Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

143results about How to "Realize continuous automatic production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

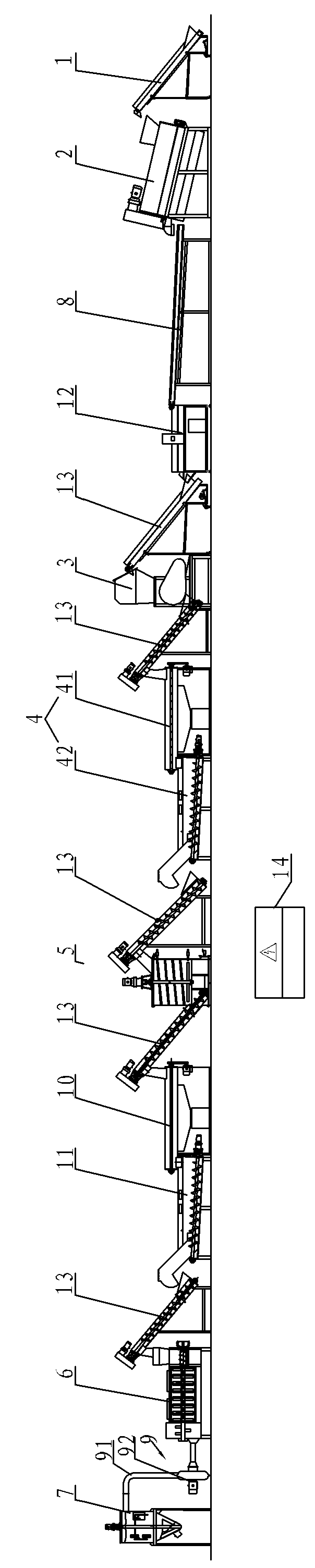

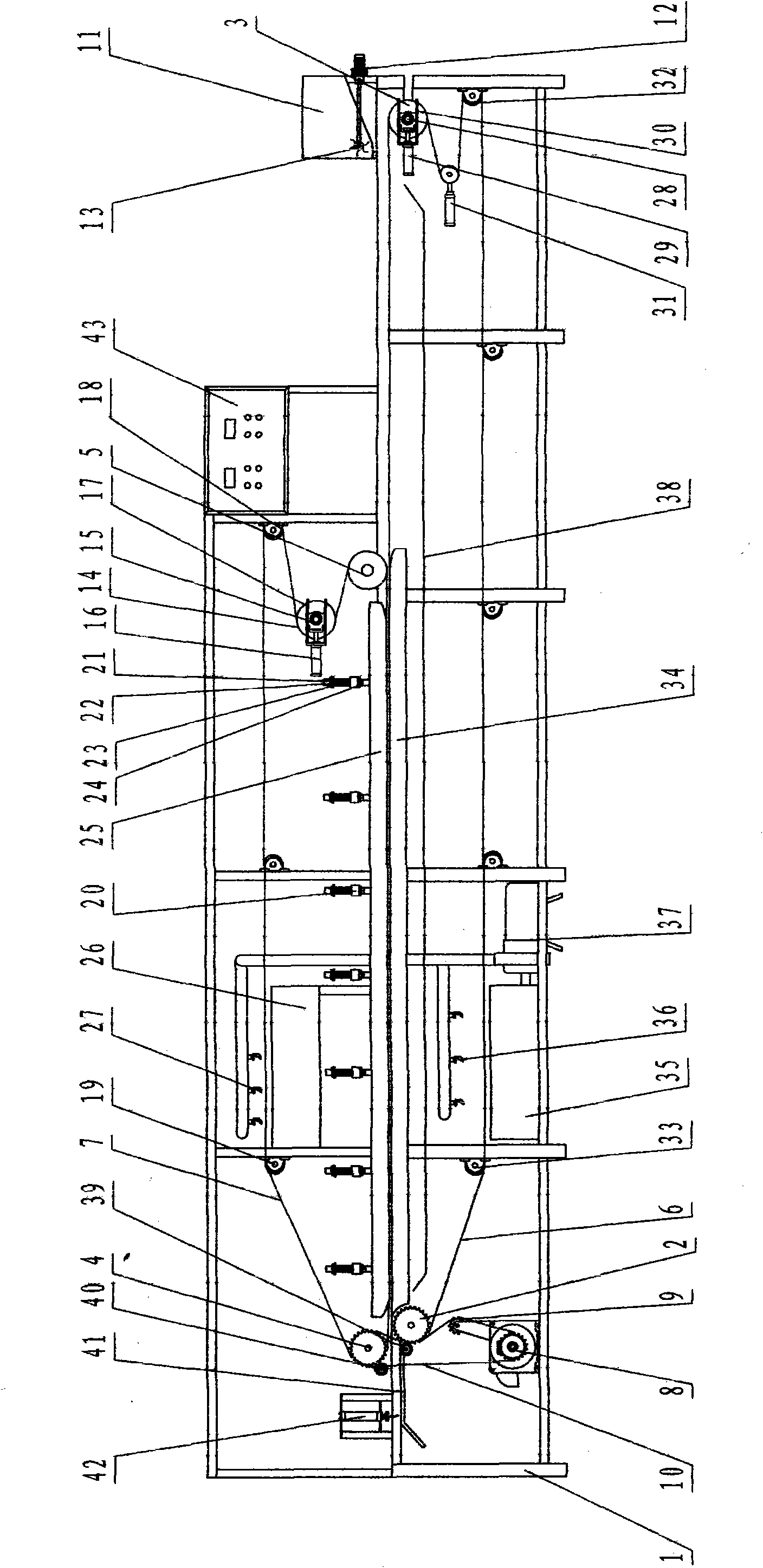

Recycling, breaking and cleaning line for polyethylene terephthalate (PET) mineral water bottle

ActiveCN102114676AGet rid of the messy situationRealize continuous automatic productionPlastic recyclingDomestic articlesPolyethylene terephthalate glycolPolyethylene terephthalate

The invention provides a recycling, breaking and cleaning line for polyethylene terephthalate (PET) mineral water bottles. The recycling, breaking and cleaning line comprises a mineral water bottle conveying belt, a label removing machine used for separating labels from the recycled mineral water bottles conveyed by the conveying belt, a breaking machine used for breaking the bottle bodies after the labels are removed, a cleaning machine used for cleaning broken bottle chips and separating bottle covers, a steamer used for cleaning the separated bottle chips again at high temperature and a dewaterer used for drying the cleaned bottle chips, which are sequentially arranged according to the process. The dewatered bottle chips enter a storage bin and are packaged for storage. By the recycling, breaking and cleaning line, continuously automatic production can be realized. Several workers are required in the work site so that the work site of the plastic recycling industry gets rid of dirty, disorderly and bad conditions. Meanwhile, by adding the label removing machine, labels on the bottle can be separated so that the broken PET mineral water bottles are more purified.

Owner:SUZHOU ZHONGSU REPROCESSING MACHINERY

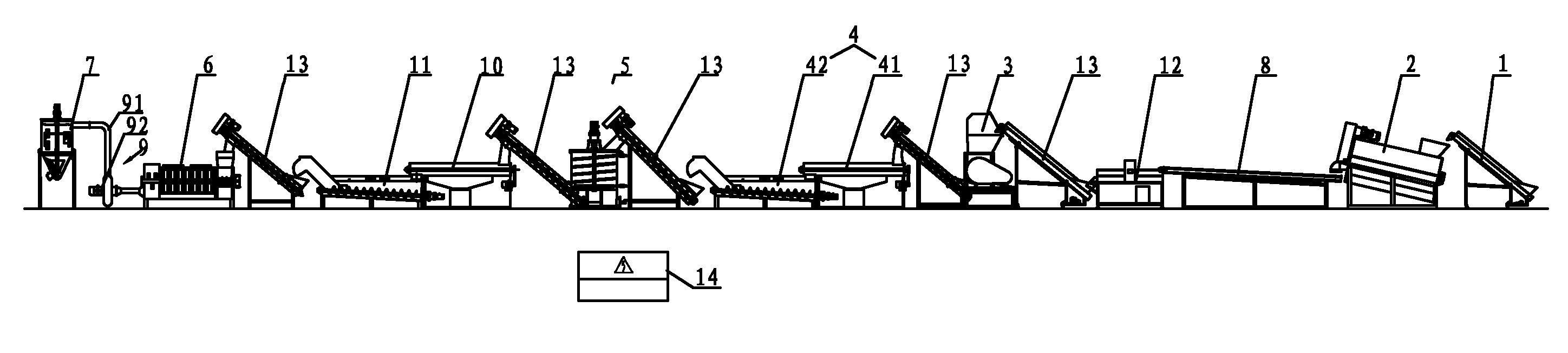

Device for manufacturing metal matrix composite or semisolid slurry and using method thereof

The invention relates to a device for manufacturing a composite or slurry and a using method of the device, in particular to a device for manufacturing a metal matrix composite or semisolid slurry and a using method of the device. The technical problems that in the process of manufacturing the metal matrix composite or the semisolid slurry through an existing stirring casting method, heat corrosion happens to a stirring bar in the stirring process, so that the service life of the stirring bar is short, impurity elements are introduced in materials, the purity of the materials is influenced, and it is difficult to manufacture the composite of a large size through the stirring bar are solved. The device is composed of a container end cover, a heating element, a smelting container, an ultrasonic device, a thermocouple, a valve switch, a discharge channel, a rotary device, a device supporting structure, a material collecting container, a transmission device, a device shell, side wall ribs, bottom ribs, a motor and a speed reducer. The device is applied to the field of manufacturing the composite or the slurry.

Owner:HARBIN INST OF TECH

Loose metal litter briquetting machine and processing method

InactiveCN102101364AImprove compression efficiencyImprove work efficiencyPressesHigh densityReciprocating motion

The invention relates to a loose metal litter briquetting machine. A vertical main cylinder is arranged at the top of a stand, a piston of the main cylinder is connected with a punch in up-and-down reciprocating motion in a final pressure swaging bucket, a soleplate for sealing the bucket bottom is arranged at the bottom of the swaging bucket and controlled by a horizontally arranged knife gate cylinder, the middle of the swaging bucket is horizontally provided with a pushing cabin which is in sealed connection and vertical intersection with the swaging bucket; the tail end of the pushing cabin is provided with a pushing head connected with a piston of a pushing cylinder piston, the pushing cabin is provided with an open side which is communicated with the bottom of a feeding hopper, a precompression pushing head is arranged at the other side of the bottom of the feeding hopper and connected with a piston of a precompression cylinder. The precompression cylinder, the pushing cylinder and the main cylinder provided by the invention respectively extrude materials in the three directions of the X axis, the Y axis and the Z axis to effectively improve the compression efficiency of the materials and finally obtain high-density litter cakes while cutting coiled wires and separating litter liquid and have high degree of automation and good economic benefits.

Owner:JIANGYIN RUIFENG HYDRAULIC MACHINE CO LTD

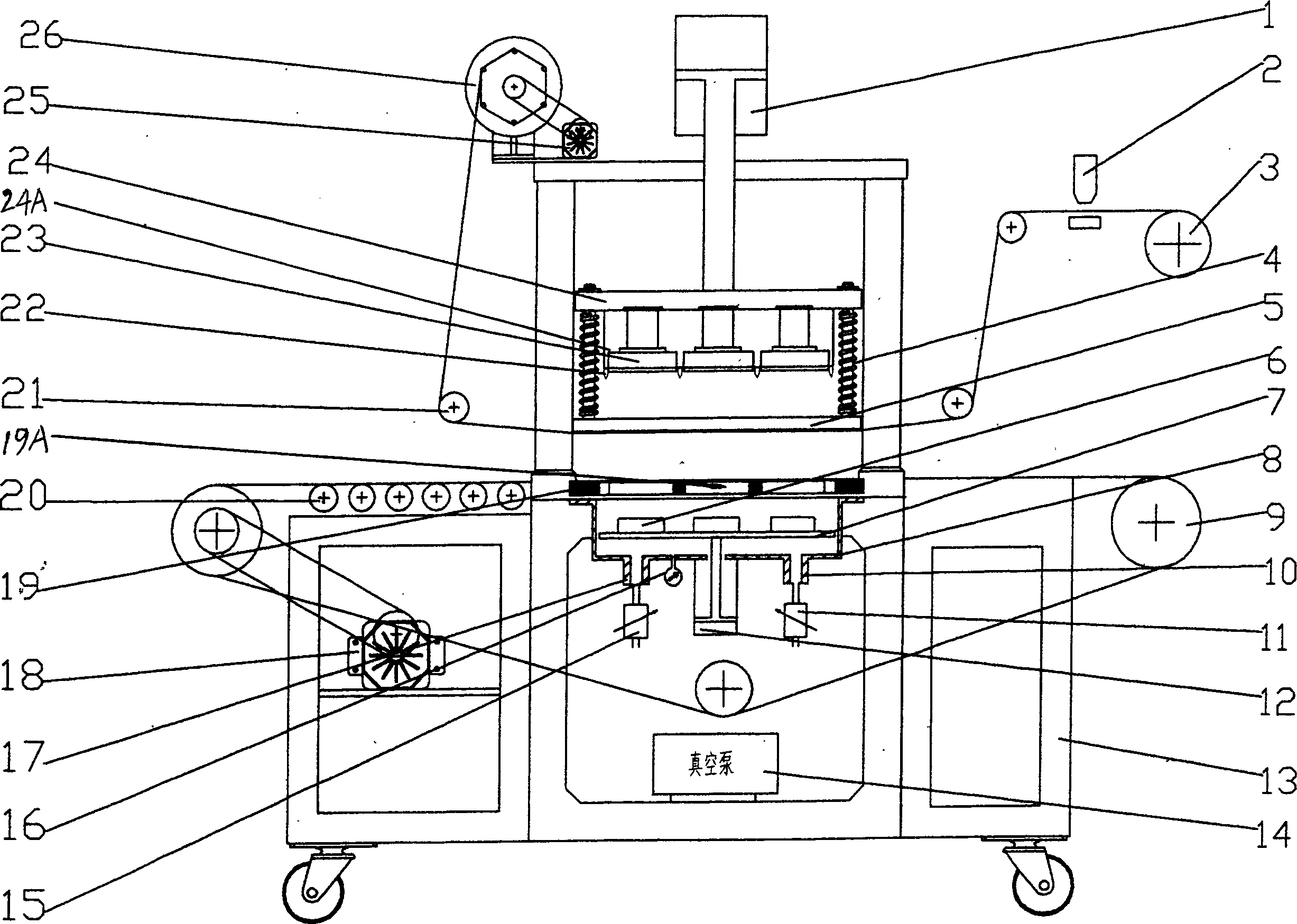

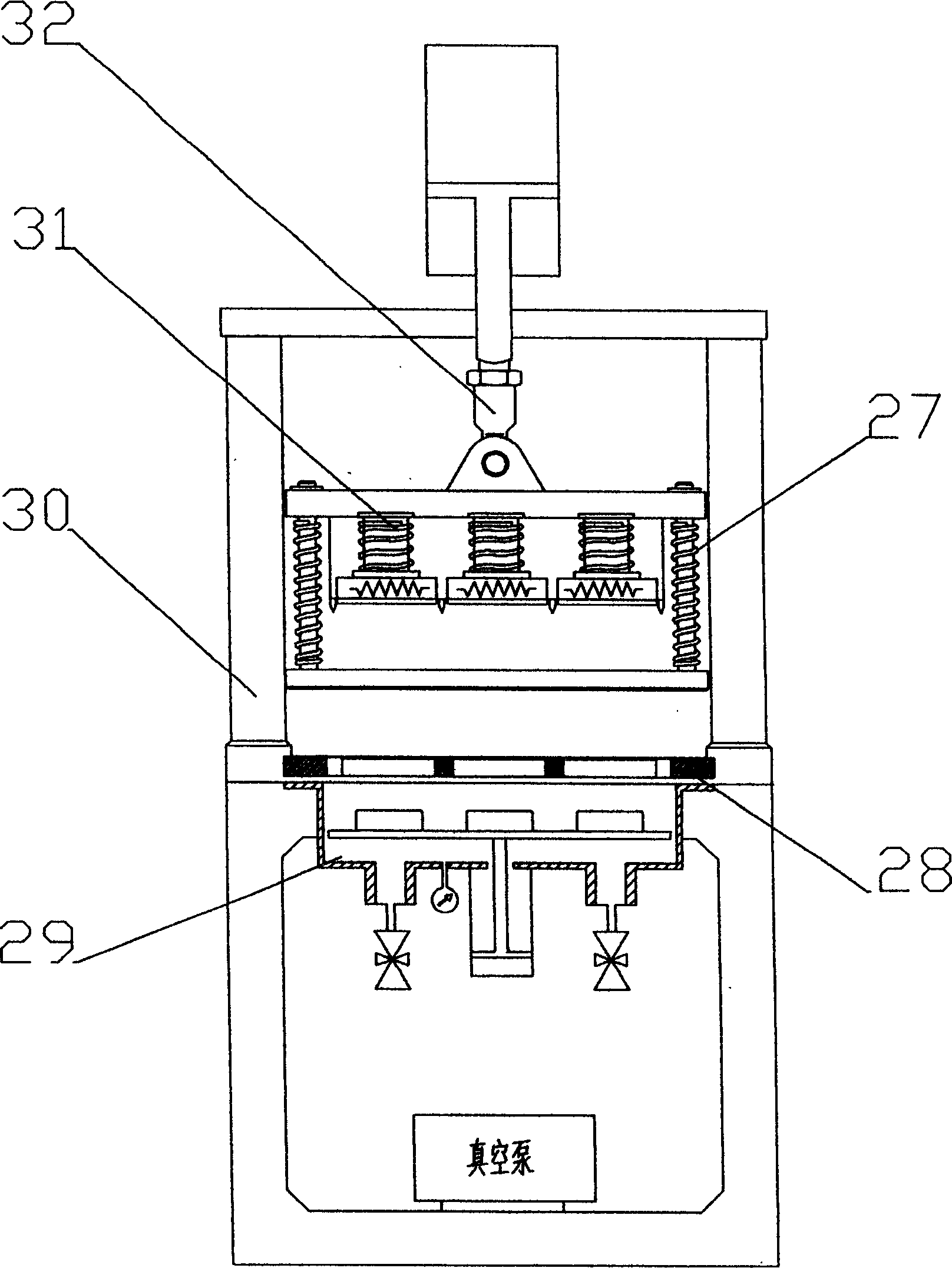

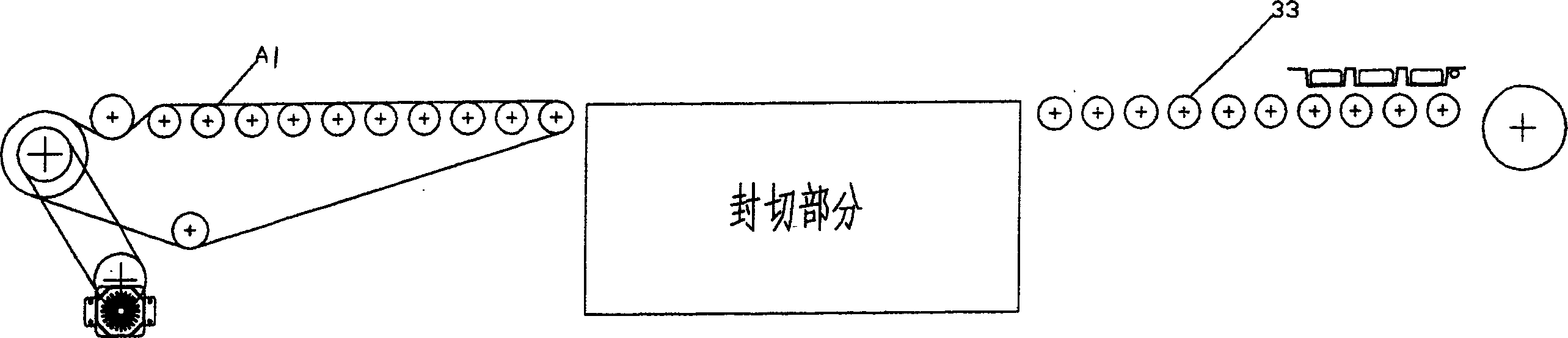

Continuous casing cake and food air conditioned preserving packers

InactiveCN1644458AAccurate identificationMake sure you are in a safe placePackaging under special atmospheric conditionsThin membraneEngineering

A continuous packing machine with gas antistaling function for the cake food box is composed of machine frame, pressure-variable sealing-cutting unit, conveyer, heating-sealing unit, cutting unit, vacuumizing-inflating unit, film winding unit, and controller. Said heating-sealing unit has upper and lower sealing dies.

Owner:苏明智

Mechanization production line of cement sand wich light wall board

InactiveCN100999104AIncrease productivityProduct quality is stableCeramic shaping plantsPress rollersManipulatorEngineering

The present invention provides a mechanization production line of cement sandwich light partition wall panel. Said production line includes mould box continuous operation equipment and successively-arranged manipulator for laying base net, pouring machine for pouring base layer slurry material, manipulator for laying core plate, pouring machine for pouring four-side and top layer slurry material, manipulator for screeding slurry, manipulator for laying upper-layer net, press roll for press-finishing slurry, manipulator for demoulding and manipulator for conveying finished product.

Owner:SHANDONG UNIV

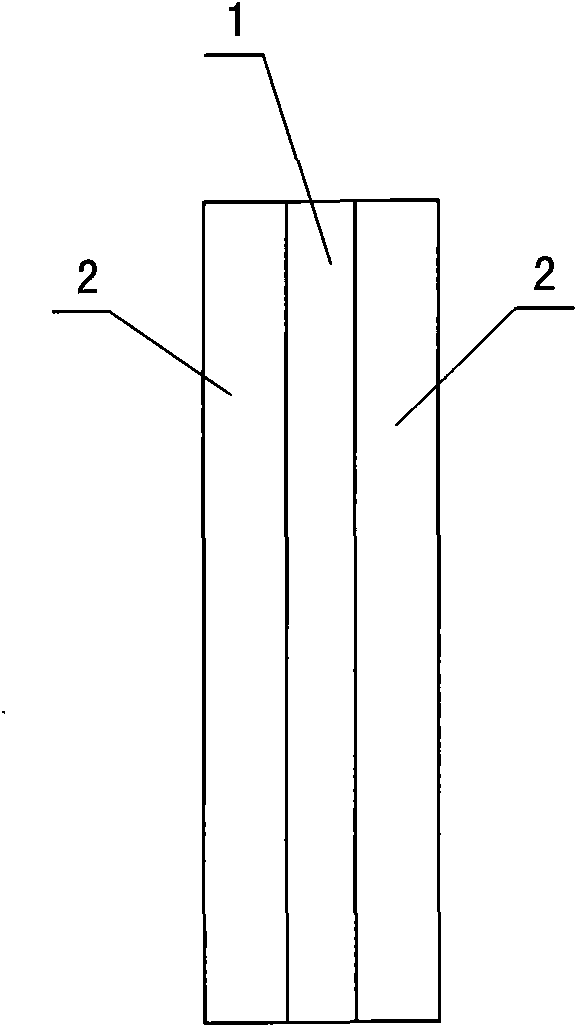

Method for manufacturing precise metal strip resistor

InactiveCN101587766AOverall goodImprove processing efficiencyResistor trimmingResistors adapted for applying terminalsElectrical resistance and conductanceMetal strips

A method for manufacturing precise metal strip resistor comprises: selecting an alloy strip and two metal strips; cleaning them; welding the two metal strips respectively on two sides of the alloy strip by high energy electron beam welding technique to form an integral resistor strip; punching the resistor strip transversely into a plurality of resistor bodies, or punching the alloy thin plate into a plurality of resistor bodies; then adjusting the numerical resistance values of the resistor bodies; and performing subsequent improvement processing to the resistor bodies to form precise metal strip resistor. Compared with the current technologies, The method provided in the invention reduces more than half of the production processes, increases the efficiency by tem times; reduces the product volume greatly, and realizes the production of surface applied precise splitter with low resistance, small volume and heavy bearable current. The resistor manufactured by the method provided in the invention has the characteristics of good performance, small volume and low material consumption.

