Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

424 results about "Gauge block" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gauge blocks (also known as gage blocks, Johansson gauges, slip gauges, or Jo blocks) are a system for producing precision lengths. The individual gauge block is a metal or ceramic block that has been precision ground and lapped to a specific thickness. Gauge blocks come in sets of blocks with a range of standard lengths. In use, the blocks are stacked to make up a desired length.

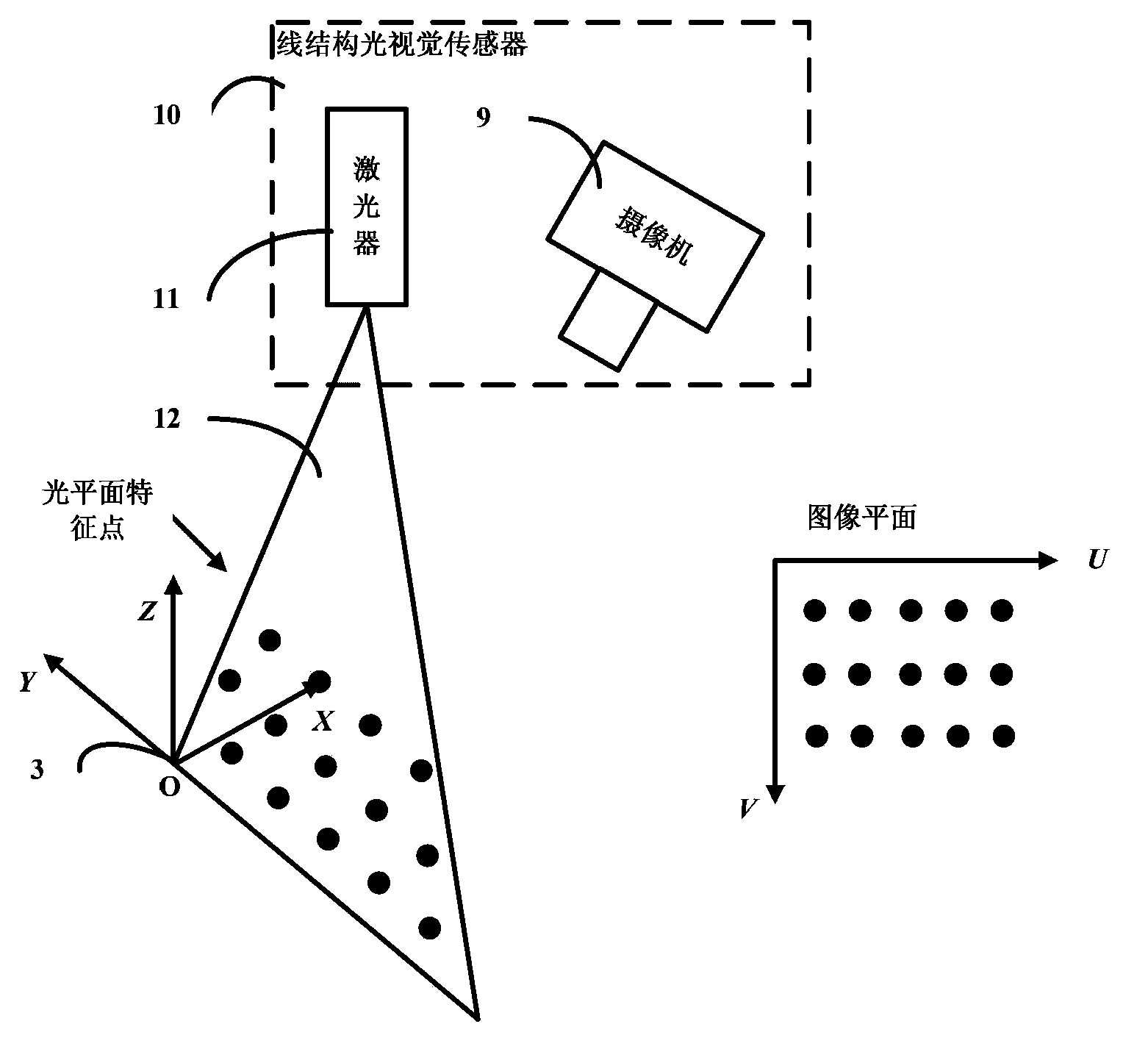

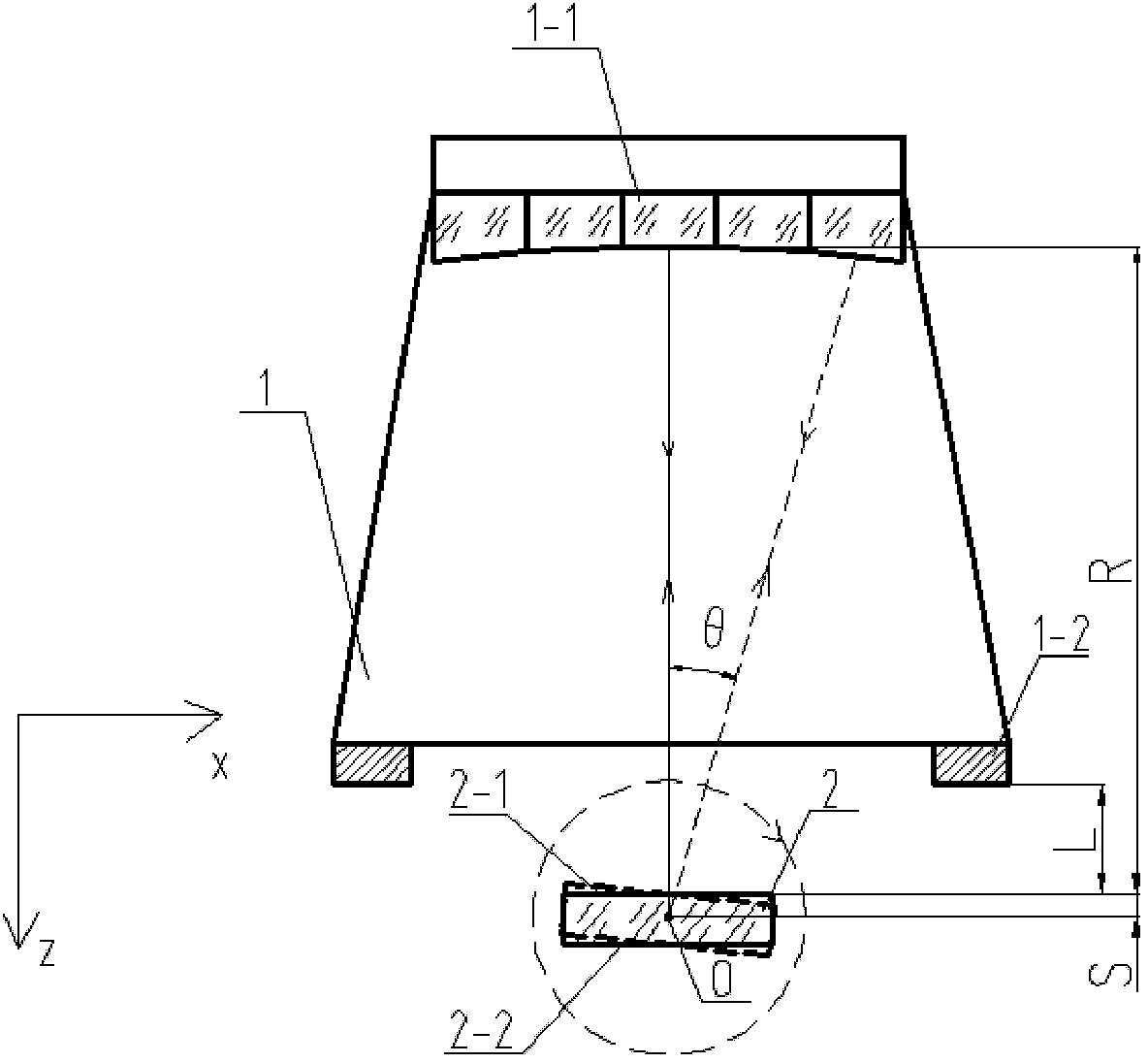

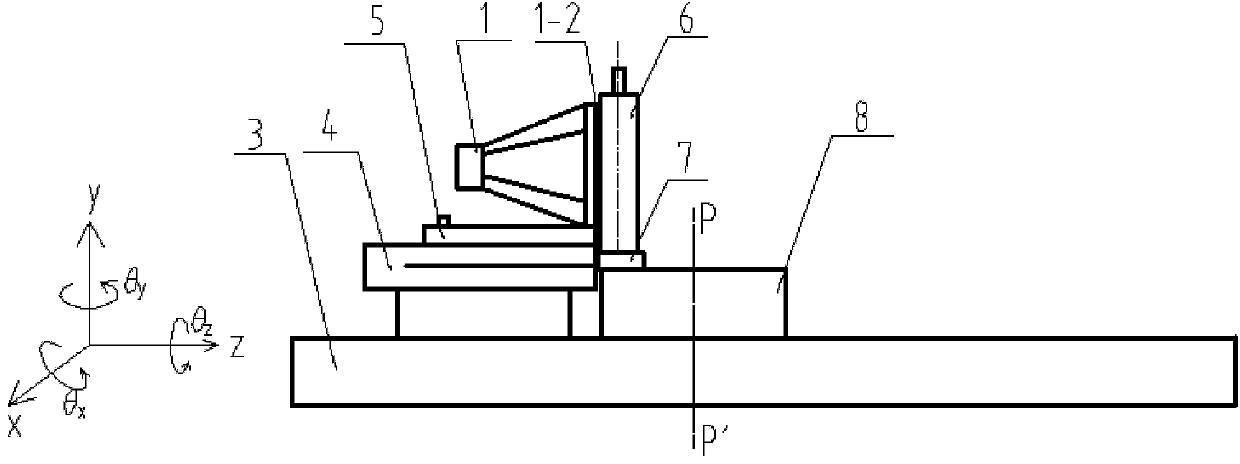

Direct calibration method for line structured light vision sensor

The invention relates to a direct calibration method for a line structured light vision sensor. The method comprises the following steps: establishing a target formed through standard gauge blocks and by utilizing a three-dimensional precision translation bench; projecting structured light plane to the target through the line structured light vision sensor to form feature points on the target; establishing a space coordinate system on the target; collecting target images and extracting the feature points; establishing a search index table including establishing a direct mapping relation between image coordinates of the feature points and space coordinate system coordinates of the feature points; carrying out calibration on the line structured light vision sensor; and based on the image coordinate of a point to be calibrated, searching the space coordinate system coordinate, which is obtained directly or obtained by utilizing a least squares fitting method, of the point in the search index table, so that the direct calibration of the line structured light vision sensor can be realized. The calibration method is used for the line structured light vision sensor which belongs to the small vision field high precision measurement application field. The calibration method is simple and direct, easy to realize, high in precision and can meet the need of measurement.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

