Shrinkage and looseness resisting casting method of air cylinder cover castings

An anti-shrinkage porosity and cylinder head technology, which is applied in the direction of casting molding equipment, molds, and mold components, can solve the problems of shrinkage porosity in conduit holes, difficulties in hot junction feeding in the middle and upper parts, and high temperature of molten iron in the middle and upper parts. The effect of reducing the occurrence probability of shrinkage porosity and improving the cooling effect of heat absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing:

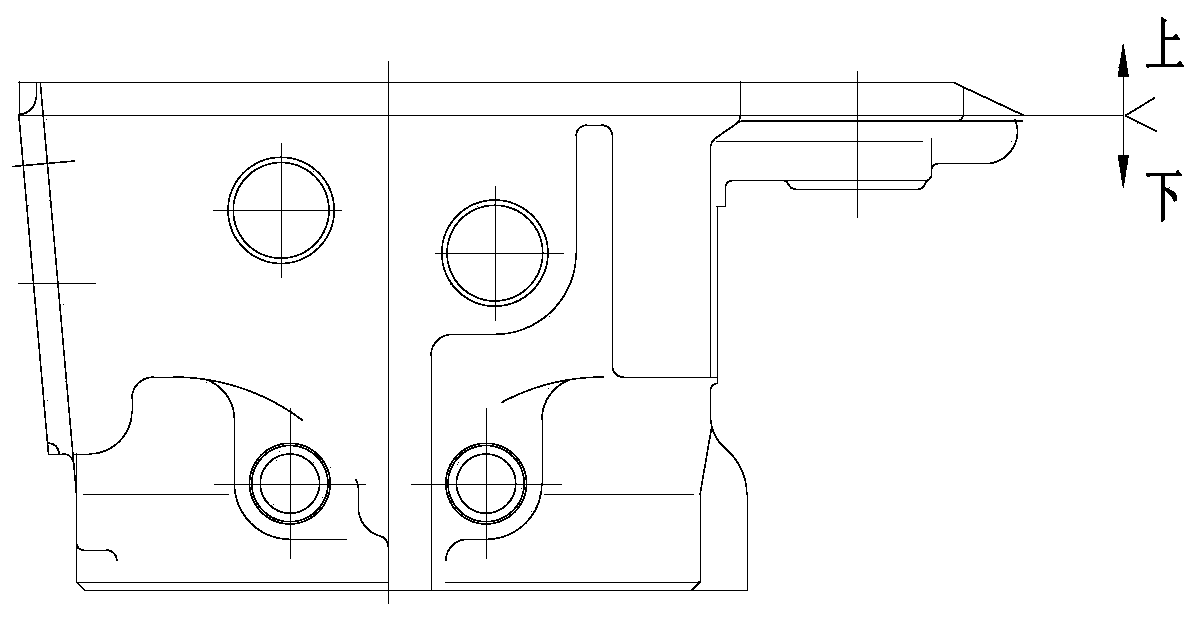

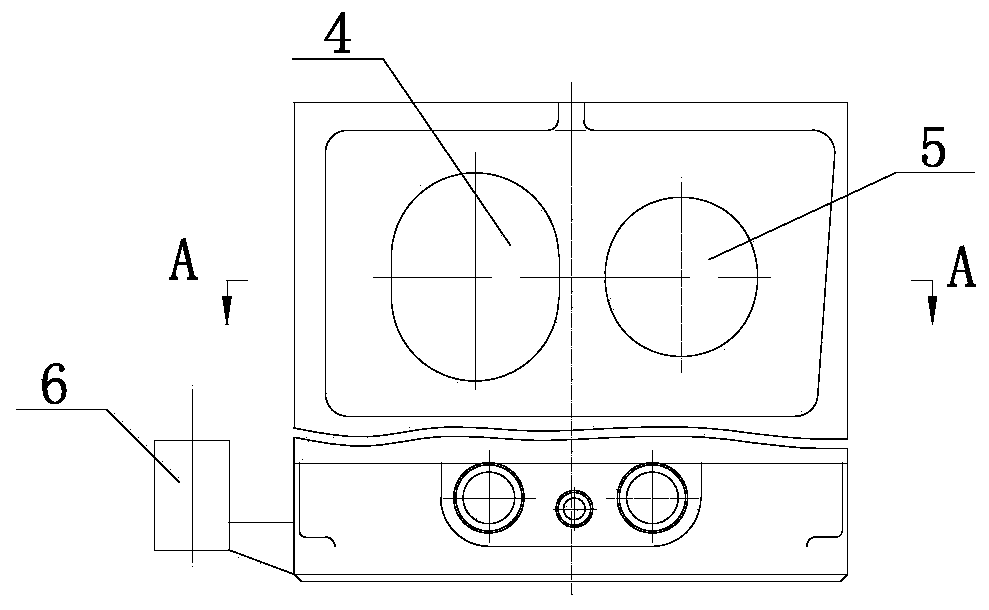

[0035] Such as Figure 1 to Figure 8 Shown, the anti-shrinkage loose casting method of cylinder head casting of the present invention is characterized in that taking the following steps:

[0036] ① Making molds;

[0037] ② Manufacture the upper sand mold, lower sand mold and sand cores, in which the air channel sand cores include the No. 1 sand core 4 and the No. 2 sand core 5, the air inlet sand core uses the No. Sand core 5 and No. 2 sand core 5 are put into No. 1 outer chill iron 8 and No. 2 outer chill iron 7 respectively;

[0038] ③Paint the paint and dry the sand core;

[0039] ④ Lower the core and place four internal cooling irons 3 at the positions corresponding to the upper sand mold;

[0040] ⑤ Fitting and fastening the sand box;

[0041] ⑥Pouring molten iron;

[0042] ⑦Unpacking, cleaning, inspection, storage.

[0043] The mold made in step ① is a wooden m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com