Direct calibration method for line structured light vision sensor

A visual sensor and line structured light technology, applied in the direction of instruments, optical devices, measuring devices, etc., can solve the problems of complex sensor calibration methods and low precision, and meet the application requirements of small field of view high-precision measurement, high precision, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

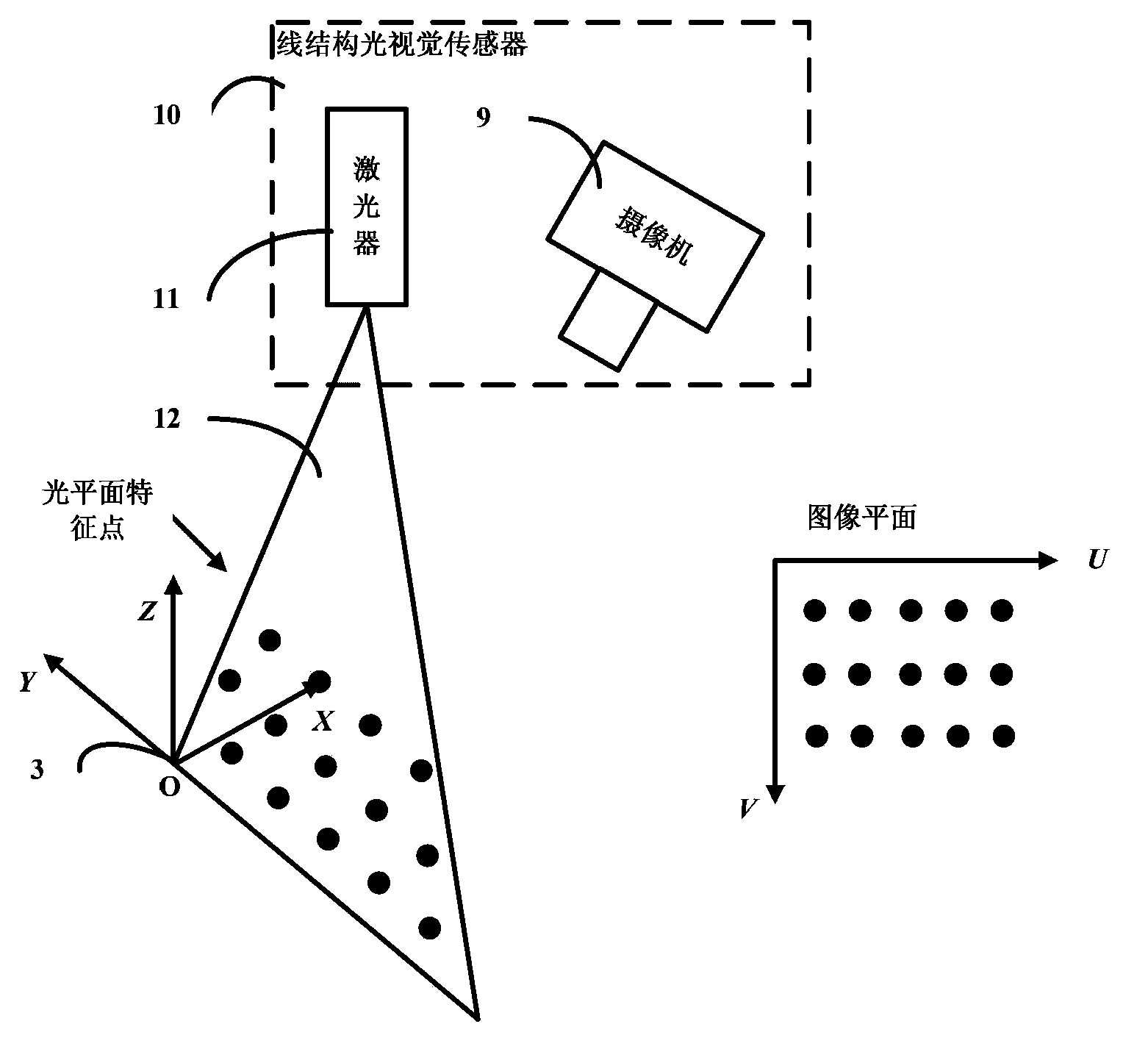

[0059] Such as figure 1 , 2 As shown, it is the principle diagram of the direct calibration method of the line structured light sensor and the flow chart of the calibration method of the line structured light visual sensor. It is a direct calibration method of a line structured light vision sensor, characterized in that: the calibration method includes the following steps:

[0060] Step (1) establishing a target formed by using a standard gauge block and using a three-dimensional precision translation stage;

[0061] Step (2) The laser in the line structured light vision sensor projects the structured light plane onto the target to generate a structured light pattern that intersects with the gauge block on the target to form a feature point on the target;

[0062] Step (3) Establish a space coordinate system OXYZ on the target, and obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com