Progressive-die forming die for automobile suspension control arm lower piece

A technology of automobile suspension and forming mold, applied in the field of progressive die, can solve the problems of slow conveying speed, producing metal broken pins, slowing conveying speed, etc., to achieve product quality assurance, reduction of metal broken pins, and improvement of feeding speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

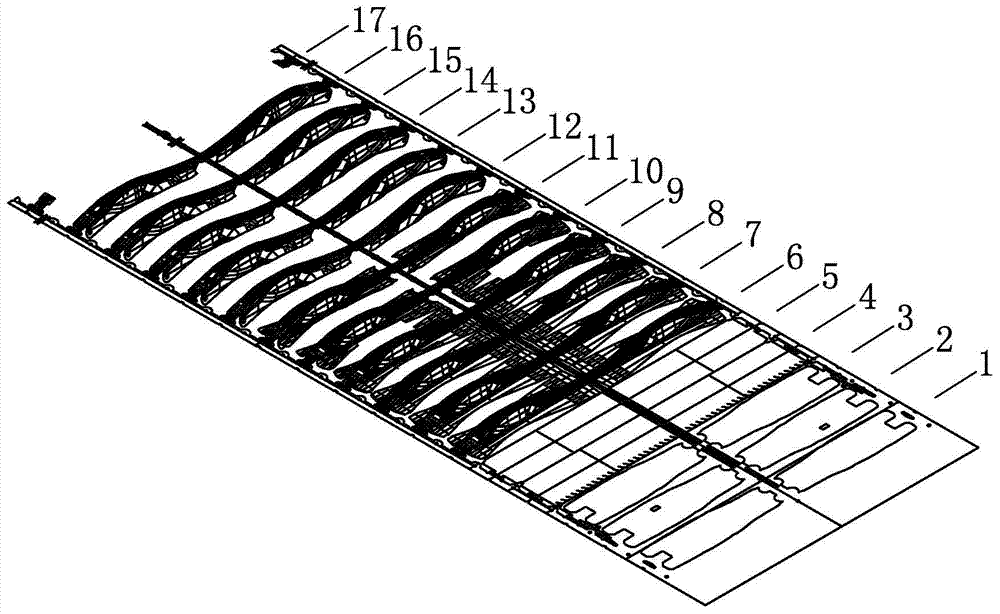

[0036] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 9 , Figure 11 , Figure 12 :

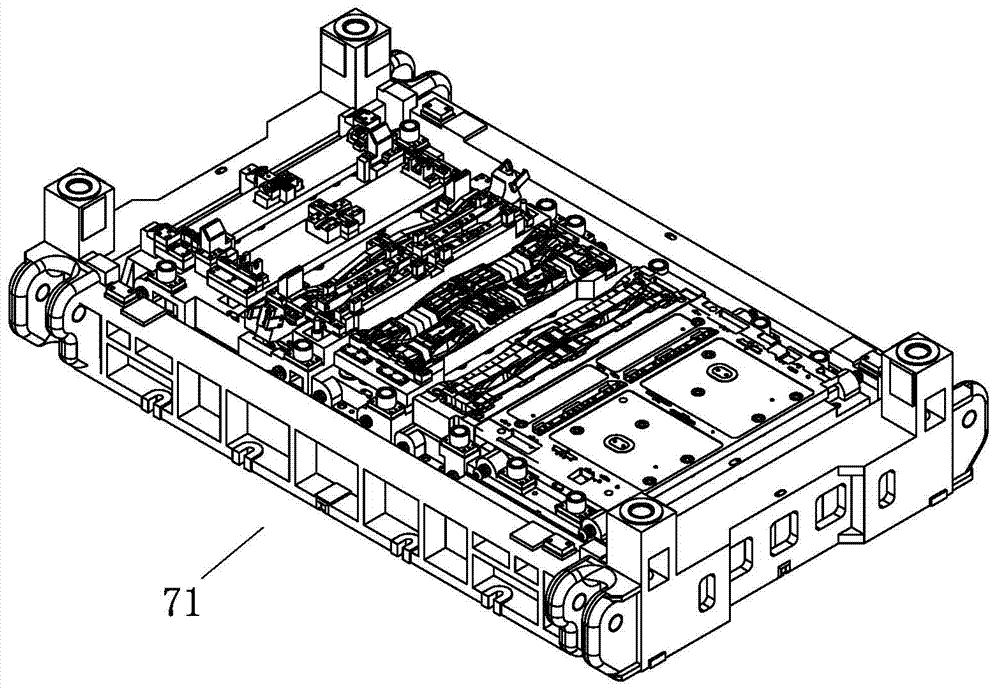

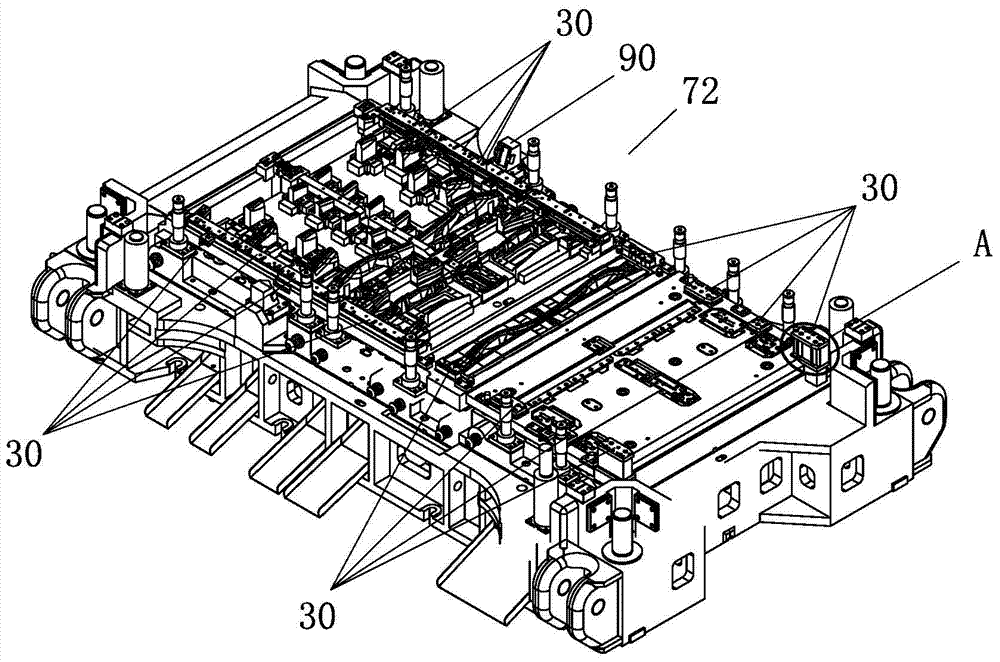

[0037]The progressive die molding die for the lower part of the automobile suspension control arm, including the upper die 71, the lower die 72, and the punching guide hole and process hole process 1, the process of punching the process hole and stamping process 2, Empty step process 3, punching process hole cutting process 4, empty step process 5, drawing process 6, empty step process 7, trimming and punching process 8, trimming process 9, trimming process 10, flanging and shaping process 11 17 processes including side hole punching process 12, empty step process 13, side hole punching process 14, empty step process 15, separation process 16, waste cutting process 17;

[0038] A plurality of feeding guide assemblies 30 are respectively fixed at intervals along the moving direction of the ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com