Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1272results about "Thermoelectric device details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

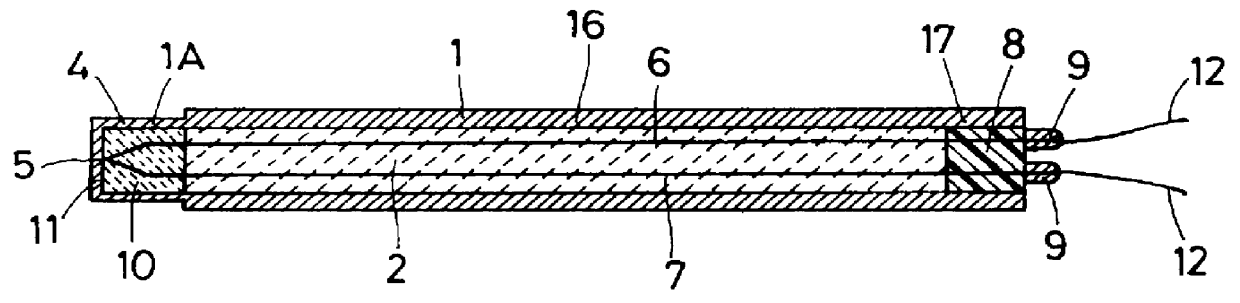

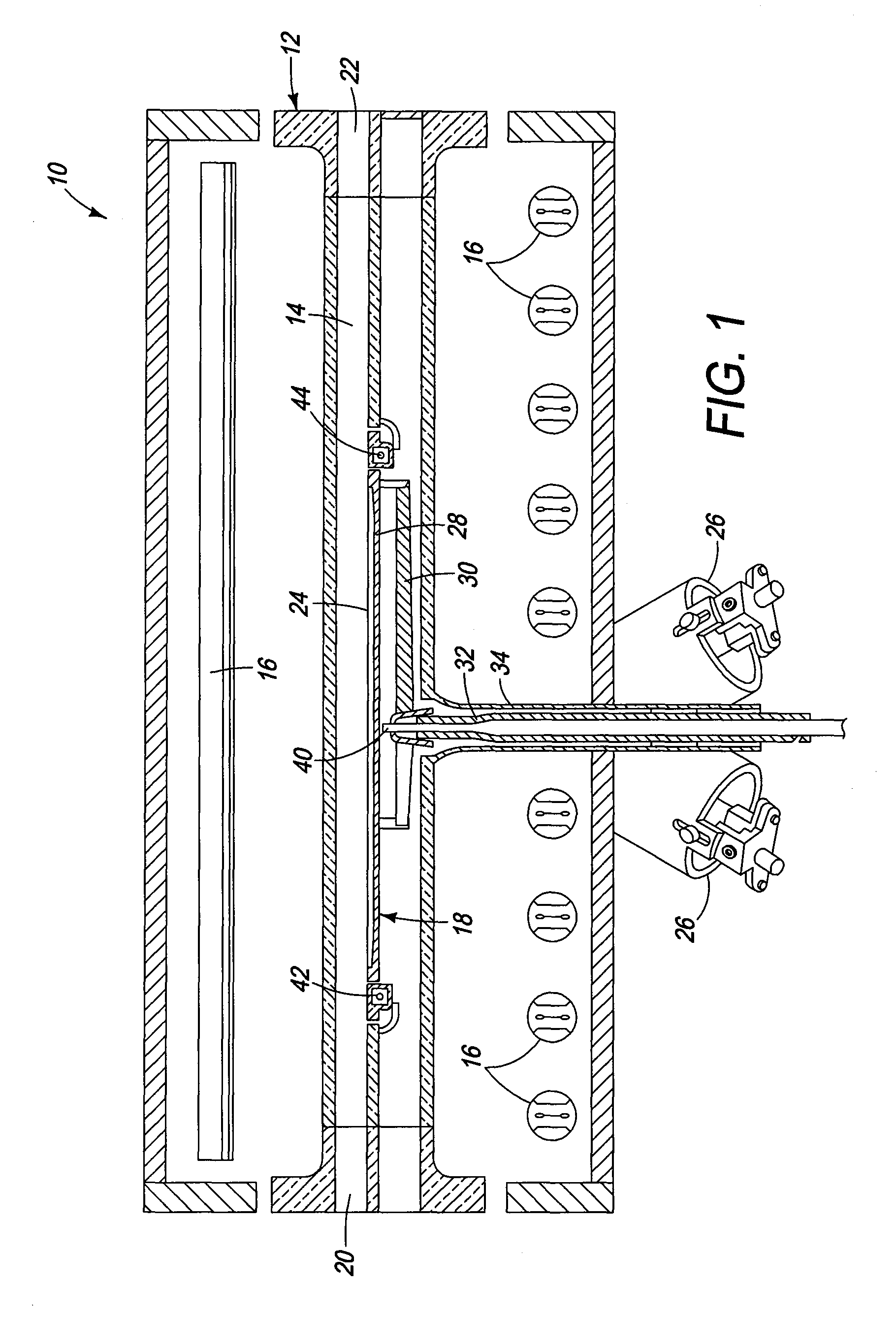

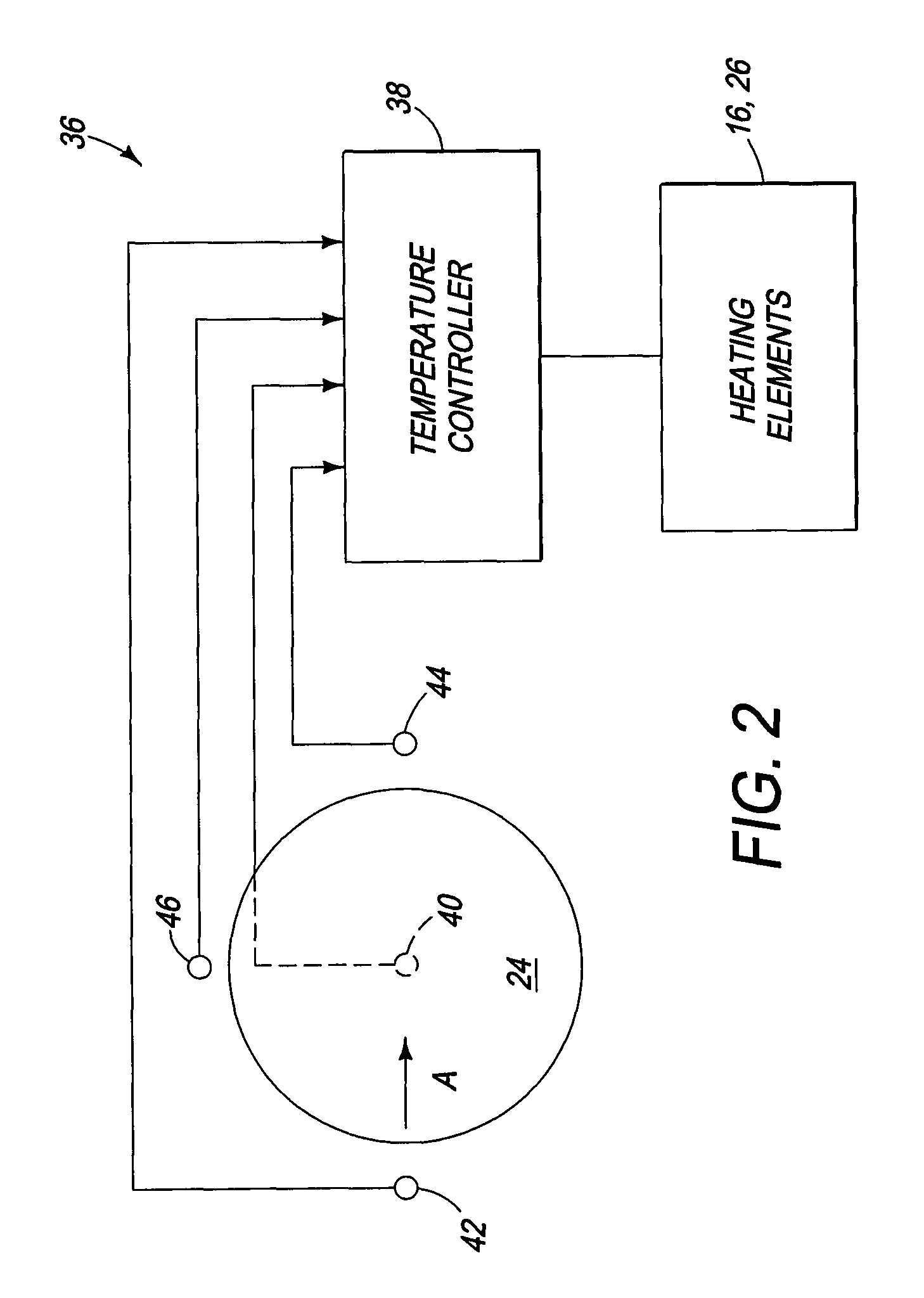

Ceramic sheath type thermocouple

InactiveUS6102565AThermometer detailsThermometers using electric/magnetic elementsHeat resistanceWhiskers

This ceramic sheath type thermocouple has a long service life, an improved temperature measuring responsibility and an improved temperature measuring precision, and enables repetitive use. The ceramic sheath type thermocouple has its protective tube 1 formed of a heat resisting ceramics selected from silicon nitride, sialon and silicon carbide. In the protective tube 1 are installed a pair of W-Re wires that are connected to form a joint portion constituting a temperature measuring point 5. A filler made of Si3N4 reaction-sintered ceramics is loaded into the front end portion of the protective tube to enclose the W-Re wires. Another filler made of SiC whisker with a heat conductivity smaller than that of the filler of the front end portion is loaded into the rear portion of the protective tube. An inert gas is sealed in the protective tube. Alternatively, the temperature measuring portion may be formed by exposing from the front end portion of the protective tube the joint portion where the ends of the W-Re wires are connected. The temperature measuring portion is coated with a cover film that is made of silicon carbide, silicon nitride or a composite of these, all having excellent heat resisting and corrosion resisting properties.

Owner:ISUZU MOTORS LTD

Thermocouple

ActiveUS8100583B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple device

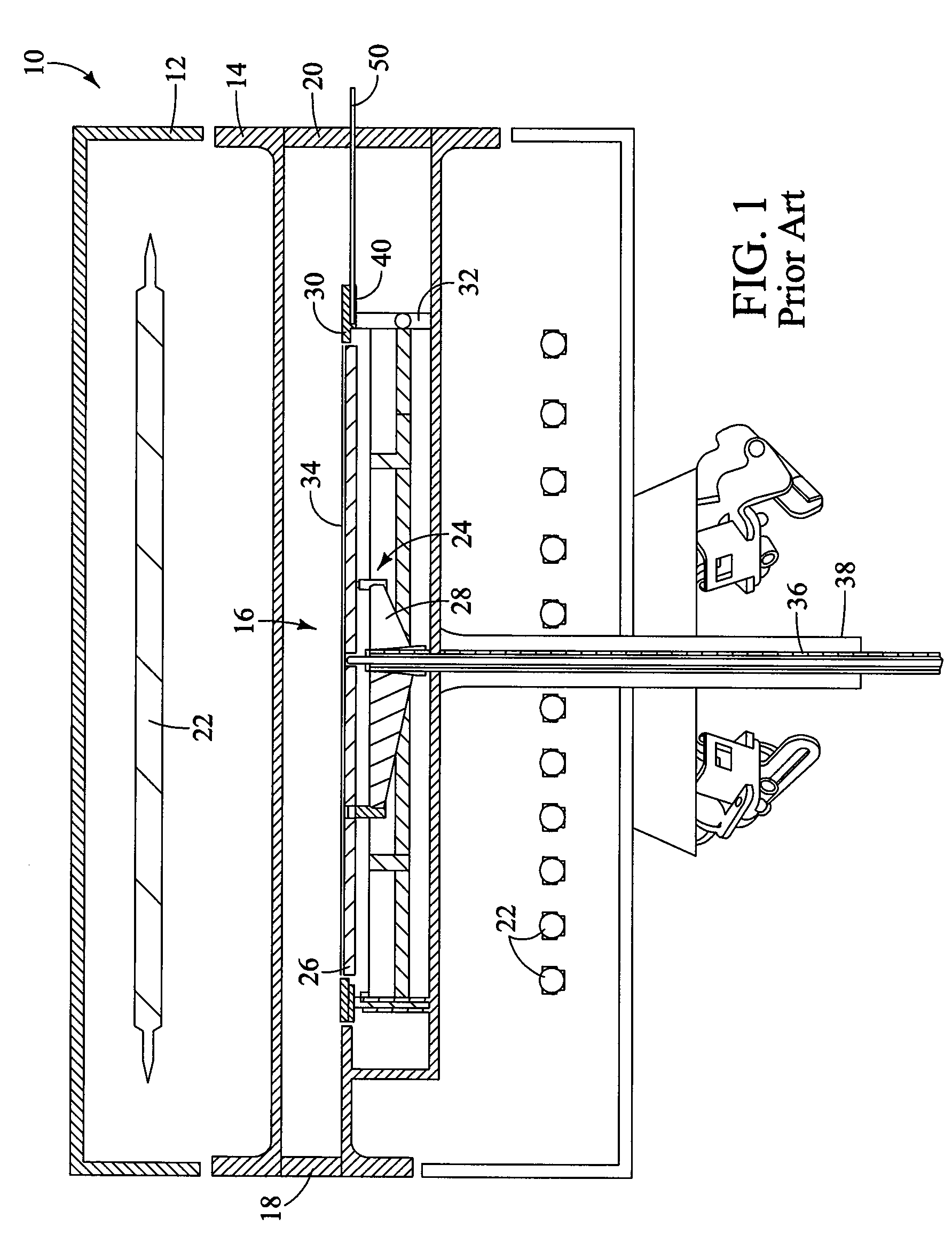

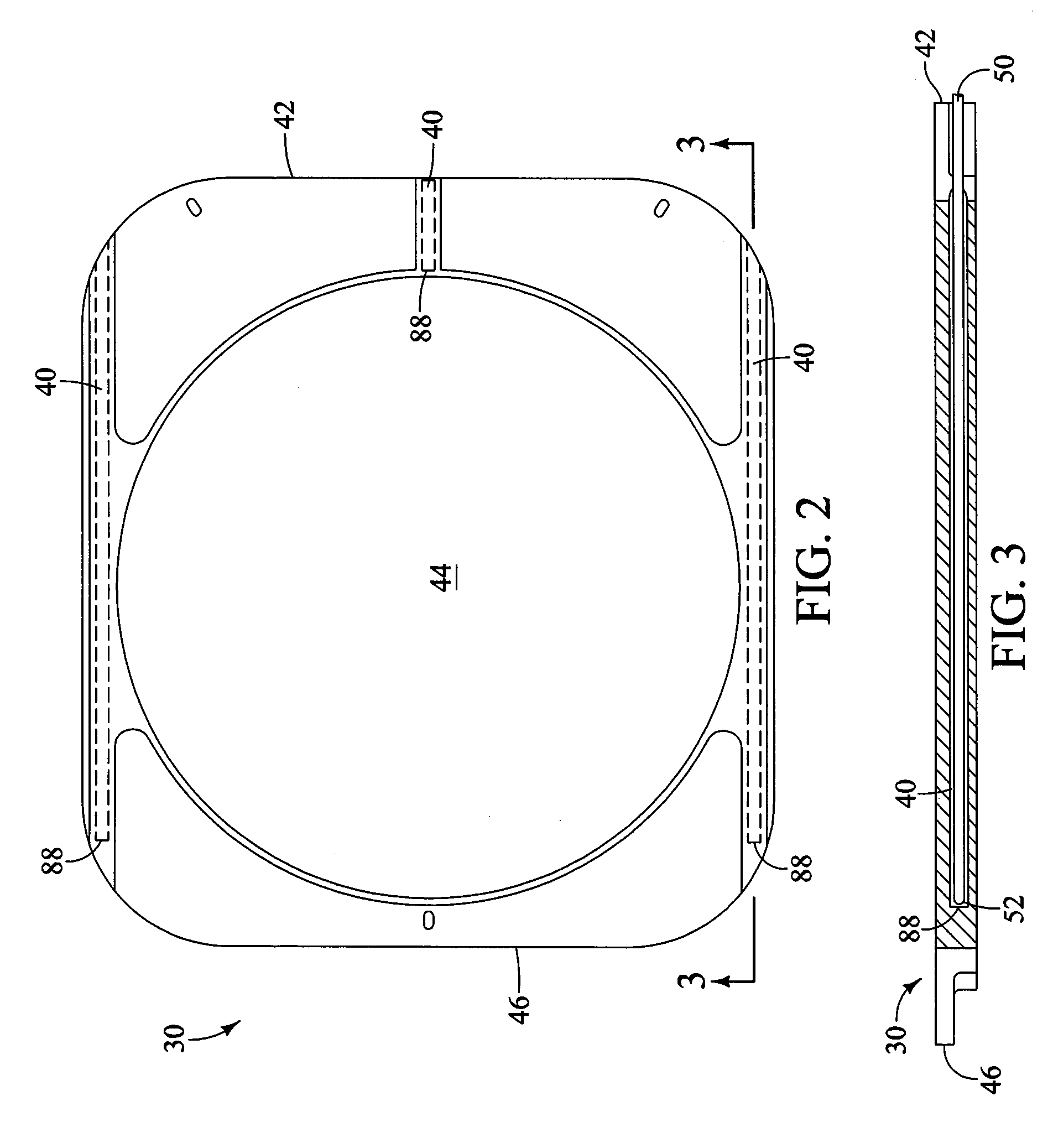

A thermocouple having at least one inner alignment feature or at least one outer alignment feature, or a combination thereof for positively positioning and aligning at least one thermocouple junction within a bore formed in a susceptor ring of a semiconductor substrate processing reactor. The outer alignment feature is configured to positively align the junction(s) longitudinally within the bore. The inner alignment feature configured to positively position the junction(s) rotationally within the sheath of the thermocouple relative to the bore.

Owner:ASM IP HLDG BV

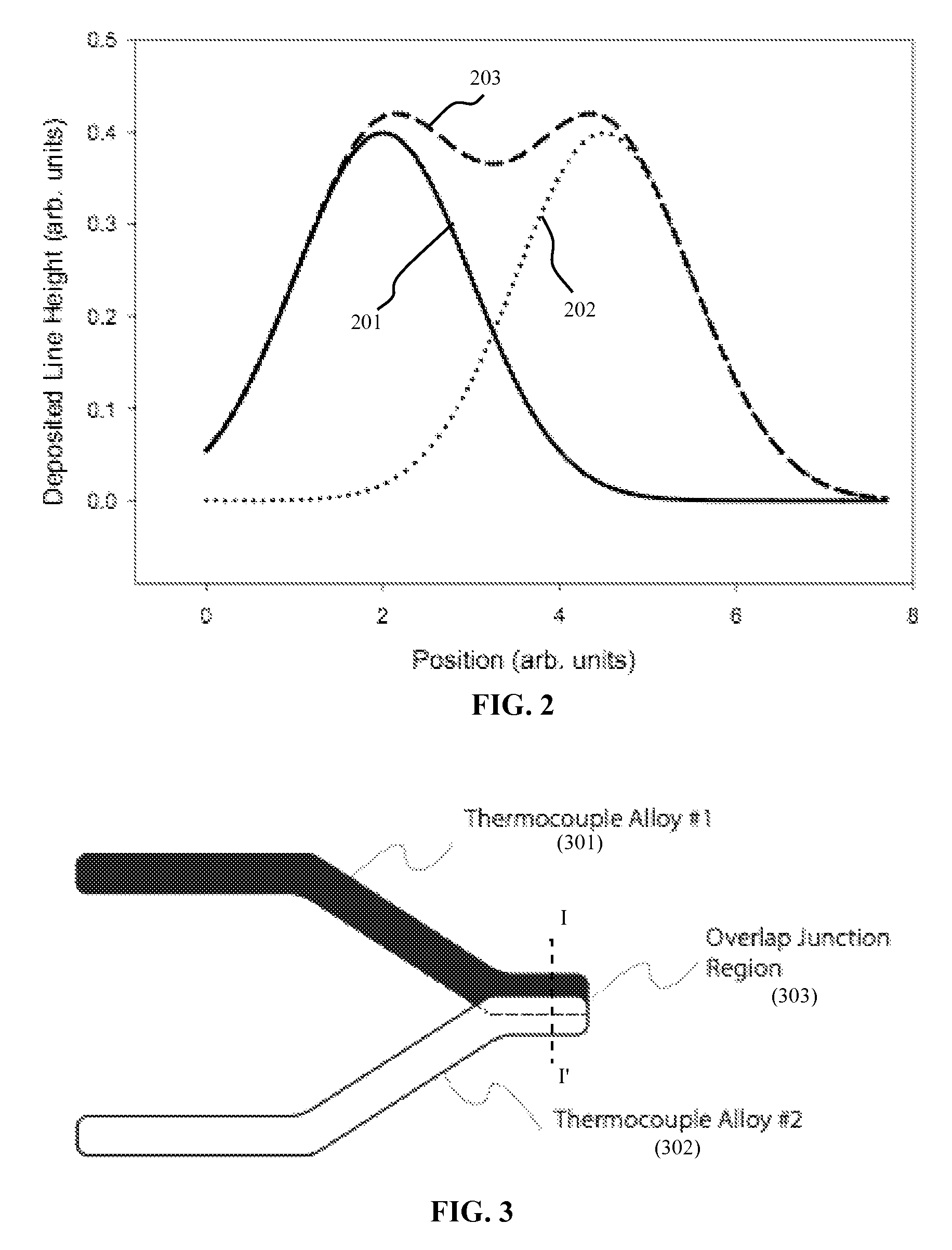

Thermocouples

ActiveUS7753584B2Thermoelectric device with peltier/seeback effectThermometers using electric/magnetic elementsThermoelectric materialsEngineering

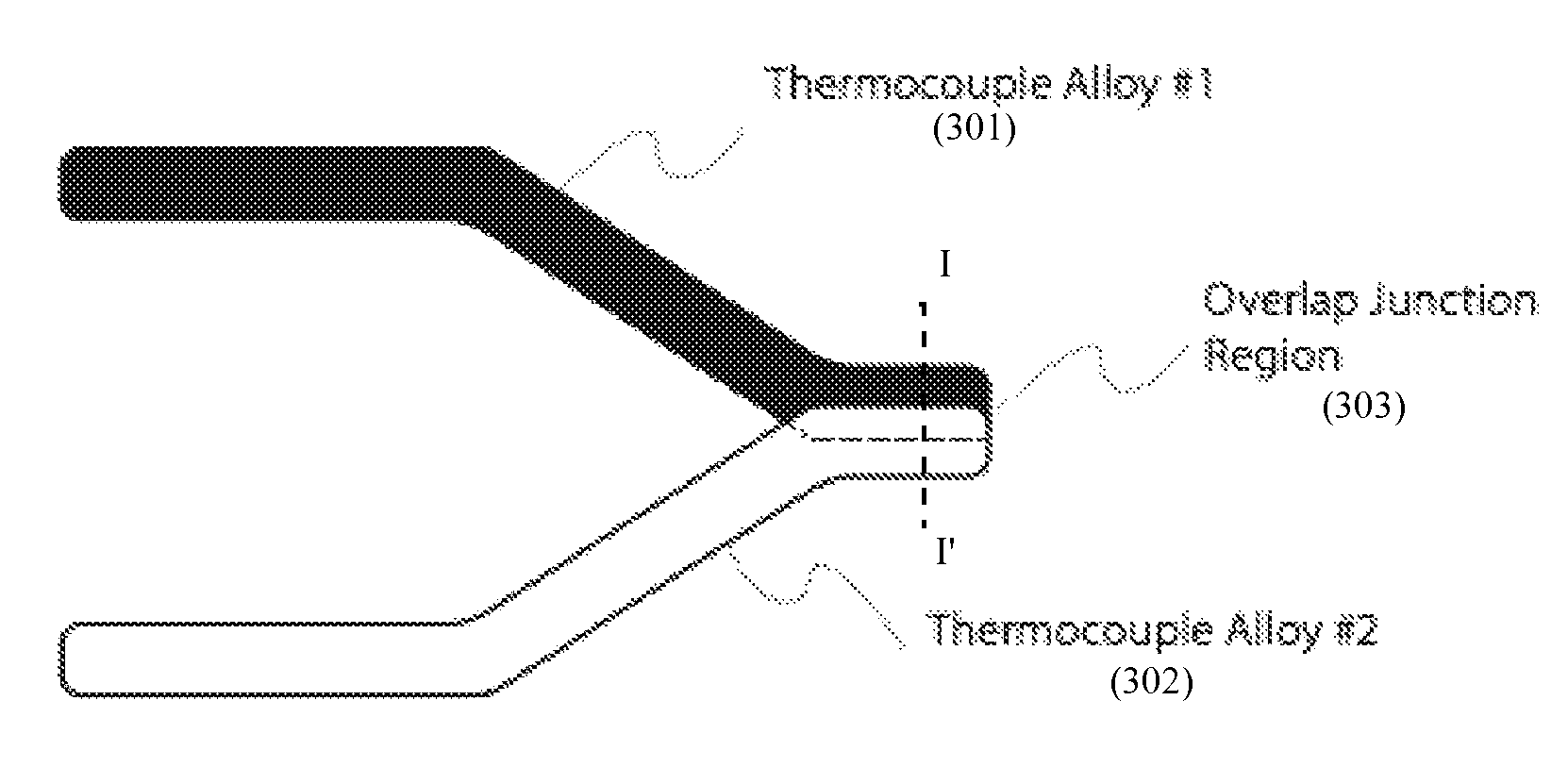

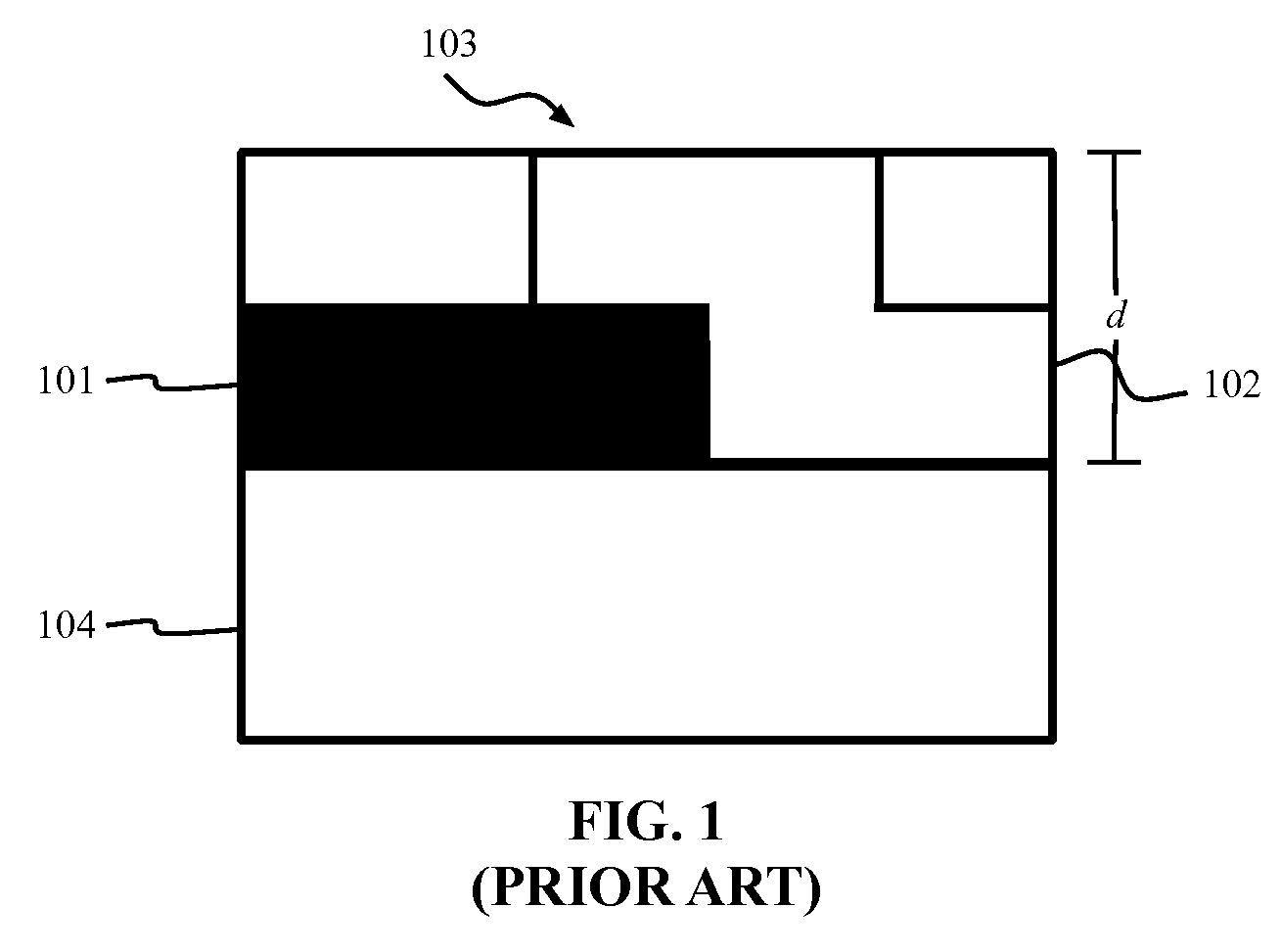

A thermocouple disposed on a substrate comprises a first leg of thermoelectric material, a second leg of thermoelectric material, and a thermocouple junction electrically connecting the first leg and the second leg, wherein a height of the thermocouple junction is substantially a height of the first or second legs.

Owner:CVD MESOSCRIBE TECH CORP

Thermocouple

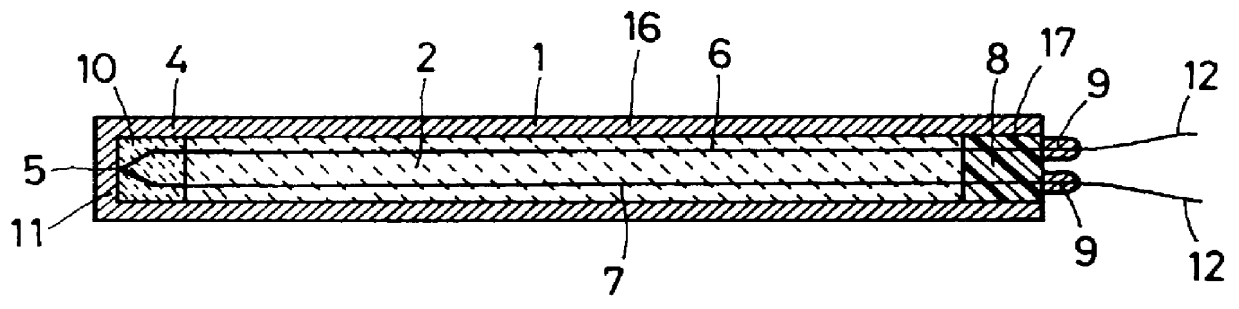

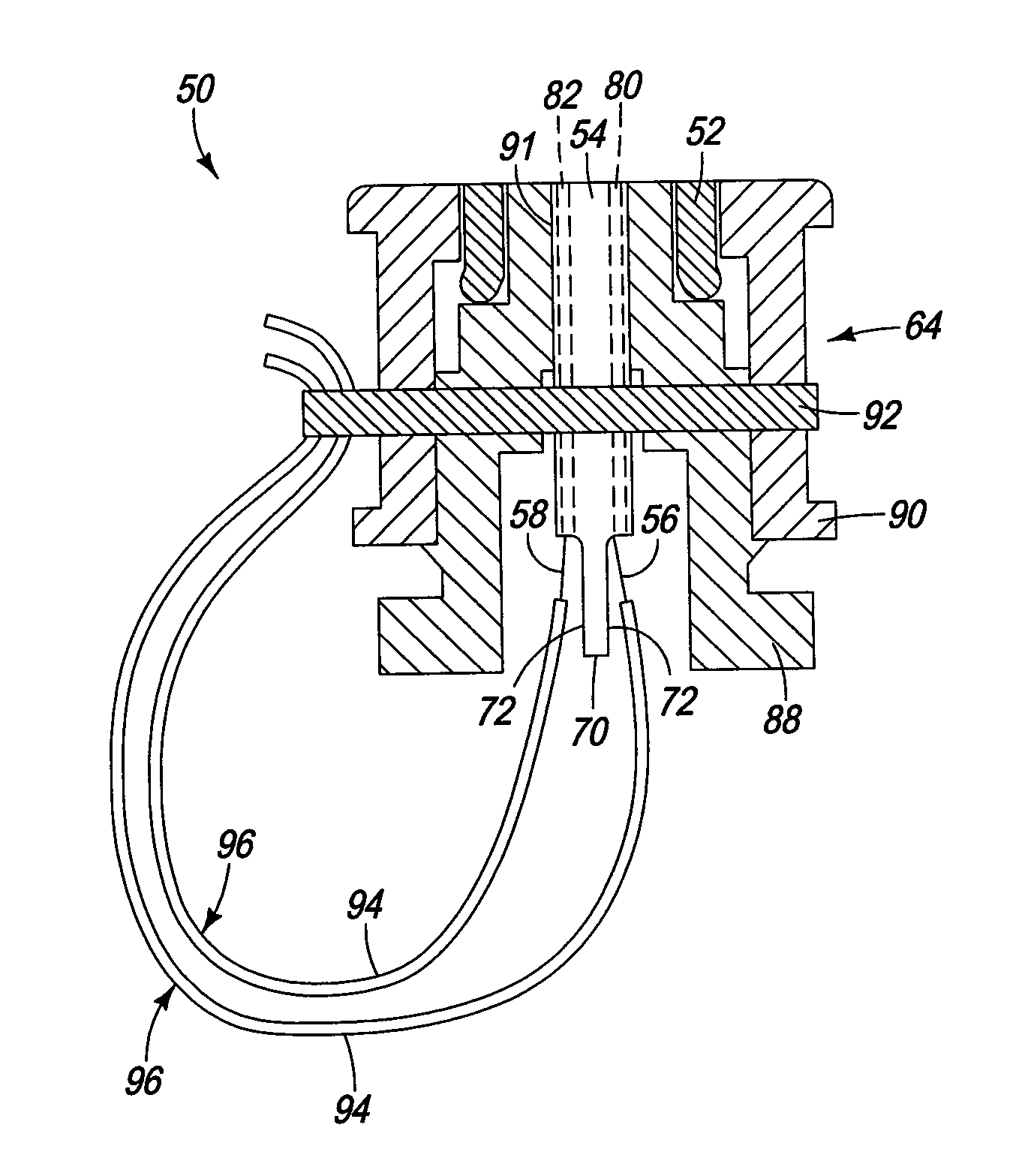

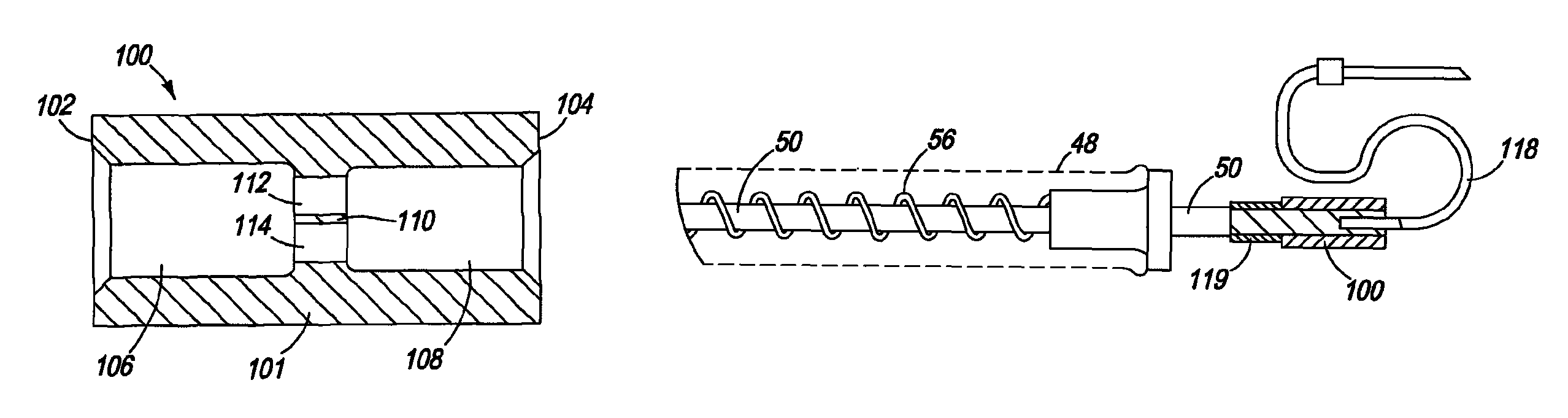

ActiveUS7946762B2Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

Thermocouple

ActiveUS7874726B2Thermometer detailsThermometers using electric/magnetic elementsThermal expansionEngineering

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Thermocouple

A thermocouple having a support tube configured to receive a pair of wires of dissimilar metals. The pair of wires of the thermocouple connected at a junction adjacent to one end of the support tube. The thermocouple further including a cap attached to the opposing end of the support tube, wherein the cap receives the free ends of the pair of wires. The cap allowing the pair of wires to translate freely therethrough to accommodate the difference in thermal expansion and contraction of the pair of wires relative to the thermal expansion and contraction of the support tube.

