Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

247results about "Resistor trimming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

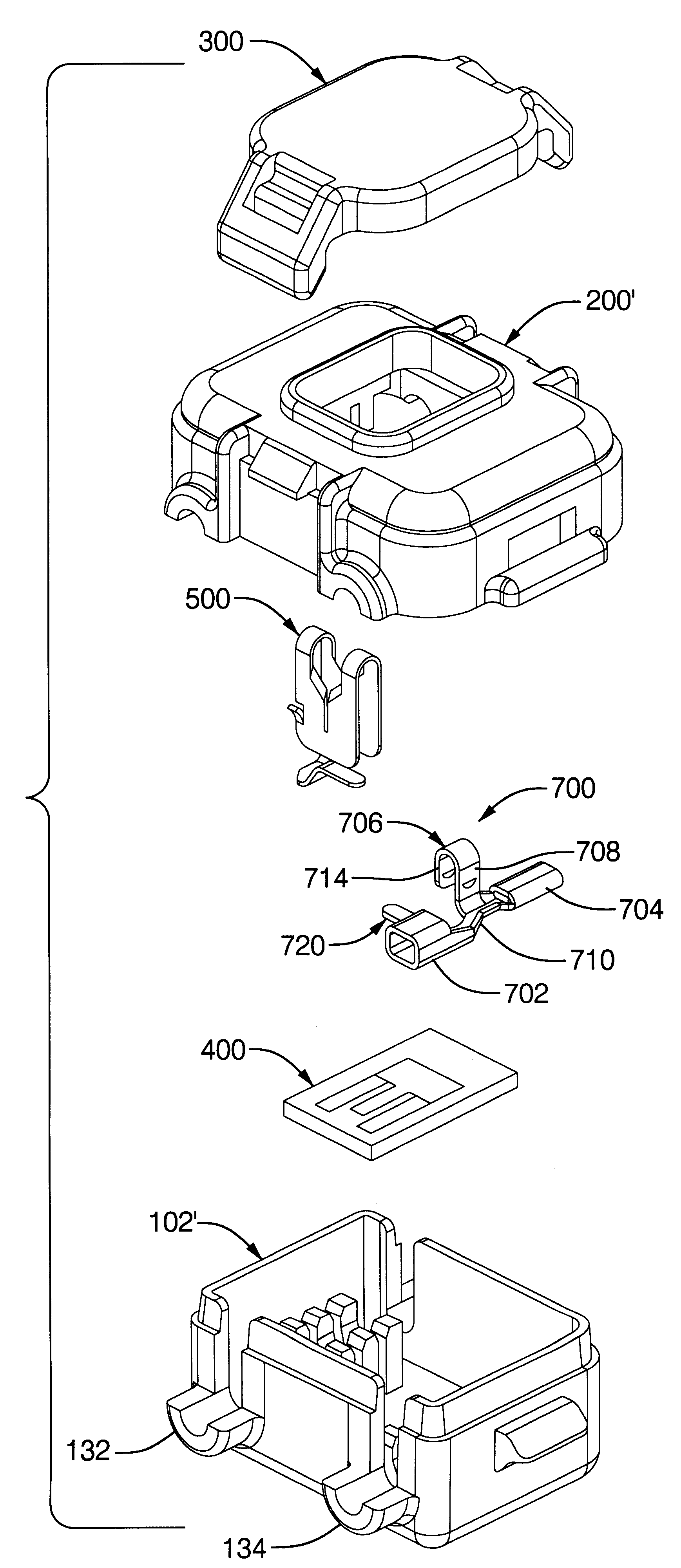

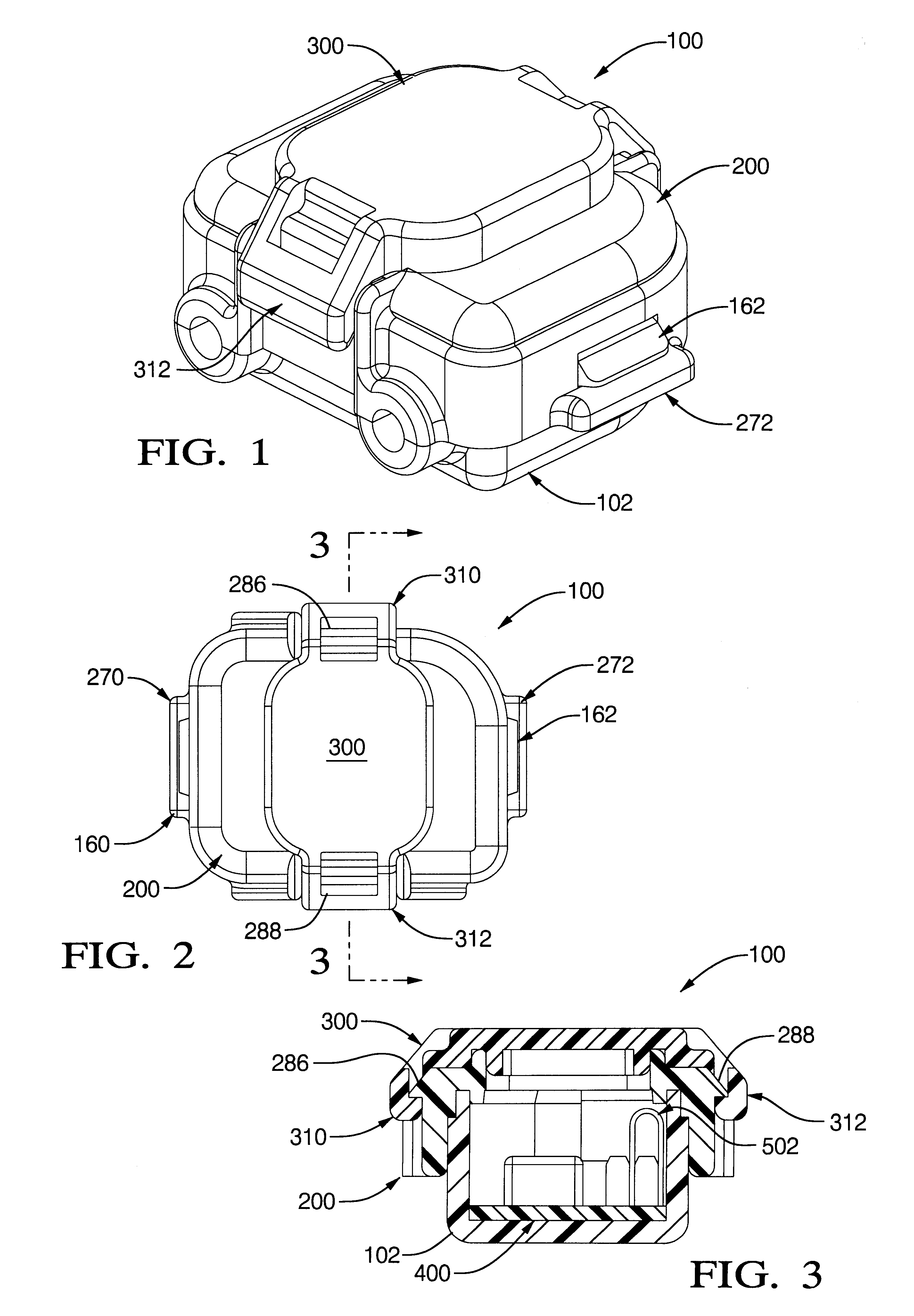

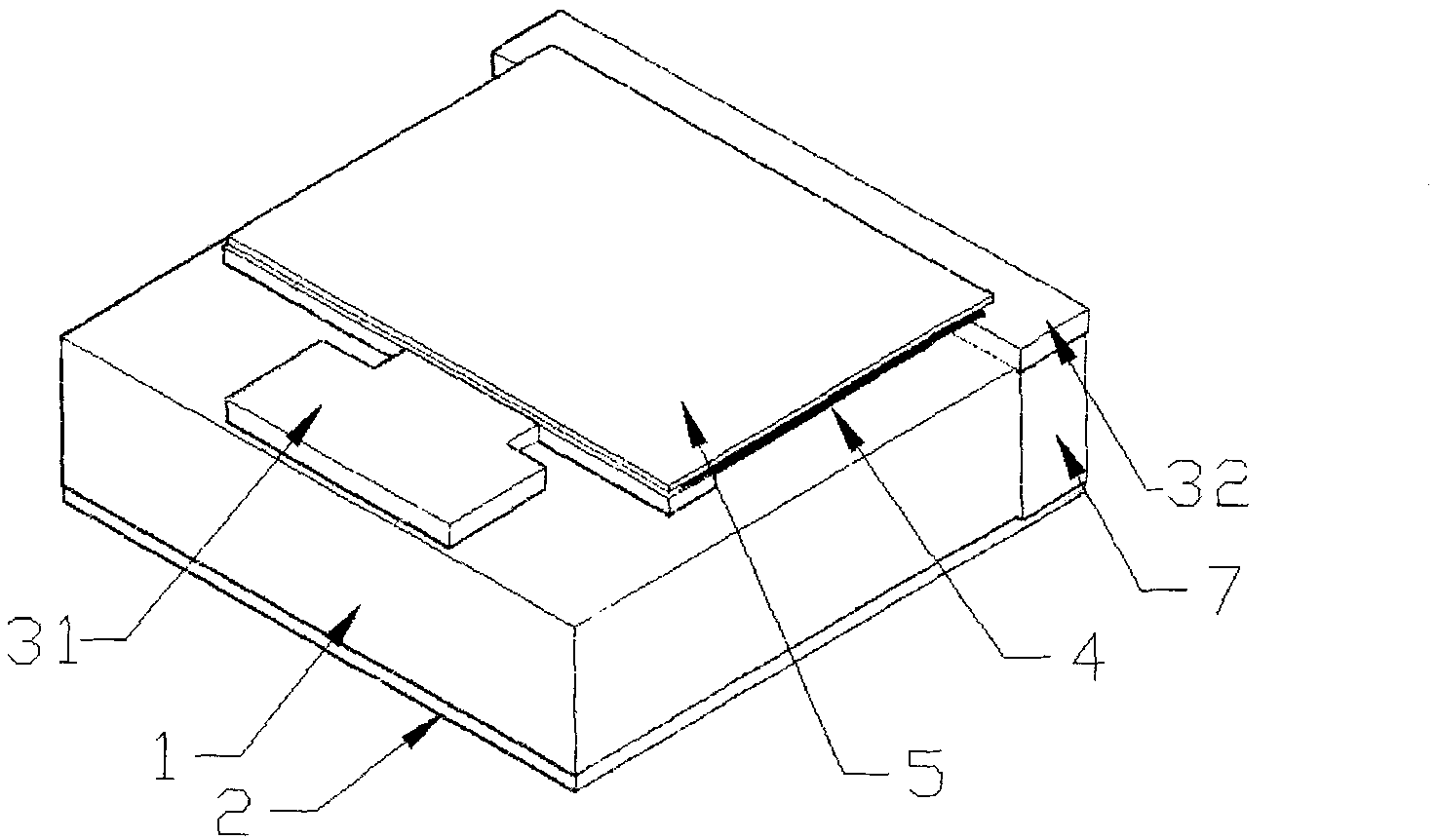

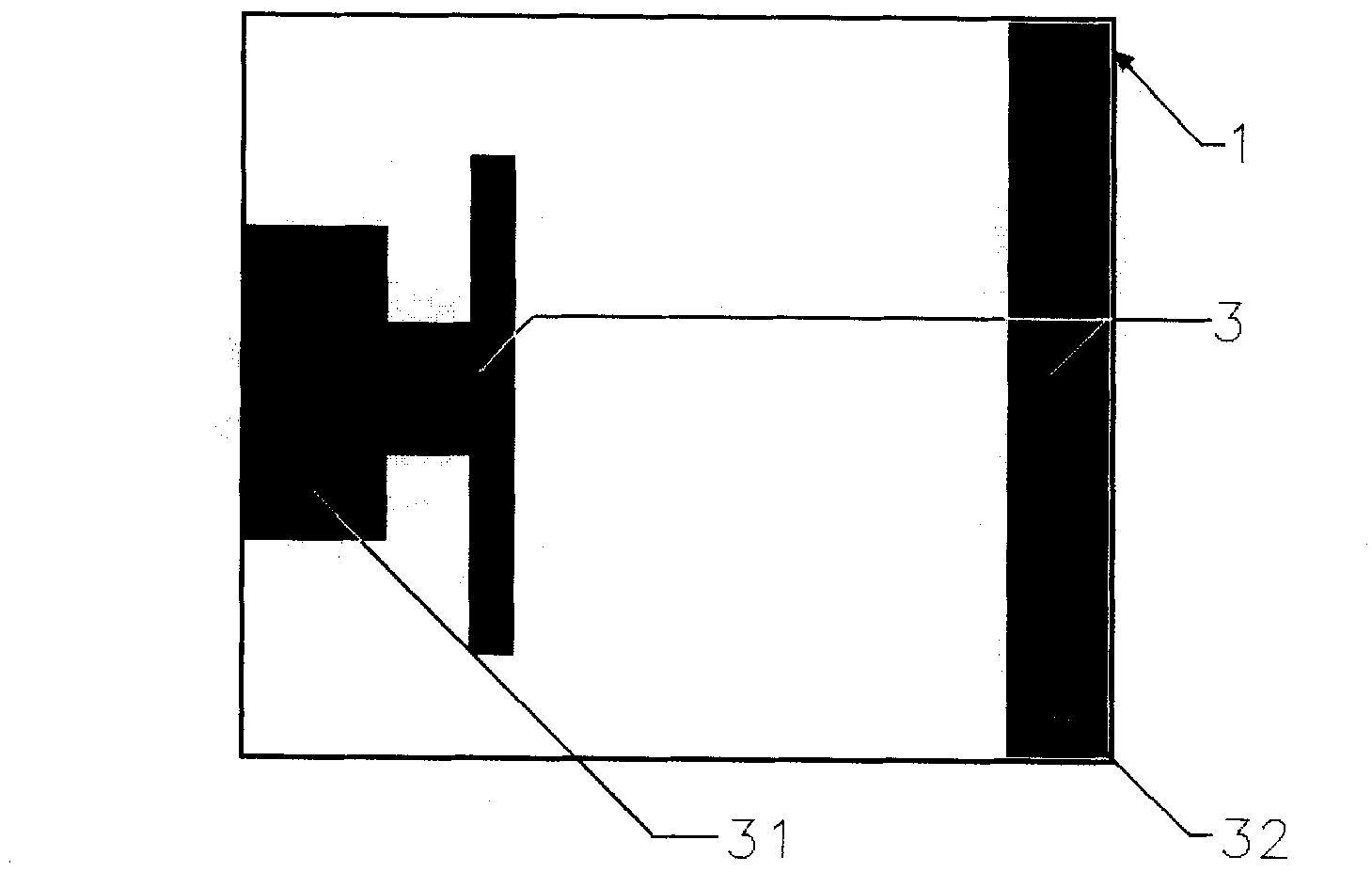

Trim resistor connector and sensor system

InactiveUS6208233B1Overcome disadvantagesFixed resistors with intervening connectorsFluid pressure measurement by electric/magnetic elementsSealantSensor system

An improved IDC trim resistor connector assembly made up of a generally open top cup shape connector with side wall slots and an interior first array of terminal posts arranged for passage therethrough of a first lead wire of sensor circuitry. A first stamped metal IDC terminal is push-on mounted on the terminal posts for IDC cradling and electrically and mechanically receiving and connecting to the first lead wire. A conventional trim resistor substrate is loose mounted but accurately positioned on the connector bottom wall and has an "E" pattern of resistive material adapted for center leg laser trimming to calibrate the associated sensor circuitry. A first IDC terminal spring leg overlap contacts one side leg of the trim resistor E-pattern and thereby spring clamps the resistor substrate. A cover is snap-latch mounted on the connector and has an access opening to enable laser trimming of the trim resistor after cover installation. One end of a second lead wire is received in a second IDC metal terminal in turn mounted on a second array of connector-interior terminal posts and also having a spring leg overlap electrically contacting and clamping the other E-pattern side leg. Spring barbs on the terminals anchor the same once fully inserted downwardly onto the terminal posts. Connector locking tangs and cover locking ears provide snap-on retention of the cover on the connector, and press-in / keeper internal cover projections cause push-down assembly of the lead wires as the cover is latched onto the connector. Cover locking tangs and cap latching ears provide snap-together locking of a cap on the cover when the cap is pushed down on the cover to seal the access opening after completion of laser trimming and in-filling of the covered container with sealant. In a second embodiment a crimp-type terminal, also provided with a spring clamping leg, is fastened to the second lead wire and has a barbed mounting strap clasping a modified second terminal post array when fully installed thereon.

Owner:DELPHI TECH INC

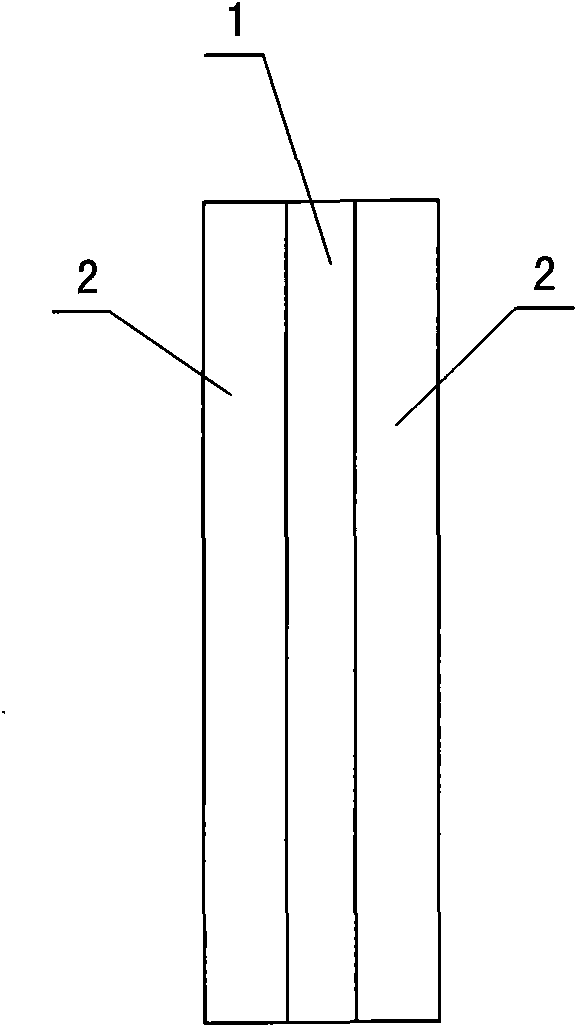

High-frequency patch resistor and manufacturing method thereof

InactiveCN101923928ALarge resistance rangeLarge scale preparationResistor trimmingResistor detailsMicrowaveCharacteristic impedance

The embodiment of the invention discloses a high-frequency patch resistor which comprises a substrate, a back electrode, a surface electrode, a resistor body and a first lateral conducting electrode, wherein in order to enable characteristic impedance to be matched with anticipatory target impedance, the resistor body is provided with an external cutting notch, i.e. cutting is started from the edge of the resistor body, the partial area of the resistor body is directly cut off from the resistor body, and the cross-sectional area of the resistor body can be decreased to a greater degree, so that the high-frequency patch resistor has a larger resistance-adjusting range and is beneficial to the matching of the characteristic impedance of the characteristic impedance resistor and the anticipatory target impedance. The invention also provides a manufacturing method of the high-frequency patch resistor to manufacture the high-frequency patch resistor with the larger resistance-adjusting range. The high-frequency patch resistor provided by the invention is suitable for microwave radio-frequency structures and chipping, and meanwhile, the high-frequency patch resistor can be manufactured in large scales and with high efficiency by utilizing the manufacturing method of the high-frequency patch resistor provided by the invention.

