Solidification forming device suitable for manufacturing aramid III fibers through dry jetting and wet spinning method

A technology of coagulation forming and wet spinning, which is applied to coagulation forming devices and spinning equipment for manufacturing aramid III fibers, can solve problems such as reasonable control, fast coagulation liquid flow rate, and fiber coagulation and forming defects, so as to reduce motion resistance, The effect of ensuring sufficient solidification and reducing the generation of fuzz

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

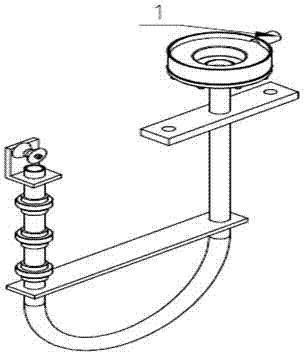

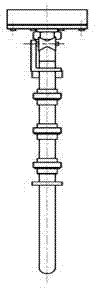

[0029] A coagulation and forming device suitable for producing aramid fiber III by dry spraying-wet spinning method, including two parts: a coagulation plate and a U-shaped coagulation tube. 4. The coagulation plate cover 2 and the overflow pipe 1 are composed. The U-shaped coagulation tube is mainly composed of a U-shaped tube 8, a regulating tube 9, and a wire outlet tube 10. One end of the U-shaped tube 8 is connected with the coagulation plate, and the other end is connected with the coagulation plate. The regulating pipe 10 is flexibly connected.

[0030] The coagulation plate is provided with a liquid inlet 6, a liquid outlet 7, and an overflow pipe 1. The U-shaped coagulation tube has a liquid inlet and a liquid outlet, and the liquid inlet of the U-shaped coagulation tube and the liquid outlet of the coagulation plate 7 connections, and a guide wheel 11 is provided at the liquid outlet of the U-shaped coagulation tube.

[0031] The liquid outlet of the U-shaped coagul...

Embodiment 2

[0038] A coagulation and forming device suitable for producing aramid fiber III by dry spraying-wet spinning method, including two parts: a coagulation plate and a U-shaped coagulation tube. 4. The coagulation plate cover 2 and the overflow pipe 1 are composed. The U-shaped coagulation tube is mainly composed of a U-shaped tube 8, a regulating tube 9, and a wire outlet tube 10. One end of the U-shaped tube 8 is connected with the coagulation plate, and the other end is connected with the coagulation plate. The regulating pipe 10 is flexibly connected.

[0039] The coagulation plate is provided with a liquid inlet 6, a liquid outlet 7, and an overflow pipe 1. The U-shaped coagulation tube has a liquid inlet and a liquid outlet, and the liquid inlet of the U-shaped coagulation tube and the liquid outlet of the coagulation plate 7 connections, and a guide wheel 11 is provided at the liquid outlet of the U-shaped coagulation tube.

[0040] The liquid outlet of the U-shaped coagul...

Embodiment 3

[0047] A coagulation and forming device suitable for producing aramid fiber III by dry spraying-wet spinning method, including two parts: a coagulation plate and a U-shaped coagulation tube. 4. The coagulation plate cover 2 and the overflow pipe 1 are composed. The U-shaped coagulation tube is mainly composed of a U-shaped tube 8, a regulating tube 9, and a wire outlet tube 10. One end of the U-shaped tube 8 is connected with the coagulation plate, and the other end is connected with the coagulation plate. The regulating pipe 10 is flexibly connected.

[0048] The coagulation plate is provided with a liquid inlet 6, a liquid outlet 7, and an overflow pipe 1. The U-shaped coagulation tube has a liquid inlet and a liquid outlet, and the liquid inlet of the U-shaped coagulation tube and the liquid outlet of the coagulation plate 7 connections, and a guide wheel 11 is provided at the liquid outlet of the U-shaped coagulation tube.

[0049] The liquid outlet of the U-shaped coagul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com