Normal measuring device and calibration method thereof

A calibration method and technology for measuring devices, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of cumbersome calibration methods, high calibration costs, and poor accuracy, and achieve the effects of simple structure, simple calibration process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, the calibration method of the present invention will be clearly and completely described with reference to the drawings and embodiments.

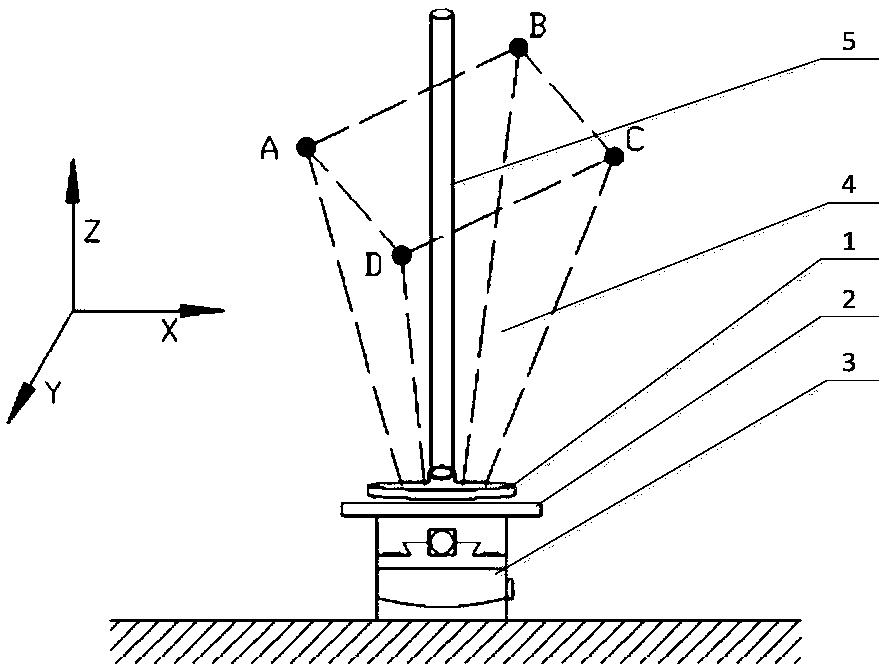

[0031] Such as figure 1 As shown, a normal direction measuring device provided by an embodiment of the present invention includes: a leveling disk 1, an angle displacement platform 3, a standard gauge block 2 and a laser distance measuring sensor assembly, wherein: the angle displacement platform Located on the workbench of the system to be calibrated; the leveling disc is installed on the processing tool spindle 5, and moves down to the upper plane of the angle displacement platform, and the leveling disc is leveled by adjusting the angle of the angle displacement platform ; A standard gauge block is arranged between the angle displacement platform and the leveling disk; the laser ranging sensor assembly includes four laser ranging sensors, which emit laser light to the angle displacement platform respectively, and to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com