A temperature difference semiconductor module with cooling and heating and temperature difference power generation function

A temperature difference semiconductor, cooling and heating technology, applied in the direction of semiconductor devices, semiconductor/solid-state device components, electric solid-state devices, etc., can solve the problems of high manufacturing process and cost, decreased system efficiency, low yield rate, etc., and achieve the manufacturing structure. Simple, flexible and accurate temperature control, high use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

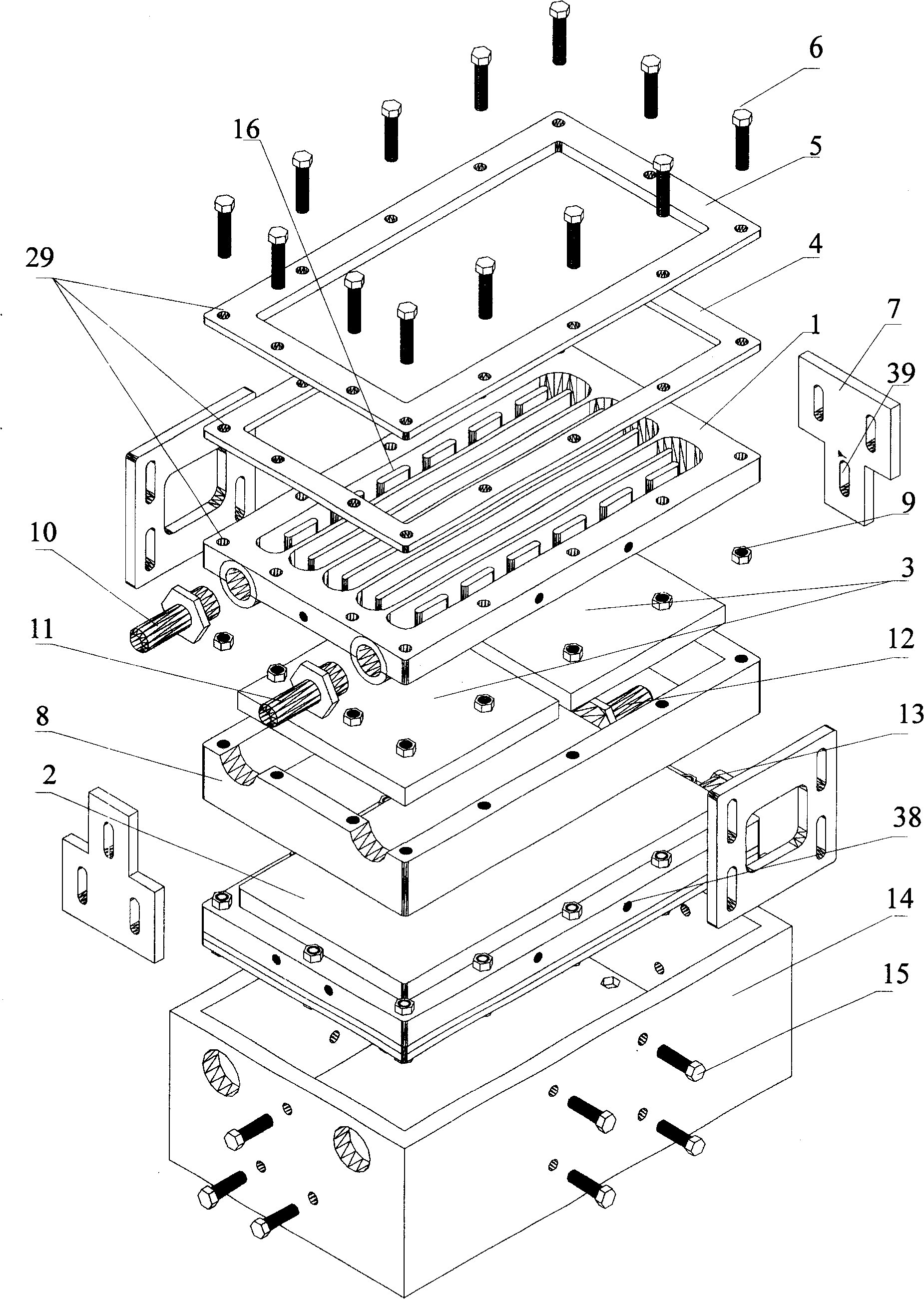

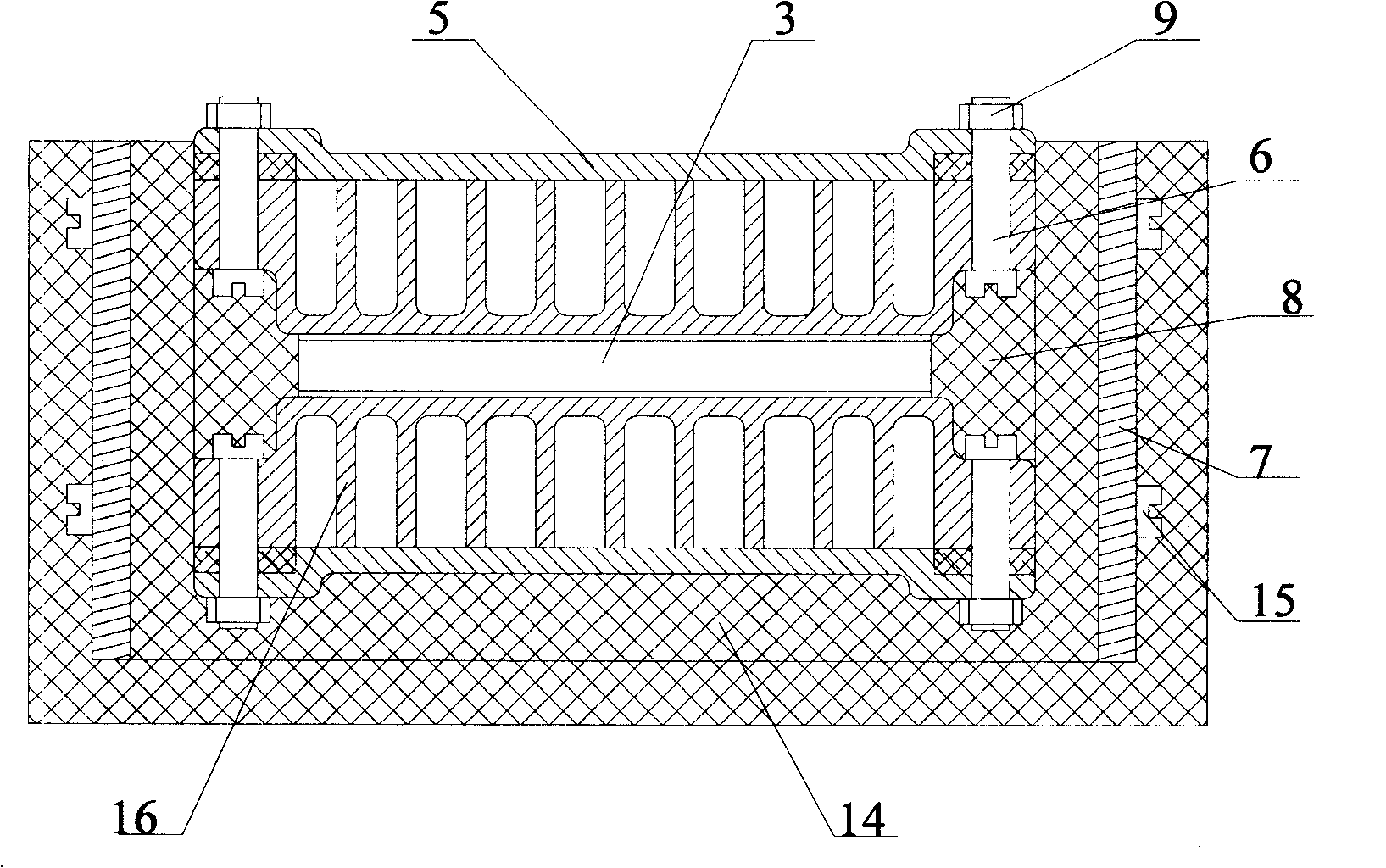

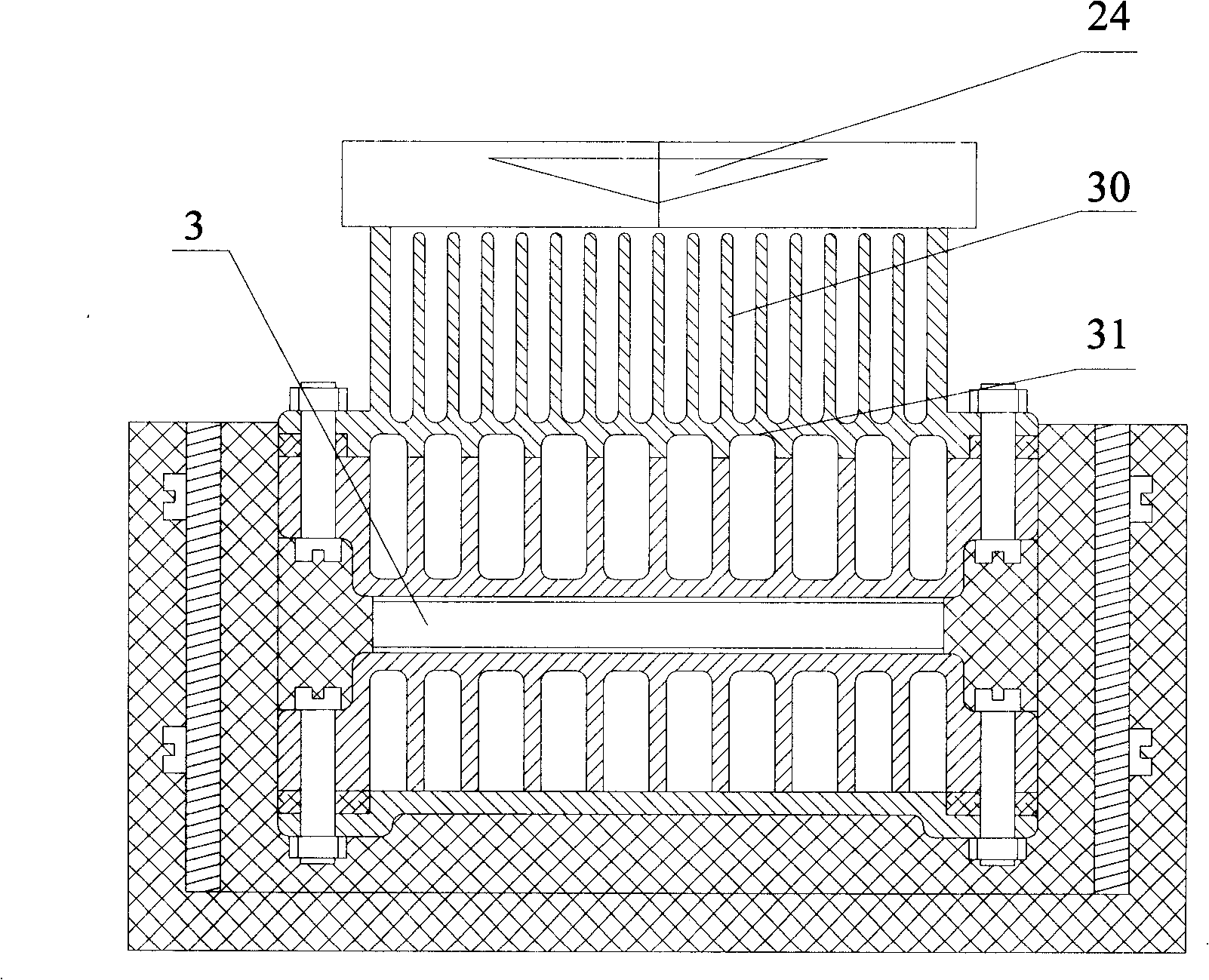

[0036] figure 1 , 2 , 5 is the first preferred embodiment of the present invention, figure 1 is a three-dimensional loading and unloading diagram, figure 2 is the cross-sectional view of the module, Figure 5 It is a top view of the openings of the heat conduction boxes and . In this embodiment, there are two heat conduction boxes , , thermoelectric semiconductor components , heat insulation layers , , and a fixed plate , among which:

[0037] Depend on figure 1 , Figure 5 It can be seen that there is a serpentine water tank inside the heat conduction box and , and there are a number of diverter fins in the tank. The surface area enhances the heat exchange capability with the thermal fluid.

[0038] In addition, the bottom of the water tank is processed into a bottom surface with a certain roughness. Its function is to increase the surface area of the bottom and the degree of turbulence of the heat transfer fluid at the bottom of the water tank, and reduce the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com