Drill hole accurate positioning method in mechanical drilling process

A technology of precise positioning and mechanical drilling, applied in the direction of using mechanical devices, mechanical measuring devices, mechanical gap measurement, etc., can solve problems such as operation accuracy or service life discount, and processing requirements cannot be met.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

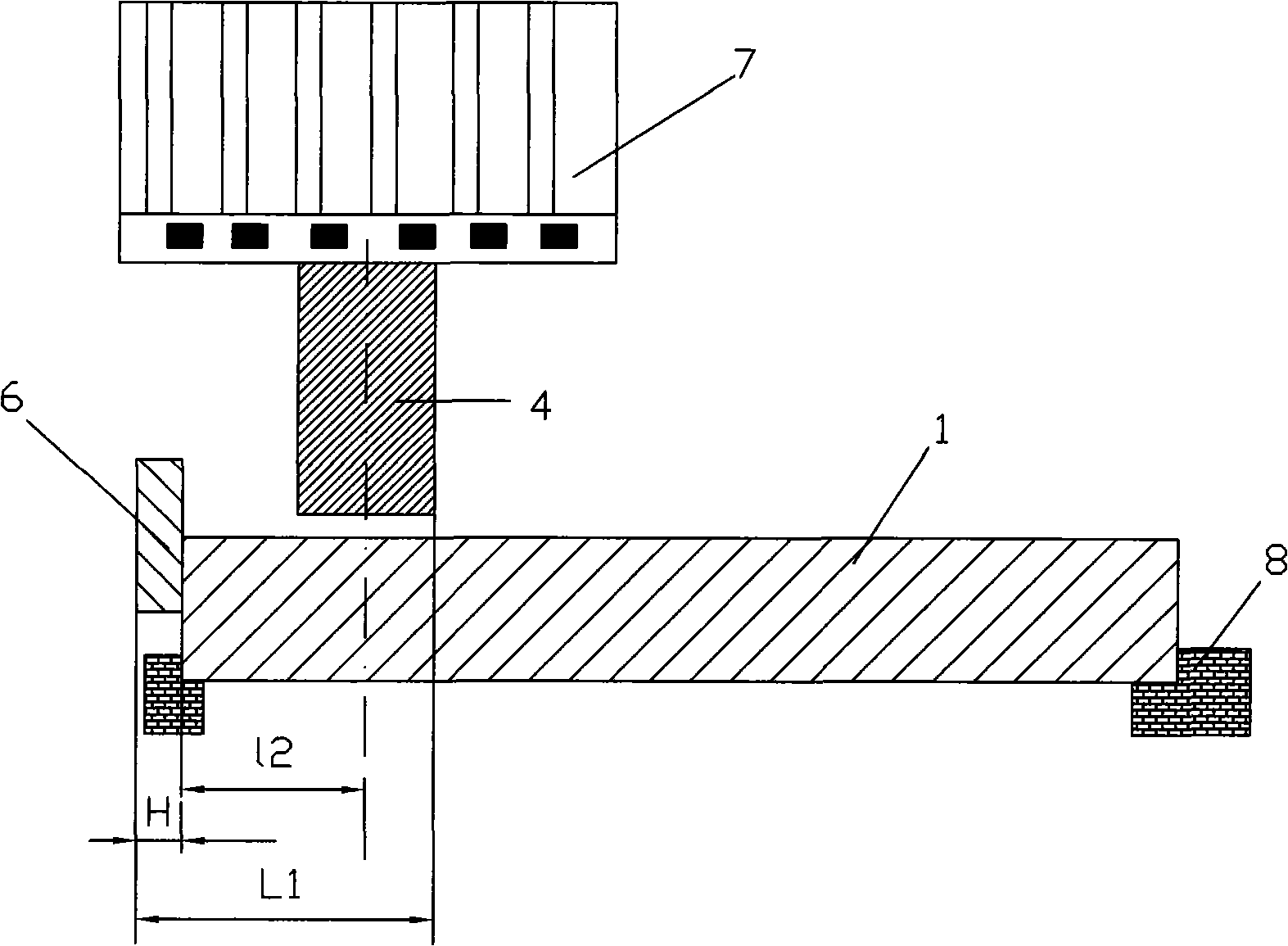

[0031] See Figure 1~ image 3 Firstly, the method of the present invention cancels the consistently used marking and sample punching positioning operations, reducing the accumulated errors in each step of operation.

[0032] l 1 , l 2 , l 3 There is an internal connection between the dimensional requirements. After any one of the dimensions deviates, the rest of the tolerance zone cannot be guaranteed, so the accuracy requirements of the first dimension must be guaranteed. So the first size l 1 There must be an accurate datum reference plane as the relative size measurement plane, considering the verticality deviation in the accumulated error, that is, choose the side of the plate 1 closest to the drilled part as the datum plane. Select two cylindrical pins 4, 5 with the same diameter as the drill bit and a standard gauge block 6 as the measuring piece;

[0033] Such as figure 2 As shown, the position of hole a2 is l 1 and l 2 The size and position of are determined. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com