Thin film thermoelectric devices for power conversion and cooling

a thermoelectric device and thin film technology, applied in the direction of thermoelectric device manufacture/treatment, thermoelectric device details, lighting and heating apparatus, etc., can solve the problems of low efficiency, limited application of thermoelectric devices in cooling and refrigeration, and low efficiency of thermoelectric conversion thermoelectric devices, etc., to achieve low external heat-flux and high internal heat-flux

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

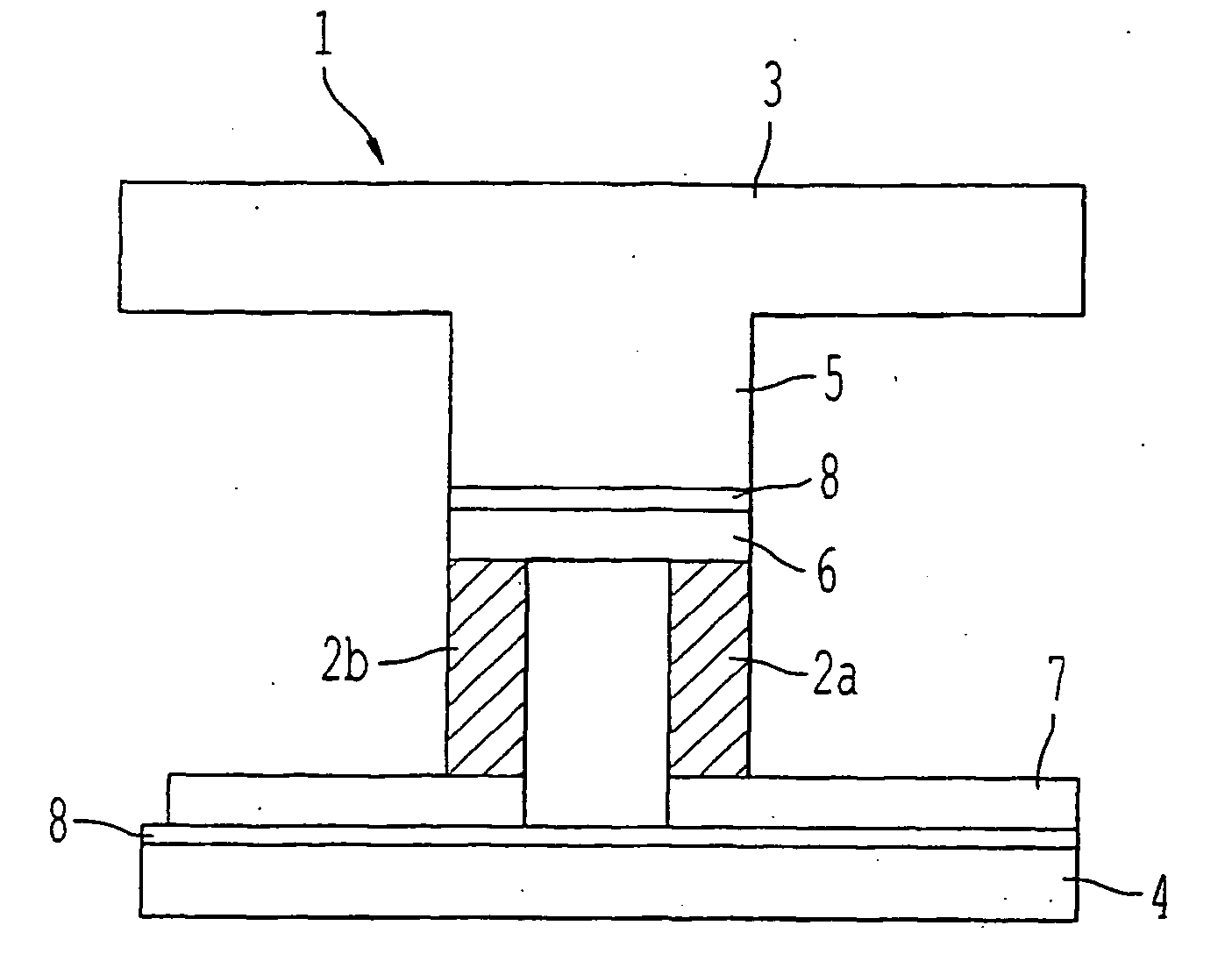

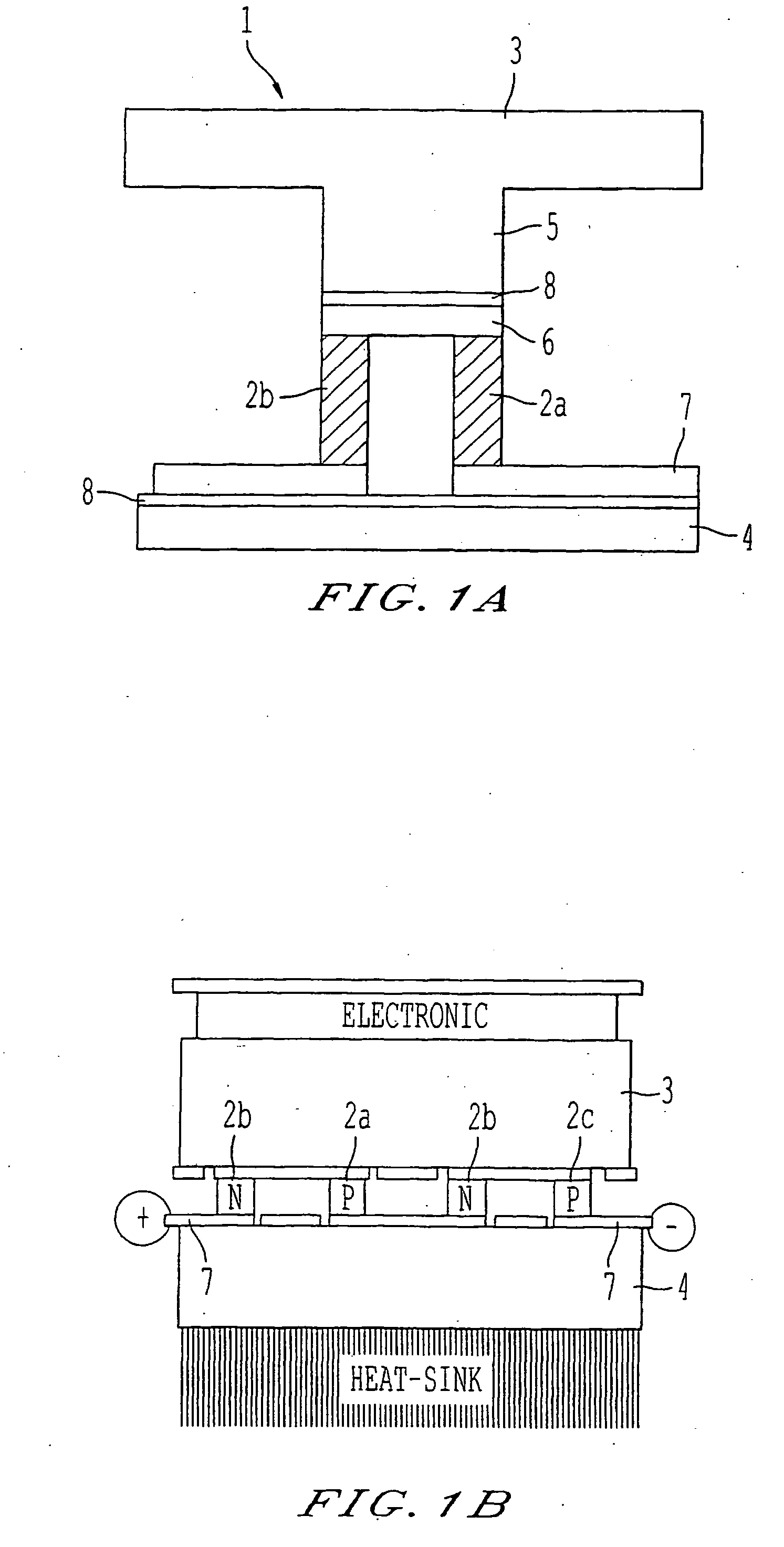

[0044]Referring now to the drawings, wherein like reference numerals designate identical, or corresponding parts throughout the several views, and more particularly to FIG. 1A thereof, FIG. 1A depicts a schematic of one embodiment of a thermoelectric device according to some embodiments of the present invention. As shown in FIG. 1A, a thermoelectric device 1 of some embodiments of the present invention includes a thermoelectric pair of n and p-type thermoelements 2a and 2b, respectively. The thermoelectric pair is connected thermally in parallel for heat conduction and electrically in series for electrical conduction. The thermoelectric pair of n and p-type thermoelements 2a and 2b are electrically adjoined together on the side coupled to an upper side header 3 by electrical connection 6, and are electrically connected separately on the side coupled to a lower side header 4 by electrical connection 7. As shown illustratively in FIG. 1A, the thermoelectric pair of n and p-type thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com