Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47results about How to "Neatly positioned" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mobile phone back housing capable of realizing wireless charging and preparation method thereof

InactiveCN105162908AImprove wireless charging efficiencyDoes not increase thicknessBatteries circuit arrangementsElectromagnetic wave systemElectricityM.2

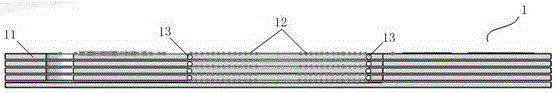

The invention discloses a mobile phone back housing capable of realizing wireless charging. The mobile phone back housing is composed of at least two layers of ceramic sheets, a coil is printed on each layer of ceramic sheet, and electric connection between the ceramic sheets is realized through through holes. The thickness of each ceramic sheet is 20 [mu]m-1000 [mu]m, and the total thickness of the mobile phone back housing is 0.2 [mu]m-2 [mu]m. Correspondingly, the invention further provides a method for preparing the mobile phone back housing capable of realizing wireless charging. According to the invention, the wireless charging efficiency of a mobile phone is improved, the wireless charging speed is substantially increased to 2-3 times of the speed of common wireless charging, the thickness of the mobile phone is not increased but decreased, the lightening and thinning requirements of a user to the mobile phone are met, and the market competitiveness is improved.

Owner:广东百工新材料科技有限公司

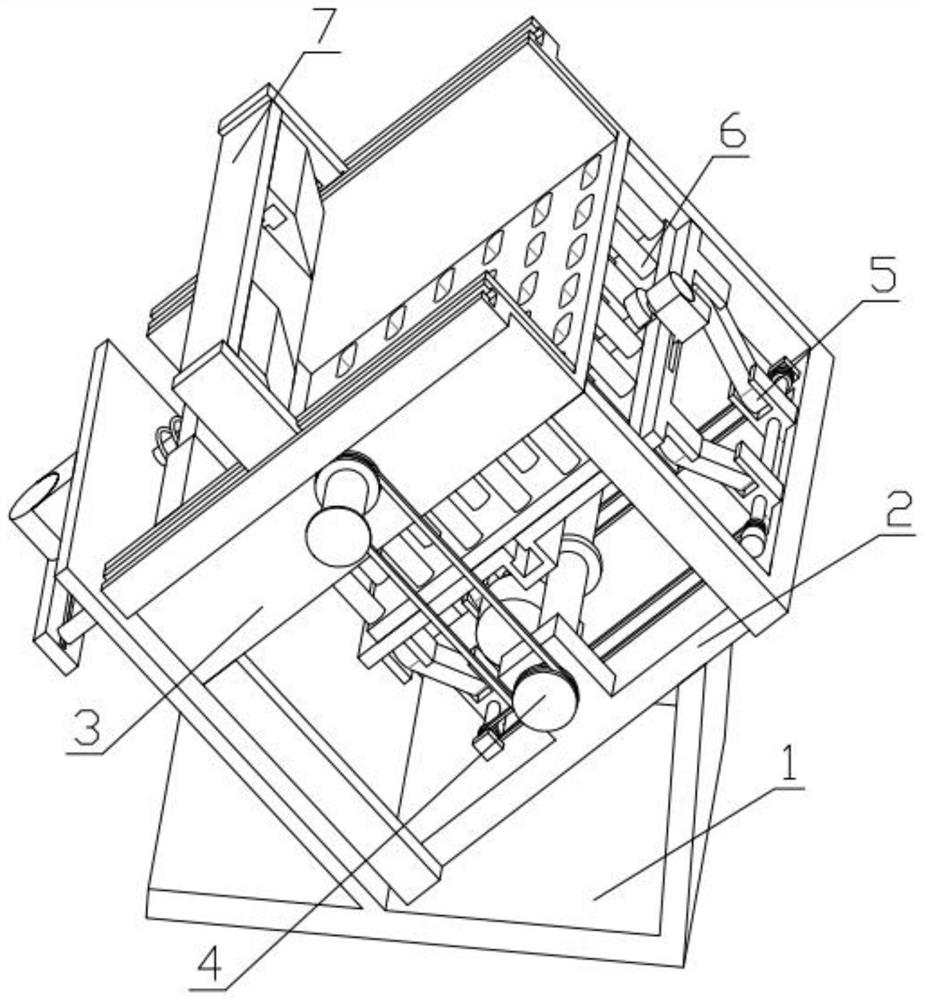

Paperboard stacking and packaging device

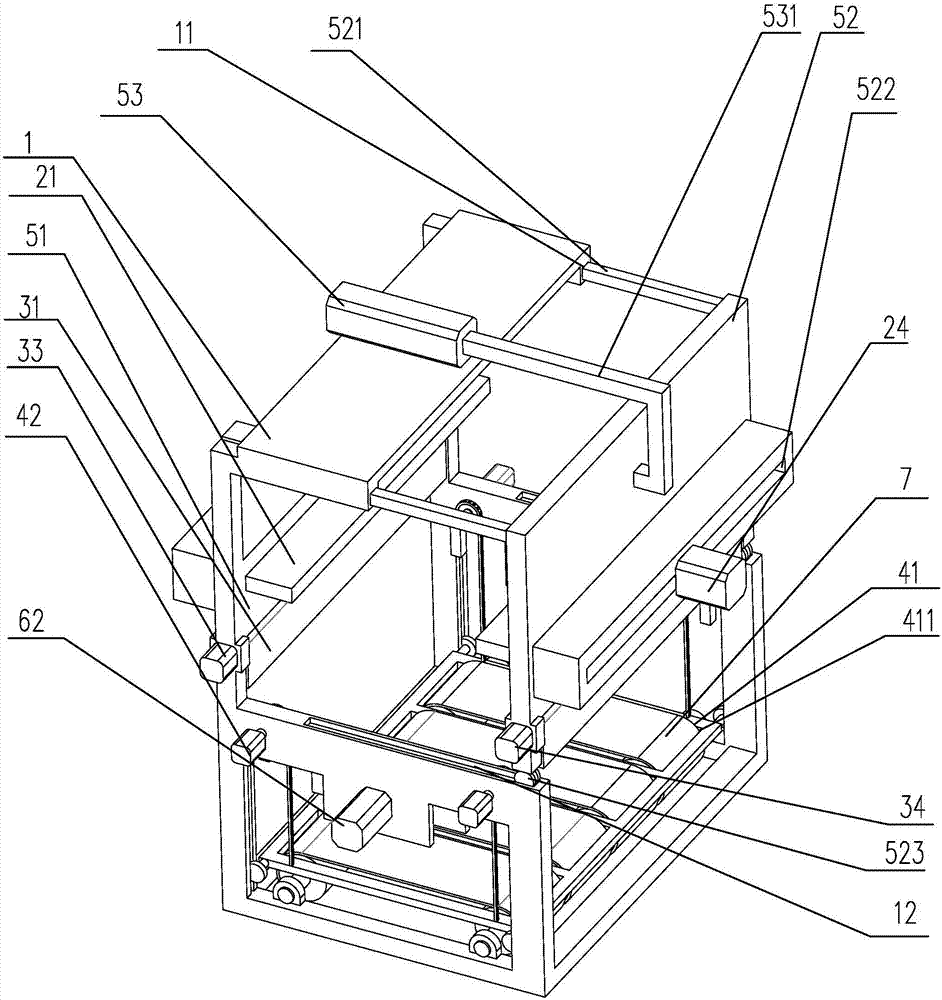

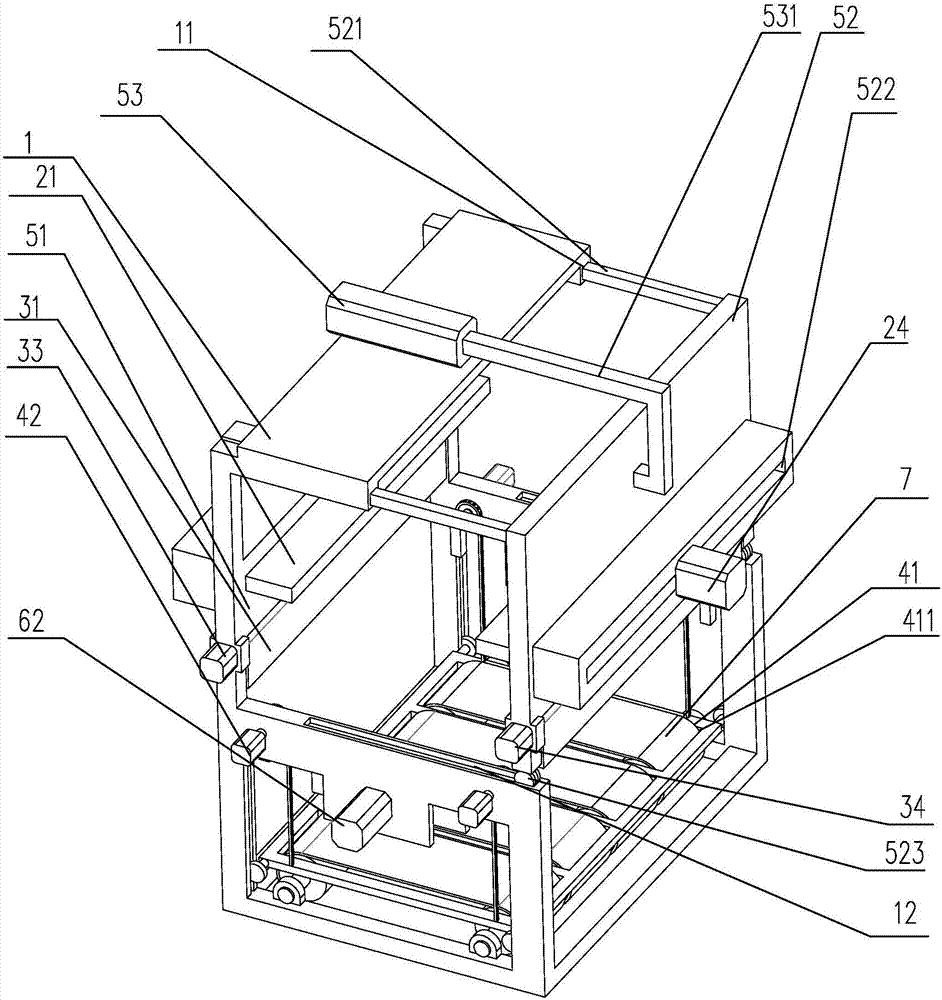

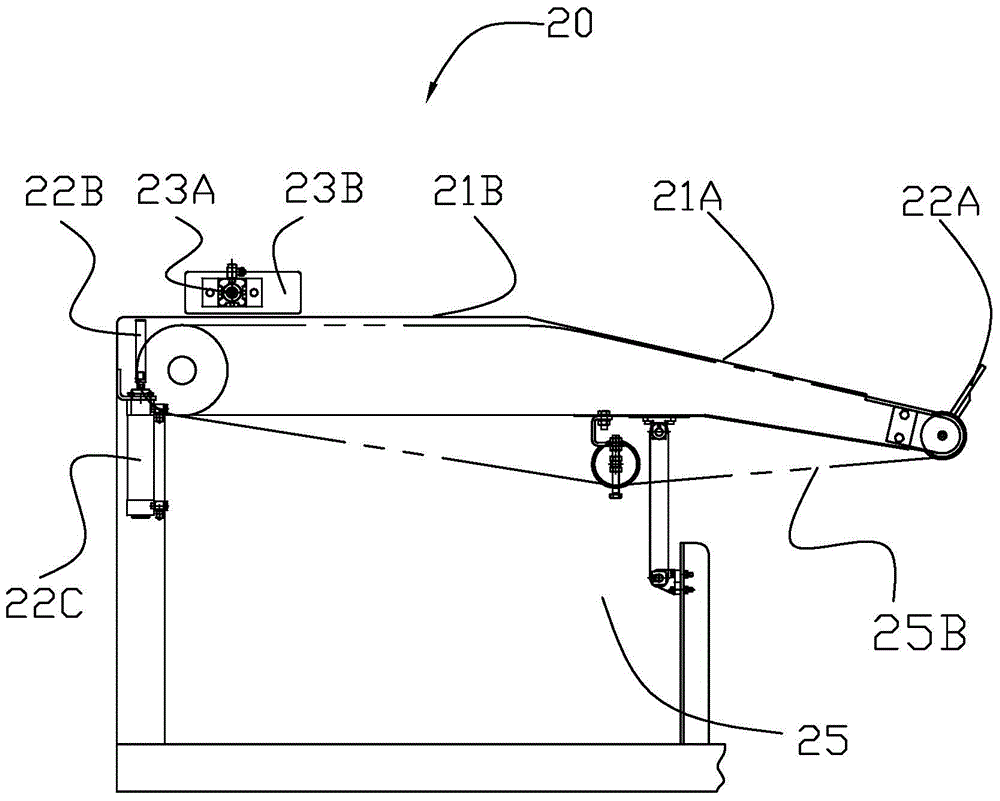

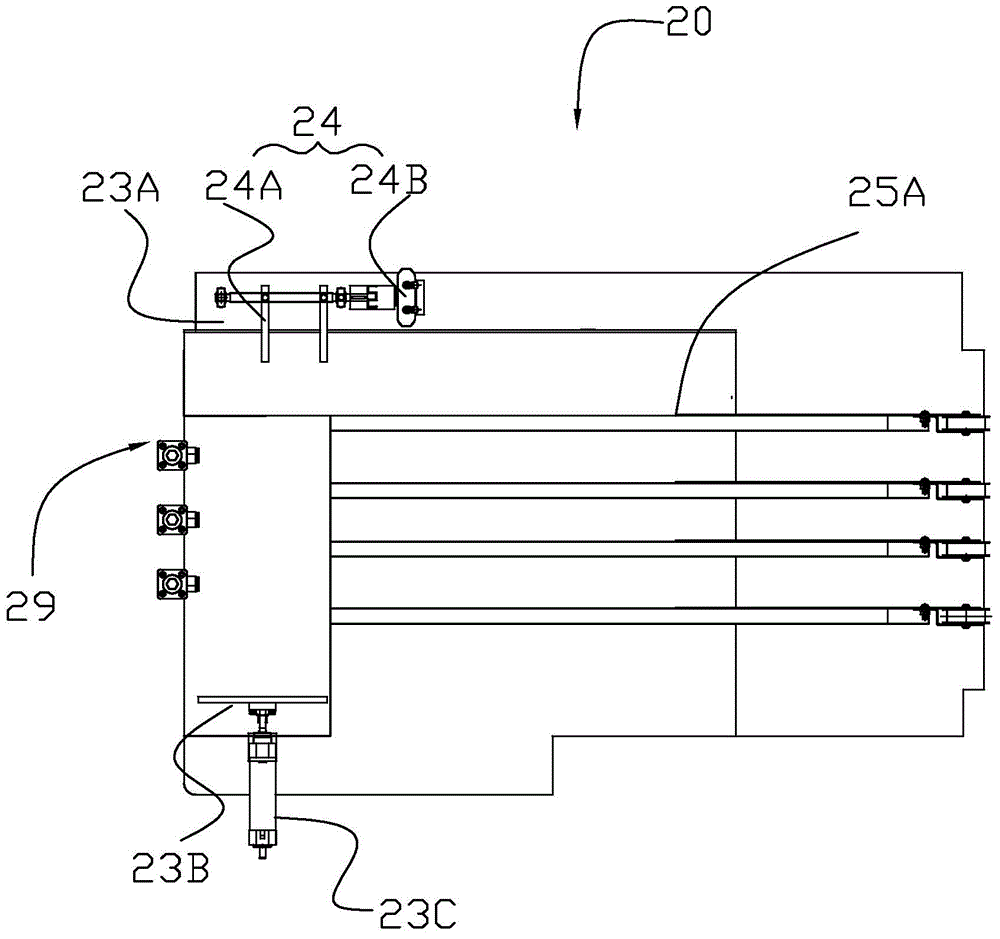

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