Owner:四平市吉华高新技术有限公司

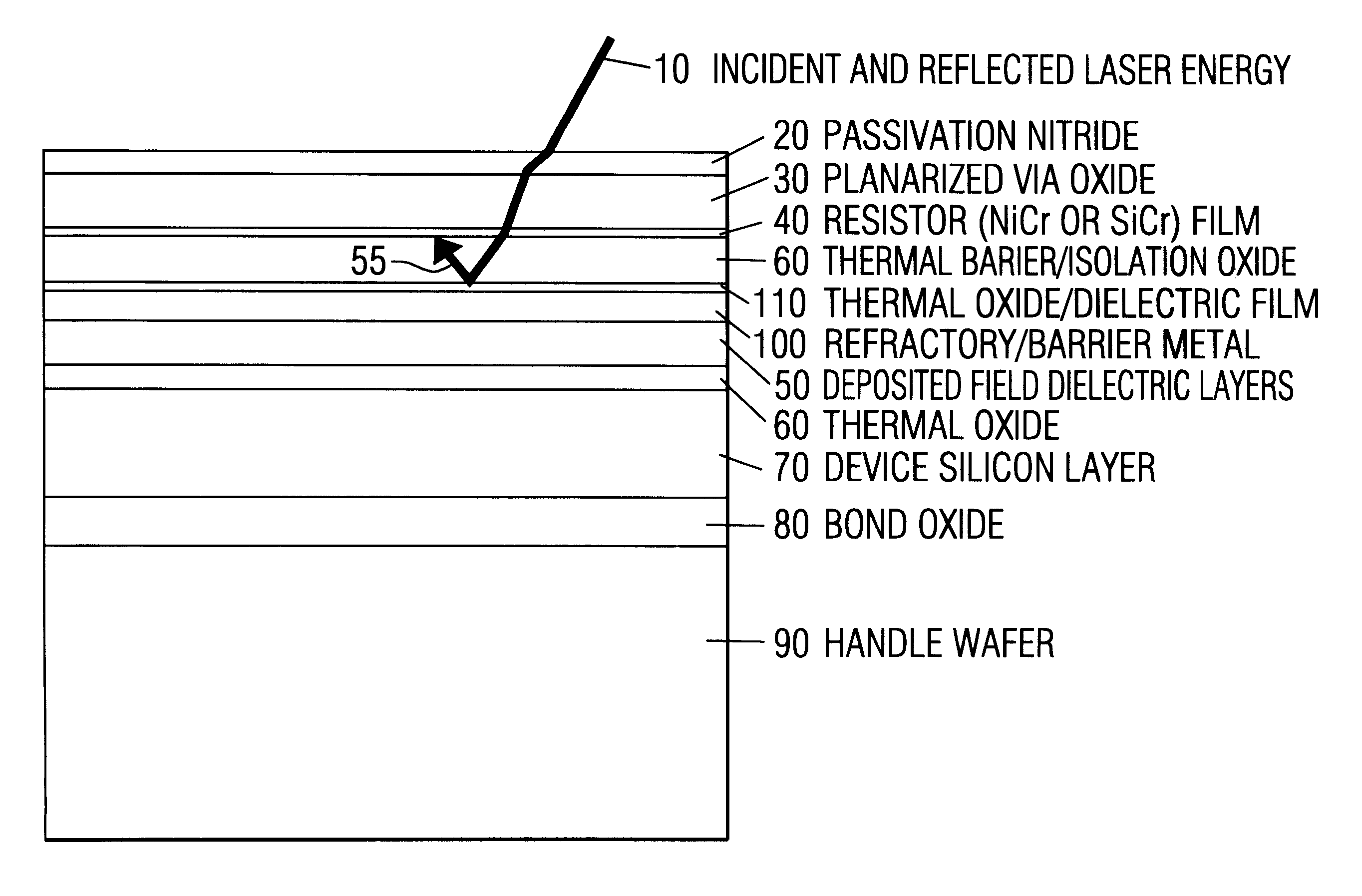

Use of barrier refractive or anti-reflective layer to improve laser trim characteristics of thin film resistors

InactiveUS6259151B1Reducing inaccuracy behaviorOptical wave guidanceSolid-state devicesTitaniumReflective layer

A precision resistor of NiCr or SiCr has a refractive and thermal barrier layer beneath the resistor. The refractive barrier is a layer of refractory metal. The refractory metal prevents the incident laser beam of a laser trimmer penetrating lower layers of the device. Unwanted reflections and refractions caused by lower layers are avoided. The reflective barrier layer is a material selected from the group consisting of tungsten, titanium, molybdenum, TiSi2l3,14, CoSi215, MoSi2, TaSi2 and WSi2.

Owner:INTERSIL INC

Drift-sensitive laser trimming of circuit elements

InactiveUS6875950B2Improve throughputPrinted electric component incorporationResistor trimmingInductorCapacitor

Owner:ELECTRO SCI IND INC

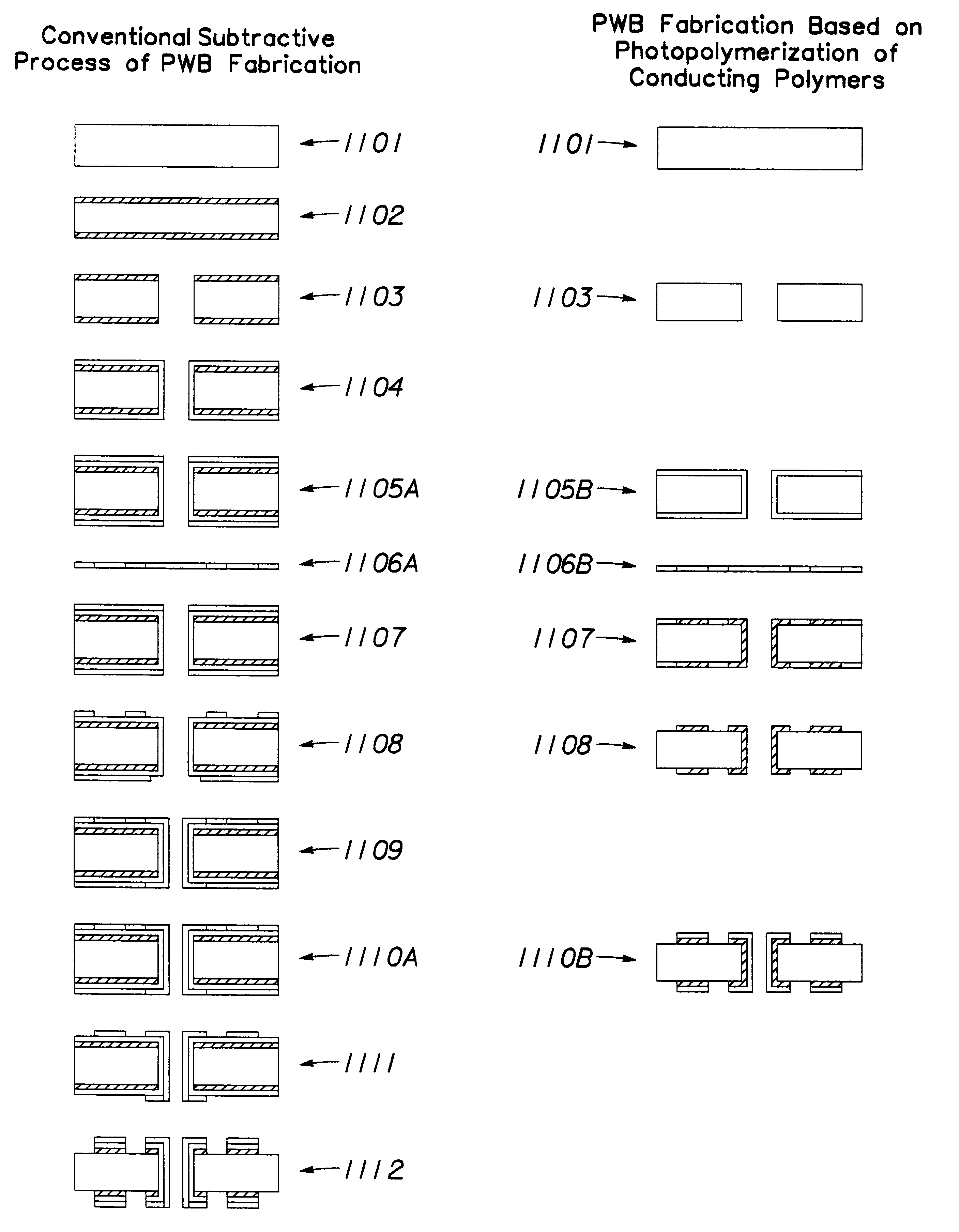

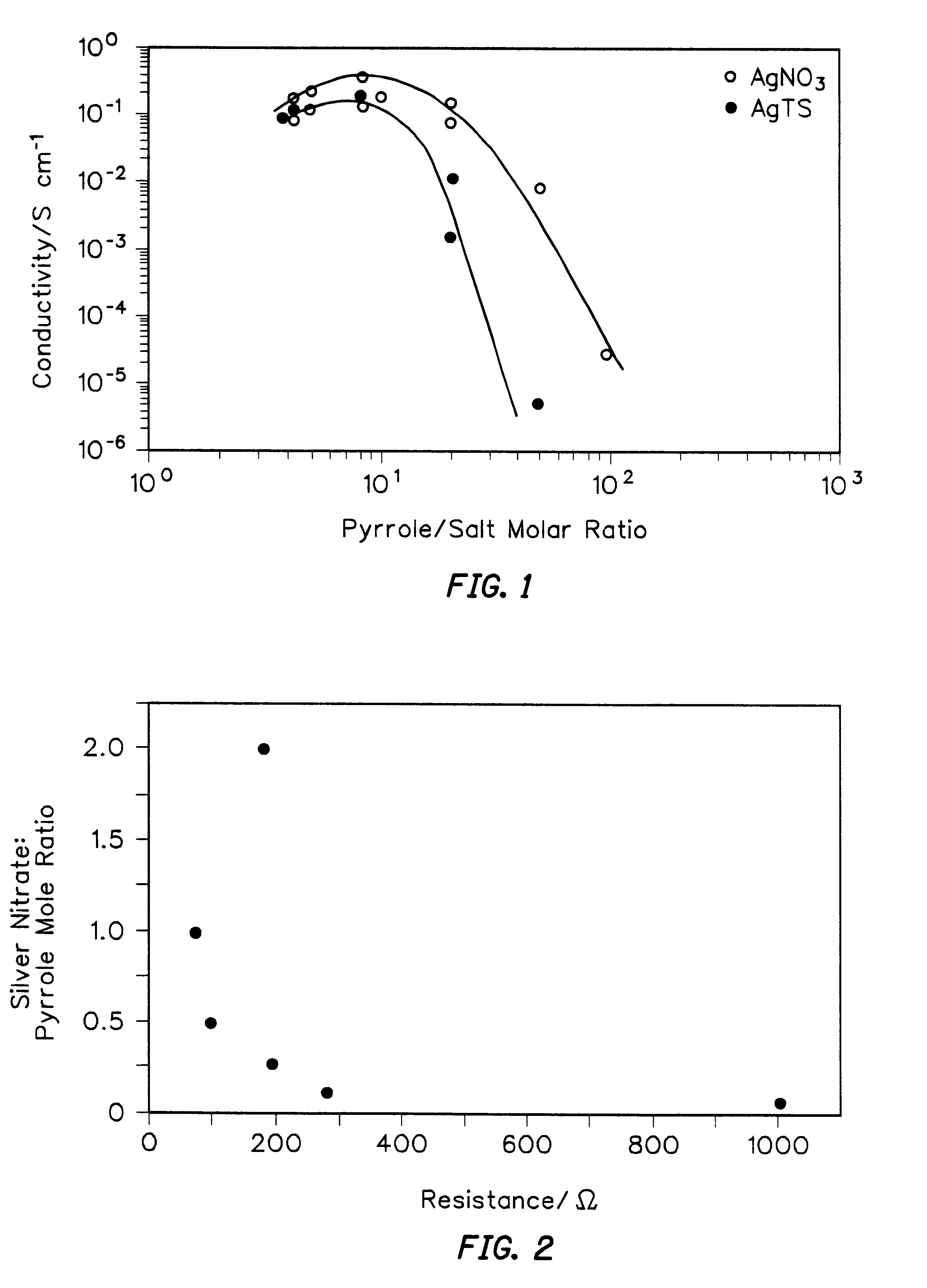

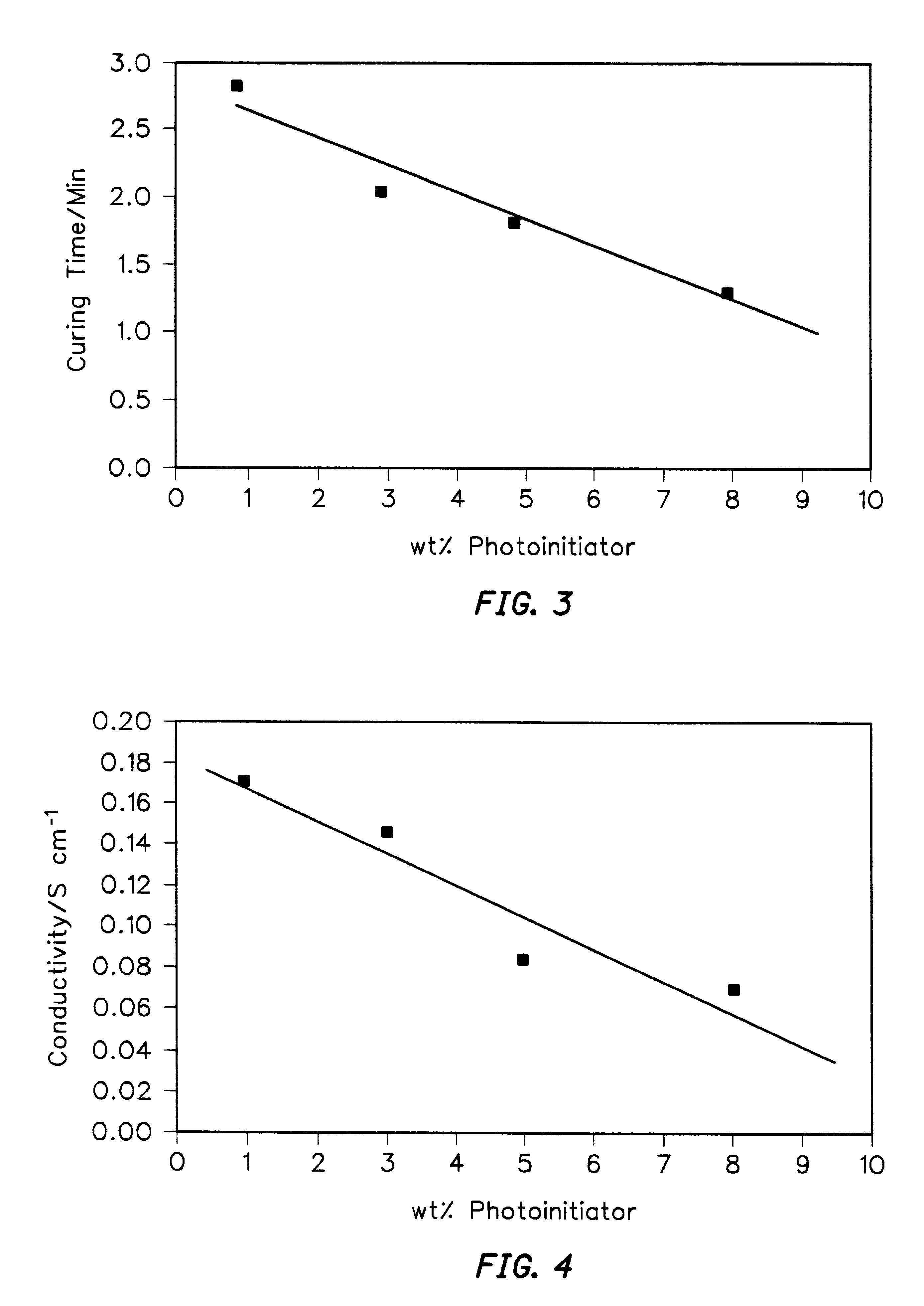

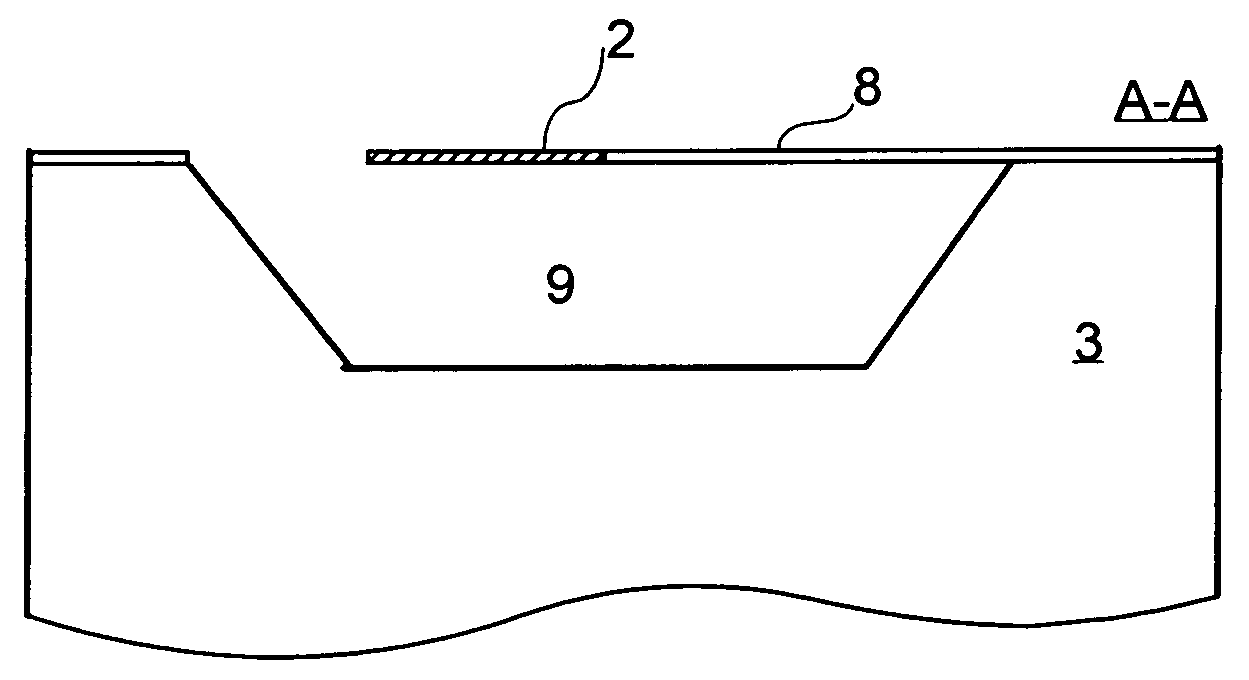

Method of forming electronically conducting polymers on conducting and nonconducting substrates

InactiveUS6210537B1Magnetic/electric field screeningPhotomechanical apparatusConductive polymerLaser light

The present invention provides electronically conducting polymer films formed from photosensitive formulations of pyrrole and an electron acceptor that have been selectively exposed to UV light, laser light, or electron beams. The formulations may include photoinitiators, flexibilizers, solvents and the like. These solutions can be used in applications including printed circuit boards and through-hole plating and enable direct metallization processes on non-conducting substrates. After forming the conductive polymer patterns, a printed wiring board can be formed by sensitizing the polymer with palladium and electrolytically depositing copper.

Owner:LYNNTECH

Method for trimming resistors

InactiveUS7119656B2Efficient pruningReduce the amount requiredSolid-state devicesSemiconductor/solid-state device manufacturingElectrical resistance and conductanceEngineering

There is provided a method and circuit for trimming a functional resistor on a thermally isolated micro-platform such that a second functional resistor on the same micro-platform remains substantially untrimmed; a method and circuit for providing and trimming a circuit such that at least two circuit elements of the circuit are subjected to a same operating environment and the operating environment is compensated for by distributing heat generated during operation of the circuit among the two circuit elements; a method and circuit for trimming a functional resistor on a thermally-isolated micro-platform such that a constant temperature distribution is obtained across the functional resistor; and a method and circuit for calculating a temperature coefficient of resistance of a functional resistor.

