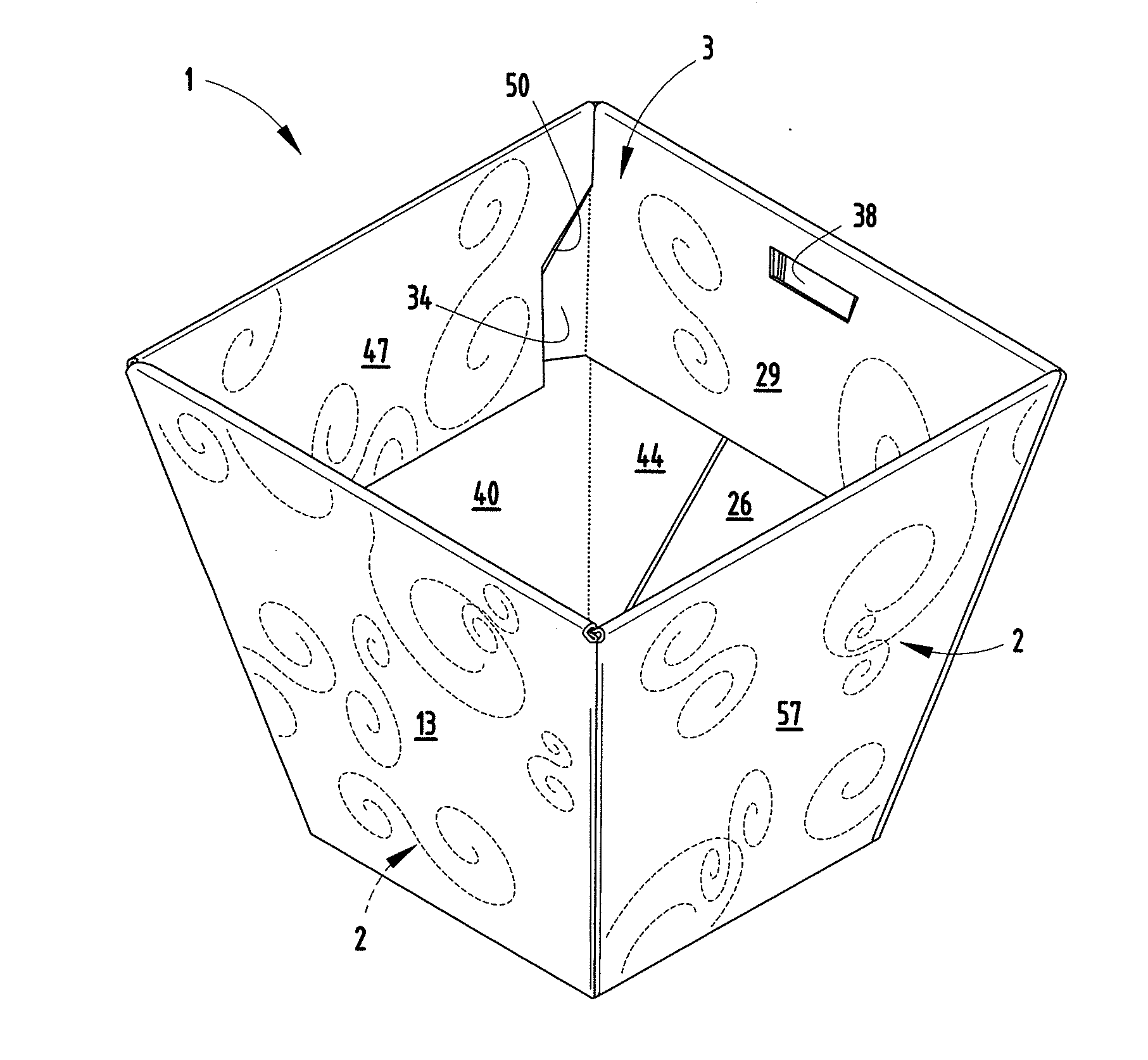

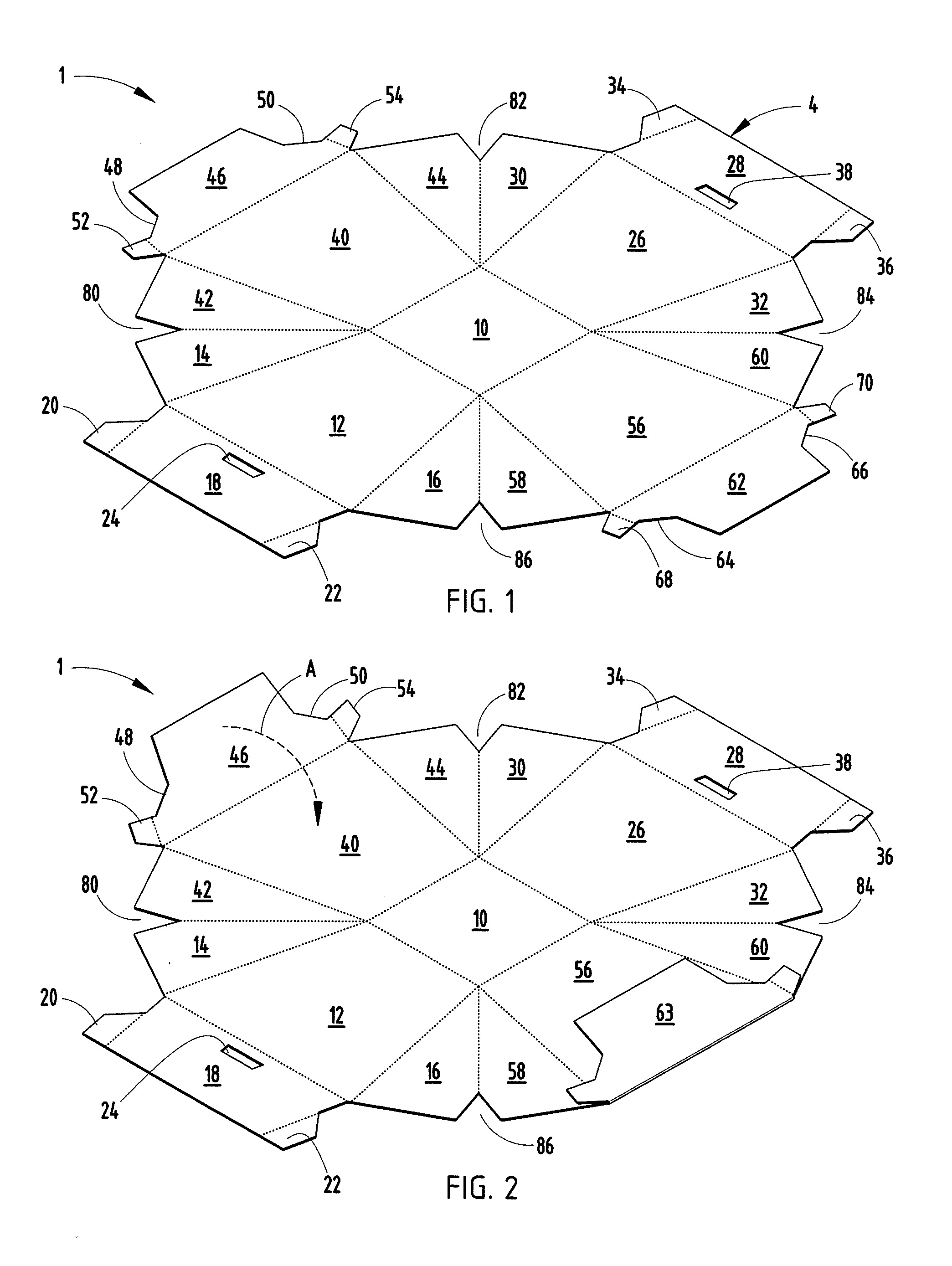

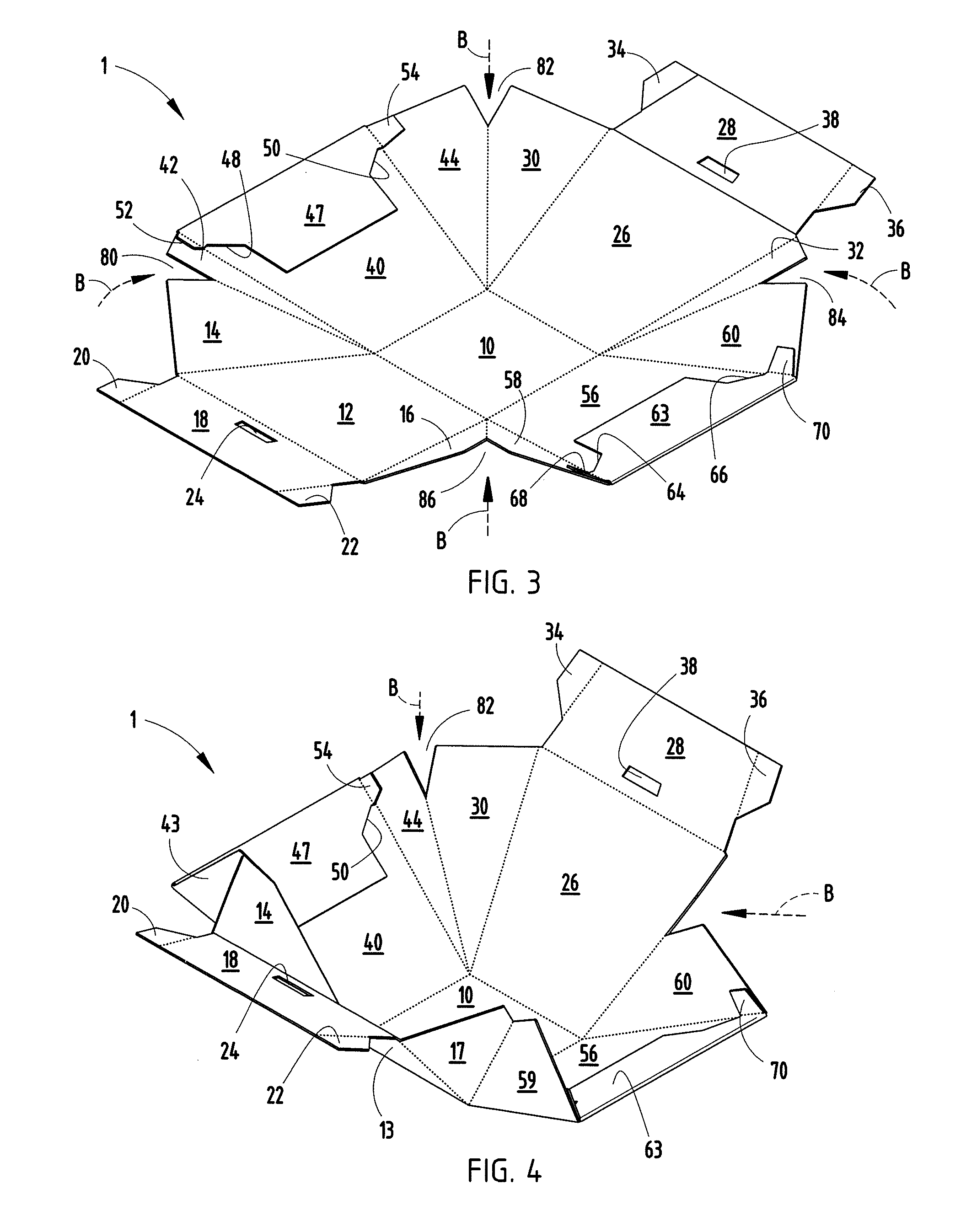

Folded pot cover

ActiveUS20110072719A1Wide sizeLiving organism packagingBoxes/cartons making machineryMechanical engineeringMoisture

Owner:MULTI PACKAGING SOLUTIONS

Preparation technology of high density molybdenum-tantalum alloy sputtering target material

InactiveCN110538993ALow oxygenHigh purityTransportation and packagingVacuum evaporation coatingSputteringHigh density

The invention provides a preparation technology of a high density molybdenum-tantalum alloy sputtering target material. The preparation technology of the high density molybdenum-tantalum alloy sputtering target material includes following steps: S1, performing hydrotreating on tantalum powder; S2, mixing raw materials; S3, preforming powder loading operation on a gum cover; S4, performing isostatic cool pressing operation: after raising pressure to certain value, keeping the pressure for a certain time, then performing decompression, and finally fetching out a compressed billet from the gum cover; S5, preforming vacuum sintering; S6, performing hot rolling operation: performing metal casing rolling on molybdenum-tantalum alloy, and removing stress through annealing after hot rolling; and S7, performing machining operation of grinding and the like, and obtaining the final product of the needed size. The preparation technology of the high density molybdenum-tantalum alloy sputtering target material is simple in technical step, and convenient and quick to operate, and the prepared molybdenum-tantalum alloy sputtering target material has the purity and the relative density which meet use demands in the high-end electronic product film plating field, and is low in production cost, wide in product size and beneficial to industrial mass production.