Owner:BDS ELECTRONICS +1

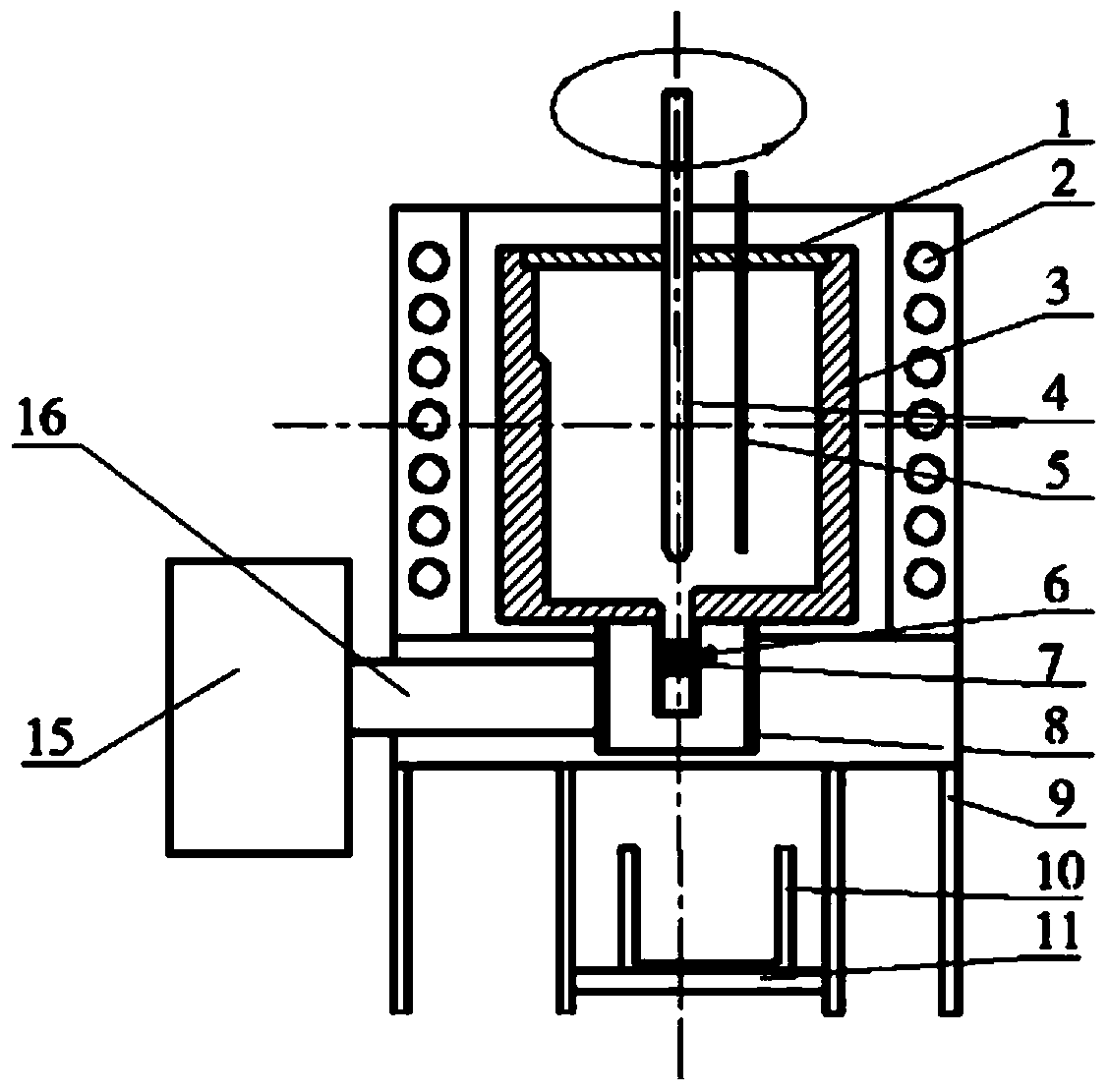

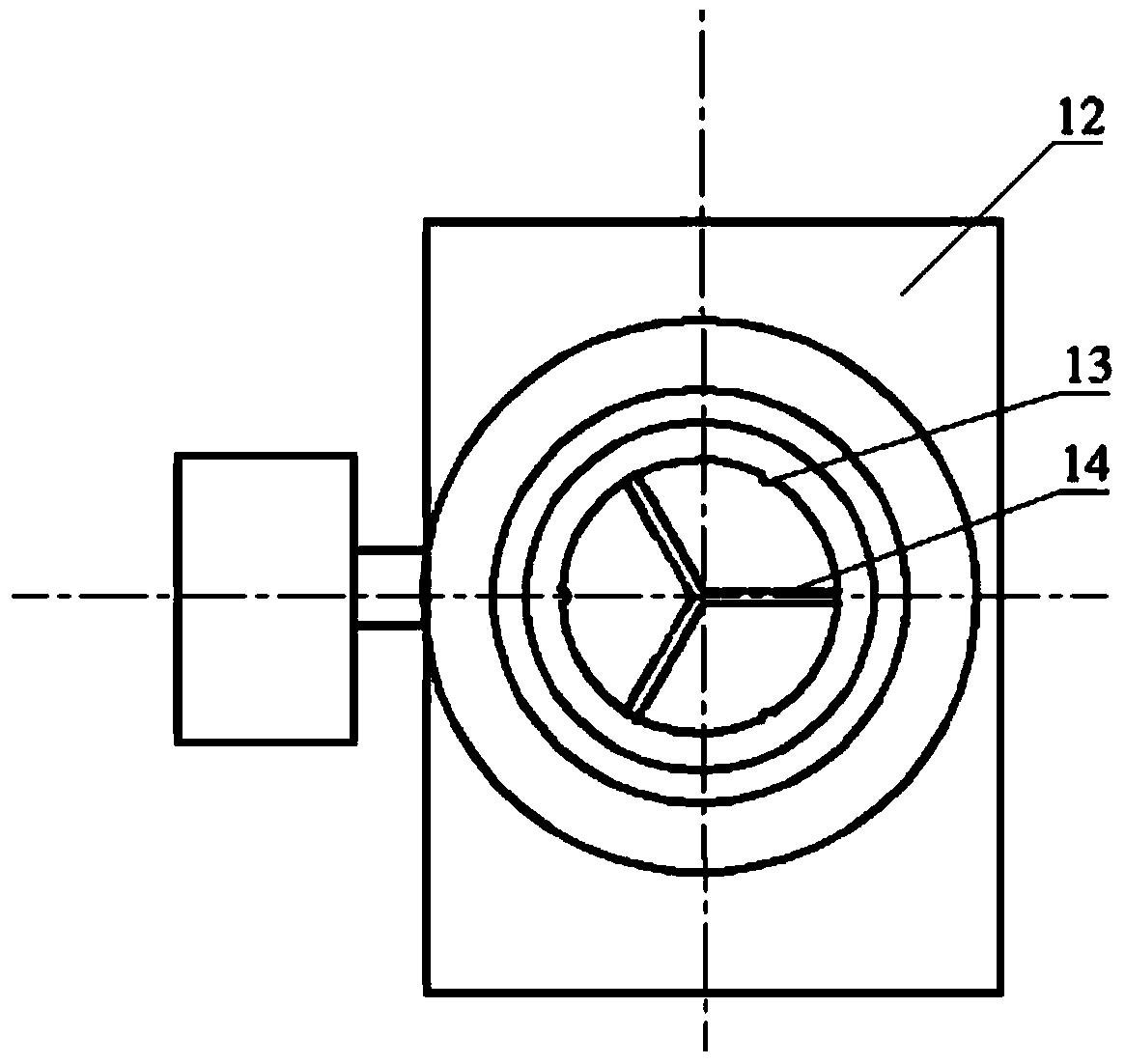

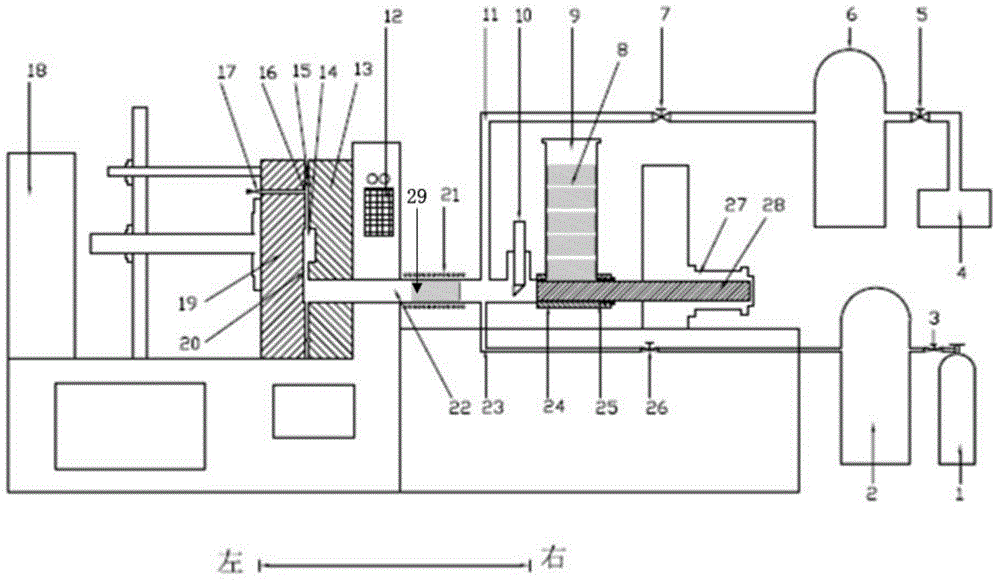

Amorphous alloy member cast forming device and process

ActiveCN104668503ASimple structureReduce usageElectric heating for furnacesGas cylinderManufactured material

Provided is a device for casting forming of amorphous alloy components. The device comprises an injection system, an alloy smelting system, a raw material feeding system, a mould system, a vacuum system and a protective atmosphere system. The vacuum system comprises a vacuum tank (6). The protective atmosphere system comprises a gas cylinder (1) for a protective atmosphere. The vacuum tank or the gas cylinder for a protective atmosphere is provided to effectively realize the acquisition of a vacuum or a protective atmosphere with a positive pressure in the forming process so as to achieve the casting forming of the amorphous alloy components under the protection of the vacuum and the protective atmosphere with a positive pressure. The mould is provided with an exhaust port to prevent the formation of micro shrinkage cavities on the surface in the process of forming the alloy components. Also provided is a process for the casting forming of the amorphous alloy components. The device and process substantially reduce the space of the vacuum or the protective atmosphere with a positive pressure, and can improve the quality of the amorphous alloy components, save on cost and improve the production efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

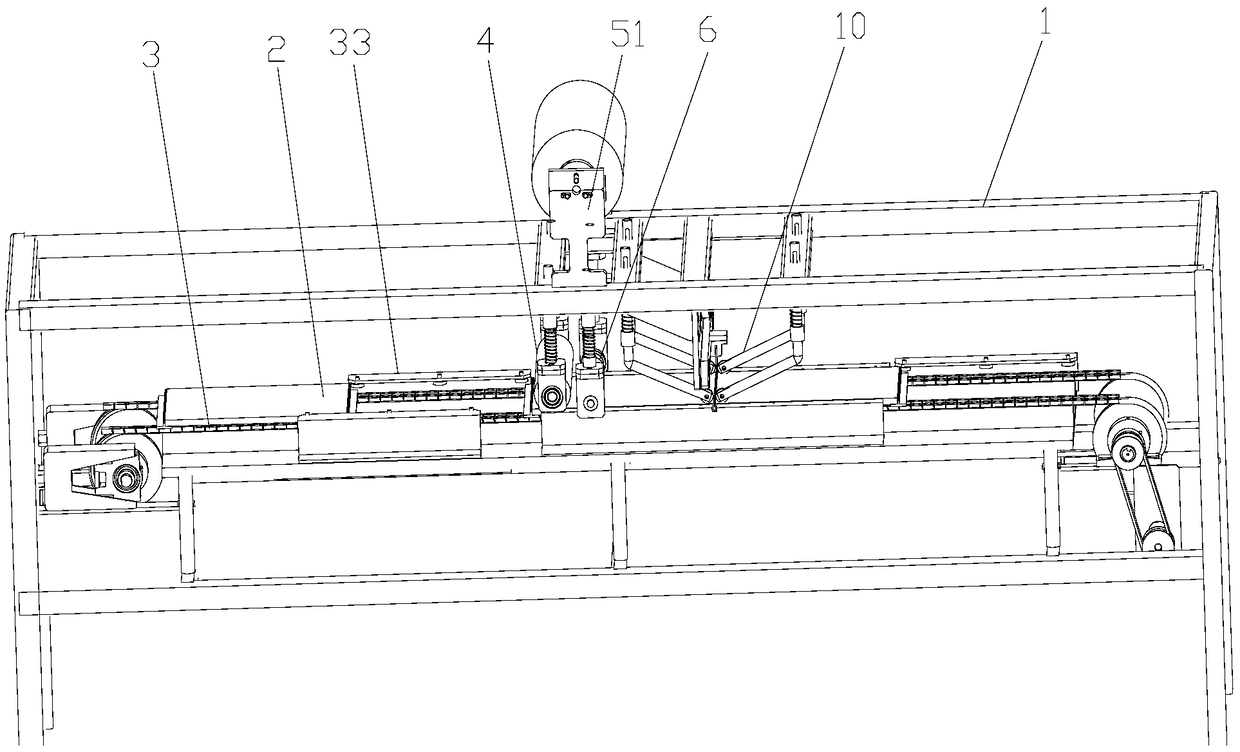

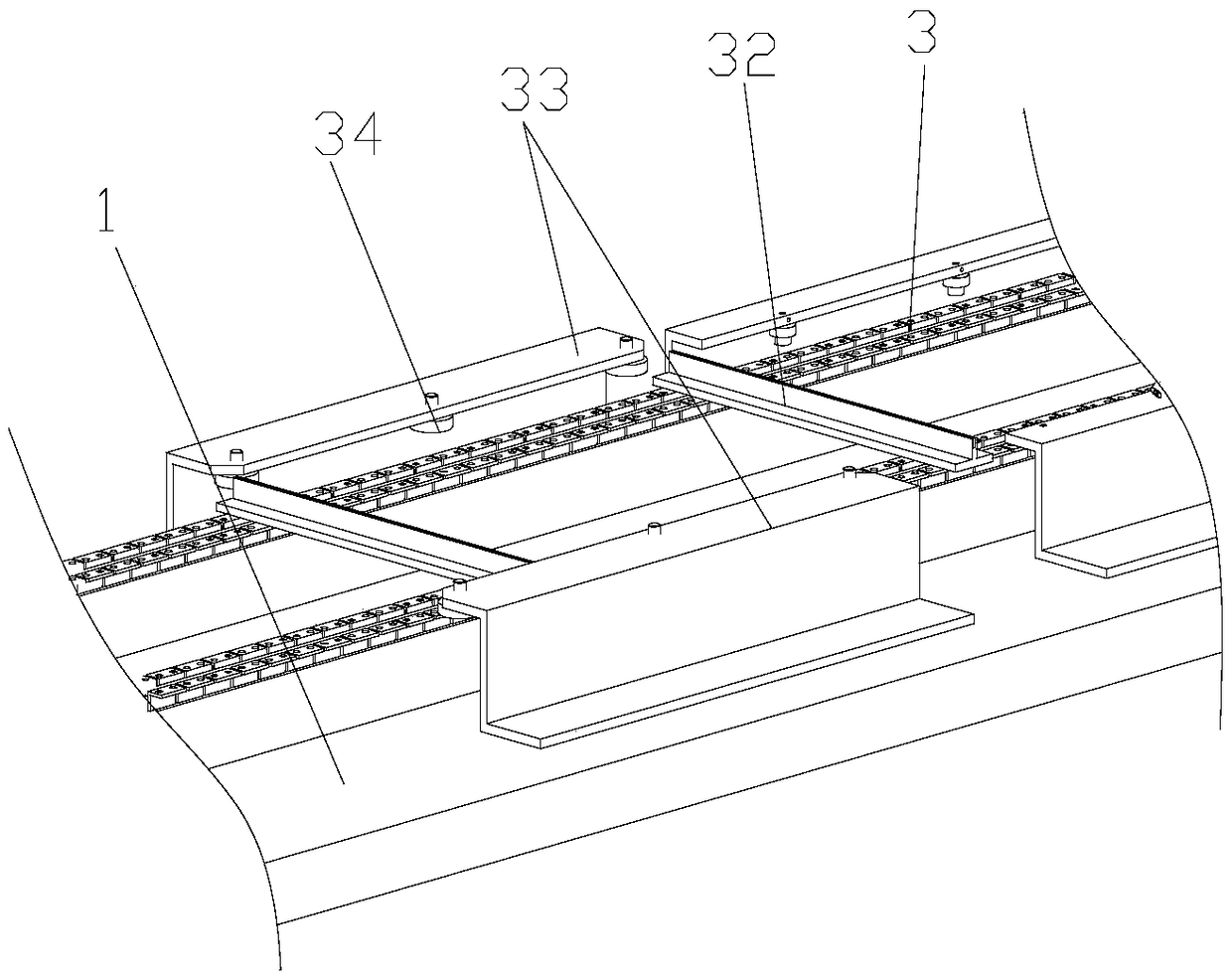

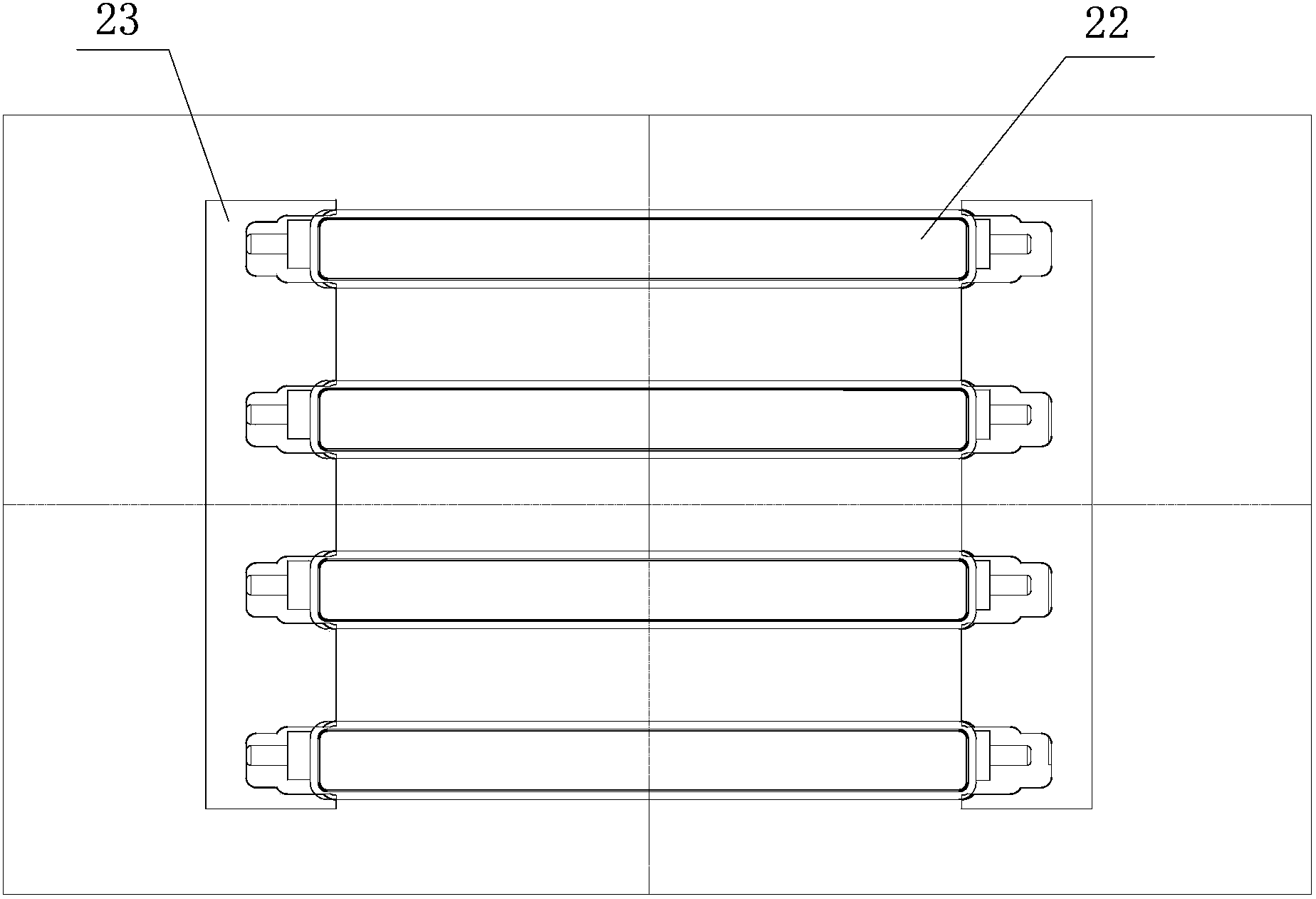

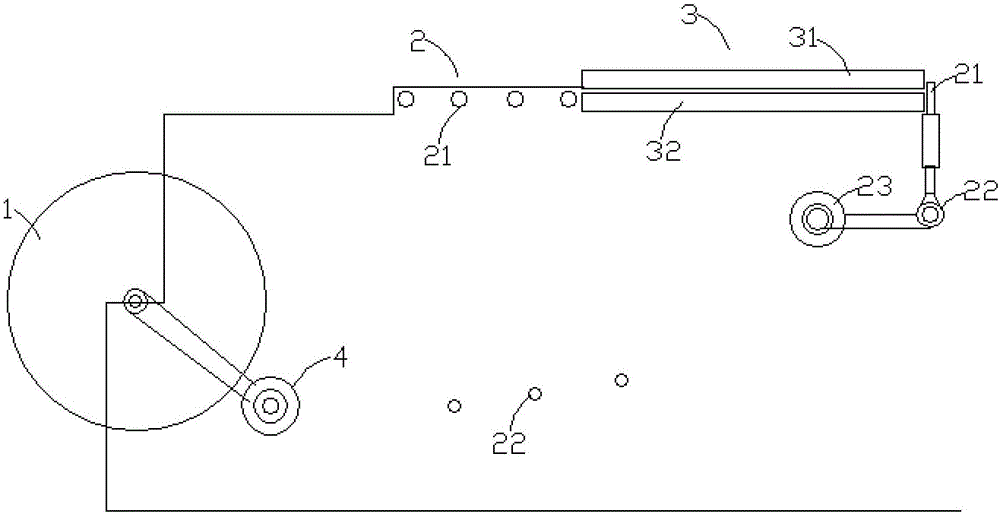

Automatic film covering equipment for plates

PendingCN108688290AAvoid damageQuality improvementLamination ancillary operationsLaminationCircular discEngineering

The invention relates to the technical field of film covering machines, in particular to automatic film covering equipment for plates. The automatic film covering equipment for the plates comprises arack, a conveying mechanism and a film covering mechanism, wherein the conveying mechanism conveys the plates on the rack and comprises a conveying belt and conveying rolls; the conveying belt is wound on the conveying rolls; a positioning baffle for positioning the front-back directions of the plates is arranged on the conveying belt; a guiding plate for limiting the left-right position of the plates is arranged on the rack; the film covering mechanism comprises a pressing and covering roll and a film supply assembly on the upper portion of the pressing and covering roll; the pressing and covering roll is movably connected with the rack; a pressure adjusting mechanism for adjusting downward pressure of the pressing and covering roll is arranged on the rack; a shaping roll is arranged on the rear side of the pressing and covering roll; disc hobs for cutting residual thin films are arranged on the shaping roll and correspond to the left sides and the right sides of the plates; side surface pressing rolls which press and cover the guiding plate are arranged at the position, which corresponds to the guiding plate, of the shaping roll; and a cutting assembly is arranged on the rear side of the shaping roll. Continuous film covering production of blocky plates is realized, after film covering, residual films are cut off and shaped immediately, the film covering quality is improved,and the production efficiency is high.