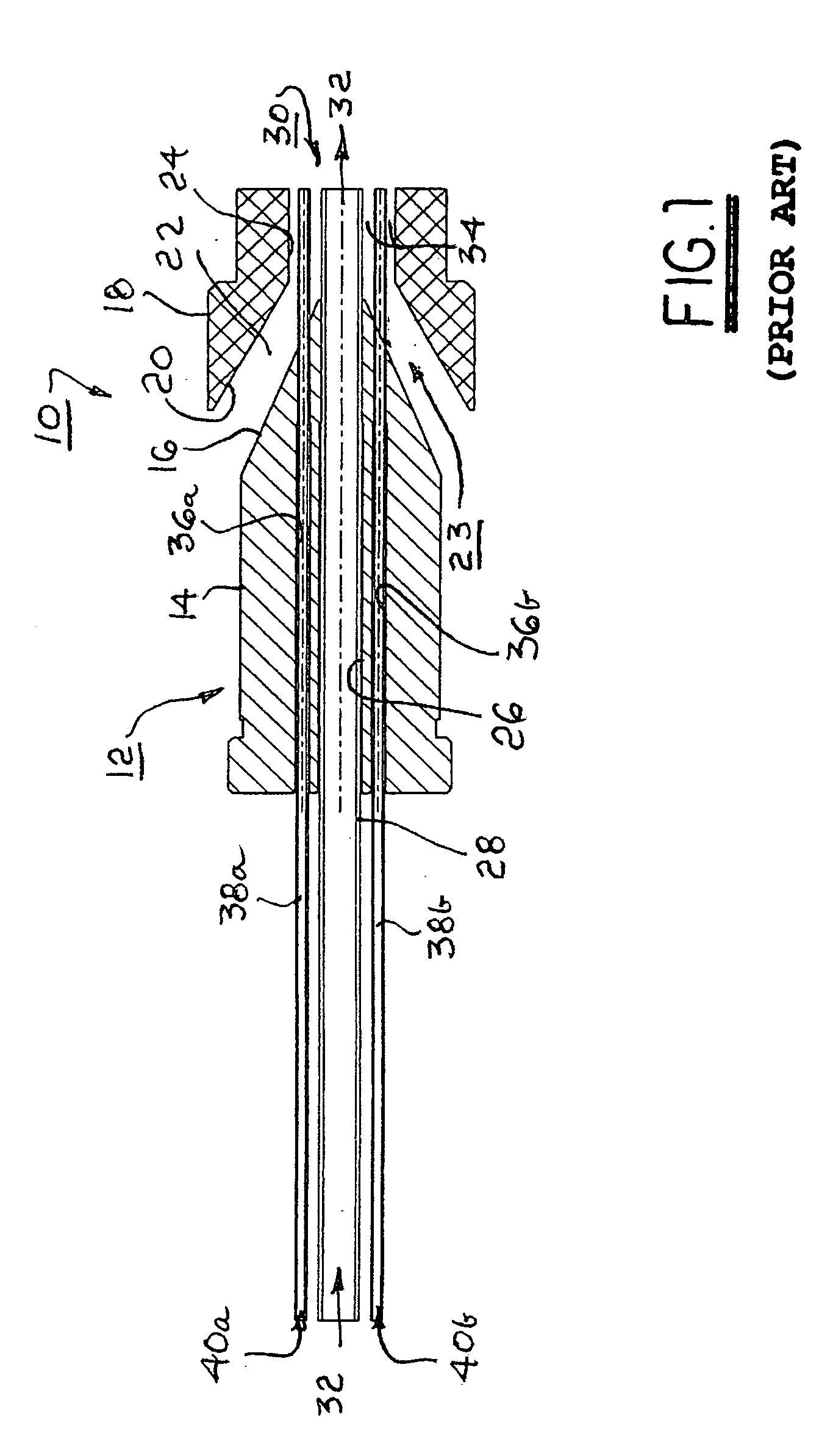

Wear gauge and method of use

InactiveUS20050284207A1Photometry using reference valueMetal rolling stand detailsMagnetic storageColor changes

A wear gauge is provided for simulating the wear of a magnetic recording component at its interface with a magnetic storage medium comprising a wear gauge block having a wear surface that substantially approximates the geometrical dimensions and contour of the working surface of the magnetic recording component, wherein the wear surface has a coating of transparent material. A test method comprises mounting the wear gauge in a test fixture, positioning a tape and adjusting the overwrap angle at edges of the wear surface, choosing the desired tape tension, speed and runtime, and running the tape, preferably unidirectionally, in operational contact with the wear surface for the desired runtime. The wear surface is inspected under white light illumination to observe and record locations of interferometric color changes on the wear surface. The color changes are correlated to thickness changes of the transparent coating on the wear surface.

Owner:GLOBALFOUNDRIES INC

Angle measurement precision detecting device of aspect angle monitor for satellite

The invention discloses an angle measurement precision detecting device of an aspect angle monitor for a satellite. A small plane mirror is connected to a mounting base plane position of the aspect angle monitor; the aspect angle monitor for the satellite is arranged on a two-dimension inclined platform and is placed on a two-dimension translation platform; a double-faced simulation swing mirror is arranged on a three-dimension adjusting platform and is placed on a digital display turntable; a first autocollimator and a second autocollimator are placed on a lifting support; the two-dimension translation platform, the digital display turntable and the lifting support are placed on a table top of a detection platform; a central spindle is sleeved in a central hole of the digital display turntable; a standard circular device is placed on a standard block and is close to the central spindle; laser beams emitted by a laser align with a central prism of a five-mirror reflector to form a detection standard optical axis; a dial indicator is fixed on the detection platform; a gauge block is placed above the digital display turntable and between the aspect angle monitor for the satellite and the double-faced simulation swing mirror; one face of the gauge block is close to the mounting base plane of the aspect angle monitor for the satellite; and the other face of the gauge block is close to a first optical surface of the double-faced simulation swing mirror.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

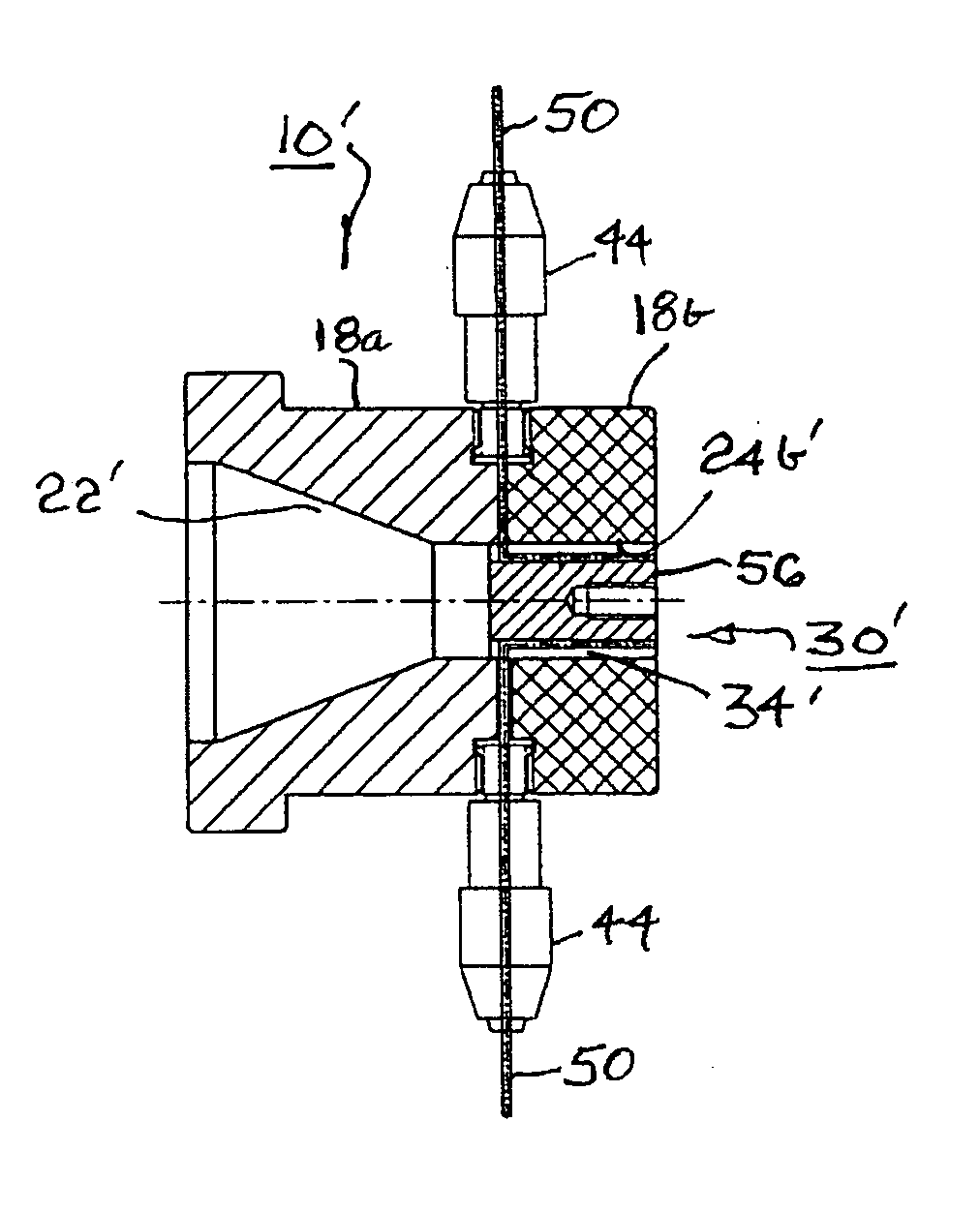

Method and apparatus for incorporating lumens into the wall of a tubular extrusion

A polymer extrusion head for forming continuous shapes having one or more lumens therein. The head includes an extrusion mandrel and die. At least one lumen pipe is disposed radially through a port in the die to intersect the polymer flow in the annular region between the tip and the die. The lumen pipe is a welded assembly having a 90° turn formed as a mitered joint with zero bend radius. The lumen pipe is held in a pin vise engaged in the die such that position of the lumen pipe may be readily adjusted. Axial and radial positions are established during assembly by means of a gauge block. A plurality of lumen pipes may be accommodated for a plurality of lumens by a manifold distribution system including individual lumen pipe assemblies.