Owner:LUOYANG SIFON ELECTRONICS

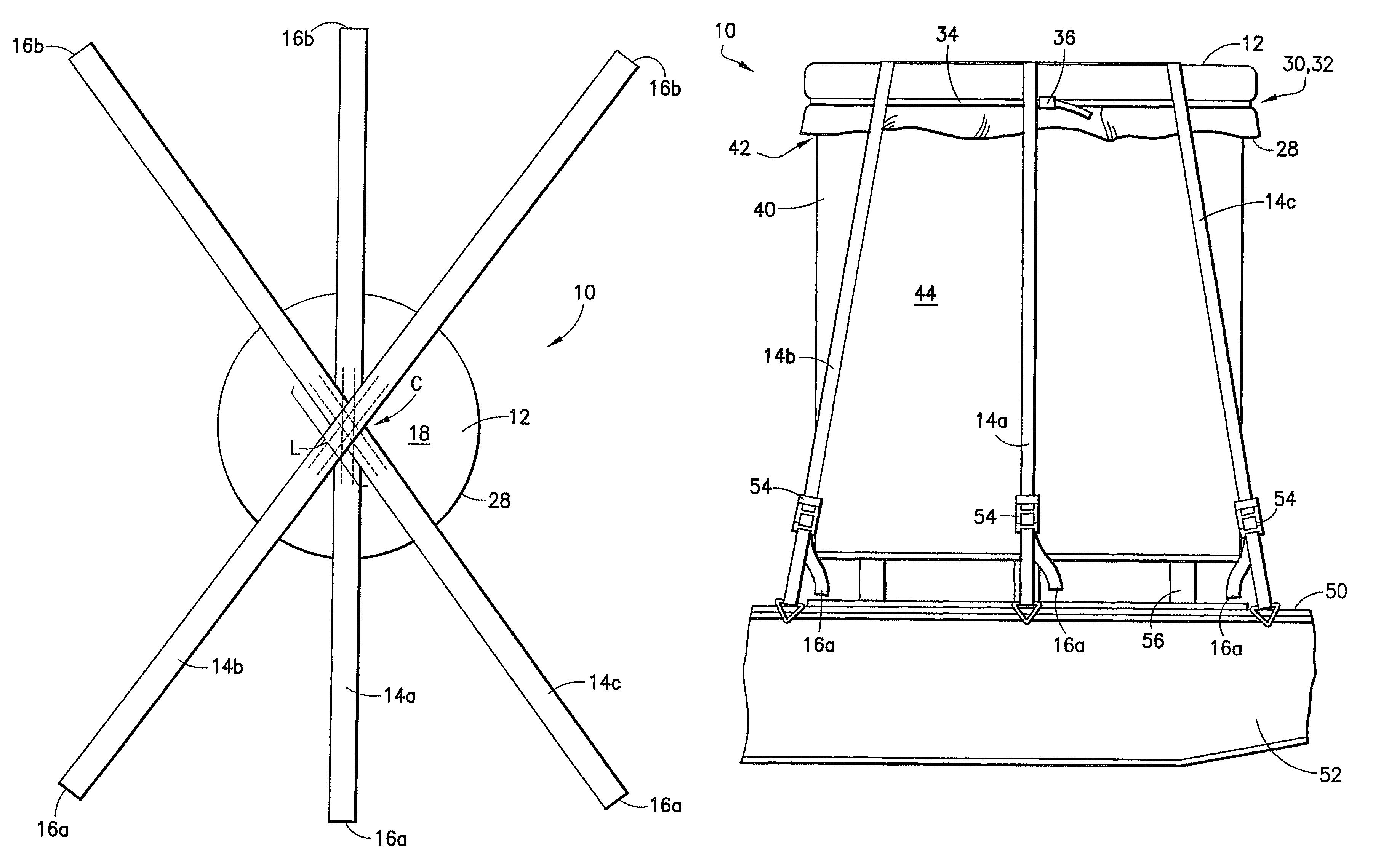

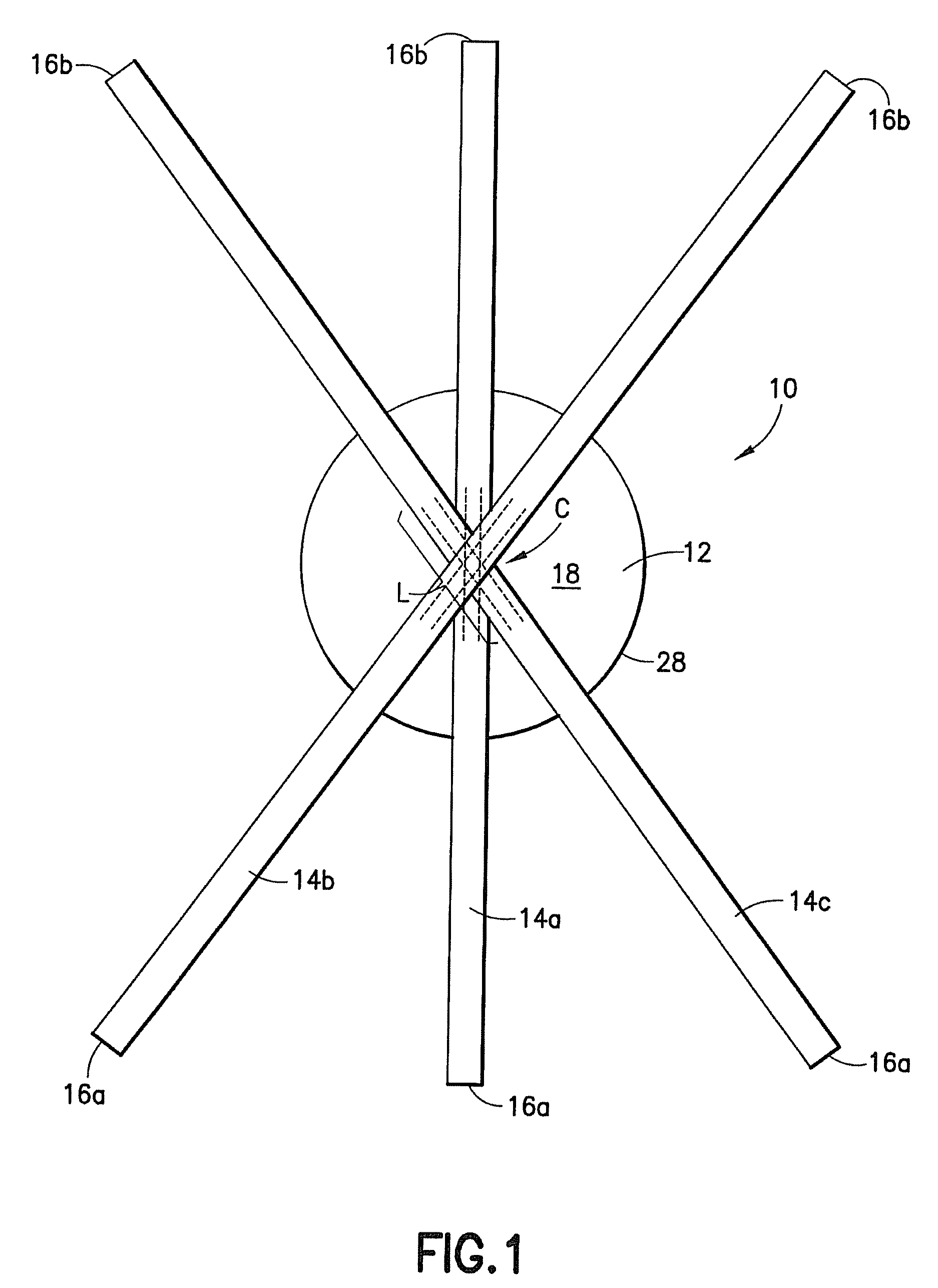

Metal coil securing apparatus and method

A metal coil securing device is disclosed including a coil cover adapted to encompass a metal coil and a plurality of tie down straps affixed to the coil cover, with each tie down secured along a portion of its length to the coil cover such that each tie down has two free ends extending outward from the periphery of the coil cover. In one embodiment, the tie down straps are secured to a circular coil cover to intersect at an approximate center of the coil cover and extend radially outward therefrom. A method of securing a metal coil to a transport trailer is also disclosed generally including associating and securing the coil cover with the metal coil, loading the metal coil with the secured coil cover onto the transport trailer, and using the free ends of the tie down straps to secure the metal coil to the transport trailer.

Owner:SEVER PAUL

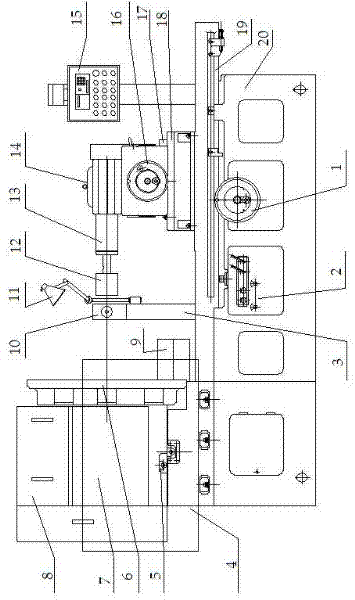

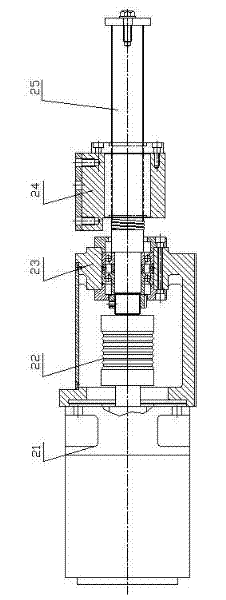

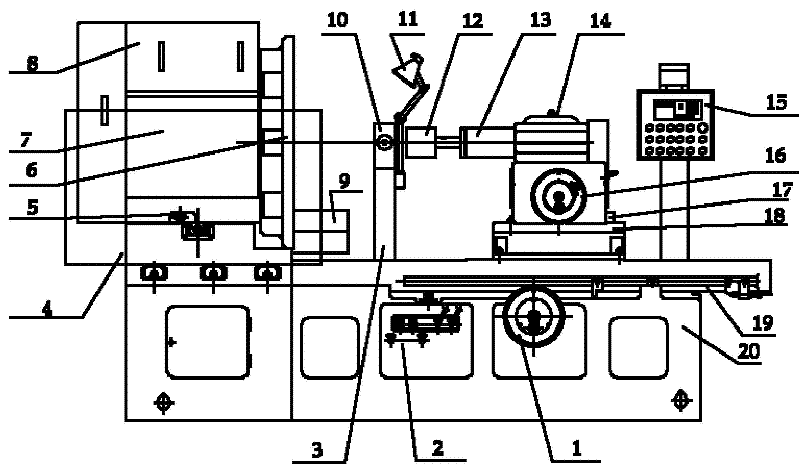

CNC (Computerized Numerical Control) automatic internal grinding machine for bearing ring

InactiveCN102211299ACompact structureImprove rigidityRevolution surface grinding machinesAbrasive surface conditioning devicesNumerical controlControl system

The invention relates to a CNC (Computerized Numerical Control) automatic internal grinding machine for a bearing ring. The internal grinding machine comprises a lathe body, a reciprocating worktable, a grinding wheel shaft assembly, a workpiece axle box, a grinding wheel dresser, a longitudinal feed transmission mechanism, a transverse feed transmission mechanism, a cooling system, a hydraulic lubrication system, a CNC control system host and operating panel, and an electrical control system, wherein the reciprocating worktable, the grinding wheel dresser and the workpiece axle box are arranged on the lathe body; the grinding wheel shaft assembly is arranged on the reciprocating worktable; the longitudinal feed transmission mechanism and the hydraulic lubrication system are arranged inside the lathe body; the transverse feed transmission mechanism is arranged on a grinding wheel seat; the cooling system and the electrical control system are arranged at the rear side of the lathe body; the CNC control system host and operating panel is arranged above the reciprocating worktable; and the reciprocating worktable is arranged on a guide rail of the lathe body. The CNC automatic internal grinding machine for the bearing ring, provided by the invention, has the outstanding advantages of simple and compact structure, strong static and dynamic rigidities, locating precision, good performances of anti-vibration and vibration reduction, good precision retentivity, light friction and abrasion, long service life, easiness for operation and maintenance, safety, saving energy, environment friendliness, attractive appearance and the like.