Owner:ASM IP HLDG BV

Thermocouple

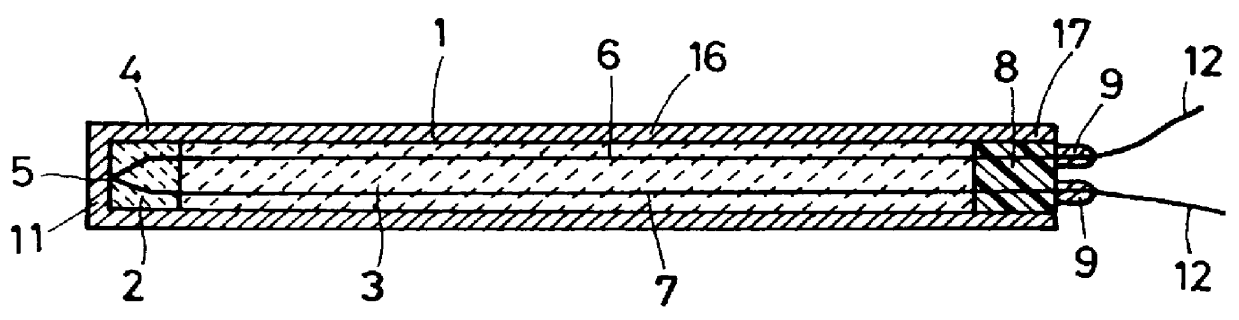

ActiveUS20090308425A1Thermometer detailsThermometers using electric/magnetic elementsEngineeringThermocouple

A thermocouple for use in a semiconductor processing reactor is described. The thermocouple includes a sheath having a measuring tip at one end and an opening at the other end. A support member having bores formed along the length is disposed within the sheath. A pair of wires formed of dissimilar metals are disposed within the bores, and one end of the wires is fused together to form a junction. The wires extend along the length of the bores. As the wires exit the bore, they are spatially or physically separated to prevent a short circuit therebetween. The ends of the wires exiting the bore are also free to thermally expand in the longitudinal manner, thereby reducing or eliminating the potential for the wires to fail due to grain slip.

Owner:ASM IP HLDG BV

Thermocouple assembly with guarded thermocouple junction

An improved thermocouple assembly for providing a temperature measurement is provided. The thermocouple assembly includes a sheath having a measuring tip, a support member received within the sheath, and first and second wires disposed within the support member. An end of each of the first and second wires are fused together to form a thermocouple junction therebetween. A recessed region is formed in a distal end of the support member, and the thermocouple junction is fixedly located at the base of the recessed region such that the recessed region maintains the thermocouple junction in a substantially fixed position relative to the measuring tip of the sheath.

Owner:ASM IP HLDG BV

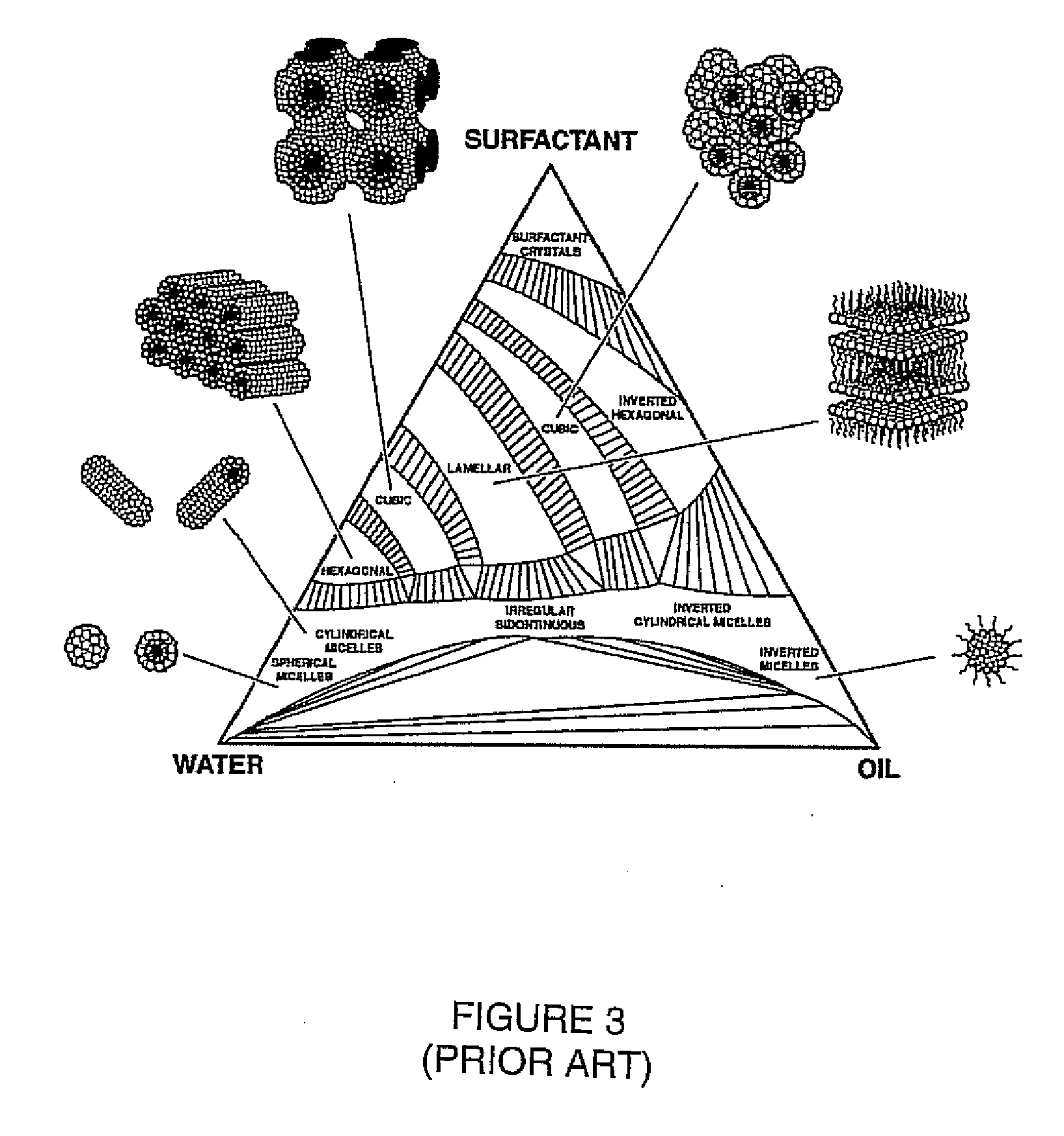

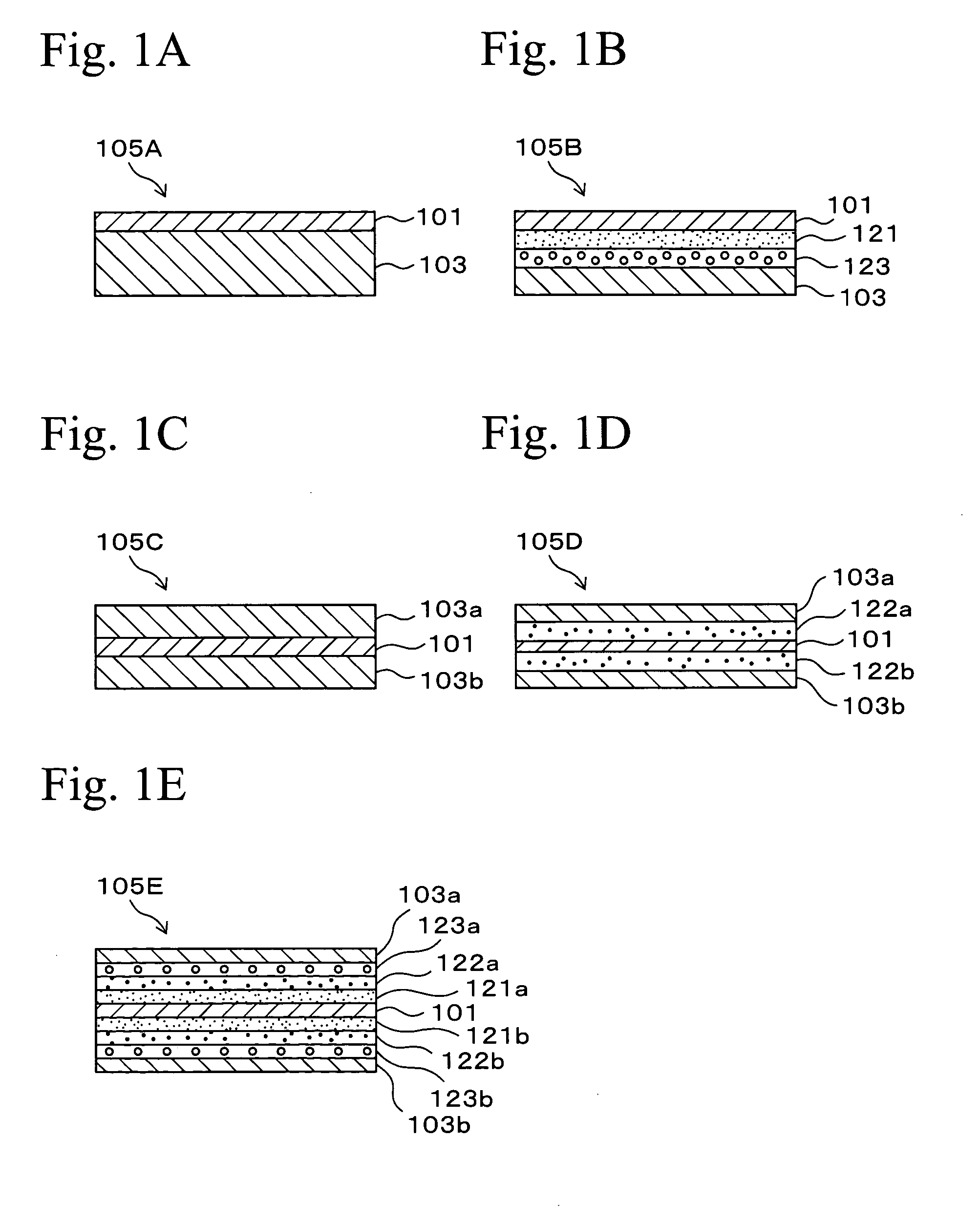

Nanostructured bulk thermoelectric material

InactiveUS20080173344A1High quality factorThermoelectric device manufacture/treatmentSemiconductor/solid-state device manufacturingThermoelectric materialsNanoparticle

A thermoelectric material includes a composite having a first electrically conducting component and second low thermal conductivity component. The first component may include a semiconductor and the second component may include an inorganic oxide. The thermoelectric composite includes a network of the first component having nanoparticles of the second component dispersed in the network.