Owner:SENSORTECHNICS

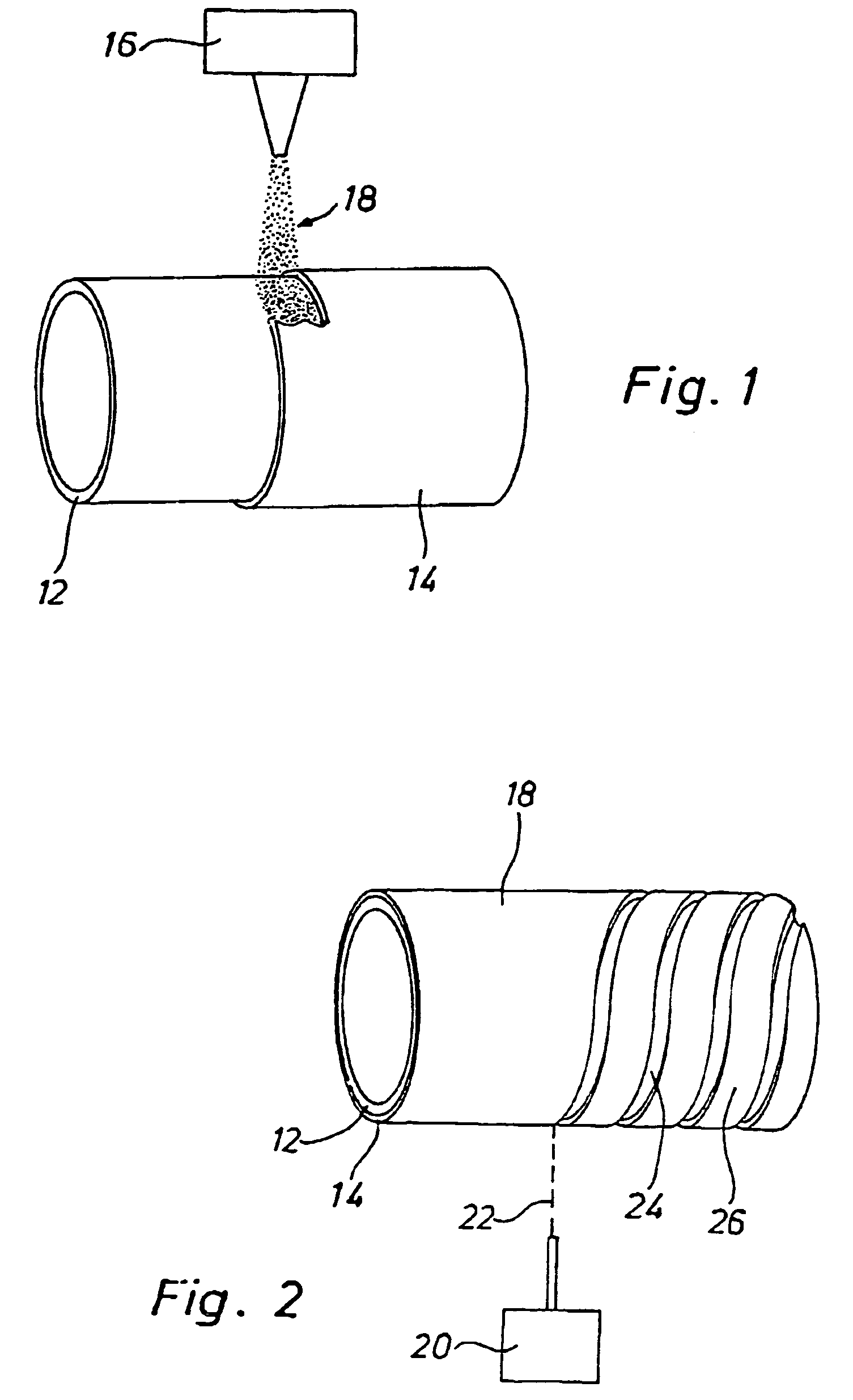

Method for the production of an electrically conductive resistive layer and heating and/or cooling device

InactiveUS7361869B2Improve adhesionCost for heatingMolten spray coatingHeating element shapesElectrical resistance and conductanceConductive materials

An electrically conductive resistive layer (26) is produced by thermally spraying an electrically conductive material (18) onto the surface of a non-conductive substrate (12). Initially, the material layer (14) arising therefrom has no desired shape. The material layer (14) is then removed (24) in certain areas so that an electrically conductive resistive layer (26) having said desired shape is produced.

Owner:WATLOW ELECTRIC MFG

Trimming temperature coefficients of electronic components and circuits

InactiveUS20060279349A1Improve accuracyDetecting faulty computer hardwareResistor trimmingEngineeringElectronic component

There is described methods and circuits for trimming a temperature coefficient of change of a parameter of at least one electrical component while maintaining a substantially constant parameter value, the method comprising applying a heating cycle to trim said parameter value away from a target parameter value and back to said target parameter value, whereby the temperature coefficient of change is modified after applying said heating cycle.

Owner:SENSORTECHNICS

Passive component

InactiveUS6529116B2High resistivityImprove signal-to-noise ratioThin/thick film capacitorStacked capacitorsElectrical resistance and conductanceEngineering

The passive component (1) has a first part (22) of a material with a first resistance value, which value can be lowered to a second value by laser trimming. The second value is at most one tenth of the first value and preferably less. The material crystallizes in a laser trimming process, which locally heats the material to at least a transition temperature. The material contains at least two different elements, which are preferably aluminum and germanium.The passive component (1) may be, for example, a resistor or a capacitor and may be part of a thin-film network of resistors, capacitors and / or inductors. In a resistor, it is preferred to have a second part (4) which contains a different resistance material with a resistance value lower than the first value and preferably higher than the second value.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Cartridge for an aerosol-generating system with customizable indentification resistance

ActiveUS20170135405A1Increase flexibilitySimplify production and manufactureTobacco devicesResistor housing/enclosing/embeddingElectrical resistance and conductanceEmbedded system

In a method of manufacturing a cartridge of an electronic vaping device, wherein the cartridge includes a pre-vapor formulation storage element, an electrical resistor is physically manipulated to change a resistance of the electrical resistor from a first resistance value to a second resistance value, the second resistance value indicative of a pre-vapor formulation substrate contained in the pre-vapor formulation storage element. The electrical resistor is then mounted to a portion of the cartridge.

Owner:AKRIA CLIENT SERVICES LLC

Thin film thermosensitive resistor and tis resistance valve regulating method

InactiveCN1409329APrevent compositional changesWith characteristicsResistor trimmingThermistorsHeat sensitiveOptoelectronics

In a thin film thermistor with a cutting portion of a metallic pattern for resistance adjustment, initially, the resistance is roughly adjusted by adjusting the film thickness of a second heat-sensitive film, and secondly finely adjusted by trimming the cutting portion by laser irradiation. Thus, the thin film thermistor with a resistance adjusted accurately can be produced.

Owner:ISHIZUKI ELECTRONICS

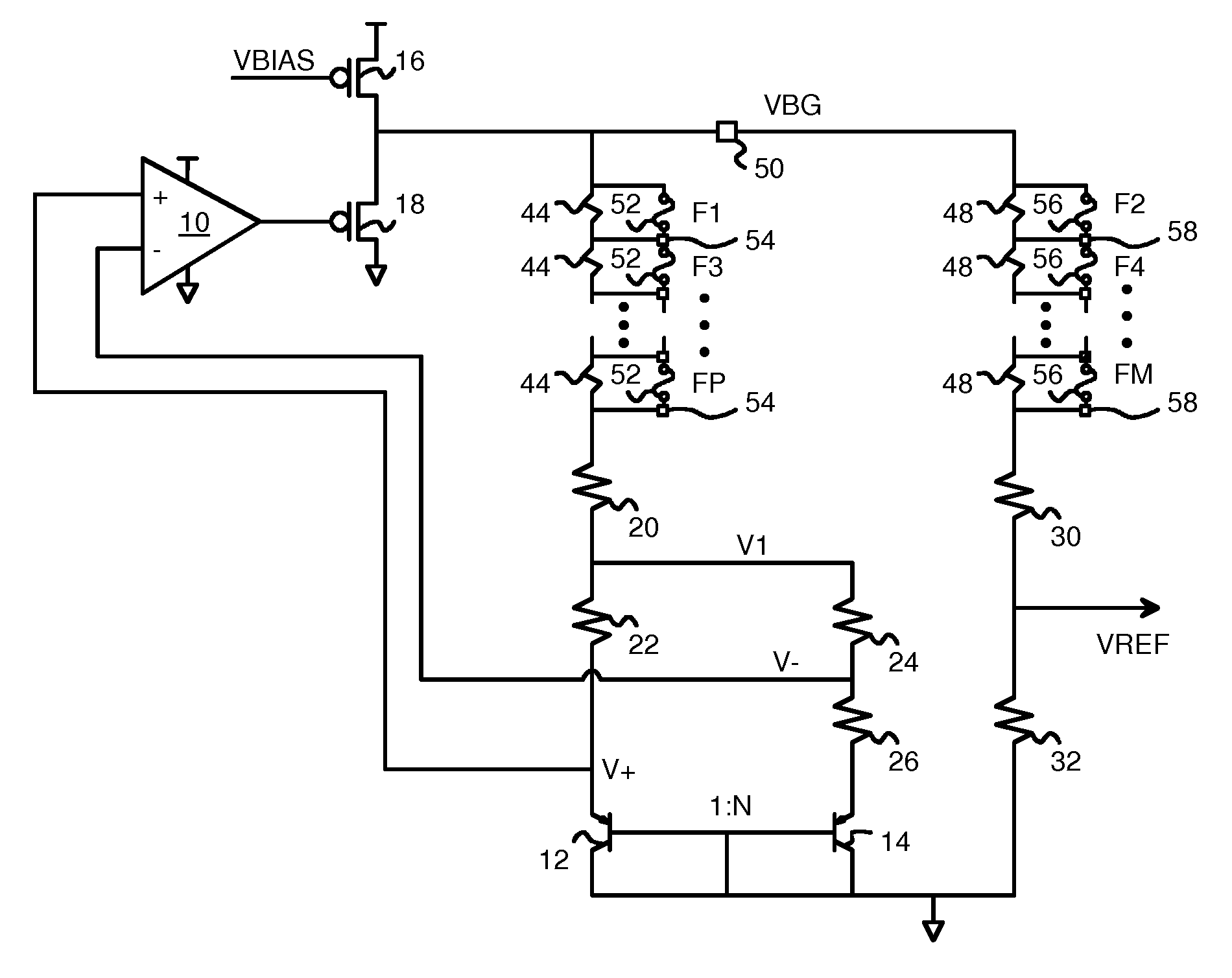

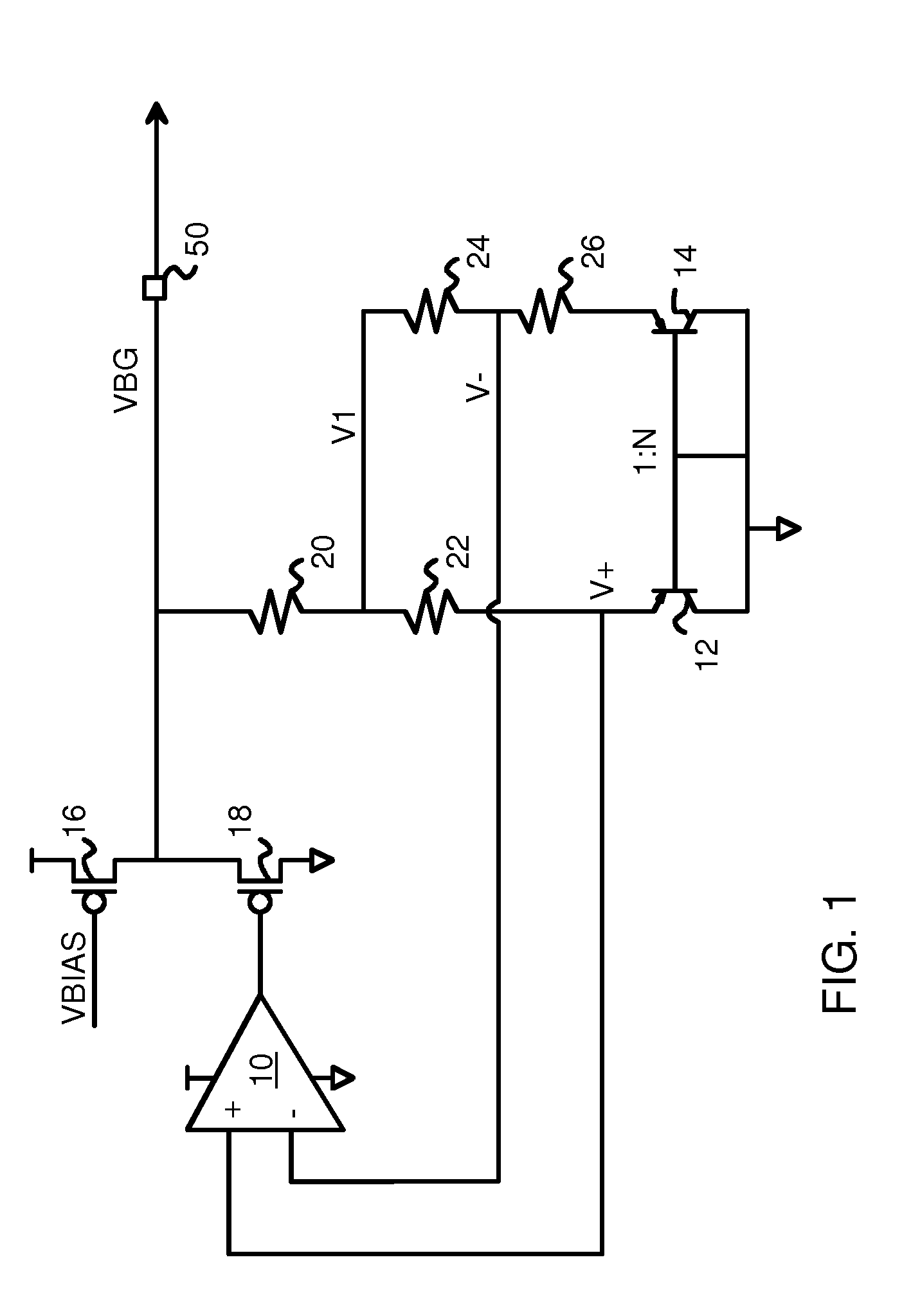

Bi-directional Trimming Methods and Circuits for a Precise Band-Gap Reference

ActiveUS20110163799A1Resistor trimmingElectric variable regulationElectrical resistance and conductanceReference circuit

A bandgap reference circuit has trimming-up resistors and trimming-down resistors for bi-directional trimming. PNP transistors have base and collectors grounded and emitters connected to parallel resistors. A difference resistor drives an inverting input of an op amp that drives a transistor that generates the bandgap reference voltage Vbg. A sensing resistor connects Vbg to a splitting node that connects to the non-inverting input through a first parallel resistor. The splitting node also connects through a second parallel resistor to the inverting input. Fuses or switches enable the trimming-up and trimming-down resistors. The trimming-up resistors are in series with the sensing resistor and the trimming-down resistors are in series with an output resistor that connects Vbg to reference voltage Vref. The circuit can be designed for a more typical process since bi-directional trimming allows Vref to be raised or lowered. Many circuits need no trimming when targeted for the typical process.