Owner:大连沃飞亚装备制造有限公司

Assistive walking device

An assistive walking rear entry device including a main frame, elongated upright body weight support members connected to each side portion of the main frame and two elongated leg members connected to each body support member one extending forwardly, the other extending rearwardly, each leg member including a rollable member attached to a distal end portion thereof. An elongated seat is attached to and supported on a lower portion of a centerpost, the centerpost being supported on the main frame. Rearwardly opening lateral torso supports are attached to the upper portion of the centerpost and make supporting contact with the thoracic area and for propelling the device during a walking gait. The seat is positioned against the perennial region to support the pelvis and to help propel the device on a “hands free” basis. The body weight support members are preferably multi-function for partial body weight support during a walking gait and in facilitating entrance and egress.

Owner:MULHOLLAND LARRY

Bike shoe slipper

Owner:GALLAGHER FRANK

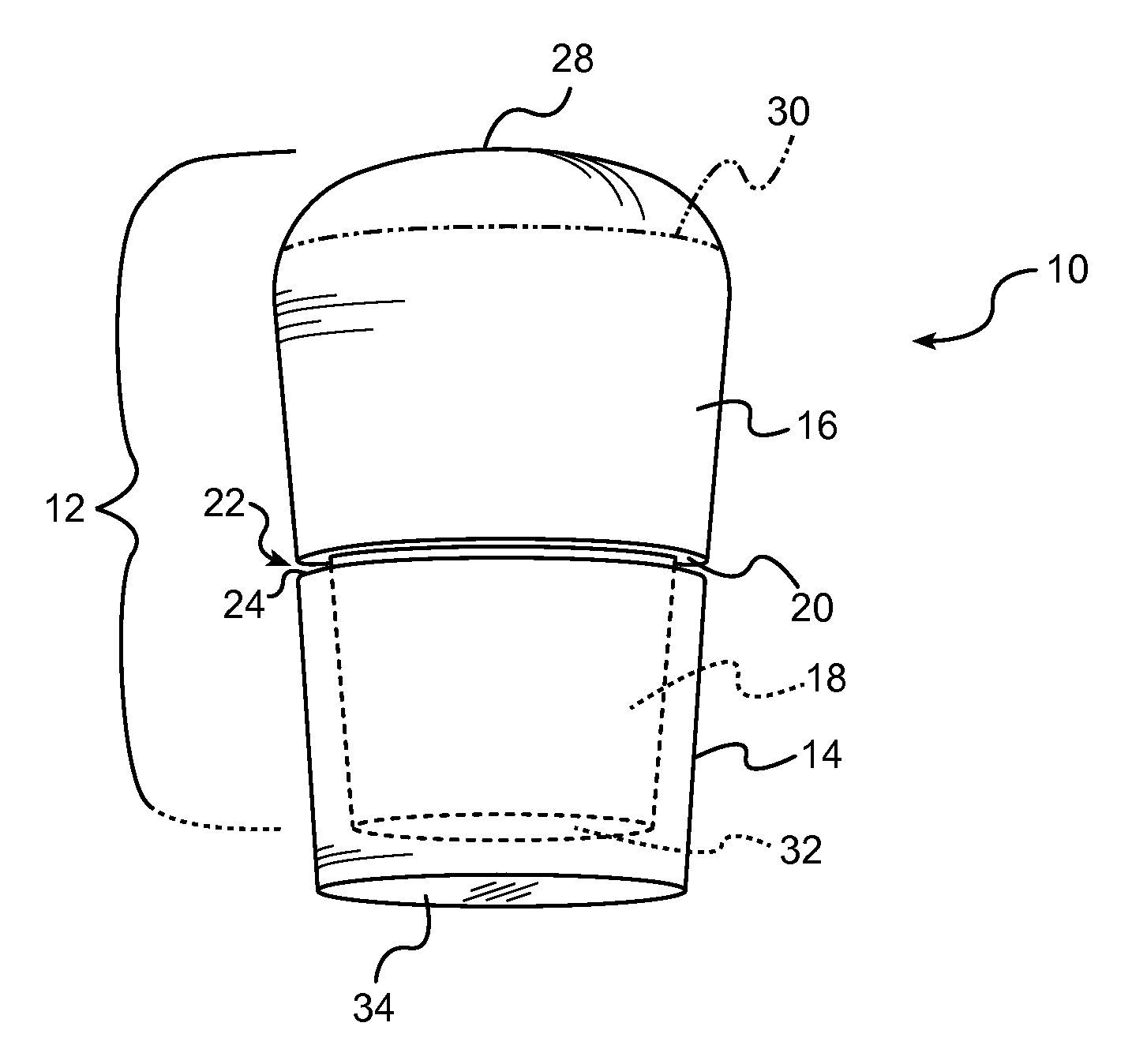

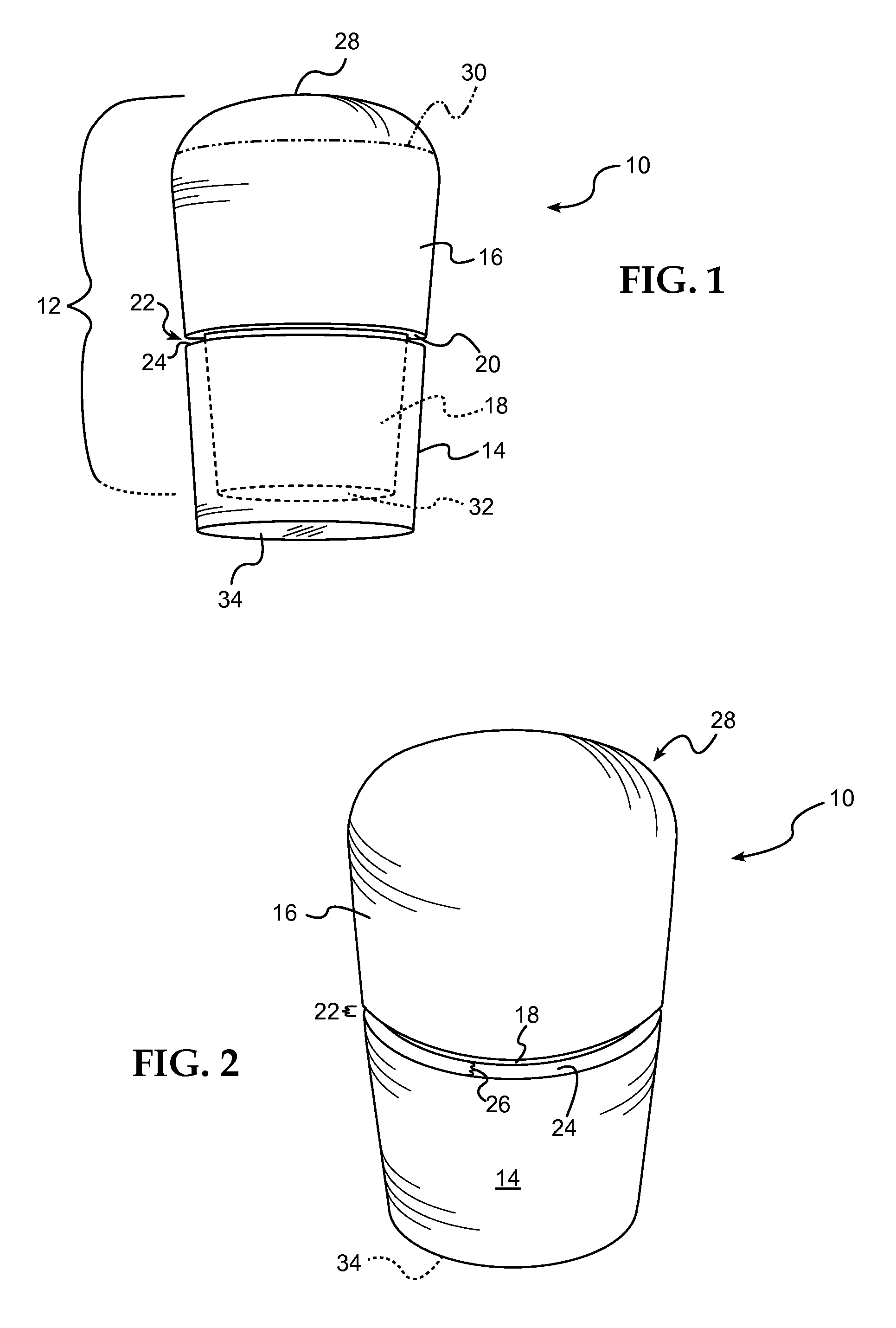

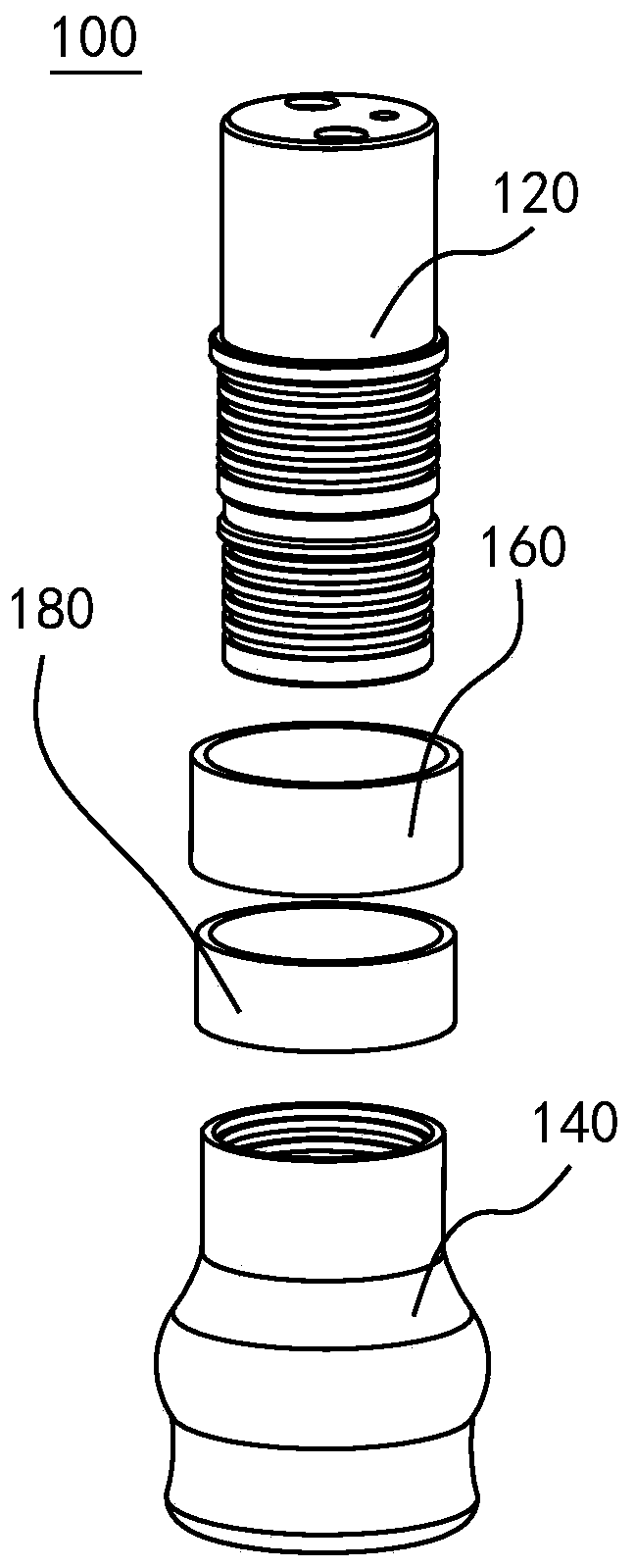

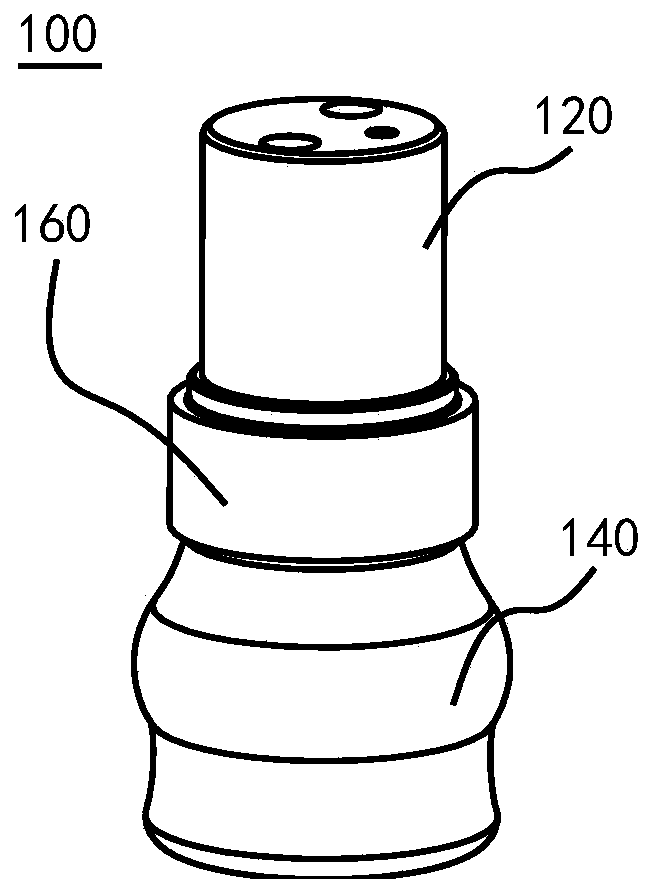

Compound bung for wine and spirits barrels