Owner:TOYOTA MOTOR CO LTD +1

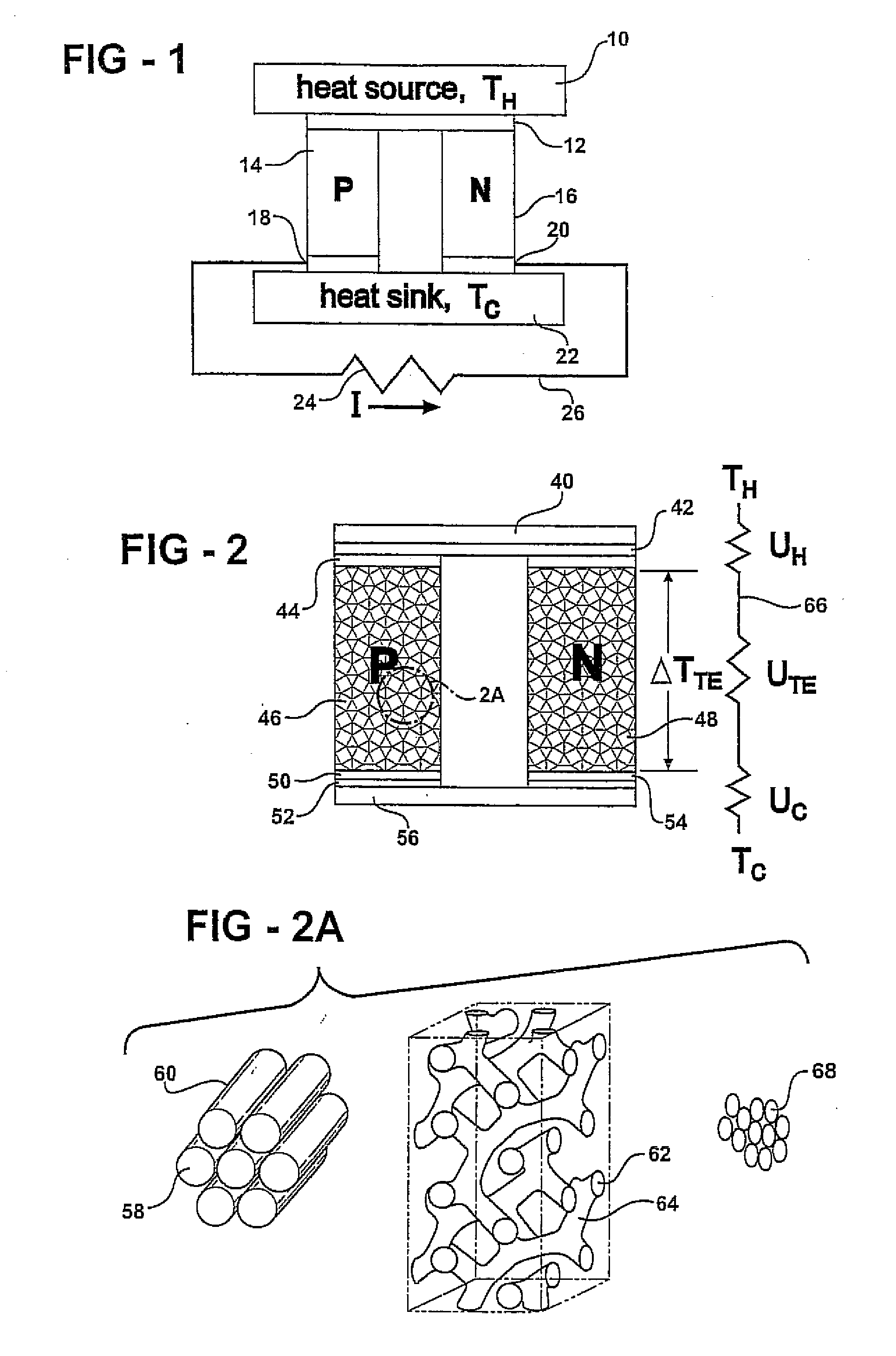

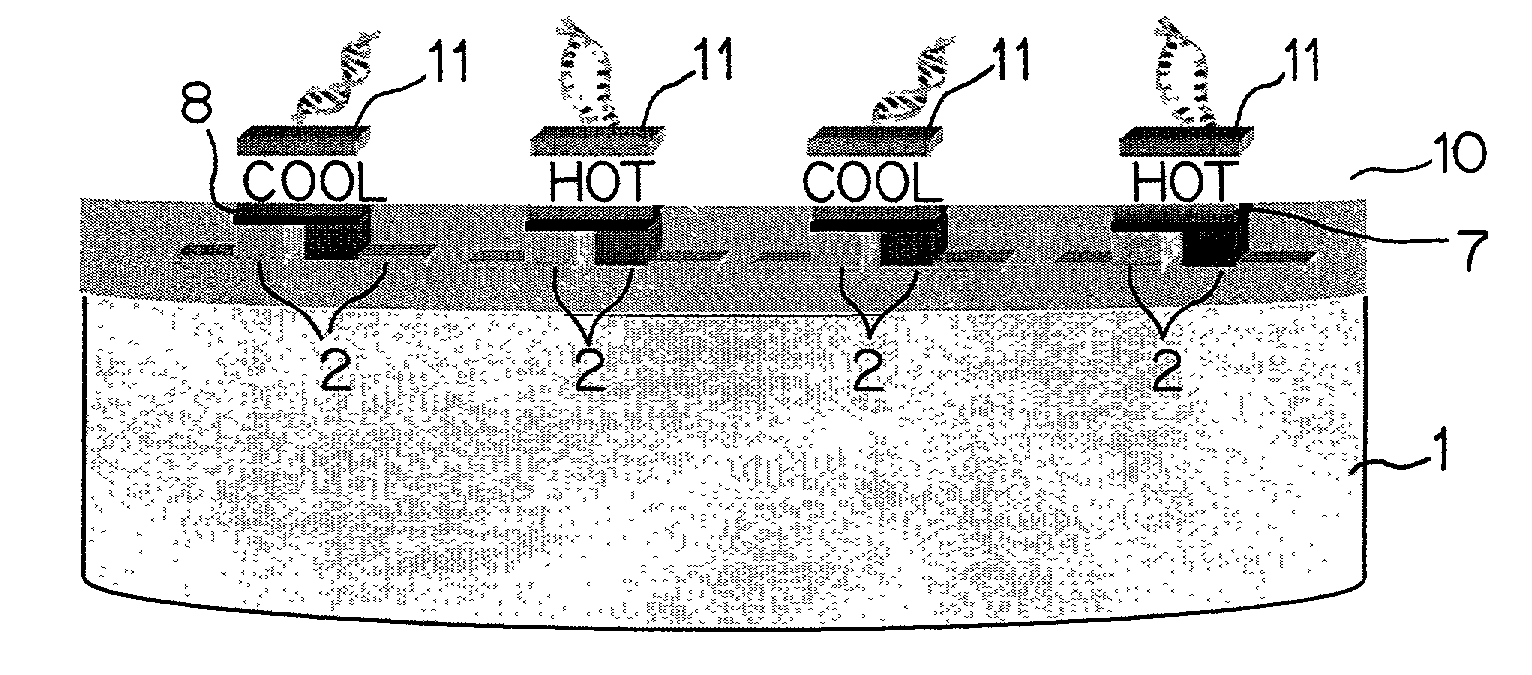

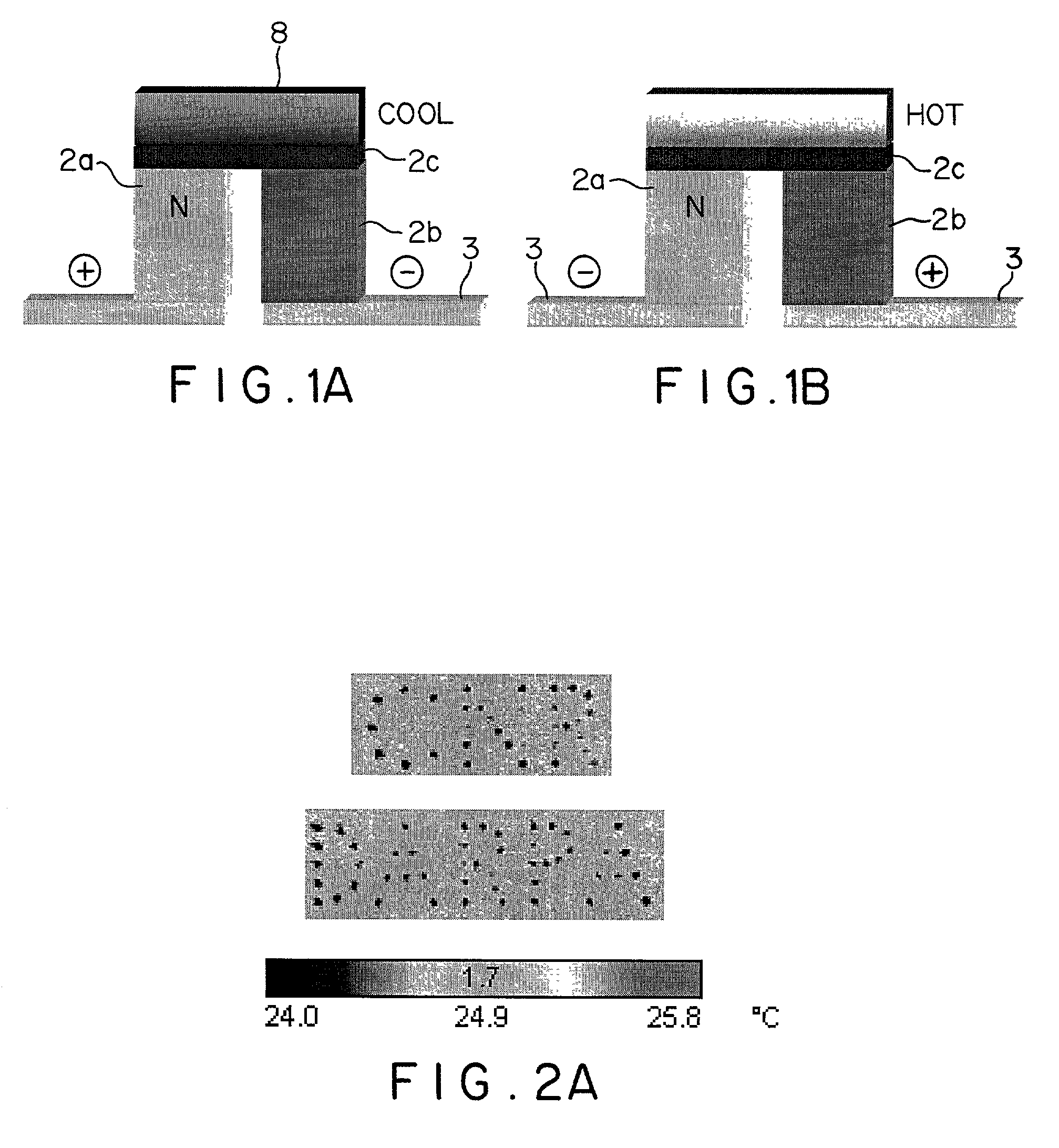

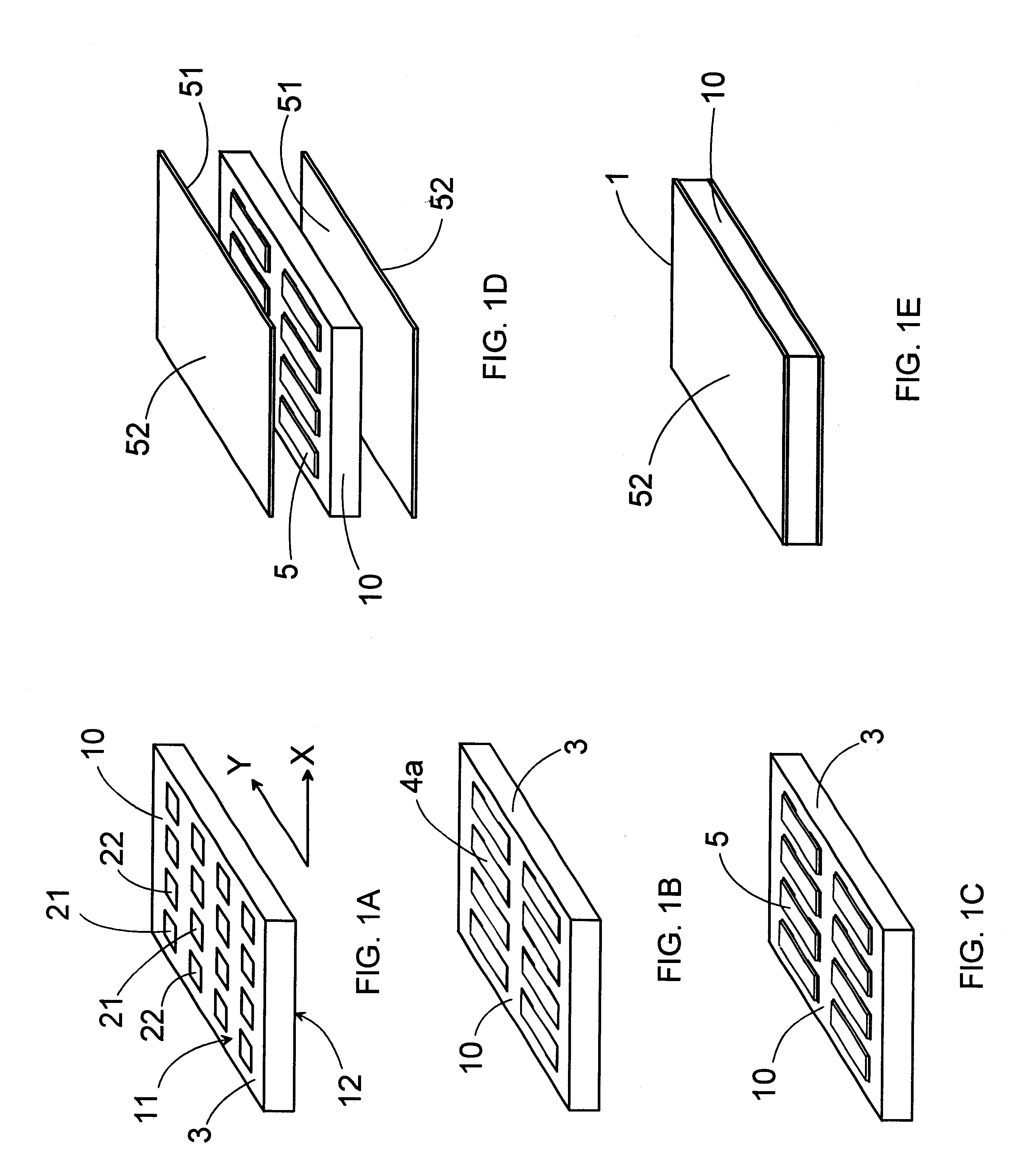

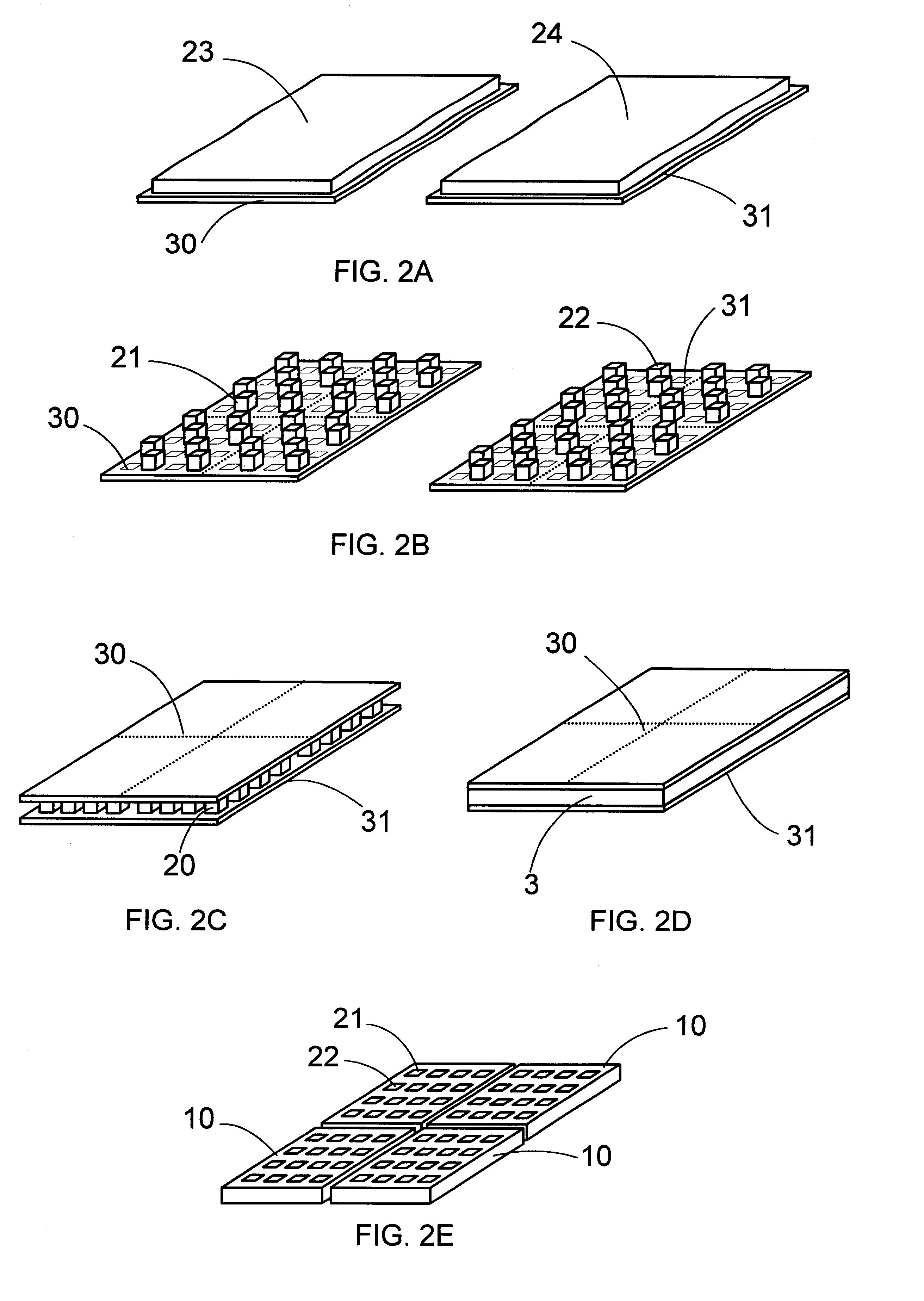

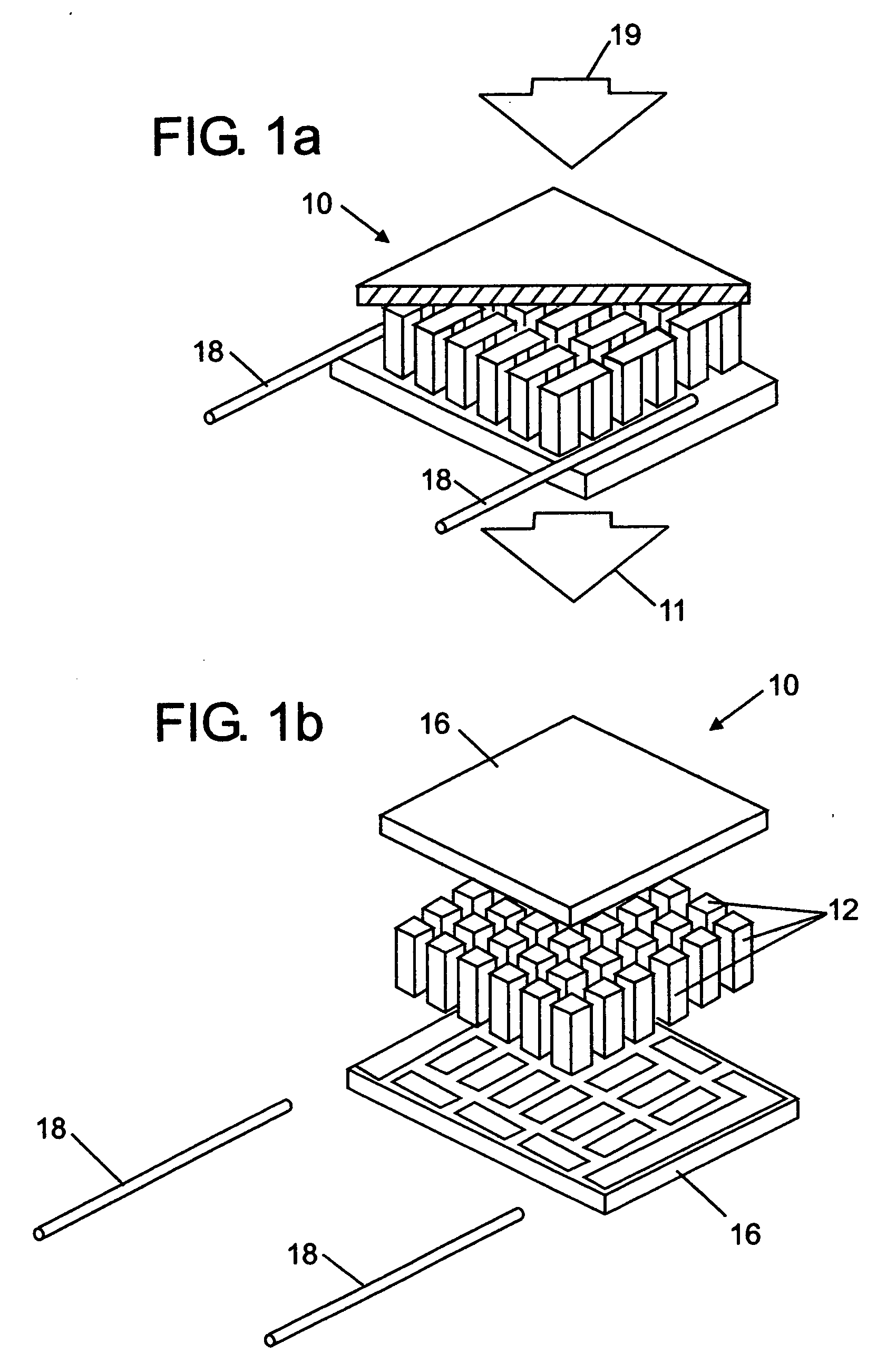

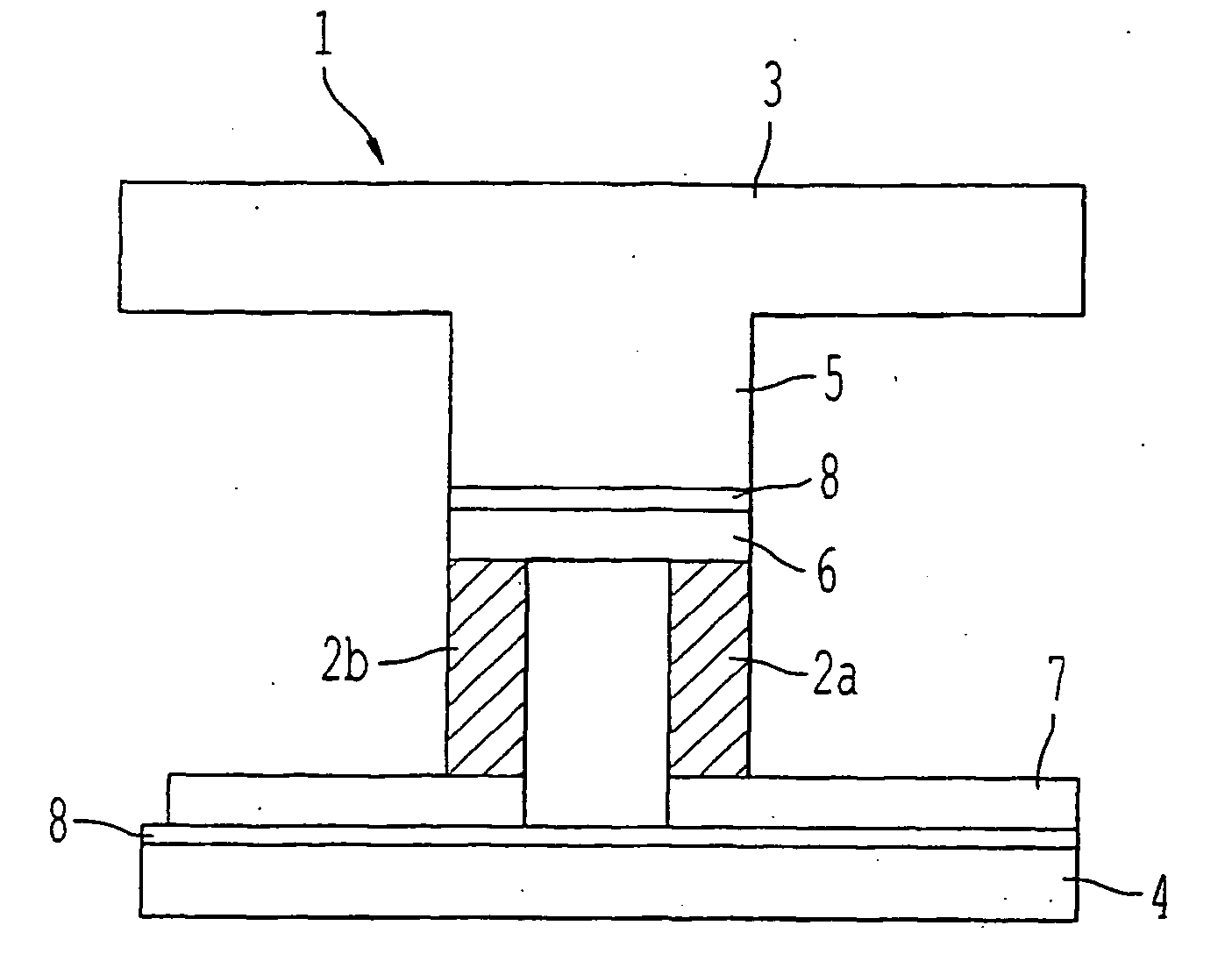

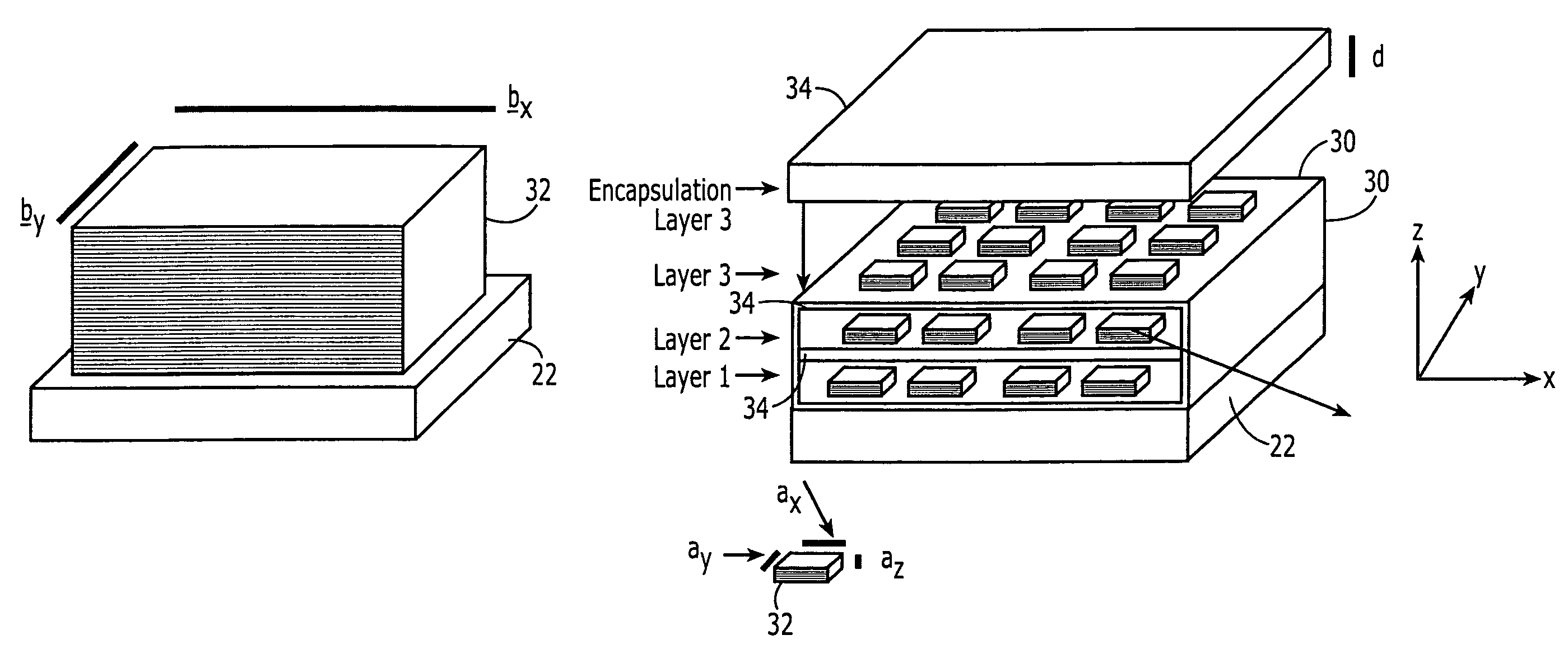

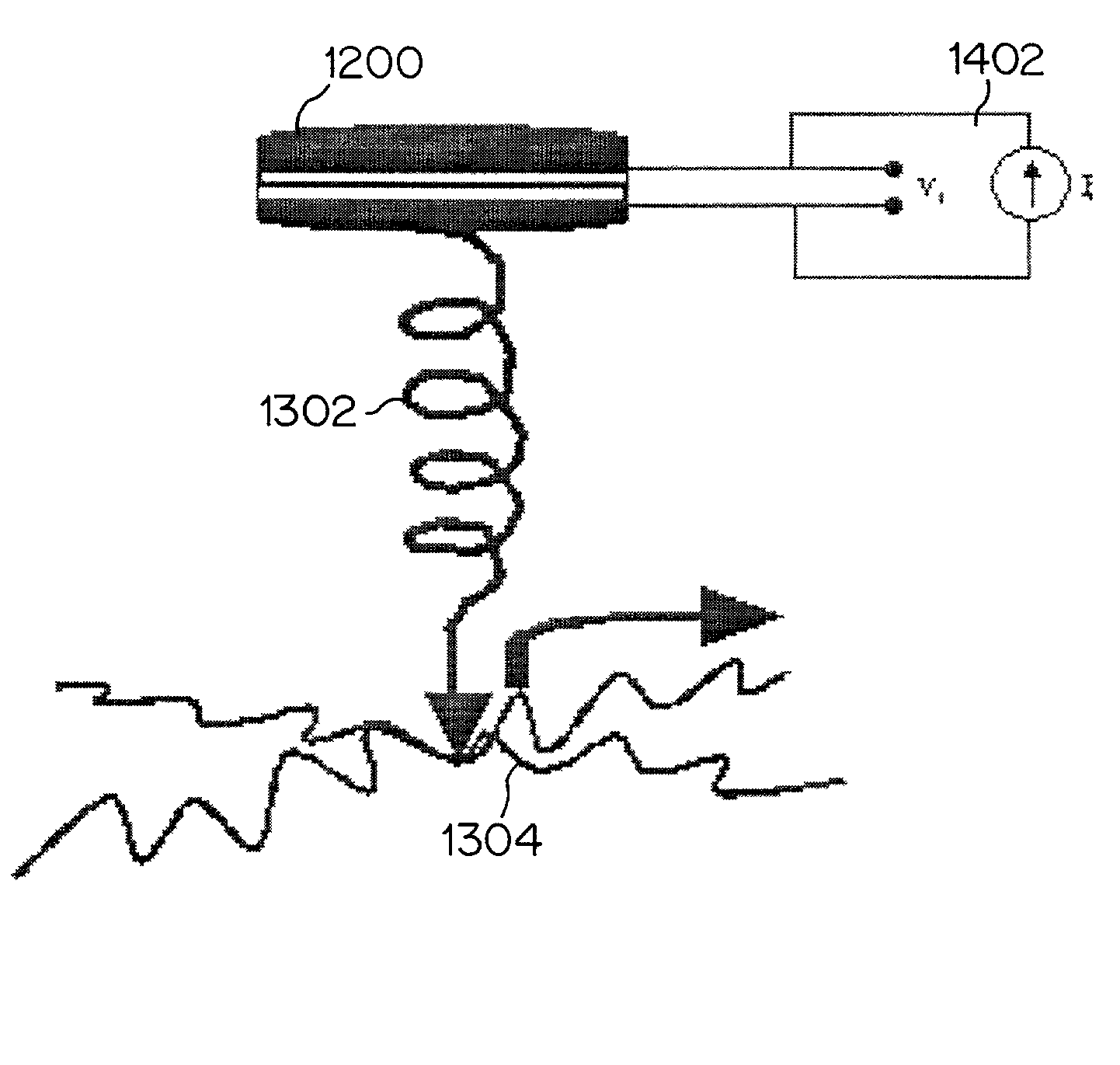

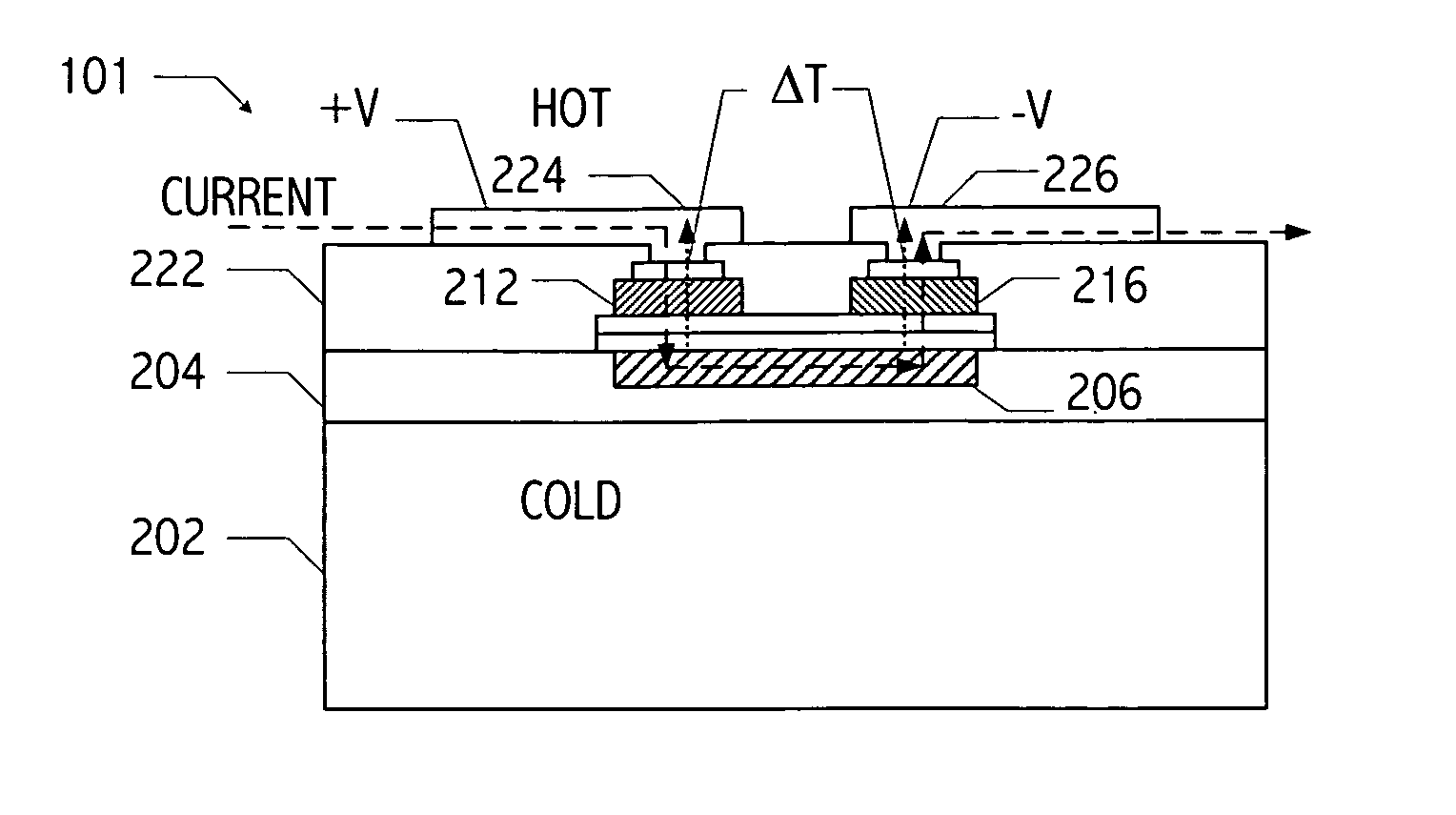

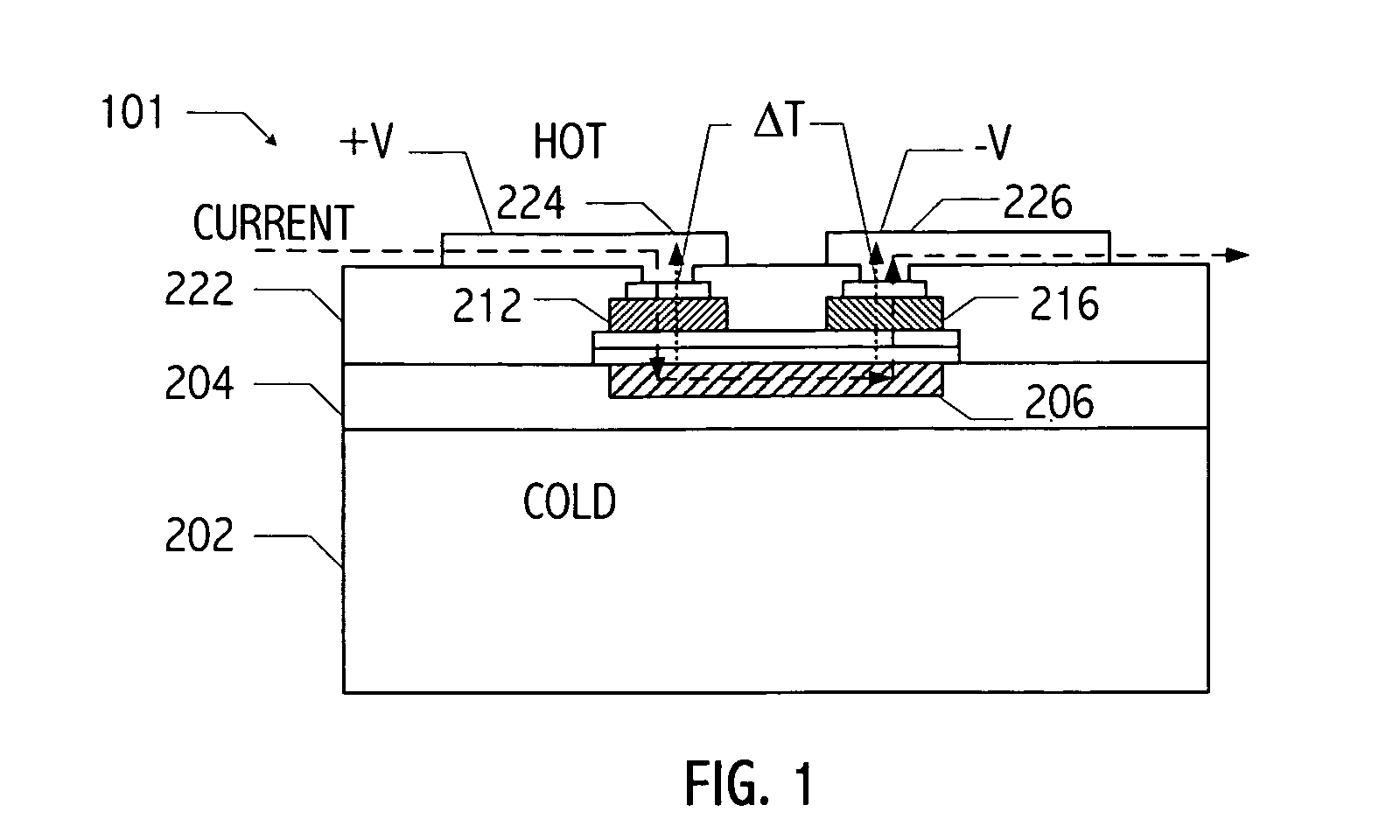

Thin-film thermoelectric cooling and heating devices for DNA genomic and proteomic chips, thermo-optical switching circuits, and IR tags

ActiveUS7164077B2Rapid heating and coolingBioreactor/fermenter combinationsNanostructure manufactureThermoelectric coolingThermoelectric materials

A thermoelectric cooling and heating device including a substrate, a plurality of thermoelectric elements arranged on one side of the substrate and configured to perform at least one of selective heating and cooling such that each thermoelectric element includes a thermoelectric material, a Peltier contact contacting the thermoelectric material and forming under electrical current flow at least one of a heated junction and a cooled junction, and electrodes configured to provide current through the thermoelectric material and the Peltier contact. As such, the thermoelectric cooling and heating device selectively biases the thermoelectric elements to provide on one side of the thermolectric device a grid of localized heated or cooled junctions.

Owner:LAIRD THERMAL SYST INC

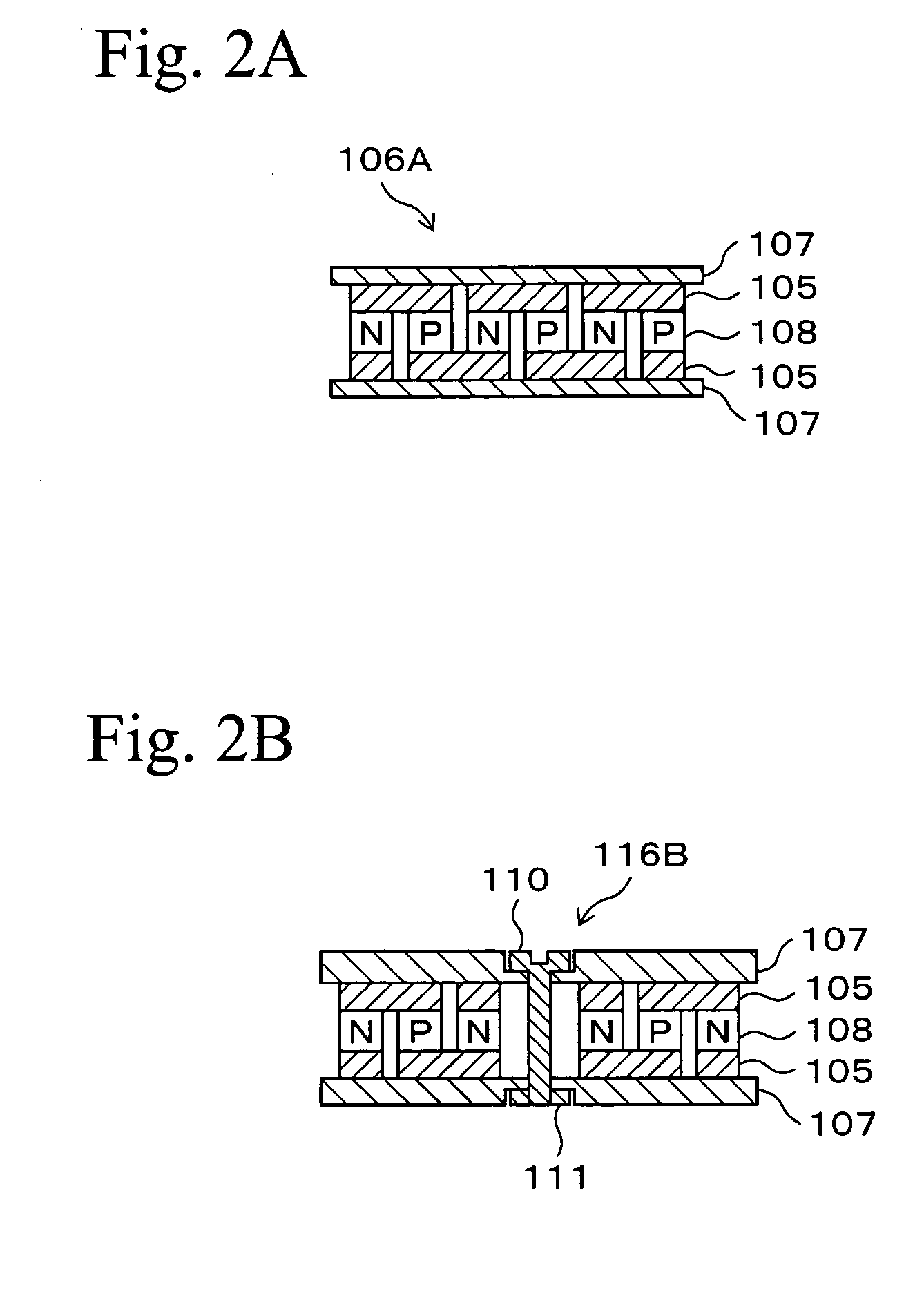

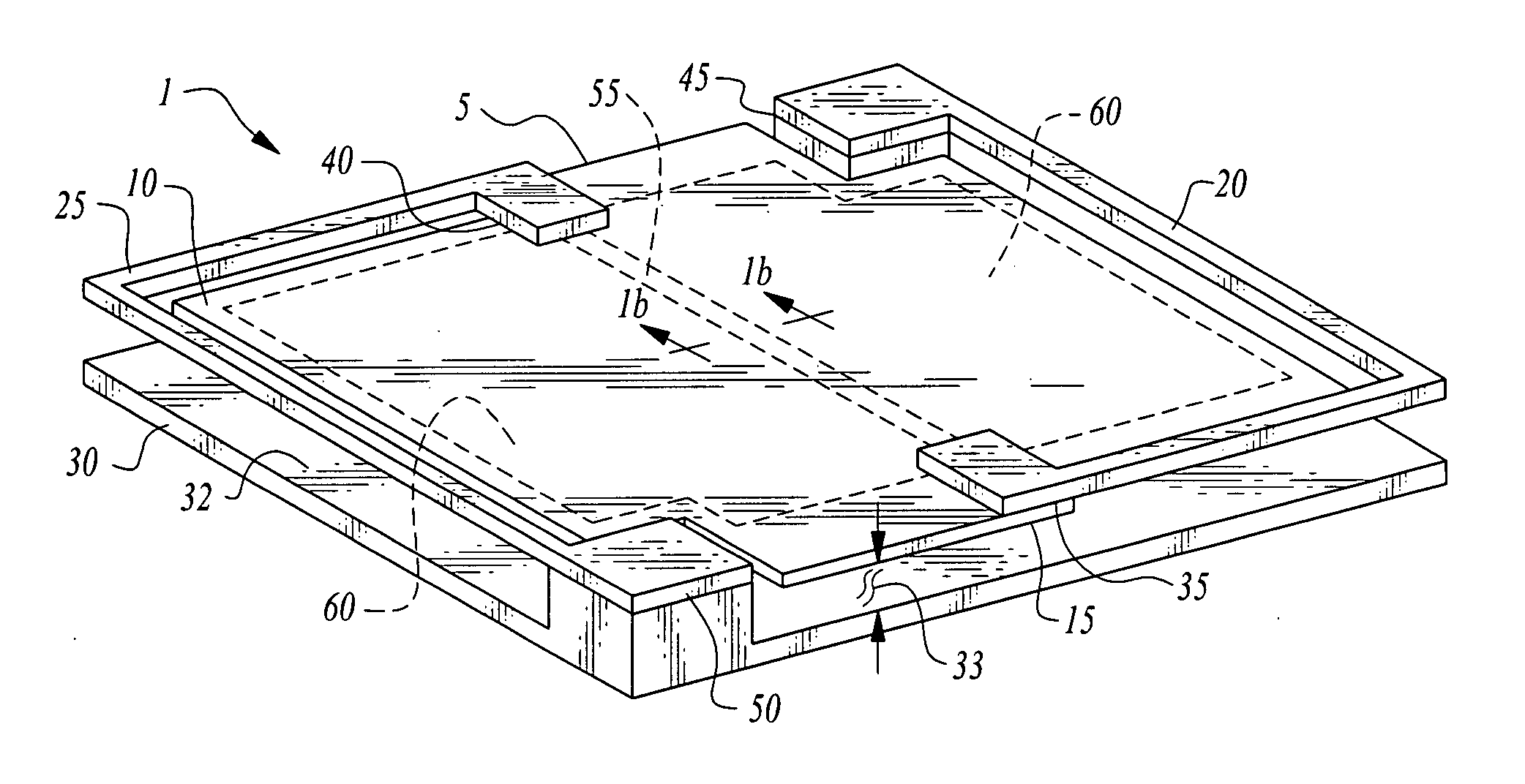

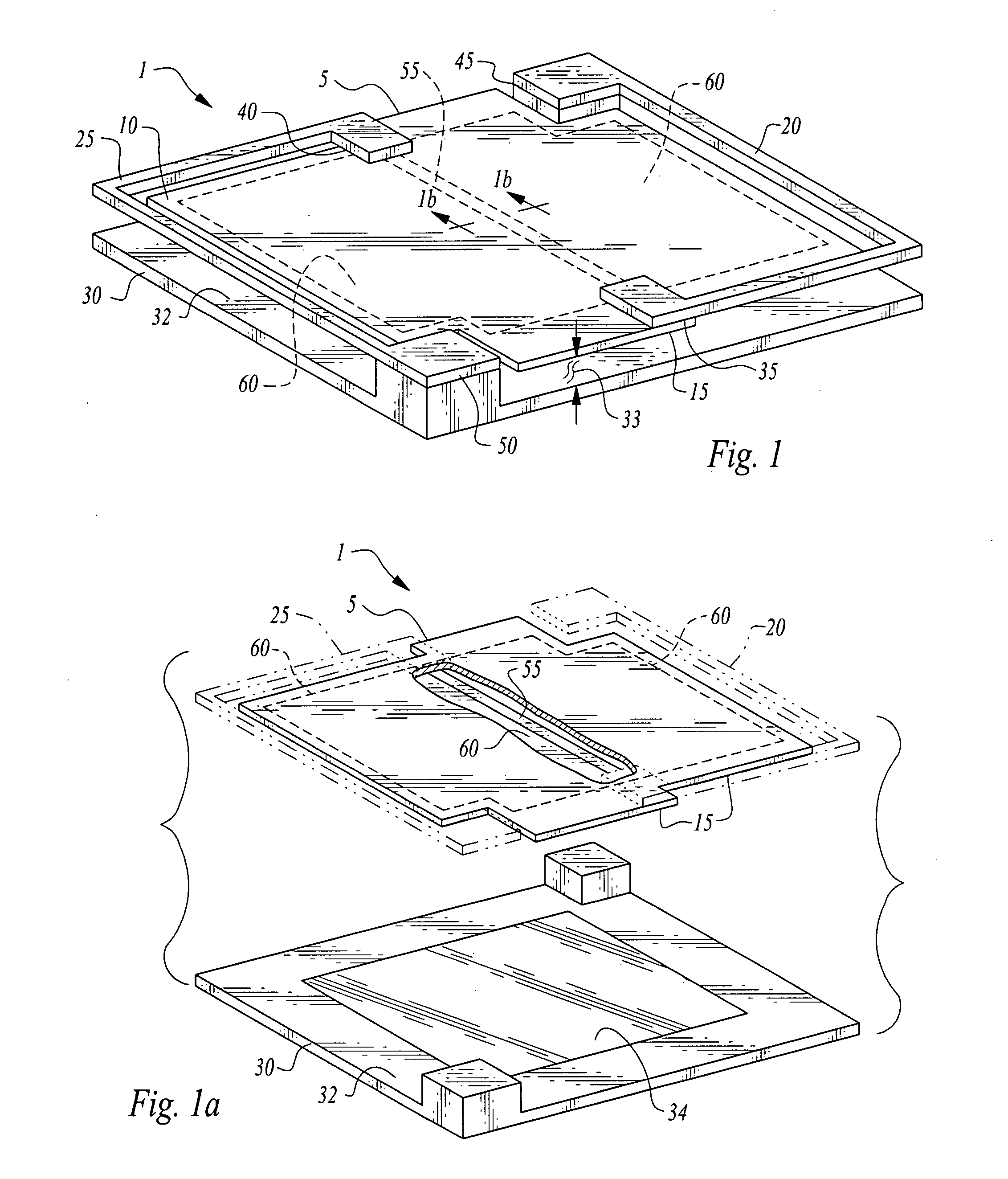

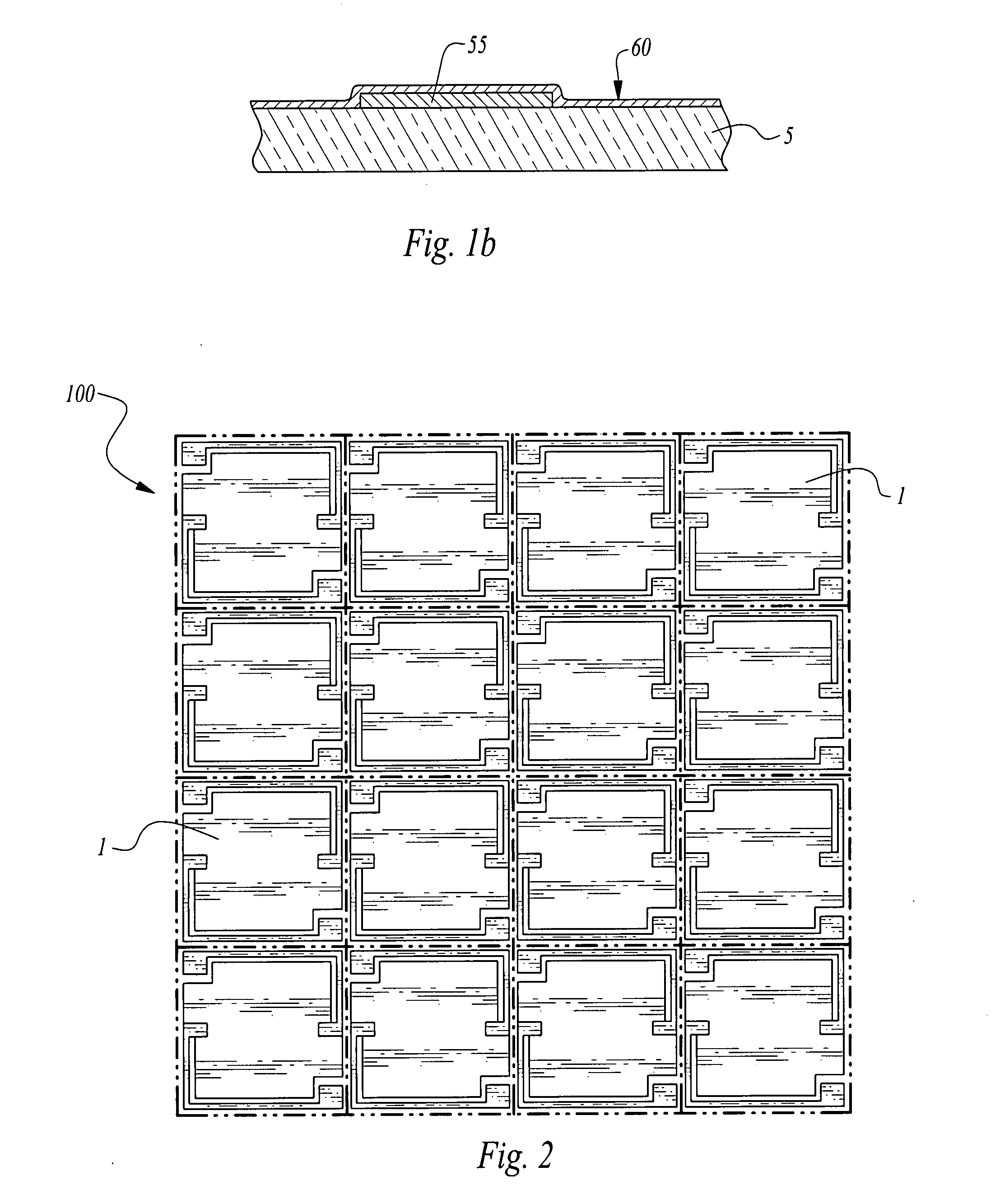

Enhanced thermally isolated thermoelectrics

InactiveUS20100031987A1Thermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsShunt DeviceEngineering

In certain embodiments, a thermoelectric system includes at least one cell. The at least one cell can include a first plurality of electrically conductive shunts extending along a first direction, a second plurality of electrically conductive shunts extending along a second direction non-parallel to the first direction, and a first plurality of thermoelectric (TE) elements. The first plurality of TE elements can include a first TE element between and in electrical communication with a first shunt of the first plurality of shunts and a second shunt of the second plurality of shunts, a second TE element between and in electrical communication with the second shunt and a third shunt of the first plurality of shunts, and a third TE element between and in electrical communication with the third shunt and a fourth shunt of the second plurality of shunts.

Owner:GENTHERM INC

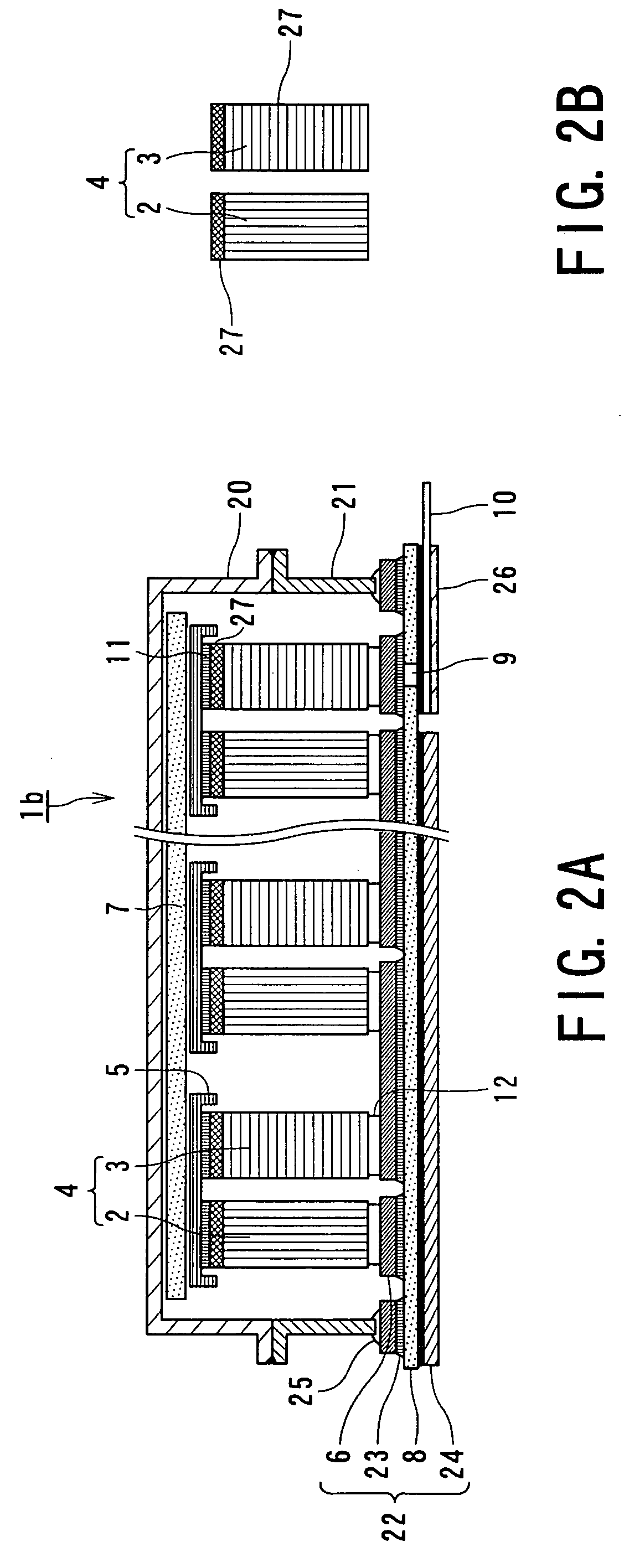

Thermoelectric module with improved heat-transfer efficiency and method of manufacturing the same

InactiveUS6274803B1Thermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentHemt circuitsEngineering

A thermoelectric chip with exposed surfaces of N-type and P-type semiconductor elements on its top and bottom surfaces is prepared by arranging the semiconductor elements in a matrix manner such that each of the N-type semiconductor elements is disposed adjacent to the P-type semiconductor element through a space, and filling the space with a first resin material having electrical insulation. A metal layer is formed on each of the exposed surfaces of the semiconductor elements. Then, first electrodes are formed on the top surface according to a first circuit pattern. Similarly, second electrodes are formed on the bottom surface according to a second circuit pattern different from the first circuit pattern. An electrical insulation sheet of a second resin material containing a ceramic powder with high thermal conductivity is bonded to the top and bottom surfaces to obtain the thermoelectric module.

