Process for manufacturing high-density molybdenum-niobium alloy sputtering target material

A molybdenum-niobium alloy and sputtering target technology, which is applied in metal material coating process, sputtering coating, ion implantation coating and other directions, can solve the problems of reducing efficiency, complex process steps, increasing target production cost and the like, Achieve the effect of reducing costs, uniform organization, and meeting the needs of high-end targets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

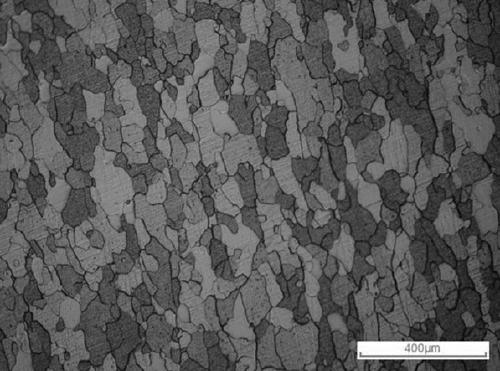

Image

Examples

Embodiment 1

[0036] This embodiment provides a high-density molybdenum-niobium alloy sputtering target preparation process, including the following steps:

[0037] S1. Raw materials are mixed, the purity of molybdenum powder and niobium hydride powder is not less than 99.5%, the molybdenum powder passes through a 200 mesh sieve, the ball milled niobium hydride powder passes through a 160 mesh sieve, and is prepared after sieving in a ratio of 9:1 by weight Add molybdenum powder and niobium hydride powder into the V-type mixer, and flush the mixing body with argon gas into the V-type mixer for 15 minutes, then close the valve at one end of the mixer, continue to fill with argon, and then close Fill the valve with argon gas to keep the positive pressure in the mixer, start the mixing machine for 8 hours and then stop it to obtain molybdenum-niobium mixed powder;

[0038] S2. For the rubber suit powder operation, according to the needs, select a rubber sleeve with a suitable size, put the mol...

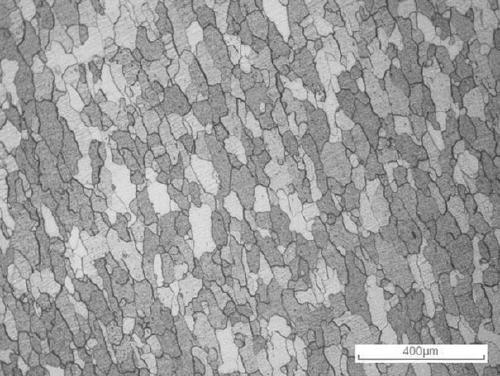

Embodiment 2

[0046] S1, the raw materials are mixed, the purity of molybdenum powder and niobium hydride powder is not less than 99.5%, the molybdenum powder is passed through a 200 mesh sieve, and the ball milled niobium hydride powder is passed through a 160 mesh sieve, and the molybdenum powder and niobium hydride powder are in a weight ratio of 9: Add the ratio of 1 to the mixer, add molybdenum powder and niobium hydride powder, flush the mixing body with argon gas in the mixer for 15 minutes, then close the valve at one end of the mixing body, continue to fill in argon, and then close the filling machine. The argon valve keeps the positive pressure in the mixer, starts the mixing machine for 8 hours and then stops it to obtain molybdenum-niobium mixed powder;

[0047] S2, rubber suit powder operation, according to the needs, select the rubber sleeve of appropriate size, put the molybdenum-niobium mixed powder obtained in step S1 into the rubber sleeve, and shake it while loading. After...

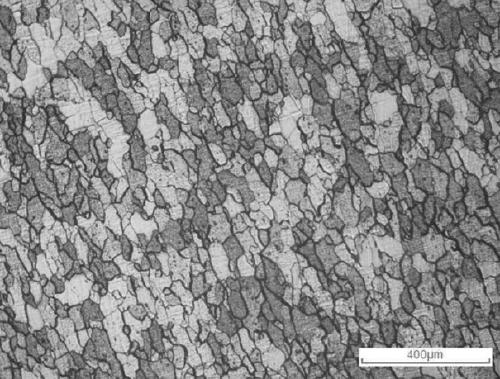

Embodiment 3

[0055] This embodiment provides a high-density molybdenum-niobium alloy sputtering target preparation process, including the following steps:

[0056] S1, the raw materials are mixed, the purity of molybdenum powder and niobium hydride powder is not less than 99.5%, the molybdenum powder is passed through a 200 mesh sieve, and the ball milled niobium hydride powder is passed through a 160 mesh sieve, and the molybdenum powder and niobium hydride powder are in a weight ratio of 9: Add the ratio of 1 to the mixer, add molybdenum powder and niobium hydride powder, flush the mixing body with argon for 15 minutes, then close the valve at one end of the mixing body, continue to fill with argon, and then close the argon filling valve to make Keep the positive pressure in the mixer, start the mixer and stop it after 12 hours to obtain molybdenum-niobium mixed powder;

[0057] S2, rubber suit powder operation, according to the needs, choose the rubber sleeve of appropriate size, put th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com