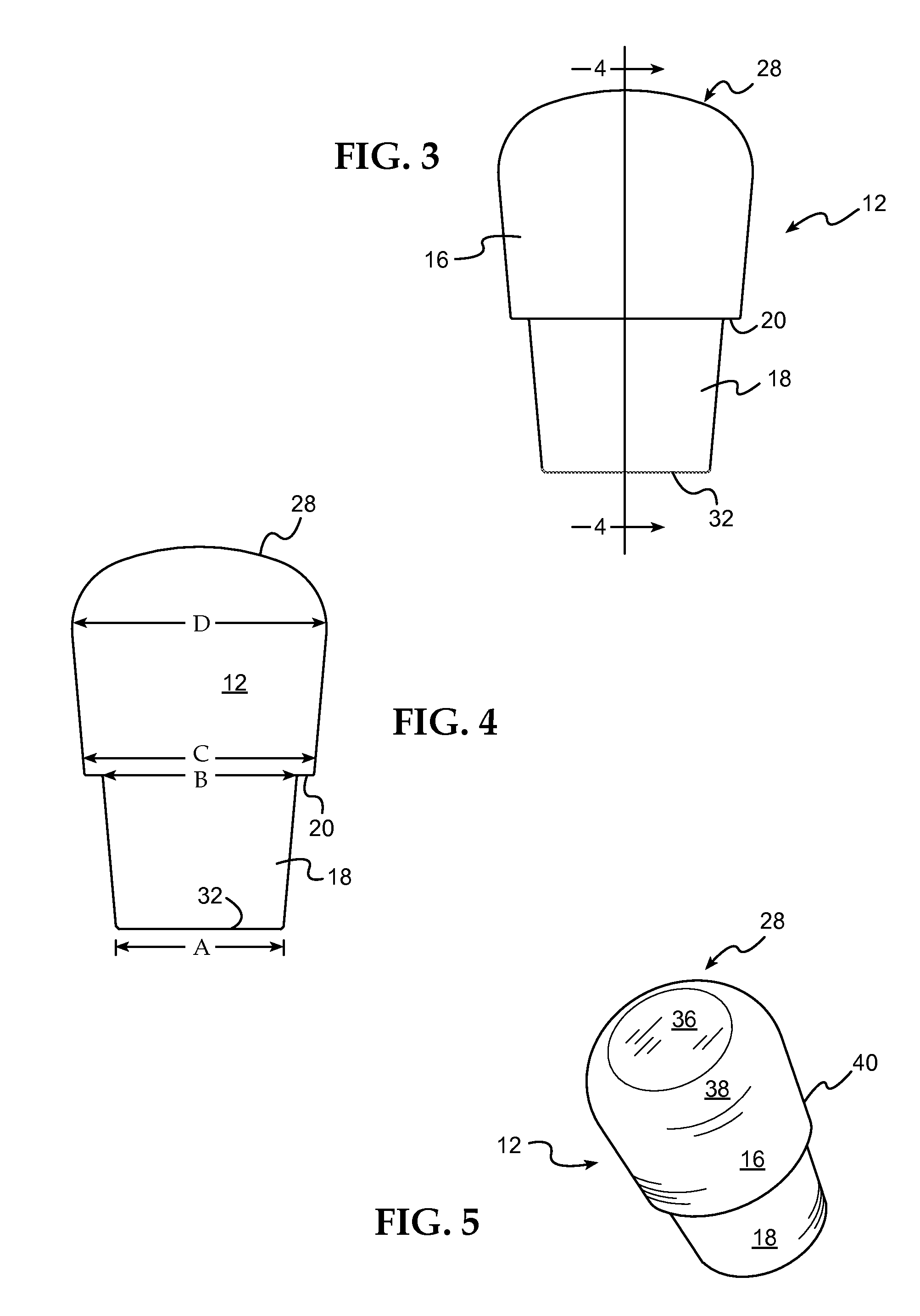

ActiveUS8714383B2Easily and comfortably graspedWide sizeClosure using stoppersLidsEngineeringGrape wine

Compound bung-type stopper assemblies for wine and spirits barrels, comprising a body having an enlarged head portion, a reduced, tapered neck portion and a tapered, disposable elastomeric cup that snugly fits over the neck. The taper permits the inventive compound bung to be universal in fit and the elastomeric material of the cup grippingly conforms to bunghole irregularities. The body can be re-used with multiple cups, each being dedicated to a different wine or spirit, or after the cup has worn out. Body materials are selected from any essentially low- or non-resilient material, including glass, hard plastic (such as polycarbonate), wood, metal or ceramic, and may be colored. The head may be domed or flat, and may be decorated, as by etching, embossing or painting with the winemakers or winery mark. The inventive compound bungs / bodies that are identified by such marks may be sold as collectibles or as commemorative devices.

Owner:CORSON FAMILY ENTERPRISES

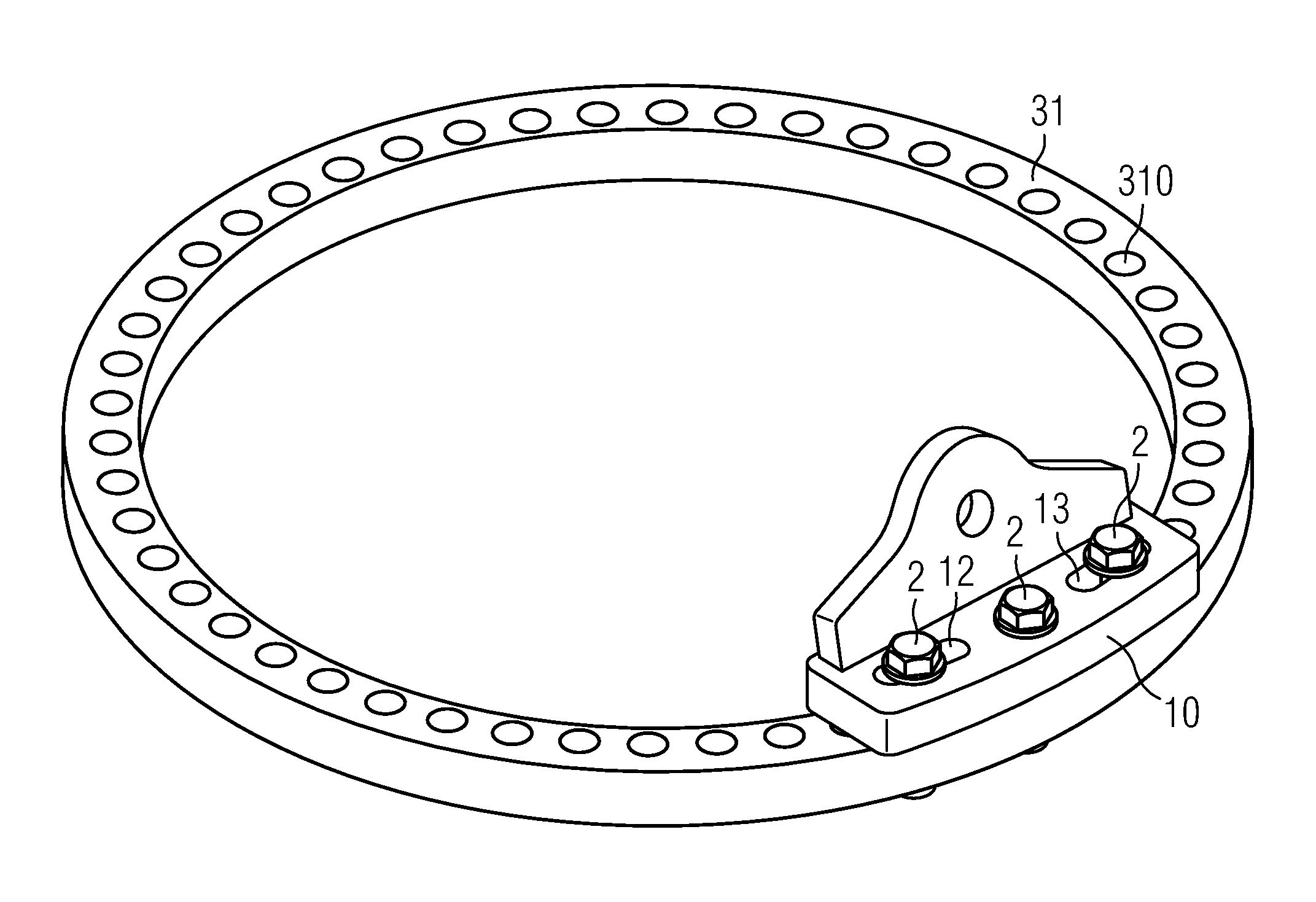

Lifting fitting

ActiveUS8678455B2Quick assemblyManufacture is particularly economical and straightforwardWind motor assemblyMachines/enginesTowerTurbine

