Verticality adjusting method

An adjustment method and verticality technology, applied in the field of measurement, can solve the problems of mirror coating damage, inability to obtain measurement accuracy, etc., and achieve the effects of easy acquisition, simple and convenient operation, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

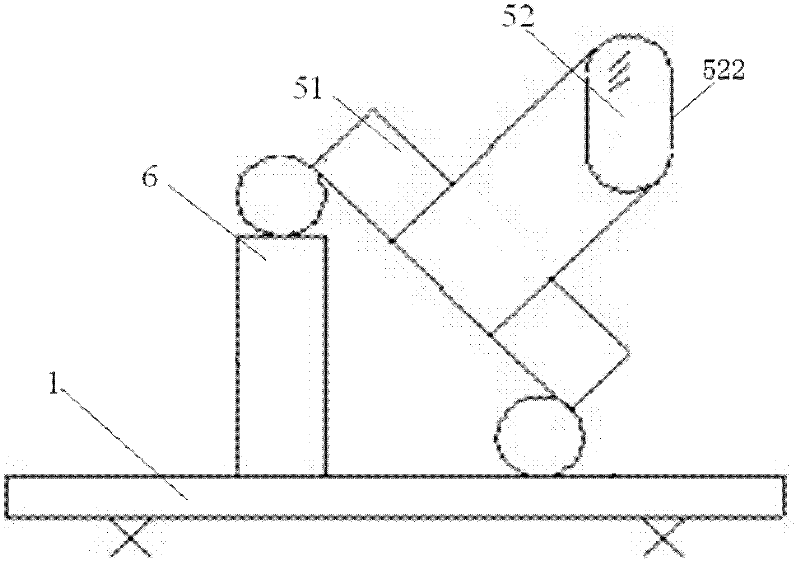

[0016] Embodiment 1 of the verticality adjustment method provided by the present invention can adopt such as figure 1 The verticality adjustment device shown is realized. The device includes a reference platform 1 , an optical autocollimator 4 , a support 3 and a standard gauge block 2 . A support 3 and the optical autocollimator 4 are placed on the reference platform 1, a fixing clip is provided on the support 3, and the standard gauge block 2 can be clamped on the support 3 by a fixing clip; The above-mentioned optical autocollimator 4 can be adjusted in height through spacers. This embodiment includes the following steps:

[0017] Step 1, adjust the height of the optical autocollimator 4 placed on the reference platform 1, so that the optical axis of the optical autocollimator 4 is basically the same as the height of the center line of the part to be adjusted in the tested part from the reference platform 1, Such as figure 1 shown. The height of the optical autocollima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com