Owner:CHANGZHOU INST OF LIGHT IND TECH

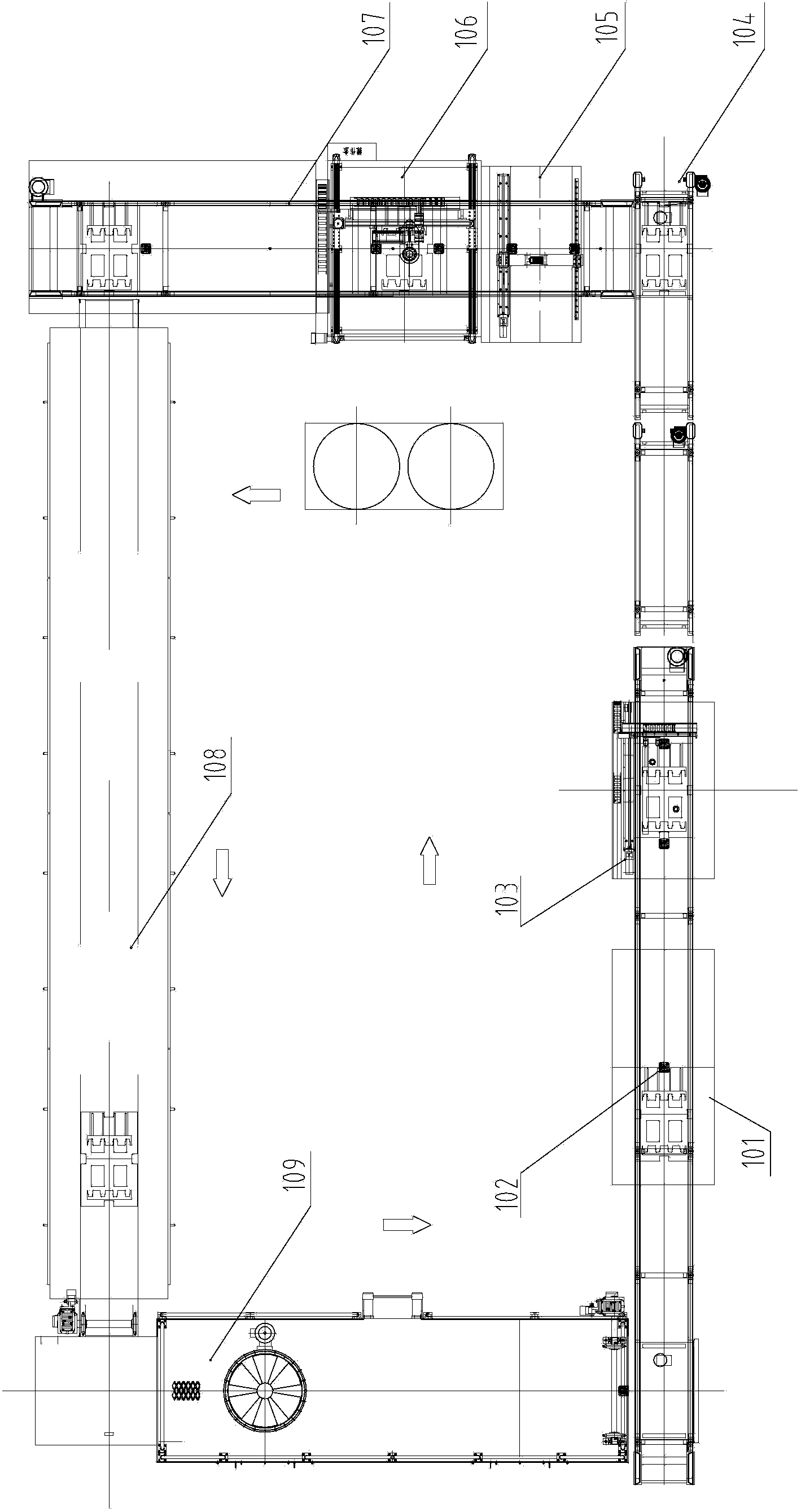

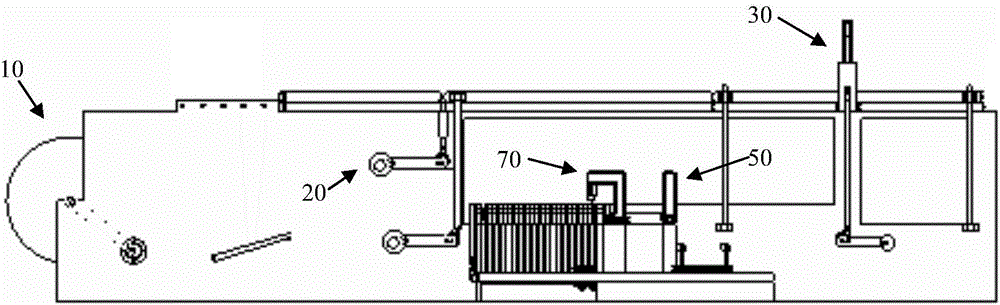

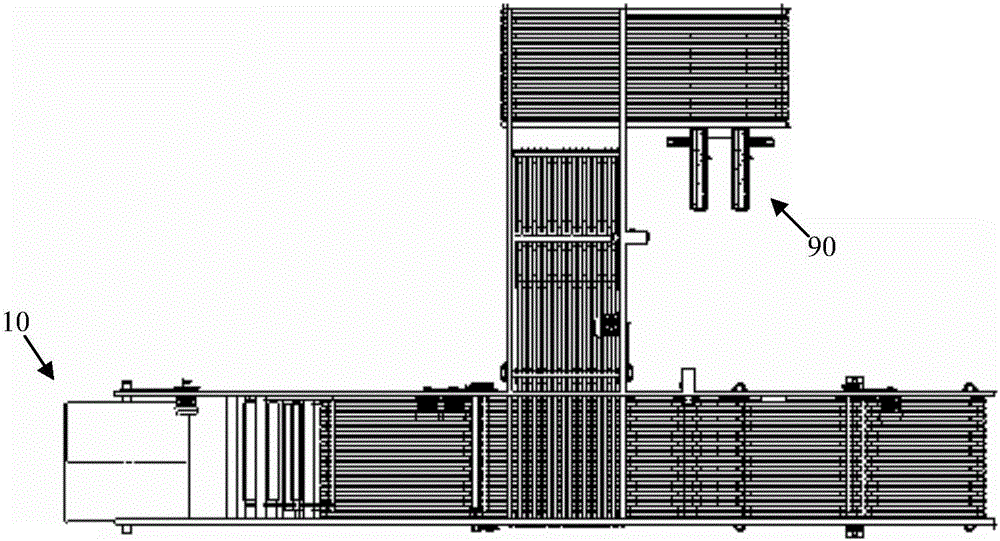

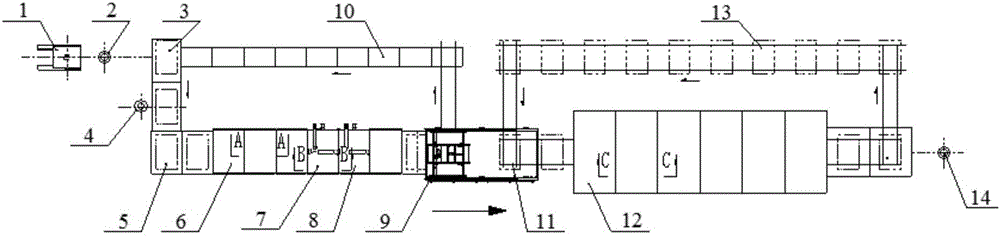

Car air-conditioning automatic gluing production line

InactiveCN103878094ARealize continuous automatic productionGuaranteed pass rateLiquid surface applicatorsCoatingsProduction lineEngineering

The invention belongs to the technical field of car air-conditioning gluing, and specifically relates to a car air-conditioning automatic gluing production line. The production line comprises a loading and unloading station, a workpiece detection unit, a plasma surface processing unit, a visual unit, a gluing unit, a drying unit, a cooling unit and a transmission mechanism. The loading and unloading station places a workpiece on a workpiece tray, then the workpiece tray is transported to the workpiece detection unit by the transmission mechanism through a conveying belt, the workpiece detection unit detects the placement stability of the workpiece, after the detection the workpiece is transported to the plasma surface processing unit, the plasma surface processing unit carries out surface processing on the workpiece, after the surface processing the workpiece is orderly transported to the visual unit and the gluing unit, the gluing unit carries out gluing on the workpiece, after the gluing process the workpiece is orderly transported to the drying unit and the cooling unit, and finally the workpiece is unloaded from the loading and unloading station. The production line can achieve the continuous automatic production of glued workpiece, and the production efficiency is improved on the basis that the production qualification rate is guaranteed.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

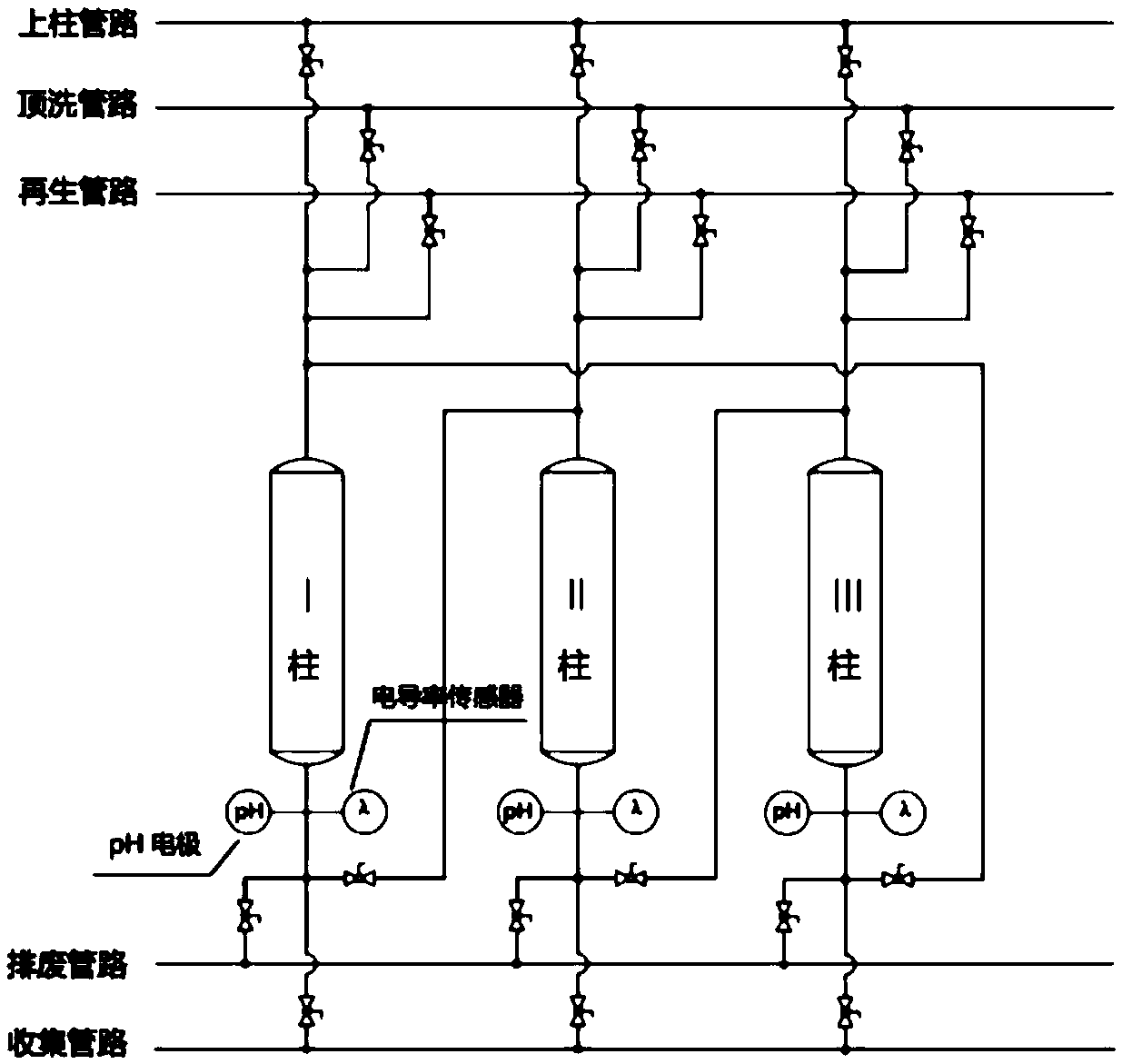

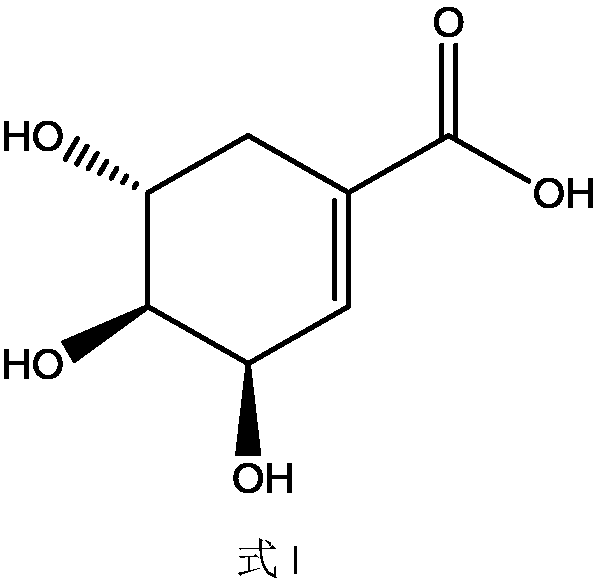

Process for efficiently purifying shikimic acid by utilizing continuous ion exchange technology

ActiveCN109721487AIncrease profitReduce usageCarboxylic compound separation/purificationShikimic acidIon exchange

The invention discloses a process for efficiently purifying shikimic acid by utilizing a continuous ion exchange technology, and the process comprises: carrying out solid-liquid separation to obtain afermentation filtrate, and carrying out pre-purification on the fermentation filtrate by virtue of cation exchange resin to obtain a pre-purified liquid a; and pre-purifying the pre-purified liquid athrough a continuous ion exchange system to obtain a pre-purified liquid b; and finally, carrying out fine purification and spray drying on the pre-purified liquid b to obtain the shikimic acid. Theprocess has the advantages that the process is simple and stable, continuous and automatic production can be realized, the chromatographic purity and the content of the prepared shikimic acid finishedproduct are both higher than 99%, the utilization rate of the resin is greatly improved, the total usage amount of the resin is reduced by about 80%, an eluent is not used in the pre-purification process, wastewater is greatly reduced, the production cost is greatly reduced, the market competitiveness of the product is enhanced, and the process is suitable for large-scale industrial production.

Owner:ZHEJIANG HISUN PHARMA CO LTD

Automatic discharging mechanism

InactiveCN108177926ARealize continuous automatic productionReduce manual operationsConveyorsConveyor partsProduction lineOsmunda cinnamomea

The invention belongs to the technical field of osmunda cinnamomea processing and particularly relates to an osmunda cinnamomeablanching production line with an automatic discharging mechanism and anosmunda cinnamomea processing system. The automatic discharging mechanism comprises a suspension type conveying chain and a screen suspended at the lower end of the suspension type conveying chain. The screen is provided with a hook, and an automatic unhooking mechanism is arranged between the hook and the suspension type conveying chain. Automatic discharging of the screen is achieved through cooperation of the automatic unhooking mechanism and a wedge block, manual operation is omitted, the production efficiency is improved, the cost is reduced, and continuous and automatic production of anosmunda cinnamomea blanching process is achieved.

