A stamping and welding axle housing processing technology

A processing technology, punching and welding bridge technology, applied in the field of punching and welding axle housing processing technology, can solve problems such as poor placement stability of disk threaded holes and through-shaft holes, solve the problem of poor positional stability, and reduce secondary positioning errors. effect of risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

[0021] Since what is described below are only some embodiments, the embodiments in the present application and the features in the embodiments can be combined with each other under the condition of no conflict.

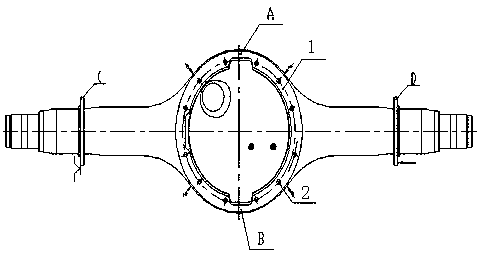

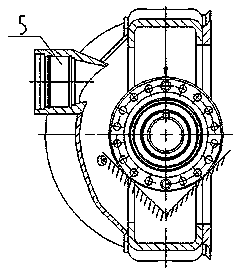

[0022] A process for stamping and welding axle housings, the steps of which include: 1) blank casting of the axle housings; 2) chamfering of the end faces; 3) rough and fine axle housing shaft heads and outer circular end faces of flanges at all levels, and threading; 4) Rough and fine milling of the end face, rough and fine boring of the inner hole, drilling and tapping of the disk surface, rough and fine boring of the inner hole and end face of the shaft at all levels; 5) Grinding the outer circle; 6) Milling the keyway; 7) Cleaning; 8) Final inspection; 9 ) storage, and the 4) process is based on the processing technology of the horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com