Owner:MATSUSHITA ELECTRIC WORKS LTD

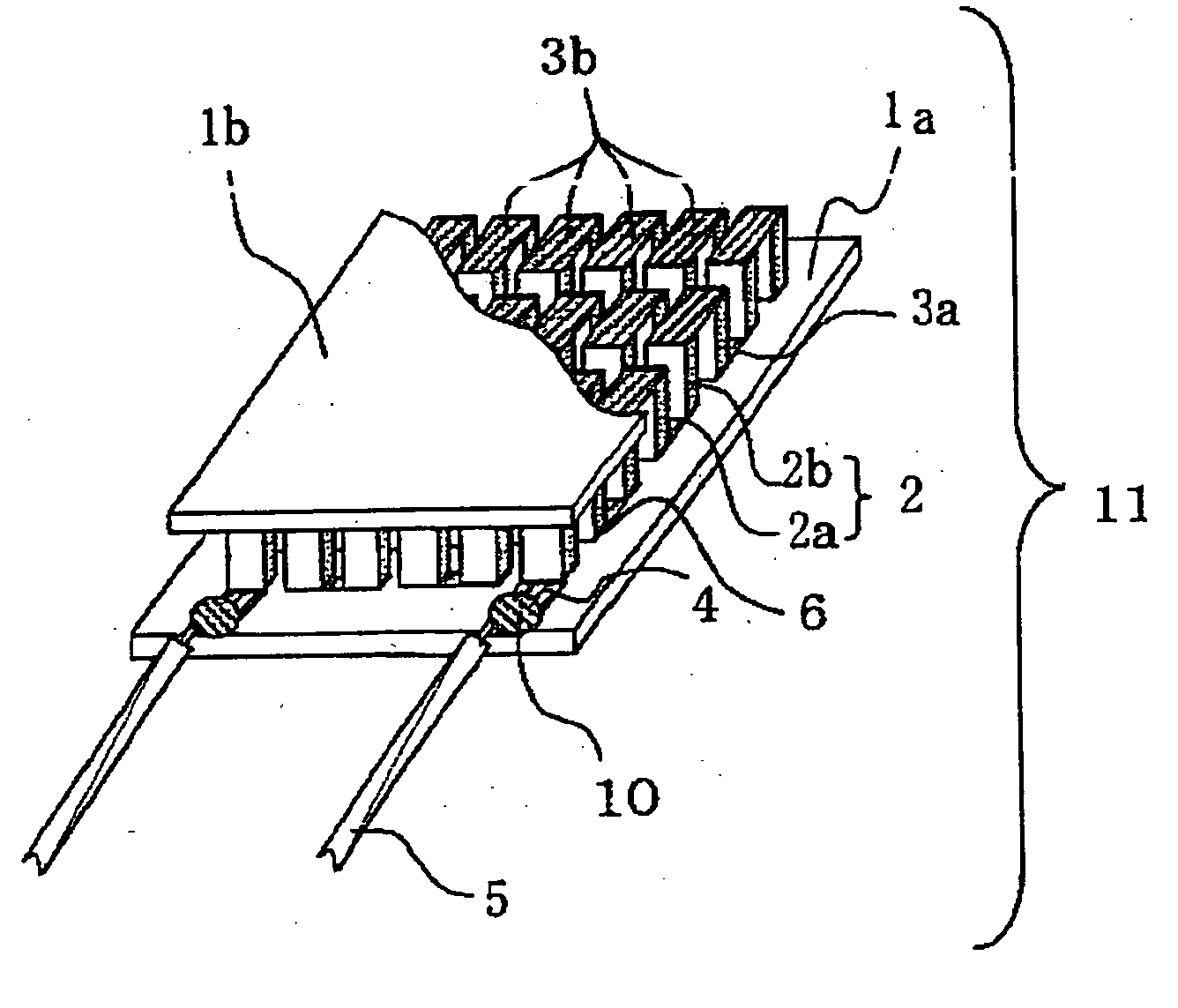

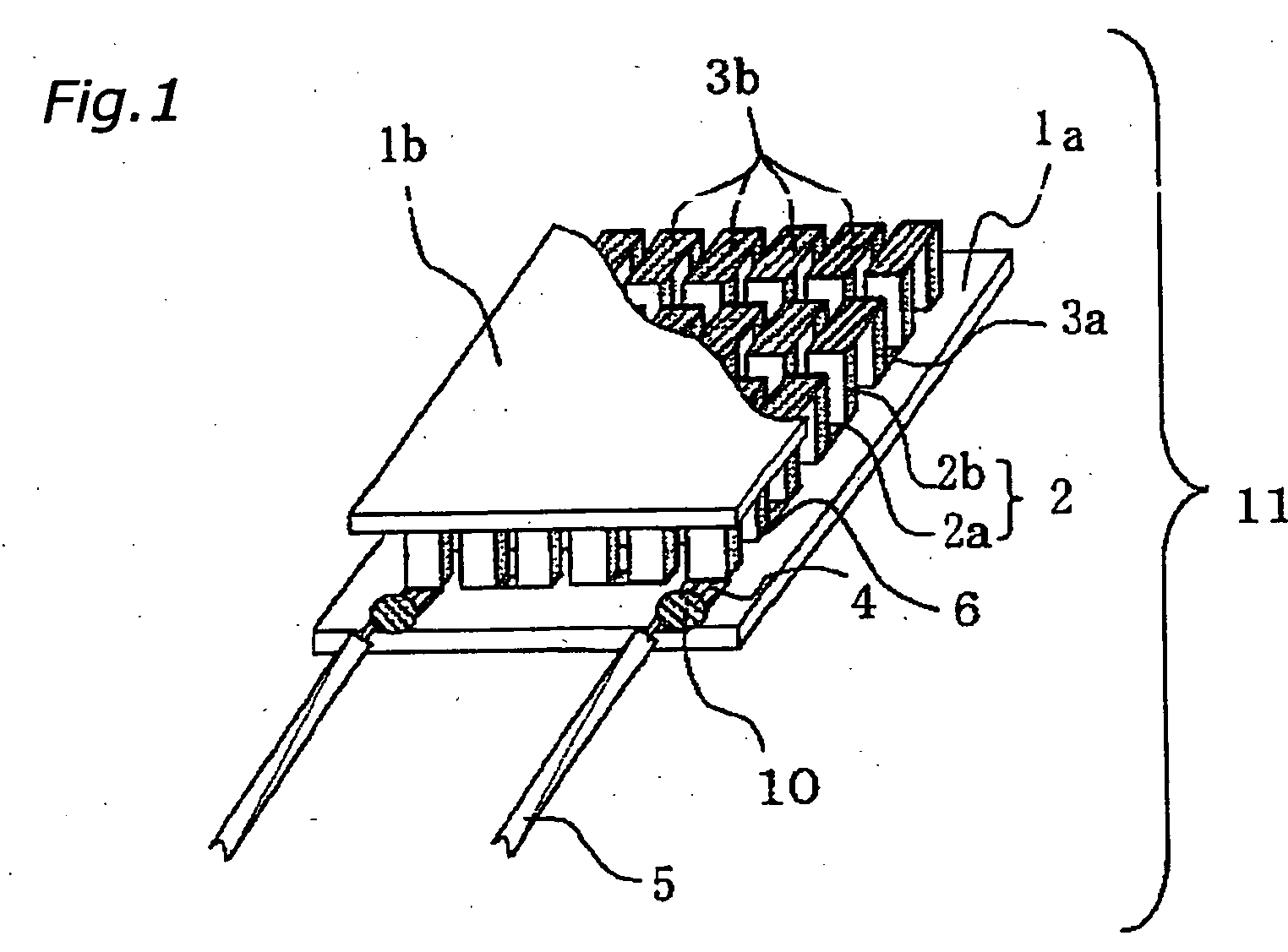

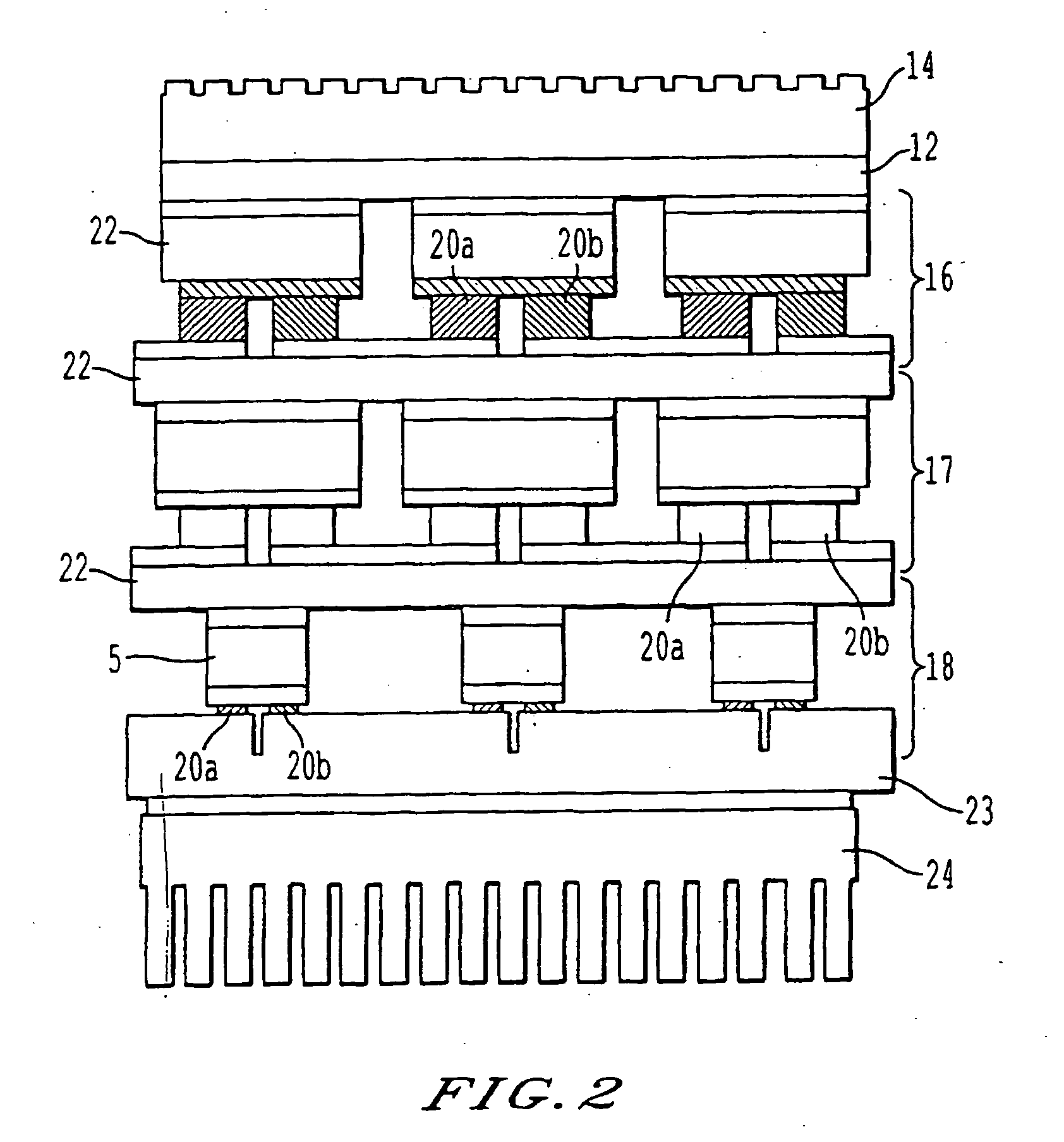

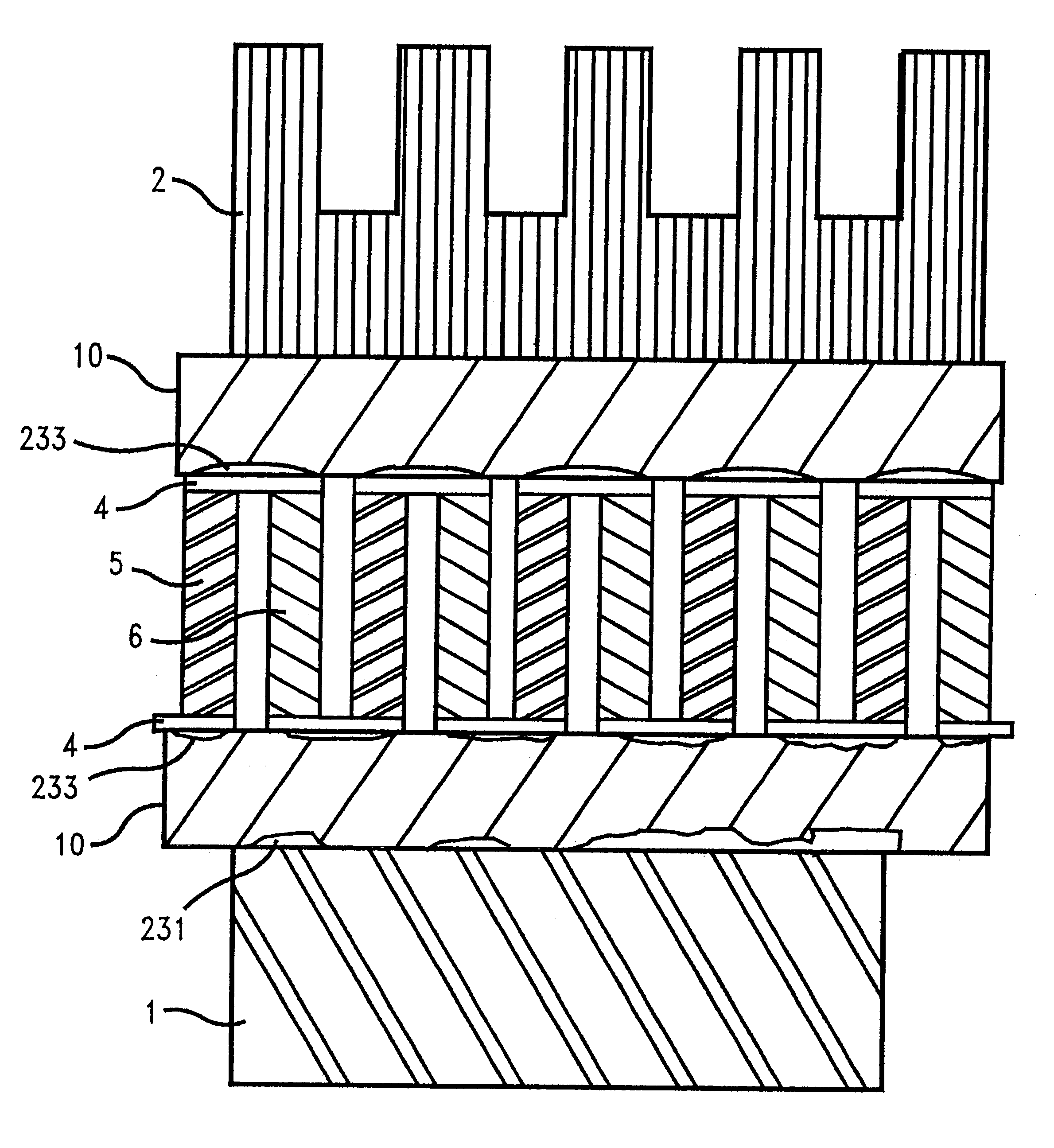

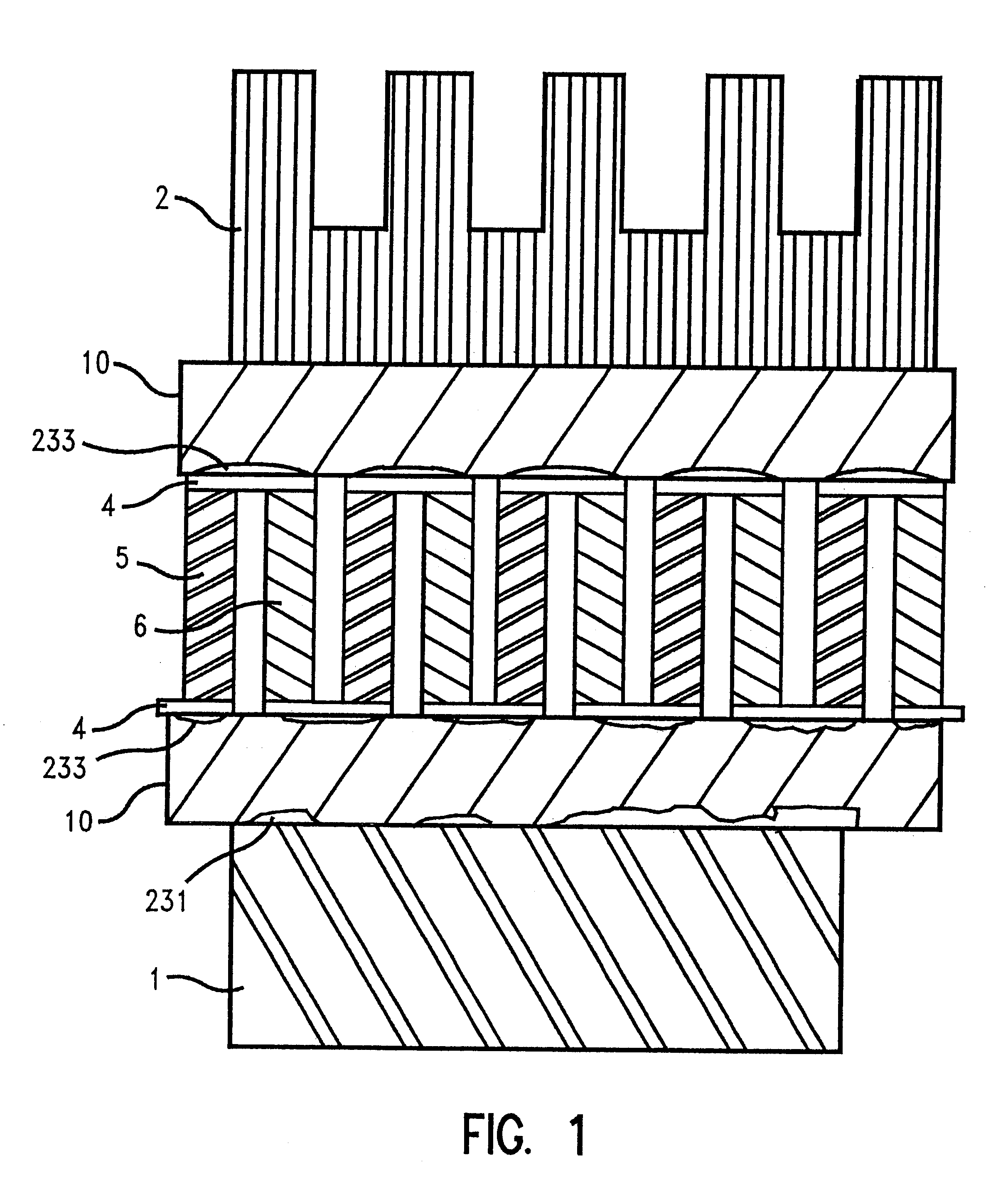

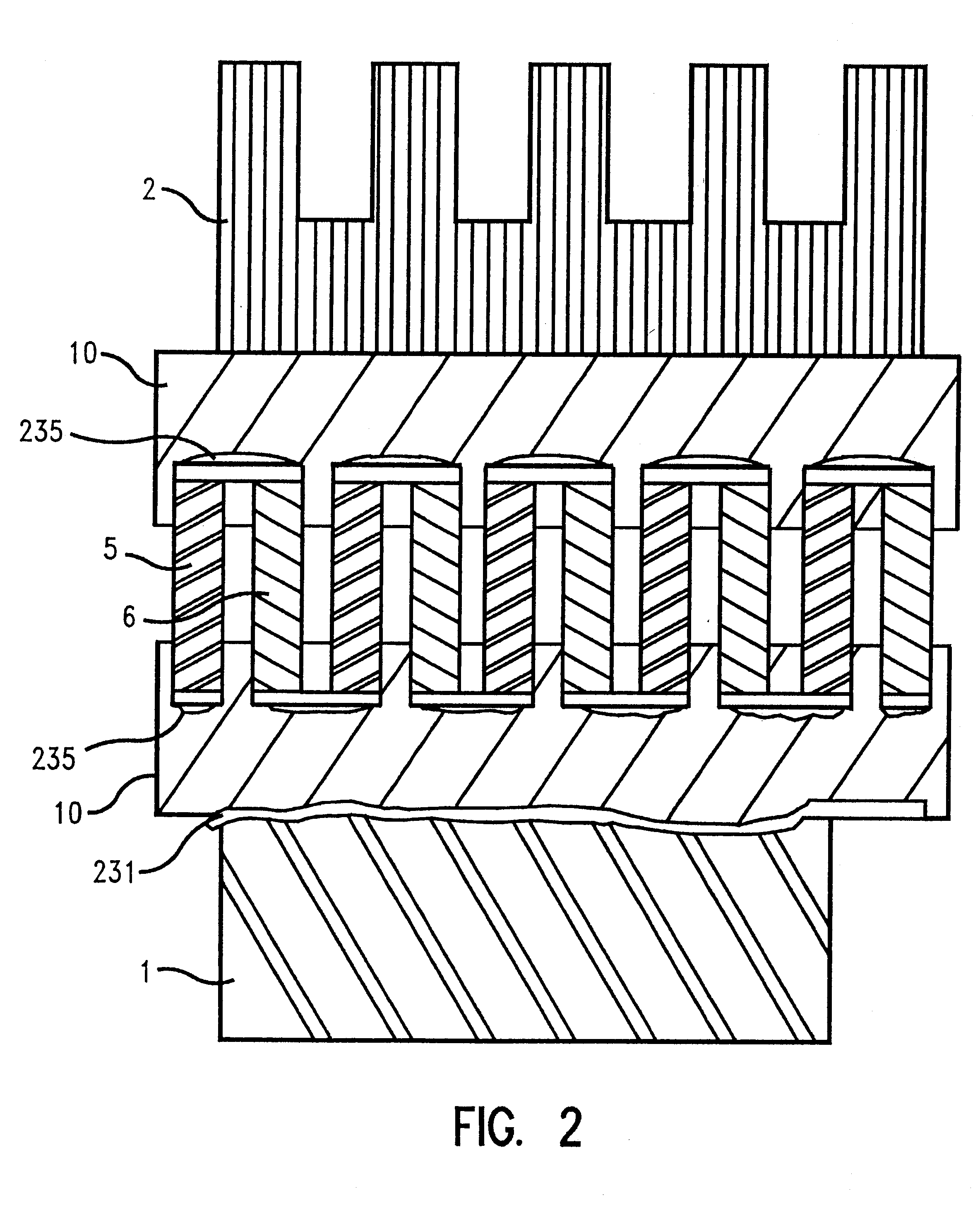

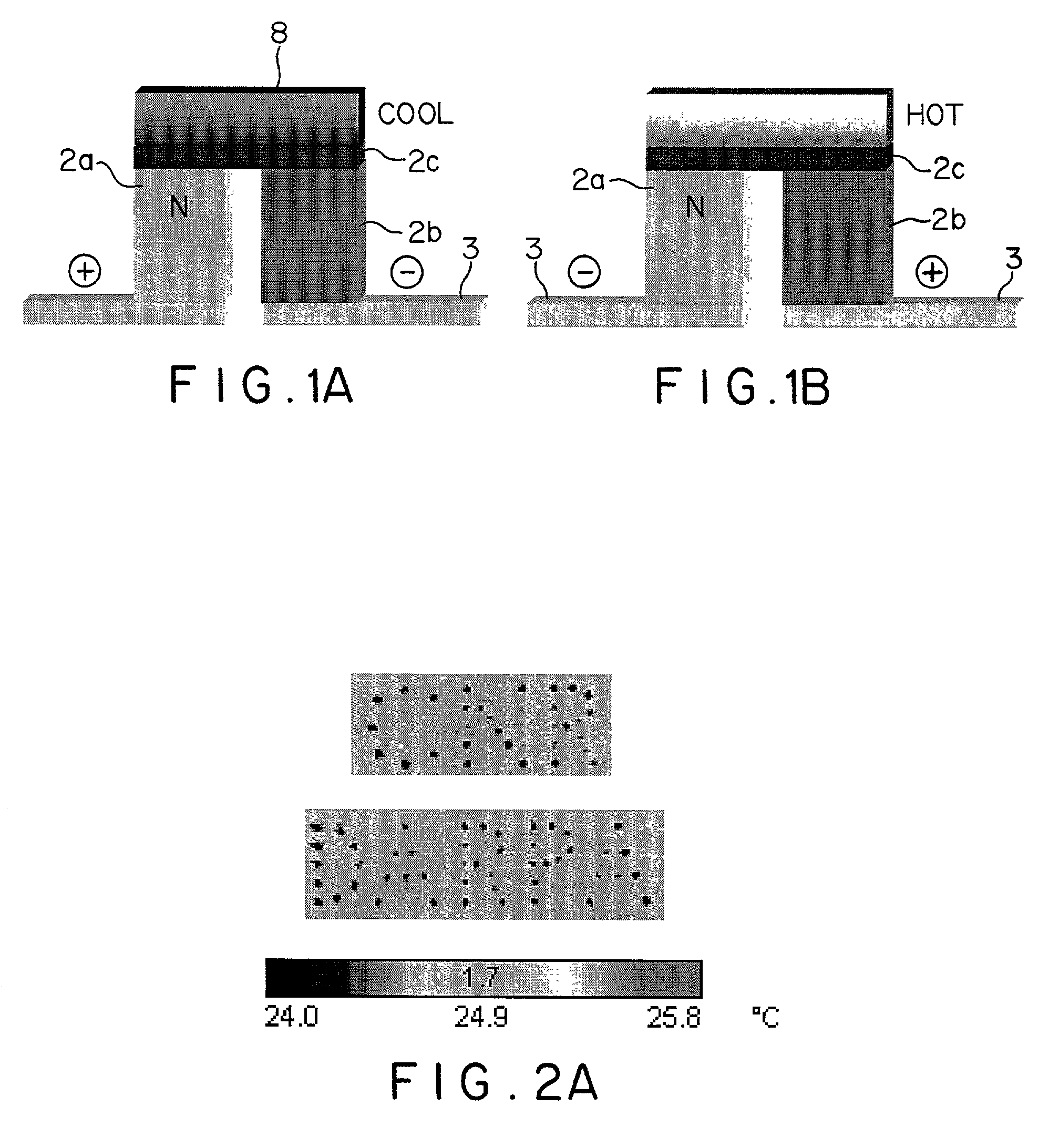

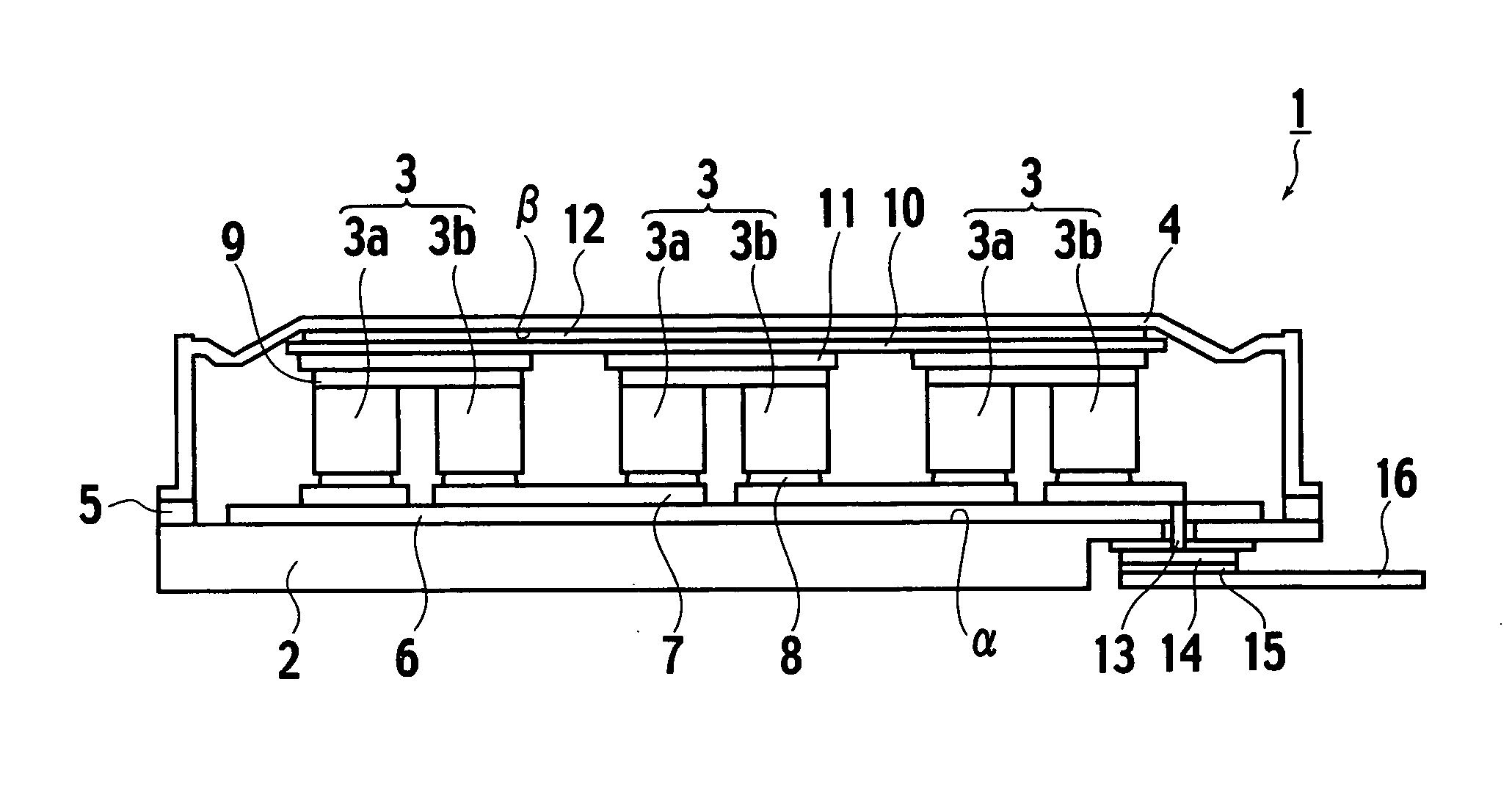

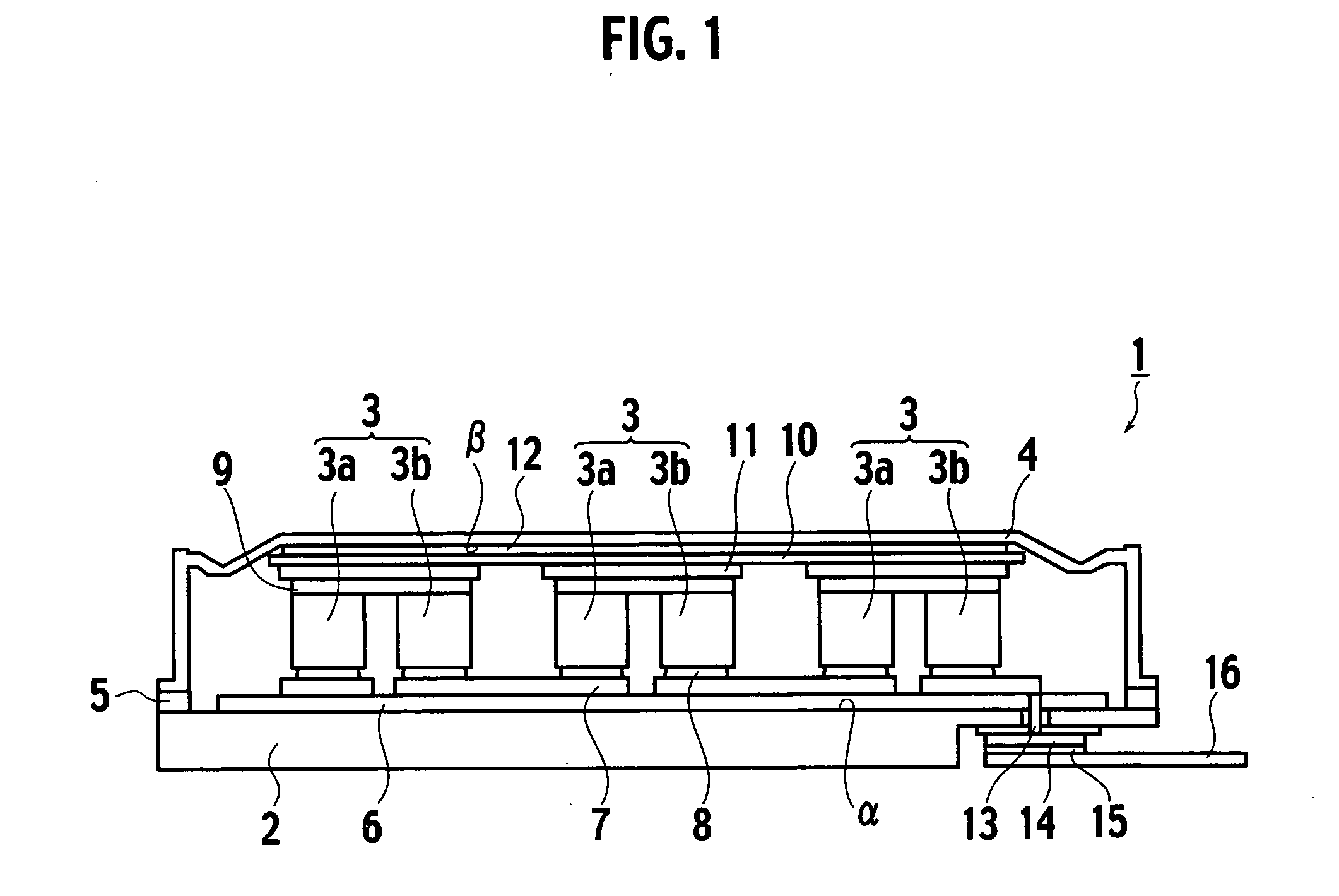

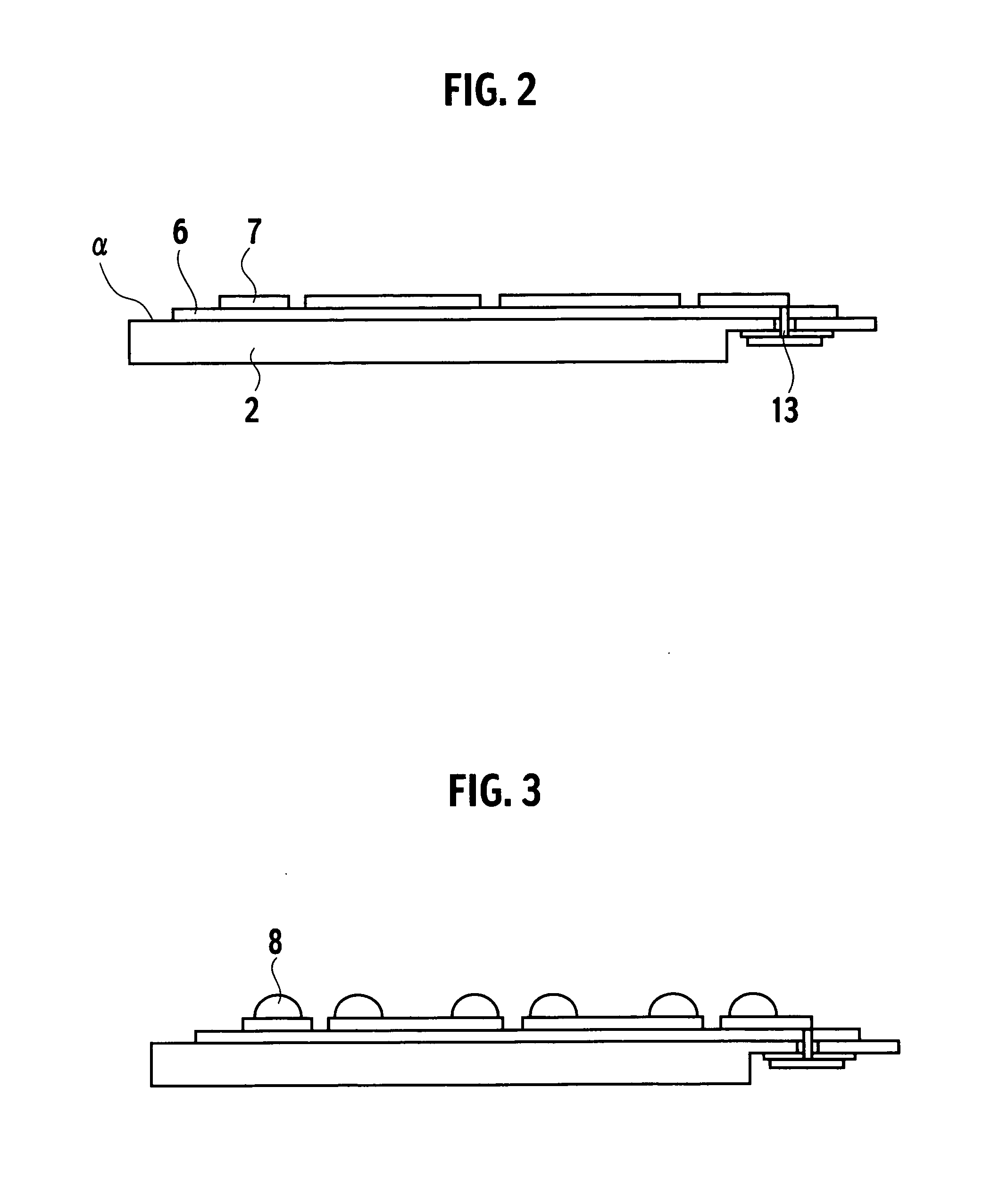

Thermoelectric Module

InactiveUS20050241690A1Lower resistanceReduce power consumptionThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentElectrical conductorEngineering

A thermoelectric module 11 includes support substrates 1a and 1b, the same numbers of N-type thermoelectric elements 2a and P-type thermoelectric elements 2b disposed on the support substrates 1a and 1b, wiring conductors 3a and 3b that electrically connect between the thermoelectric elements in series and an external connection terminal 4 electrically connected to the wiring conductor 3a. The N-type thermoelectric elements 2a and the P-type thermoelectric elements 2b have different values of resistivity.