Owner:HONG KONG APPLIED SCI & TECH RES INST

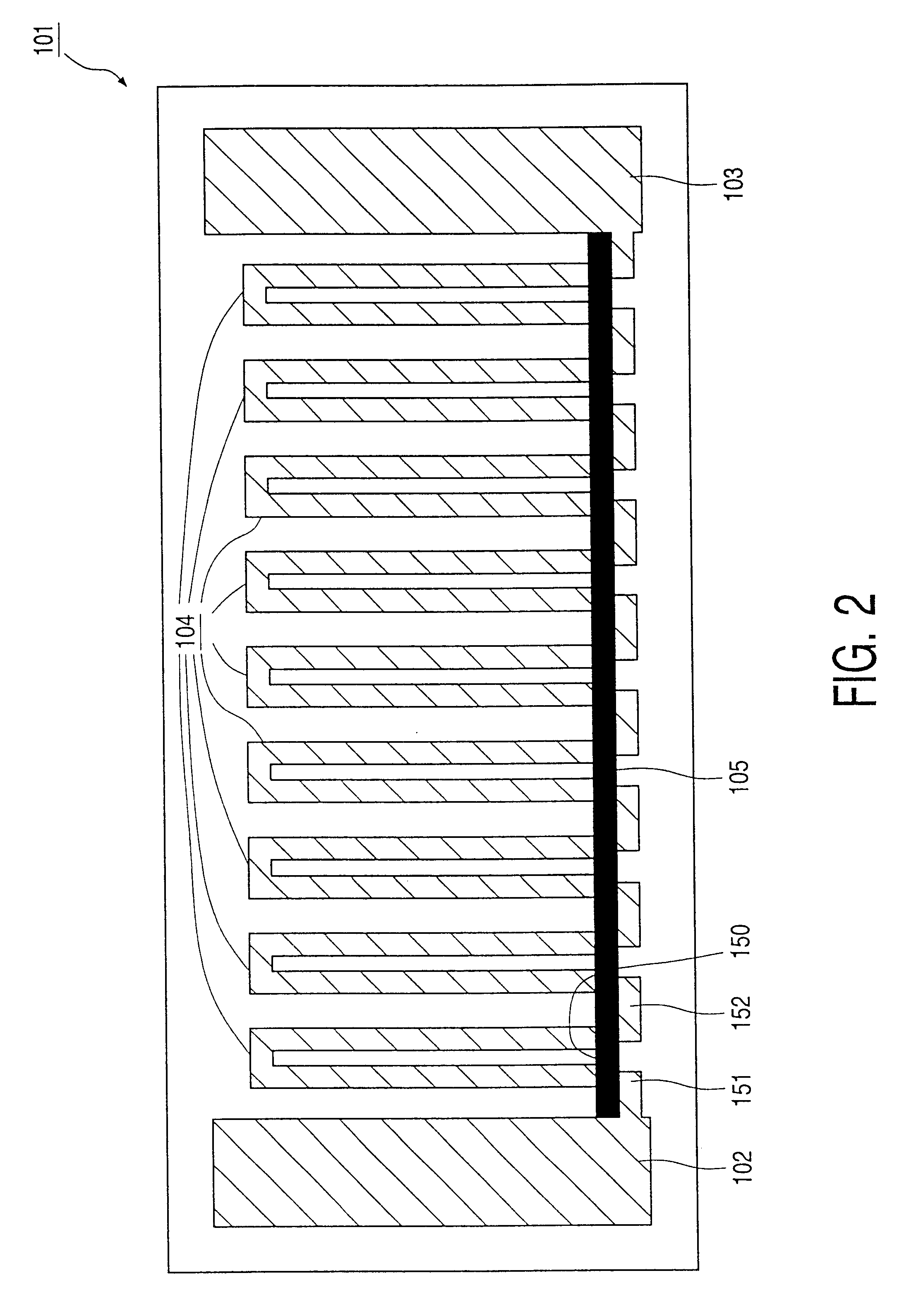

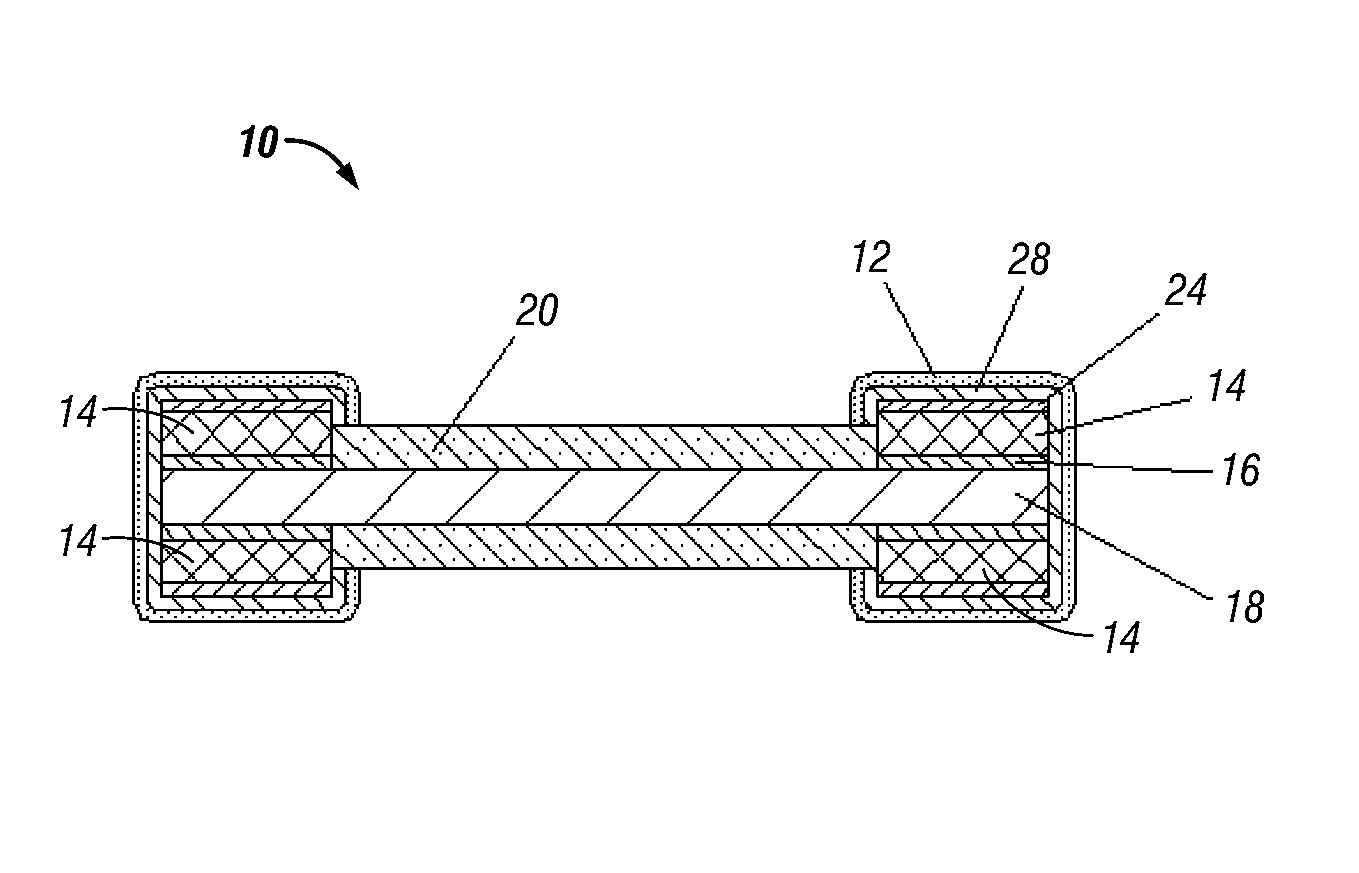

Power resistor

InactiveUS7843309B2Spread heatElongated resistive elementResistor cooling/heating/ventillationMetal stripsElectrical resistance and conductance

A resistor includes first and second opposite terminations, a resistive element formed from a plurality of resistive element segments between the first and second opposite terminations, at least one segmenting conductive strip separating two of the resistive element segments, and at least one open area between the first and second opposite terminations and separating at least two resistive element segments. Separation of the plurality of resistive element segments assists in spreading heat throughout the resistor. The resistor or other electronic component may be packaged by bonding to a heat sink tab with a thermally conductive and electrically insulative material. The resistive element may be a metal strip, a foil, or film material.

Owner:VISHAY DALE ELECTRONICS INC

Method of making circuitized substrates having film resistors as part thereof

InactiveUS20090178271A1Low costPrinted circuit aspectsInspection/indentification of circuitsElectrical resistance and conductanceEngineering

A method of making a circuitized substrate which involves forming a plurality of individual film resistors having approximate resistance values as part of at least one circuit of the substrate, measuring the resistance of a representative (sample) resistor to define its resistance, utilizing these measurements to determine the corresponding precise width of other, remaining film resistors located in a defined proximity relative to the representative resistor such that these remaining film resistors will include a defined resistance value, and then selectively isolating defined portions of the resistive material of these remaining film resistors while simultaneously defining the precise width of the resistive material in order that these film resistors will possess the defined resistance.

Owner:I3 ELECTRONICS

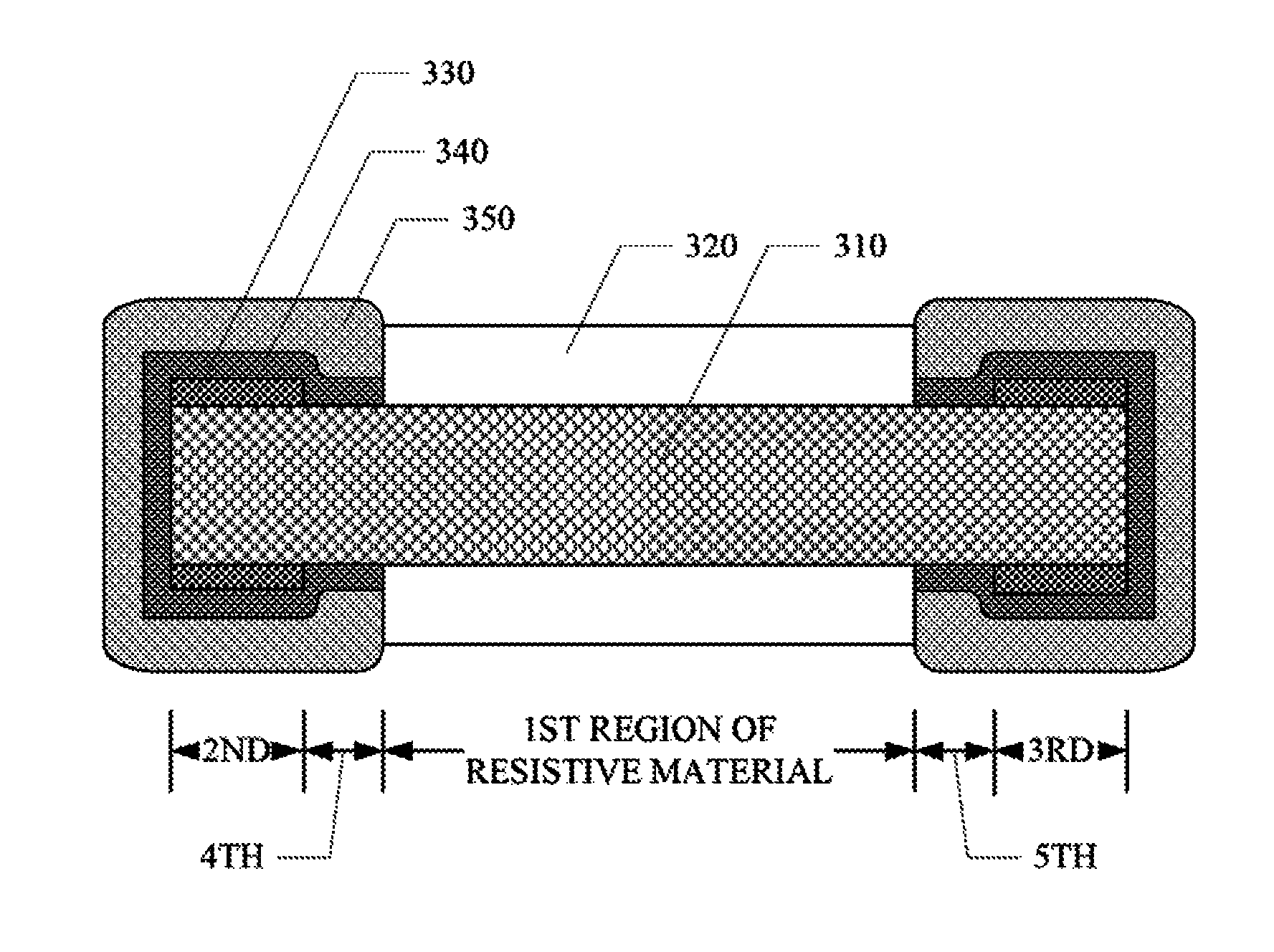

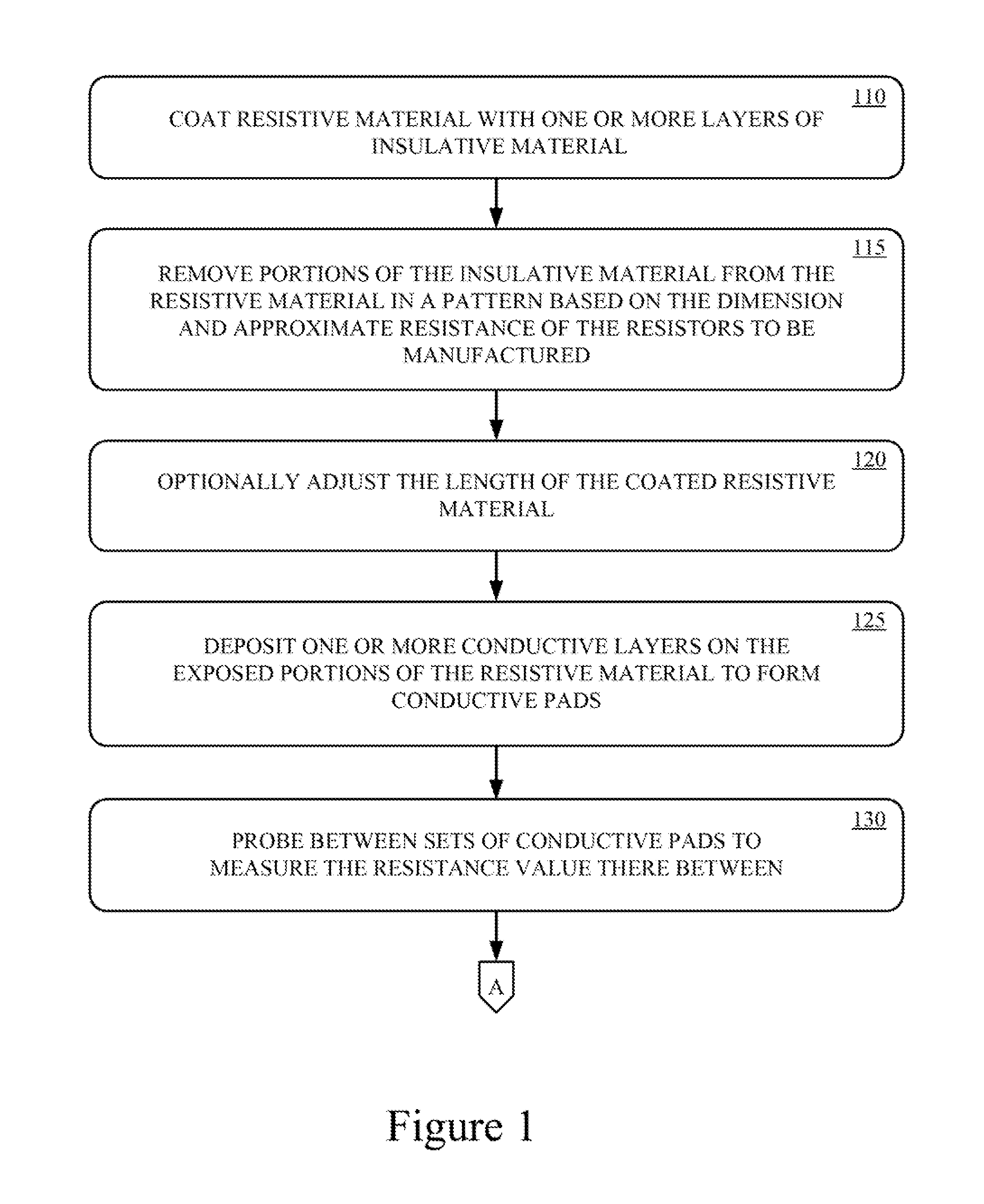

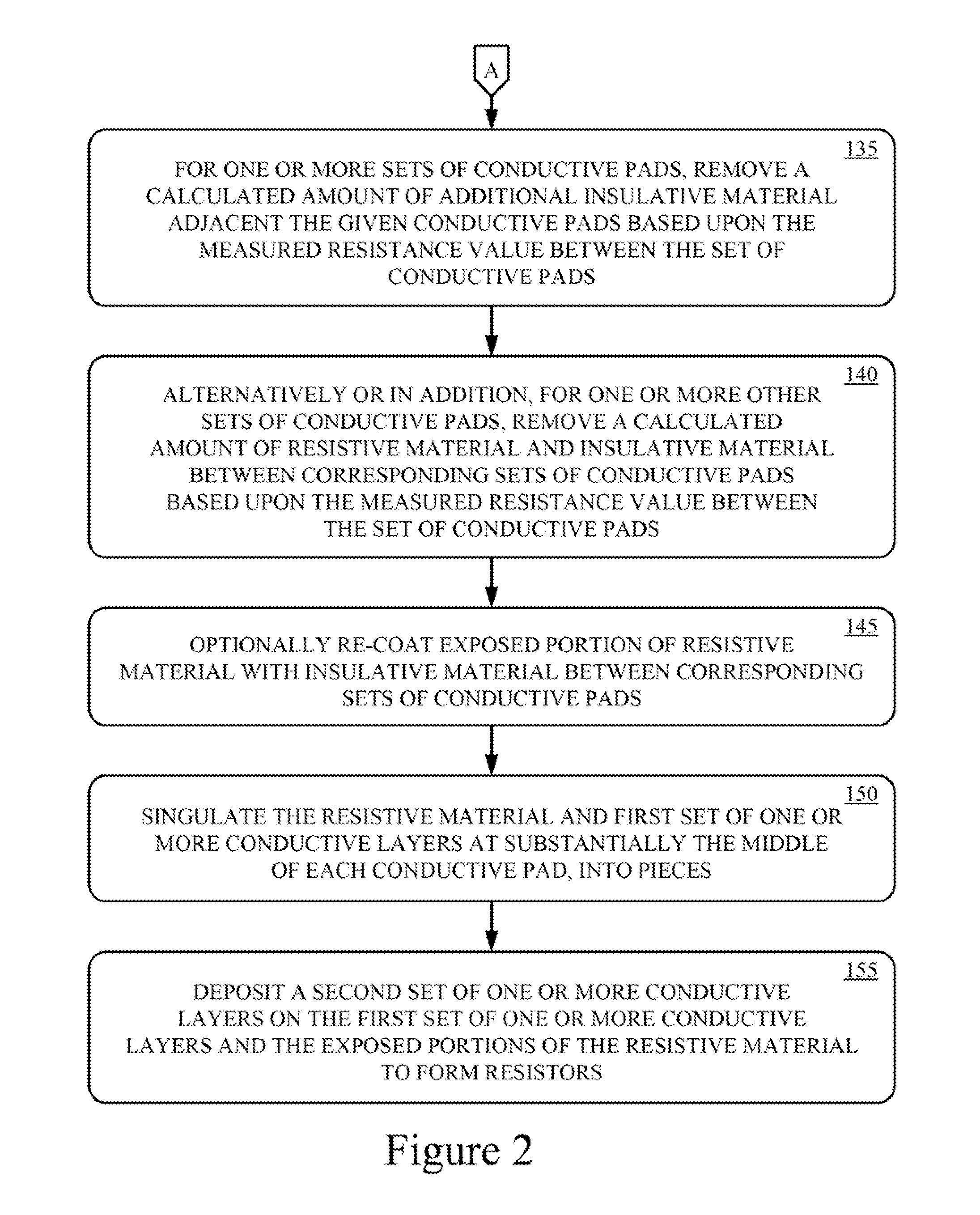

Resistor and method of manufacture

ActiveUS9396849B1Mass resistorsEnvelope/housing resistor manufactureResistorElectrical and Electronics engineering

The present technology is directed toward a resistor and method of manufacturing the resistor. One or more layers of insulative material are formed on a length of resistive material. Portions of the one or more layers insulative material are removed from the resistive material in a pattern based on a predetermined approximate dimension and predetermined approximate resistance value. A first set of one or more conductive layers are formed on the portions of the resistive material exposed by the insulative coating to form a plurality of conductive pads on the resistive material between the patterned insulative material. The sets of conductive pads are probed to measure a preliminary resistance value between the sets of conductive pads. For one or more sets of conductive pads, a calculated amount of additional insulative material adjacent the respective conductive pads is removed based upon the preliminary resistance value between the corresponding set of conductive pads and a final resistance value to exposed additional portions of resistive material. The conductive pads and resistive material is cut at substantially the middle of each conductive pad to form pieces. A second set of one or more conductive layers are formed on the first set of one or more conductive layers at opposing ends of each piece, and the additionally exposed portions of the resistive material.

Owner:VISHAY DALE ELECTRONICS INC

Method for trimming resistors

InactiveUS7249409B2Efficient pruningReduce the amount requiredWave amplification devicesThermometers using electric/magnetic elementsElectrical resistance and conductanceTemperature coefficient

There is provided a method and circuit for trimming a functional resistor on a thermally isolated micro-platform such that a second functional resistor on the same micro-platform remains substantially untrimmed; a method and circuit for providing and trimming a circuit such that at least two circuit elements of the circuit are subjected to a same operating environment and the operating environment is compensated for by distributing heat generated during operation of the circuit among the two circuit elements; a method and circuit for trimming a functional resistor on a thermally-isolated micro-platform such that a constant temperature distribution is obtained across the functional resistor; and a method and circuit for calculating a temperature coefficient of resistance of a functional resistor.

Owner:SENSORTECHNICS

Method for measurement of temperature coefficients of electric circuit components

InactiveUS20070109091A1Efficient measurementNegative temperature coefficient thermistorsPositive temperature coefficient thermistorsElectronic componentTemperature coefficient

There is described a method and circuit for determining a temperature coefficient of change of a parameter of an electrical component, the method comprising: providing at least one thermally-isolated micro-platform on a substrate; placing an electrical component on the at least one thermally-isolated micro-platform; heating the electrical component; measuring a parameter value of the electrical component at a plurality of temperatures; and determining the temperature coefficient based on the measured parameter values.

