Preparation technology of high density molybdenum-tantalum alloy sputtering target material

A sputtering target material and preparation process technology, applied in metal material coating process, sputtering coating, metal processing equipment, etc. The finished product rate and qualified rate, the convenience of industrialized mass production, and the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

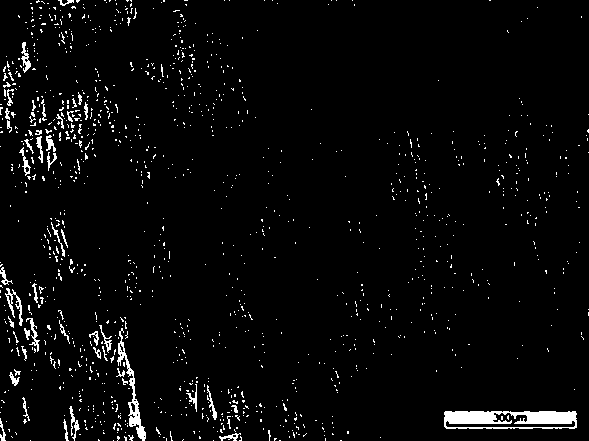

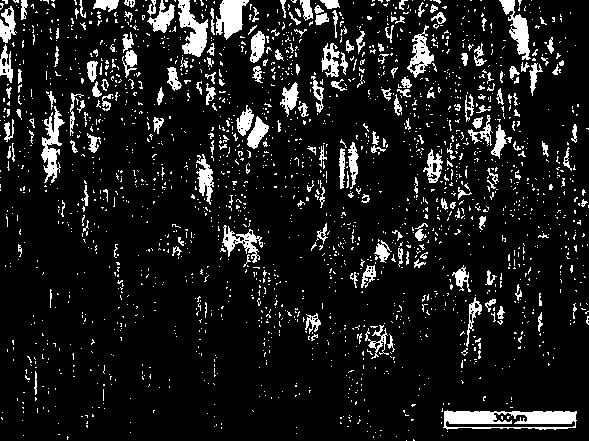

Image

Examples

Embodiment 1

[0032] A preparation process for a high-density molybdenum-tantalum alloy sputtering target, comprising the following steps:

[0033] S1. Hydrogenation treatment of tantalum powder: Put the high-purity tantalum powder in a sintering furnace and roast it with hydrogen gas. The roasting temperature is controlled at 500°C and the roasting time is controlled at 1 hour to obtain hydrogenated tantalum hydride powder, and then ball mill the tantalum hydride powder , the ball milling time is controlled at 16 hours, and the tantalum hydride powder with the required particle size is obtained;

[0034] S2. Raw material mixing: Add molybdenum powder and tantalum hydride powder into the mixer at a weight ratio of 9:1. The purity of molybdenum powder and tantalum hydride powder is not less than 99.5%. Molybdenum powder passes through a 200-mesh sieve and ball mills The tantalum hydride powder is passed through a 160-mesh sieve. After adding the ball-milled molybdenum powder and tantalum hyd...

Embodiment 2

[0042] This embodiment includes the following steps:

[0043] S1. Hydrogenation treatment of tantalum powder: Put the high-purity tantalum powder in a sintering furnace and roast it with hydrogen gas. The roasting temperature is controlled at 500°C and the roasting time is controlled at 1 hour to obtain hydrogenated tantalum hydride powder, and then ball mill the tantalum hydride powder , the ball milling time is controlled at 16 hours, and the tantalum hydride powder with the required particle size is obtained;

[0044] S2. Raw material mixing: Add molybdenum powder and tantalum hydride powder into the mixer at a weight ratio of 9:1. The purity of molybdenum powder and tantalum hydride powder is not less than 99.5%. Molybdenum powder passes through a 200-mesh sieve and ball mills The tantalum hydride powder passed through a 160-mesh sieve, after adding molybdenum powder and tantalum hydride powder into the mixer, flush the mixing body with argon for 15 minutes, then close the...

Embodiment 3

[0052] This embodiment includes the following steps:

[0053] S1. Hydrogenation treatment of tantalum powder: put a certain amount of high-purity tantalum powder in a sintering furnace and roast it with hydrogen gas. The roasting temperature is controlled at 500°C and the roasting time is controlled at 1 hour. The hydrogenated tantalum hydride powder is obtained, and then the tantalum hydride powder is ball milled, and the ball milling time is controlled at 16 hours to obtain the tantalum hydride powder with the required particle size.

[0054] S2. Raw material mixing: Add molybdenum powder and tantalum hydride powder into the mixer at a weight ratio of 9:1. The purity of molybdenum powder and tantalum hydride powder is not less than 99.5%. Molybdenum powder passes through a 200-mesh sieve and ball mills The tantalum hydride powder passed through a 160-mesh sieve, after adding molybdenum powder and tantalum hydride powder into the mixer, flush the mixing body with argon for 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com