Owner:KYOCERA CORP

Thermoelectric devices with controlled current flow and related methods

InactiveUS20060048809A1Improve thermoelectric performanceReduce joule heatingThermoelectric device with peltier/seeback effectNanoinformaticsThermal energyElectrical resistance and conductance

Thermoelectric devices comprising at least a first conductive material, a first semiconductive material, a second conductive material, and a third conductive material. The second conductive material may be contacting, disposed within, or operably connected to the first semiconductive material. Semiconductive materials may be depleted, undoped, p-doped, or n-doped, nanotubes, nanowires, and others. Conductive materials may be metals, alloys, conductive materials, nanotubes, nanowires, and others. The effective electrical resistance between the first conductive material and the third conductive materials is reduced below the series electrical resistance of the first semiconductive material by design, reducing the associated Joule heating. Peltier cooling and Peltier heating counteract each other within the second conductive material as electrical current flows. Heat exchanged between the first conductive material and the third conductive material creates a temperature differential therebetween. Thermoelectric devices can reversibly heat or cool, and use the Seebeck effect to generate electrical power from thermal energy.

Owner:OROBRIDGE

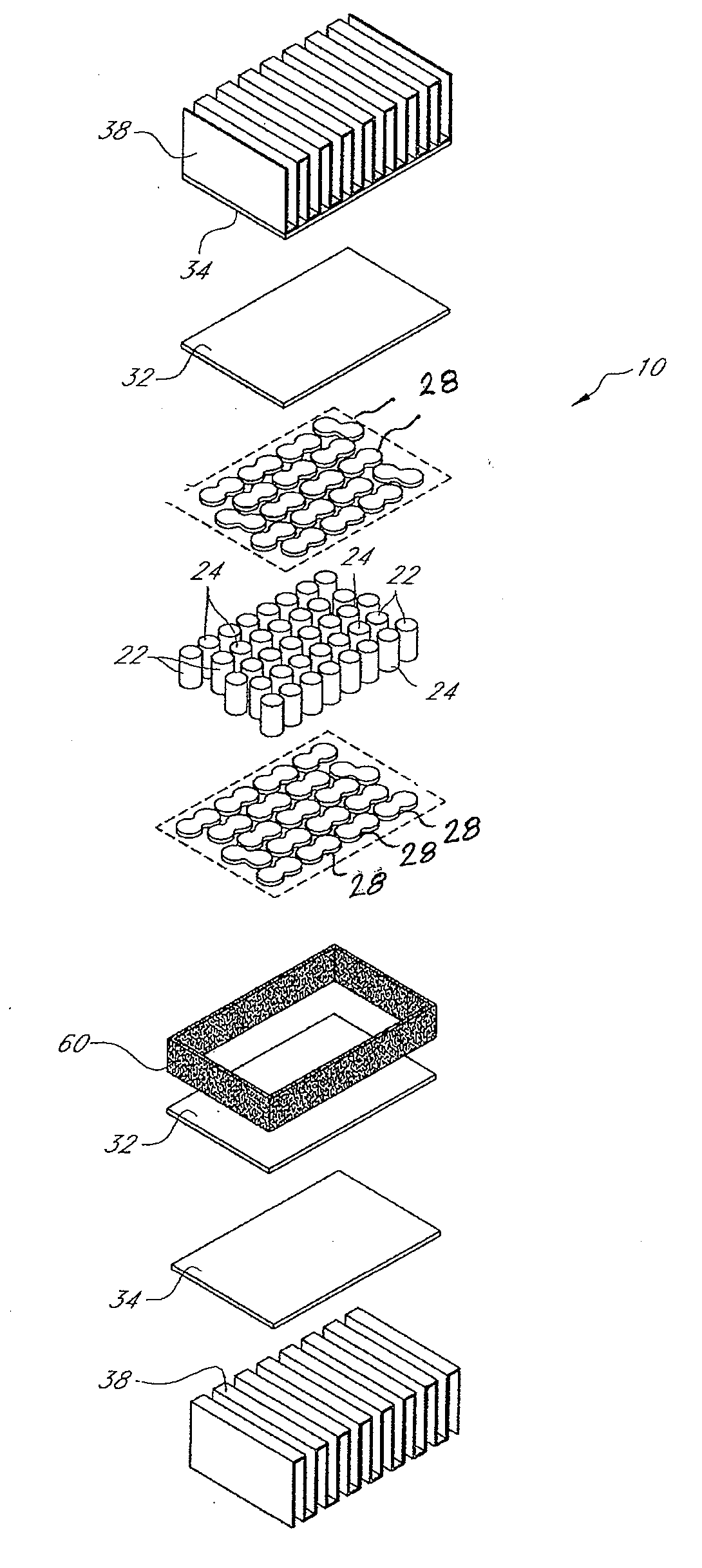

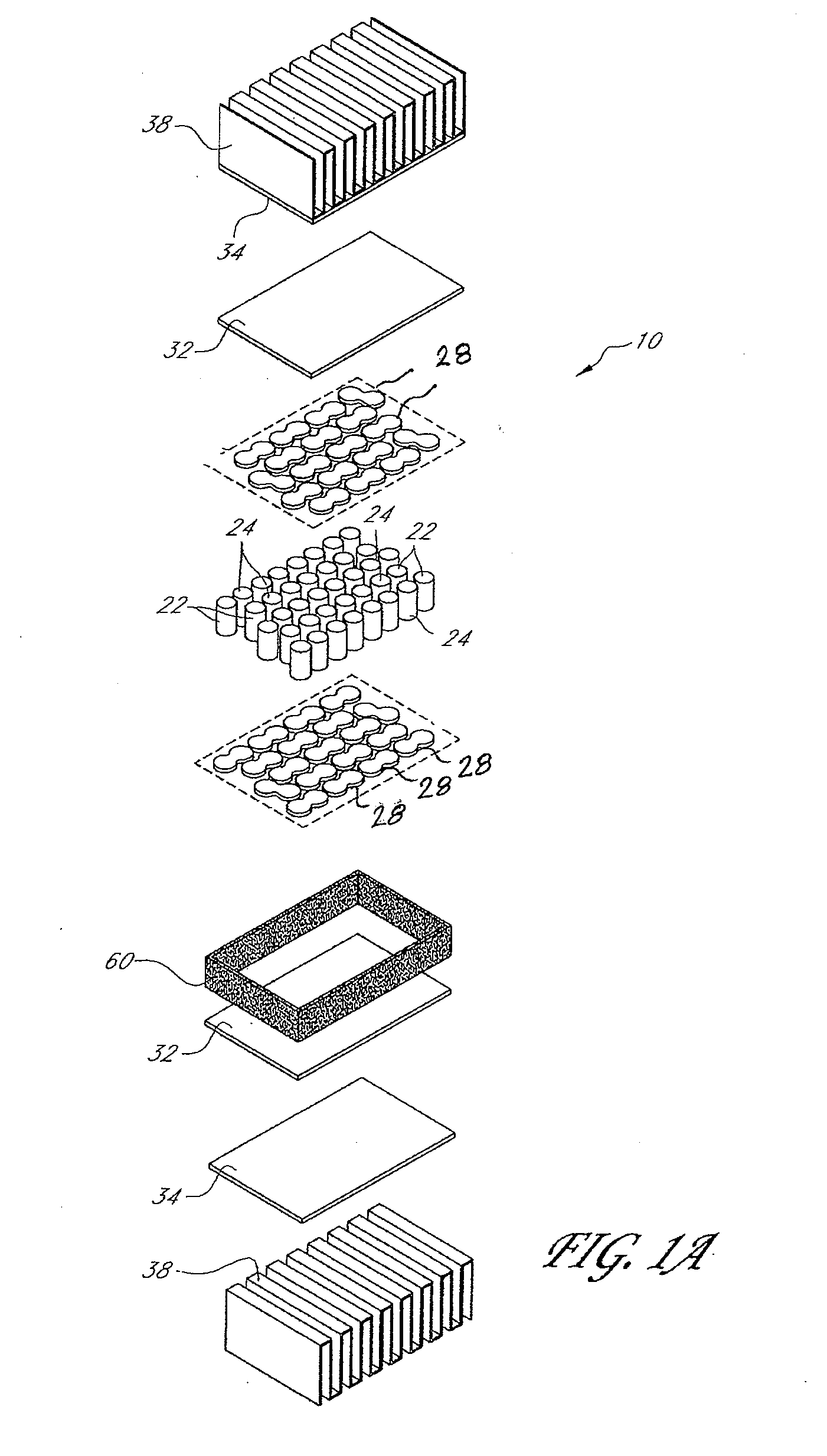

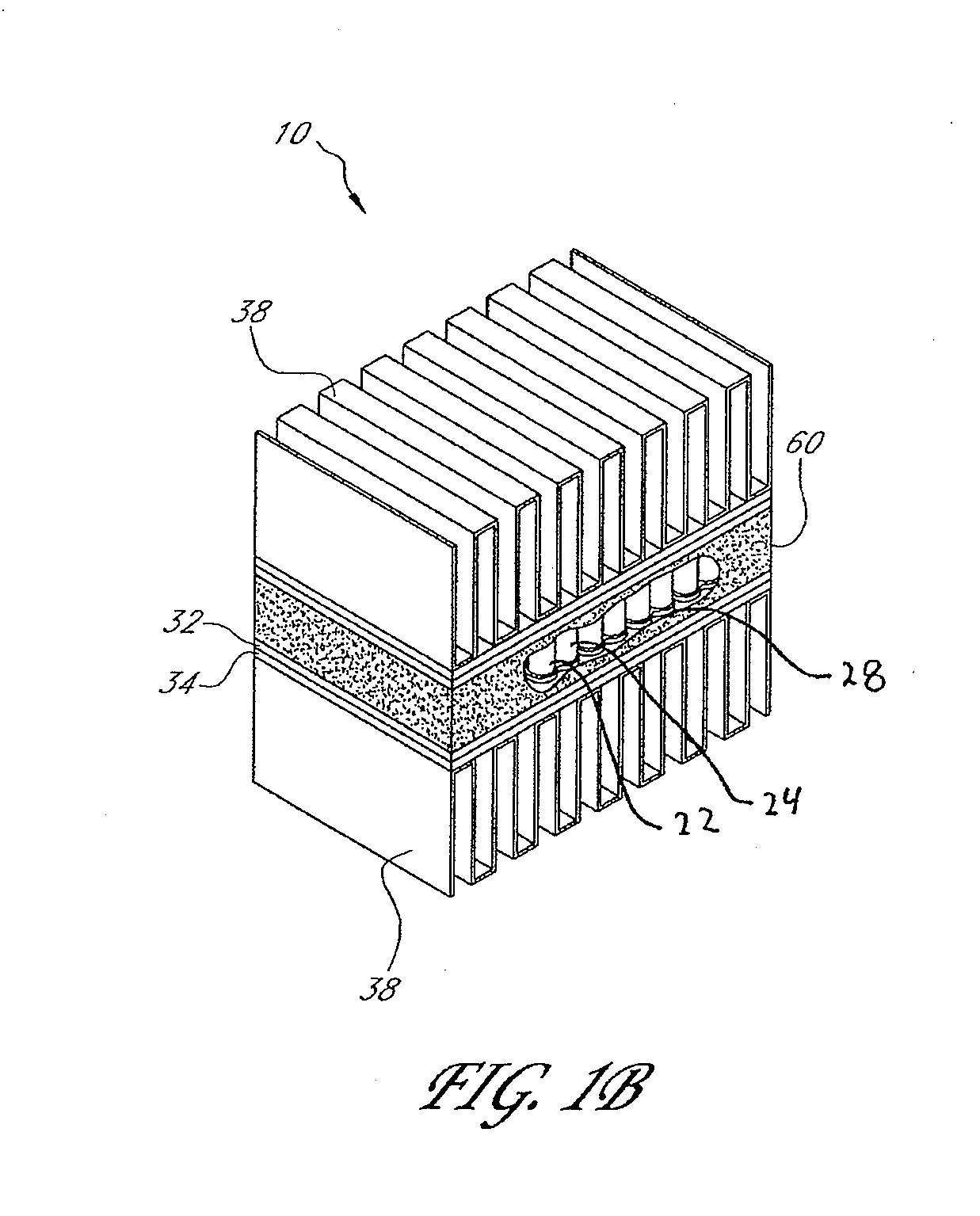

Thermoelectric device

InactiveUS20080047598A1High densityVehicle seatsThermoelectric device with peltier/seeback effectElectrical conductorEngineering

A thermoelectric device comprises a plurality of semiconductor elements comprising a first set of semiconductor elements and a second set of semiconductor elements, which include dissimilar electrical properties. The semiconductor elements are oriented in a substantially hexagonal array that includes rows in which semiconductor elements of the first and second sets of semiconductor elements alternate. The thermoelectric device also comprises a first set of electrical conductors and a second set of electrical conductors; each of the first set of electrical conductor being electrically coupled to the first end of a semiconductor element of the first set of semiconductor elements and the first end of a semiconductor element of the second set of semiconductor elements, each of the second set of electrical conductors are electrically coupled to the second end of a semiconductor element of the first set of semiconductor elements and the a second end of a semiconductor element of the second set of semiconductor elements such that the plurality of semiconductor elements are electrically coupled to each other in series.

Owner:GENTHERM INC

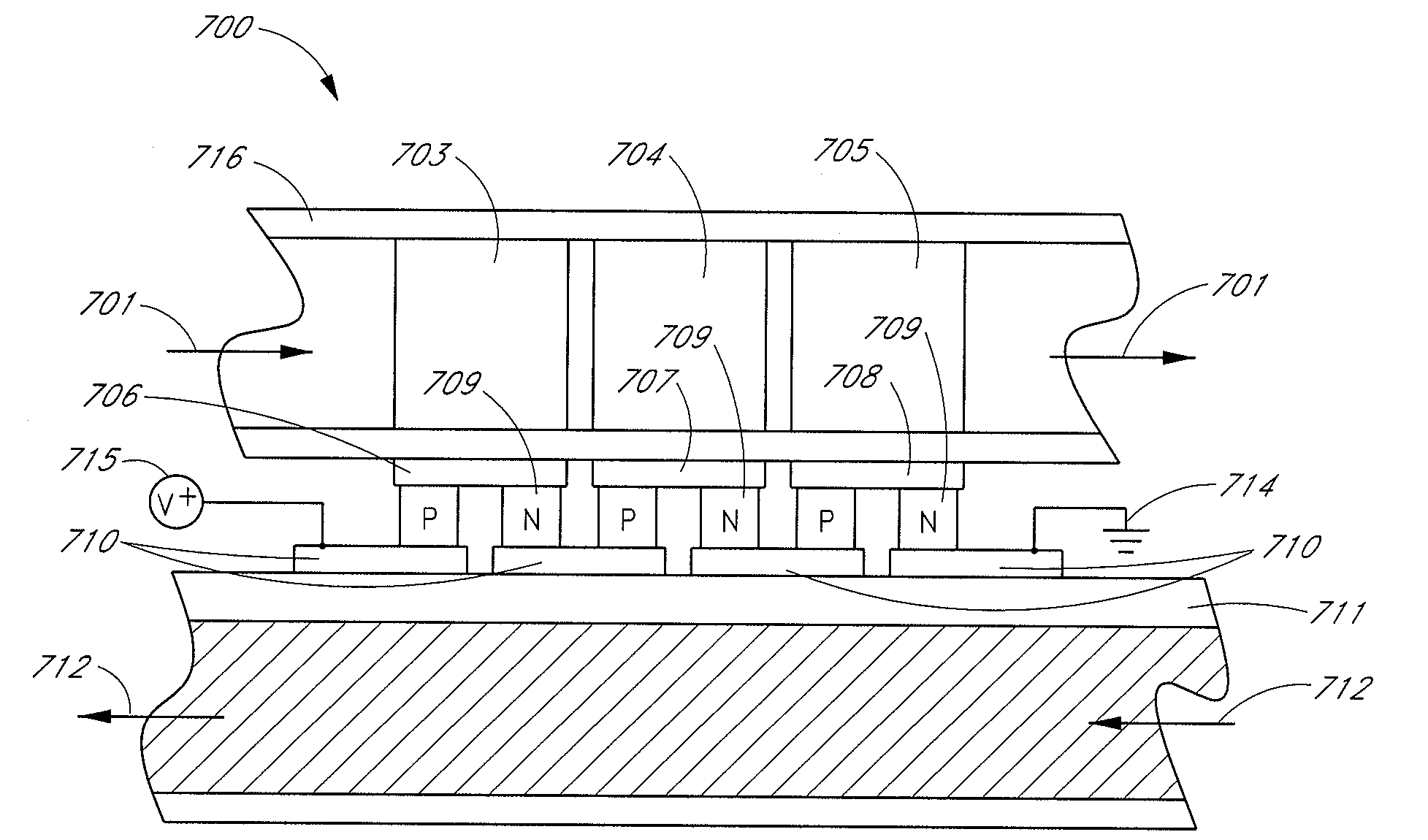

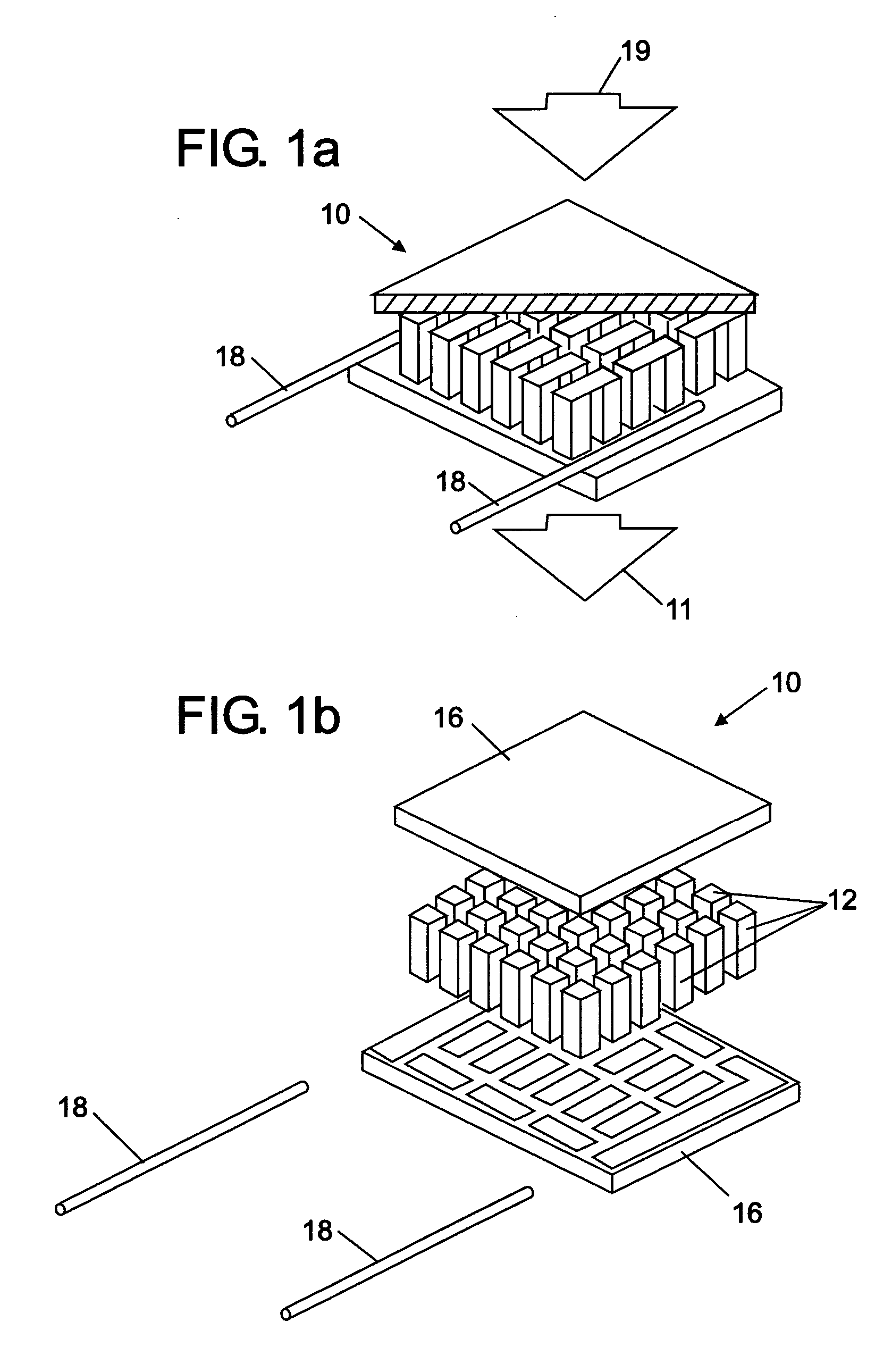

Thin film thermoelectric devices for power conversion and cooling

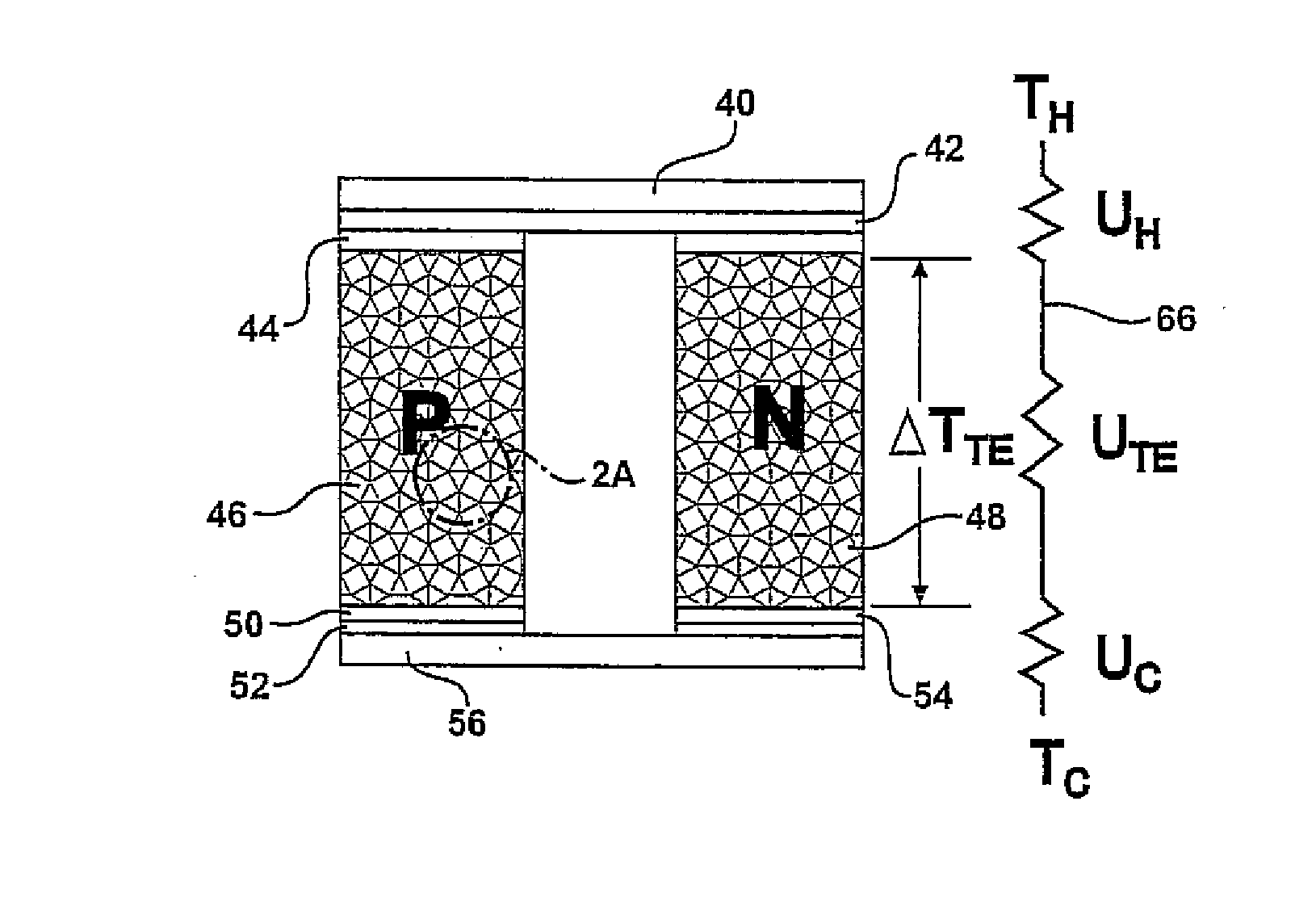

InactiveUS20100257871A1High internal heat-fluxLow external heat-fluxThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentEngineeringThermoelectric element

A thermoelectric device having at least one thermoelectric unit including at least one thermoelectric pair of n-type and p-type thermoelements, a first header coupled to one side of the thermoelectric pair, and a second header coupled to a second side of the thermoelectric pair. The thermoelectric pair has a thermal conduction channel area smaller than an area of the first header or the second header such that the thermal conduction area is a fraction of the area of the first header or the second header.

Owner:NEXTREME THERMAL SOLUTIONS

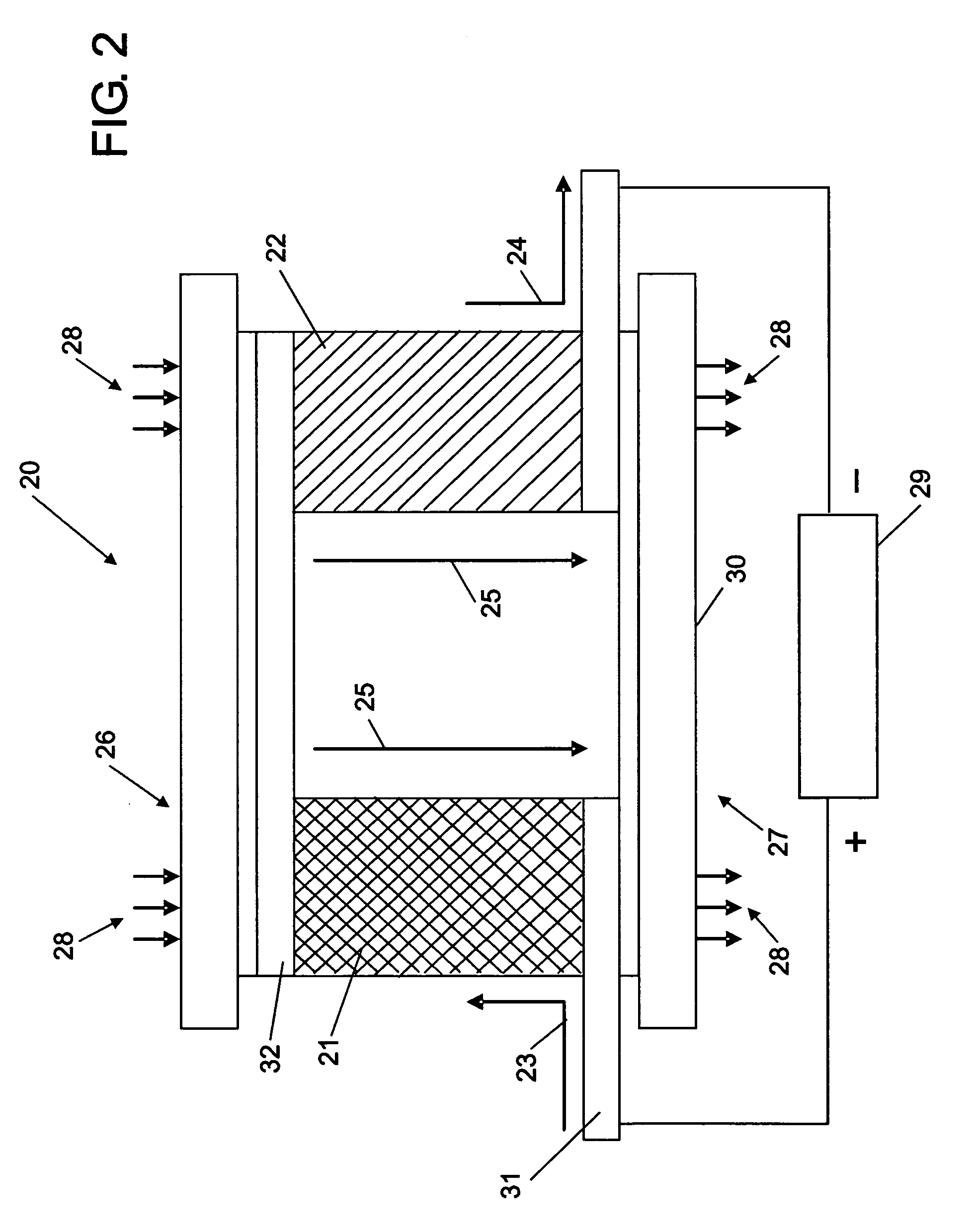

Thermoelectric direct conversion device

InactiveUS20060118159A1Improve power generation effectInhibited DiffusionThermoelectric device with peltier/seeback effectThermoelectric device detailsDiffusion barrierThermoelectric conversion

A thermoelectric direct conversion device is foemed of a plurality of thermoelectric direct conversion semiconductor pairs each including a p-type semiconductor and an n-type semiconductor; a plurality of high-temperature electrodes and a plurality of low-temperature electrodes each electrically connecting the p-type semiconductor and the n-type semiconductor; a high-temperature insulating plate and a low-temperature insulating plate each thermally connected to the plurality of thermoelectric direct conversion semiconductor pairs via the plurality of high-temperature electrodes and the plurality of low-temperature electrodes, respectively; at least one diffusion barrier layer is disposed between the high- or low-temperature electrodes and the thermoelectric direct conversion semiconductor pairs, and the entire device is hermetically sealed up within an airtight case containing a vacuum or inert gas atmosphere, whereby diffusion between the electrodes and the semiconductor pairs is prevented to provide a thermoelectric conversion devise exhibiting excellent power generation performances for a long time period.