Owner:MICROBRIDGE TECH INC

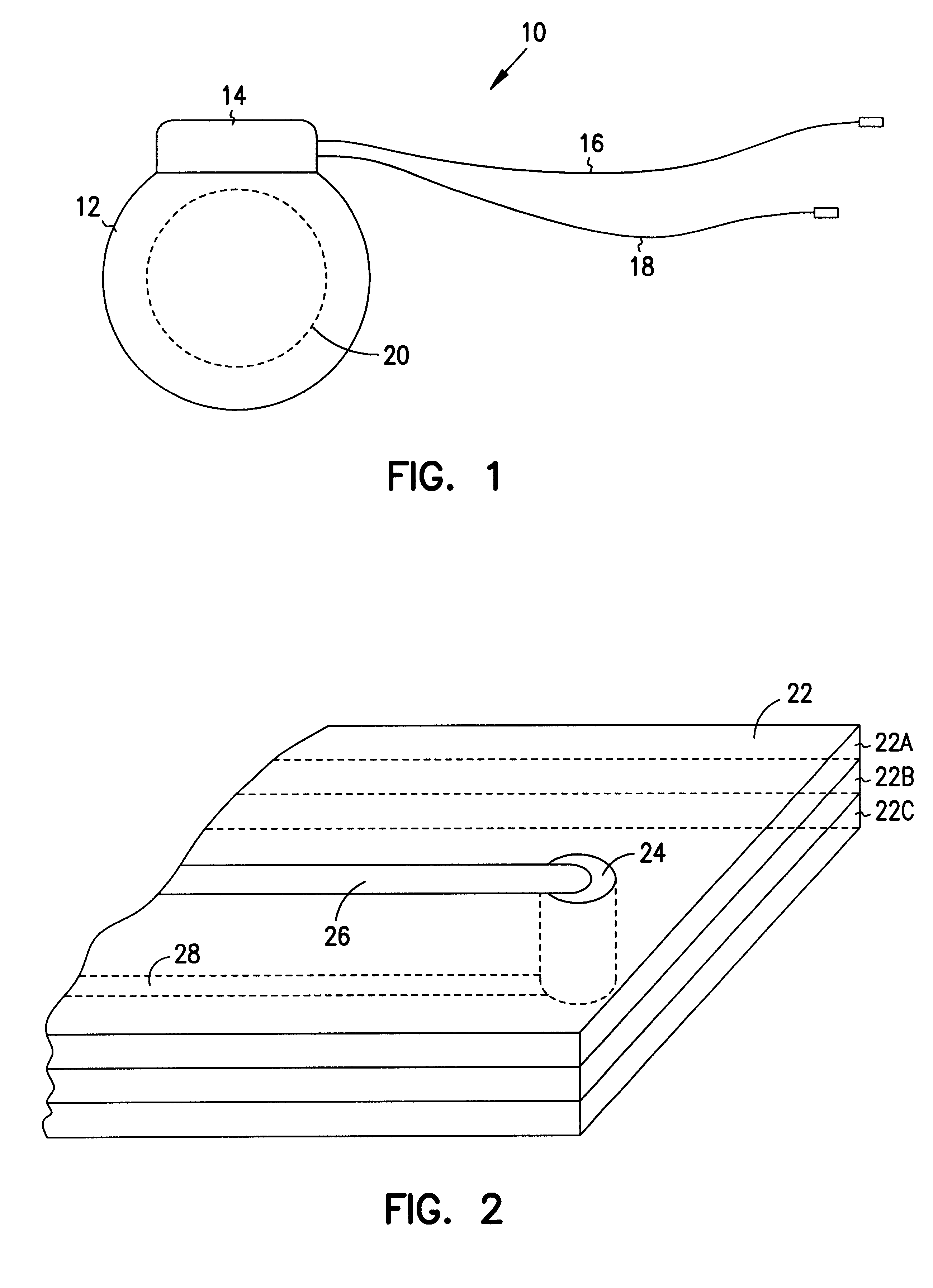

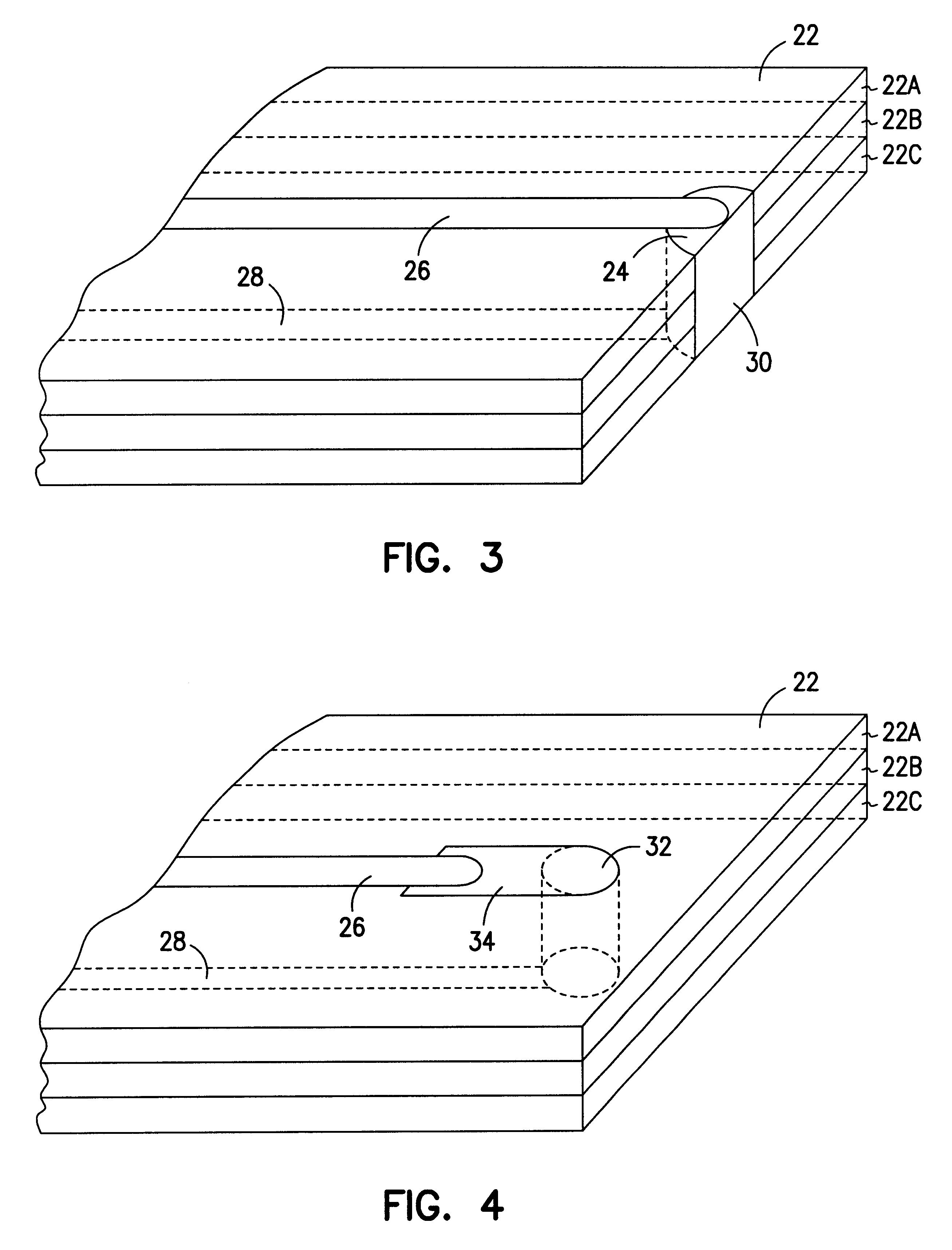

Embedded trimmable resistors

InactiveUS6047463APrinted circuit aspectsInsulating layers/substrates workingResistorElectrical and Electronics engineering

A resistor may be embedded into a substrate. A portion of the resistor may be exposed, by segmenting the substrate, for instance, so that the resistor may be trimmed to a desired resistance level. Alternatively, a portion of a resistor may be embedded into a substrate, with another portion of the resistor being disposed on the outer surface of the substrate. The portion of the resistor on the outer surface may be trimmed to adjust the resistance of the resistor to a desired level.

Owner:INTERMEDICS

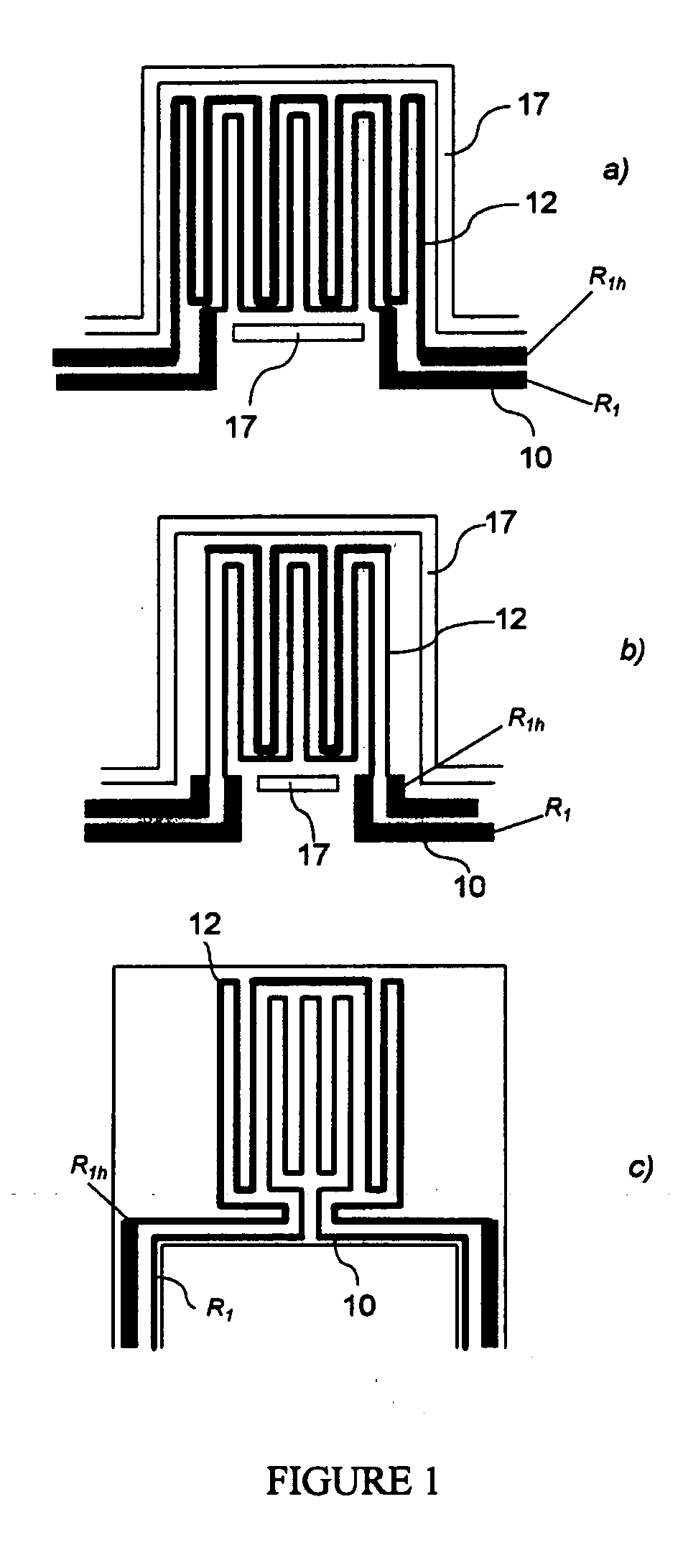

Trimmed surge resistors

InactiveUS6107909AFixed resistors with intervening connectorsCurrent responsive resistorsElectrical resistance and conductanceEngineering

An electrical resistor having a resistance value and capable of withstanding high power surges, utilizing a thick film deposited on a substrate and trimmed with one or more cuts configured to maintain a level of current crowding while increasing the resistance value of the resistor. A surge resistor can be modified in a similar fashion.

Owner:MMC BIDDING

Method for manufacturing precise metal strip resistor

InactiveCN101587766AOverall goodImprove processing efficiencyResistor trimmingResistors adapted for applying terminalsElectrical resistance and conductanceMetal strips

A method for manufacturing precise metal strip resistor comprises: selecting an alloy strip and two metal strips; cleaning them; welding the two metal strips respectively on two sides of the alloy strip by high energy electron beam welding technique to form an integral resistor strip; punching the resistor strip transversely into a plurality of resistor bodies, or punching the alloy thin plate into a plurality of resistor bodies; then adjusting the numerical resistance values of the resistor bodies; and performing subsequent improvement processing to the resistor bodies to form precise metal strip resistor. Compared with the current technologies, The method provided in the invention reduces more than half of the production processes, increases the efficiency by tem times; reduces the product volume greatly, and realizes the production of surface applied precise splitter with low resistance, small volume and heavy bearable current. The resistor manufactured by the method provided in the invention has the characteristics of good performance, small volume and low material consumption.

Owner:BDS ELECTRONICS +1

Resistor and method for making same

ActiveUS8242878B2Increase heightLower resistanceResistor manufacture by lithographyResistor mounting/supportingMetal stripsElectroplating

A metal strip resistor is provided. The metal strip resistor includes a metal strip forming a resistive element and providing support for the metal strip resistor without use of a separate substrate. There are first and second opposite terminations overlaying the metal strip. There is plating on each of the first and second opposite terminations. There is also an insulating material overlaying the metal strip between the first and second opposite terminations. A method for forming a metal strip resistor wherein a metal strip provides support for the metal strip resistor without use of a separate substrate is provided. The method includes coating an insulative material to the metal strip, applying a lithographic process to form a conductive pattern overlaying the resistive material wherein the conductive pattern includes first and second opposite terminations, electroplating the conductive pattern, and adjusting resistance of the metal strip.

