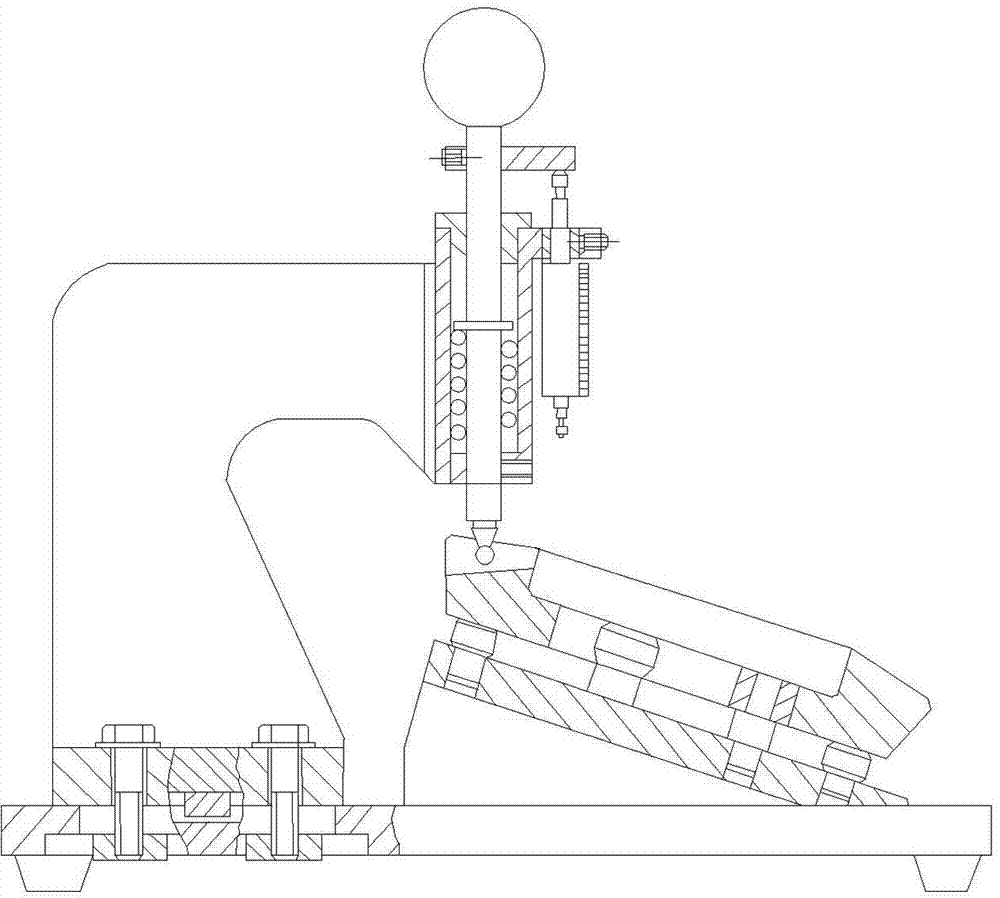

Device and method for measuring tooth thickness of medium and small modulus bevel gear

A measuring device and a technology of small and medium modulus, which is applied in the direction of mechanical thickness measurement, etc., to achieve the effect of convenient measurement, high measurement accuracy and improved processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

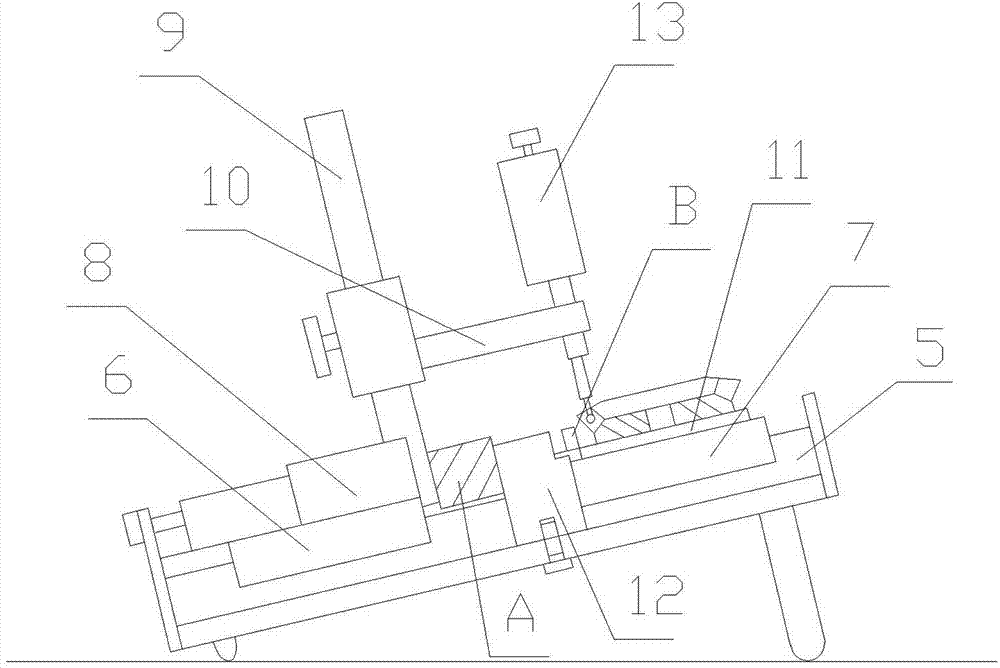

Embodiment 1

[0052] Measured gear parameters

[0053] Z 大 =37, Z 小 =9, interaxial angle δ=90°

[0054] ω 模数 =1.387β 螺旋角 =35° α 齿形角 =20° tooth width B

[0055] Calculate the measuring ball diameter d=φ1.75 (rounded)

[0056] Calculate the installation size: A=22.25, B=14.40

[0057] Gear production adopts this tooth thickness measurement method to control the tooth thickness quality of the processed gear, together with Figure 7 , 8 The three-dimensional digital measurement method of gear teeth is shown to control the quality of gear teeth and combined with traditional contact zone control. The small modulus bevel gear produced by this method can replace the traditional large and small wheel matching production mode. The large and small wheels produced in large quantities can be installed interchangeably and maintain the same meshing quality.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com