Owner:KK TOSHIBA

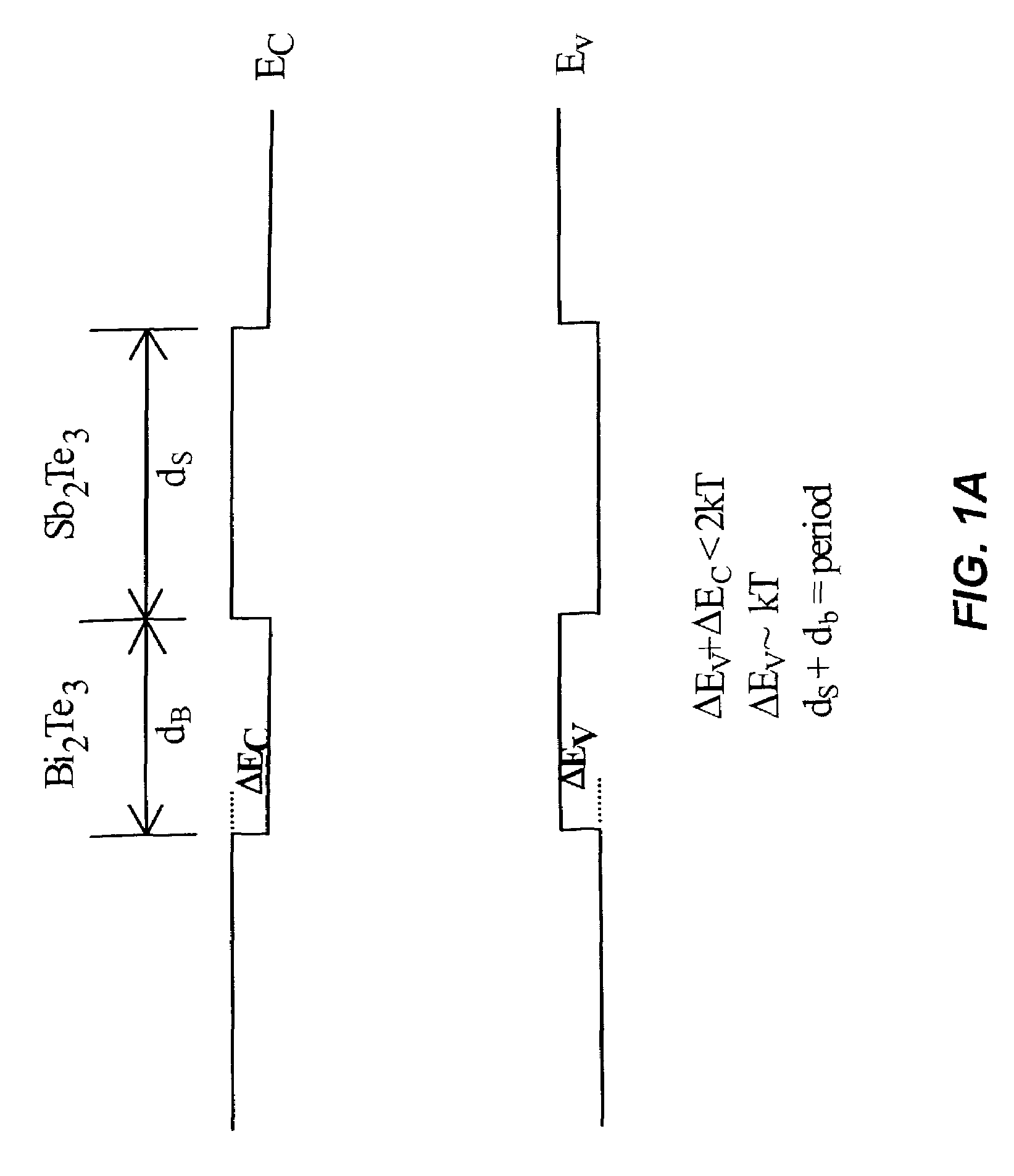

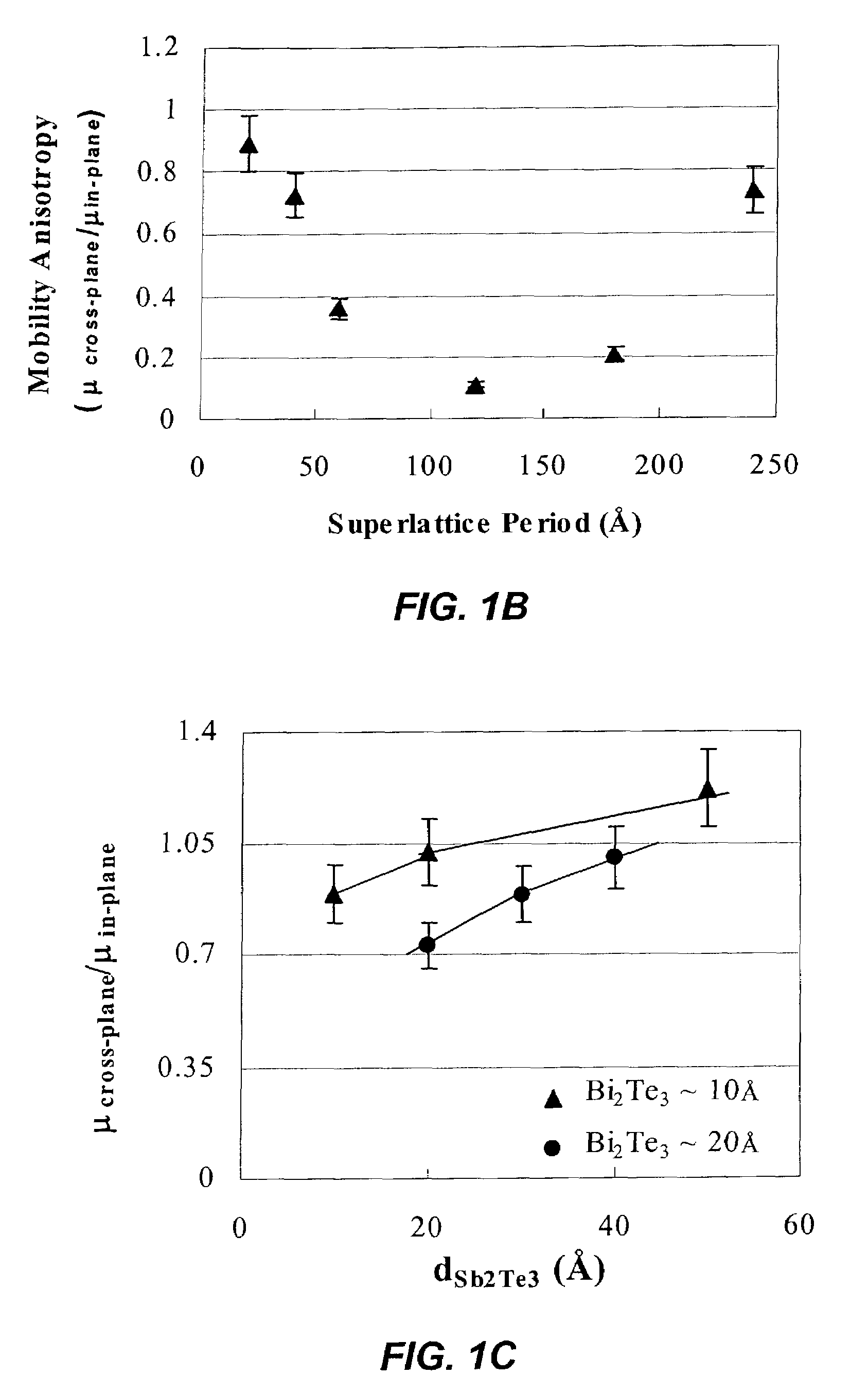

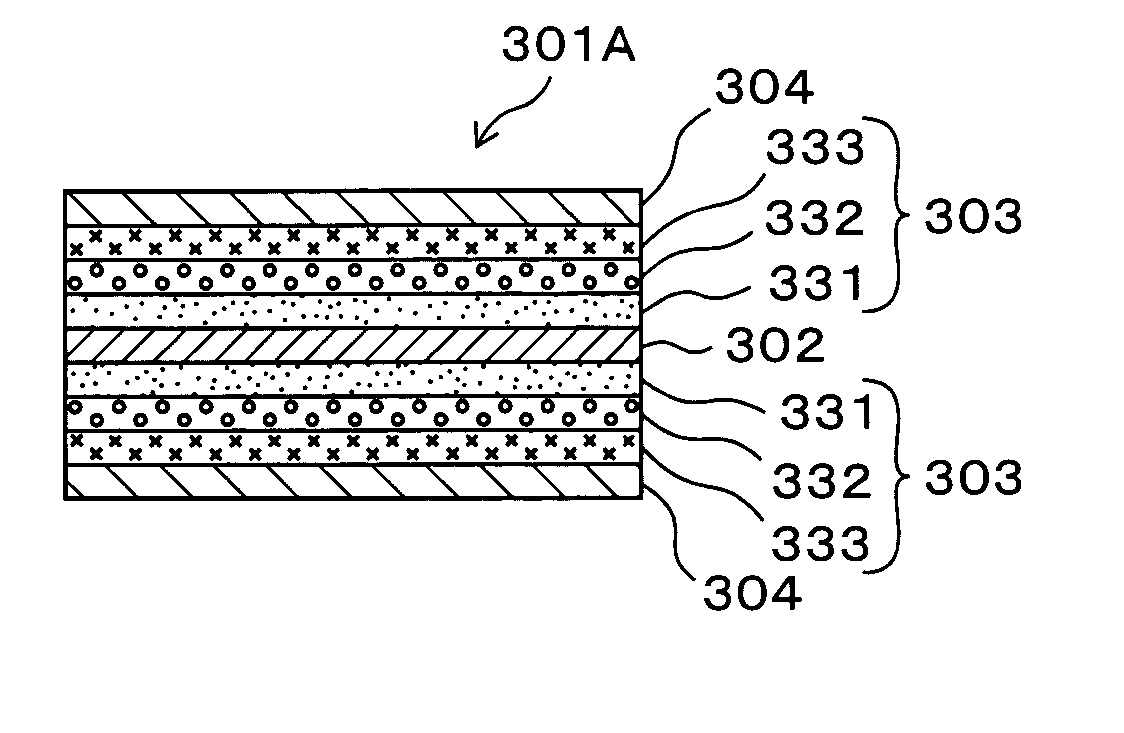

Phonon-blocking, electron-transmitting low-dimensional structures

ActiveUS7342169B2Lower lattice thermal conductivityImprove ZTThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentLattice mismatchCharge carrier

A thermoelectric structure and device including at least first and second material systems having different lattice constants and interposed in contact with each other, and a physical interface at which the at least first and second material systems are joined with a lattice mismatch and at which structural integrity of the first and second material systems is substantially maintained. The at least first and second material systems have a charge carrier transport direction normal to the physical interface and preferably periodically arranged in a superlattice structure.

Owner:LAIRD THERMAL SYST INC

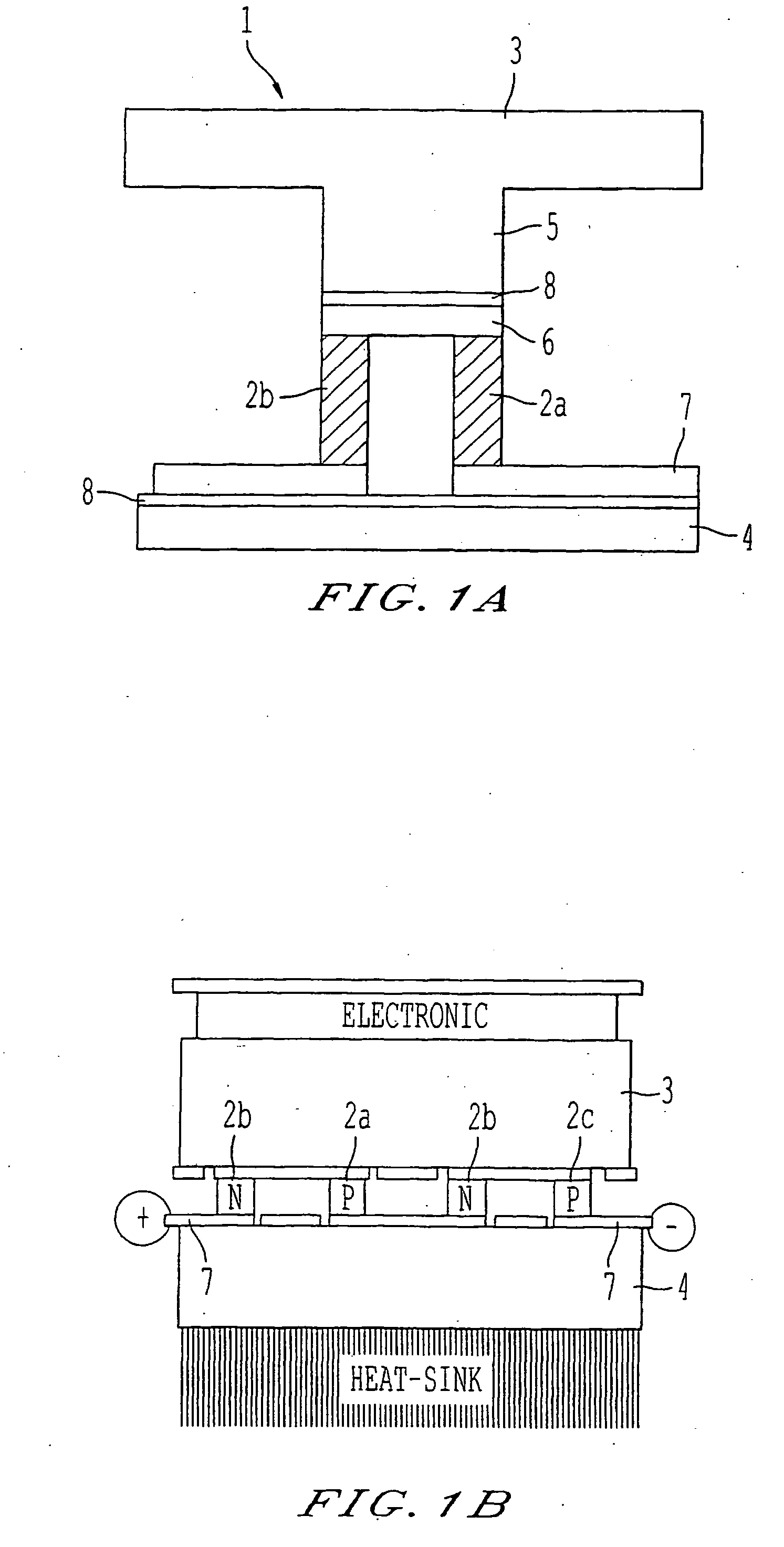

Thermoelectric devices and methods for making the same

InactiveUS6262357B1Maximize heat flowMaximize flowThermoelectric device with peltier/seeback effectSemiconductor/solid-state device detailsThermal energyScreening techniques

Thermoelectric devices having enhanced thermal characteristics are fabricated using multilayer ceramic (MLC) technology methods. Aluminum nitride faceplates with embedded electrical connections provide the electrical series configuration for alternating dissimilar semiconducting materials. Embedded electrical connections are formed by vias and lines in the faceplate. Methods for forming tunnels through lamination and etching are employed. A portion of the dissimilar materials are then melted within the tunnels to form a bond. Thermal conductivity of the faceplate is enhanced by adding electrically isolated vias to one surface, filled with high thermal conductivity metal paste. A low thermal conductivity material is also introduced between the two high thermal conductivity material faceplates.Alternating semiconducting materials are introduced within the varying thermal conductivity layers by punching vias within greensheets of predetermined thermal conductivity and filling with n-type and p-type paste. Alternating semiconducting materials may also be patterned in linear or radial fanout patterns through screening techniques and lamination of wire structures. A liquid channel within the faceplate is used to enhance thermal energy transfer.Thermoelectric devices are physically incorporated within the IC package using MLC technology.

Owner:INT BUSINESS MASCH CORP

Production method for sintered metal-ceramic layered compact and production method for thermal stress relief pad

InactiveUS20050002818A1Reduce in quantityEfficient executionThermoelectric device manufacture/treatmentTransportation and packagingMicrowaveStress relief

The present invention provides a production method for a sintered metal-ceramic layered compact, comprising steps of: filling and layering a metal powder and a ceramic powder, or filling and layering a metal powder, a mixed powder of a metal powder and a ceramic powder, and a ceramic powder; forming a green compact of the layered powders by compacting the layered powders; and sintering a layer including the metal of the green compact at a temperature of lower than a melting point of the metal by heating by irradiation of microwaves in a non-oxidizing atmosphere.

Owner:HITACHI POWDERED METALS COMPANY

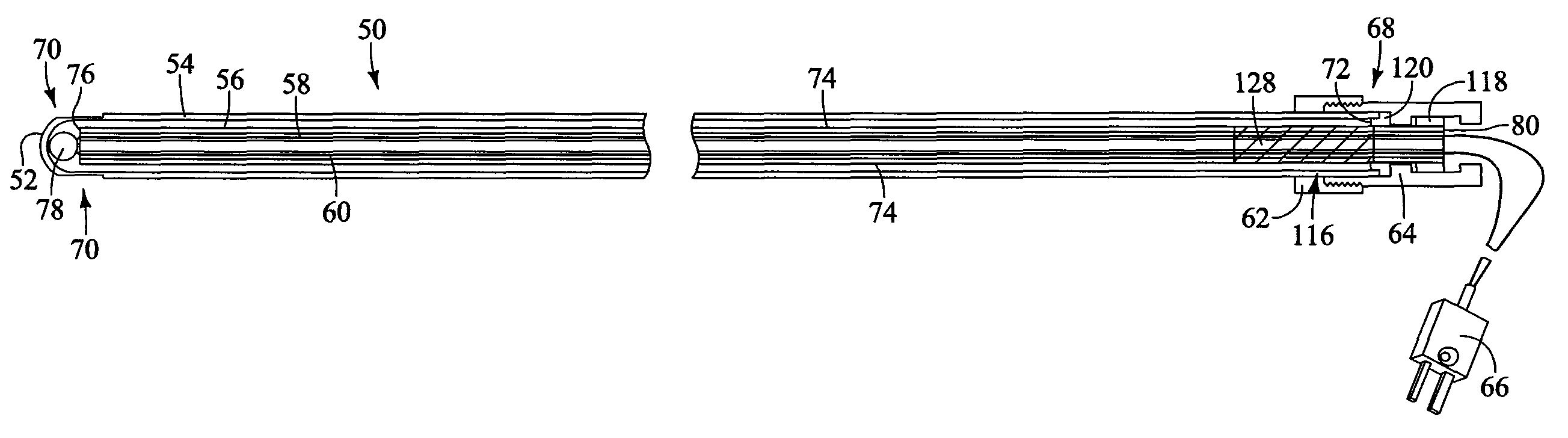

Thin-film thermoelectric cooling and heating devices for DNA genomic and proteomic chips, thermo-optical switching circuits, and IR tags

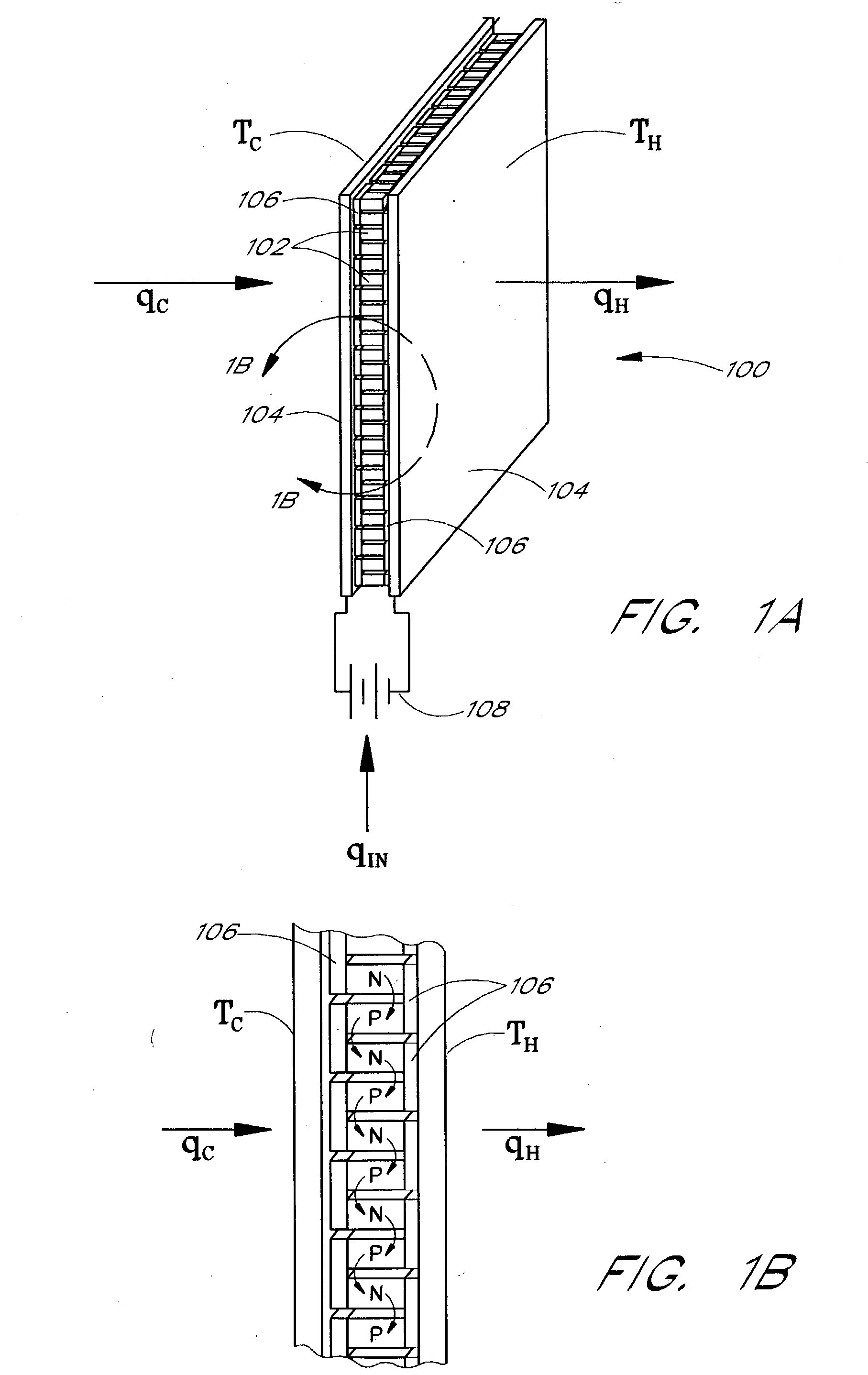

ActiveUS20020174660A1Fast heatingFast coolingBioreactor/fermenter combinationsNanostructure manufactureThermoelectric coolingThermoelectric materials

A thermoelectric cooling and heating device including a substrate, a plurality of thermoelectric elements arranged on one side of the substrate and configured to perform at least one of selective heating and cooling such that each thermoelectric element includes a thermoelectric material, a Peltier contact contacting the thermoelectric material and forming under electrical current flow at least one of a heated junction and a cooled junction, and electrodes configured to provide current through the thermoelectric material and the Peltier contact. As such, the thermoelectric cooling and heating device selectively biases the thermoelectric elements to provide on one side of the thermolectric device a grid of localized heated or cooled junctions.

Owner:LAIRD THERMAL SYST INC

Thermoelectric conversion module and thermoelectric conversion apparatus

InactiveUS20080163916A1Low costOptimize spaceThermoelectric device with peltier/seeback effectMachines using electric/magnetic effectsElectricityThermoelectric conversion

According to one embodiment, a thermoelectric conversion module includes a thermoelectric conversion portion, a first external electrode, and a second external electrode. The thermoelectric conversion portion includes a single thermoelectric conversion portion element, or electrically connected thermoelectric conversion portion elements. The thermoelectric conversion portion element includes a high temperature electrode, low temperature electrodes, and an n-type and a p-type thermoelectric conversion semiconductor layer disposed between the high temperature electrode and the low temperature electrodes. The first and the second external electrode are electrically connected to one of the low temperature electrode and another one of the low temperature electrode respectively. The first external electrode and the second external electrode are disposed opposite each other with the thermoelectric conversion portion therebetween in such a manner that the centerlines of the first and second external electrodes are aligned substantially in line with each other.