Owner:CANGEN HLDG

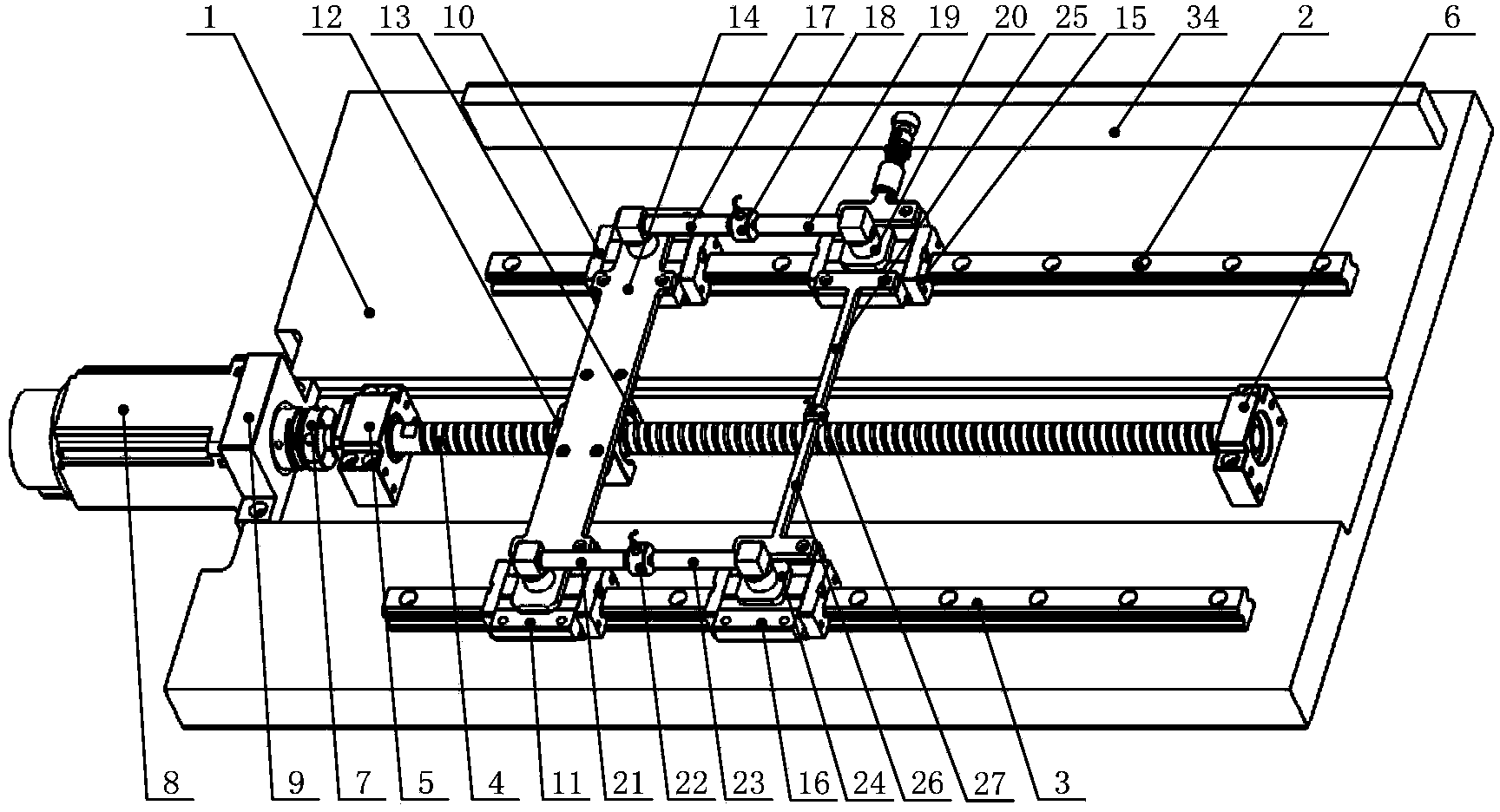

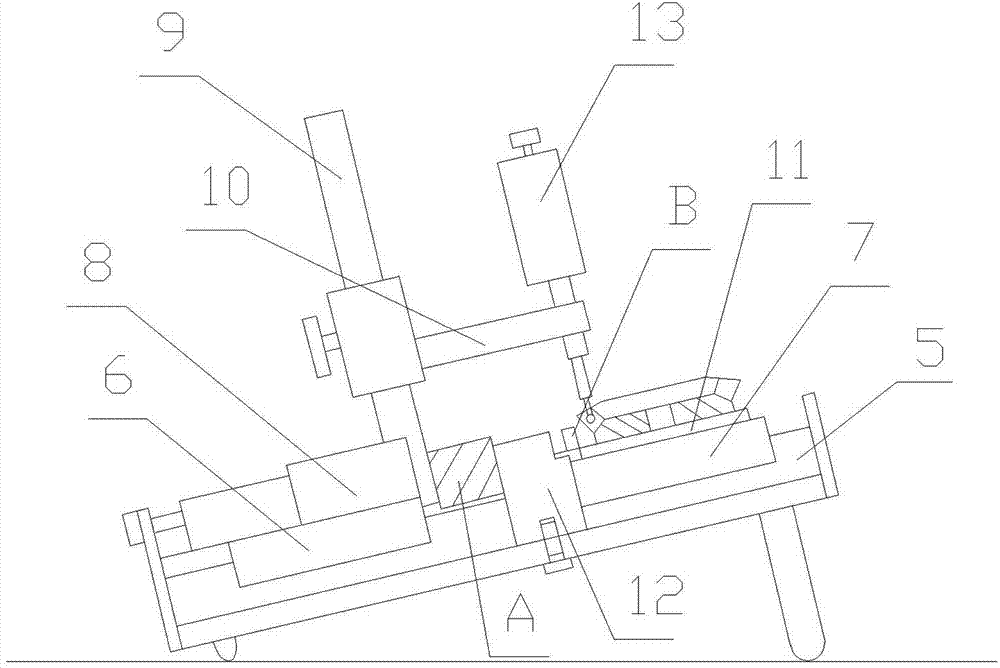

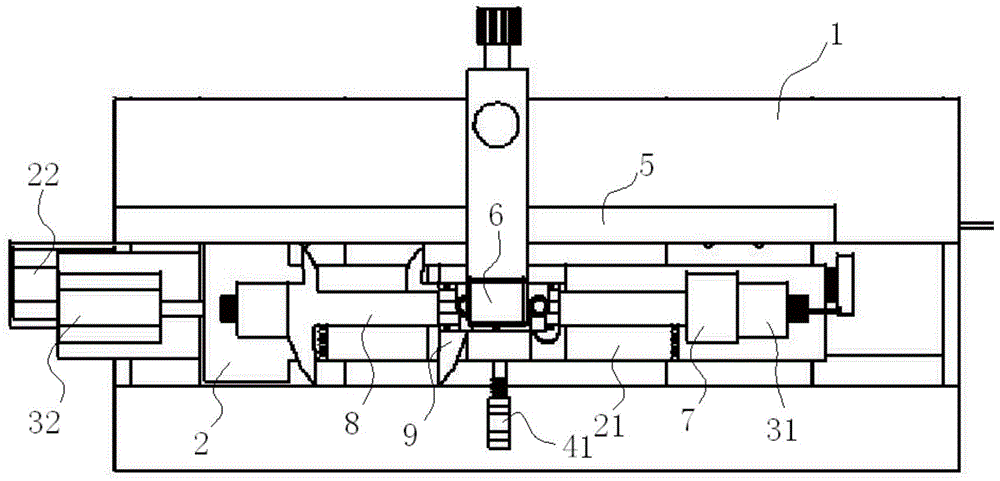

Device for comprehensively measuring linear guide rail friction force and manufacturing and mounting errors

InactiveCN103940471AEnabling Dynamic Friction MeasurementsMovement speed is stableMeasurement devicesMeasurement deviceEngineering

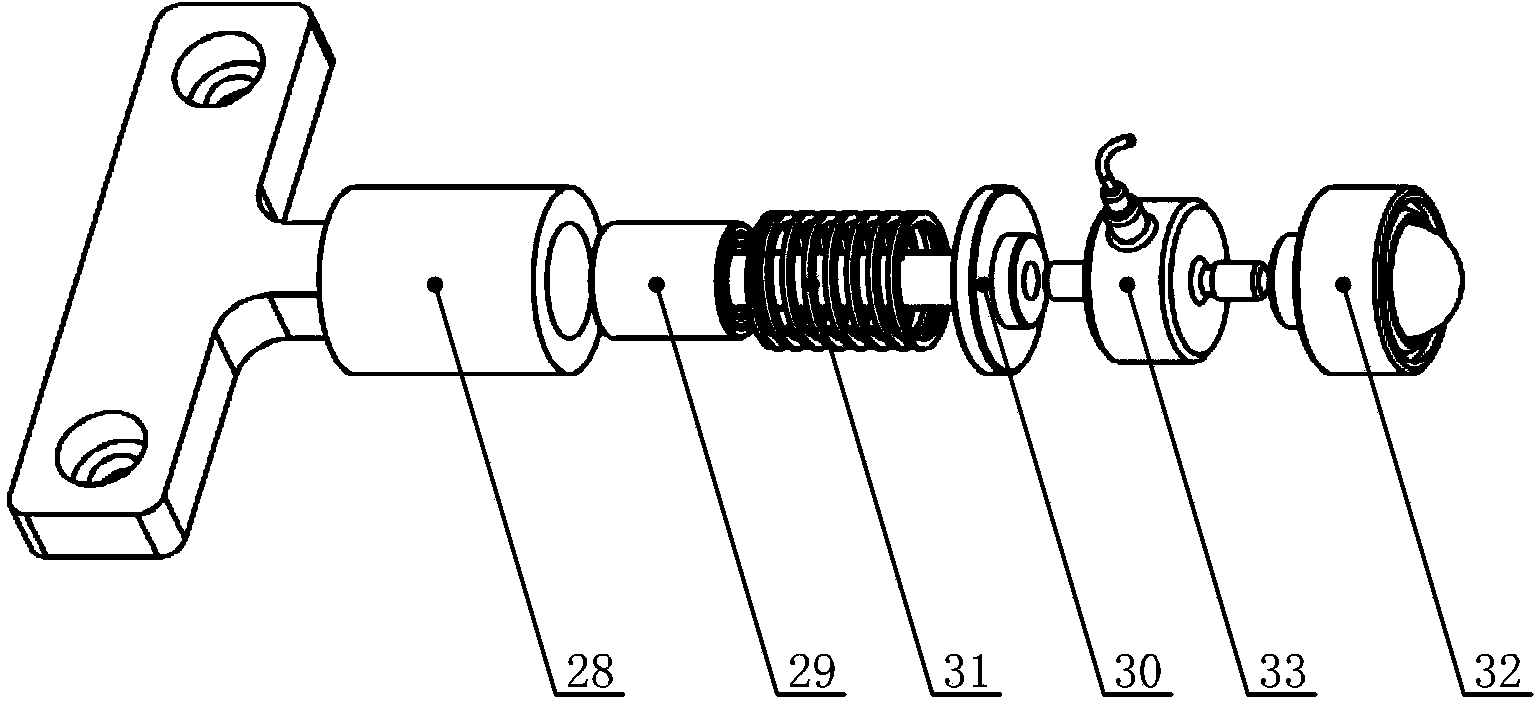

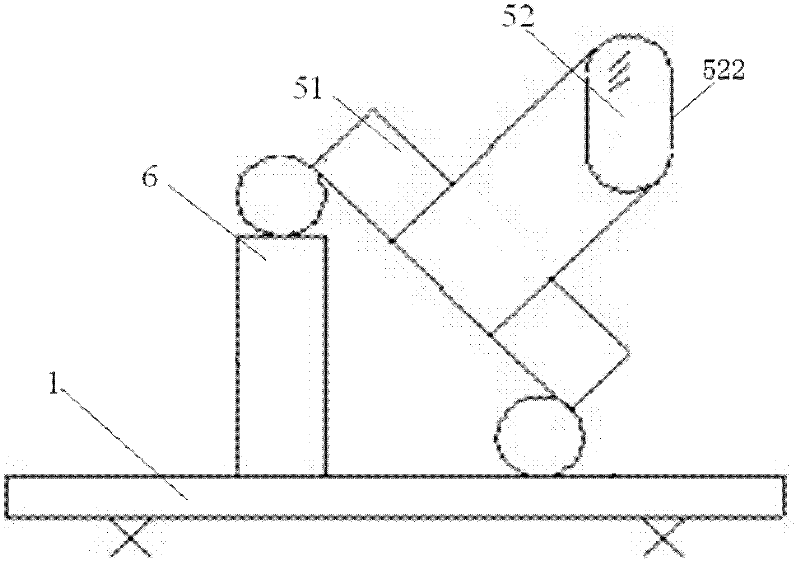

The invention discloses a device for comprehensively measuring linear guide rail friction force and manufacturing and mounting errors, and belongs the technical fields of measurement. The device for comprehensively measuring the linear guide rail friction force and the manufacturing and mounting errors mainly comprises a linear feeding system, a guide rail and sliding block friction force measuring device, a guide rail linearity error measuring device and a guide rail mounting parallelism error measuring device. The guide rail and sliding block friction force measuring device drives a sliding block to move through a servo motor to achieve measurement of the dynamic friction force of the sliding block at different running speed and under different loading effects, and the value of the friction force can be obtained by utilizing a pull pressure sensor. The guide rail mounting parallelism error measuring device converts parallelism errors among guide rails into internal stress of a connecting rod, and the values of the parallelism errors can be obtained through measurement of the pull pressure sensor. A standard straight gauge block is utilized by the guide rail linearity error measuring device as a reference of measurement, the linearity error of the guide rails is converted into changes of compression amount of a spring, a least square method is utilized for processing, measurement is convenient, and measurement accuracy is high.

