Integrated sightseeing lift with steel-structured hoistway

A sightseeing elevator and steel structure technology, which is applied in the field of mechanical lifting, can solve the problems that the installation of elevators cannot be realized, the total cost of installing elevators increases, and the construction period is long.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

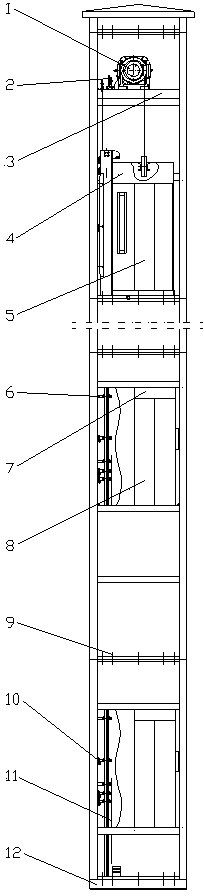

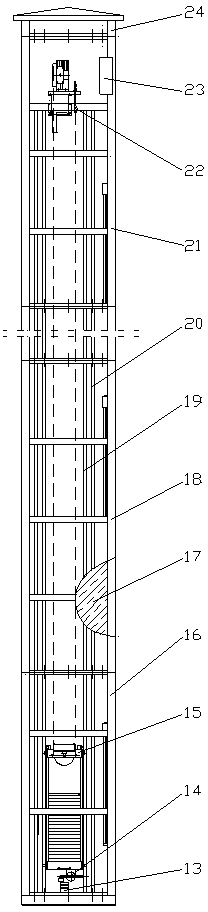

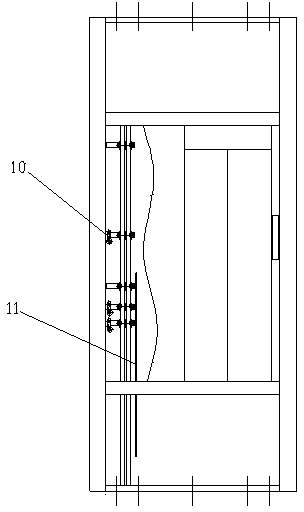

[0022] refer to Figure 1~2 , a sightseeing elevator with a steel structure hoistway integrated, comprising a car 4 and a counterweight device 15, characterized in that it also includes a base 12, a bottom frame 16, a plurality of intermediate frames 18, and a top frame from bottom to top 21 and top cover 24, the base 12, the bottom frame 16, a plurality of intermediate frames 18, the top frame 21 and the top cover 24 are stacked and installed to form a steel structure hoistway, and the car is installed in the top frame 21. 4. The traction system for lifting and lowering in the steel structure hoistway. The bottom frame 16, the multiple intermediate frames 18 and the top frame 21 are respectively installed with guides that enable the car 4 and the counterweight device 15 to move up and down along the guide rails. system and the door system that seals the entrance of the landing; above the four columns of the bottom frame 16, a plurality of intermediate frames 18 and the top fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com