Owner:KK TOSHIBA

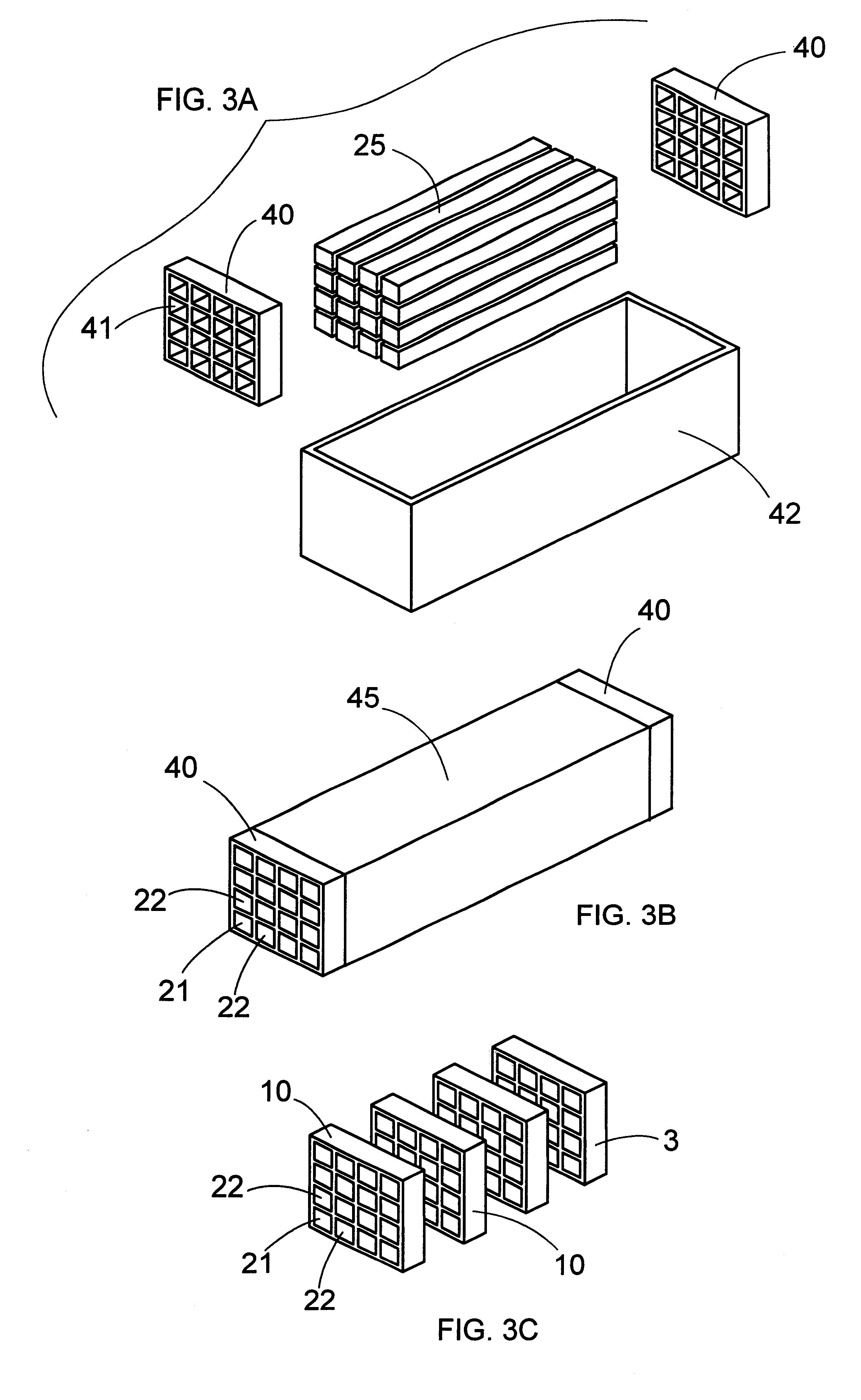

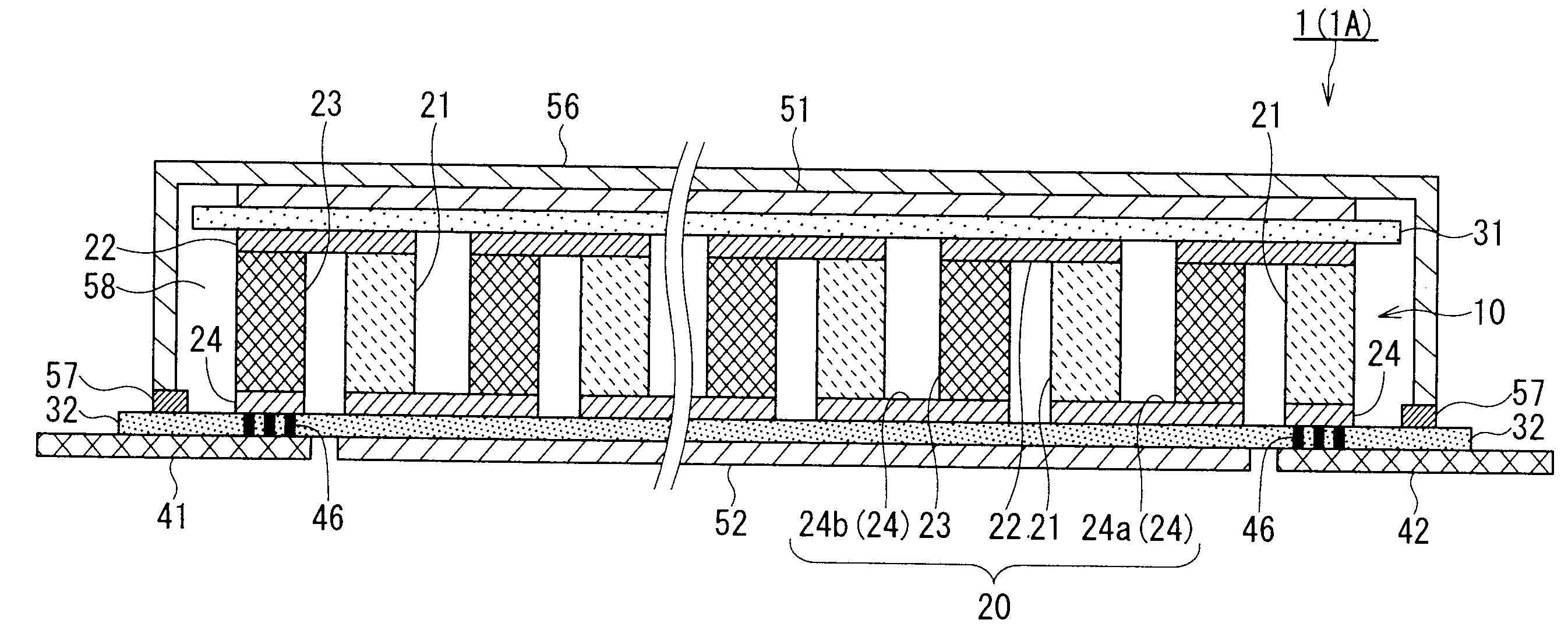

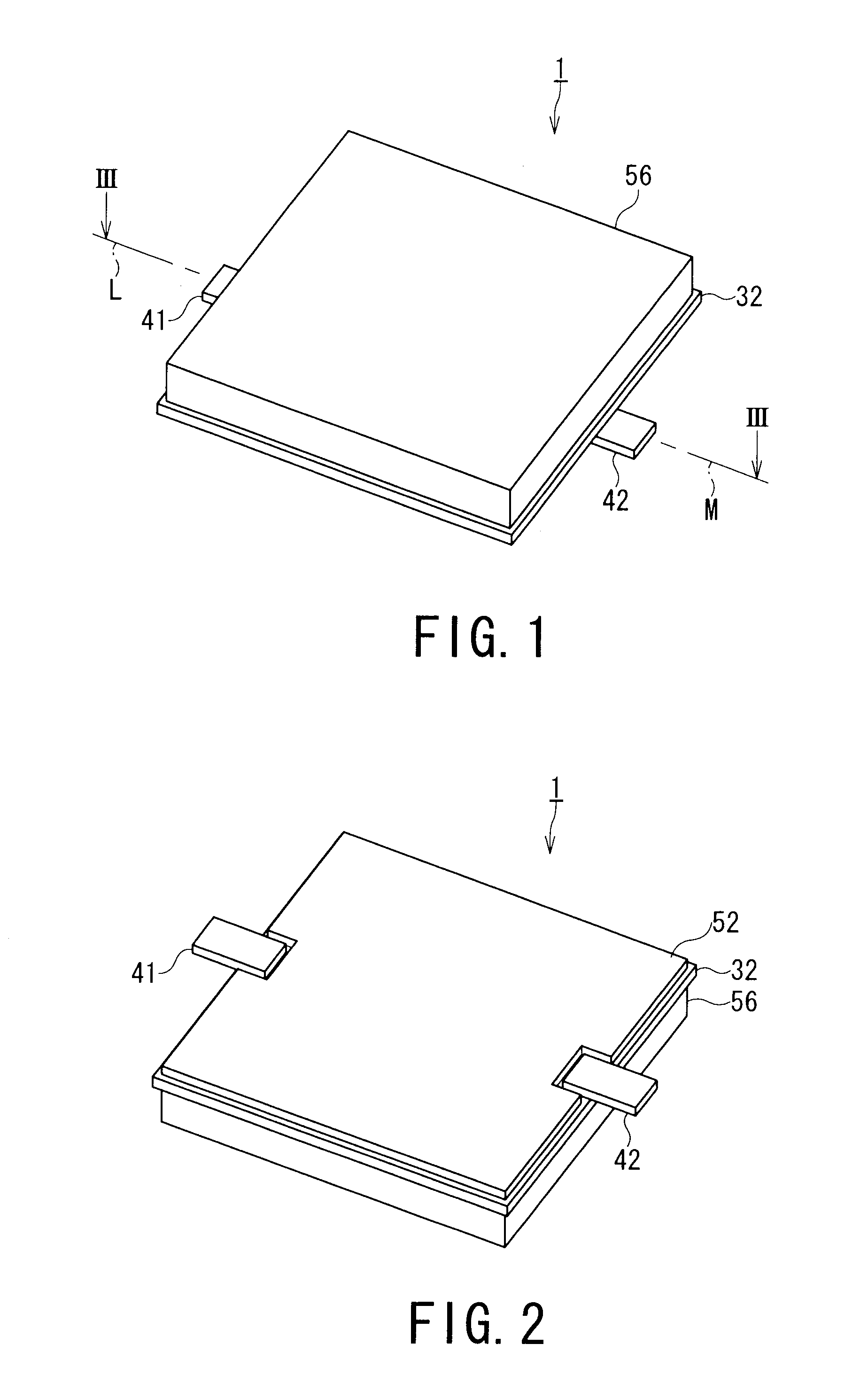

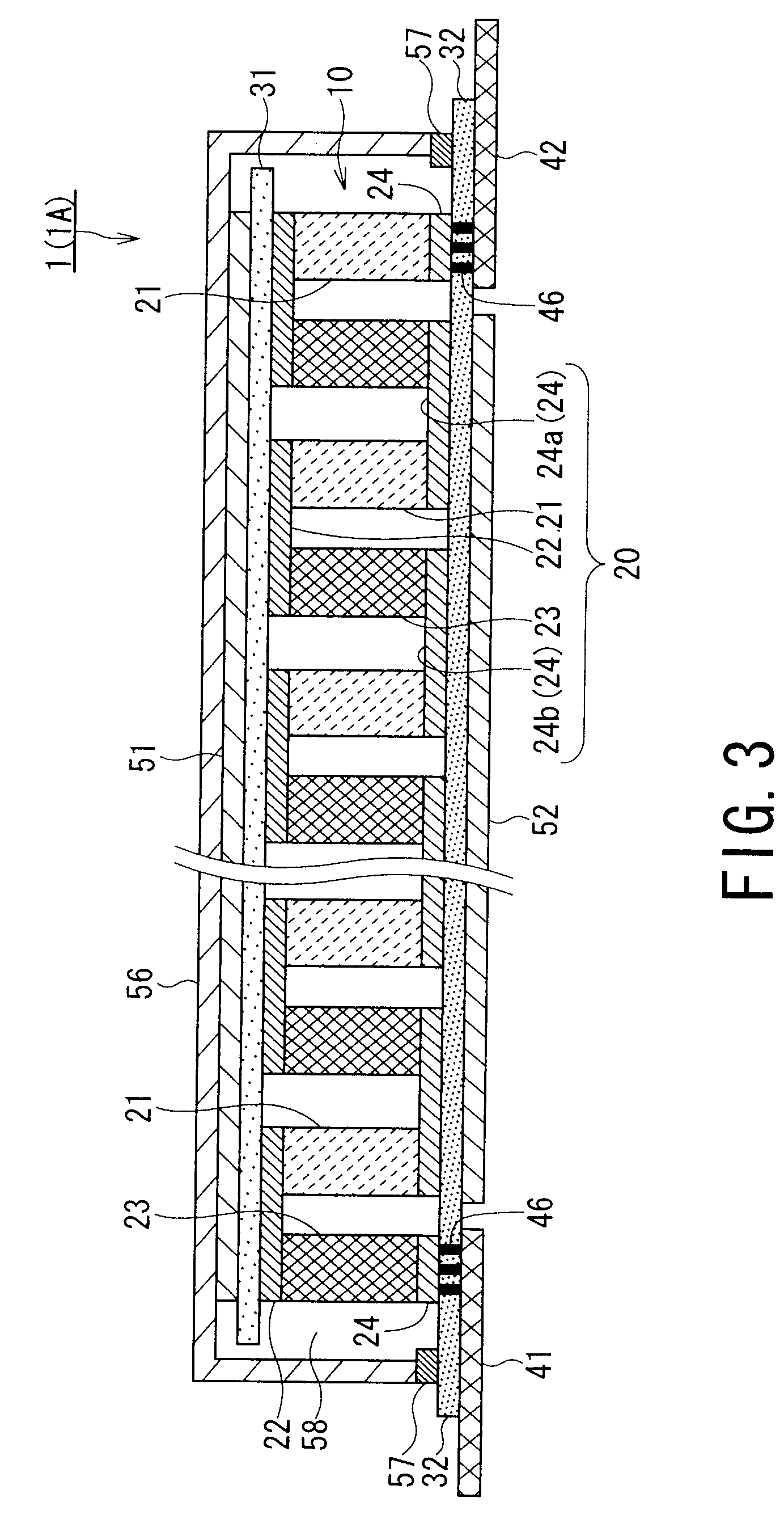

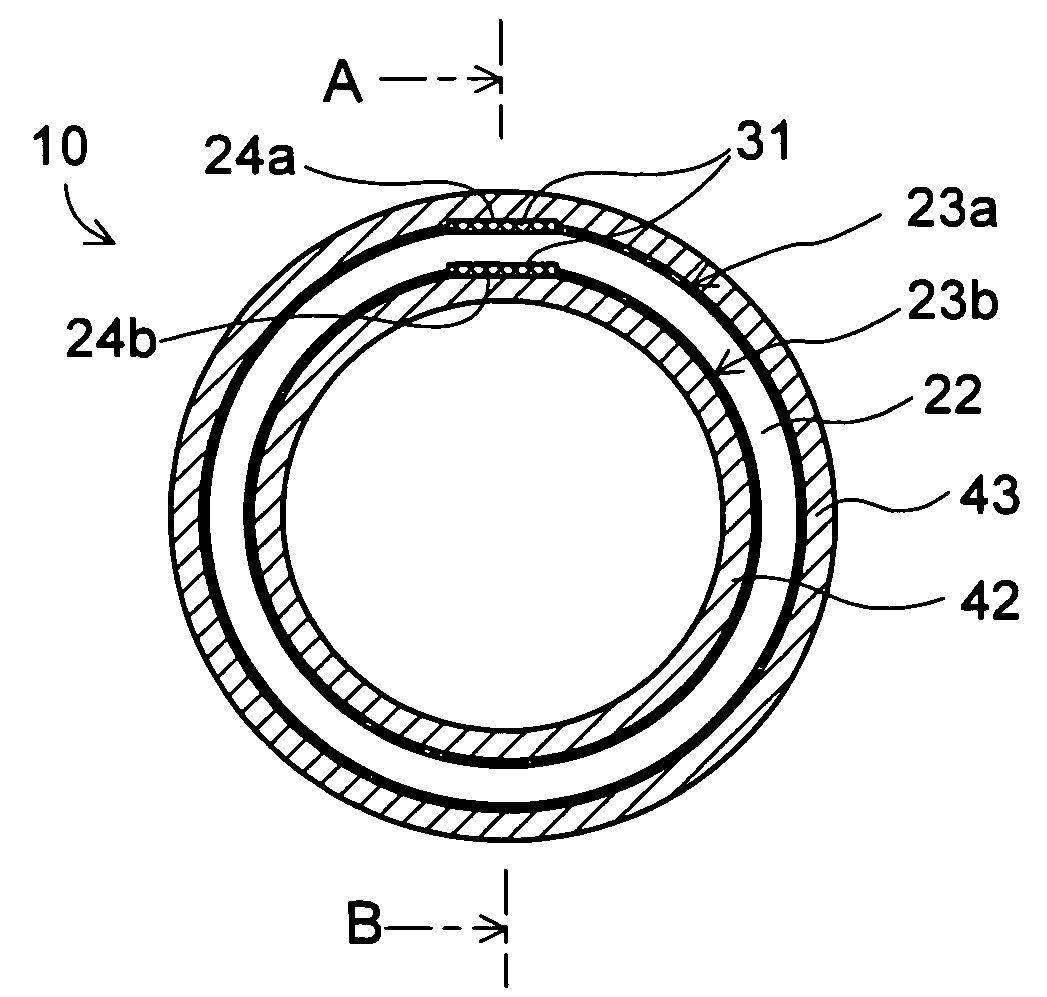

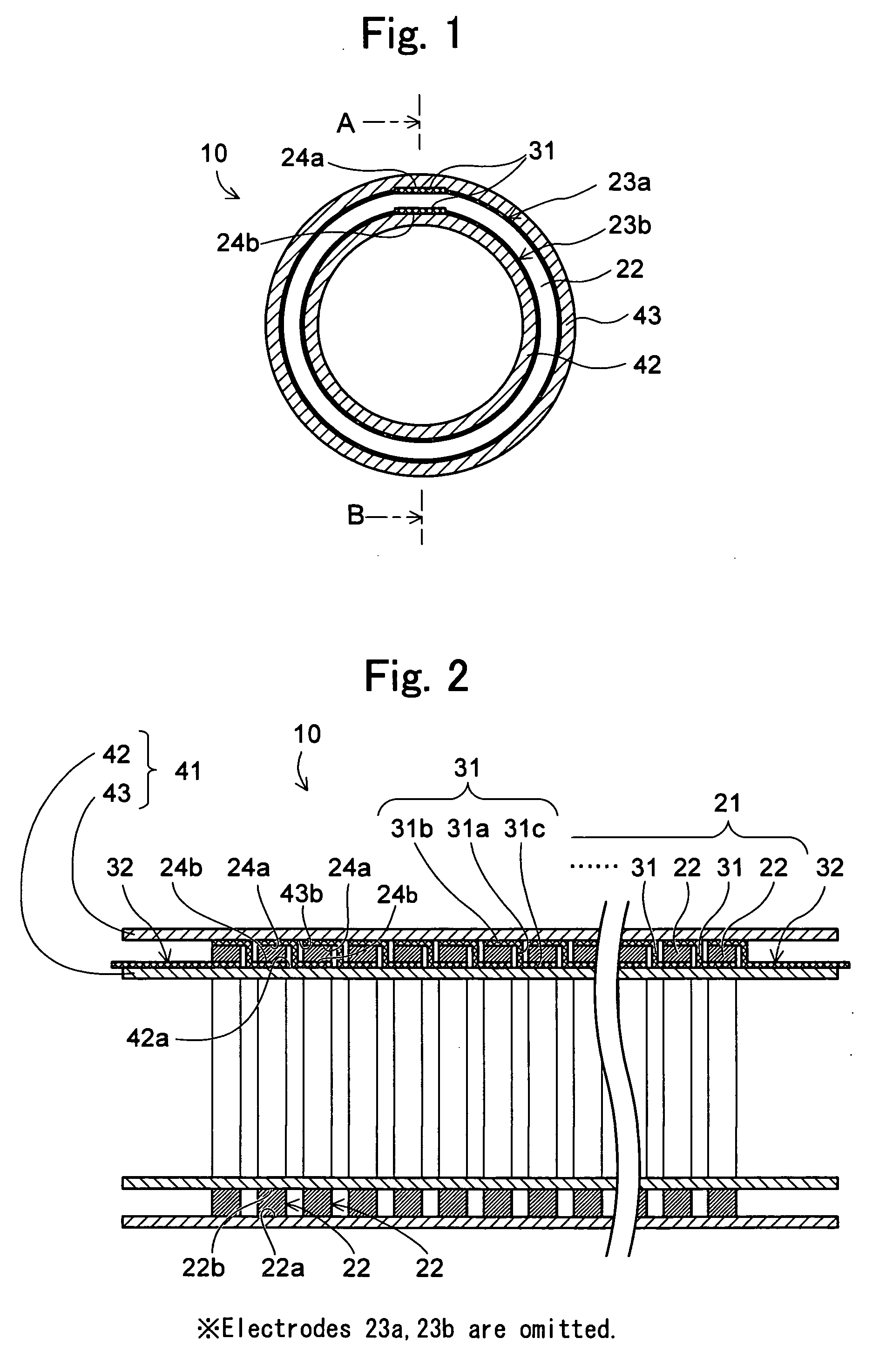

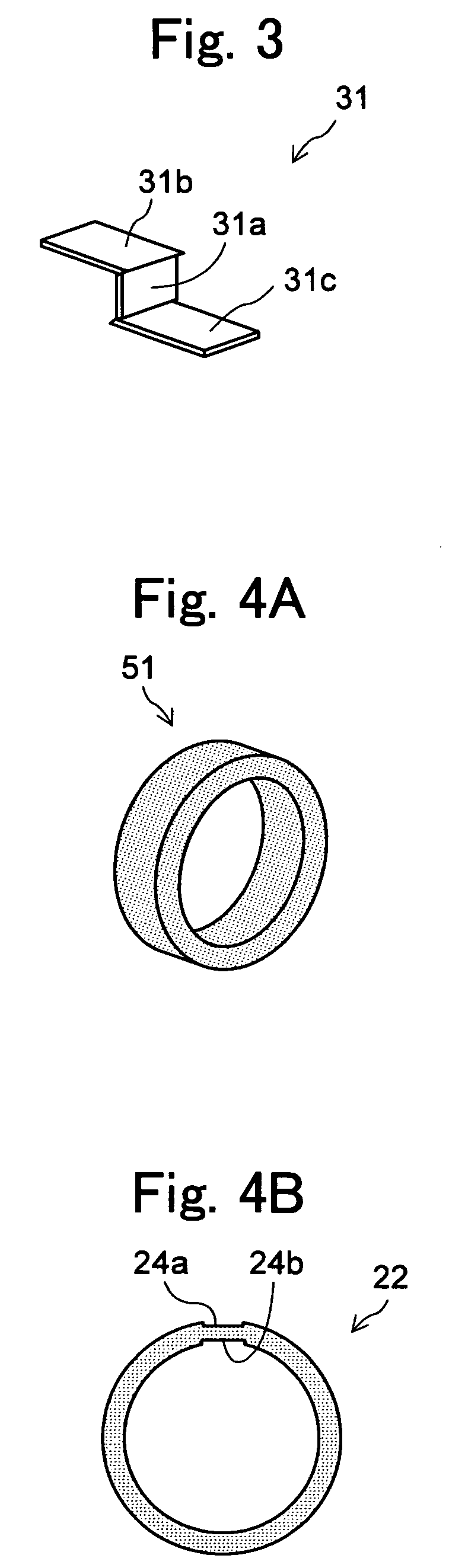

Thermoelectric Conversion Module

InactiveUS20090133734A1Simple structureShorten the timeThermoelectric device with peltier/seeback effectGenerators/motorsTemperature differenceEngineering

To provide a thermoelectric conversion module enabling cost reduction by reducing time and work required for assembly, and so on. A thermoelectric conversion module 10 comprises a tubular element unit 21 having a plurality of ring-like thermoelectric elements 22 coaxially arranged with air as an insulator sandwiched inbetween, wherein the ring-like thermoelectric element 22 is covered approximately entirely with electrodes 23a, 23b at its outer circumference surface 22a and inner circumference surface 22b, respectively, and generates electricity by temperature difference between the outer circumference surface 22a and the inner circumference surface 22b, a lead wire 31 electrically connecting the electrode 23a covered on the outer circumference surface 22a of one ring-like thermoelectric element 22 among the plurality of ring-like thermoelectric elements 22 to the electrode 23b covered on the inner circumference surface 22b of another ring-like thermoelectric element 22 adjacent to this one ring-like thermoelectric element 22, and a doubled cylindrical support unit 41 consisting of a SUS tube 42 whose outer circumference surface 42a supports the tubular element unit 21 and a SUS tube 43 whose inner circumference surface 43b supports the tubular element unit 21.

Owner:UNIVERSAL ENTERTAINMENT CORP

Thermoelectric device and method of manufacturing the same

InactiveUS20070028955A1Increase power generation capacitySimple structureThermoelectric device with peltier/seeback effectPrinted circuit aspectsProduction rateOptoelectronics

There is provided a thermoelectric device capable of improving a power generation performance while keeping a hermetic sealing after a heat cycle is applied, and also achieving simplification of a structure and improvement in productivity and reliability of a device by reducing the number of articles, and a method of manufacturing the same. A thermoelectric device, includes a metal substrate 2, a thermoelectric element 3 mounted on a center portion of a surface of the metal substrate 2, a metal lid 4 for covering an upper surface and side surfaces of the thermoelectric element 3, and a joining metal member 5 provided to a peripheral portion of a surface of the metal substrate 2 to hermetically seal a space between the metal substrate 2 and the lid 4.

Owner:KK TOSHIBA

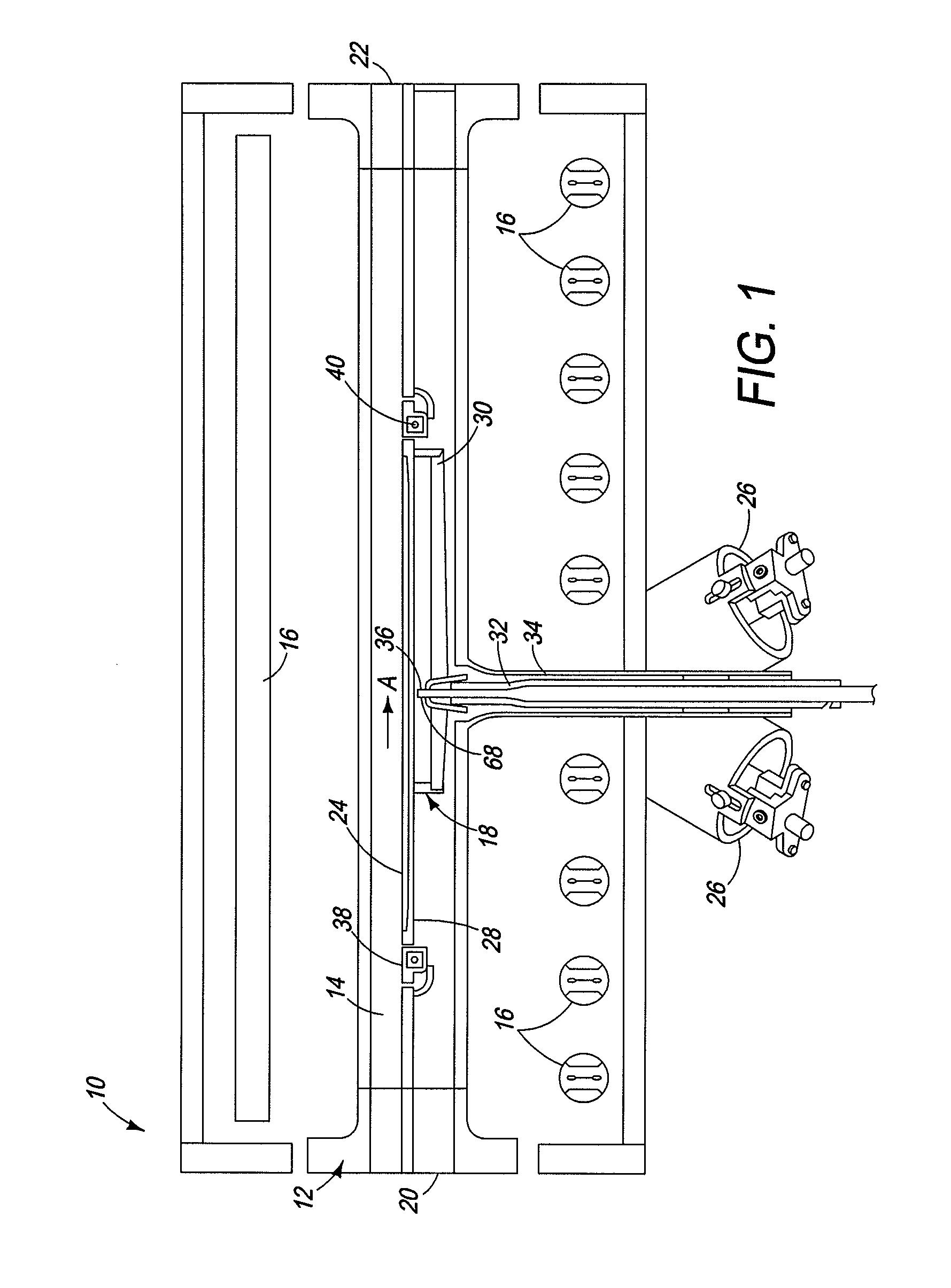

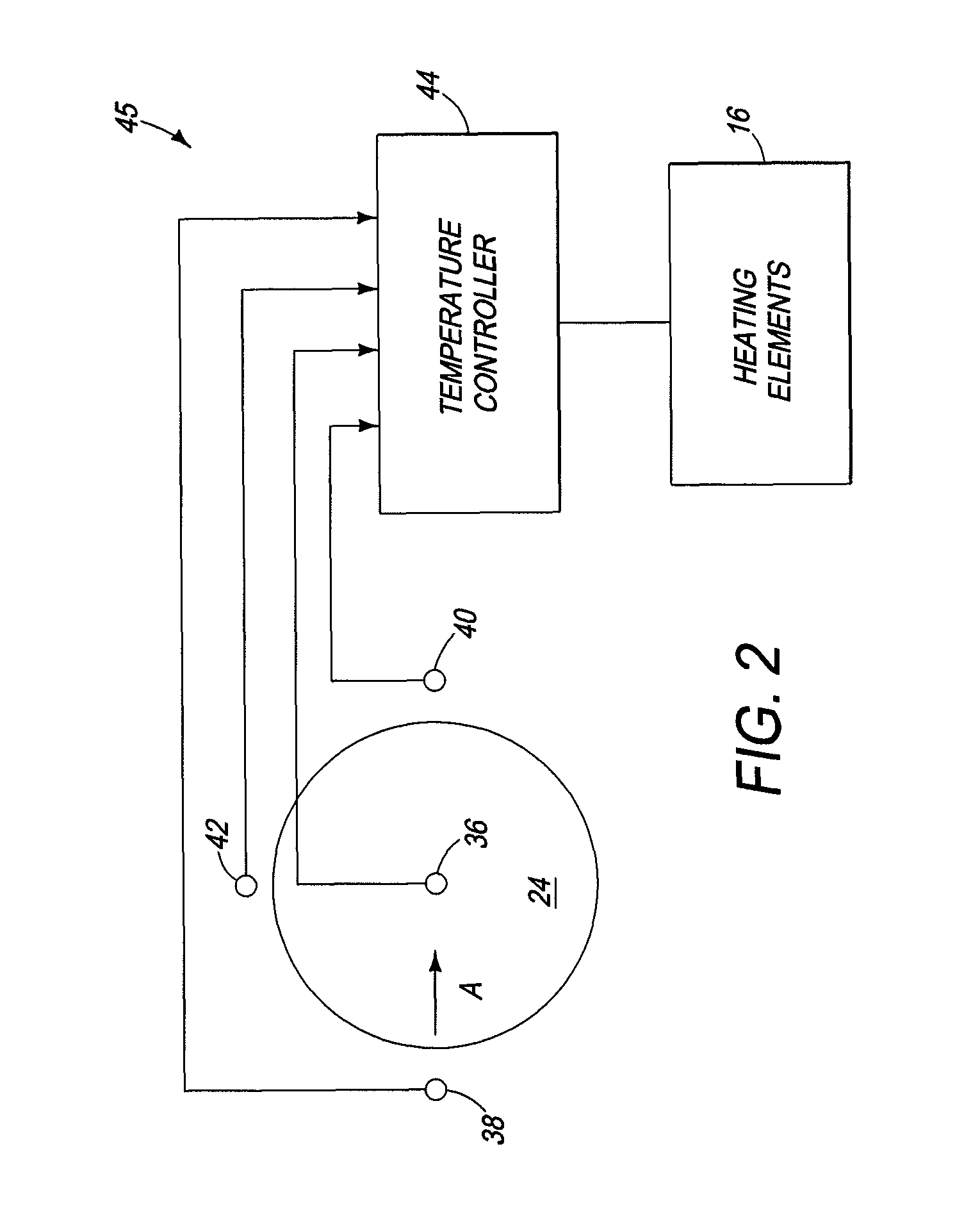

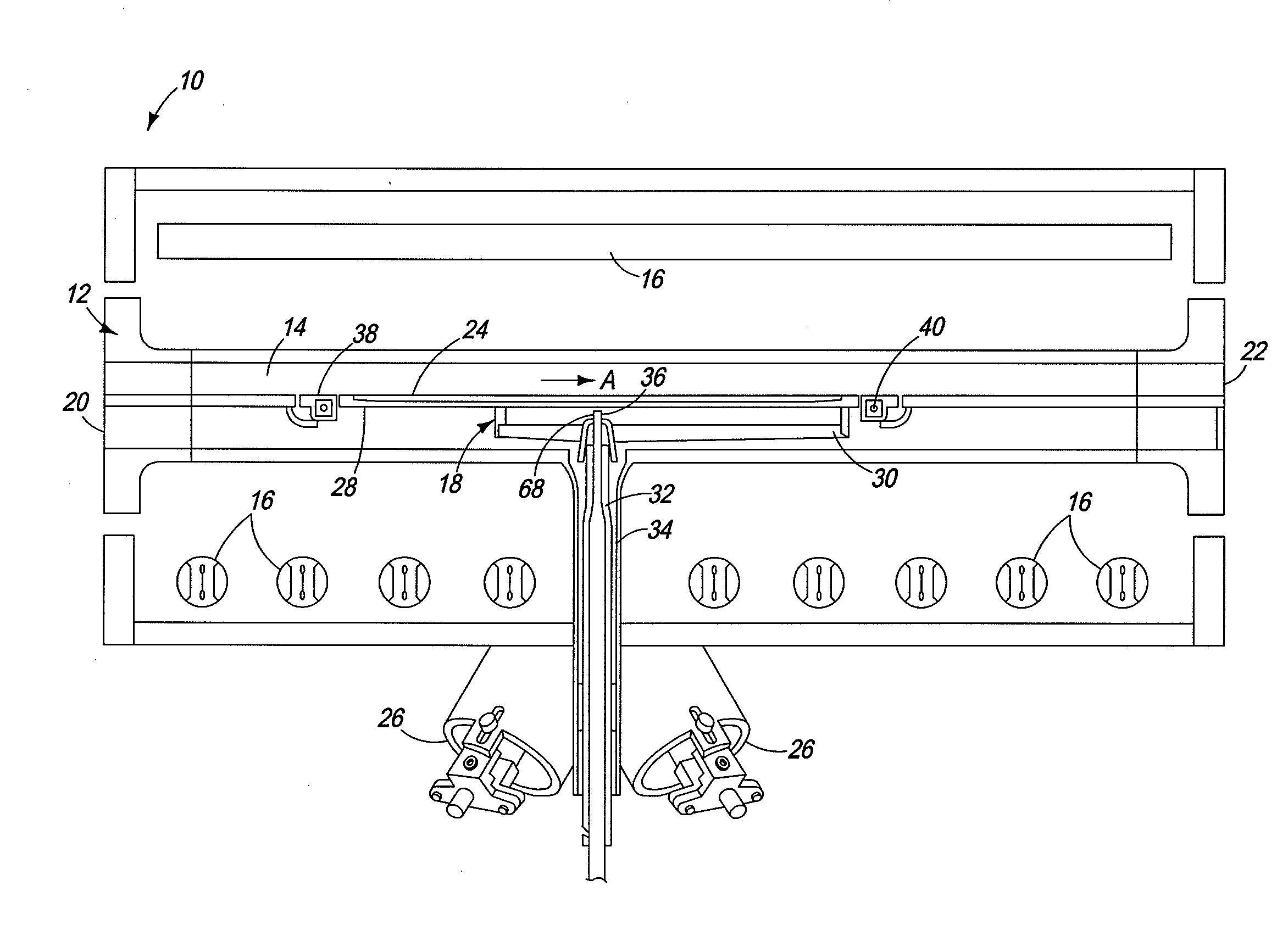

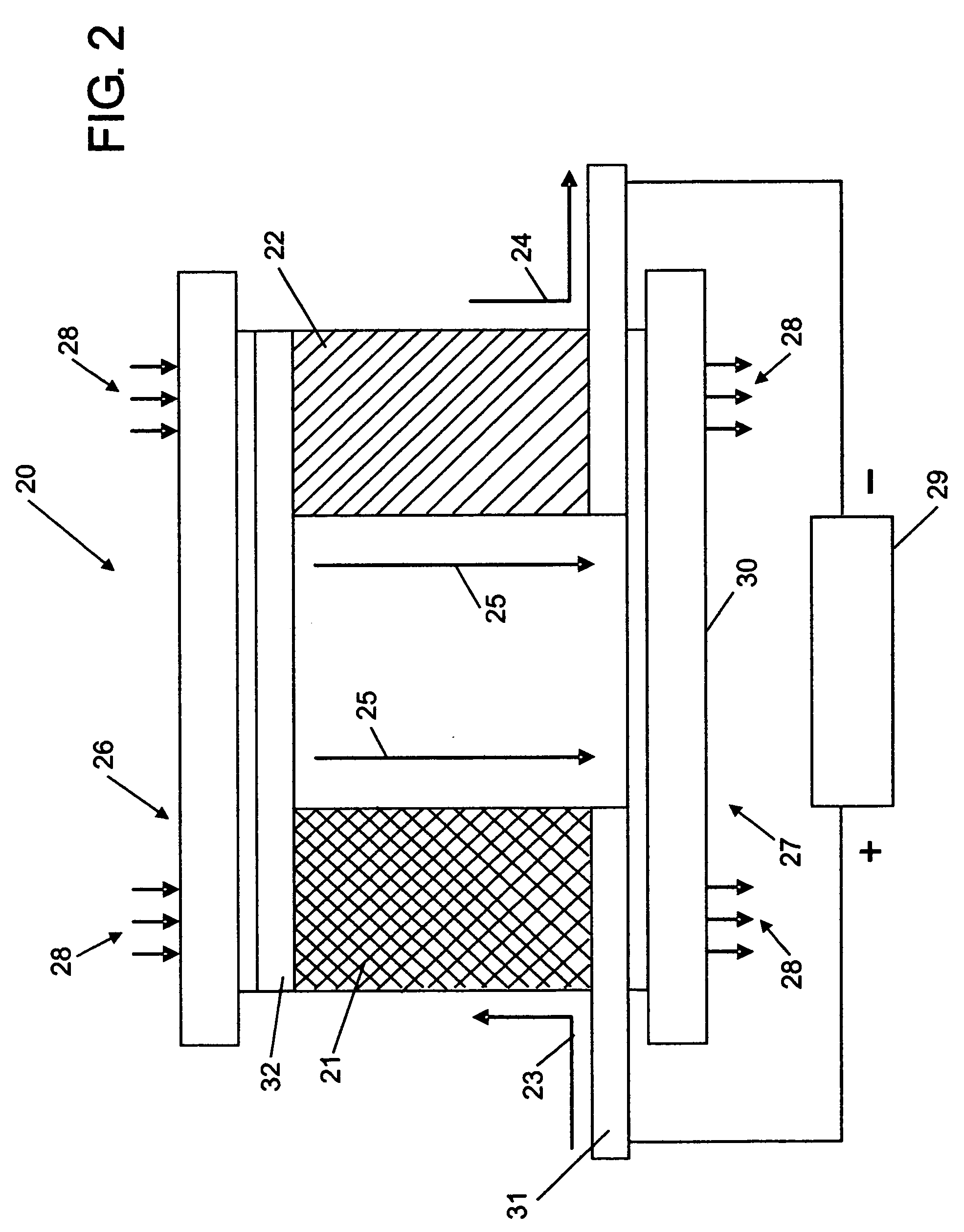

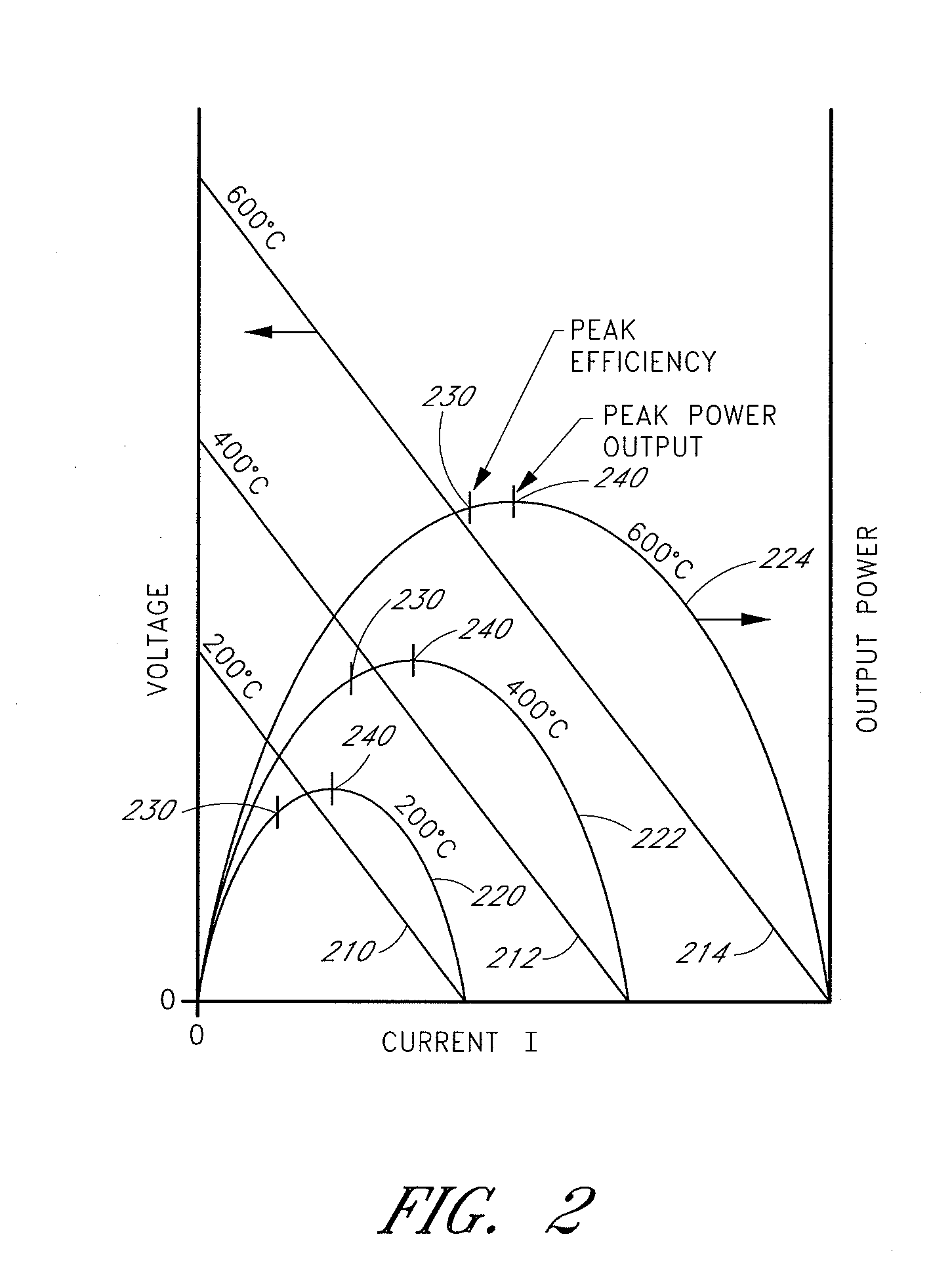

Thermoelectric power generator for variable thermal power source

InactiveUS20100024859A1Avoid flowInternal combustion piston enginesThermoelectric device with peltier/seeback effectWorking fluidEngineering

A thermoelectric generator includes a first thermoelectric segment including at least one thermoelectric module. The first thermoelectric segment has a working fluid flowing therethrough with a fluid pressure. The thermoelectric generator further includes a second thermoelectric segment including at least one thermoelectric module. The second thermoelectric segment is configurable to allow the working fluid to flow therethrough. The thermoelectric generator further includes at least a first variable flow element movable upon application of the fluid pressure to the first variable flow element. The first variable flow element modifies a flow resistance of the second thermoelectric segment to flow of the working fluid therethrough.

Owner:GENTHERM INC

Large format thermoelectric infrared detector and method of fabrication

ActiveUS20100031992A1Promote absorptionSimple structureThermoelectric device with peltier/seeback effectSemiconductor/solid-state device manufacturingNano compositesBismuth telluride

The thermoelectric detector consists of an absorber structure supported by two electrically connected beams made of thermoelectric materials such as polysilicon, polysilicon / germanium, bismuth-telluride, skutterrides, superlattice structures, nano-composites and other materials. One end of the thermoelectric beam connects to the absorber structure; the other end connects to the substrate. Infrared radiation incident on the absorber heats up the absorber, resulting in a temperature gradient along the length of the thermoelectric legs, and generating an electrical voltage. The detector arrays are fabricated using micromachining process. The absorber structure is formed over a sacrificial material that is removed at the end of the processing, leaving the detector suspended and thermally isolated. The sacrificial processing method enables the production of small pixel thermoelectric detectors in large two-dimensional arrays with high sensitivity.