Owner:TSINGHUA UNIV

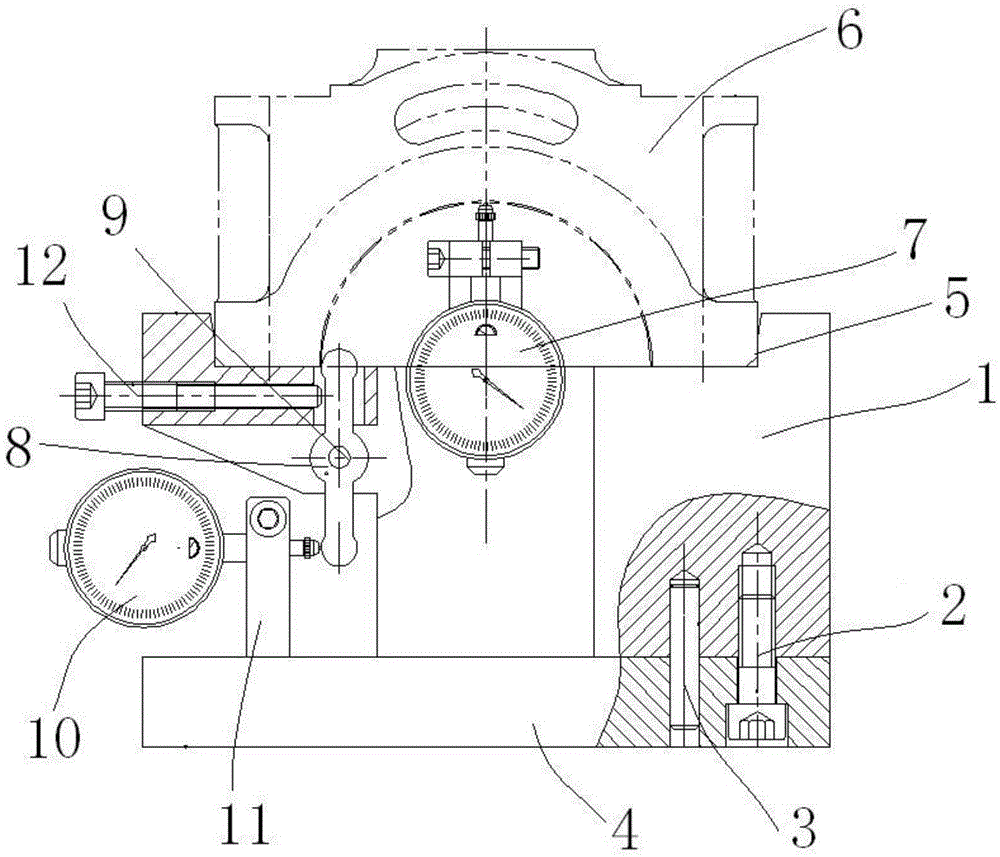

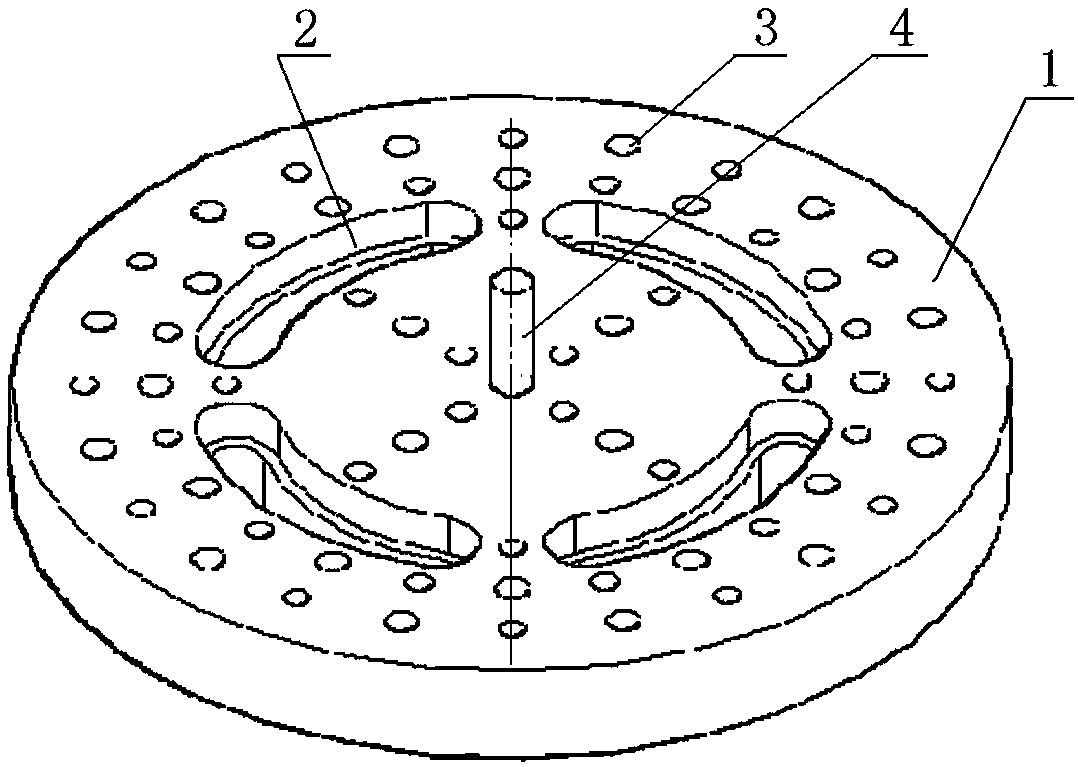

Method for detecting multiple technical indexes of turntable bearing by using detecting platform

InactiveCN102032848AGuaranteed accuracyThe detection method is simpleAngles/taper measurementsSpring scaleModel Number

The invention discloses a method for detecting multiple technical indexes of a turntable bearing by using a detecting platform. The method relates to the detecting platform (1) and detecting accessories, wherein the detecting accessories comprise a first dial gauge (2), a second dial gauge (4), a first upright post (5), a mandrel (6), a second upright post (7), a fastening bolt, a gauge block and a spring scale. In the method, an actual condition of the turntable bearing (3) is simulated, an outer ring radial runout value, an outer ring axial runout value, an actual measurement starting torque value, an actual measurement stationary torque value, an actual measurement height error mean value, an inner ring radial runout value and an inner ring axial runout value of the turntable bearing can be respectively detected under the same detecting environments and conditions by using the detecting platform and the detecting accessories, and the accuracy of the detected result is guaranteed. The detection method is simple and practical, can be used for detecting bearings of different specifications and types, and has instructive significance for detecting multiple technical indexes of the bearing simultaneously.

Owner:LUOYANG BEARING RES INST CO LTD

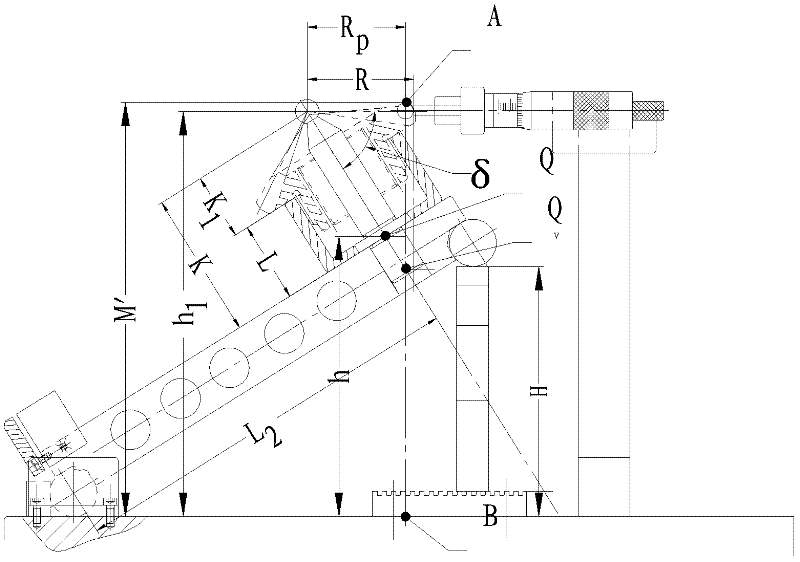

Device and method for measuring tooth thickness of medium and small modulus bevel gear

ActiveCN102901428AEasy to measureHigh measurement accuracyMechanical thickness measurementsMeasurement deviceEngineering

The invention provides a device for measuring tooth thickness of a medium and small modulus bevel gear. The device comprises a guide rail, a block gauge A and a block gauge B, wherein a guide rail sliding block I and a guide rail sliding block II, which can move forwards and backwards, are arranged on the guide rail, and are respectively connected with a dial indictor and a measuring worktable; the block gauge A and the block gauge B are matched with a measured gear in dimension; and the tooth thickness of the gear can be measured by lifting the dial indicator and replacing a measuring ball which is connected with the dial indicator; and the dimension of the measuring ball is in match with the tooth thickness of the measured gear. The device is convenient for measurement and high in measurement precision and is efficient and reliable. According to the device, the actual value of the tooth thickness can be obtained by calculating according to diameter data of the block gauge A, the block gauge B and the measuring ball and under the condition that the measuring ball can be replaced. The invention also provides an efficient and reliable measuring method adopting the measuring device. According to the method, a mounting base surface of the measured gear serves as a measuring reference surface, and the measuring method controls the tooth thickness to ensure the consistency between the tooth thickness on the mounting base surface and the mounting distance of the measured gear.

Owner:ZHEJIANG FENGLI INTELLIGENT TECH CO LTD

Method for positioning through hole of pipe truss

ActiveCN102953552AImprove assembly accuracyFast positioningBuilding material handlingEngineeringGauge block

The invention relates to a method for positioning a through hole of a pipe truss. The method comprises a horizontal frame, a semi-cylindrical gauge block and an inclinometer, wherein the semi-cylindrical gauge block is a semi cylinder which is uniformly distributed along an axis, the upper semi-round surface and the lower semi-round surface of the semi-cylindrical gauge block are vertical to an equipartition surface, and the radius of the protruded semi cylinder of the semi-cylindrical gauge block is matched with the curve of a through hole of a pipe truss chord member. The method comprises the following steps that the pipe truss chord member is installed on the horizontal frame and is fixed; the semi-cylindrical gauge block is clamped in the through hole of the pipe truss chord member; the inclinometer is used to measure the inclination angles of the axial equipartition surface and two semi-round surfaces of the semi-cylindrical gauge block; the pipe truss chord member is adjusted to the required position and is welded with a pipe truss base rod into a whole; and the previous steps are repeated, and all the pipe truss chord members are welded on the pipe truss base rod. The method has the advantages that the splicing precision of the through hole of the pipe truss is increased, the relative processes for positioning the through hole of the pipe truss are reduced, the speed for positioning the through hole of the pipe truss is increased, and the accuracy for positioning the through hole of the pipe truss is ensured.