Owner:王传财

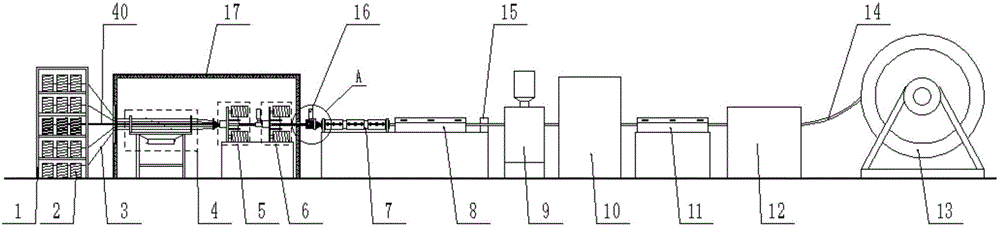

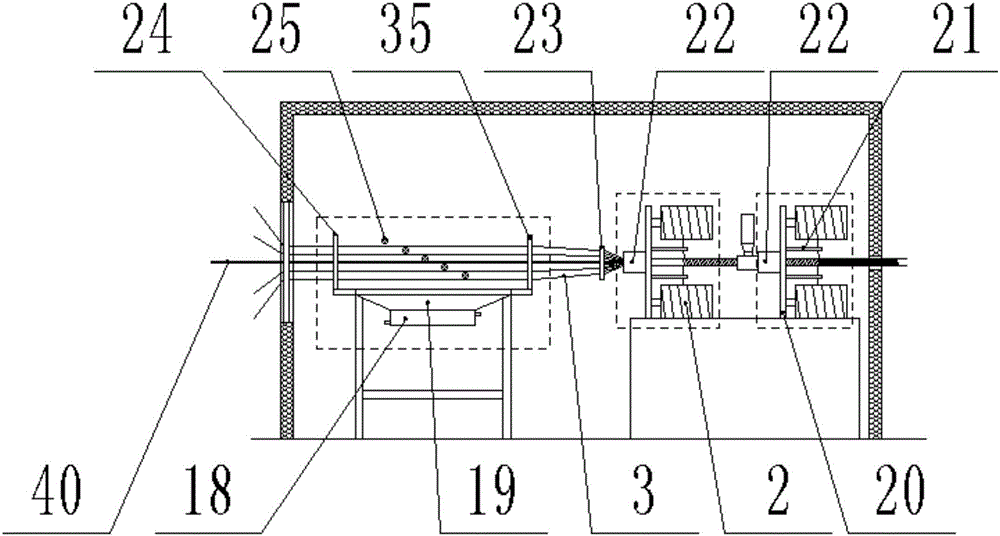

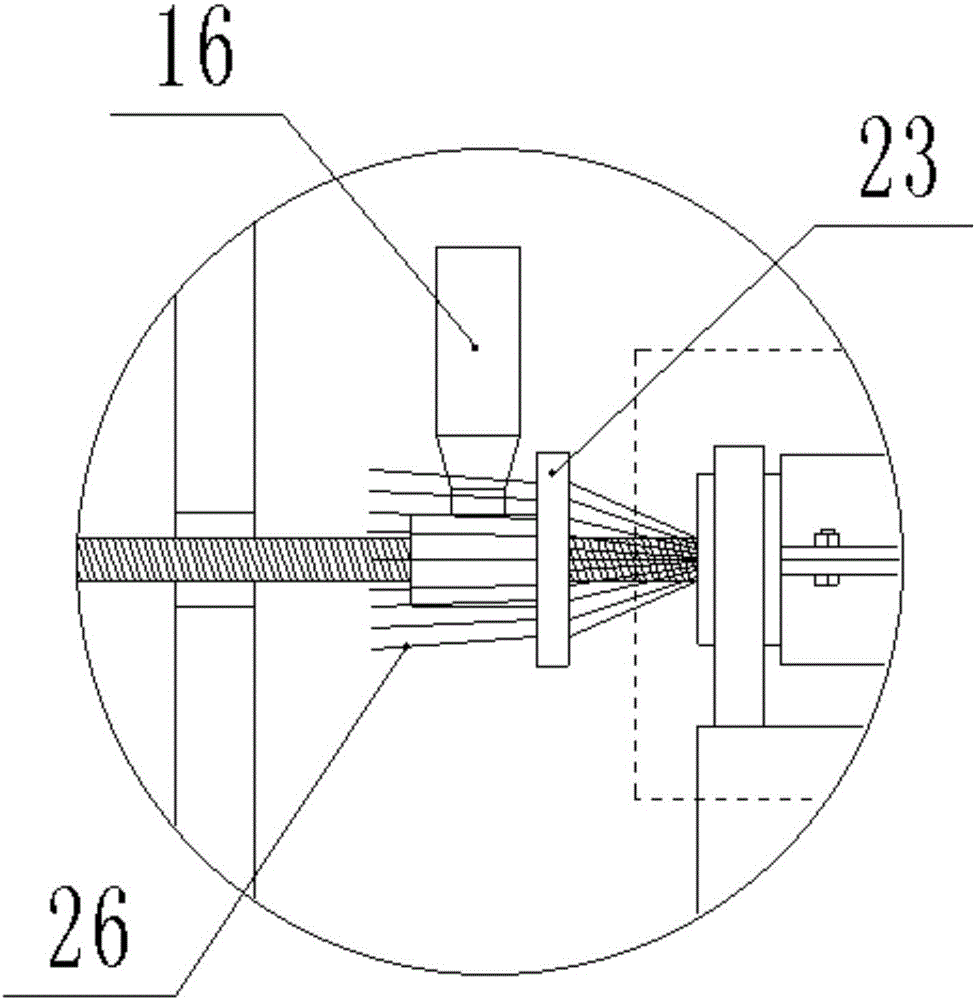

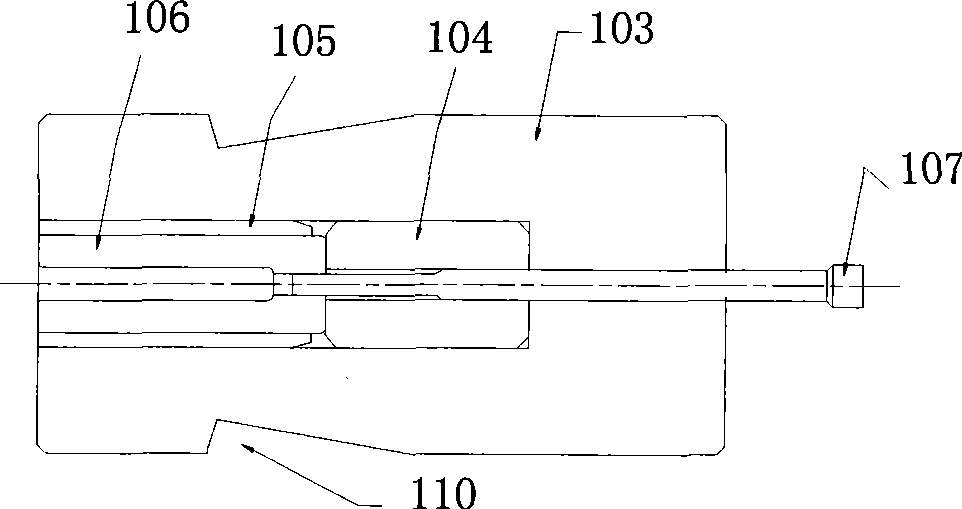

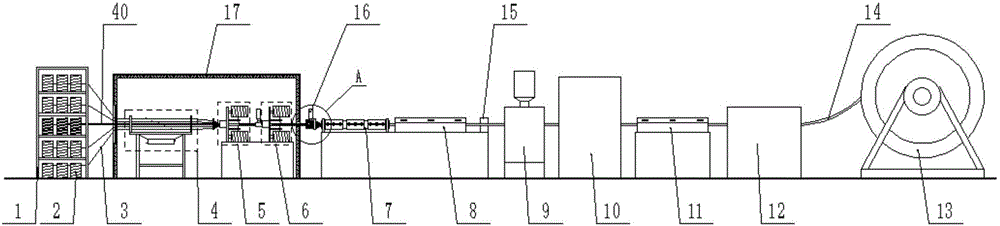

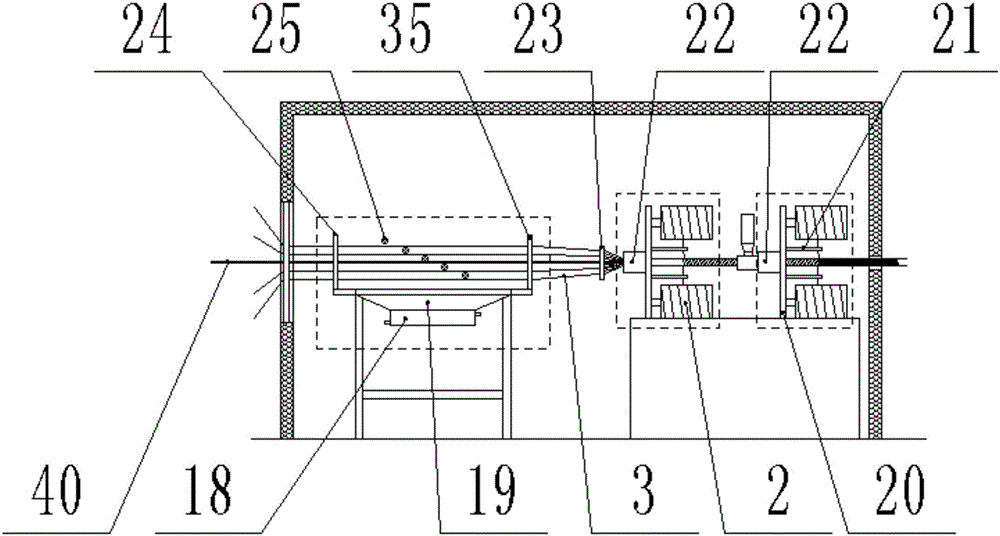

Constant-temperature heat tracing carbon fiber continuous sucker rod, and preparation device and preparation method thereof

InactiveCN106761444APrevent waxingReduce weightDrilling rodsDrilling casingsElectric heatingParaffin oils

The invention belongs to the field of oil extraction equipment in oil fields, and in particular relates to a constant-temperature heat tracing carbon fiber continuous sucker rod, and a preparation device and a preparation method thereof. The sucker rod comprises a carbon fiber core, a glass fiber layer coating the outer side of the carbon fiber core, and an epoxy resin layer coating the outer side of the glass fiber layer, wherein an electric heating strip A is arranged at the center of the carbon fiber core, the carbon fiber core is formed by carbon fiber bundles adhered by resin, the glass fiber layer is composed of a glass fiber winding layer and a longitudinal glass fiber layer, the glass fiber winding layer is wound on the outer side of the carbon fiber core, and glass fibers and carbon fibers forming the longitudinal glass fiber layer are arranged in parallel. The sucker rod provided by the invention is simple in technology and reasonable in layout; according to the preparation method provided by the invention, the multi-layer friction-resistant continuous sucker rod with a constant-temperature heating function and being capable of preventing paraffin precipitation can be produced, and the produced sucker rod has the multiple advantages of light weight, friction resistance, and high torsional strength, shearing strength and tensile strength.

Owner:大庆市华禹石油机械制造有限公司

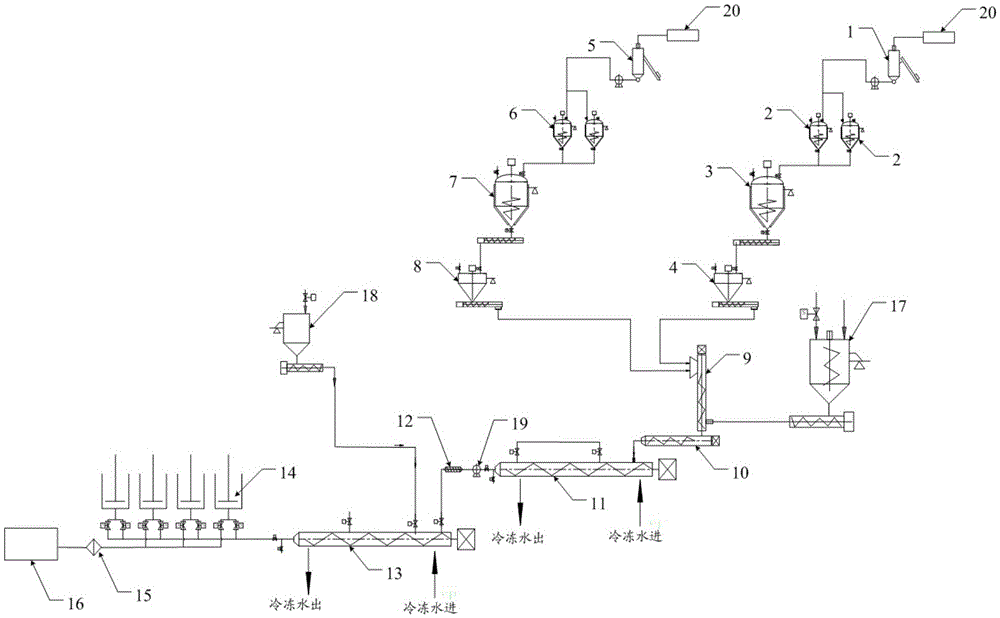

Continuous and automatic production line of polyurethane adhesive and production method thereof

ActiveCN105647455ARealize continuous automatic productionPrevent crustingNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesProduction linePolyurethane adhesive

The embodiment of the invention discloses a continuous and automatic production line of a polyurethane adhesive and aims to solve the problem that since the materials are in contact with air, crust is generated and influence is caused on the product quality in the intermittent production process of the existing polyurethane adhesive. The continuous and automatic production line of the polyurethane adhesive comprises a calcium powder bale breaker, a calcium powder drying tank, a calcium powder cooling storehouse and a calcium powder measuring tank which are successively connected with one another via a pipeline; a carbon black powder bale breaker, a carbon black powder drying tank, a carbon black powder cooling storehouse and a carbon black powder measuring tank are successively connected with one another via the pipeline; a side feeder, a pre-mixing screw machine, a first-stage screw machine, a high-viscosity material cooler, a second-stage screw machine, a material pressing machine, a filter and a split charging device are connected with one another via the pipeline; the outlets of a prepolymer measuring tank, the calcium powder measuring tank and the carbon black powder measuring tank are communicated with the inlet of the side feeder via the pipeline; the outlet of a catalyst measuring tank is communicated with the inlet of the second-stage screw machine via the pipeline.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

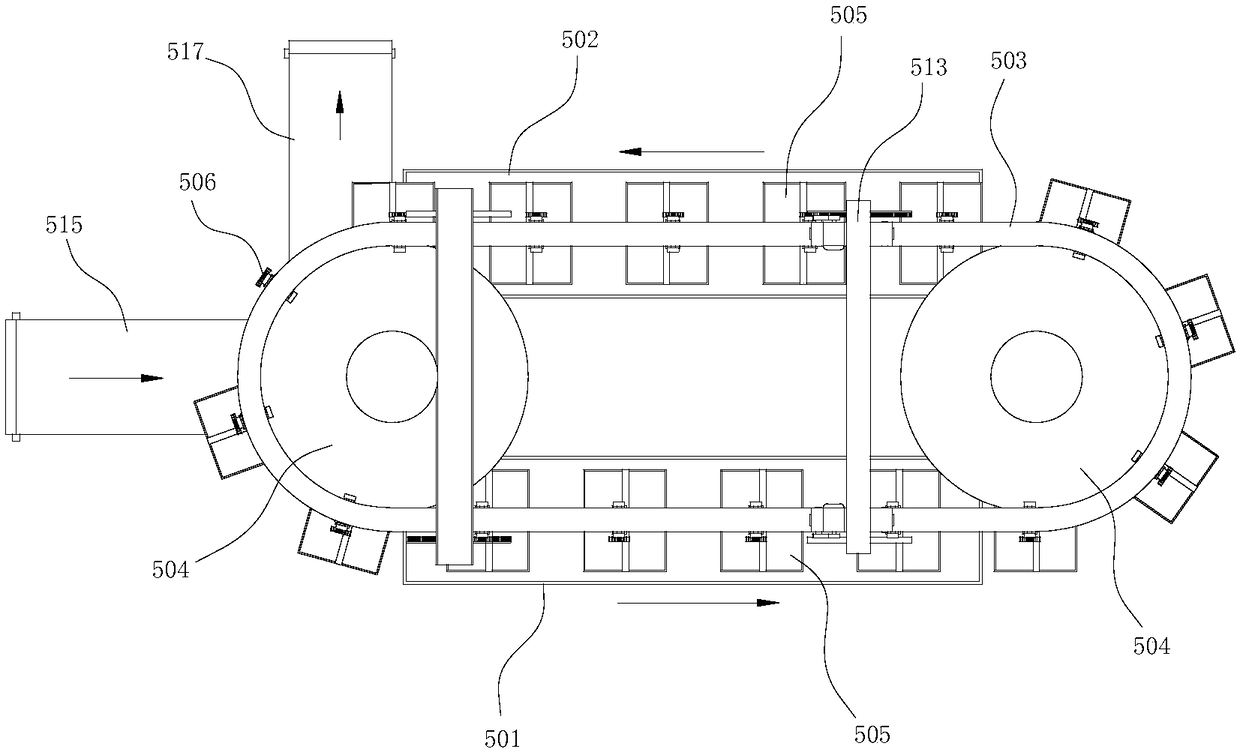

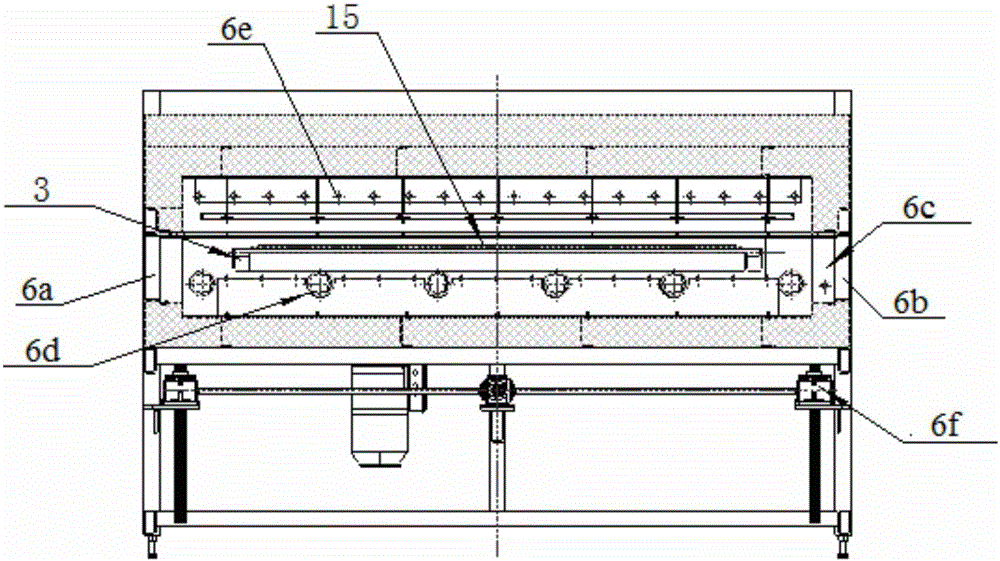

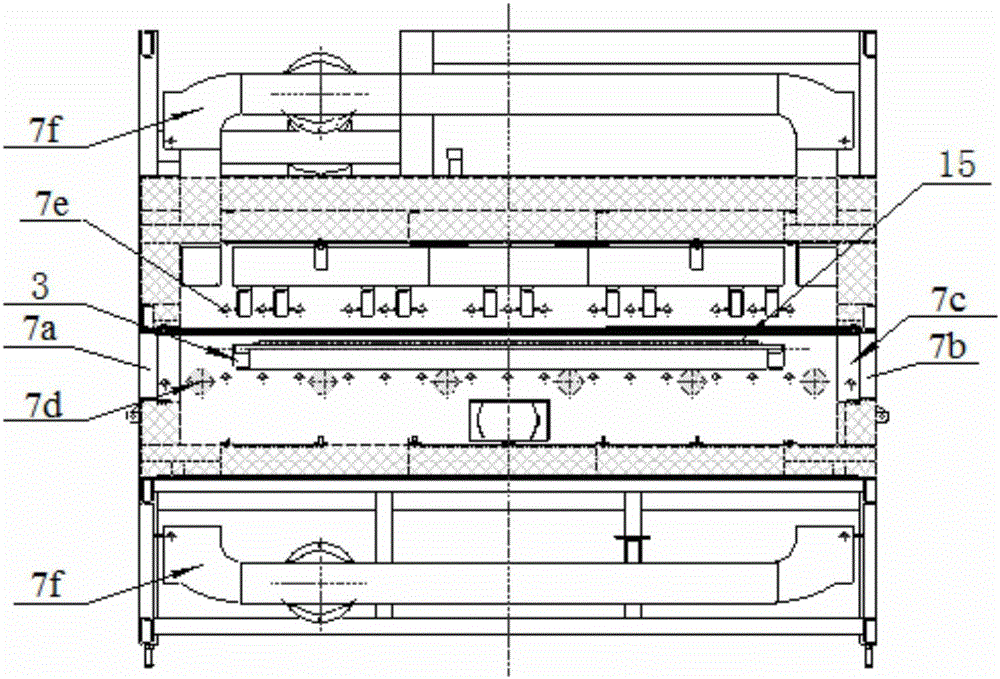

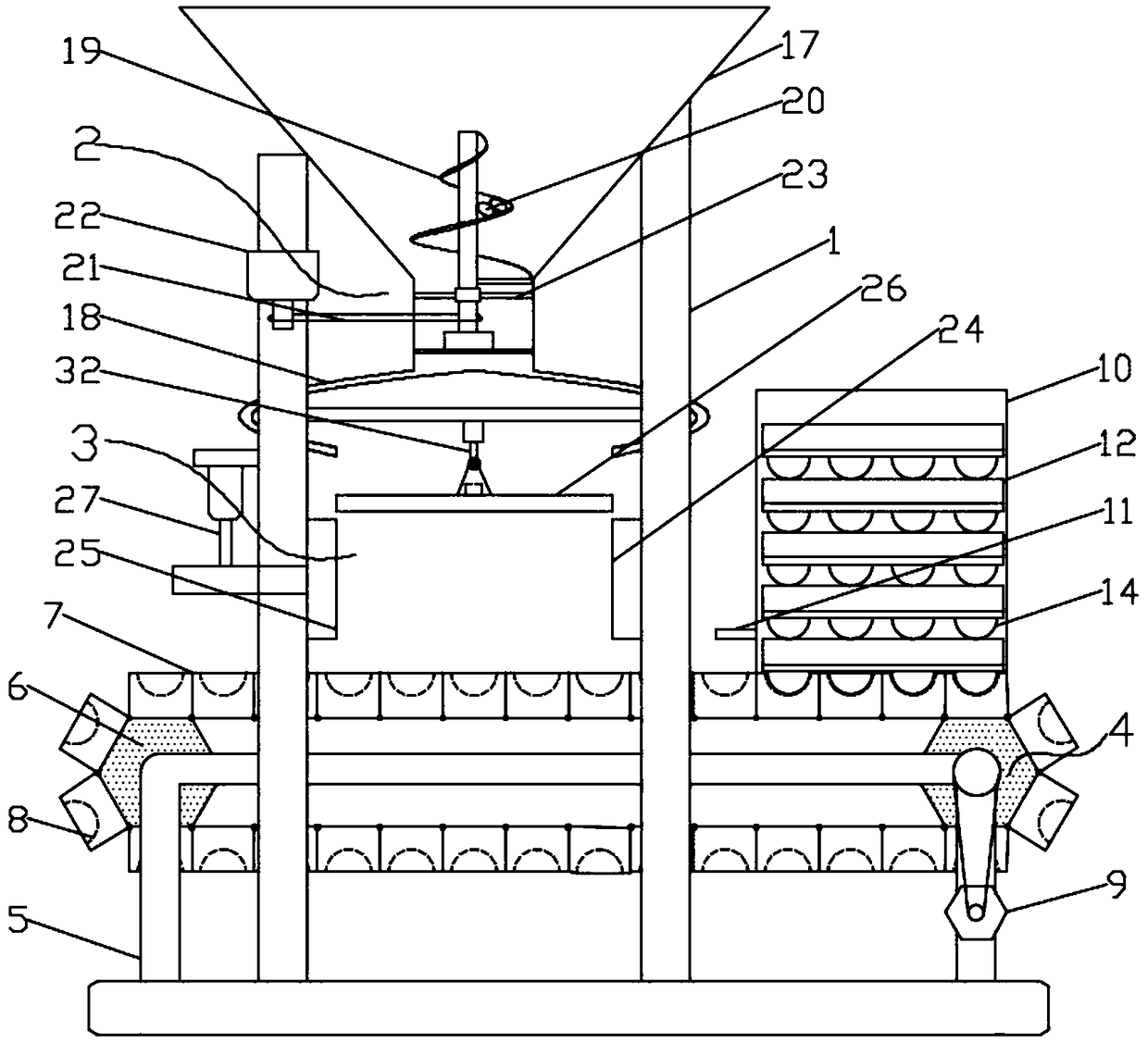

Thin-layer self-control static solid fermentation integrated optimizing method and device thereof

InactiveCN103966084ALarge capacityIncrease the areaBioreactor/fermenter combinationsBiological substance pretreatmentsAutomatic controlAir volume

The invention relates to a thin-layer self-control static solid fermentation integrated optimizing method and a device thereof. To solve the problems existing in the prior art, the method comprises the following steps: paving solid fermentation materials, which have been sterilized and inoculated, on a multi-layer movable slat fermentation bed in a sterile fermentation room to form a thin layer at a time, automatically controlling the sterile air volume, temperature and humidity to carry out solid fermentation according to the different fermentation phases, starting the driving device of the multi-layer movable slat fermentation bed to move the materials out of the fermentation room after the fermentation of the solid materials is finished, and finally carrying out a product post-treatment. The device comprises a sterile air adjusting system, a movable bacterium sterilizing and inoculating tank, a spiral paving machine, a multi-layer movable slat fermentation bed, and a sterile fermentation room. The method and device have the following advantages: (1) the hyphae of zymocyte are not easy to break, the growth of zymocyte is good, and the device is especially good for the enzyme-producing and enzymolysis solid fermentation; (2) the massive production bottleneck of thin-layer static solid fermentation is broken down, the industrial scale-production degree is high, the equipment investment is little, and the production efficiency is high.

