Large-size bulging bridge shell tube blank local annealing device and process

A hydraulic bulging and partial annealing technology, which is applied in the direction of improvement of process efficiency, manufacturing tools, furnace types, etc., can solve the problems that the tube billet cannot be partially annealed, and achieve the effects of continuous automatic production, energy saving and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

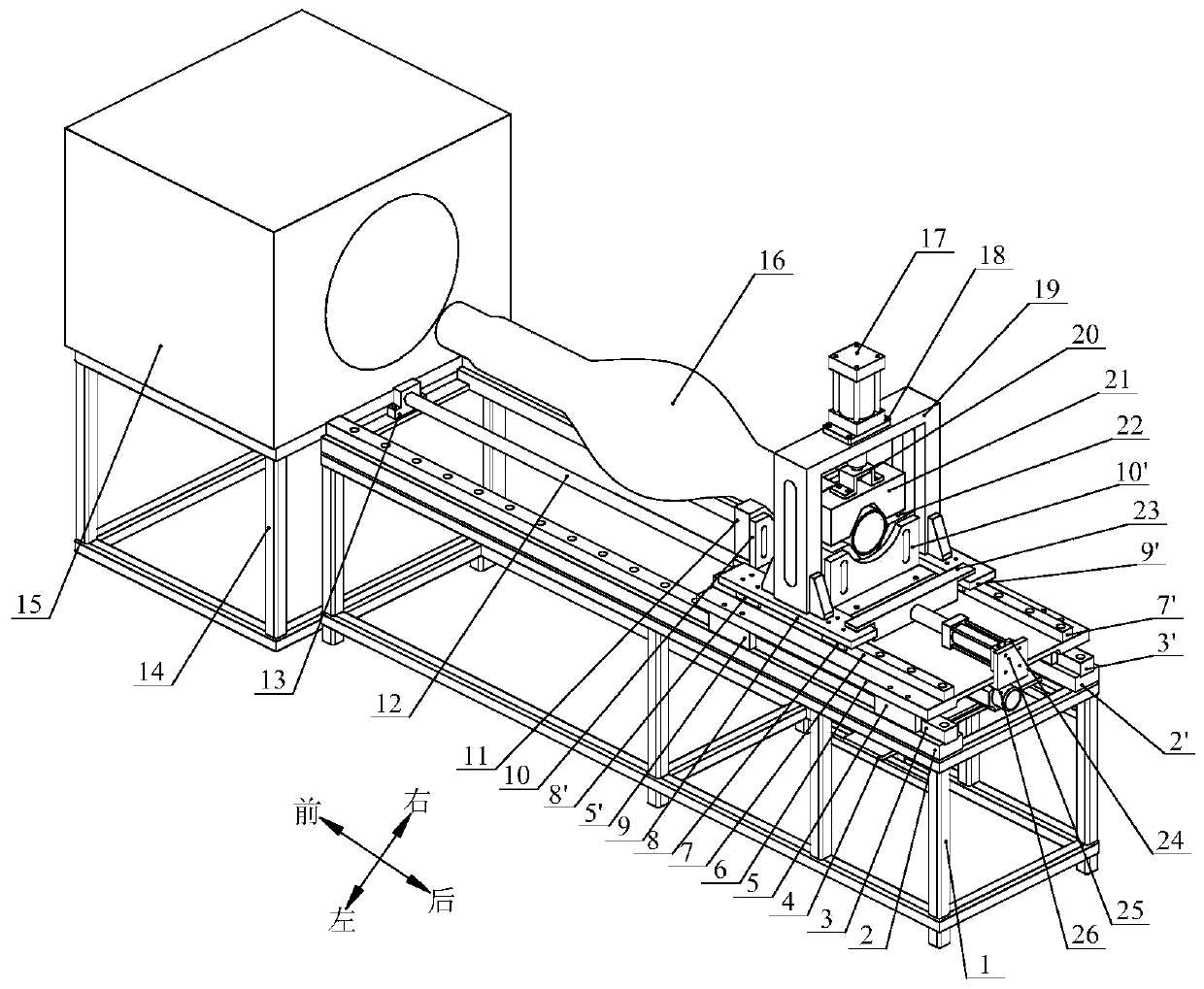

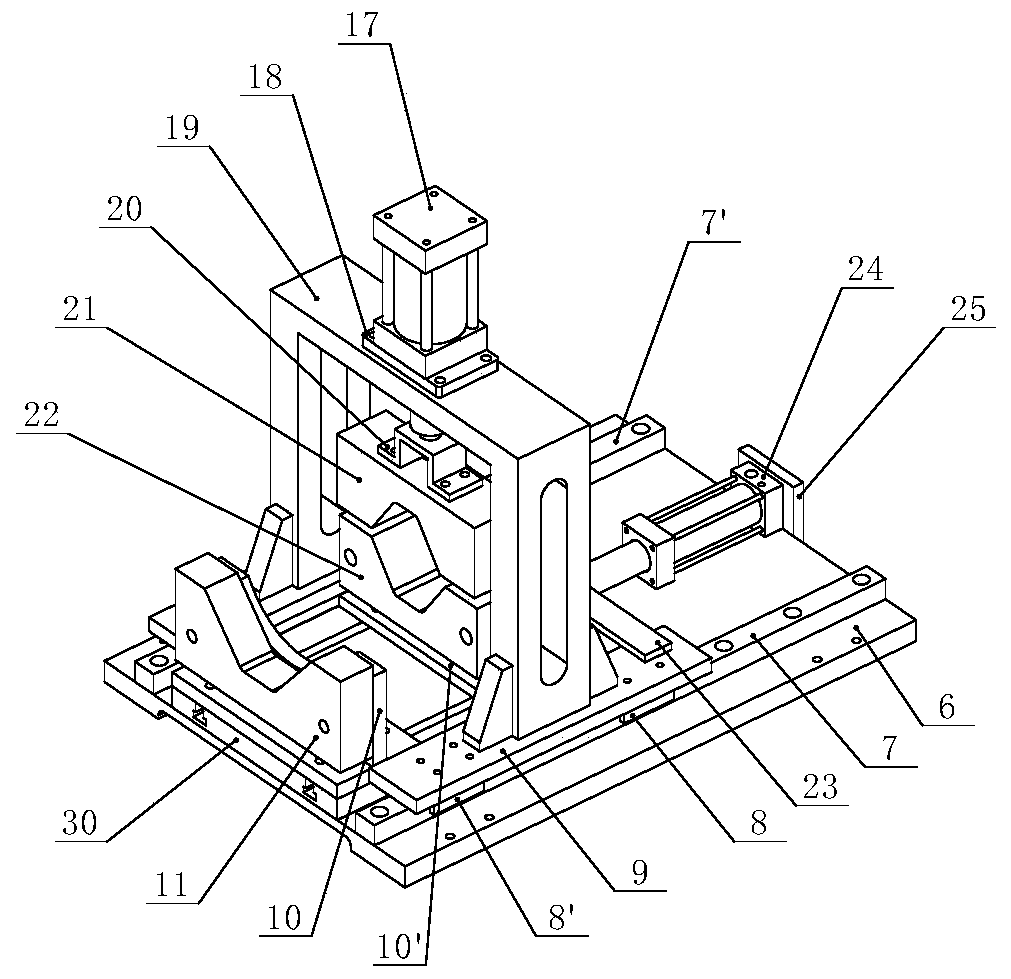

[0031] figure 2 It is an embodiment of a local annealing device for a large-sized bulging hydraulic bulging axle housing tube blank disclosed by the invention. The device includes a barrel-type intermediate frequency annealing furnace 15, a pipe end clamping mechanism and a longitudinal moving mechanism. The device is used in conjunction with other material transfer equipment to realize continuous operation of the liquid bulging forming axle housing automation production line.

[0032] Described cylindrical intermediate frequency annealing furnace 15 (see image 3 ), the furnace body is in the shape of a cuboid, installed on the annealing furnace seat 14, the middle part of the barrel type intermediate frequency annealing furnace 15 furnace body is provided with a cylindrical furnace, and the outer side of the furnace is arranged with an intermediate frequency induction heating coil 27, and the intermediate frequency induction The heating coil 27 has a non-equidistant spiral s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com