A lifting fitting for lifting a series of elements of different sizes in a wind turbine is proposed. The lifting fitting has a base plate having at least one central slotted hole shaped to accommodate a fastener for fastening the lifting fitting to an element to be lifted, at least two outer slotted holes each shaped to accommodate a further fastener for fastening the lifting fitting to an element to be lifted. The outer slotted holes are arranged transverse to the central slotted hole. The lifting fitting is connected to a lifting apparatus for lifting the element. A method of assembling the series of elements is proposed. The elements are successively lifted into place. The lifting fitting can be used in the assembly of a wind turbine tower having individually liftable tower sections for lifting the tower sections into place.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

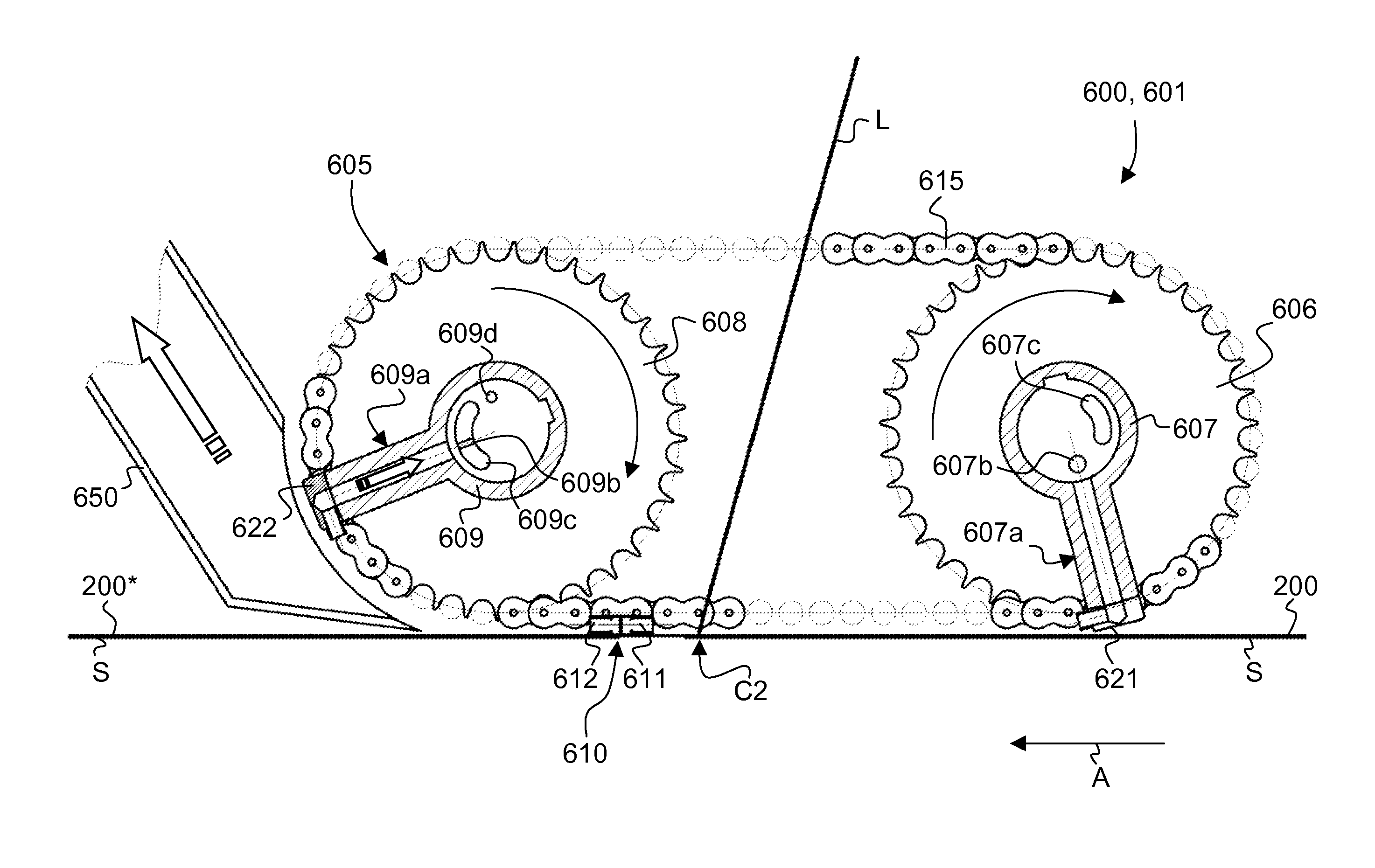

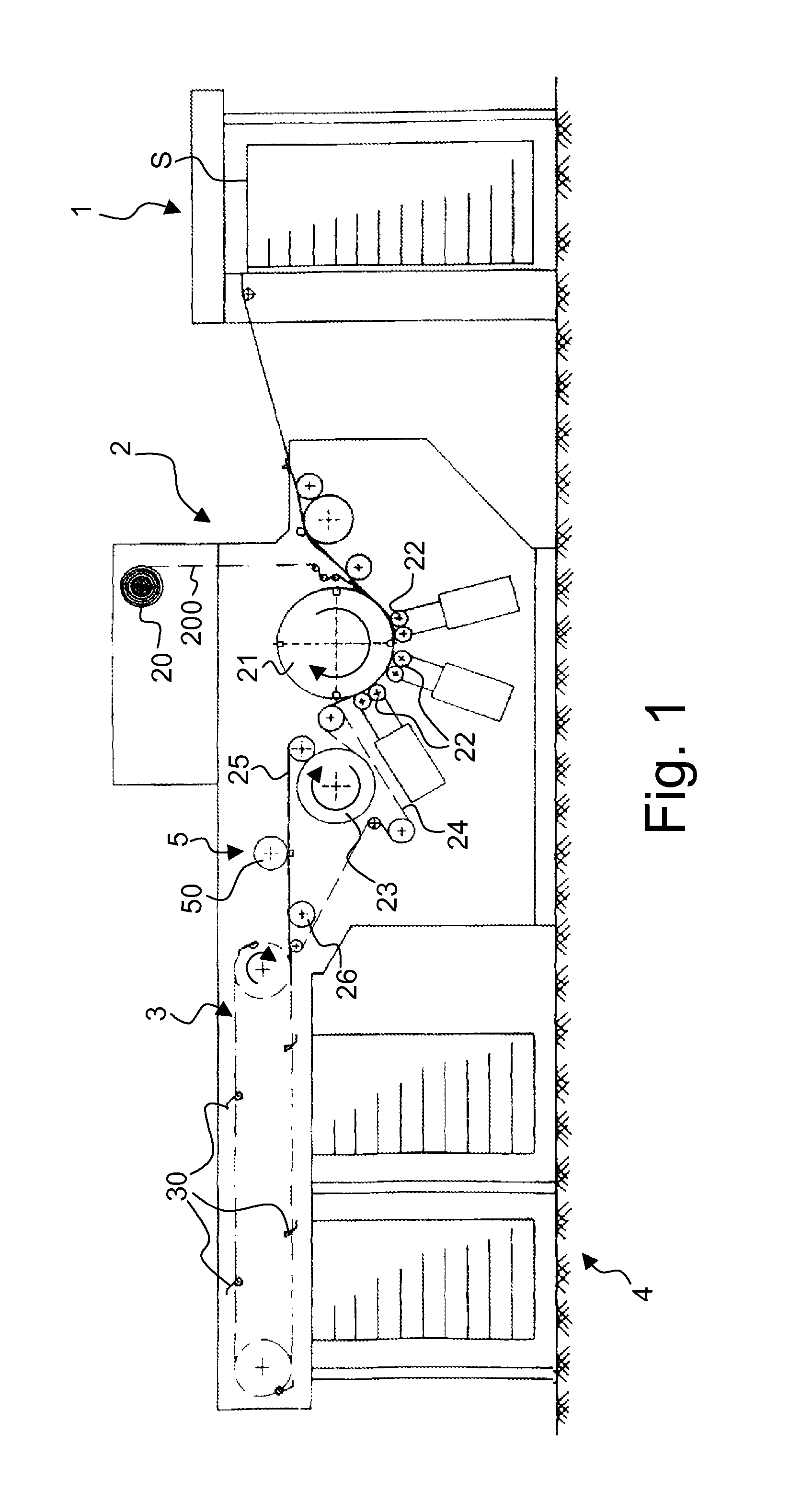

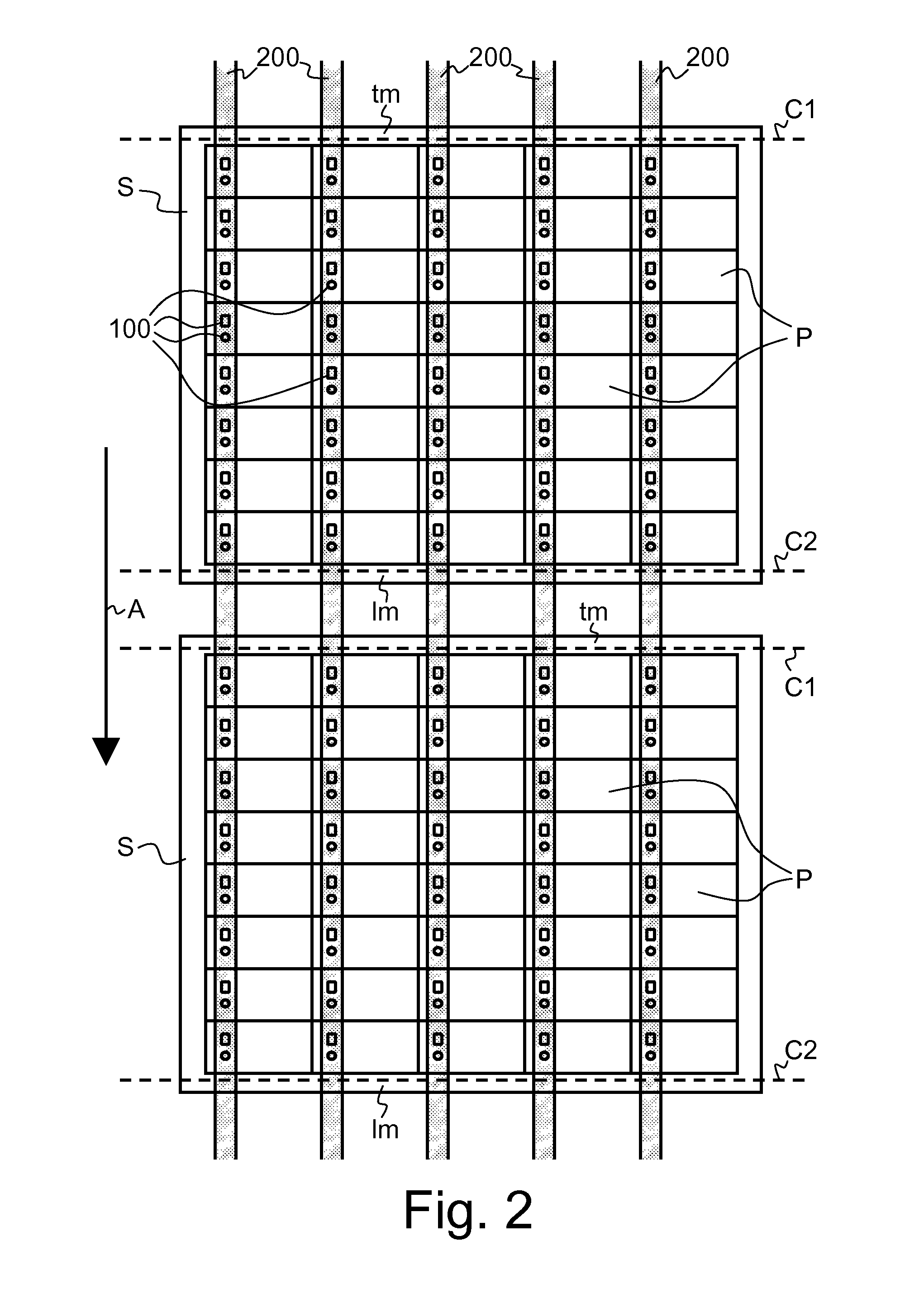

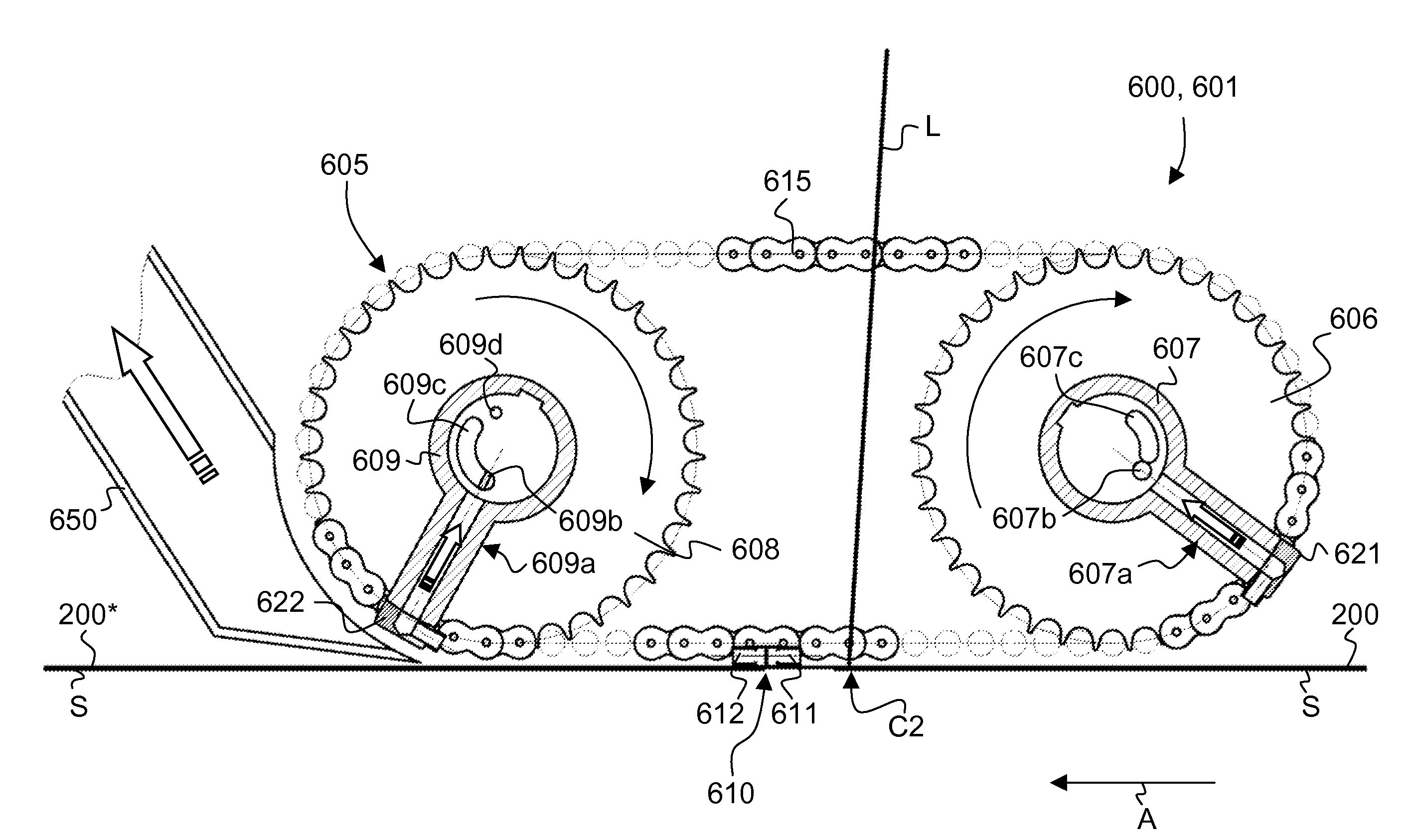

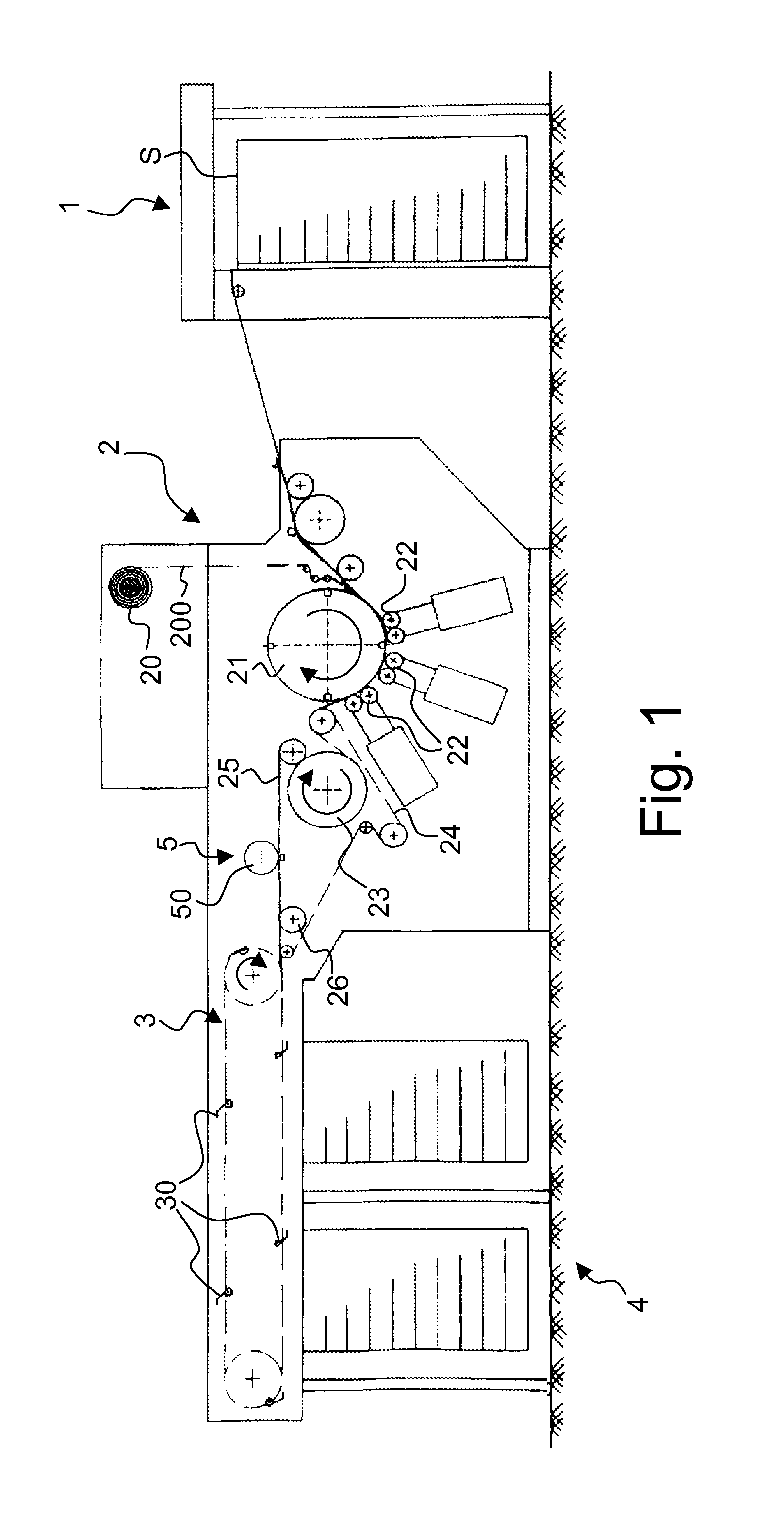

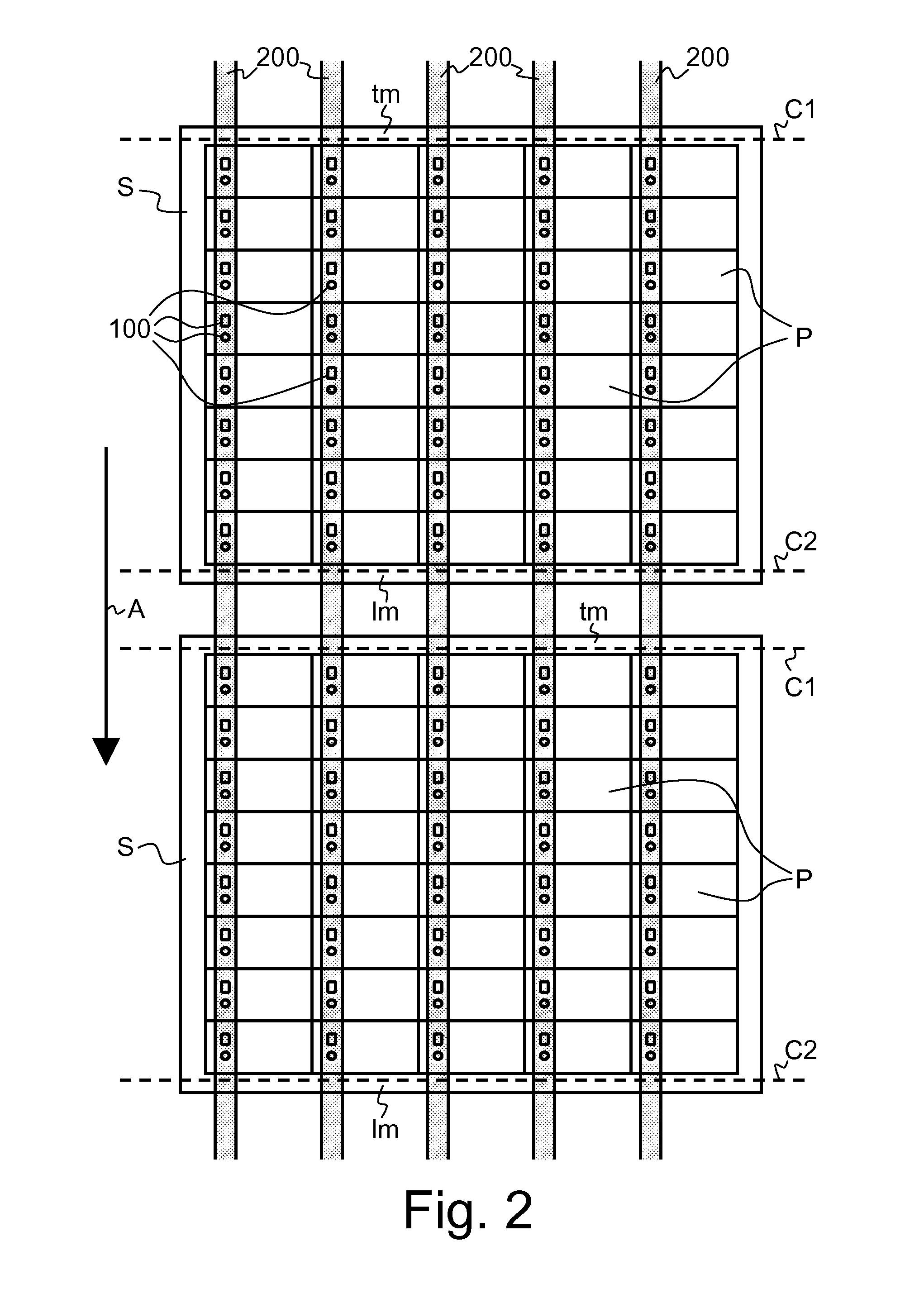

Method and installation for applying foil material onto successive sheets

InactiveUS8967221B2Precise applicationWide sizeOther printing matterRecord carriersEngineeringContinuous flow

There is described a method for applying foil material (200) onto successive sheets (S), especially sheets for the production of securities, such as banknotes. In a first step, individual sheets (S) are transported in succession along a sheet transport path. In a second step, at least one continuous band of foil material (200) is applied onto the individual sheets (S) along a direction substantially parallel to a direction of displacement (A) of the individual sheets, thereby forming a continuous flow of sheets linked to one another by the said at least one continuous band of foil material (200). In a third step, the said at least one continuous band of foil material (200) is cut by means of a laser beam (L) such that the continuous flow of sheets is again separated into individual sheets (S) with portions of foil material (200*) remaining on the sheet. The cutting is performed at positions located on the sheets (S) such that said portions of foil material (200*) remaining on the sheets do not extend beyond leading and trailing edges of the sheets (S). Waste portions (205) of said at least one continuous band of foil material (200) that are not to remain on the sheets (S) are seized prior to cutting by the laser beam (L) and are held throughout the cutting process. There is also described an installation for carrying out the above method.