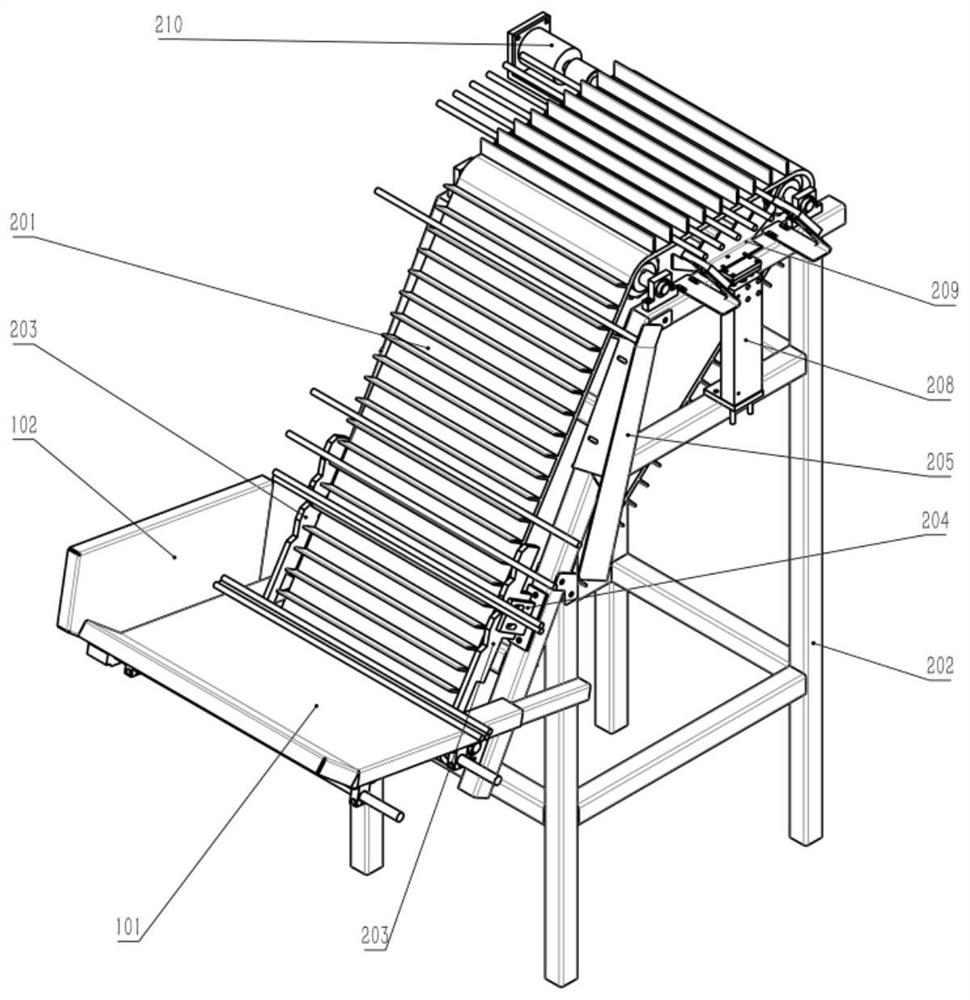

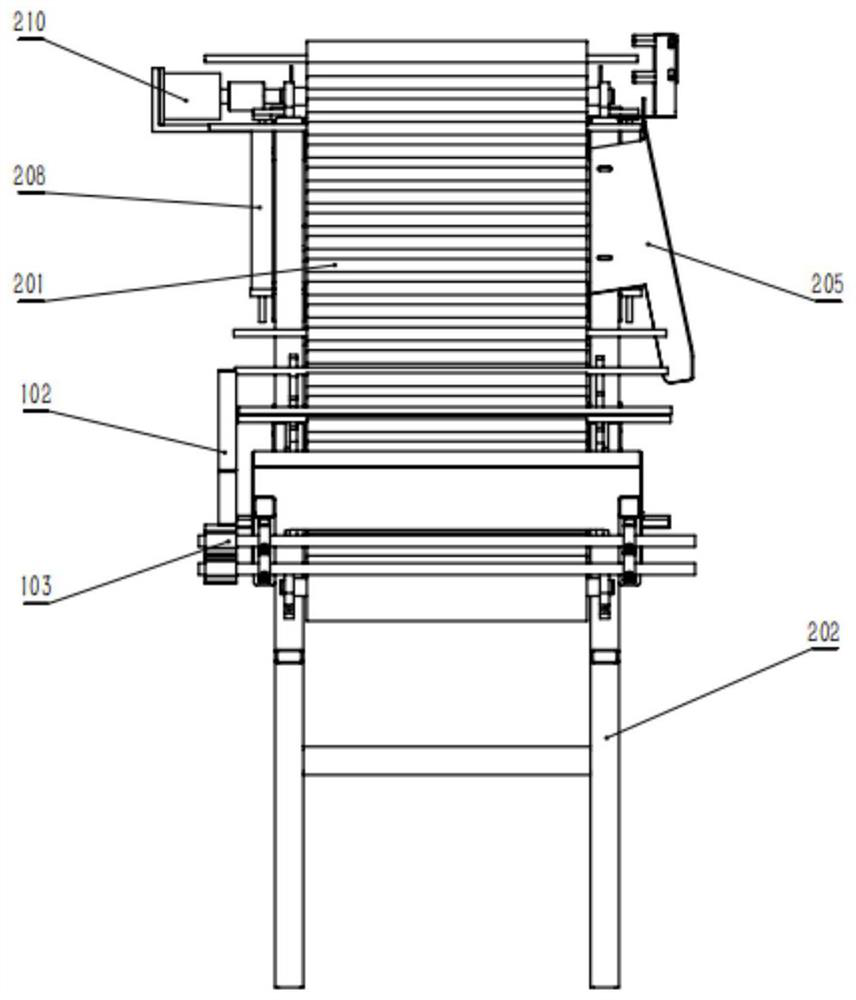

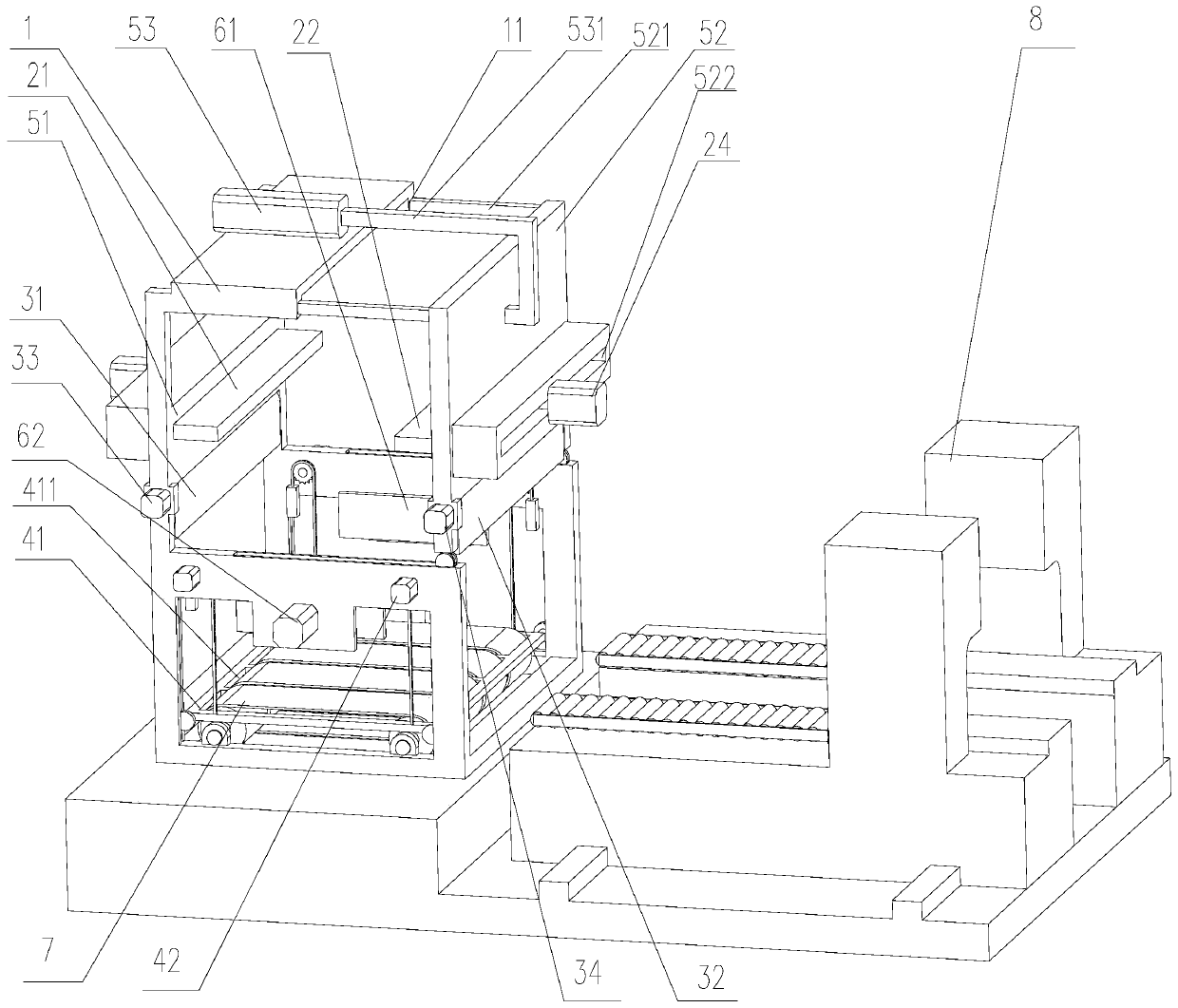

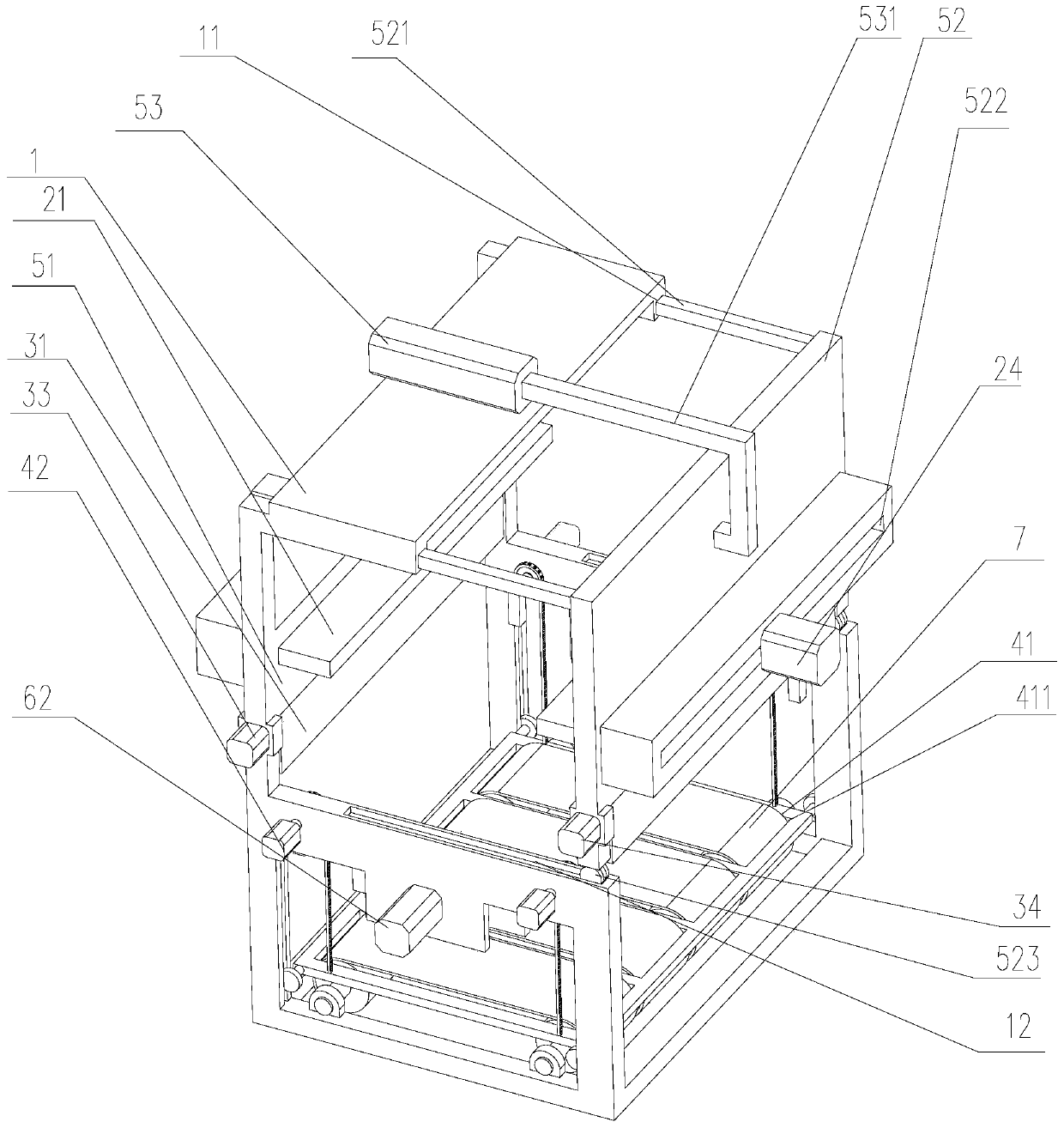

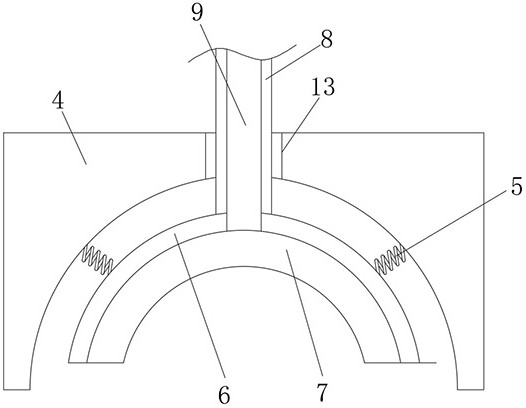

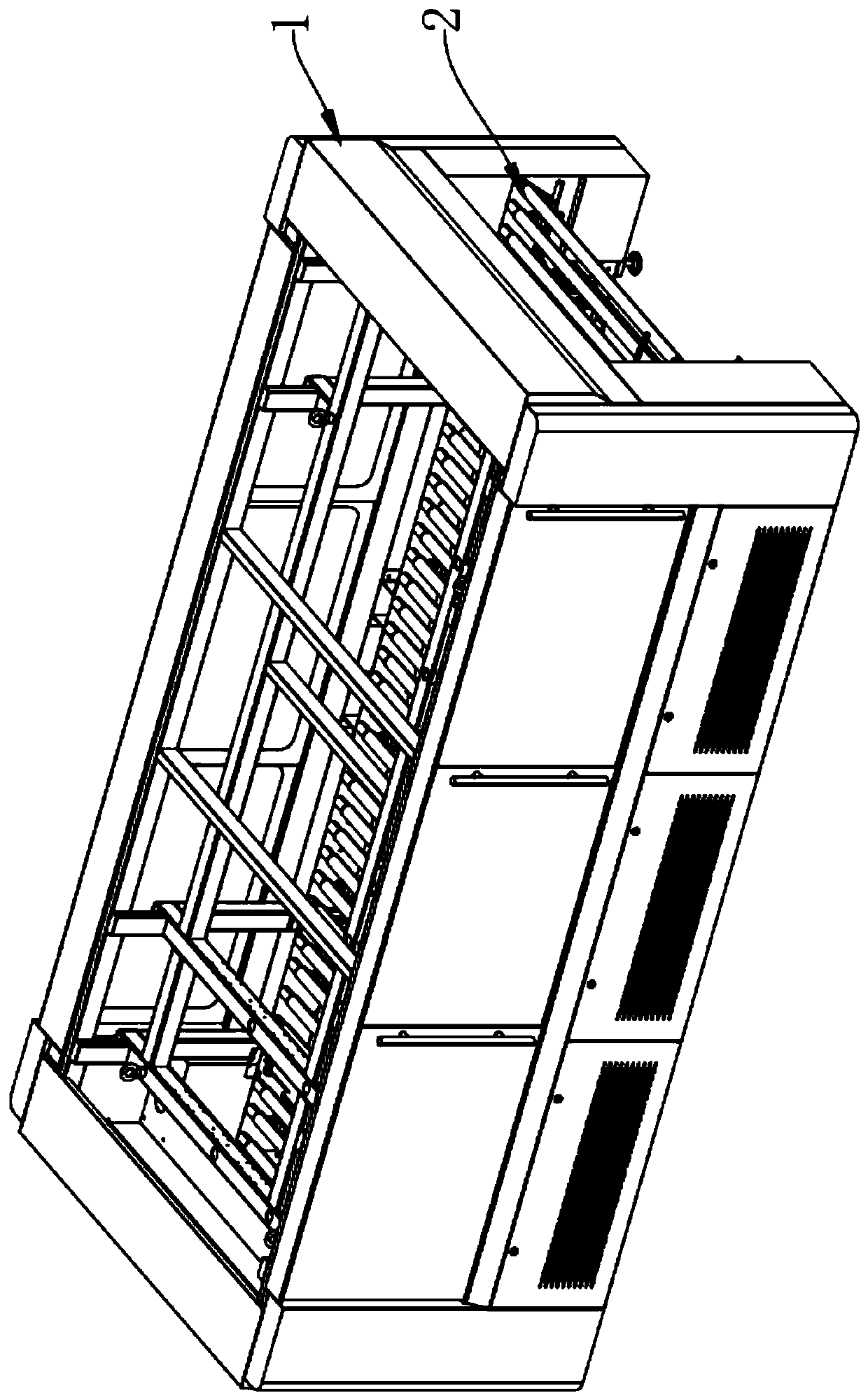

Paperboard stacking device

The invention discloses a paperboard stacking device. The paperboard stacking device comprises a bracket, a partition board, a collecting carrier, a pushing plate and a lifting plate, wherein baffles capable of sliding forwards and backwards are arranged at the front and rear sides of the bracket; both the collecting carrier and the partition board are arranged on the baffles; the partition board is arranged above the collecting carrier; the lifting plate is arranged below the collecting carrier and is in sliding fit with the bracket; and the pushing plate is arranged on the bracket, a conveyor belt is arranged below the lifting plate, and a plurality of through grooves for helping the conveyor belt be in contact with a paperboard stack are arranged in the lifting plate at intervals. The paperboard stacking device is simple in structure and can collect paperboards with different sizes and at the same time tidily stack the paperboards, thereby facilitating the following operation.