Owner:VISHAY DALE ELECTRONICS INC

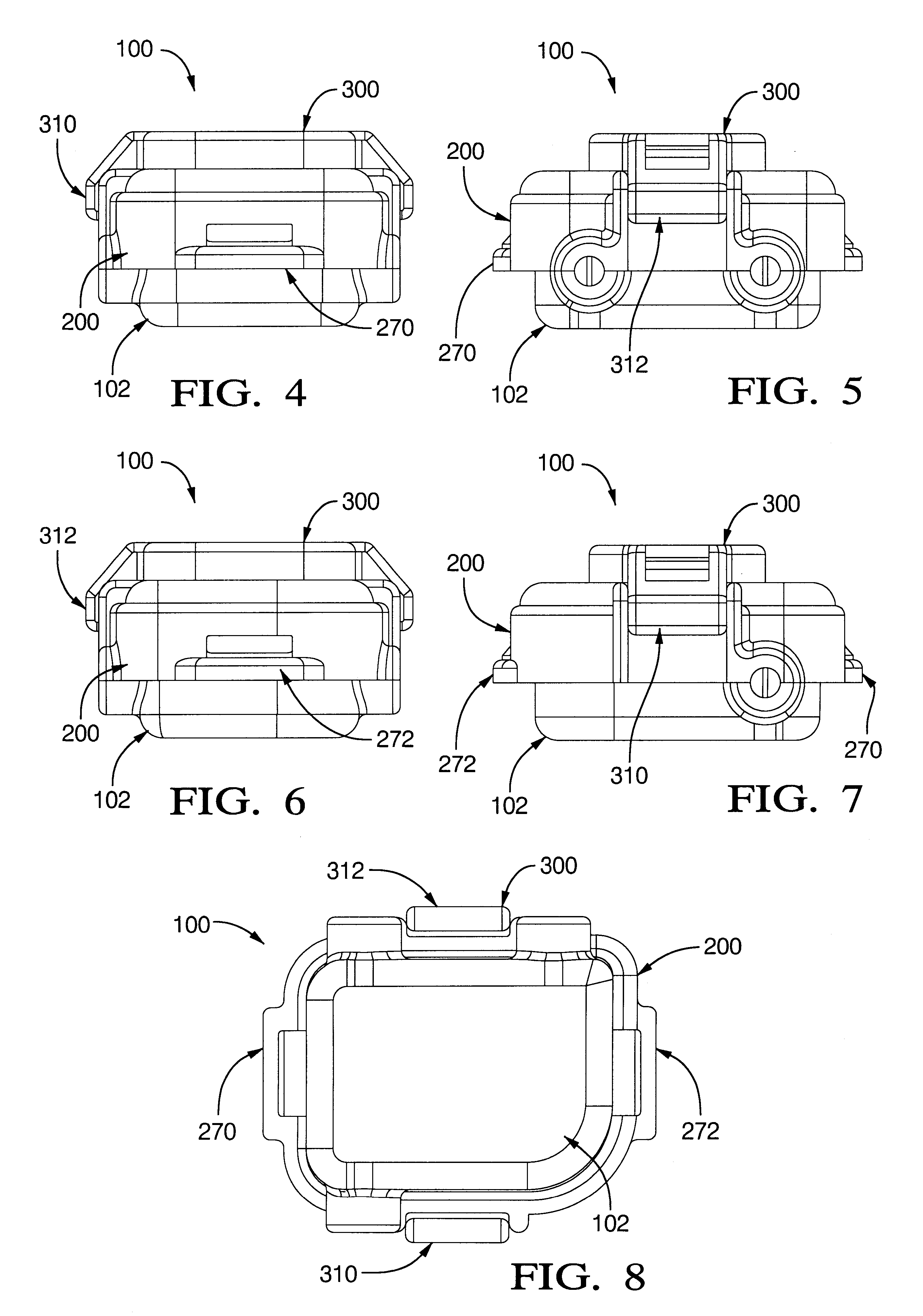

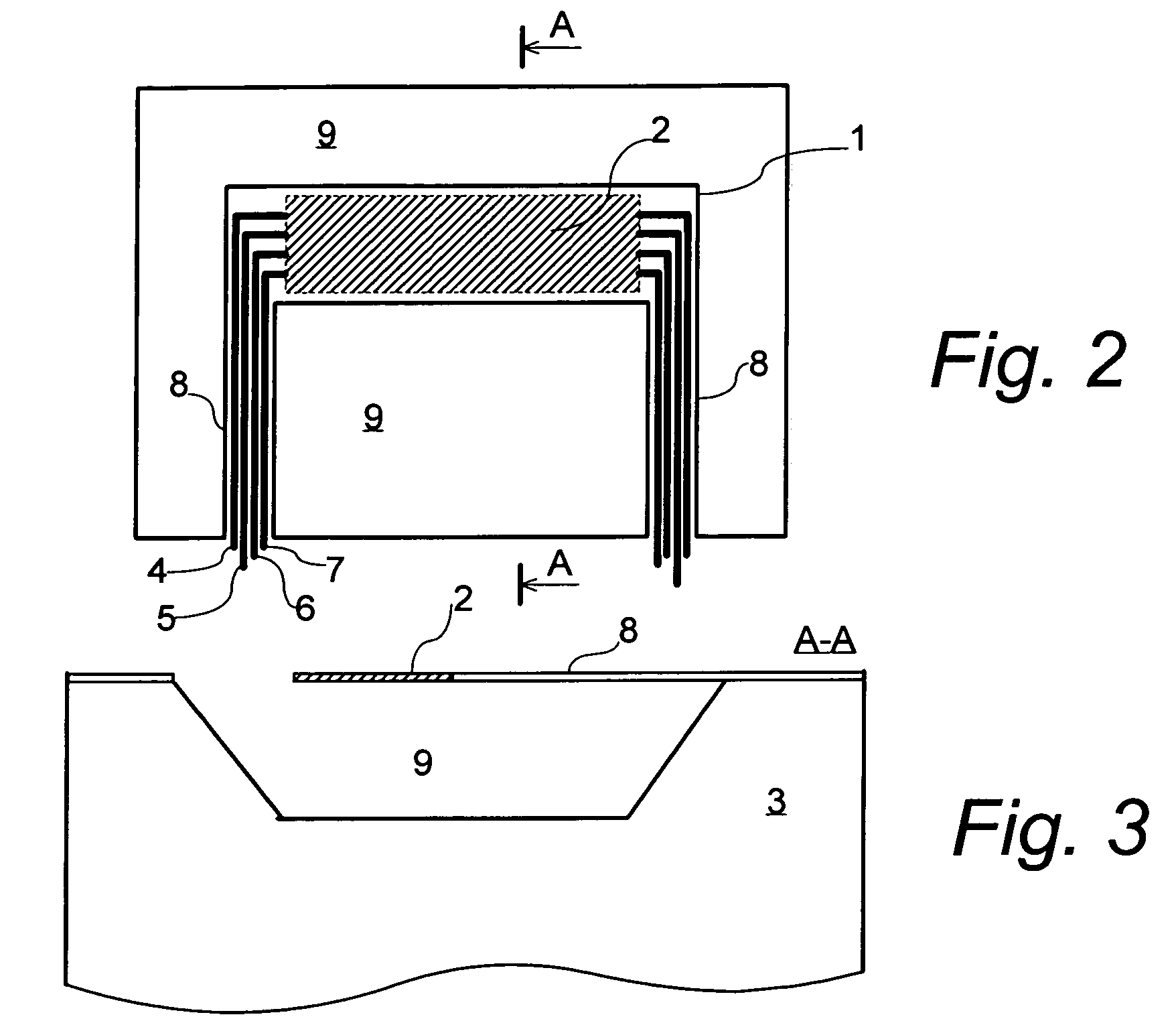

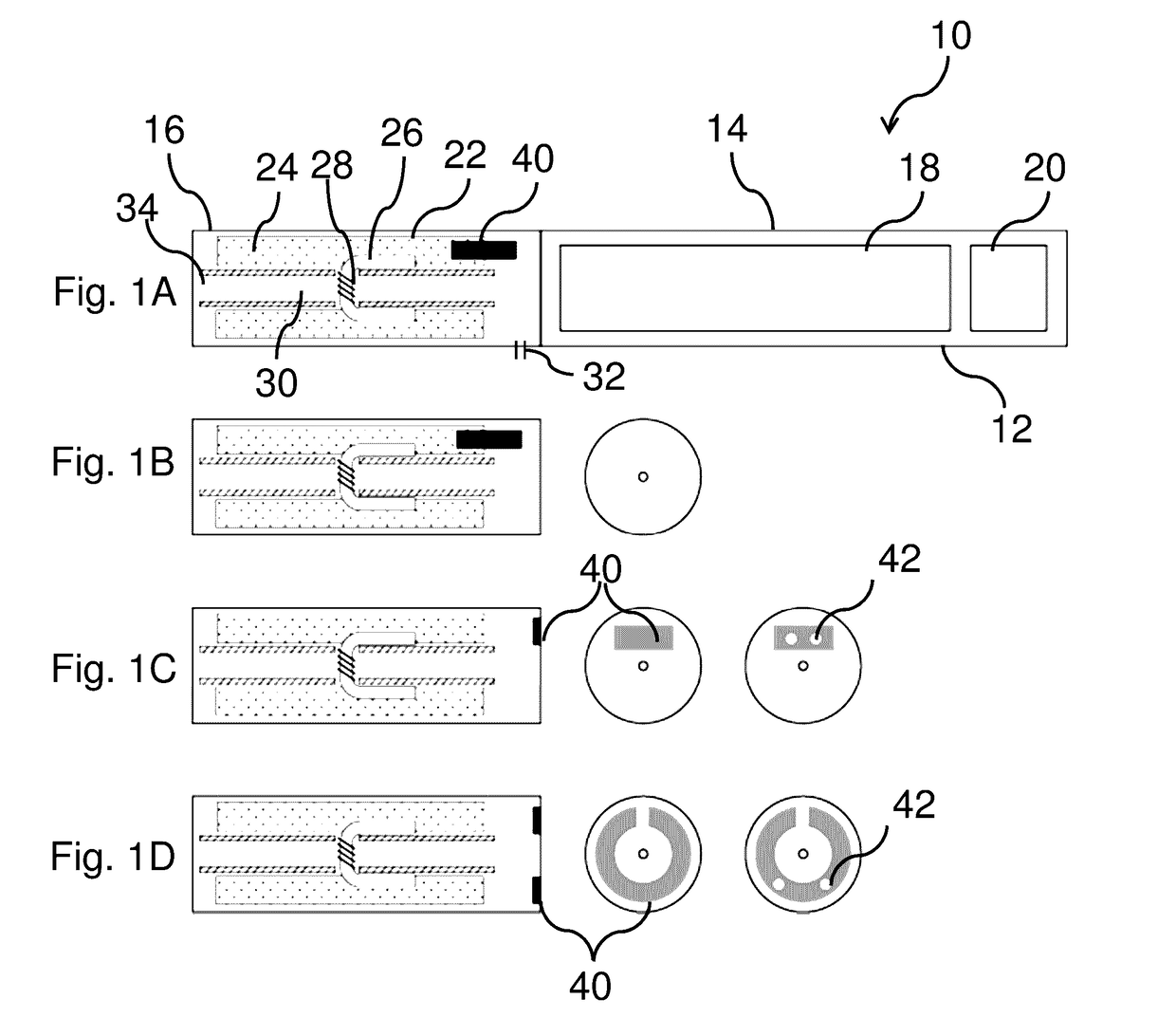

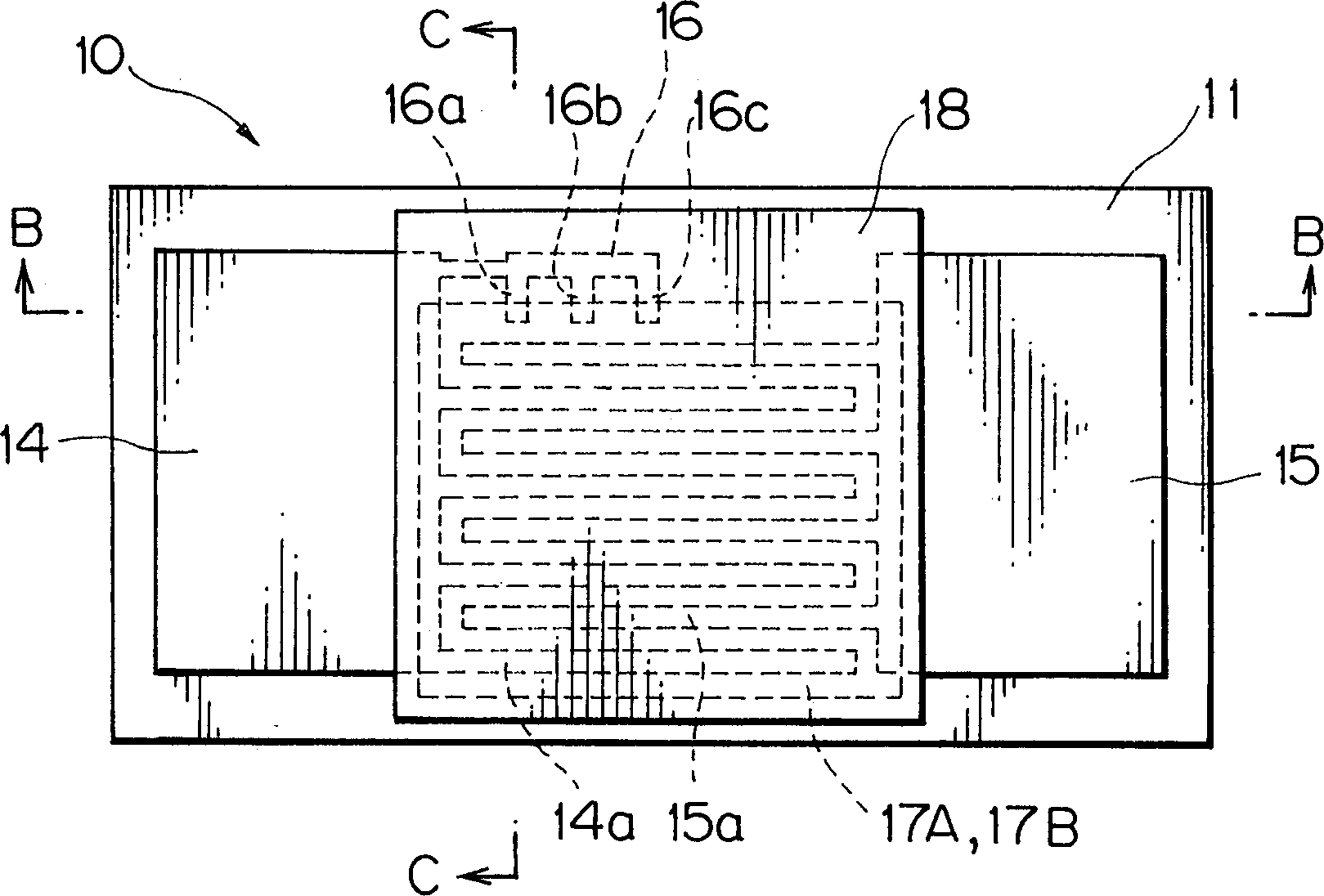

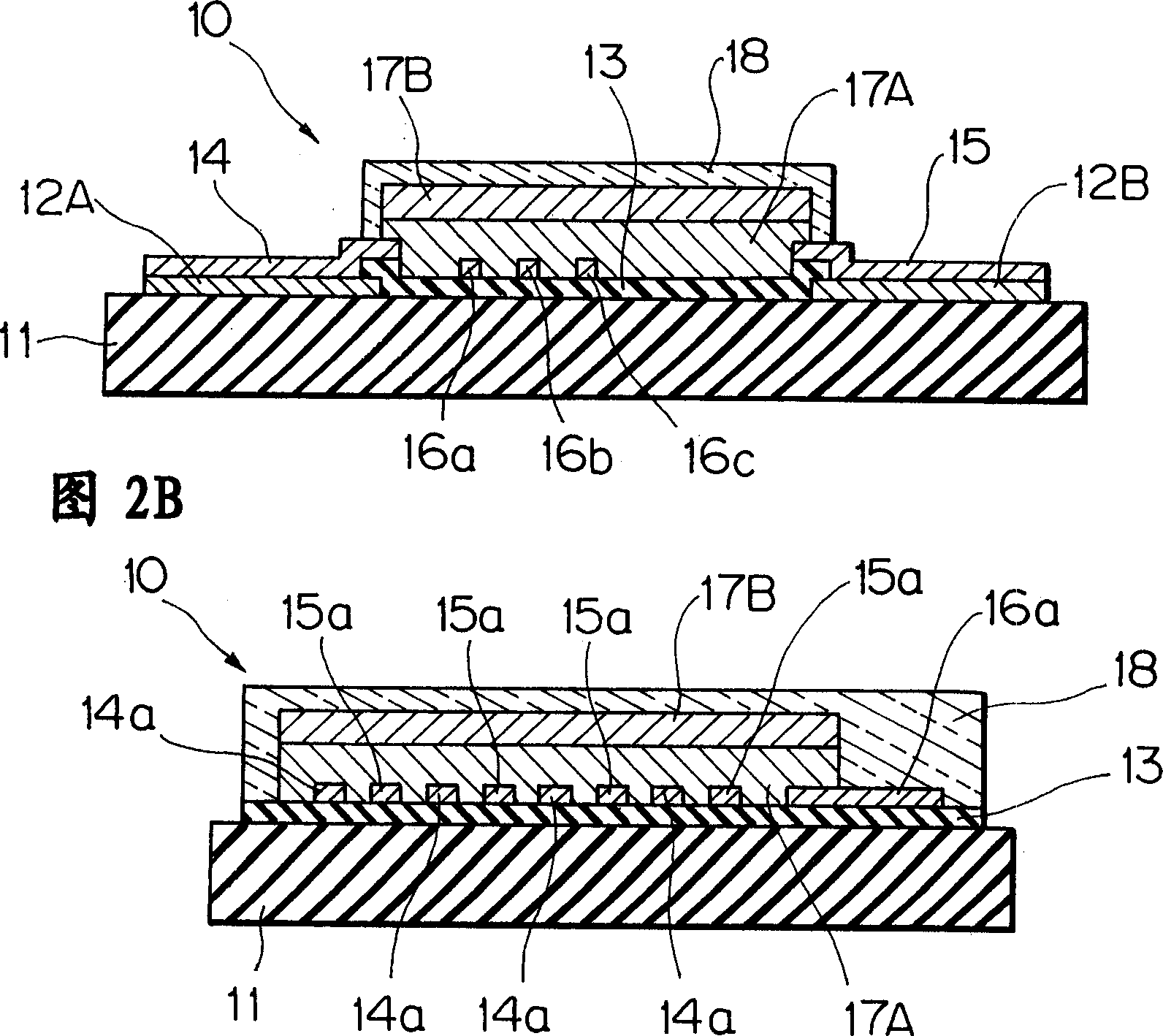

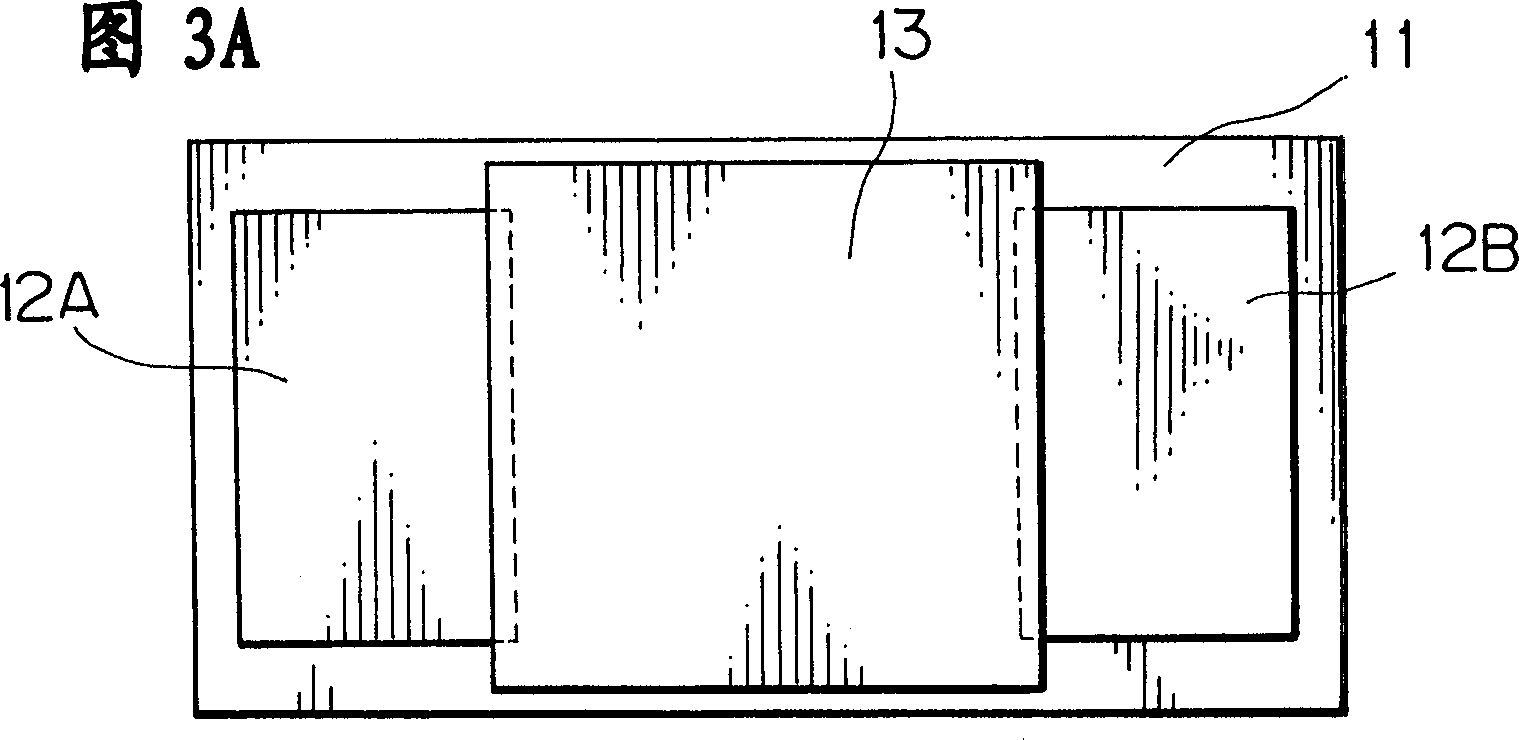

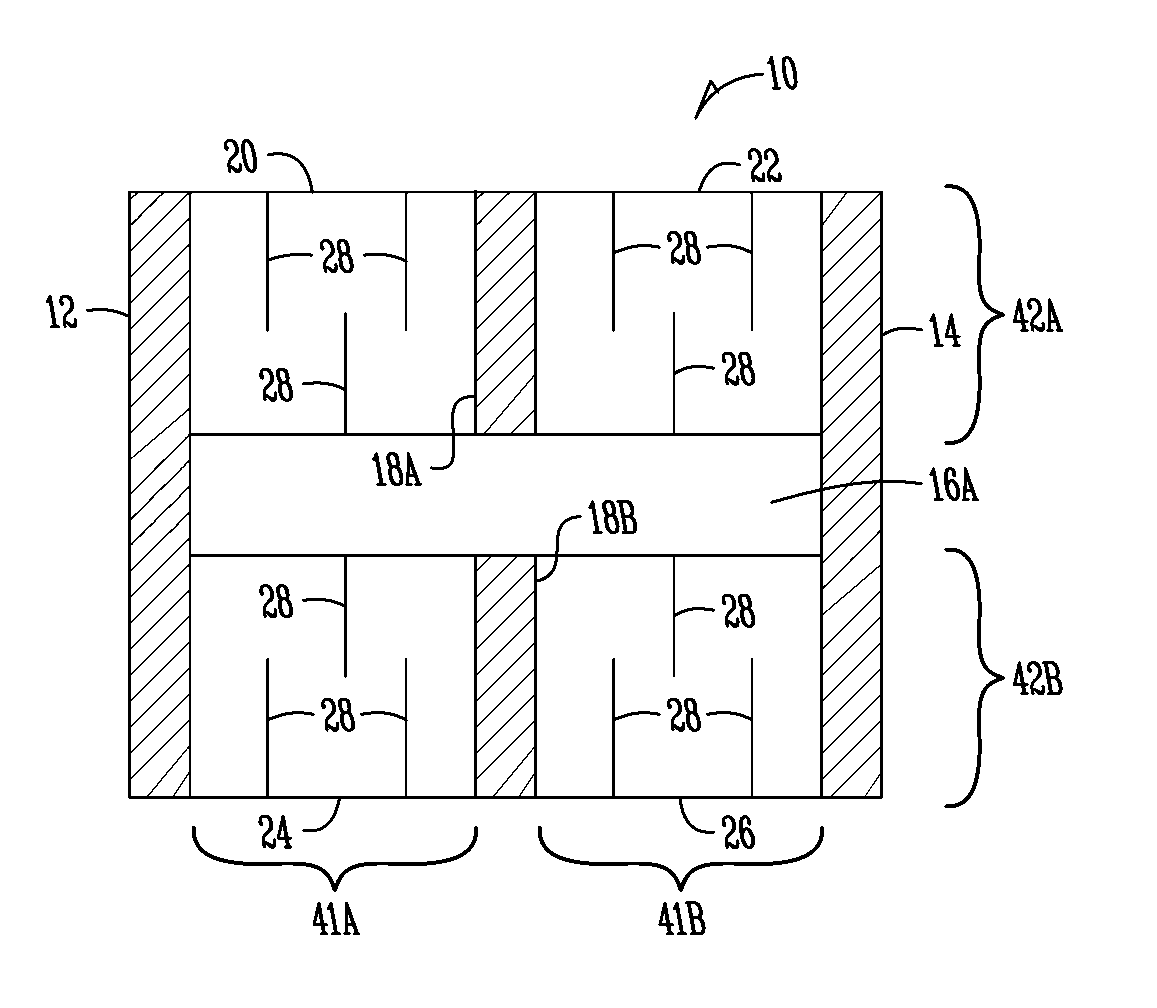

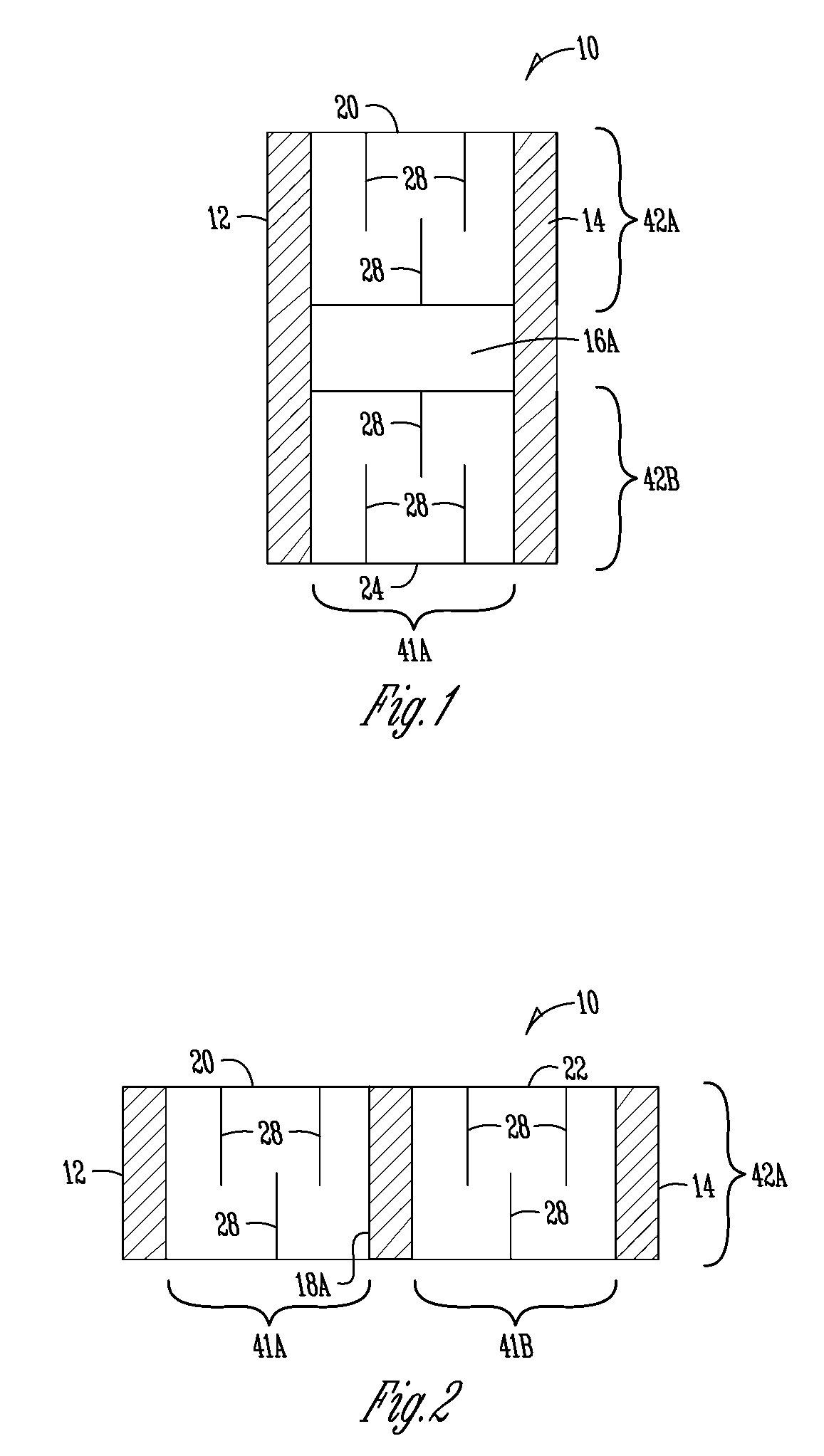

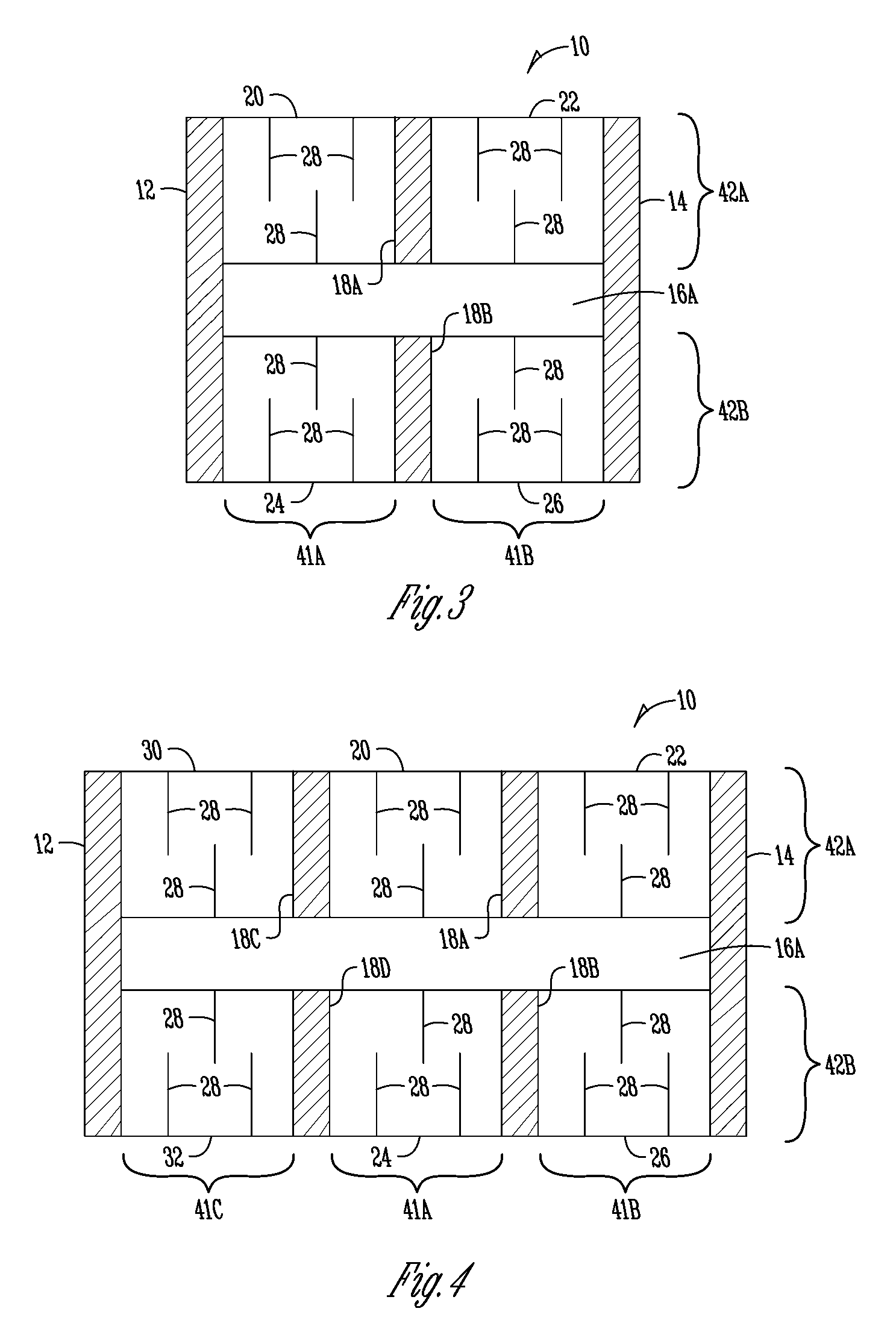

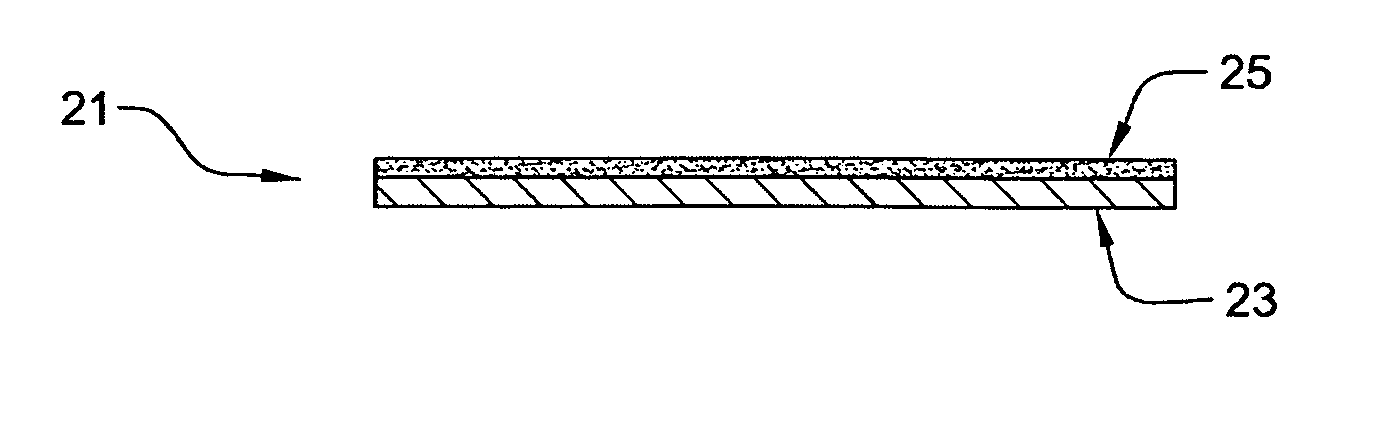

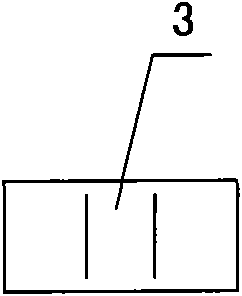

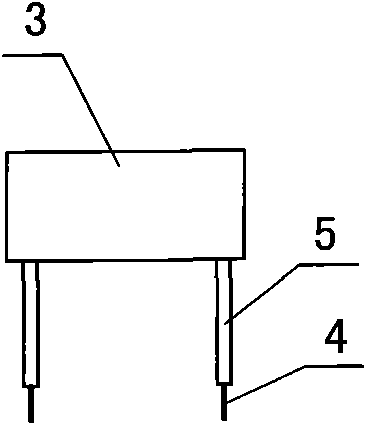

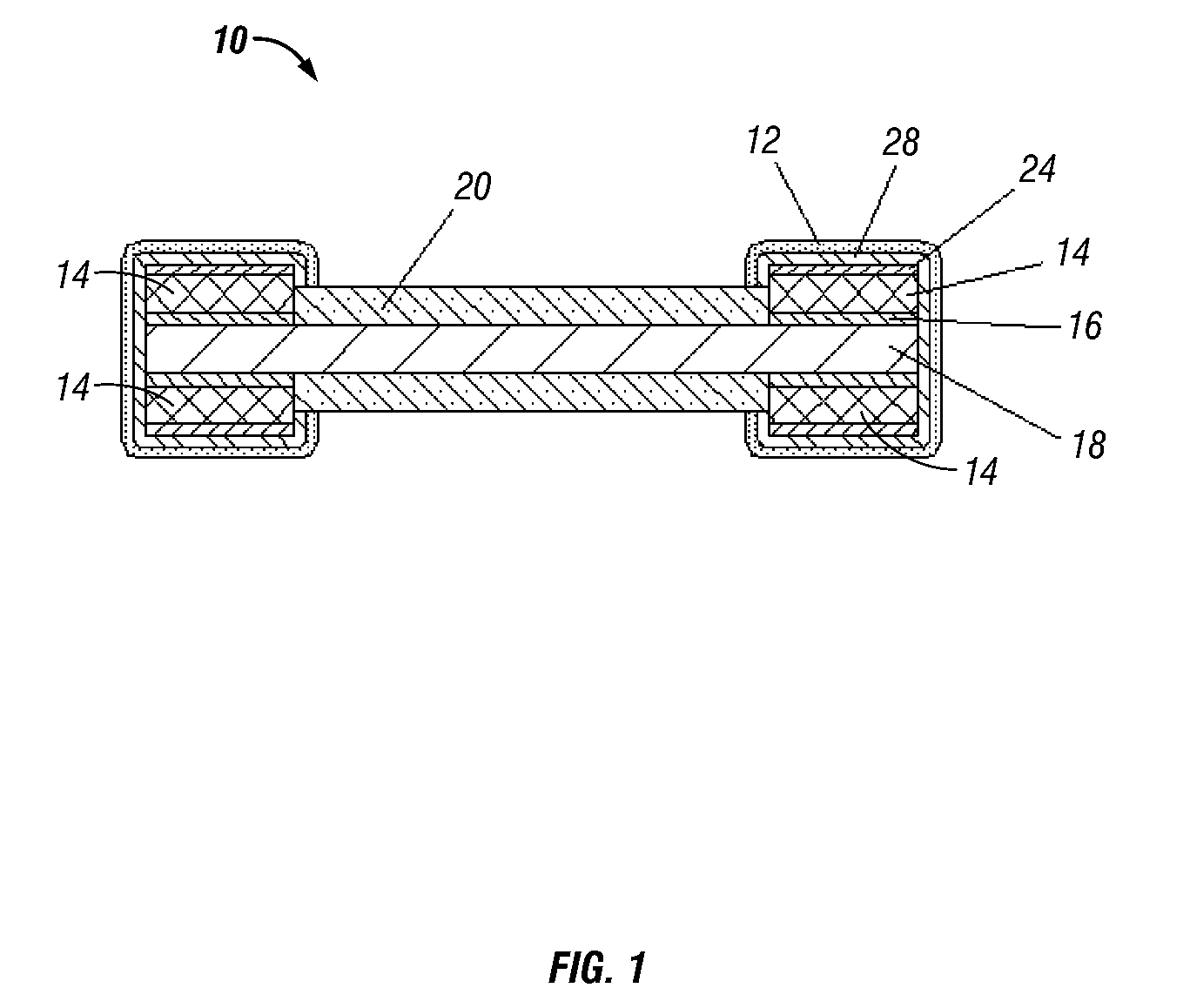

Injection molded trim resistor assembly

InactiveUS7161461B1Strengthen and seal jointConvenience to mergeResistor housing/enclosing/embeddingResistor trimmingElectrical resistance and conductanceContact pad

A trim resistor assembly includes a trimmable resistor element embedded within a polymeric housing. The trimmable resistor element includes trimmable resistive film disposed on a nonconductive substrate. Lead wires are connected to contact pads on the substrate. The resistor element and wires are pre-assembled and placed within a mold defining a cavity. The mold includes a pedestal that covers a central region of the substrate that includes the trimmable resistive film. A polymeric material is injected into the cavity to form an integrally molded body that is the polymeric housing. In addition to the trim resistor element and the bare end sections of the wires, the section of the wires that are adjacent the end sections and include the polymeric sheath are also embedded in the housing to strengthen and seal the joint. The pedestal forms an opening in the housing that exposes the resistive film to provide access for trimming the resistance to a desired value. By embedding the trimmable resistor element and the electrical connections within an integral body, the dimensions of the housing may be minimized, and damage to the electrical connections is reduced.