Owner:SHANGHAI ERSHIYE CONSTR CO LTD +2

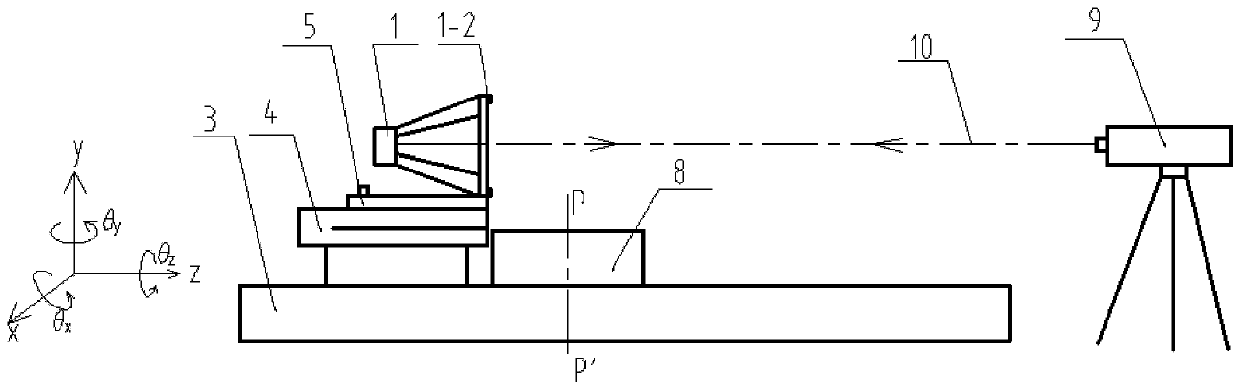

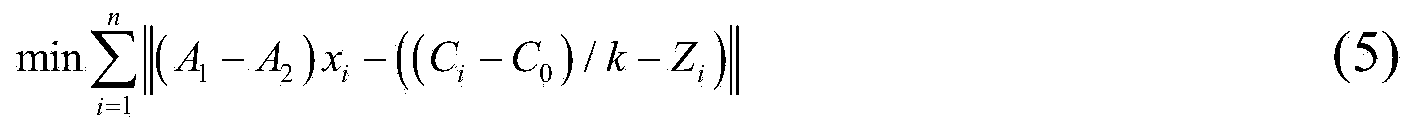

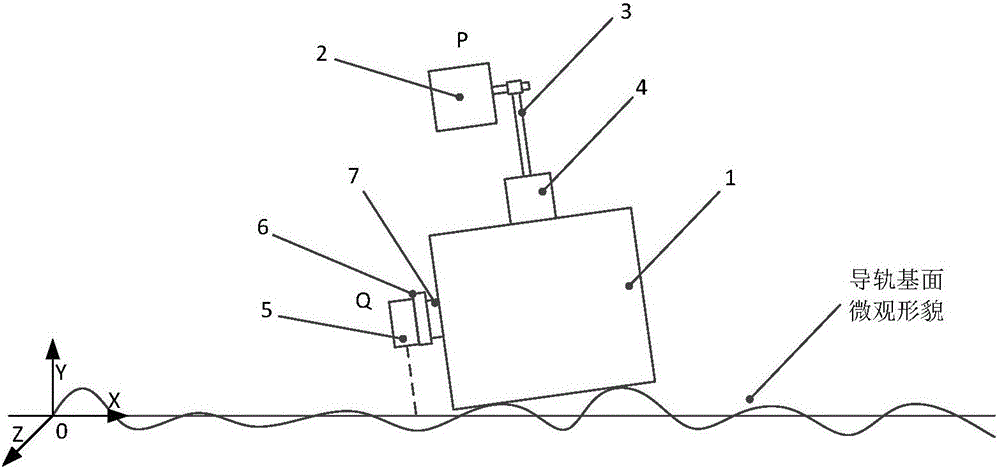

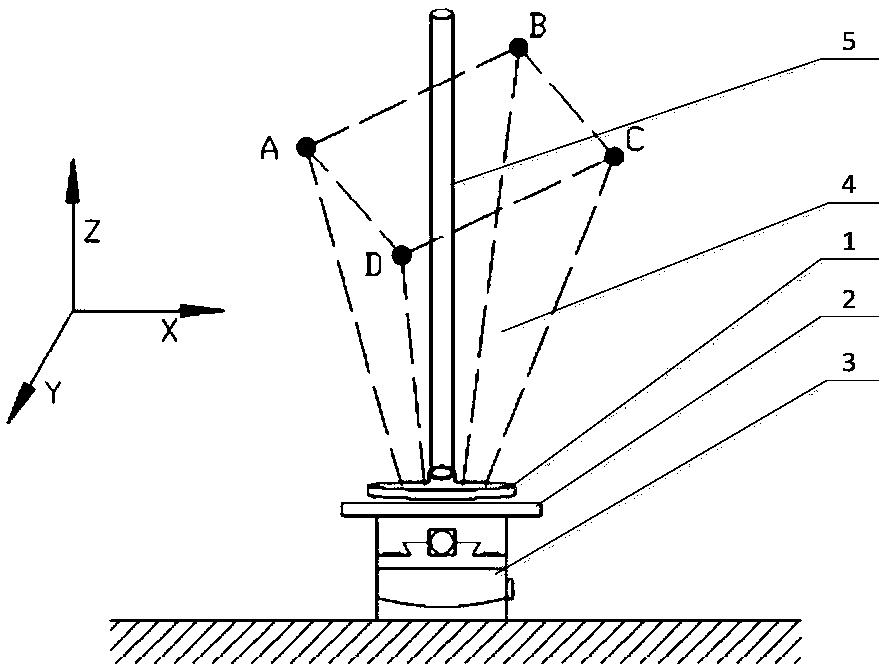

Guide rail basal plane straightness error decoupling and identifying method

The invention discloses a guide rail basal plane straightness error decoupling and identifying method. According to the method, a laser interferometer is utilized to measure straightness error and angle error of a standard gauge block in sliding and reading error measured by a laser displacement sensor, movement of all parts is expressed based on a spinor theory, and a guide rail basal plane straightness error value can be finally calculated out through an error decoupling data processing method; therefore, the purpose of measuring precise guide rail basal plane straightness error is achieved, and the guide rail basal plane straightness error decoupling and identifying method has an advantage of accuracy and certain practicability, and can be applied to researches of numerical control machine tool production quality detection analysis or machine tool precision analysis.

Owner:HUAZHONG UNIV OF SCI & TECH

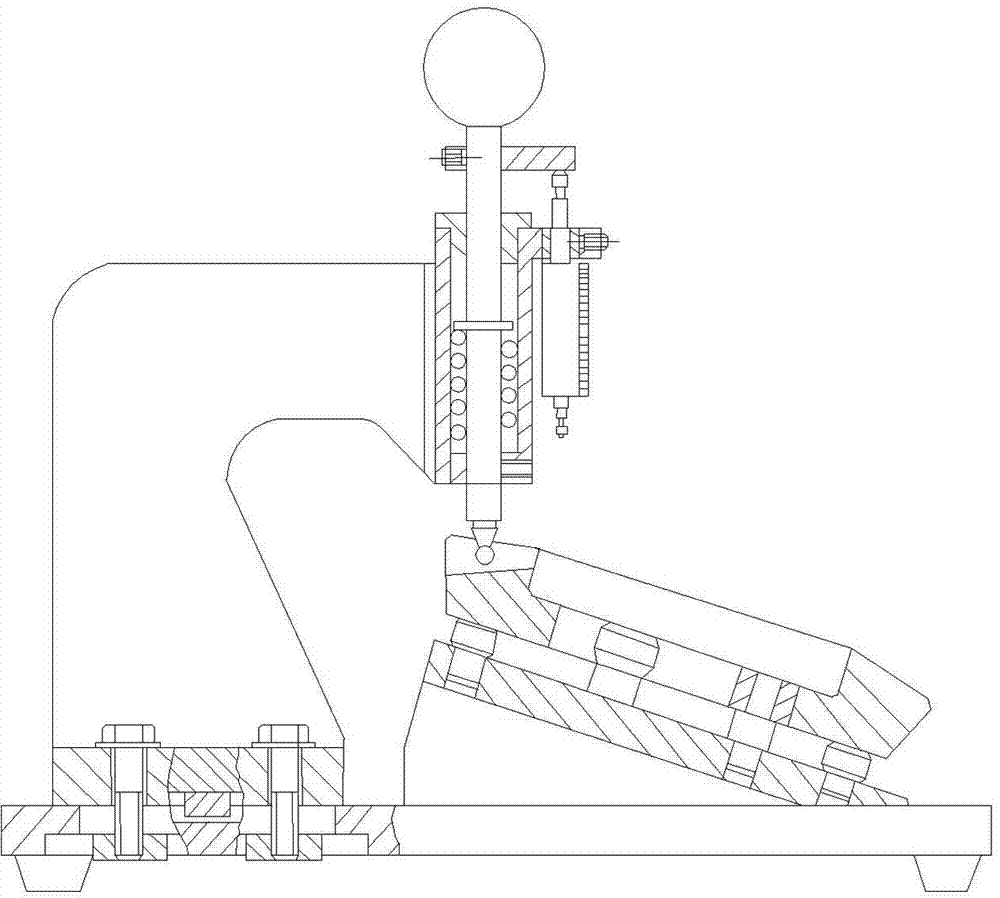

Normal measuring device and calibration method thereof

ActiveCN108917604ASimple structureSimplify the calibration processUsing optical meansLaser rangingCircular disc

The embodiment of the invention provides a normal measuring device. The normal measuring device includes a leveling disc, an angular displacement table, a standard gauge block and a laser ranging sensor assembly, wherein the angular displacement table is located on a workbench of a to-be-calibrated system; the leveling disc is installed on a main shaft of a machining tool and is moved down to theupper plane of the angular displacement table, the leveling disc is leveled by adjusting the angle of the angle displacement table; the standard gauge block is arranged between the angular displacement table and the leveling disc; the laser ranging sensor assembly comprises four laser ranging sensors which emit lasers to the angular displacement table and the standard gauge block on the angular displacement table correspondingly to obtain the numerical difference of the laser ranging sensors and the height of the standard gauge block; according to the numerical difference of the laser rangingsensors and the height of the standard gauge block, the angle between the lasers emitted from the laser ranging sensors and the upper plane of the angular displacement table is calculated to be used for calibration of the to-be-calibrated system.

Owner:SHANGHAI AEROSPACE EQUIP MFG GENERAL FACTORY

Resolution detecting and calibrating method for ultrasonic microscope

ActiveCN103822971AEasy to operateEasy to implementMaterial analysis using sonic/ultrasonic/infrasonic wavesMicro imagingMicro nano

The invention belongs to the technical field of ultrasonic non-destructive detection, and relates to a resolution detecting and calibrating method for an ultrasonic microscope, which can be used for verifying transverse defect detection capability and longitudinal defect detection capability of an ultrasonic detection system, and enable the detection to be more accurate through calibrating a detection result of the ultrasonic microscope. The method comprises the following steps: etching a series of micron-size holes in the upper surface of an optical sheet glass through the laser micro-nano technology, wherein the dimension of the least micron-size hole that can be identified by ultrasonic micro imaging is the transverse detecting resolution; realizing transverse calibration by calculating a pixel compensation value through ultrasonic microscopic measurement for the longitudinal section of a standard gauge block; designing a glass wedge block sample and measuring the thickness with an acoustic time method, wherein the thickness of the thinnest water layer measured is the longitudinal detecting resolution; realizing longitudinal calibration by obtaining a linear fitting equation through analyzing a measured value and a theoretical calculating value. The method is simple to operate, is easy to realize, solves the problem of objective evaluation on ultrasonic defect detection capability, and enables the detection result of the ultrasonic microscope to be more reliable.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