Owner:徐少云

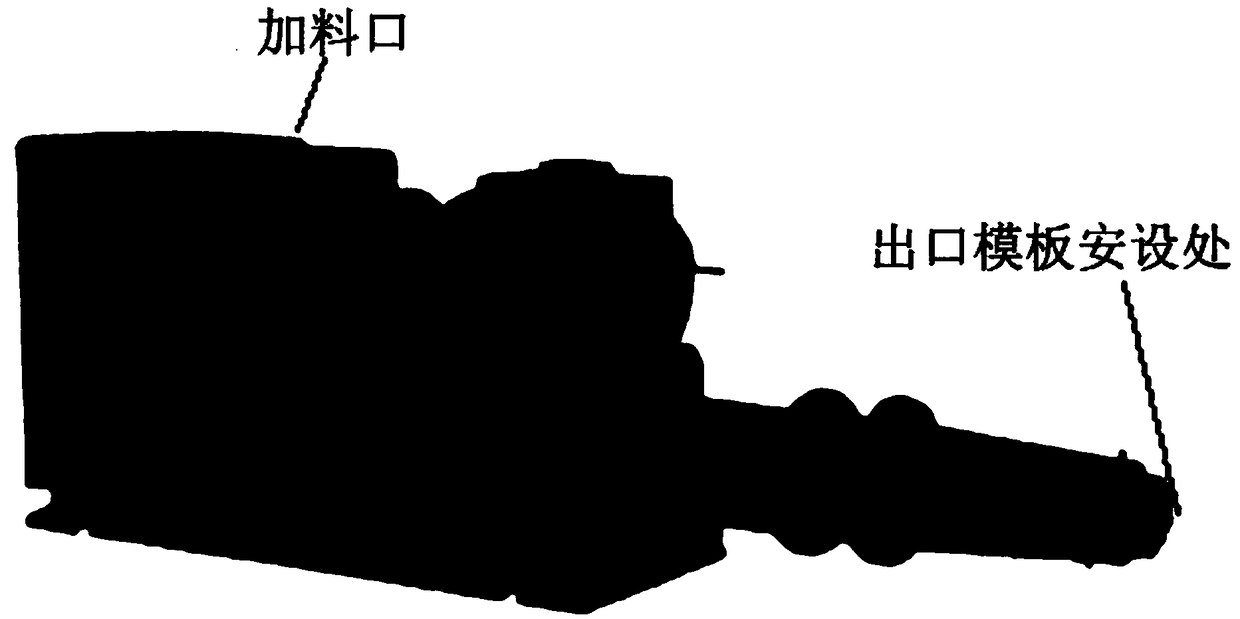

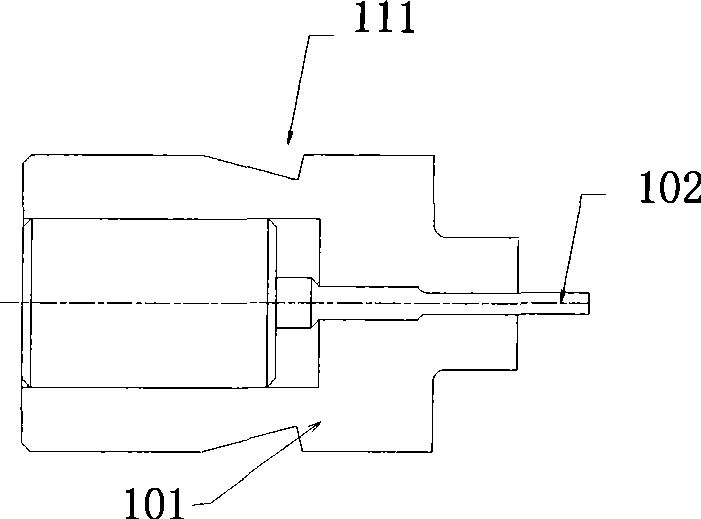

Manufacturing method of abrasion-resisting layer of screw machine barrel

ActiveCN107214320AThe performance is exactly the sameStrong combinationFurnace typesHeat treatment furnacesHeating furnaceHeating temperature

A manufacturing method of an abrasion-resisting layer of a screw machine barrel comprises the following steps that 1, abrasion-resisting powder is added into an inner cavity of the machine barrel (4), and openings of the two ends of the machine barrel (4) are sealed; 2, the machine barrel (4) is conveyed into a heating furnace with the temperature of 1000-1300 DEG C to be heated, and keeps rotating in the radial direction and moving back and forth in the axial direction while being heated in the heating furnace; 3, the machine barrel is subjected to centrifugation in a centrifugation part; and 4, the machine barrel (4) is conveyed to a heat preservation part after being subjected to centrifugation, tempering is conducted on the machine barrel, the machine barrel (4) is subjected to heat preservation in the heat preservation part of the machine barrel for 8-9 hours and then taken out from the heat preservation part, and then the machine barrel with the abrasion-resisting layer is prepared. The manufacturing method has the advantages that the defect that when a machine barrel is disposed in the heating furnace, the heating temperature of the two ends is low while the temperature of the middle is high is overcome, the abrasion-resisting powder disposed in the inner cavity of the machine barrel is heated evenly so as to be melted and oxidized at the same temperature, accordingly, molten liquid evenly covers the inner circumferential surface of the inner cavity of the machine barrel, and the abrasion-resisting layer is completely coincident in performance.

Owner:浙江华业塑料机械股份有限公司

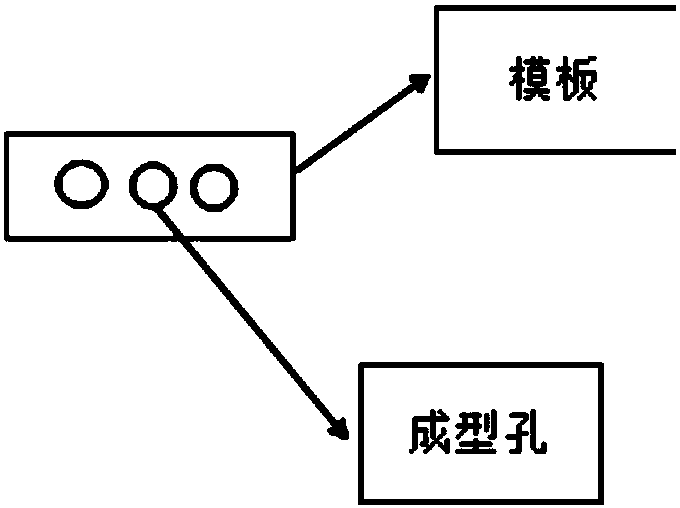

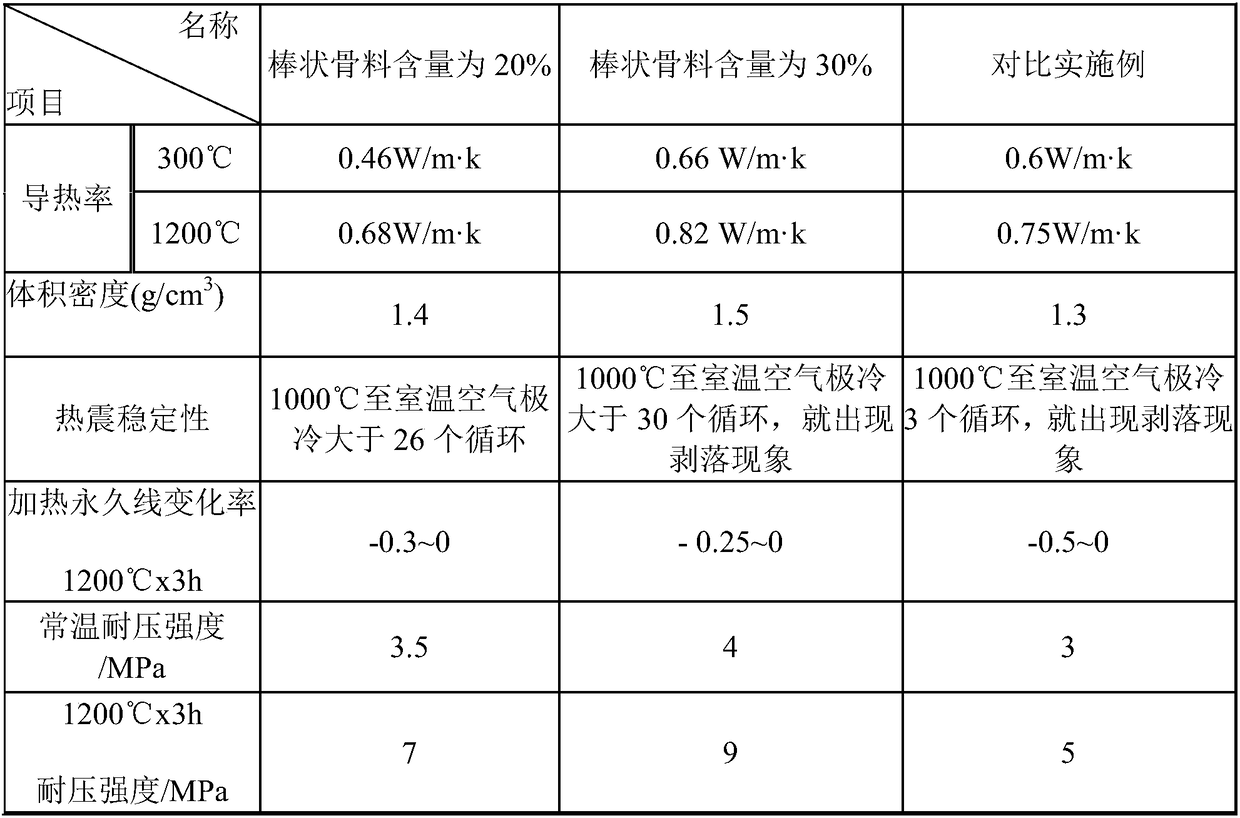

Light-weight casting material

ActiveCN108249934AReduce replacementRealize continuous automatic productionFloating microspheresThermal shock

The invention provides a light-weight casting material. The light-weight casting material is prepared by mixing raw materials including 10 to 50 percent of rod-shaped aggregate, 0 to 45 percent of light-weight aggregate, 4 to 10 percent of silicon ash with the granularity less than or equal to 0.2mu m, 17 to 30 percent of bauxite cement, 8 to 20 percent of floating microspheres, 5 to 10 percent ofclosed-pore pearlite, 0 to 10 percent of high alumina bauxite powder and a water reducing agent. According to the light-weight casting material provided by the invention, the small-size rod-shaped aggregate is uniformly dispersed so that the firing after-shrinkage of a product is reduced, the thermal shock resistance of the casting material is remarkably improved and the service life is greatly prolonged; different amounts of the light-weight aggregate which is continuously graded are added, so that the casting material has high strength and good flowability and casting materials with different thermal conductivity coefficients can be prepared, and furthermore, an application range of the casting material is expanded.

Owner:郑州市裕丰耐火材料有限公司

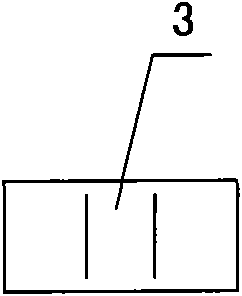

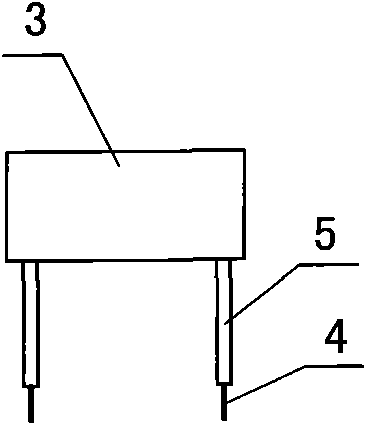

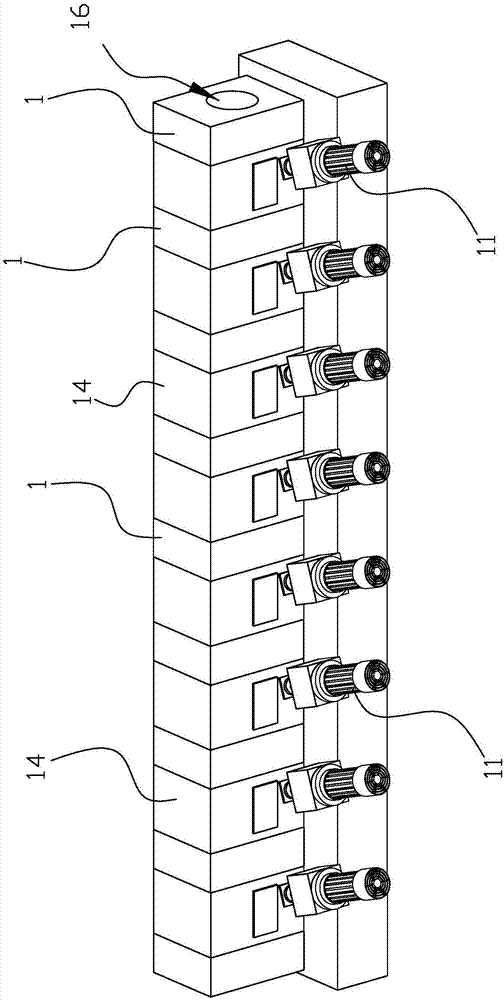

Relay flat iron core machining method and apparatus

ActiveCN101383249APrevent rotationEliminate glitch-prone defectsInductances/transformers/magnets manufactureRelaysPunchingMachining

The invention relates to a relay flat iron core processing method and a device thereof. The method comprises the steps: the relay flat iron core is cold-forged by three moulds and three strokes, a flat wire is cut into a proper length in a cutting fixing mould, and then the iron core is moulded in the three main moulds. The device comprises a fixing and cutting mould which is used for cutting the flat wire, the three main moulds, three punching moulds and a removing clamp with a U-shaped groove, wherein the three main moulds and the three punching moulds are used for cold-forging and moulding the flat wire. The relay flat iron core processing method and the device enable the flat wire to be moulded in a sealing mold cavity and eliminate the defect that the head of a square part is easy to generate fuzzy grains when being upset, and meanwhile, the automation continuous production can be realized.

