Tobacco Leaf Leaf Rebaking Front Stage Process Treatment Method

A processing method and technology of tobacco leaves, applied in the field of redrying, can solve problems such as lack of research, achieve the effects of reducing tobacco leaf crushing, realizing flexible processing, and reducing processing intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

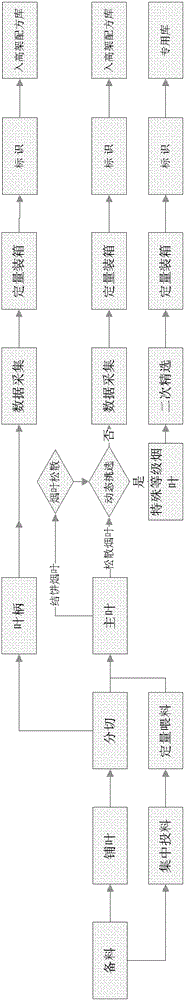

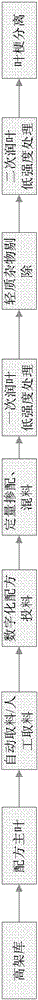

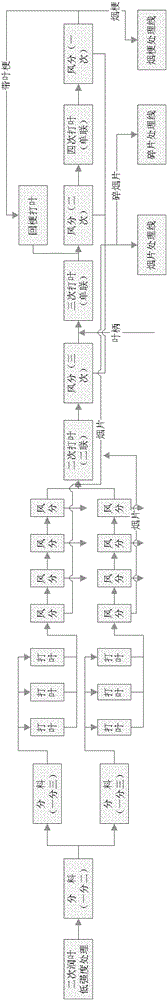

[0025] Utilize the method of the present invention to carry out the pretreatment of tobacco leaf loose leaf, specific method is: (1) loose leaf formula pretreatment: loose tobacco leaf is passed artificial leaf laying, cutting, respectively obtains petiole, main leaf, then through data acquisition, quantitative packing , mark storage and form semi-finished products waiting for processing, or directly enter data collection and subsequent processes through centralized feeding and quantitative feeding without leaf laying and cutting; for a production line with a design capacity of 900,000 tons, select 40% according to the needs, and pick 3 out of them %, pick out 540 tons of special-grade tobacco leaves; for tobacco leaves that do not need to be cut, they are directly boxed through centralized fixed-point feeding and quantitative feeding; centralized feeding sets up 6 stations, reducing the number of employees by 72, according to 20 % Tobacco leaves do not need to be cut and calcu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com