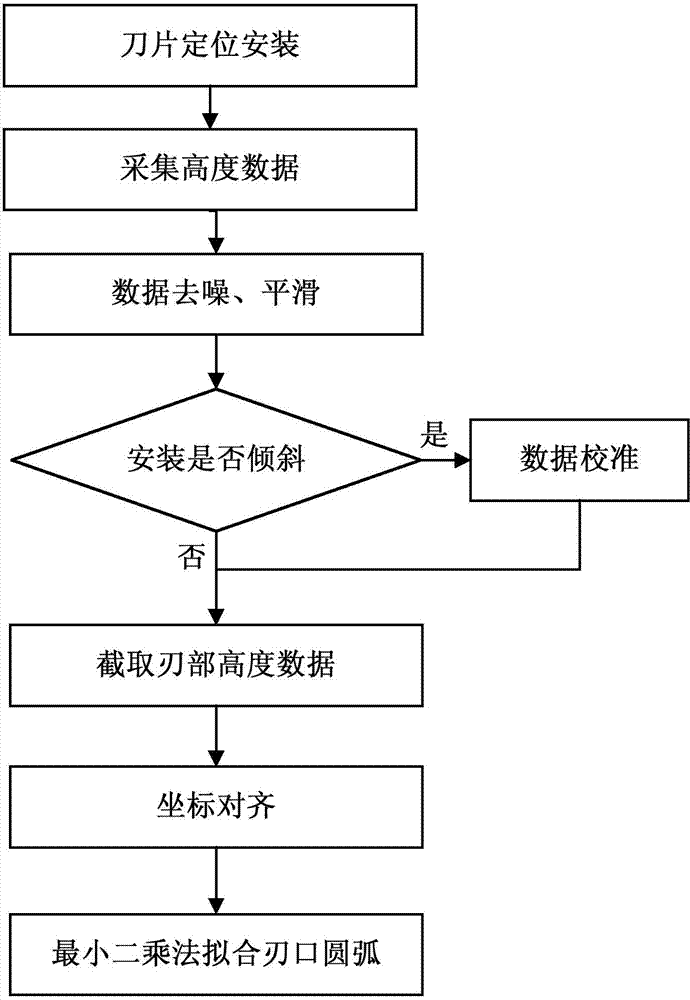

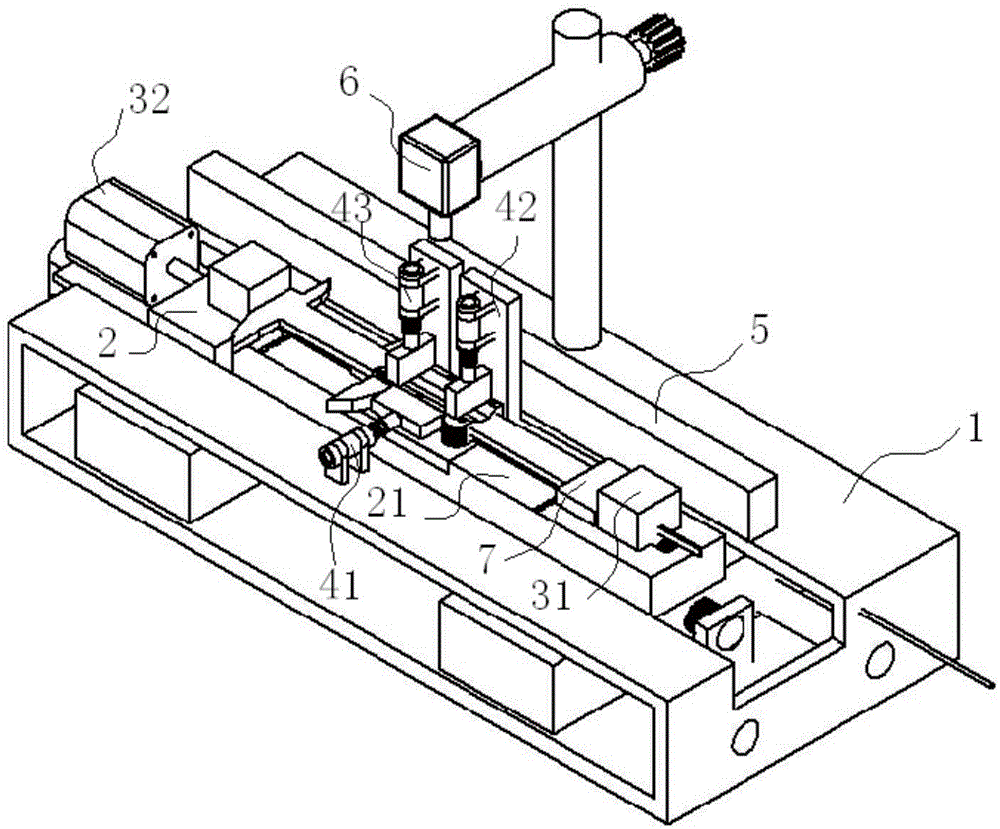

Numerically controlled tool cutting edge measuring method based on laser scanning confocal technology

The invention discloses a numerically controlled tool cutting edge measuring method based on a laser scanning confocal technology. The numerically controlled tool cutting edge measuring method is characterized by including the steps of preprocessing of a tool cutting edge, installation of a tool, acquisition of data of the tool cutting edge and postprocessing of the data. The preprocessing of the tool cutting edge includes the steps that the tool cutting edge is cleaned, and residual chips of the cutting edge after cutter sharpening are removed to guarantee measurement accuracy. The installation of the tool includes the steps that a gauge block with the appropriate angle is selected, and the tool is correctly installed on a clamp to guarantee that the cutting edge is located at the appropriate measurement position; the acquisition of the data of the tool cutting edge includes the steps that the tool cutting edge is positioned and focused through a laser scanning confocal microscope, and layering scanning is conducted to acquire three-dimensional images of the cutting edge. The postprocessing of the data includes the steps of data smooth denoising, data calibration and cutting edge transition circular arc fitting. Representation of the transition circular arc of the tool cutting edge is completed according to the cutting edge acquired by the laser confocal scanning microscope. The method has the advantage that measurement accuracy of the cutting edge can be effectively improved without damaging the structure of the tool.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Vernier caliper calibrating device

The invention discloses a vernier caliper calibrating device. The calibrating device comprises a base, and further comprises a movable platform, a first clamp, a second clamp, an image acquisition device and a grating scale, wherein the movable platform is arranged on the base in a sliding manner; the first clamp is arranged on the movable platform, and is used for fixing the body of the vernier caliper; the second clamp is fixedly arranged on the base, and is used for fixing the vernier of the vernier caliper; the image acquisition device is fixedly arranged on the base, and is used for acquiring the scale images of the vernier caliper; the grating scale comprises an indicative grating and a scale grating; the indicative grating is fixed on the base; the scale grating is fixed on the movable platform. The calibrating device takes the grating scale with high precision to replace a standard gauge block for calibrating as calibrating standard; the precision of the vernier caliper calibrating device is improved; the whole calibrating process can be operated automatically; manual labor is saved; the calibrating efficiency is improved.

Owner:CHINA JILIANG UNIV

Bevel gear tooth thickness measurer

The invention provides a bevel gear tooth thickness measurer, which comprises an operation table, a sine gauge, a mandrel, a right-angled curved ruler, a height gauge, a gauge block and a micrometer. The bevel gear tooth thickness measurer is characterized in that the sine gauge and the right-angled curved ruler are mounted at two ends of the operation table respectively, mounting angles of the sine gauge and the right-angled curved ruler are mutually parallel, the height gauge and an adjusting sleeve are arranged on the right-angled curved ruler and movably connected with the operation table, the micrometer with a holder, an anvil and a locking device removed is mounted on the adjusting sleeve, the micrometer is parallel to a basal plane of the operation table, an axillary steel ball is placed in the middle of a tooth space of the bevel gear to be measured and slightly close to a small end, and positioned in the middle of a contact area, and then relevant dimensional data are measured. The tooth thickness of a portion, where the steel is positioned, of the bevel gear is obtained by calculating, and the tooth thickness of a large end of the measured bevel gear is obtained. The bevel gear tooth thickness measurer can be used for measuring the thickness of optional-section teeth, especially in the middle of the contact area, and no back cone needs to be used as a measurement datum.

Owner:天津天海同步科技有限公司

Readable testing fixture for location degree of semicircle orifice of bearing cover

InactiveCN105627870AAccurately measure the actual position sizeReasonable designMechanical measuring arrangementsEngineeringGauge block

Disclosed in the invention is a readable testing fixture for a location degree of a semicircle orifice of a bearing cover. The testing fixture comprises a testing fixture body; a clamp groove, a first indicating gauge, a measuring lever gauge block, and a second indicating gauge. A clamp groove is formed in the testing fixture body; and a to-be-detected bearing cover is arranged on the clamp groove and the lower surface of the bearing cover is in contact with the bottom of the clamp groove. The first indicating gauge is arranged at the bottom of a semicircle orifice of the bearing cover; and an intersected point wherein the horizontal line of the bottom of the clamp groove is intersected with the diameter of the semicircle orifice of the bearing cover is overlapped with the center of the first indicating gauge. The measuring lever gauge block is arranged on the testing fixture in a rotatable mode; and the upper end of the measuring lever gauge block is arranged at the opening of the semicircle orifice of the bearing cover. And a measuring head of the second indicating gauge is in contact with the lower end of a measuring lever. According to the invention, the provided readable testing fixture has advantages of reasonable design, compact structure, and convenient and reliable usage; the actual position dimension of the semicircle orifice can be measured accurately; and the detection precision and the detection speed can be enhanced obviously.

Owner:GUANGXI YULIN LANGTAI AUTO PARTS

Device and method for detecting symmetry of key groove

InactiveCN102183192AEasy to adjustConvenience to workMechanical measuring arrangementsEmbedded systemStructural engineering

Owner:广州康迪克竞和机械制造有限公司

Dual-layer vibration-damping fastener for city railway

The invention discloses a dual-layer vibration-damping fastener for a city railway. The dual-layer vibration-damping fastener comprises a base, an insulation buffer cushion plate, an elastic cushion layer, an upper-layer iron cushion plate, an insulation gauge block, a steel rail, an under-rail rubber cushion plate, a nut, a flat washer, T-shaped bolts, an elastic strip, anchor bolts, heavy spring washers, pressing plates, an insulation press cover, an iron connecting rod, and a nylon sleeve pipe. The dual-layer vibration-damping fastener disclosed by the invention has the beneficial effects that a creative designed structure without a lower-layer iron cushion plate is adopted, a special tool is not needed, and the dual-layer vibration-damping fastener can be manually disassembled; the elastic cushion layer is simple to repair and replace, and the conservation and the repair are facilitated; the iron connecting rod is used, so that the two anchor bolts are stressed at the same time, the operating state of the anchor bolts is optimized, the safety of the fasteners is improved, besides, the structure is simple, and the cost is low.

Owner:ANHUI CHAOHU CASTING FACTORY +1

Wear gauge and method of use

InactiveUS7509833B2Material analysis by optical meansCleaning recording headsMagnetic storageColor changes

A wear gauge is provided for simulating the wear of a magnetic recording component at its interface with a magnetic storage medium comprising a wear gauge block having a wear surface that substantially approximates the geometrical dimensions and contour of the working surface of the magnetic recording component, wherein the wear surface has a coating of transparent material. A test method comprises mounting the wear gauge in a test fixture, positioning a tape and adjusting the overwrap angle at edges of the wear surface, choosing the desired tape tension, speed and runtime, and running the tape, preferably unidirectionally, in operational contact with the wear surface for the desired runtime. The wear surface is inspected under white light illumination to observe and record locations of interferometric color changes on the wear surface. The color changes are correlated to thickness changes of the transparent coating on the wear surface.