Owner:NYTELL SOFTWARE LLC

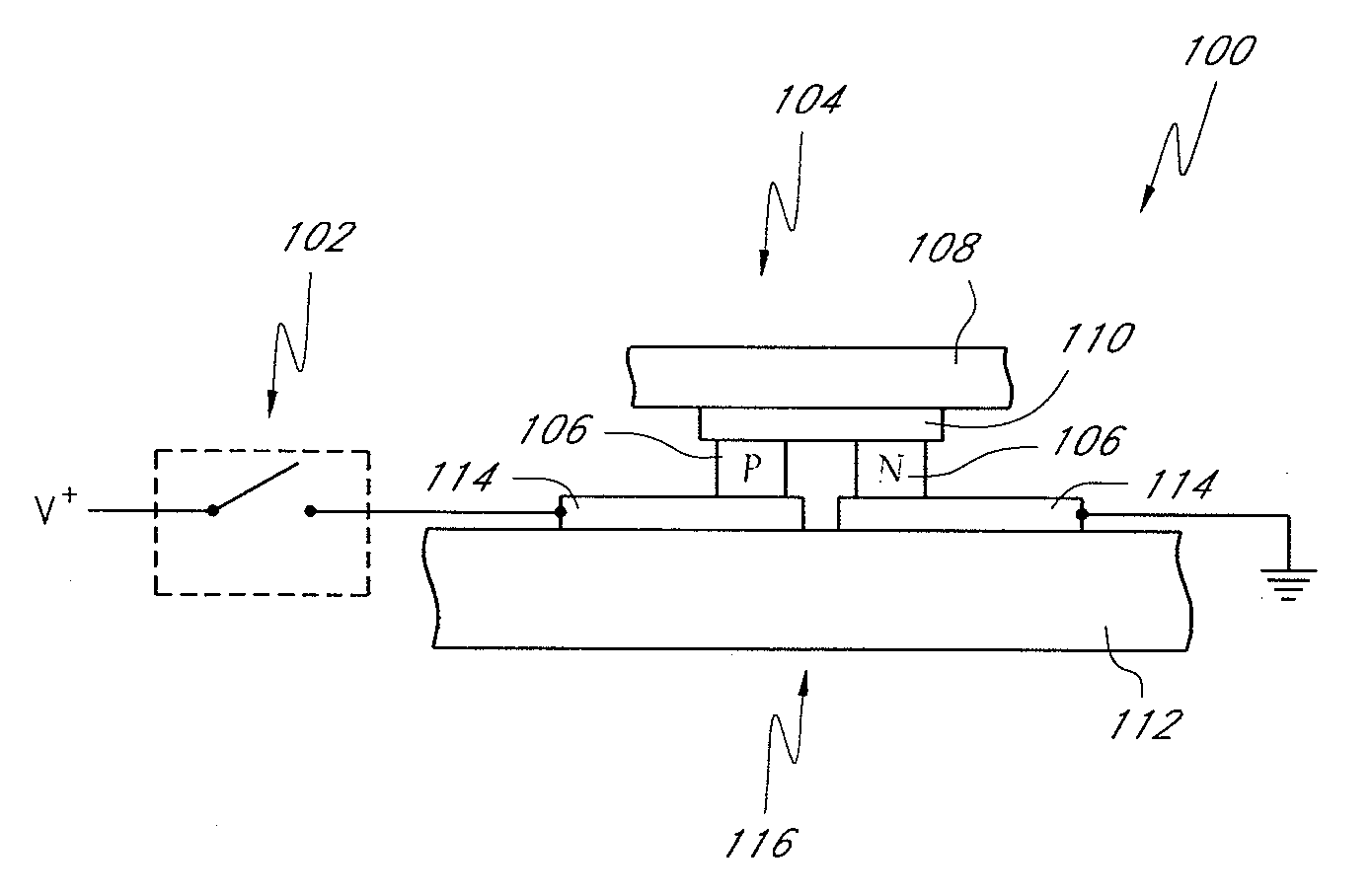

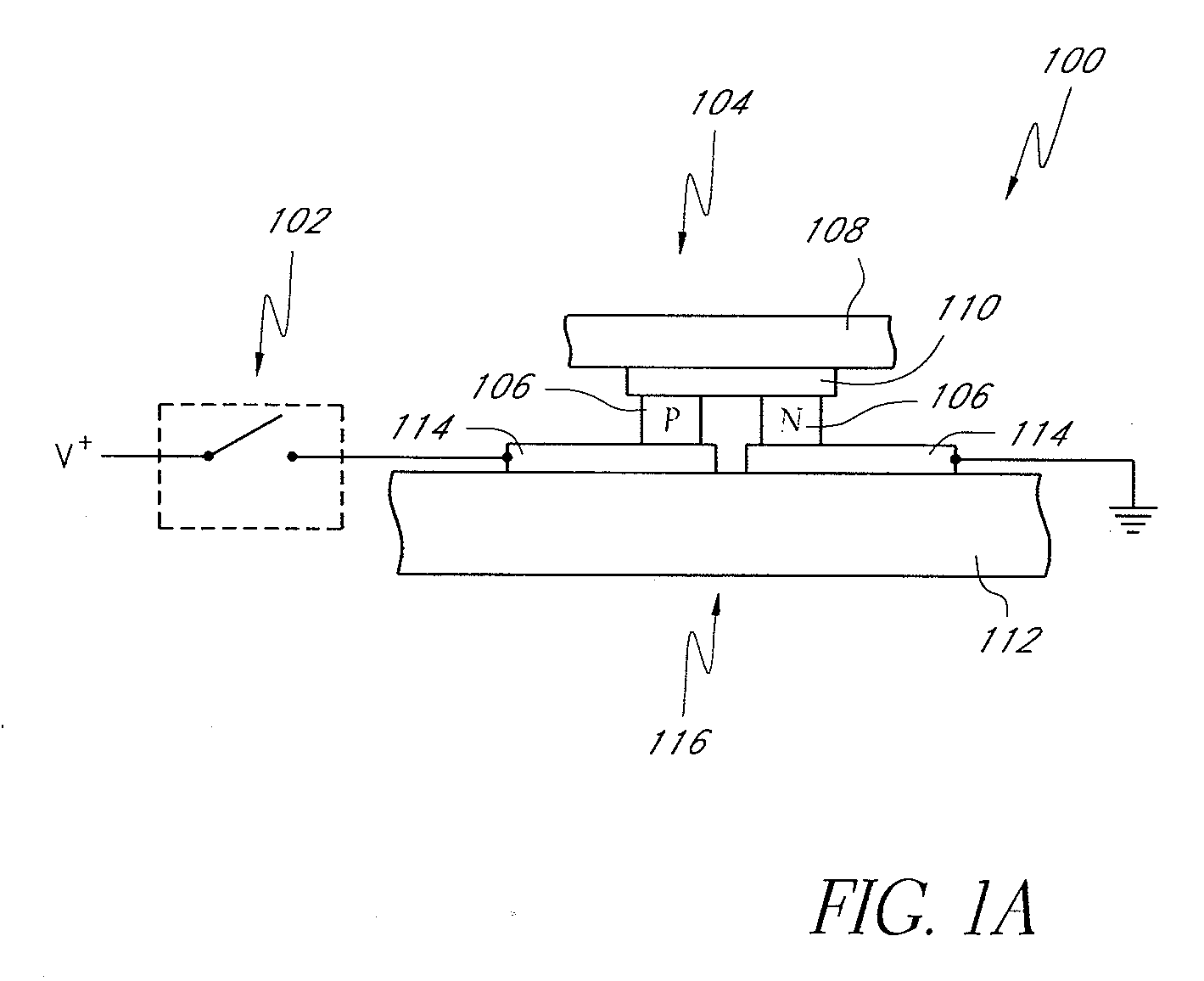

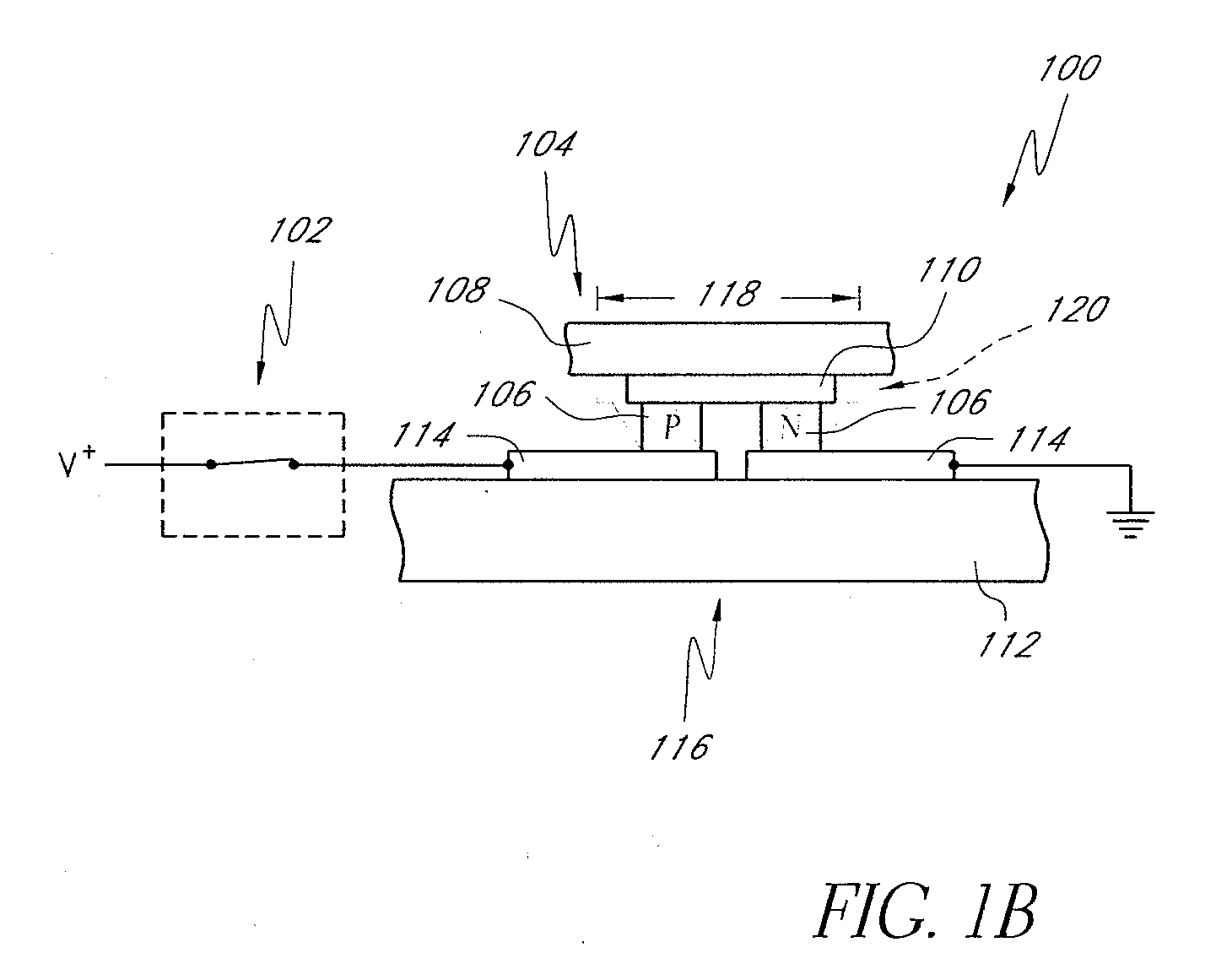

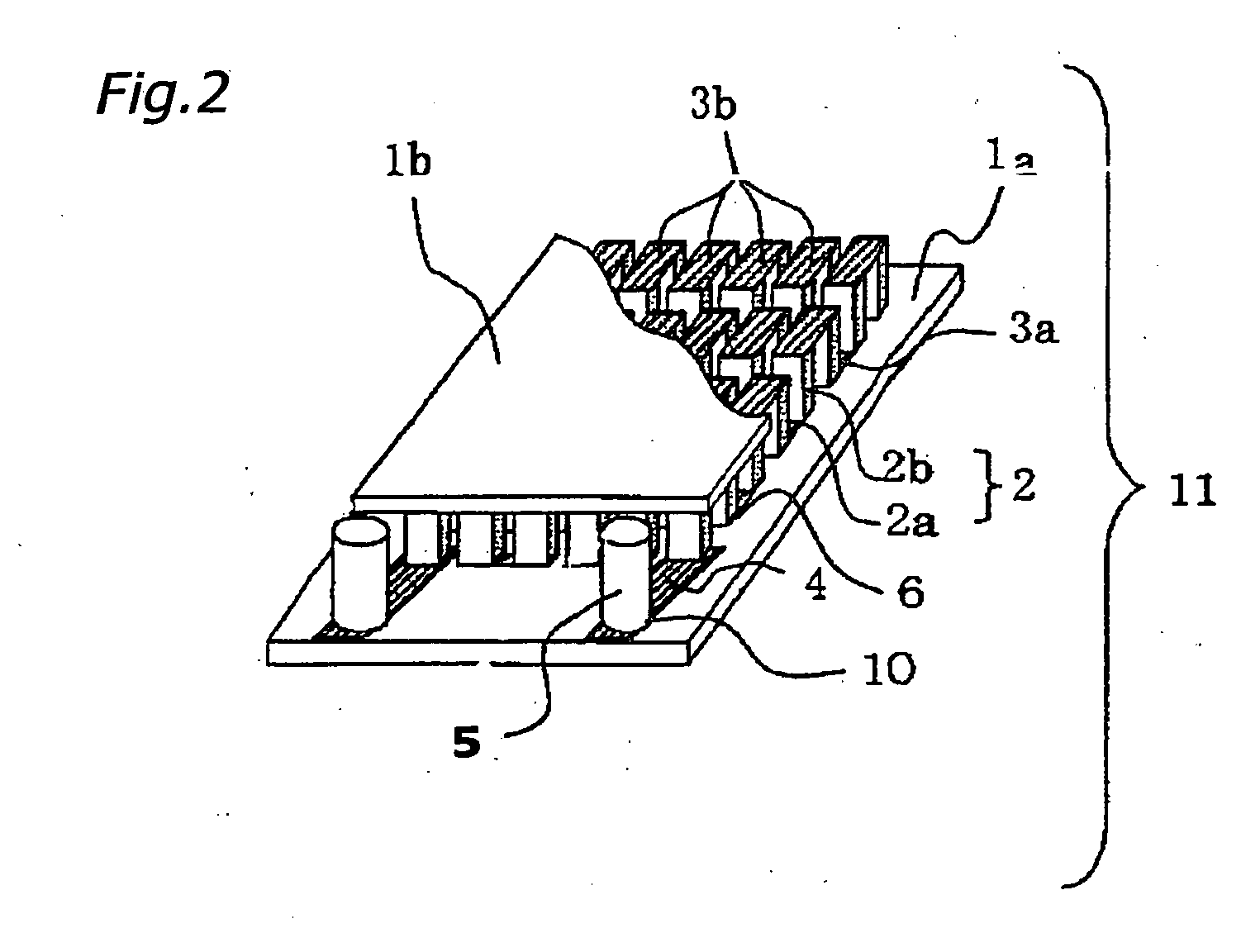

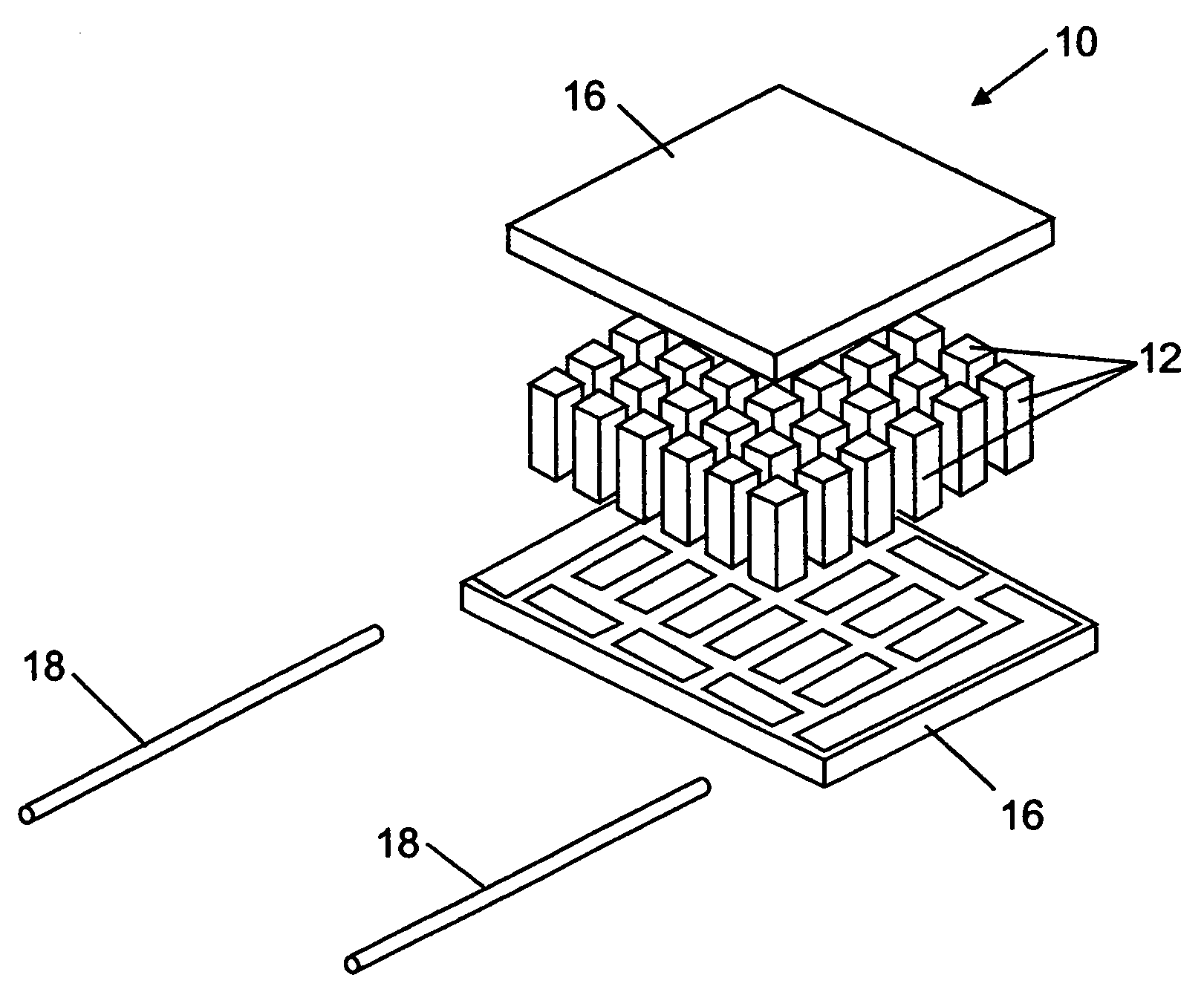

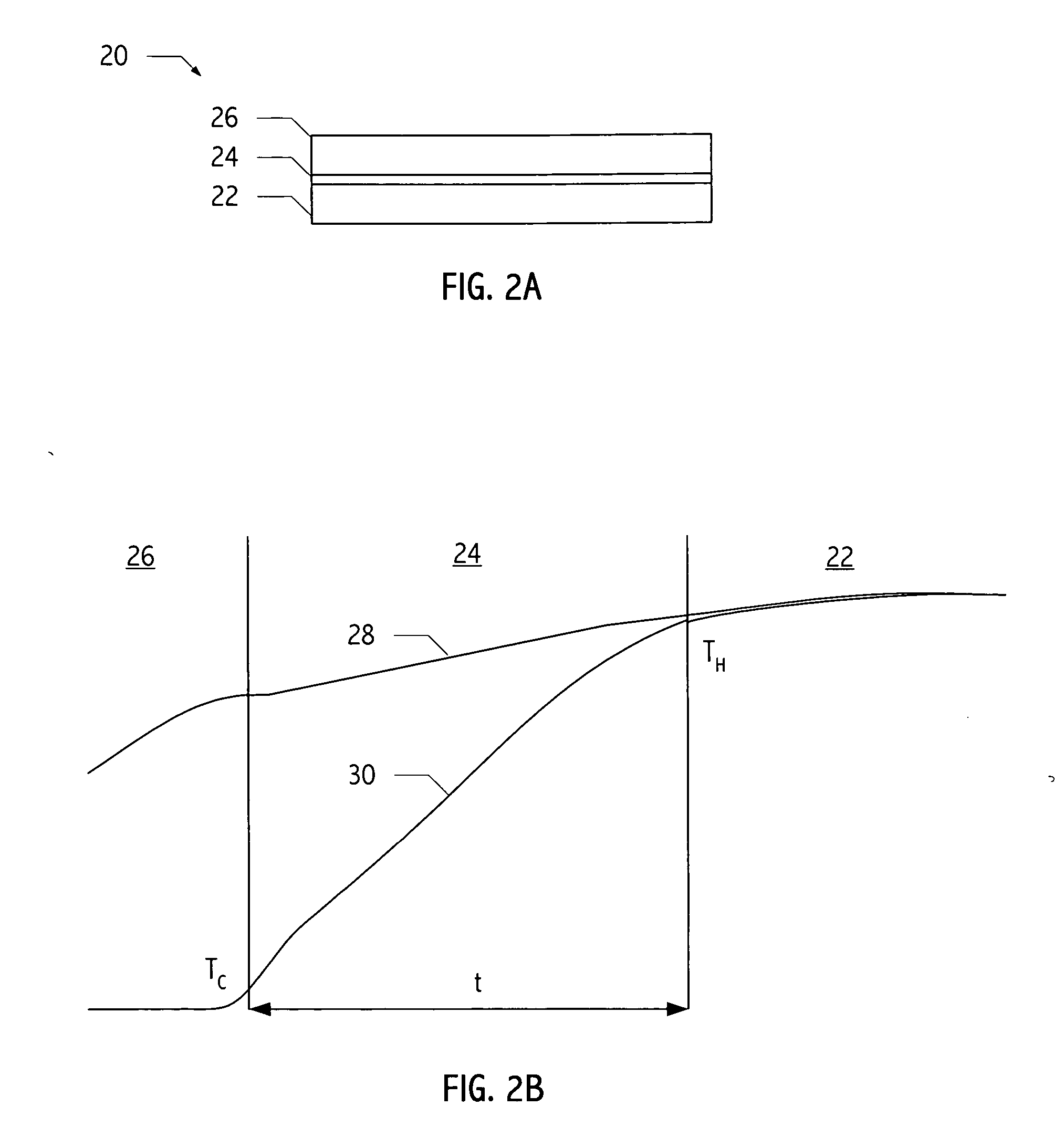

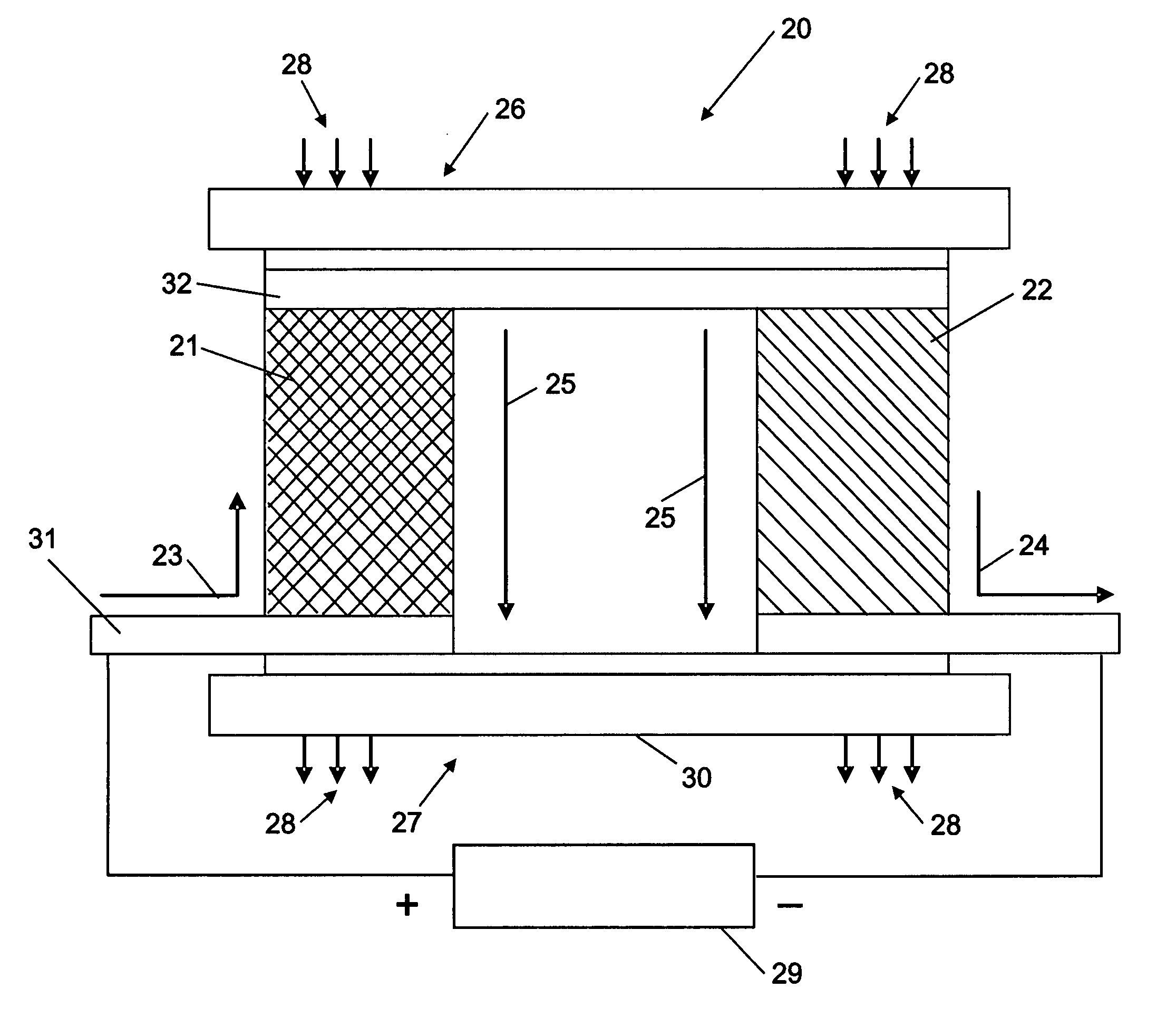

Thermoelectrics utilizing thermal isolation

InactiveUS20050072165A1Improve efficiencyMaintain thermal isolationThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric materialsThermal isolation

An improved efficiency thermoelectric system and method of making such a thermoelectric system are disclosed. Significant thermal isolation between thermoelectric elements in at least one direction across a thermoelectric system provides increased efficiency over conventional thermoelectric arrays. Significant thermal isolation is also provided for at least one heat exchanger coupled to the thermoelectric elements. In one embodiment, the properties, such as resistance or current flow, of the thermoelectric elements may also be varied in at least one direction across a thermoelectric array. In addition, the mechanical configuration of the thermoelectric elements may be varied, in one embodiment, according to dynamic adjustment criteria.

Owner:GENTHERM INC

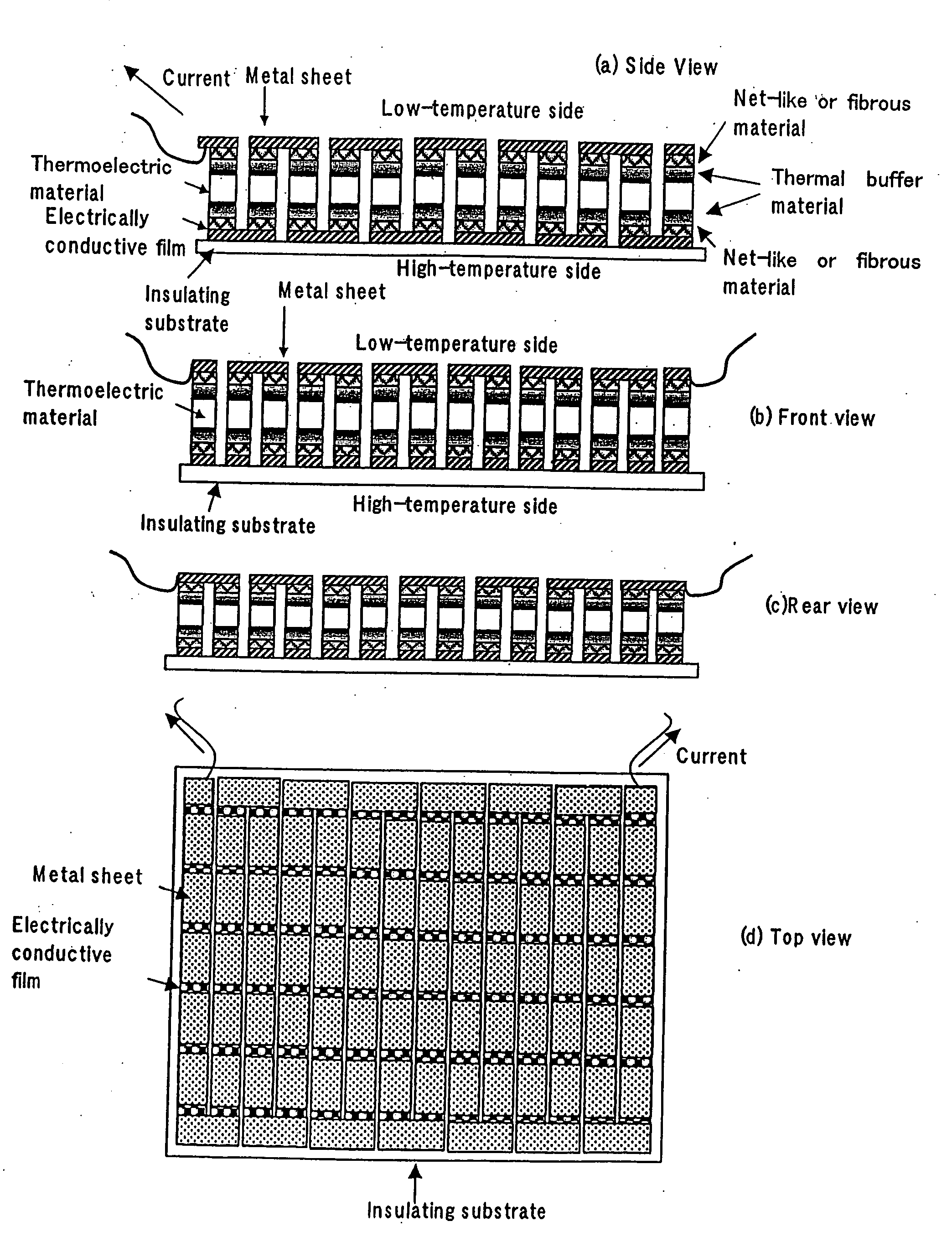

Thermoelectric element and thermoelectric module

InactiveUS20060118160A1Improve thermoelectric conversion efficiencyExcellent chemical durabilityThermoelectric device with peltier/seeback effectThermoelectric device detailsThermoelectric materialsThermal dilatation

The present invention provides a thermoelectric element comprising an electrically conductive substrate, a p-type thermoelectric material, and an n-type thermoelectric material; the p-type thermoelectric material being positioned on the substrate via an electrically conductive thermal buffer material, and the n-type thermoelectric material being positioned on the substrate via an electrically conductive thermal buffer material; wherein each thermoelectric material comprises a specific oxide and each electrically conductive thermal buffer material comprises an electrically conductive material having a thermal expansion coefficient between that of the thermoelectric material to which the thermal buffer material is bonded and that of the substrate. The invention also provides a thermoelectric module comprising a plurality of the thermoelectric elements. The thermoelectric element and the thermoelectric module have both a high thermoelectric conversion efficiency and excellent properties in terms of thermal stability, chemical durability, etc.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Monolithic thin-film thermoelectric device including complementary thermoelectric materials

InactiveUS20050150539A1Reduce needReduction in electron thermal conductivityThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentLiquid metalThermoelectric element

A vertical, monolithic, thin-film thermoelectric device is described. Thermoelectric elements of opposing conductivity types may be coupled electrically in series and thermally in parallel by associated electrodes on a single substrate, reducing the need for mechanisms to attach multiple substrates or components. Phonon transport may be separated from electron transport in a thermoelectric element. A thermoelectric element may have a thickness less than an associated thermalization length. An insulating film between an electrode having a first temperature and an electrode having a second temperature may be a low-thermal conductivity material, a low-k, or ultra-low-k dielectric. Phonon thermal conductivity between a thermoelectric element and an electrode may be reduced without a significant reduction in electron thermal conductivity, as compared to other thermoelectric devices. A phonon conduction impeding material may be included in regions coupling an electrode to an associated thermoelectric element (e.g., a liquid metal).

Owner:NANOCOOLERS

Thermoelectric alternators and thermoelectric climate control devices with controlled current flow for motor vehicles

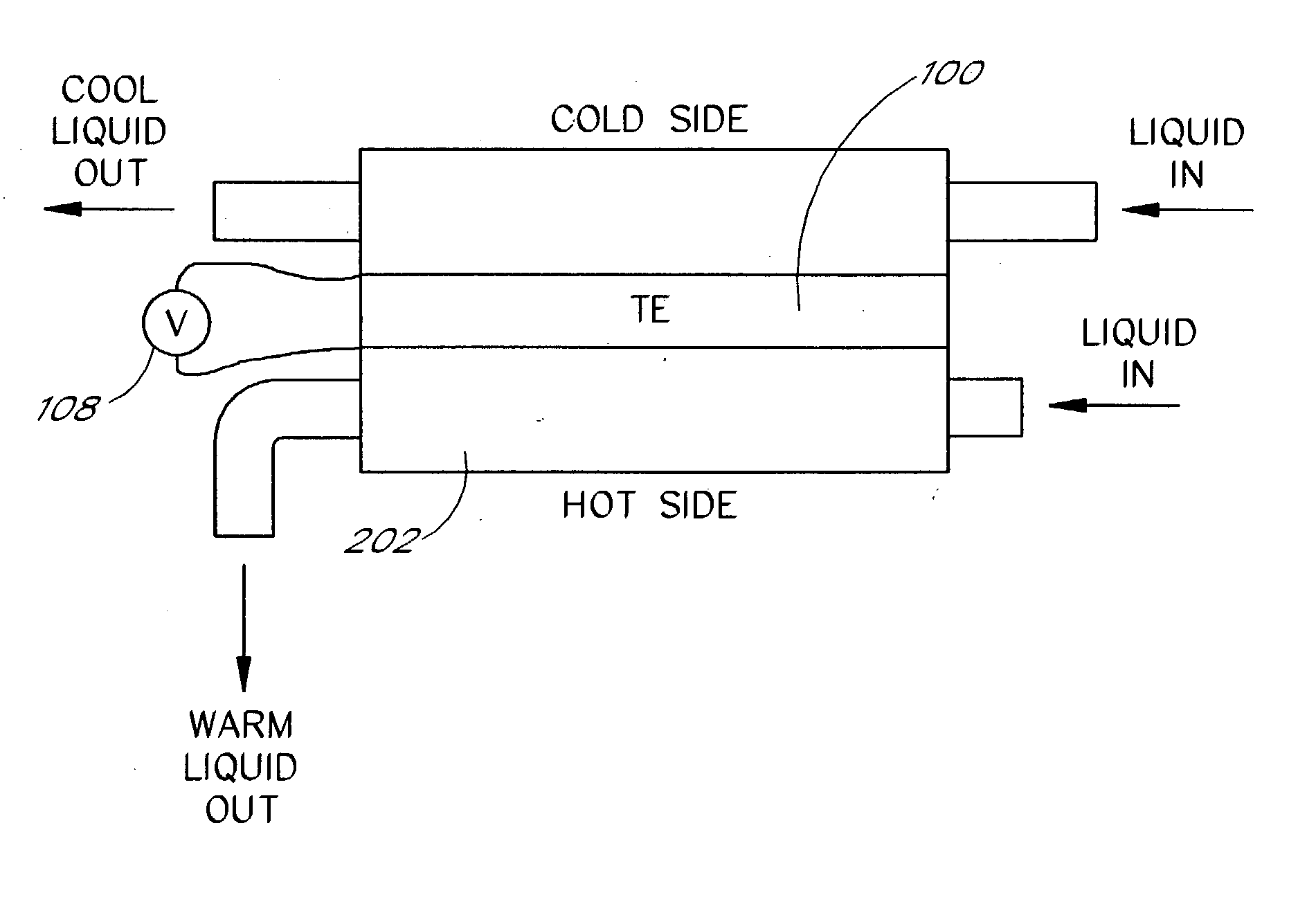

InactiveUS20060090787A1Electric power generatedEffective resistanceThermoelectric device with peltier/seeback effectThermoelectric device detailsThermal energyEngineering

Thermoelectric devices with controlled current flow are provided for motor vehicle applications including but not limited to electrical power generation applications such as thermoelectric alternators, alternator supplements, generators, and battery chargers. Further, thermoelectric devices with controlled current flow are provided for other motor vehicle climate control applications such as air conditioning, cooling, heating, and refrigeration. Thermoelectric devices and systems are disposed between heat sources and heat sinks of a motor vehicle, or between hot surfaces and cooler surfaces of a motor vehicle. For power generation applications, thermoelectric devices convert the temperature gradient between a heat source and a heat sink into electrical energy for the motor vehicle. For climate control applications, thermoelectric devices are driven by electrical current such that thermal energy is transferred between a heat source and a heat sink to provide heating, cooling, or both. Methods related to the above are also provided.

Owner:OROBRIDGE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com