Owner:SHENZHEN DONGYANGWANGHE IND CO LTD

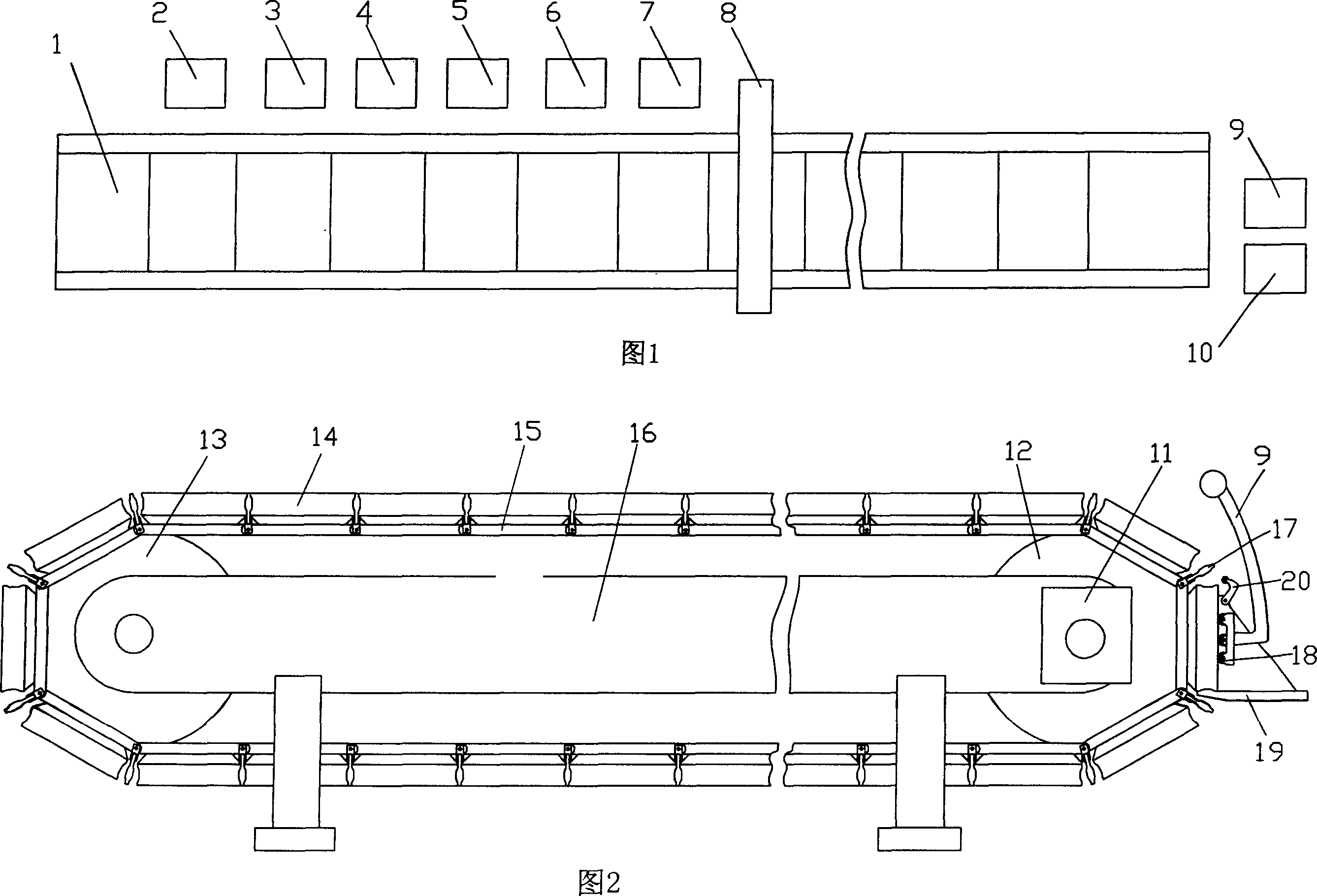

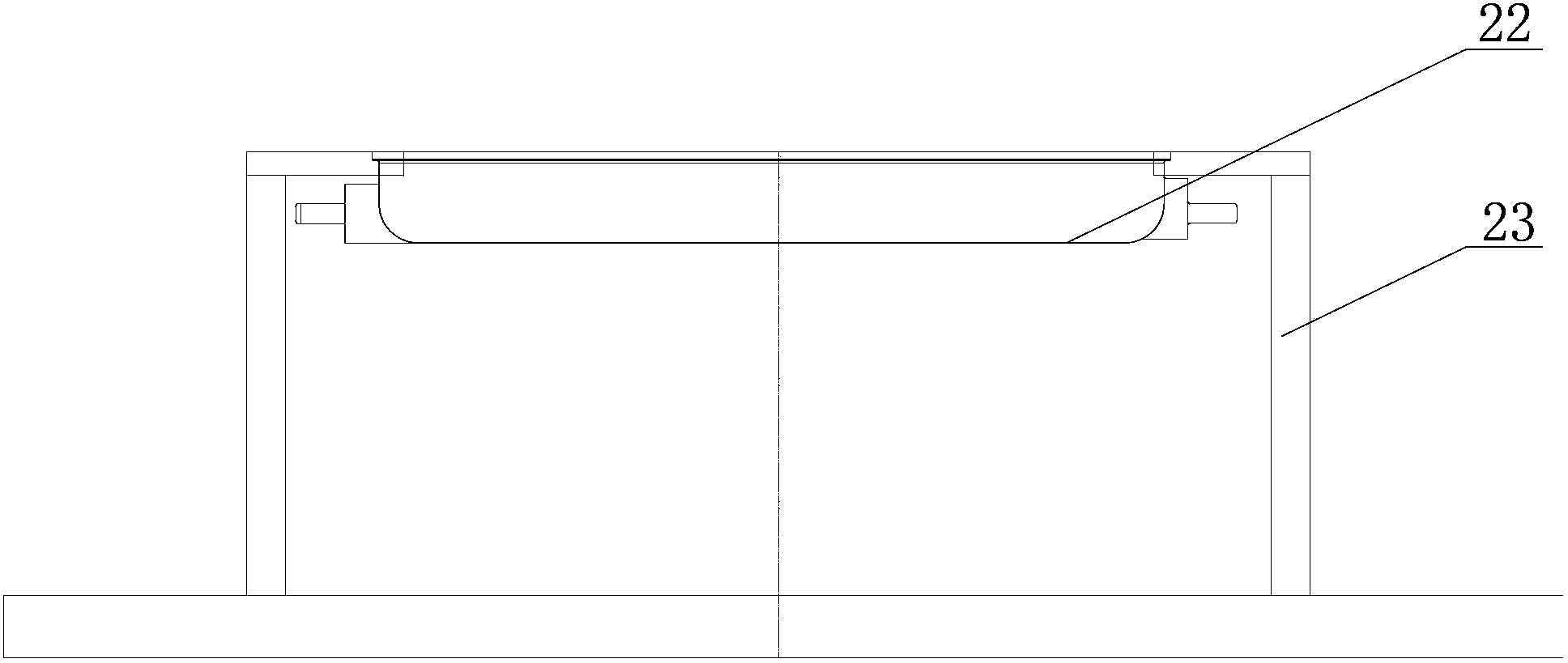

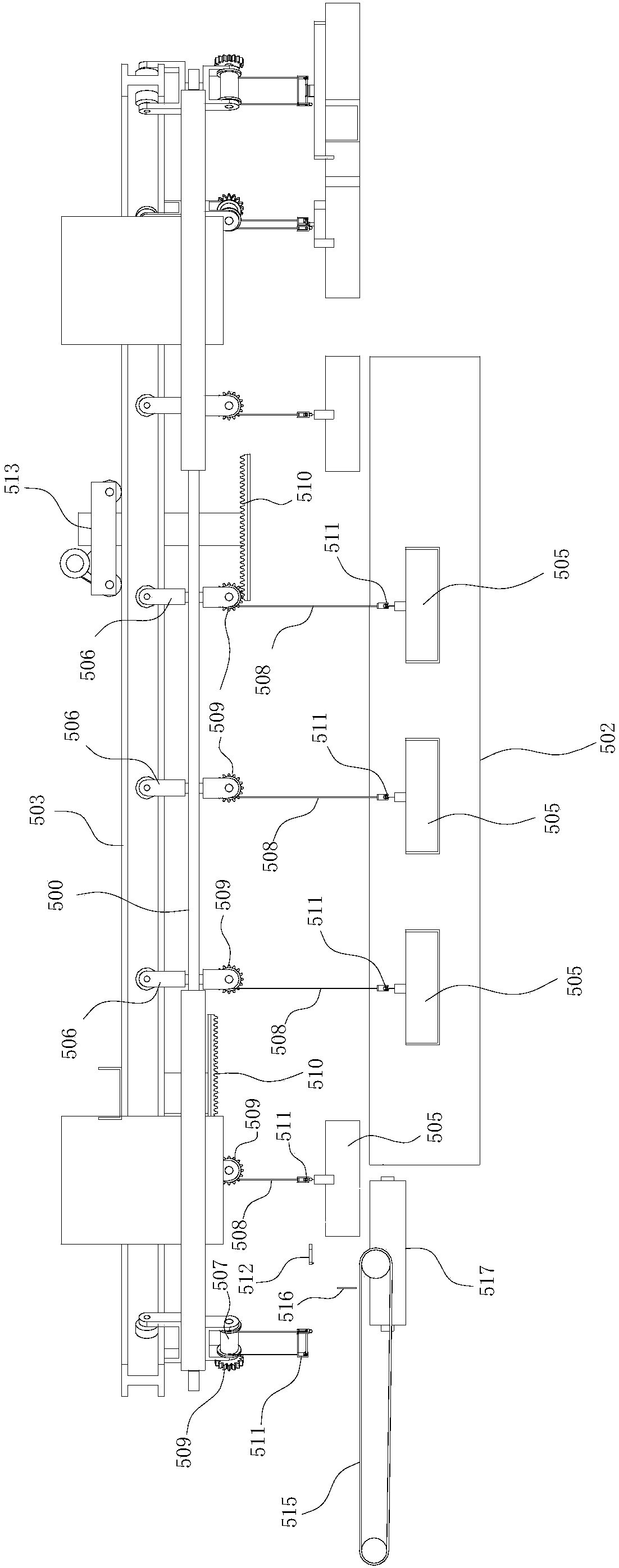

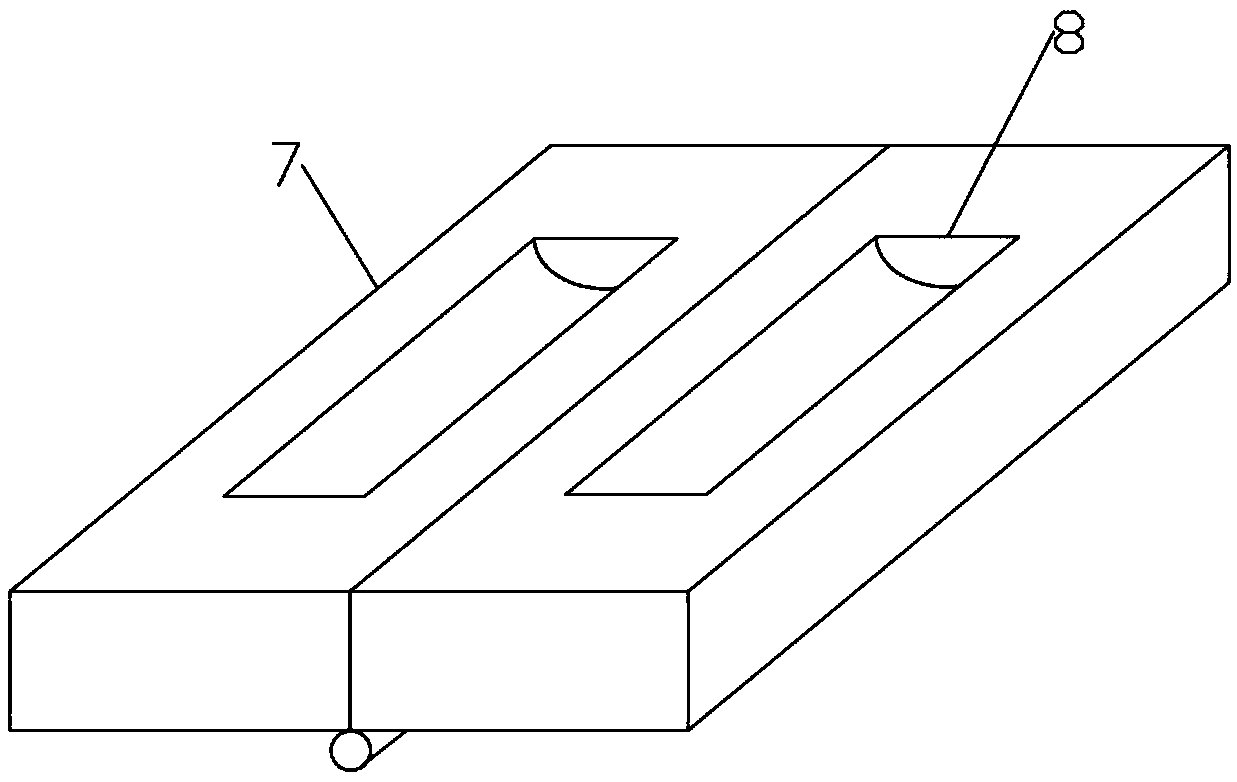

Full-automatic bean product pressing production line

ActiveCN101664133AAchieve recyclingIncrease profitCheese manufactureFood shapingProduction lineGear wheel

The invention provides a full-automatic bean product pressing production line, solving the problem that mass production cannot be realized owing to complex post processing production technique. The invention comprises a structure of arranging an annular upper extrusion screen band (7) between a driving roller (4) of the upper extrusion screen band and a driven roller (5) of the upper extrusion screen band, arranging an annular conveying and draining extrusion screen band (6) between a driving roller (2) of the conveying and draining extrusion screen band and a driven roller (3) of the conveying and draining extrusion screen band, penetrating a driving chain (10) sequentially though a driving gear which is fixedly arranged on the output shaft of a speed regulating driving motor (8), a driving gear which is arranged on the driving roller (2) of the conveying and draining extrusion screen band, and a driving sprocket which is arranged on the driving roller (4) of the upper extrusion screen band, and arranging the lower-half annular screen band of the upper extrusion screen band above the upper-half annular screen band of the conveying and draining extrusion screen band, thus realizingcontinuous automatic production of boiled beanmilk coagulating and beancurd sheet pressing.

Owner:SHANXI RUIFEI MECHINE MFG

Bag making machine

InactiveCN106476326AIncrease productivityOvercome defectsBag making operationsPaper-makingProduction lineFlanging

The invention provides a bag making machine comprising a feeding device, a hot cutting device, a folding device, a flanging device, a first sewing device, a reversing and flanging device, a second sewing device, a bag collecting device and a bag tying device which are sequentially arranged. The bag making machine provided by the invention is high in production efficiency, low in equipment cost and capable of overcoming defects existing in the existing packaging bag making machine, realizing continuous automatic production of packaging bags on one production line and sufficiently meeting the requirement of modern industrial production.

Owner:苏州万洋精密机械有限公司

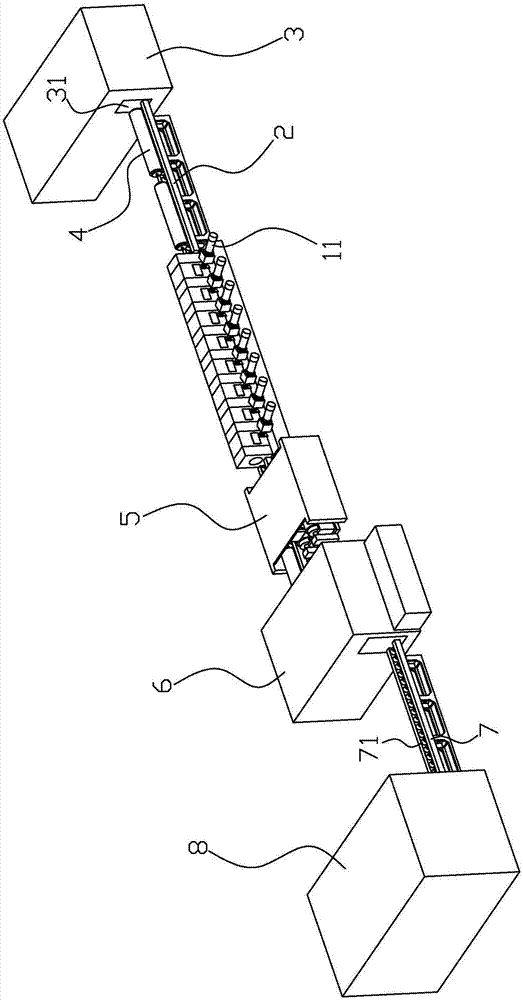

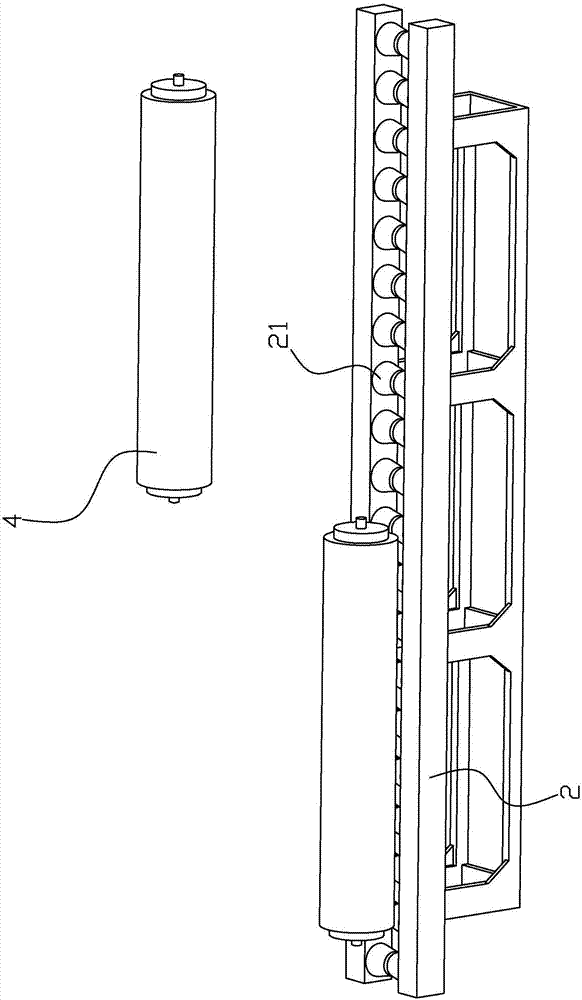

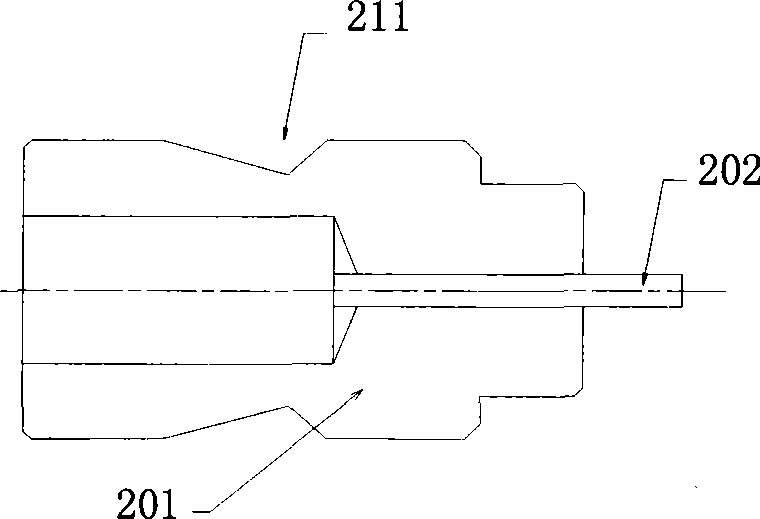

Continuous sucker rod with communication function and preparation device and preparation method thereof

InactiveCN106761447AReduce weightRealize continuous automatic productionDrilling rodsDrilling casingsGlass fiberEpoxy

The invention belongs to the field of oil extraction devices for oil fields and especially relates to a continuous sucker rod with the communication function and a preparation device and a preparation method thereof. The device comprises carbon fiber core body, a glass fiber layer wrapping outside the carbon fiber core body and an epoxy resin layer wrapping outside the glass fiber layer; the center of the carbon fiber core body is provided with a ribbon heater; the carbon fiber core body is made of carbon fiber bundles which are bonded with resin; the glass fiber layer is made of a winding glass fiber layer and a vertical glass fiber layer; the winding glass fiber layer spirally winds outside of the carbon fiber core body; the glass fiber and the carbon fiber forming the vertical glass fiber layer are parallelly arranged. The technology of the invention is simple; the layout is reasonable; by means of the method, a multi-layer antifriction continuous sucker rod can be produced; the sucker rod is provided with thermostatic heating function and can prevent wax precipitation; the sucker rod is light, stands wear and tear and has high twisting strength, shearing strength and tensile strength.

Owner:DAQING CITY HUAYU PETROLEUM MASCH MFG CO LTD

Process method for producing membrane electrode

ActiveCN113517459ASimple processComposite effect is goodFinal product manufactureCell electrodesManufacturing engineeringCarbon paper

The invention relates to the technical field of membrane electrode production processes, and provides a process method for producing a membrane electrode. The process method comprises a thermal transfer printing process method, a thermal compounding process method, a carbon paper laminating process method and a hot pressing process method. The thermal transfer printing process method comprises the following steps that S11, thermal transfer printing is performed on a material A and a material B; and S12, the material A and the material B subjected to heat transfer printing are rolled. The thermal compounding process method comprises the steps that S21, a material A subjected to thermal transfer printing is cut into sheets, and the sheets are transferred and pasted to the position above a lower frame material belt; and S22, an upper frame material belt is arranged above the material A subjected to heat transfer printing, and a semi-finished product material belt is formed through heating and rolling. The carbon paper laminating process method comprises the following steps: S31, respectively transferring and laminating carbon paper above and below a semi-finished product material belt; and S32, heating, rolling and compounding, and cutting into sheets. The hot-pressing process method comprises the following step of S41, carrying out hot pressing on a sheet material. Continuous automatic production of the membrane electrode is realized, and the production efficiency and quality of the membrane electrode are improved.

Owner:SHANDONG HOACO AUTOMATION TECH

Method and apparatus for continuous conversion production of sodium nitrate

InactiveCN105236451AFully oxidizedImprove pass rateAlkali metal nitratesChemical industryInorganic ChemicalCirculating pump

The invention discloses a method and an apparatus for continuous conversion production of sodium nitrate, and belongs to the technical field of production of inorganic chemical engineering products. The method mainly comprises the processes of mother liquor pre-conversion, conversion absorption and tail gas separation. The system of the apparatus mainly comprises a conversion absorption tower, a converter, an absorption separator, a matching pump and a matching pipeline, and the conversion absorption tower is a packed tower, and comprises an upper portion pre-conversion segment, a middle portion conversion absorption segment and a lower portion solution storage tank; and a conversion solution obtained after pre-conversion and conversion reactions of a mixed mother liquor and a circulating solution enters the solution storage tank, parts of the conversion solution returns to the conversion absorption tower through a conversion circulating pump, the remaining conversion solution is pumped into the converter in order to produce solid sodium nitrate, and generated tail gas is sent to a 4# alkali absorption tower, and is absorbed to produce sodium nitrite. The method and the apparatus optimize technological operation, improve the sodium nitrite conversion rate and the qualified rate of sodium nitrate, enlarge the productivity, reduce the production cost, realize continuous and automatic production of sodium nitrate and are in favor of realizing energy saving and emission reduction.

Owner:临沂鲁光化工集团有限公司

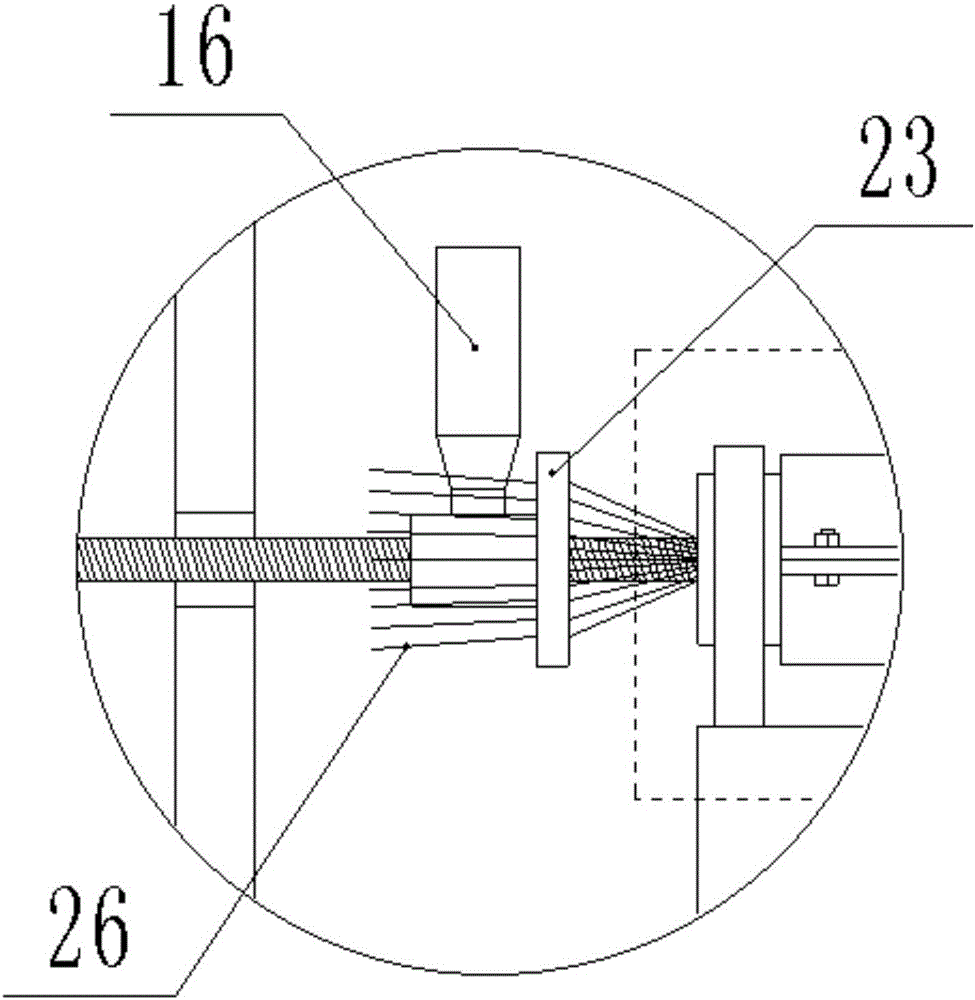

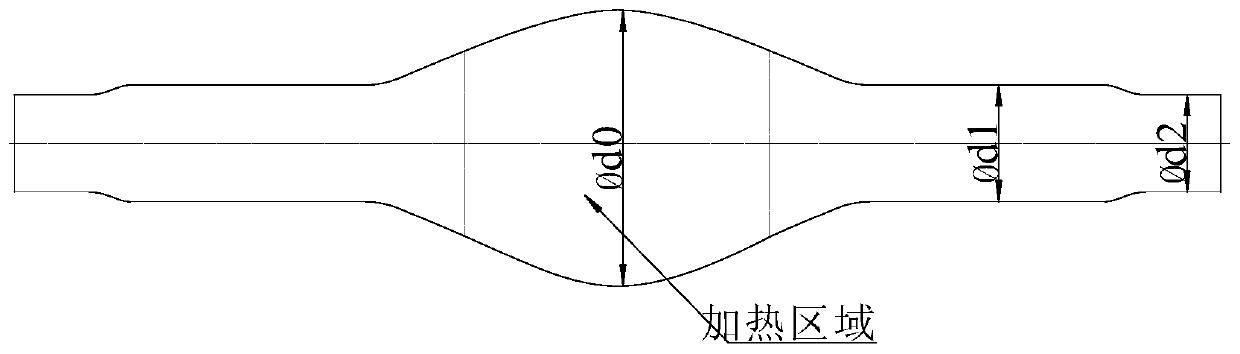

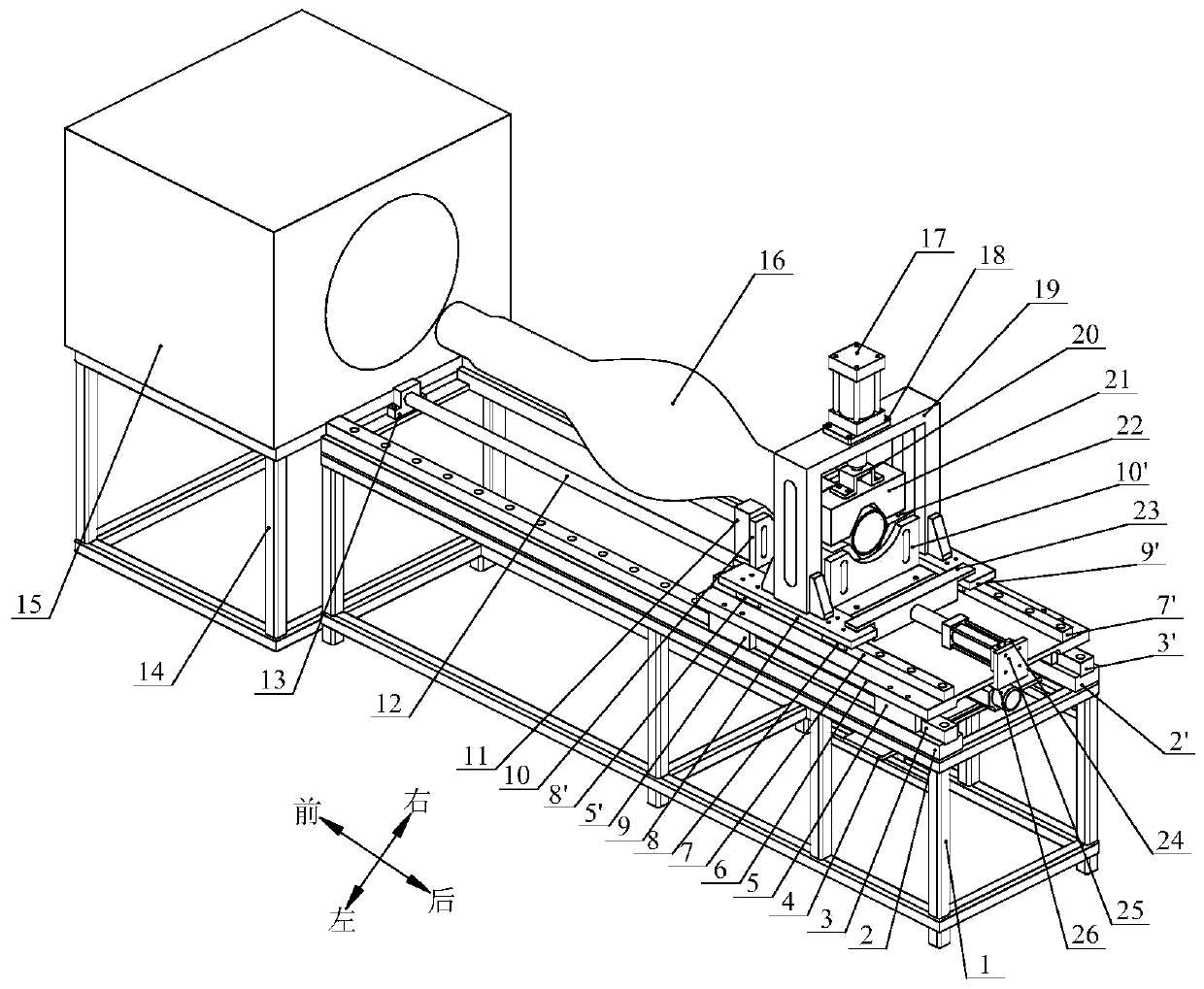

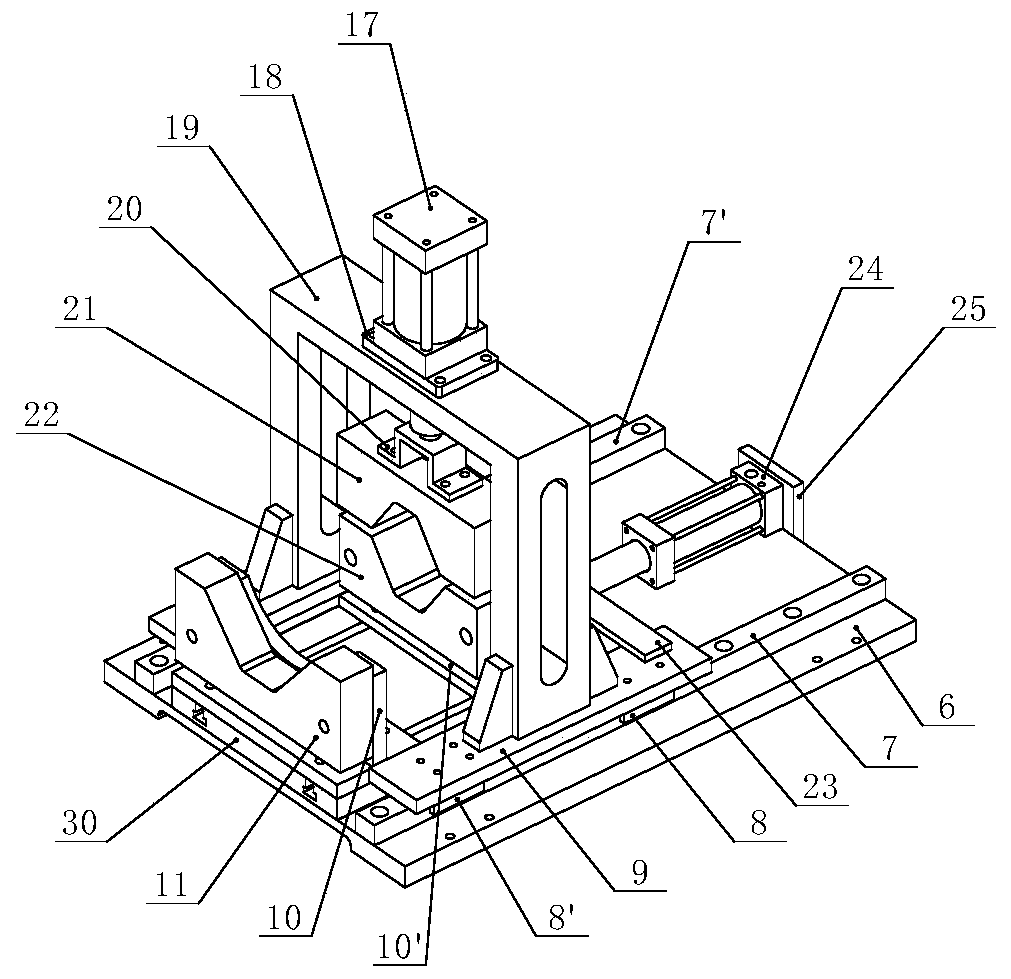

Large-size bulging bridge shell tube blank local annealing device and process

ActiveCN110016540AReduced precision requirementsRealize continuous automatic productionFurnace typesIncreasing energy efficiencyProduction lineMotor drive