Owner:KBA NOTASYS SA

Method and Installation for Applying Foil Material onto Successive Sheets

InactiveUS20110259513A1Precise applicationWide sizeMechanical working/deformationRecord carriersEngineeringContinuous flow

There is described a method for applying foil material (200) onto successive sheets (S), especially sheets for the production of securities, such as banknotes. In a first step, individual sheets (S) are transported in succession along a sheet transport path. In a second step, at least one continuous band of foil material (200) is applied onto the individual sheets (S) along a direction substantially parallel to a direction of displacement (A) of the individual sheets, thereby forming a continuous flow of sheets linked to one another by the said at least one continuous band of foil material (200). In a third step, the said at least one continuous band of foil material (200) is cut by means of a laser beam (L) such that the continuous flow of sheets is again separated into individual sheets (S) with portions of foil material (200*) remaining on the sheet. The cutting is performed at positions located on the sheets (S) such that said portions of foil material (200*) remaining on the sheets do not extend beyond leading and trailing edges of the sheets (S). Waste portions (205) of said at least one continuous band of foil material (200) that are not to remain on the sheets (S) are seized prior to cutting by the laser beam (L) and are held throughout the cutting process. There is also described an installation for carrying out the above method.

Owner:KBA NOTASYS SA

Preparation method of molybdenum-tungsten alloy sputtering target material

InactiveCN111254396AHigh sintering activityEasy to densifyVacuum evaporation coatingSputtering coatingGrindingTungsten trioxide

The invention provides a preparation method of a molybdenum-tungsten alloy sputtering target material. The preparation method includes the following steps that step 1, a certain proportion of molybdenum powder, tungsten powder and tungsten trioxide powder are taken, ball milling and mixing are performed under a protective atmosphere, and the materials are mixed uniformly; step 2, the uniformly mixed materials are subjected to powder filling in a rubber sleeve, and then cold isostatic pressing forming is performed to obtain a blank body; step 3, the blank body is sintered in two stages under ahydrogen protective atmosphere to obtain a sintered blank; step 4, the sintered blank is heated under the protection of hydrogen or argon, then hot rolling and leveling are performed, and finally, annealing is performed under hydrogen or vacuum to obtain a molybdenum-tungsten alloy slab; and step 5, the molybdenum-tungsten alloy slab is subjected to grinding and other machining as required to obtain a molybdenum-tungsten alloy product. The preparation method is simple in preparation step, the purity and relative density of the prepared molybdenum-tungsten alloy sputtering target material bothmeet the usage requirements in the TFT-LCD display film-coating field, the production cost is low, the product size is wide, and industrial mass production is convenient.

Owner:LUOYANG SIFON ELECTRONICS

Air bag type manipulator and mechanical device

The invention discloses an air bag type manipulator. The air bag type manipulator comprises a driving rod and an air bag, wherein the driving rod is used for driving the manipulator to take and placea target object; the air bag is used for clamping the target object in the taking and placing work of the manipulator; the shape of the air bag is changed through an air bag space arranged inside theair bag so as to adapt to the shape of the target object to realize clamping; and the air bag is connected with the driving rod in a manner that the air bag space wraps the outer wall of the driving rod. The invention further discloses a mechanical device comprising the air bag type manipulator. The air bag type manipulator is easy to adjust the shape of the air bag type manipulator to be matchedwith the target object, wide in grabbing range and high in applicability; the air bag type manipulator has very good flexibility, can avoid damage such as collision to the target object and effectively guarantees the safety of the target object; and in addition, the air bag type manipulator is simple in structure and low in manufacturing cost.