Owner:DELPHI TECH INC

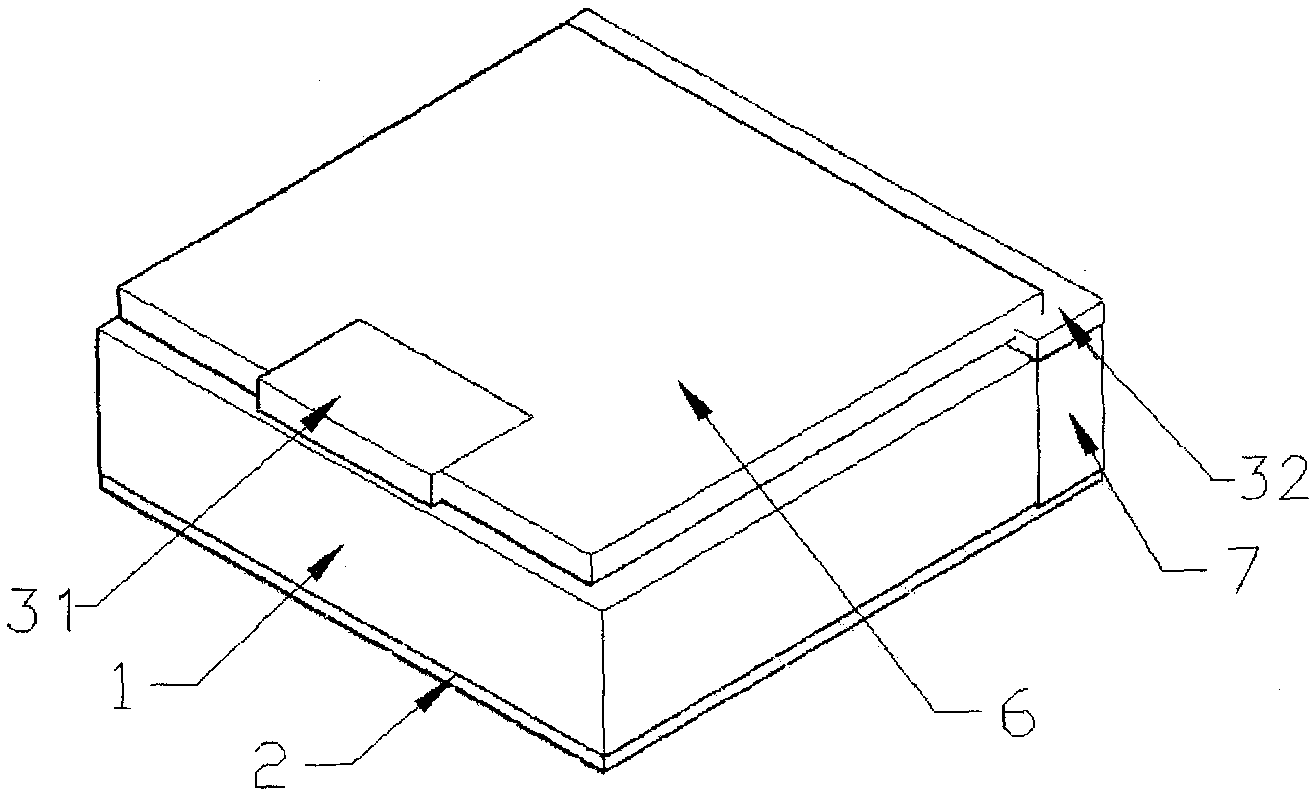

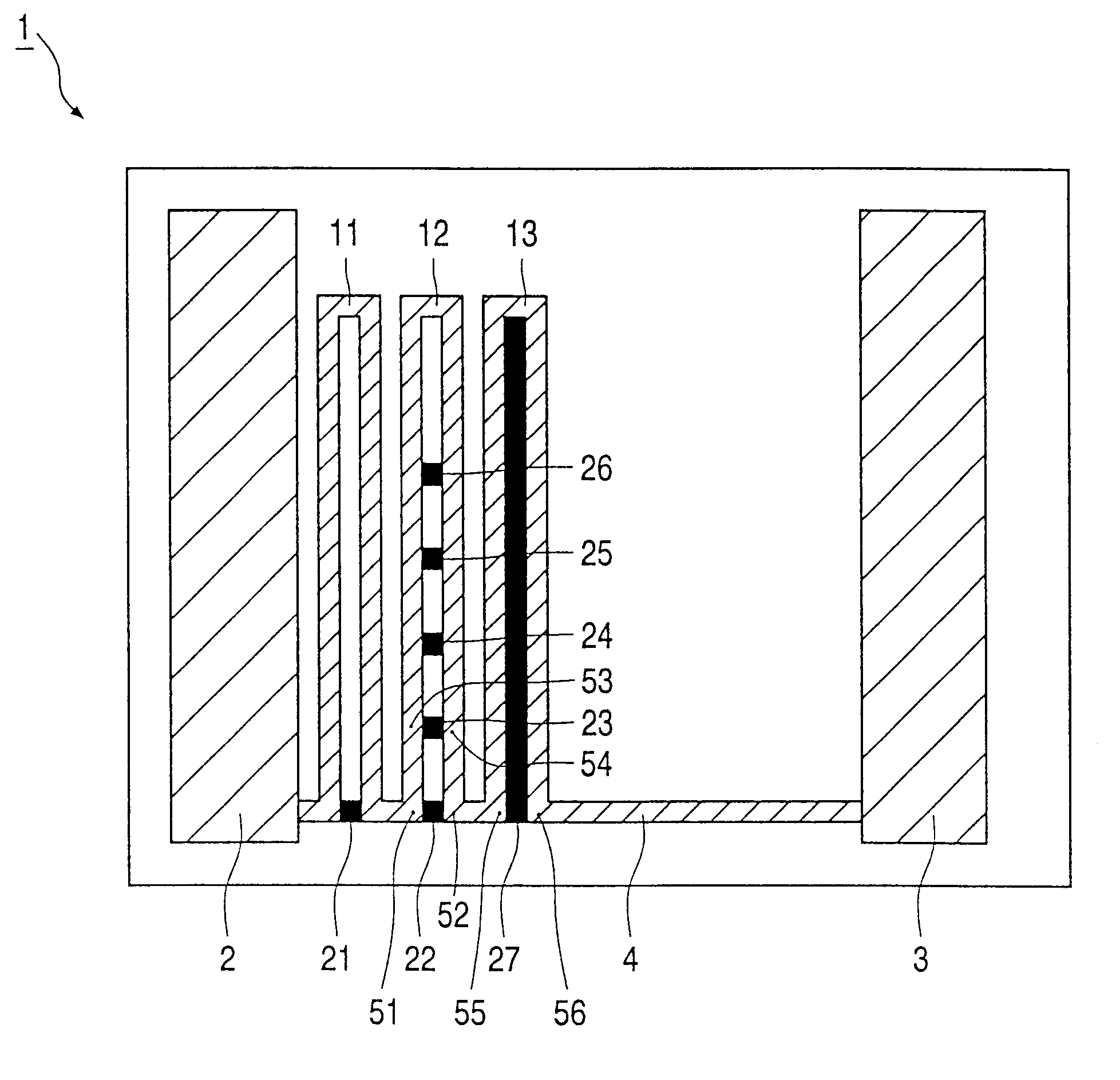

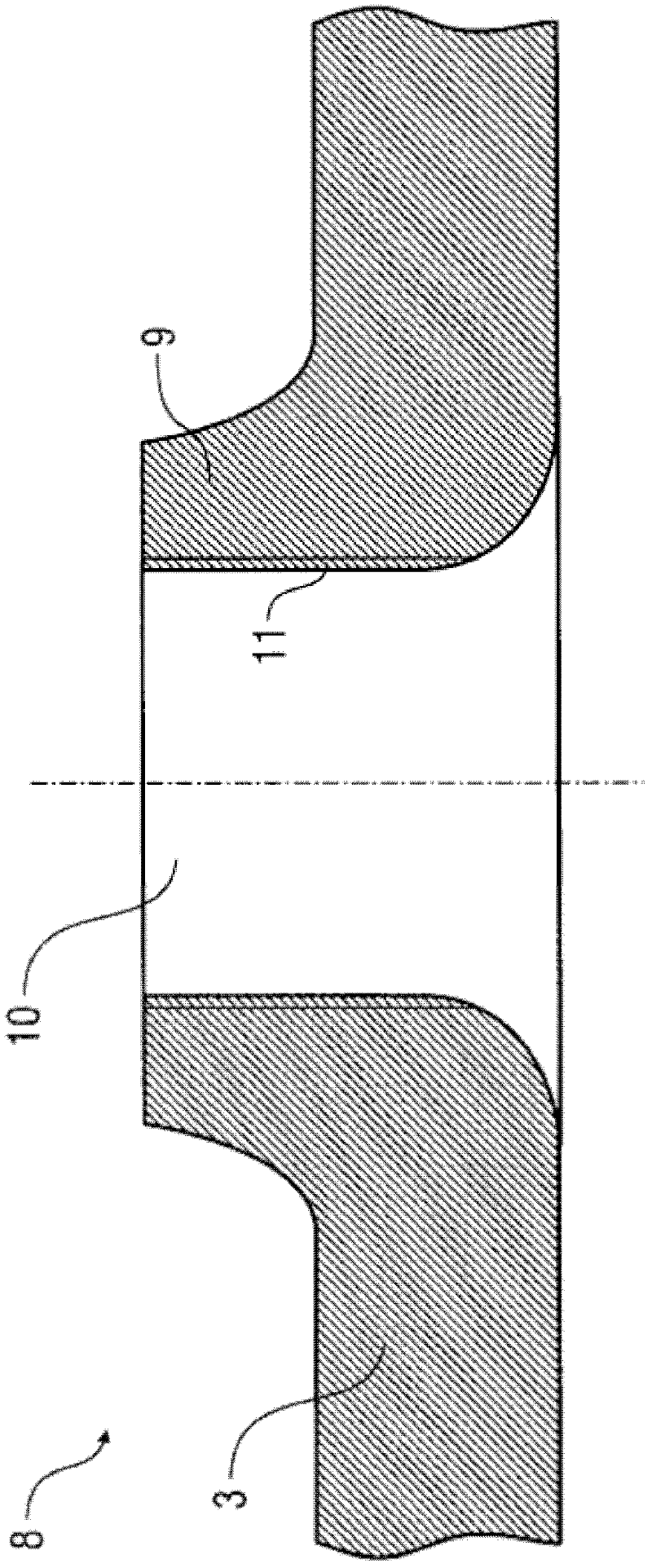

Electronic component and corresponding production method

InactiveCN102473492AElectrical measurement instrument detailsResistor terminals/electrodesElectrical resistance and conductanceOvercurrent

The invention relates to an electronic component (1), in particular a low-ohm current-sense resistor, comprising at least one plate-shaped section (2, 3) and at least one terminal (7, 8) to electrically contact the plate-shaped section (2, 3). According to the invention, the terminals (7, 8) for measuring the voltage drop created by the current flow are formed by means of stamping and thread-shaping in the plate-shaped sections (2, 3).

Owner:ISABELLENHUTTE HEUSLER

Electronic component value trimming systems

InactiveUS20050127978A1Coupling noiseCancel noiseReliability increasing modificationsElectric signal transmission systemsShift registerControl vector

Described is a system for trimming the value of an electronic component. The system comprises: at least one trimming component, each trimming component having an associated switch for selectively connecting that trimming component to the electronic component in response to a corresponding bit in a control vector. A comparator is included for generating an output bit having a first value if a net value of the electronic component and any connected trimming components differs from a desired value. A controller connected to the switches and the comparator generates the control vector in dependence on the output of comparator, the controller comprising a shift register for sequentially receiving successive output bits from the comparator; wherein the control vector comprises the contents of the shift register and wherein a bit of said first value in control vector effects switching of the corresponding switch.

Owner:IBM CORP

Semiconductor apparatus and method of trimming voltage

ActiveUS20120105142A1Electric signal transmission systemsResistor trimmingVoltage referenceSemiconductor

A semiconductor apparatus includes: a master chip and at least one slave chip configured to be stacked one on top of another; and a through-silicon via (TSV) configured to penetrate and electrically couple the master chip and the at least one slave chip, wherein the at least one slave chip receives a reference voltage generated from the master chip via the TSV and independently trims the reference voltage and then generates an internal voltage with the trimmed reference voltage.

Owner:SK HYNIX INC

Bi-directional trimming methods and circuits for a precise band-gap reference

ActiveUS8193854B2Resistor trimmingElectric variable regulationElectrical resistance and conductanceReference circuit

A bandgap reference circuit has trimming-up resistors and trimming-down resistors for bi-directional trimming. PNP transistors have base and collectors grounded and emitters connected to parallel resistors. A difference resistor drives an inverting input of an op amp that drives a transistor that generates the bandgap reference voltage Vbg. A sensing resistor connects Vbg to a splitting node that connects to the non-inverting input through a first parallel resistor. The splitting node also connects through a second parallel resistor to the inverting input. Fuses or switches enable the trimming-up and trimming-down resistors. The trimming-up resistors are in series with the sensing resistor and the trimming-down resistors are in series with an output resistor that connects Vbg to reference voltage Vref. The circuit can be designed for a more typical process since bi-directional trimming allows Vref to be raised or lowered. Many circuits need no trimming when targeted for the typical process.

Owner:HONG KONG APPLIED SCI & TECH RES INST

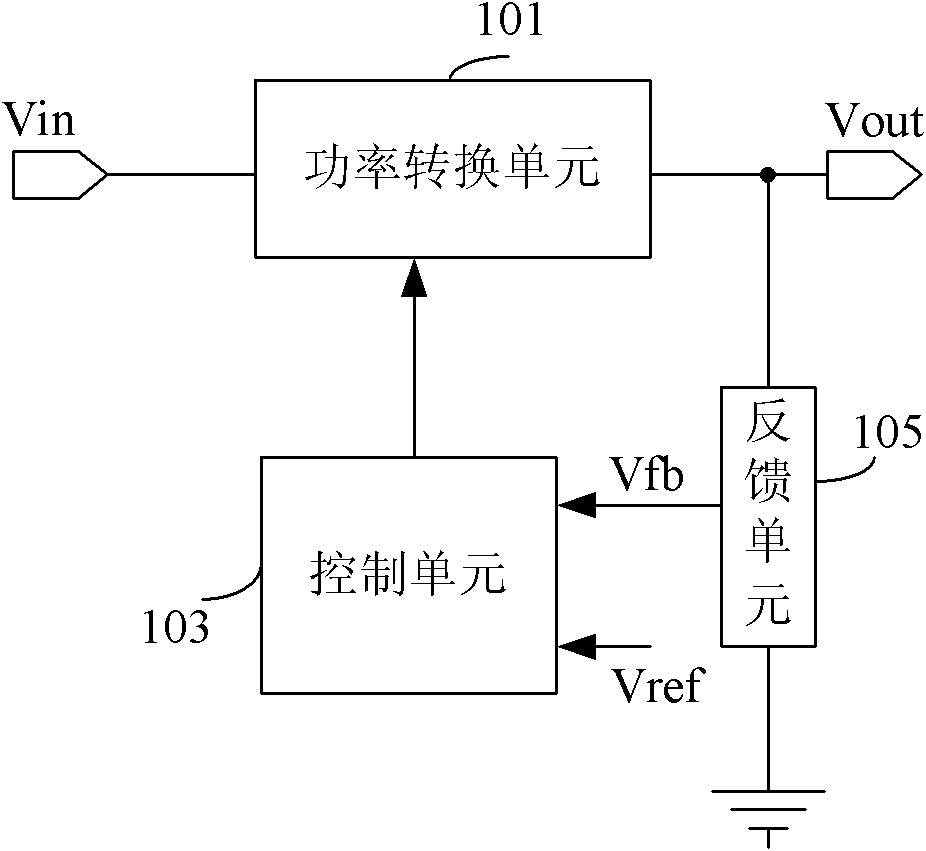

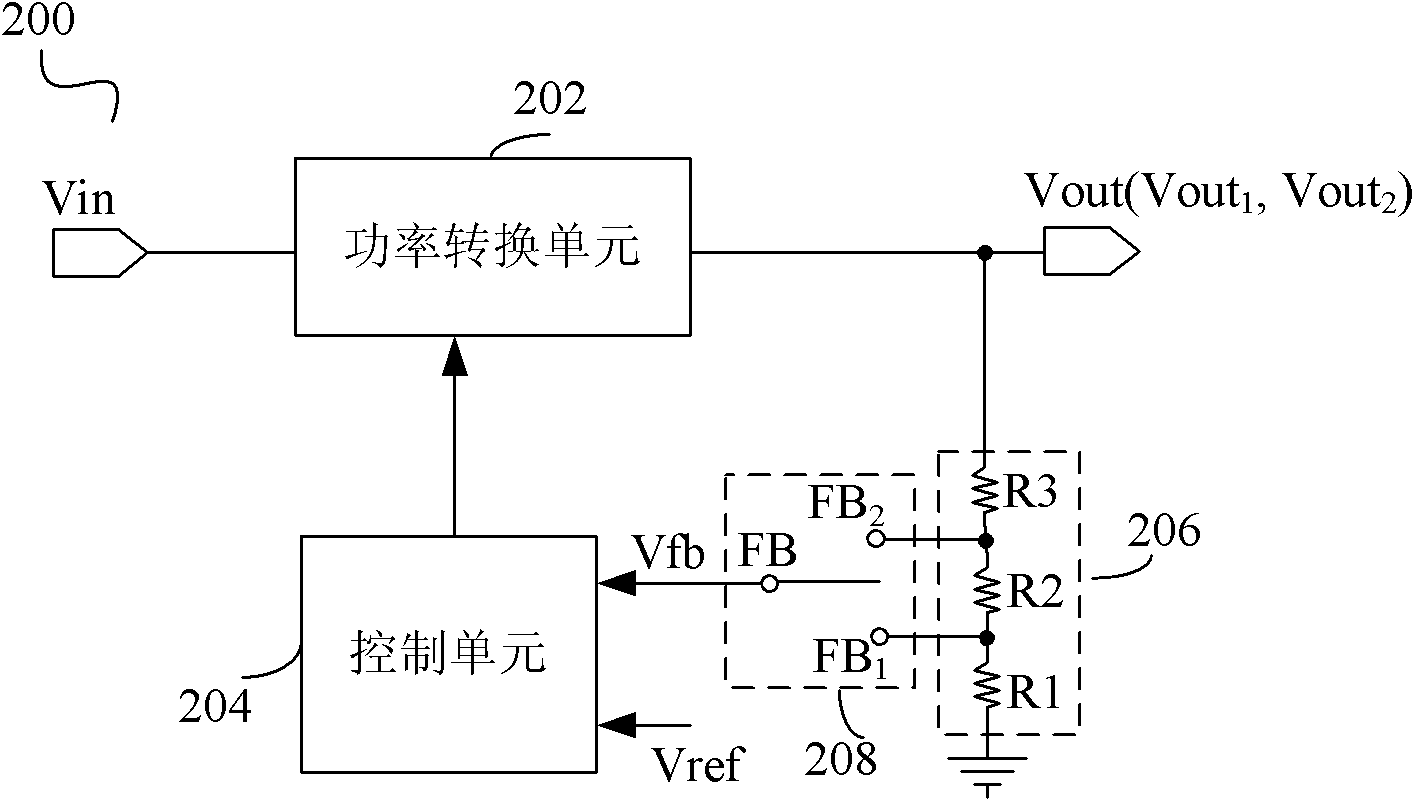

Device and method for trimming output voltage of voltage adjuster

ActiveCN102467144AReduce power consumptionSmall sizeResistor trimmingElectric variable regulationVoltage regulationPower consumption

The invention discloses a device and a method for trimming an output voltage of a circuit of a voltage adjuster, and relates to the circuit of the voltage adjuster, aiming at providing a simple and easy trimming circuit, so that the trimming power consumption of the circuit of the voltage adjuster can be reduced, and the size of a chip can be reduced. The trimming device provided by the embodiment of the invention is used for dividing the output voltage of the circuit of the voltage adjuster by a set of voltage dividing devices which are connected with one another in series and generating a plurality of different feedback voltages which show the output voltage, wherein the different feedback voltages correspond to the different output voltage values of the output voltage one by one; the different feedback voltages are sequentially trimmed, so that the different output voltage values can be sequentially trimmed; and the former trimmed output voltage value can not be influenced by the trimming of the later output voltage value.

Owner:CHENGDU MONOLITHIC POWER SYST

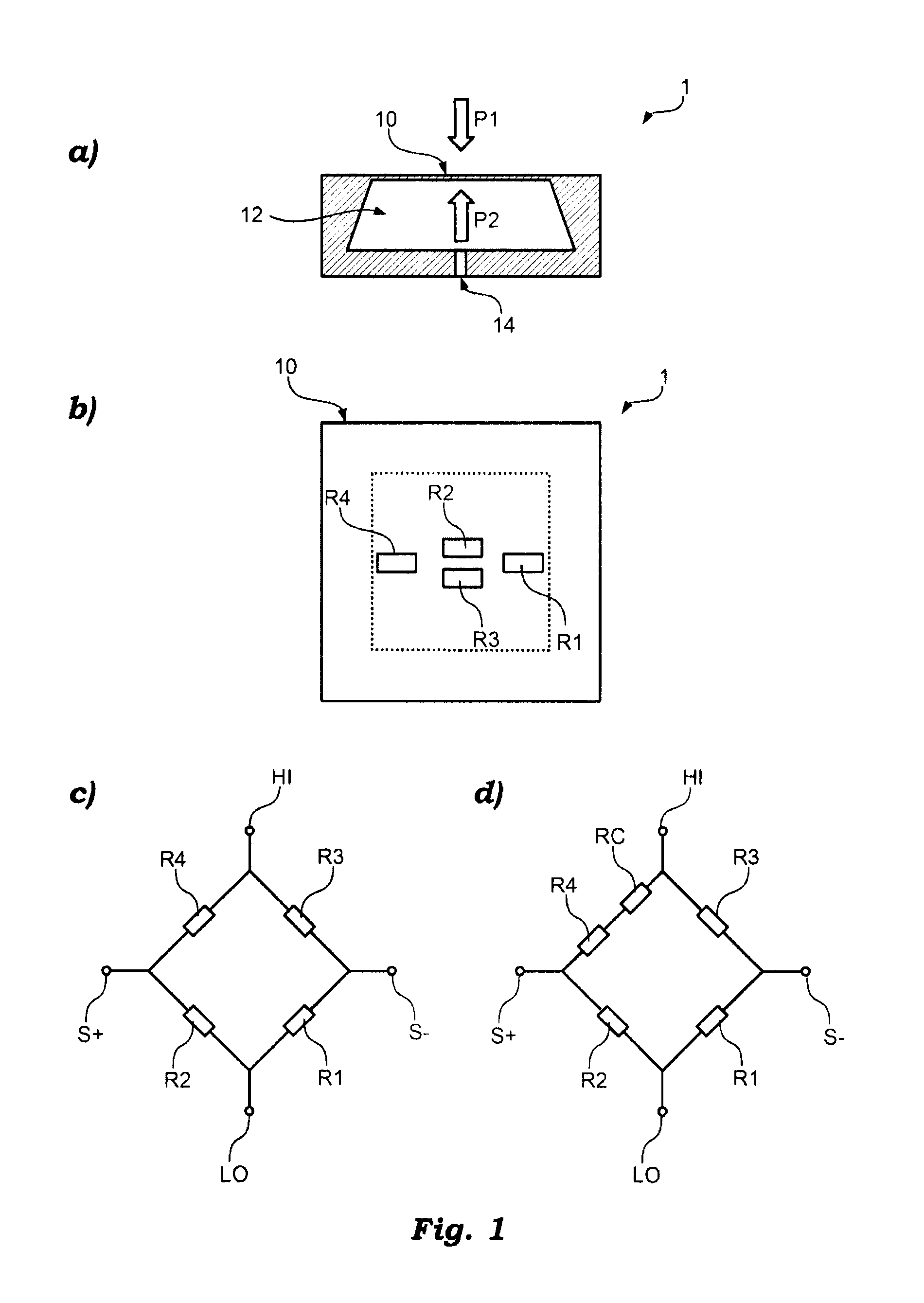

Method for adjusting a calibration element, and corresponding device

ActiveUS9460834B2Simple and precise wayImprove reliabilityFluid pressure measurement using ohmic-resistance variationForce/torque/work measurement apparatus calibration/testingEngineeringElectrical and Electronics engineering

A method for adjusting the electrical behavior or characteristics of a calibration element includes adjusting the electrical behavior or characteristics of the calibration element by making one or more incisions or cuts in the calibration element. The calibration element has a plurality of apertures, and the method includes making an incision or cut in the calibration element between an edge thereof and at least one of the apertures, and / or making an incision or cut in the calibration element between at least two of the apertures.

Owner:METALLUX SA

Embedded trimmable resistors

InactiveUS6288627B1Printed circuit aspectsResistor mounting/supportingResistorElectrical and Electronics engineering

Owner:INTERMEDICS

Electronic component value trimming systems

InactiveUS7081842B2Simple controllerEasy to implementReliability increasing modificationsElectric signal transmission systemsShift registerControl vector

Described is a system for trimming the value of an electronic component. The system comprises: at least one trimming component, each trimming component having an associated switch for selectively connecting that trimming component to the electronic component in response to a corresponding bit in a control vector. A comparator is included for generating an output bit having a first value if a net value of the electronic component and any connected trimming components differs from a desired value. A controller connected to the switches and the comparator generates the control vector in dependence on the output of comparator, the controller comprising a shift register for sequentially receiving successive output bits from the comparator; wherein the control vector comprises the contents of the shift register and wherein a bit of said first value in control vector effects switching of the corresponding switch.

Owner:IBM CORP

Popular searches

Couplings bases/cases Contact members penetrating/cutting insulation/cable strands Welding/soldering/cutting articles Metal working apparatus Laser beam welding apparatus Semiconductor devices Special data processing applications Adjustable resistors Photodevelopable thick film Printed resistor incorporation

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com