Electronic component and corresponding production method

A technology of electronic components and manufacturing methods, which can be used in electrical components, electrical solid devices, resistance terminals/electrodes, etc., and can solve problems such as high cost and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

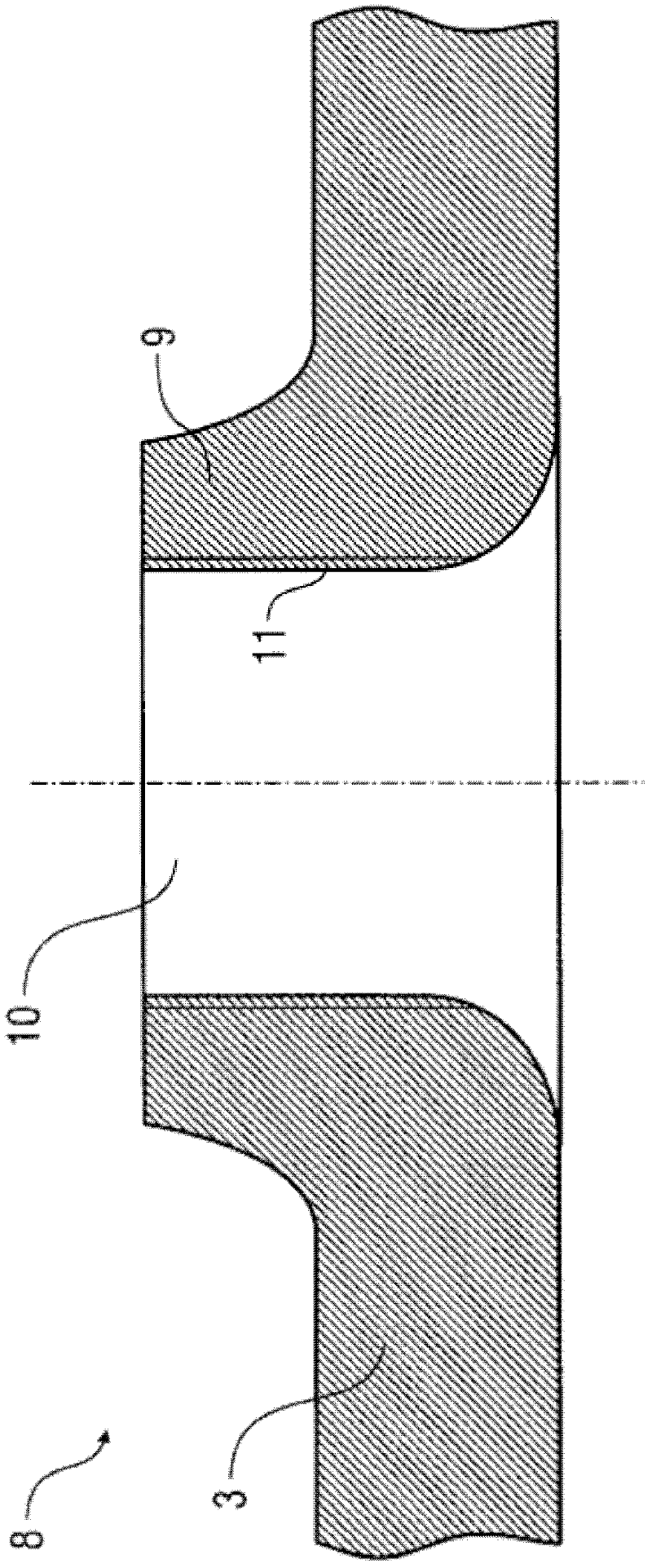

[0071] Figures 1A-1C A current sensing resistor 1 according to the invention is shown, which can be used, for example, in an on-board electrical system to measure the battery current I.

[0072] The current sensing resistor 1 is mainly composed of two plate-shaped connecting parts 2, 3 made of copper, and a resistance element 4, which is also plate-shaped and made of copper-manganese-nickel alloy (such as ), wherein the resistance element 4 is inserted between the two connection parts 2, 3, and welded on the two connection parts 2, 3 by electron beam.

[0073] For supplying or discharging the battery current I to be measured, the current sensing resistor 1 has 2 conventional connection contacts 5, 6, each of which in this embodiment comprises a connection part 2, 1 round hole in 3.

[0074] Furthermore, the current sensing resistor 1 has 2 connection contacts 7, 8 for voltage measurement, which are formed in a novel way and each comprise a plate-shaped connection part 2, 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com