Owner:JIANGXI UNIV OF SCI & TECH

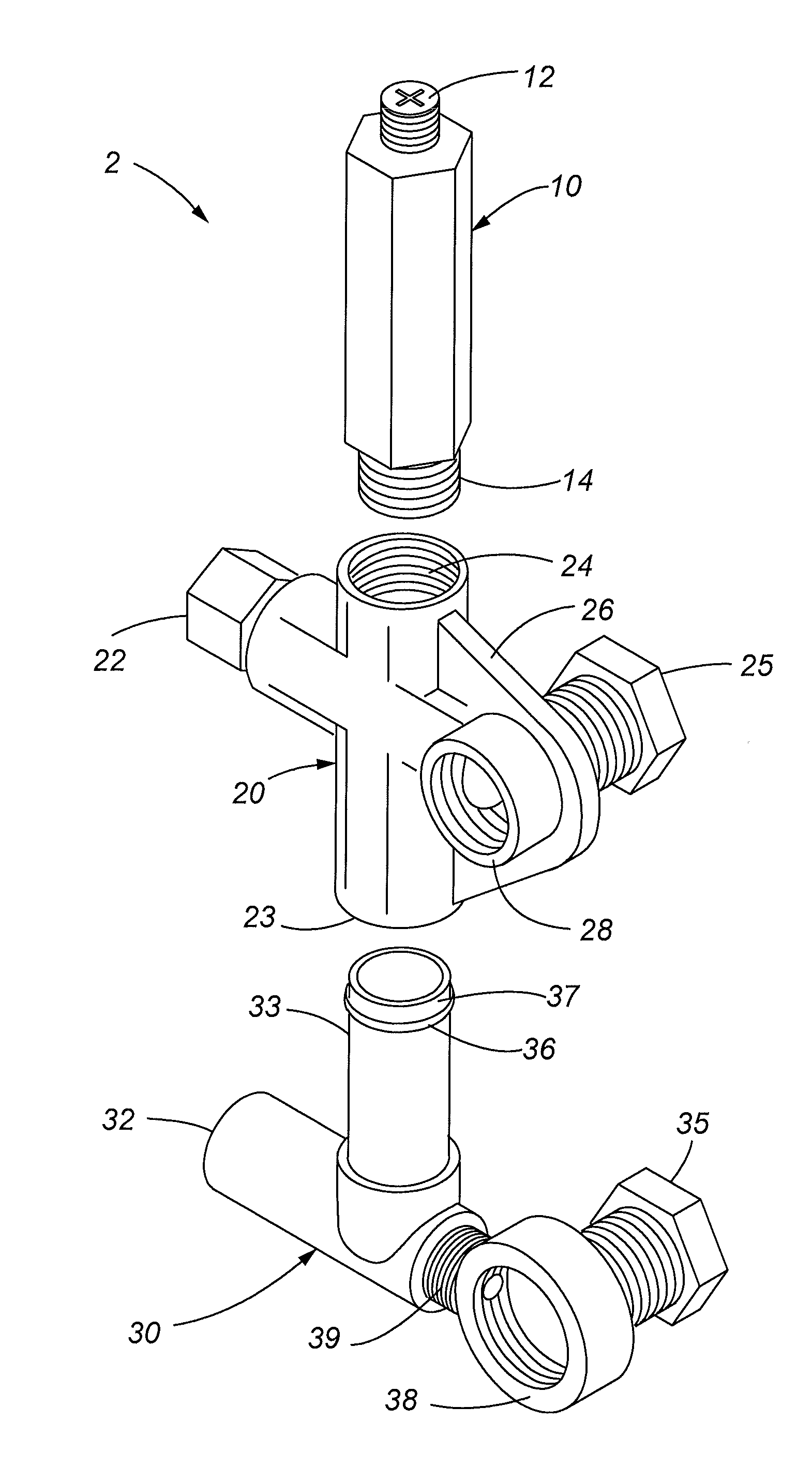

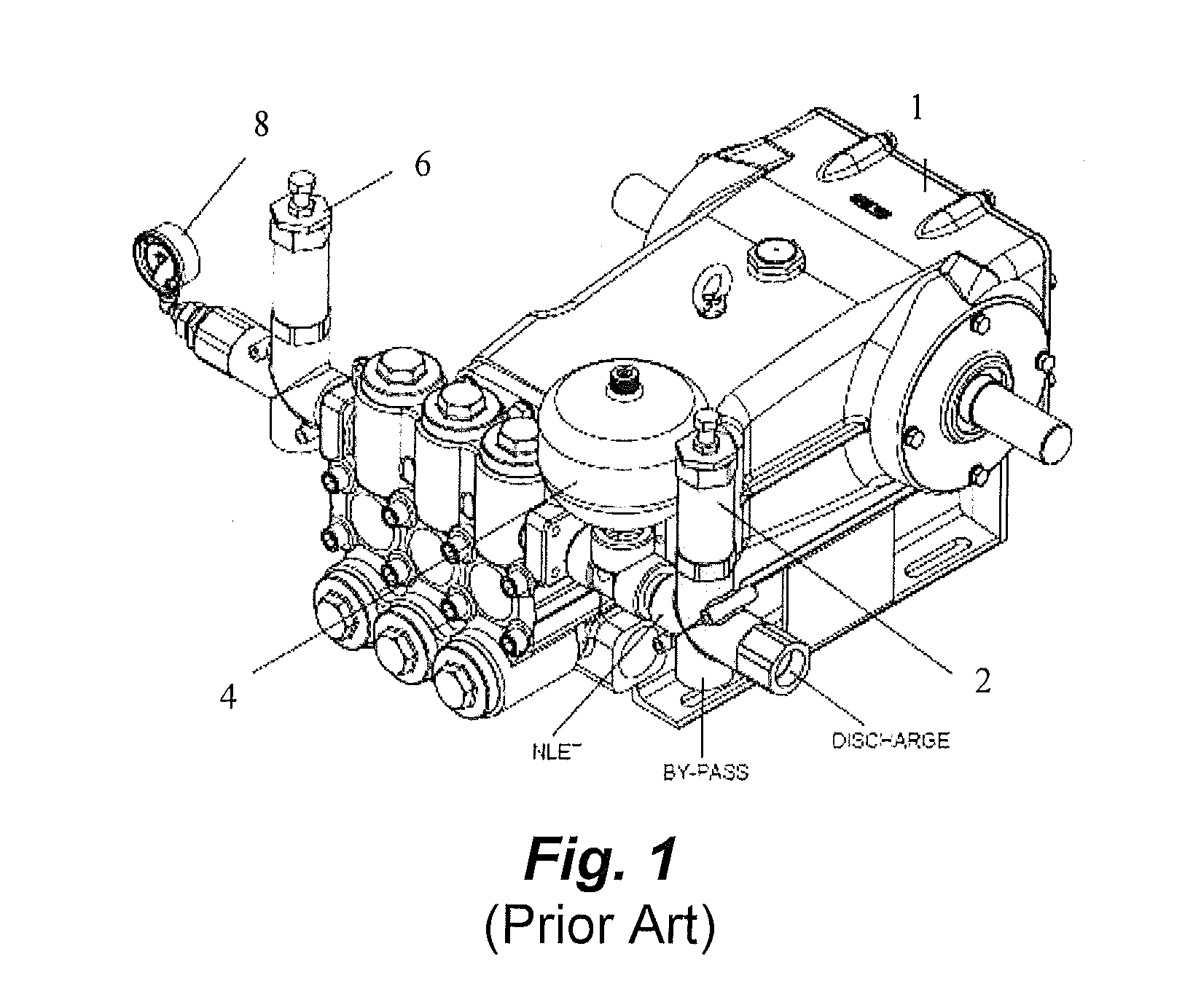

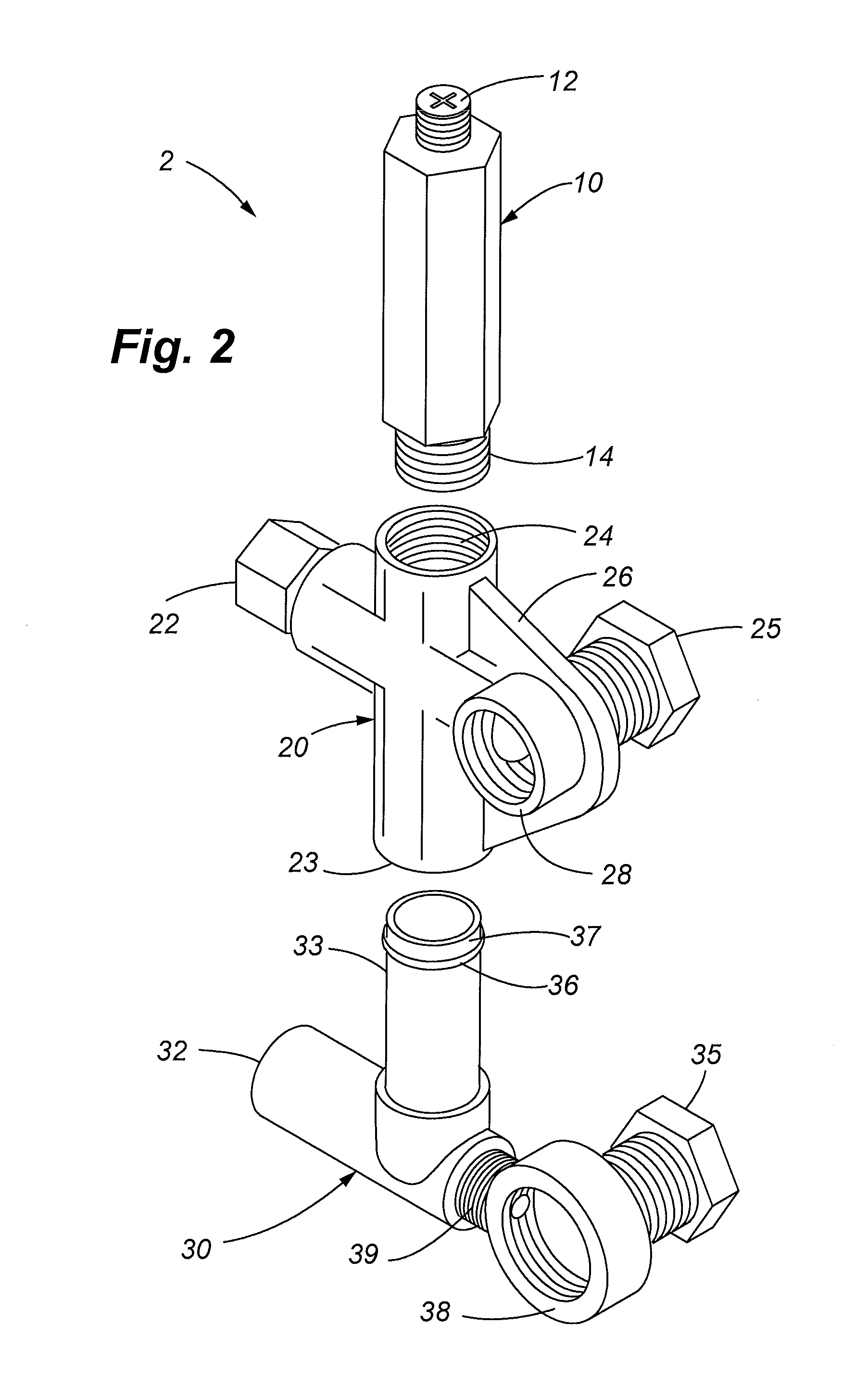

Adjustable unloader valve

A pressure unloader valve is disclosed having inlet and outlet connections adjustable about two dimensions to adapt to a wide variety of high pressure pumps and similar equipment associated with such applications. According to one embodiment, the inlet and outlet connections are adjustable about both a horizontal and a vertical axis. A method for regulating pressure in a valve and pump assembly is also disclosed.

Owner:KARCHER NORTH AMERICA INC

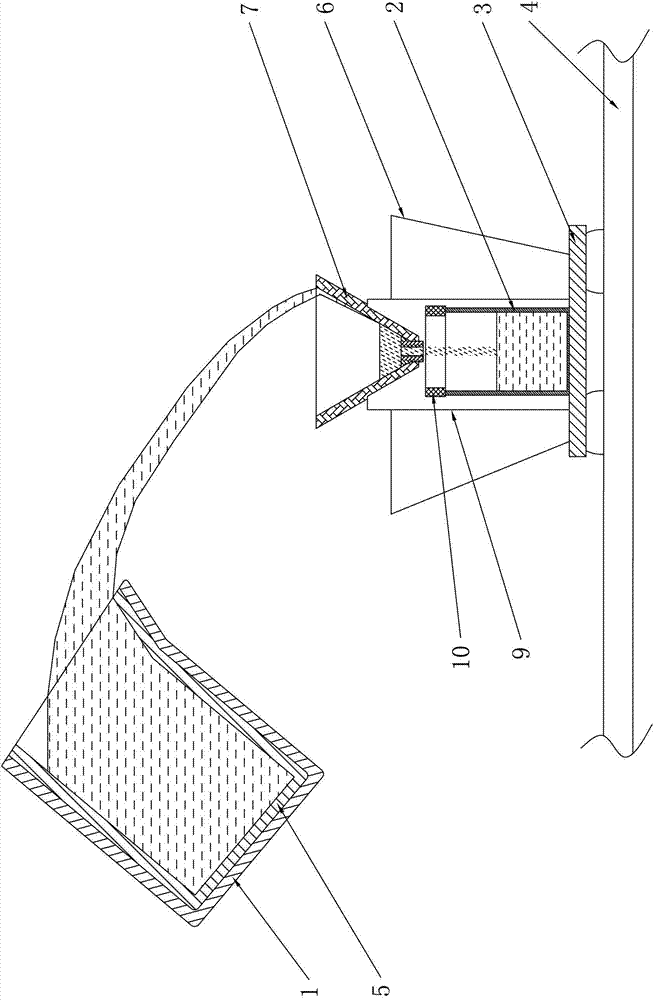

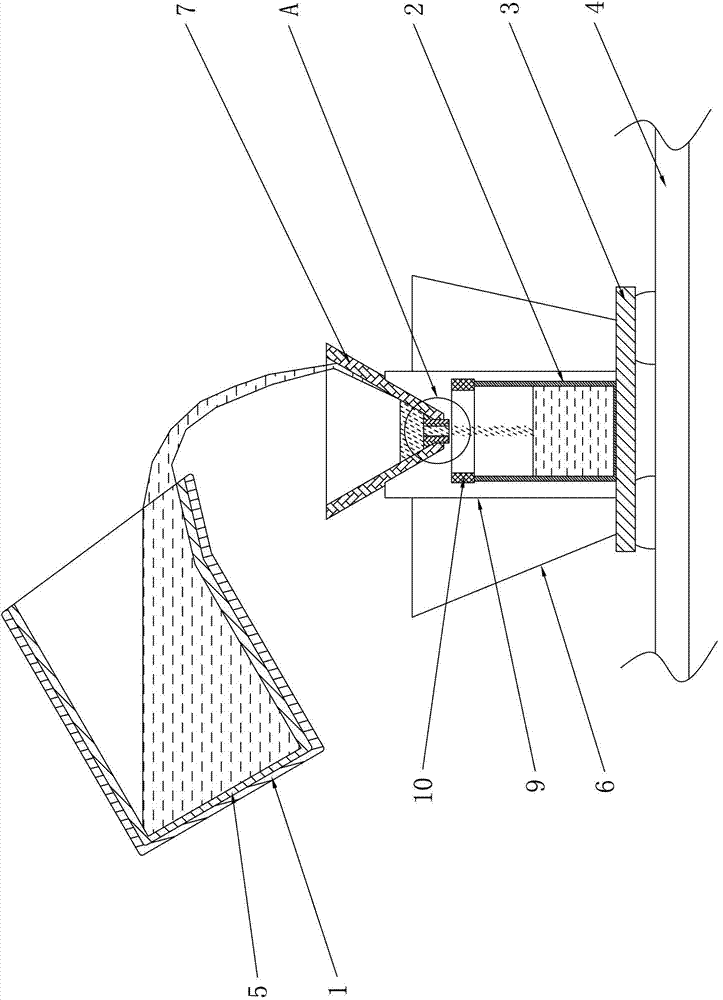

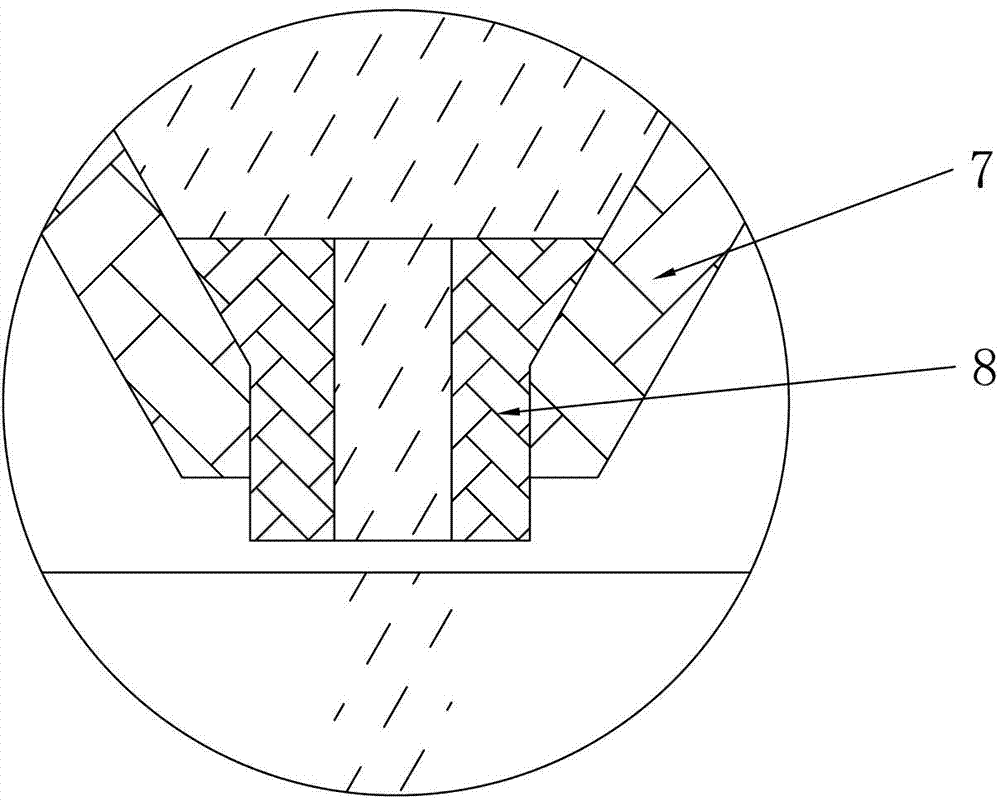

Novel convenient casting device for experiment

The invention discloses a novel convenient casting device for experiment, which is characterized by comprising a furnace body, a casting mould, a mobile trolley and a guide rail. The furnace body is a dumping electric induction furnace, a flat graphite crucible is arranged in the furnace body, the dumping angle of the furnace body is 0-110 degrees, the casting mould is arranged on the mobile trolley, the guide rail is an angle iron guide rail, the mobile trolley is arranged on the guide rail, a support frame is arranged on the mobile trolley, the casting mould is located in the support frame, a funnel made of graphite is arranged on the support frame, the funnel is located above the casting mould, a funnel plug is arranged in the funnel, and a through hole is formed in the funnel plug. The novel convenient casting device is wide in ingot casting production size and weight range, and is very suitable for material research and development; less scrap is generated in fusion casting production; capacity of the crucible is increased, and yield is high; and the novel convenient casting device is simple, easy to use, low in graphite change frequency, labor-saving, material-saving and cost-saving, convenient to operate, safe, simple and efficient, and high in casting quality.

Owner:NINGBO SHENGFA COPPER IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com