Owner:GLOBALFOUNDRIES INC

Conducting ring brush wire contact pressure detection method and device

ActiveCN103411719AContact pressure measurementMeasurement of force applied to control membersContact pressureEngineering

The invention relates to a conducting ring brush wire contact pressure detection method and device, and belongs to the technical field of force measurement. A special standard gauge block is installed on clamp tools. Force measurement sensor probes are driven through a linear displacement locating mechanism to be in contact with the special standard gauge block, and therefore the location positions of the force measurement sensor probes are determined. The special standard gauge block is taken down, and a detected conducting ring is installed on the clamp tools. The force measurement sensor probes are driven through the linear displacement locating mechanism to reach the previously located positions, the force measurement sensor probes are in contact with a brush wire of the detected conducting ring, and the output value of the force measurement sensor probes is the contact pressure value of the brush wire of the conducting ring.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Automatic measurement system for surface parameters of prefabricated component of three-dimension braiding composite material

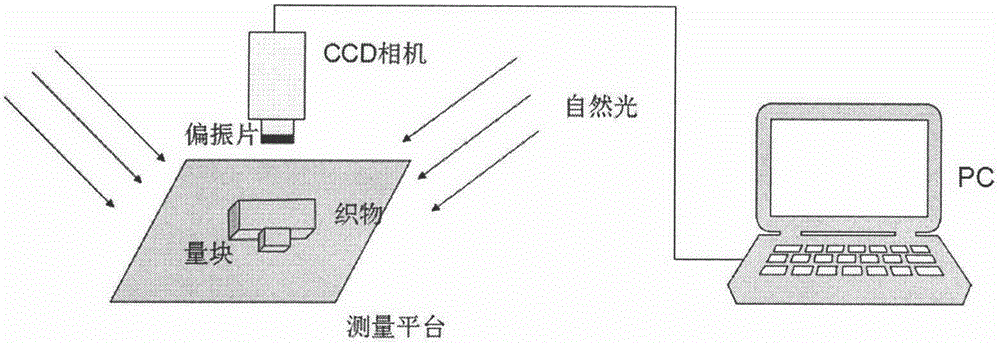

The invention relates to an automatic measurement system for the surface parameters (the braiding angle and the pitch) of a prefabricated component of a three-dimension braiding composite material. The system comprises a hardware portion and a software portion; The hardware portion serves as a collection system of fabrics, and comprises image calibration based on a gauge block and image collection based on a natural light plus Polaroid plus CCD camera scheme; and the software portion serves as a processing system of fabrics images, and comprises image preprocessing with histogram equalization and BMED (block matching 3D) filter, angular point detection and parameter measurement. The Polaroid principle is combined with the CCD camera to effectively reduce adverse influence, caused by surface reflection of the prefabricated component of the carbon fiber material, on image processing; the angular point detection algorithm, in which clone connection, least square fitting, autocorrelation and ACSS are combined, improves the accuracy of ACSS angular point detection algorithm; and each braiding angle and each pitch of images of the prefabricated component of the three-dimension braiding composite material can be measured automatically.

Owner:思腾合力(天津)科技有限公司

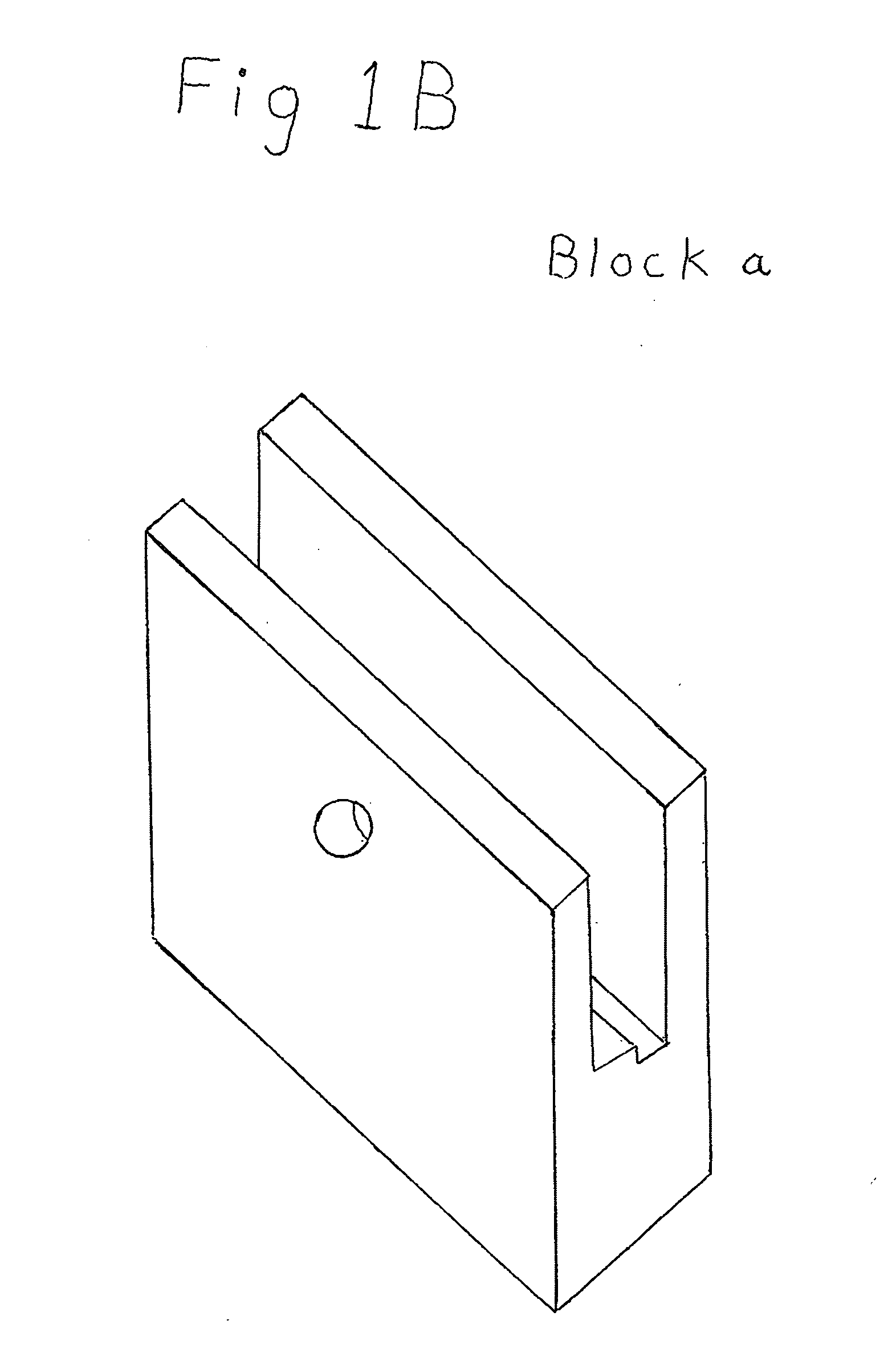

Gauge for aligning hair trimmer blades

A gauge for setting the trimmer blades of a vibratory hair trimmer comprising of a gauge block with a slot in it of the shape of a perfectly adjusted set of trimmer blades.One embodiment, the gauge block has a hole in the front that would line up with hole in the front of the trimmer blade set. A pin with a diameter slightly smaller is inserted into the hole and pushed up with the thumb. The pin cantilevers on the edge of the hole and forces the front blade down into the slot. The back blade is forced down with the forefinger as the adjustment screws are tightened.Another embodiment has a spring clipped to the front of the front blade of the blade set and forces it into the groove when the adjustment screws are tightened.

Owner:TONALAN RUSSELL +1

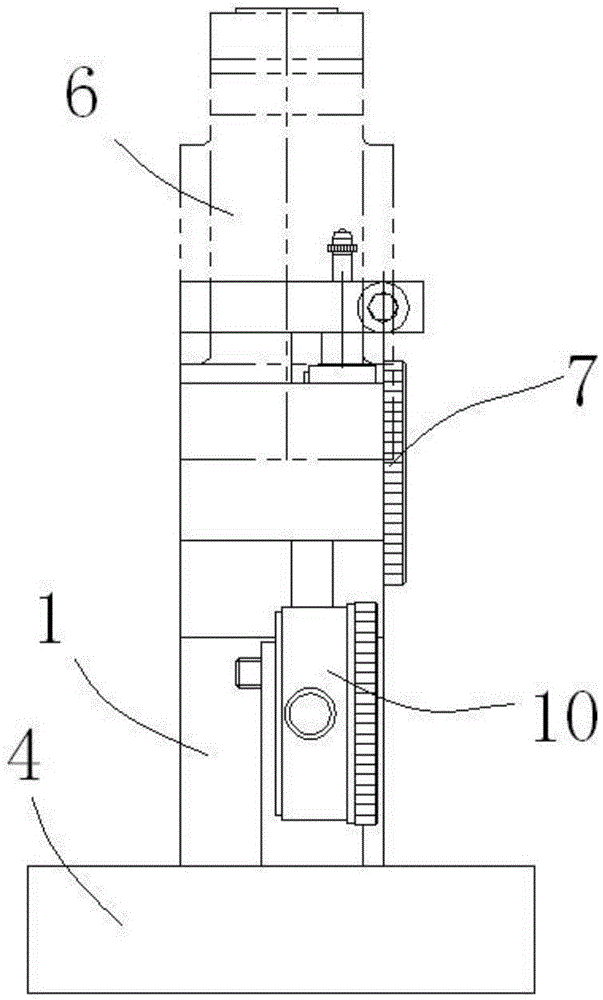

Verticality adjusting method

The invention provides a verticality adjusting method. The verticality adjusting method comprises the steps of: performing verticality zero-position reference determination on an optical autocollimator by using a standard gauge block firstly; and then, adjusting one of two parts required to be vertical to each other in measured parts based on the verticality zero-position reference. According to the verticality adjusting method, the adopted measuring tools are all common instruments and measuring tools and are easily obtained, the whole method is simple and convenient to operate, and the adjustment and test result accuracy is high, so that the verticality adjusting method can be widely applied to the adjustment of accessory manufacture of similar detection devices and measurement instruments.