The invention discloses a large-size bulging bridge shell tube blank local annealing device and process. The device comprises a tubular medium-frequency annealing furnace, a tube end clamping mechanism and a longitudinal moving mechanism, wherein the device is cooperatively used with other material transferring equipment, and the continuous operation of an automatic production line of a liquid expansion forming bridge shell can be realized. According to the process, a vertical air cylinder drives an upper clamping V-shaped block to move downwards, and the upper clamping V-shaped block is matched with A lower clamping v-shaped block to clamp the end part of one side of a tube blank, a supporting V-shaped block is arranged at the front part of the lower clamping V-shaped block to support a round tube at the inner side of the tube blank, the vertical air cylinder and the upper clamping V-shaped block are arranged on a door-shaped frame, and the horizontal air cylinder drives the door-shaped frame to move longitudinally; and a servo motor drives a lead screw to rotate so as to drive a mobile platform to move longitudinally. According to the large-size bulging bridge shell tube blank local annealing device, the bulging-shaped area in the middle of the large-size bulging bridge shell tube blank with the large size after the hydraulic bulging can be uniformly heated, and the large-size bulging bridge shell tube blank local annealing device has the advantages of being energy-saving, safe in operation, reliable in clamping, convenient to operate to operate and the like, and can remarkably improve the production efficiency.

Owner:YANSHAN UNIV +1

Transverse tappet production device

ActiveCN106042082ARealize flexible processingRealize continuous automatic productionLiquid surface applicatorsMulti-purpose machinesPulp and paper industryTappet

The invention proposes a transverse tappet production device. The transverse tappet production device comprises a sizing mechanism, an adjusting mechanism, a drilling and milling mechanism and a painting mechanism; a feed end of the sizing mechanism is communicated with a supply mechanism; transverse tappet blanks are fed in the sizing mechanism by the supply mechanism; the sizing mechanism performs the sizing and cutting treatment for the transverse tappet blanks according to specifications; a discharge end of the sizing mechanism is communicated with the adjusting mechanism; the sizing mechanism feeds the transverse tappet blanks after the sizing and cutting treatment into the adjusting mechanism; the adjusting mechanism performs the direction adjustment for the transverse tappet blanks; a discharge end of the adjusting mechanism is communicated with the drilling and milling mechanism; the adjusting mechanism feeds the transverse tappet blanks after the direction adjustment into the drilling and milling mechanism; the drilling and milling mechanism drills and mills the transverse tappet blanks; a discharge end of the drilling and milling mechanism is communicated with the painting mechanism; the drilling and milling mechanism feeds the drilled and milled transverse tappet blanks into the painting mechanism; and the painting mechanism paints the transverse tappet blanks. The production device realizes automation from sizing to gluing and tenoning of tappets so as to facilitate improvement of the production efficiency.

Owner:MENGTIAN HOUSEHOLD GRP CO LTD

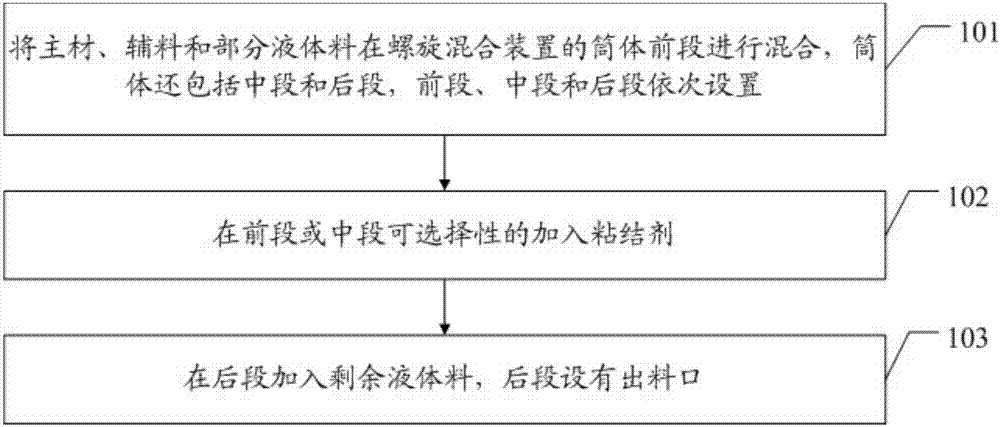

Lithium battery slurry continuous efficient production process

InactiveCN107297168ARealize continuous automatic productionIncrease productivityCell electrodesFinal product manufactureProduction linePulp and paper industry

The invention provides a lithium battery slurry continuous efficient production process. According to the process, bonding agents can be directly added into a continuous production line; the glue liquid prefabrication by the bonding agent is not needed; the production efficiency is improved. The lithium battery slurry continuous efficient production process has the technical scheme that firstly, major materials, auxiliary materials and partial liquid materials are mixed at the front section of a tube body of a spiral mixing device; the tube body also comprises a middle section and a back section; the front section, the middle section and the back section are sequentially arranged; secondly, the bonding agents can be selectively added in the front section or the middle section; finally, the rest liquid material is added into the back section; the back section is provided with a discharging opening.

Owner:FOSHAN GOLD SILVER RIVER INTELLIGENT EQUIP CO LTD

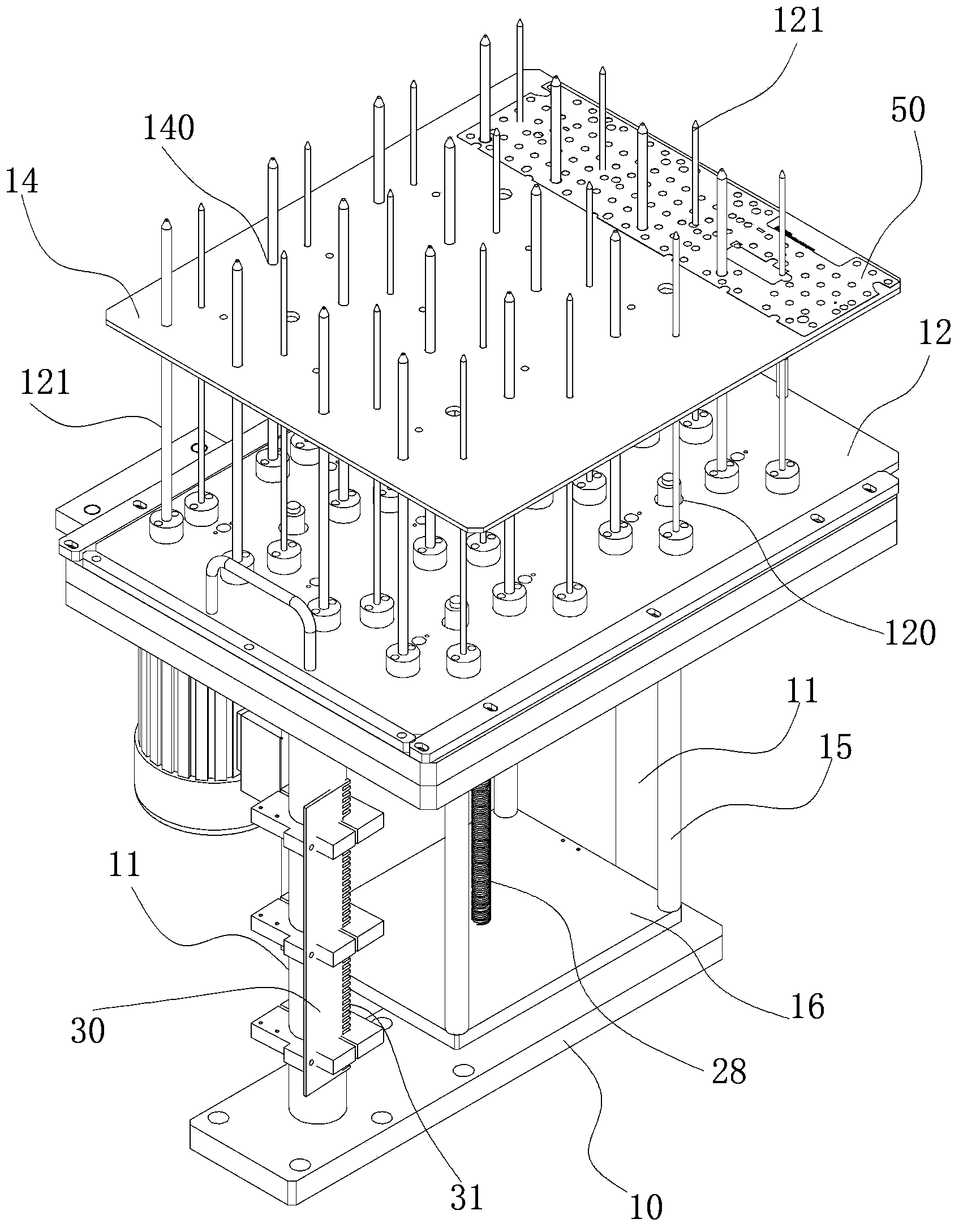

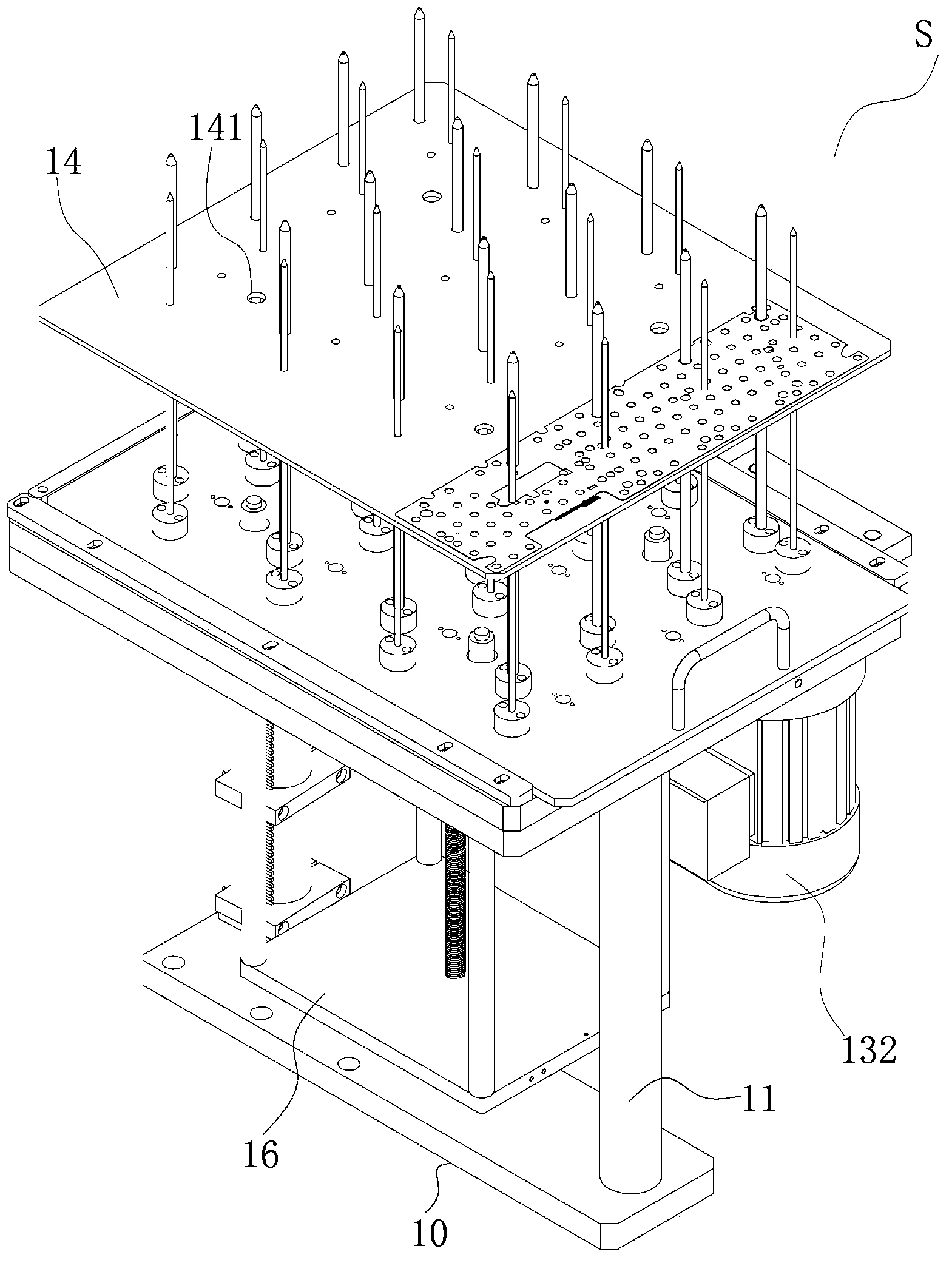

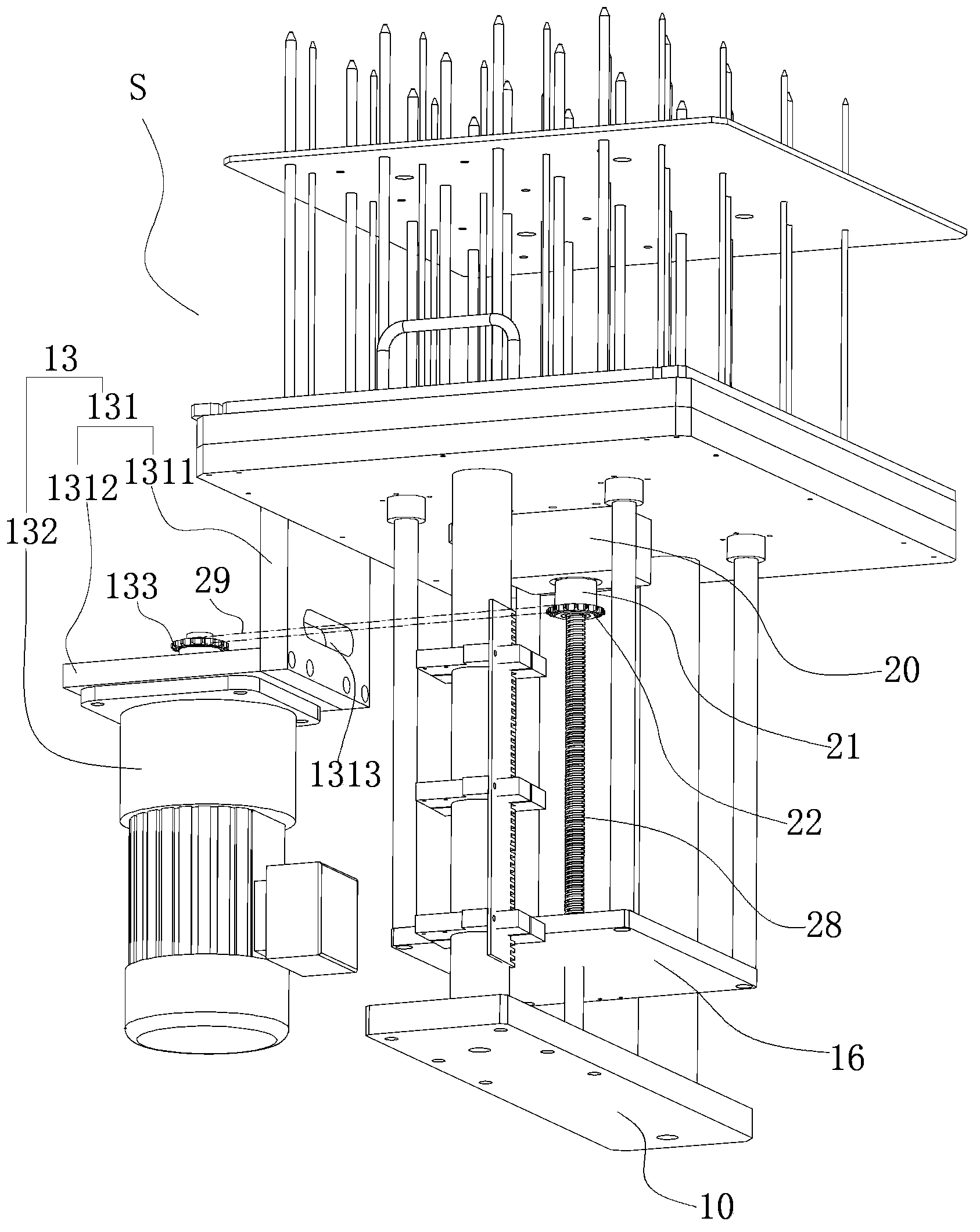

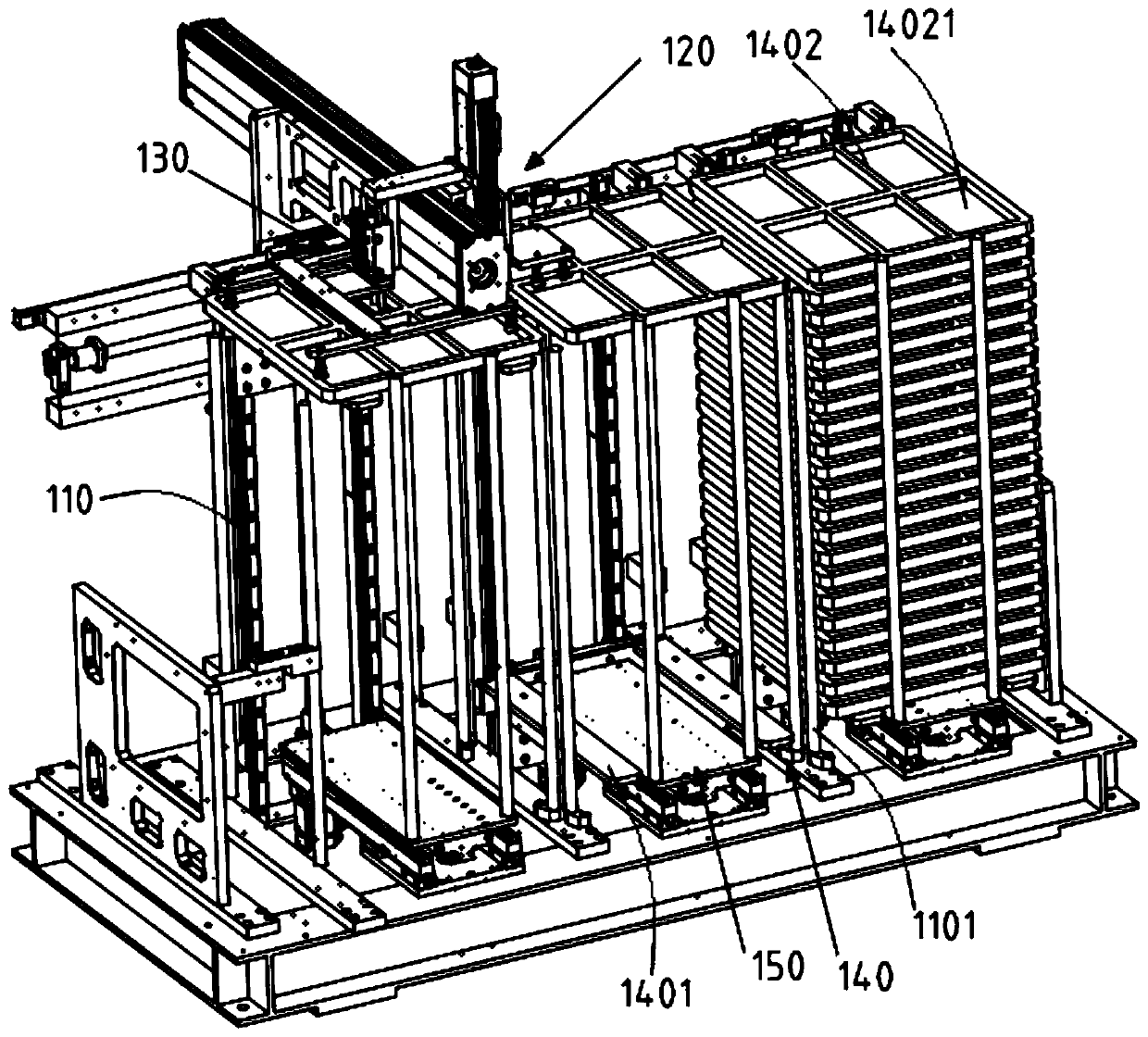

Lifting type material supporting mechanism and material collecting device of conducting film assembly

InactiveCN103407825ANeatly positionedRealize automatic receivingPile receiversArticle deliveryManipulatorRobot

The invention discloses a lifting type material supporting mechanism and a material collecting device of a conducting film assembly. The lifting type material supporting mechanism comprises a base plate, a fixed plate, a motor assembly, a material supporting plate, a plurality of guiding rods, a nut base and a screw rod, wherein two stand columns are arranged above the base plate, the fixed plate is fixed at the upper end of each stand column, the motor assembly is provided with a driving wheel, the material supporting plate is arranged above the fixed plate, the guiding rods penetrate through guiding holes formed in the fixed plate, the upper end of each guiding rod is fixedly connected with the material supporting plate, and the lower end of each guiding rod is fixedly connected with a lower connecting plate, the nut base is provided with a driven wheel which is connected with the driving wheel in a transmission mode, and the screw rod is in threaded connection with a nut hole. In the process of stacking materials, the positions of the materials are neat and cannot be changed easily, the material placement positions do not need to be changed when a mechanical arm or a robot places the materials, the using efficiency of the robot or the mechanical arm is improved easily, and productivity is improved. According to the material collecting device of the conducting film assembly, the automatic material collection of the FPC conducting film assembly is achieved, manual material collecting is not needed, labor cost is reduced, and material collecting efficiency is improved.