Owner:CRRC DALIAN CO LTD

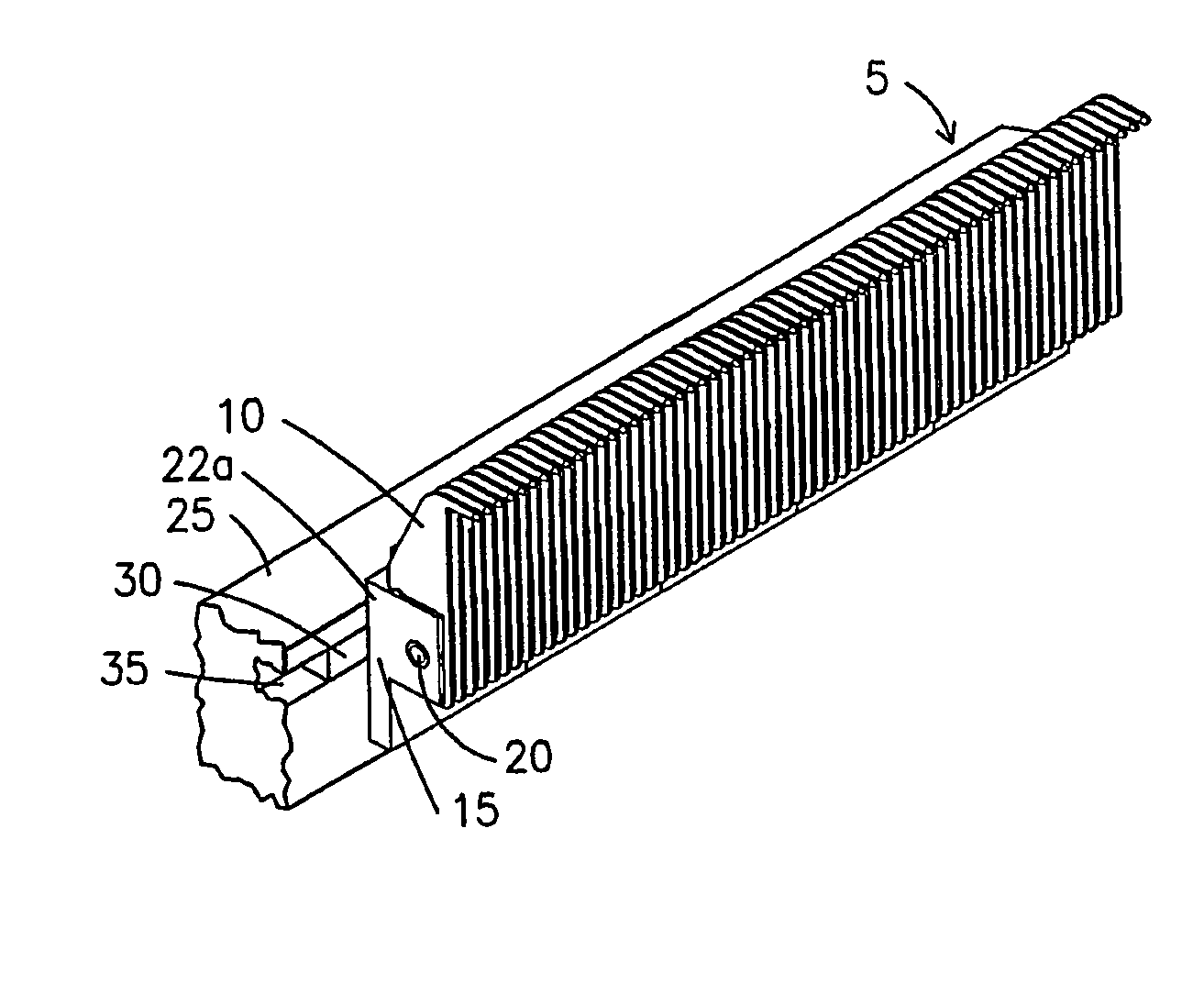

Modular gauge block assembly with secure lateral pins

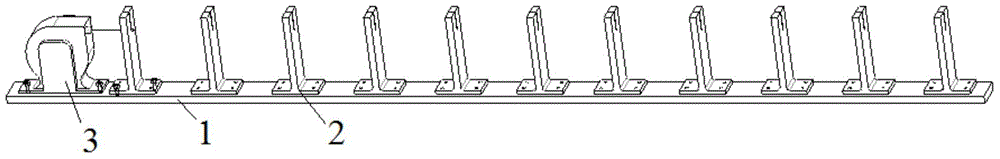

Lateral pins (20) are used to provide a tufting machine modular gauge assembly that allows damaged or broken gauge elements (10) to be replaced individually. The modular gauge assembly consists of a gauge bar (25) with a plurality of modular blocks (15) removably attached to the bar. The modular blocks are six sided with a detent (110) and fastener mechanism (65) for attaching the block to the gauge bar. The gauge elements may be attached to the block by dedicated screw-pins (145) or by a lateral pin (20) that passes through all the gauge elements within a block. The lateral pin may either pierce the gauge elements (at 70) or abut the gauge elements. Abutting pins may be malleable and segmented and secured in position by set screws.

Owner:TUFTCO

Modular gauge block assembly with secure lateral pins

Lateral pins (20) are used to provide a tufting machine modular gauge assembly that allows damaged or broken gauge elements (10) to be replaced individually. The modular gauge assembly consists of a gauge bar (25) with a plurality of modular blocks (15) removably attached to the bar. The modular blocks are six sided with a detent (110) and fastener mechanism (65) for attaching the block to the gauge bar. The gauge elements may be attached to the block by dedicated screw-pins (145) or by a lateral pin (20) that pastes through all the gauge elements within a block. The lateral pin may either pierce the gauge elements (at 70) or abut the gauge elements. Abutting pins may be malleable and segmented and secured in position by set screws.

Owner:TUFTCO

Device and method for calibrating stay wire displacement sensor

Owner:CHERY AUTOMOBILE CO LTD

Detection method for included angle deviation of raceway of cylindrical roller bearing inner ring and reference end surface

InactiveCN102620631AResolve detectionReduce the influence of human factorsAngles/taper measurementsAngular deviationEngineering

The invention provides a detection method for an included angle deviation of a raceway of a cylindrical roller bearing inner ring and a reference end surface. The bearing inner ring of which the inner diameter is greater than 300mm is self-defined as a large thin-wall sealed intersectional cylindrical roller bearing inner ring and is called as inner ring (5) for short, wherein the raceway of the inner ring is in a V shape; the two raceway edges of the V-shaped raceway are intersected to form an angle of 90DEG and respectively form angles of 45DEG relative to the symmetrical centerline of the V-shaped raceway; and the detected included angle deviation is compared with delta beta' in a graph 3 in a CSBTSTC98-13-1997 standard, so as to be judged whether satisfies the requirement of the standard or not. A dial indicator (1), a magnetic indicator stand (2), a sine gauge (3) and a block gauge (4) are used in the detection method, the difficult problems that the large bearing inner ring is difficult to detect and is detected incorrectly are solved, and angle deviations of raceways of inner rings in the whole batch can be detected repeatedly and rapidly after the sine gauge and the block gauge are well adjusted once, the influence of personal factors is reduced, the detection efficiency is obviously improved and the detection cost is saved.

Owner:LUOYANG BEARING RES INST CO LTD

Angle deflection adjusting combined clamp for numerical control machine tool machining

ActiveCN109014998AGuaranteed machining accuracyReduce manufacturing costPositioning apparatusMetal-working holdersNumerical controlGauge block

The invention discloses an angle deflection adjusting combined clamp for numerical control machine tool machining. The angle deflection adjusting combined clamp is provided with an angle working tablewhich comprises a lower foundation plate, an upper foundation plate, a bearing piece and a connecting plate. The bearing piece is vertically fixed to the lower foundation plate, and the upper foundation plate and the lower foundation plate have an included angle. A second circular foundation plate is fixedly connected to the upper foundation plate of the angle working table, and a first circularfoundation plate and an angle deflection positioning assembly are arranged on the second circular foundation plate. The first circular foundation plate rotates around a center shaft of the second circular foundation plate. The angle deflection positioning assembly comprises a first V-shaped block, a second V-shaped block, a first step positioning pin, a second step positioning pin and a cuboid adjusting gauge block assembly. According to the angle deflection adjusting combined clamp for numerical control machine tool machining, the structure is adopted, thus high-precision positioning and machining for angle deflection of a numerical control machine tool in the same plane can be completed, the machining precision is ensured, and the manufacturing cost is lowered.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

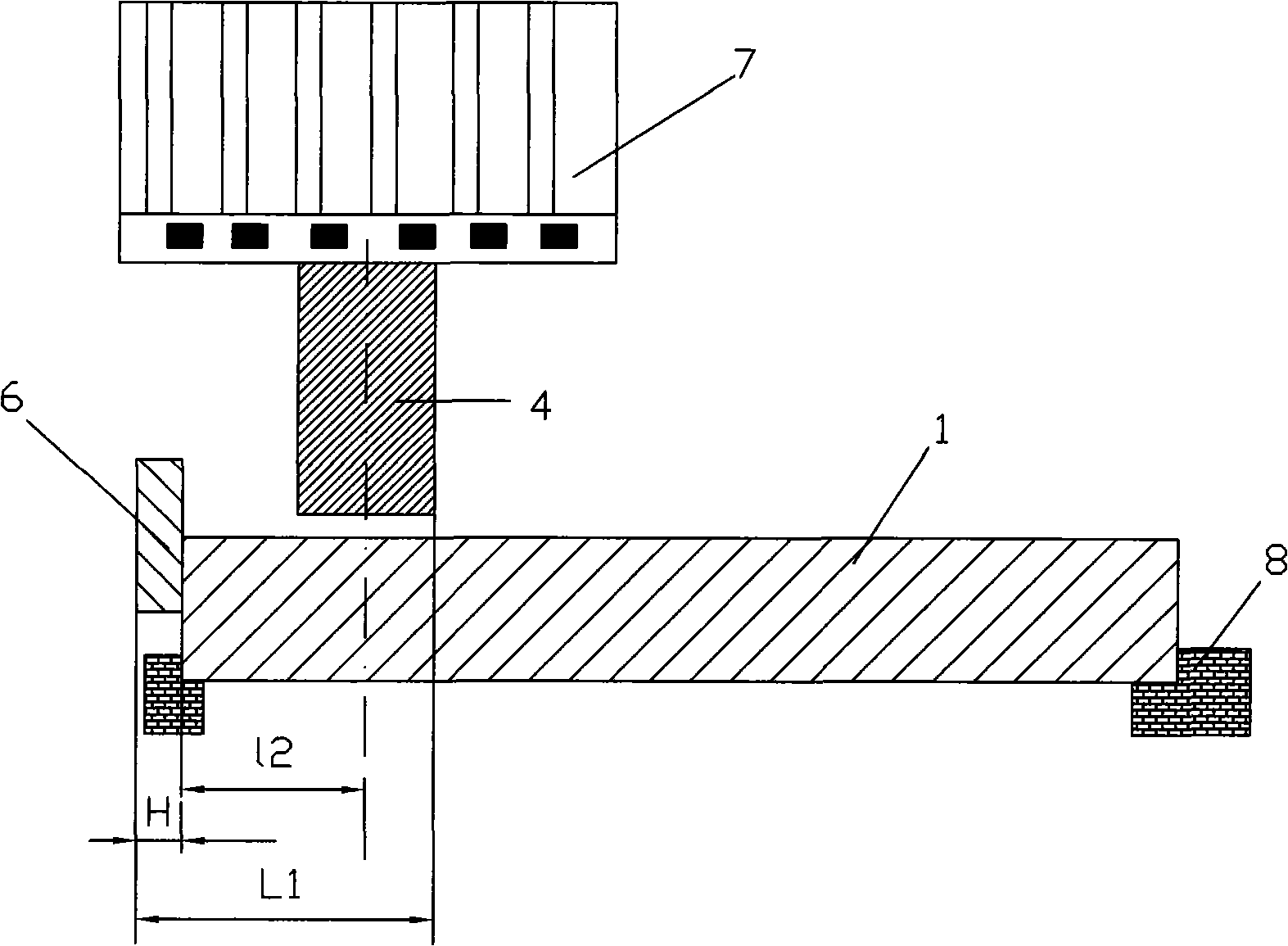

Drill hole accurate positioning method in mechanical drilling process

InactiveCN101985178AGuaranteed geometric toleranceMechanical clearance measurementsNumerical controlPosition tolerance

The invention relates to a drill hole accurate positioning method in mechanical drilling process, including the following steps: 1) the datum plane of a plate is selected, two cylindrical pins with the same diameter of a drill head and a standard gauge block are selected as measuring pieces; 2) distance l2 between a hole a and one side of the plate is determined; 3) distance l1 between the hole a and the other side of the plate is determined; 4) the cylindrical pin in a drill fixture of a drilling machine is replaced into the drill head, and drilling is carried out on the positioning points, thus completing drilling of the hole a; 5) the center of a hole b is determined; 6) drilling of the hole b is completed according to the central position of the hole b. The invention is applicable to processing of general machine tool, operation is easy, side hole with high accuracy is processed, and high accuracy drill hole positioning by side and side hole as well as hole pitch is realized, so that processing accuracy thereof can be almost close to the processing accuracy of a numerical control machine and form and position tolerance is ensured to be within the processing requirement.

Owner:BAOSHAN IRON & STEEL CO LTD

System for measuring composite coordinate based on multi-aiming device

ActiveCN106352823ARealize measurementRealize 1D high-precision contact measurement functionMeasurement devicesCoordinate-measuring machineData treatment

The invention relates to a system for measuring a composite coordinate based on a multi-aiming device and belongs to the field of measurement technology. The system provided in the invention comprises a coordinate measurer, a laser interferometer, an inductance micrometer, a photoelectric microscope, a mechanical kinematic system, an adjustable working table and an embedding control and data processing system. One-dimensional high-precision contacting coordinate measuring system composed of the embedding control system, mechanical kinematic system, laser interferometer, inductance micrometer and adjustable working table and conforming to the Abbe principle and one-dimensional non-contacting coordinate measuring system composed of the embedding control system, coordinate measuring machine, mechanical kinematic system, laser interferometer, photoelectric microscope and adjustable working table and conforming to Abbe principle can realize testing different testing pieces,such as realizing the needed measuring function of multiple length measurers of a club, a stepgage, a gauge block, a caliper gauge, a ring gauge, a screw, a linear scale, a dividing plate and the like. The machine has multi-purpose and wide social benefit and prospect.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com