Owner:SHENZHEN RAPOO TECH

Automatic grinding production line

PendingCN110405574ARealize continuous automatic productionFully automatedEdge grinding machinesGrinding wheel securing apparatusProduction lineControl system

The invention discloses an automatic grinding production line. The automatic grinding production line comprises a loading device, a plurality of grinding machines, a cleaning machine and an unloadingdevice which are arranged according to the processing flow. The automatic grinding production line further comprises a first conveying device and a second conveying device, wherein the first conveyingdevice is used for conveying workpieces to be ground from the loading device to the grinding machines; and the second conveying device is used for conveying the ground workpieces from the grinding machines to the cleaning machine. The production line further comprises a control system and a control cabinet, wherein the control system is arranged in the control cabinet. The grinding machine comprises a tool changing device. The automatic grinding production line can realize the continuous and automatic production of sheets through the design of the loading device, the grinding machines, the cleaning machine, the unloading device, the first conveying device, the second conveying device and the like, integrates the functions of loading, grinding, cleaning and unloading the sheets, has high integration level, improves the production efficiency and product quality and realizes one-worker multiple machines.

Owner:KUNSHAN HENGDA PRECISION MACHINERY IND CO LTD

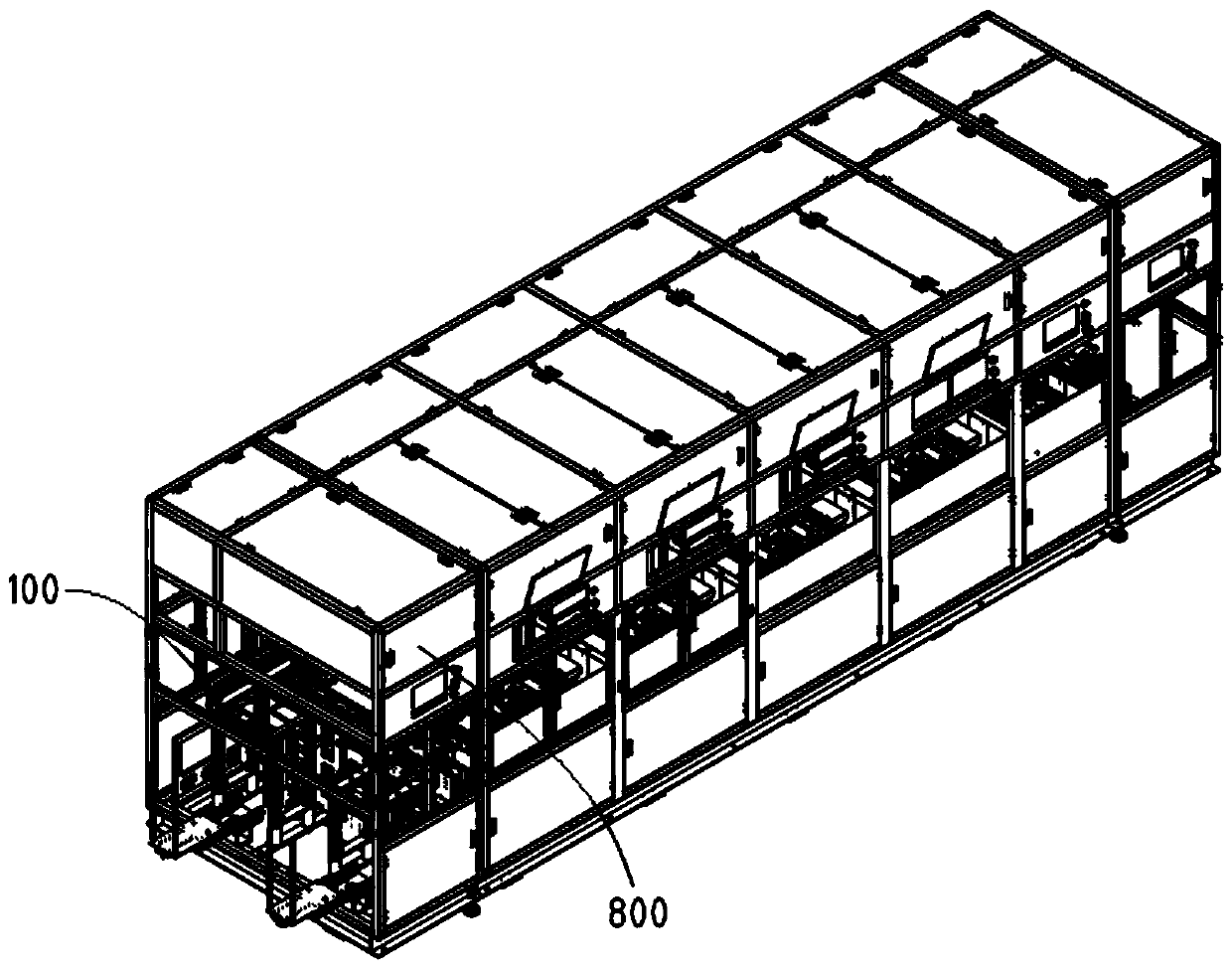

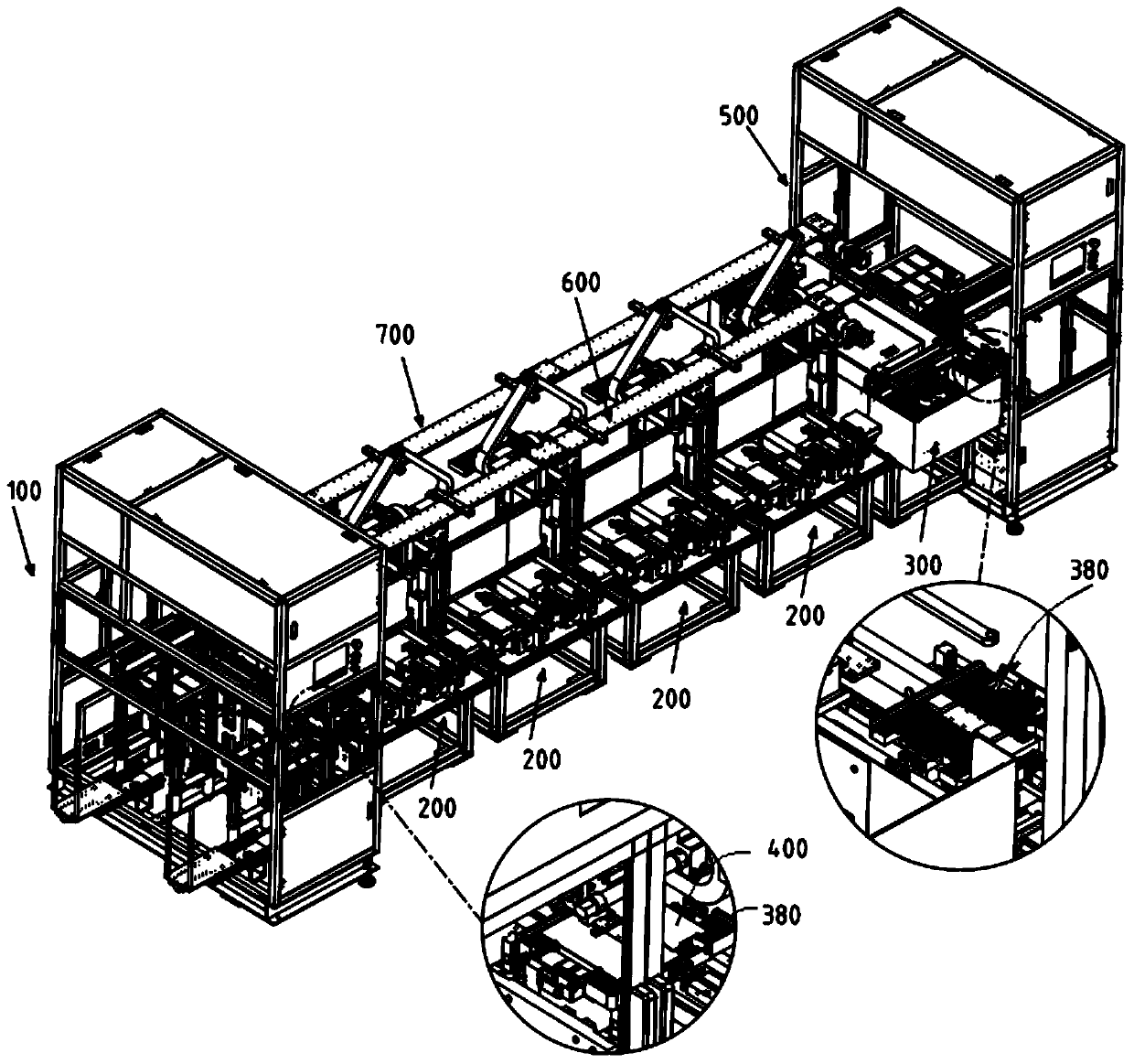

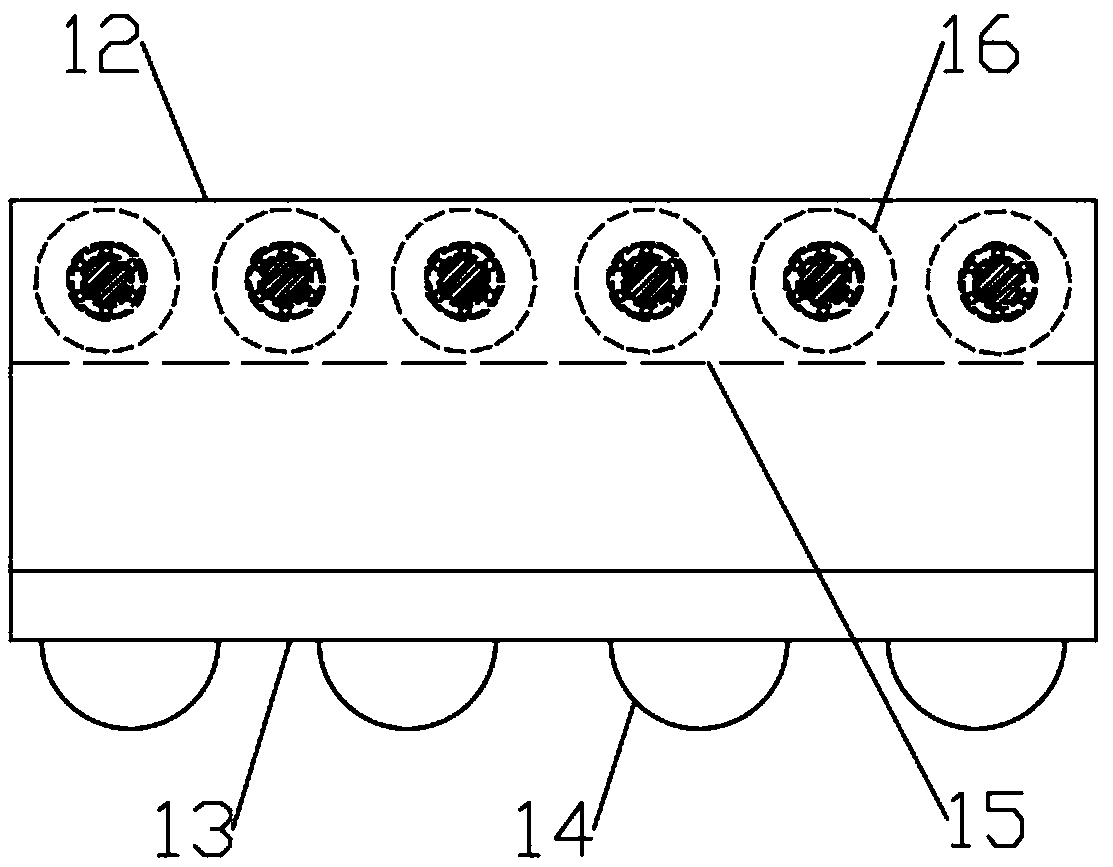

Production device capable of achieving continuous automatic production of semi-tempered plate vacuum glass

ActiveCN105837060ARealize continuous automatic productionMany workstationsGlass tempering apparatusEngineeringTransmission system

A production device capable of achieving continuous automatic production of semi-tempered plate vacuum glass comprises a glass loading mechanism, a first transmission system, a tray, a point distribution and gluing mechanism, a heating and edge-sealing device, a semi-tempering device, a cooling device, an edge-sealed glass translation mechanism, a tray rotary mechanism, a second transmission system, a vacuumizing mouth-sealing vehicle, a vacuumizing mouth-sealing heating device, a vacuumizing mouth-sealing vehicle rotary mechanism, and a glass unloading mechanism. The production device can achieve continuous automatic production of the semi-tempered plate vacuum glass, and has the characteristics of continuous type, multiple work stations, low energy consumption, and high efficiency.

Owner:沈阳玖通玻璃科技有限公司

Full-automatic production equipment for building prefabricated parts and manufacturing process of building prefabricated parts

ActiveCN109176860ARealize continuous productionReduce labor costsMouldsCeramic shaping plantsSurface mountingArchitectural engineering

The invention provides full-automatic production equipment for building prefabricated parts. The full-automatic production equipment comprises a mounting frame, a spiral mixing device, a forming compacting device and a supporting plate connecting and rotating device; the supporting plate connecting and rotating device comprises a conveying frame; the two ends of the conveying frame are provided with transmission rollers; a conveying crawler belt is connected between the transmission rollers; a transmission groove is formed in the conveying crawler belt; a conveying motor is connected with thetransmission rollers; a supporting plate bin is arranged above the transmission rollers; a plate outlet opening is formed in the left side surface of the supporting plate bin; supporting plates are stacked in the supporting plate bin; conveying support plates are mounted on the lower surfaces of the supporting plates; transmission protrusions are arranged at the bottoms of the conveying support plates; two mounting grooves are formed above the supporting plates; and sliding sleeves are mounted in the mounting grooves. Continuous automatic production of the building prefabricated parts is achieved through the four processes of raw material preparation, mold assembly, product molding and product output, the production cost of building prefabricated parts is reduced, and the production efficiency of the building prefabricated parts is improved while the quality of the building prefabricated parts is improved.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

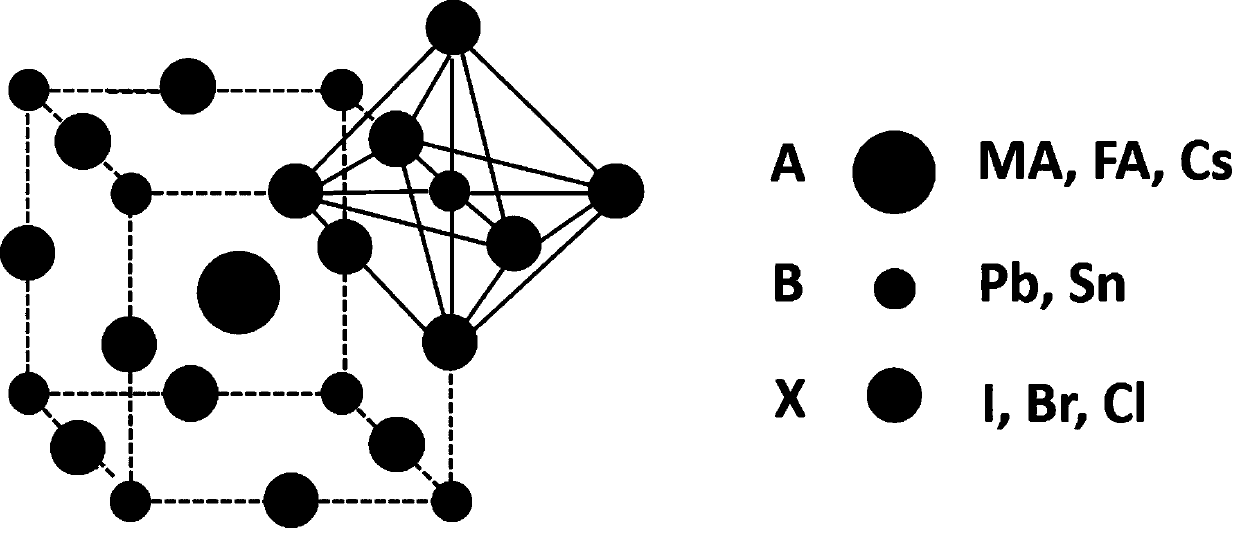

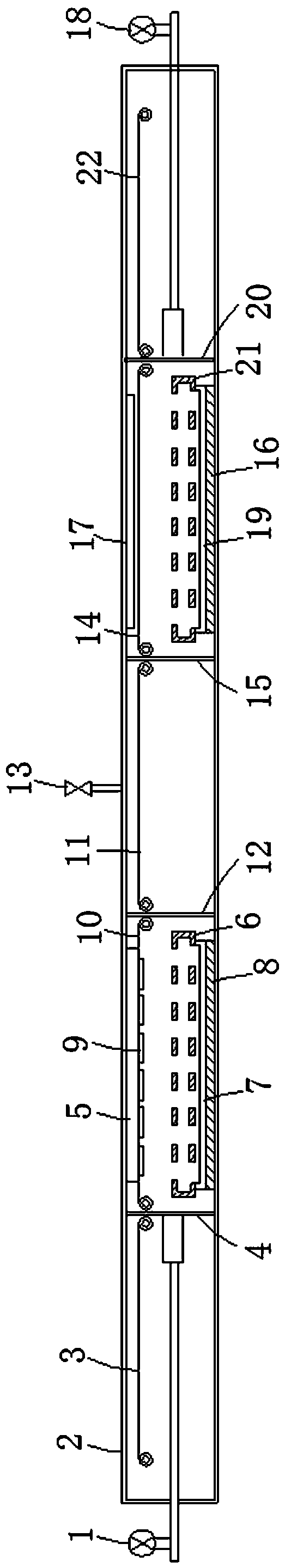

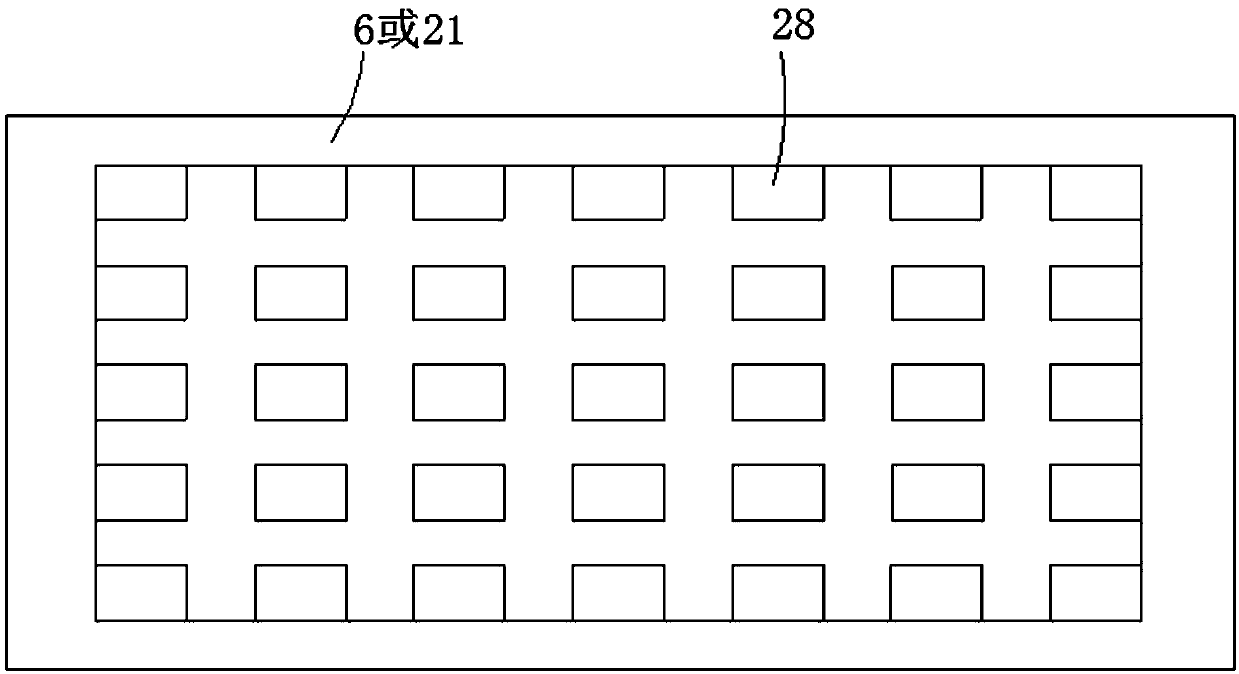

Forming method and forming device of perovskite layer film and use method and application thereof

PendingCN107779844ARealize continuous automatic productionIncrease productivityChemical vapor deposition coatingThin membranePerovskite

The invention relates to a forming method and forming device of a perovskite layer film and a use method and application thereof. The forming method is characterized in that a tubular cavity is sequentially provided with five parts including a substrate entering section, a depositing cavity, a transition cavity, an annealing section and a substrate removing section, wherein a conveying device is arranged in the tubular cavity; a loading platform, an air pressure regulating device and a heating device are correspondingly arranged in the depositing cavity and the annealing cavity; adjacent sections are separated from the cavity through separating plates, and the cavities are separated through the separating plate; the substrate to be deposited with the film is positioned on a substrate rackand sequentially continuously passes through the depositing cavity, the transition cavity and the annealing cavity from the substrate entering section through the conveying device; then the substrateon which a perovskite layer film is deposited is removed from the substrate rack in the substrate removing section. According to the method, the depositing filming and the annealing technology are integrated to realize the continuous production of the perovskite layer film product. The perovskite layer film manufactured through the device is uniform in crystal particle size, design in crystal particle, and high in photoelectric conversion efficiency.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com