Owner:ZHEJIANG DONGJIN TECH CO LTD

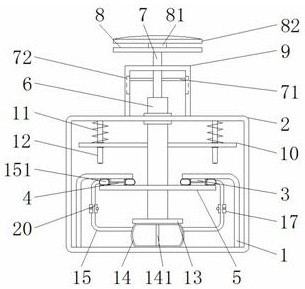

Emergency power-off device for electrical automation equipment failure

ActiveCN110676082AEasy to operateImprove safety performanceContact operating partsSwitch power arrangementsStructural engineeringElectrical and Electronics engineering

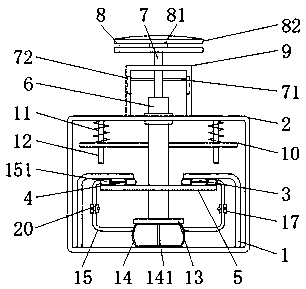

The invention discloses an emergency power-off device for electrical automation equipment failure. The emergency power-off device comprises a metal sheet, a first contact sheet, a second contact sheetand a metal plate. The metal sheet is fixed inside the device shell. A first connecting air pipe and a second connecting air pipe are distributed in an L-shaped structure, and a clamp ring is arranged outside the middle vertical part of the first and second connecting air pipes. The clamp ring is located inside the device shell, and the clamp ring is connected with one end of a fixing rod. A clamping plate is arranged on the opposite surface of the clamp ring. A sleeve is rotatably connected at the center of a transverse plate. The surface of the sleeve is hinged with a driving rod, and the sleeve is connected with a knob through a rotating rod. According to the emergency power-off device for the electrical automation equipment failure, the upward and downward movement of the metal platecan be stably limited fixed and operation is quite convenient. Meanwhile, the safety performance of the device operation can be improved by locking the connecting air pipes to close the air passage while the contact piece is sealed and protected by the air bag.

Owner:GUANGDONG OCEAN UNIVERSITY

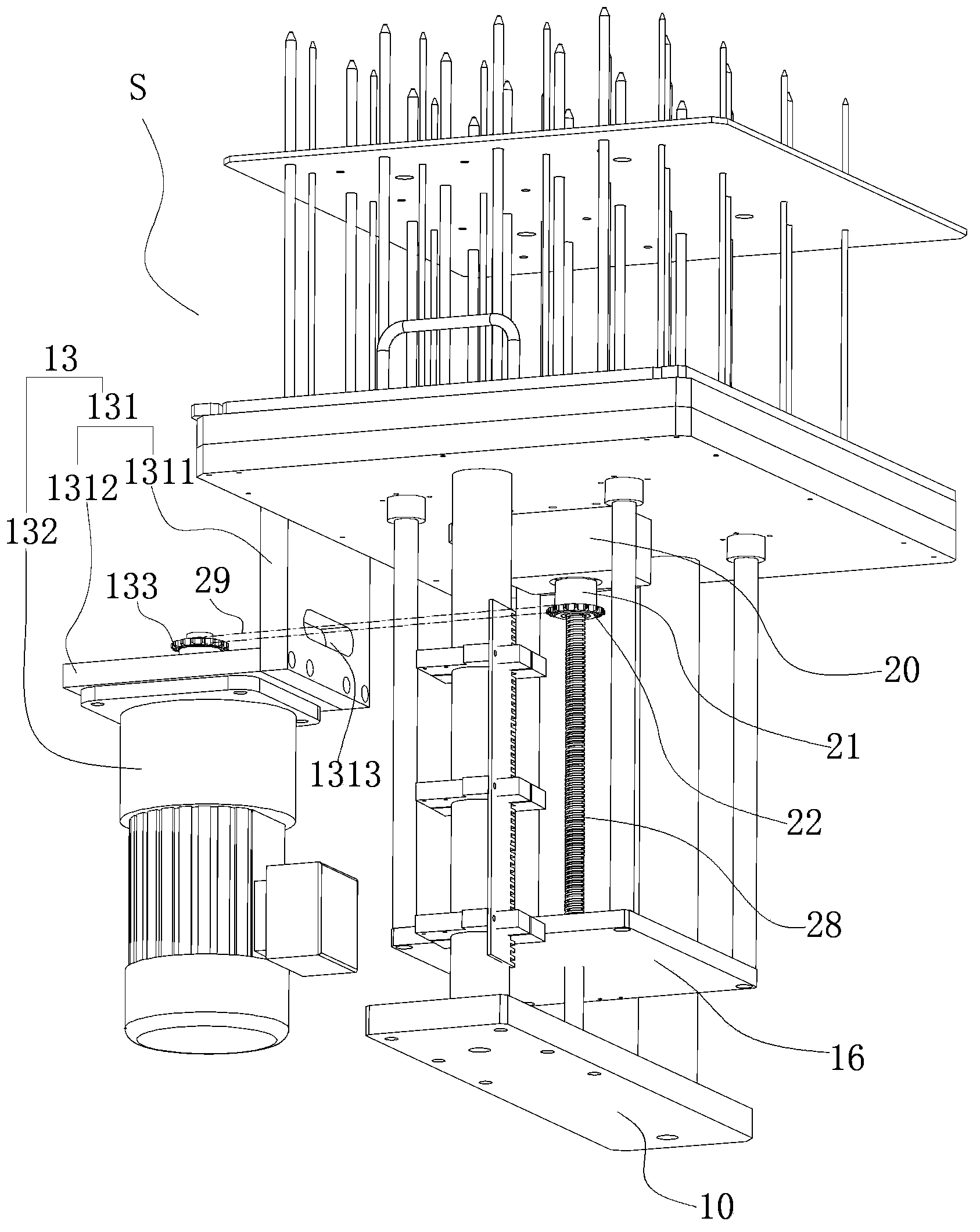

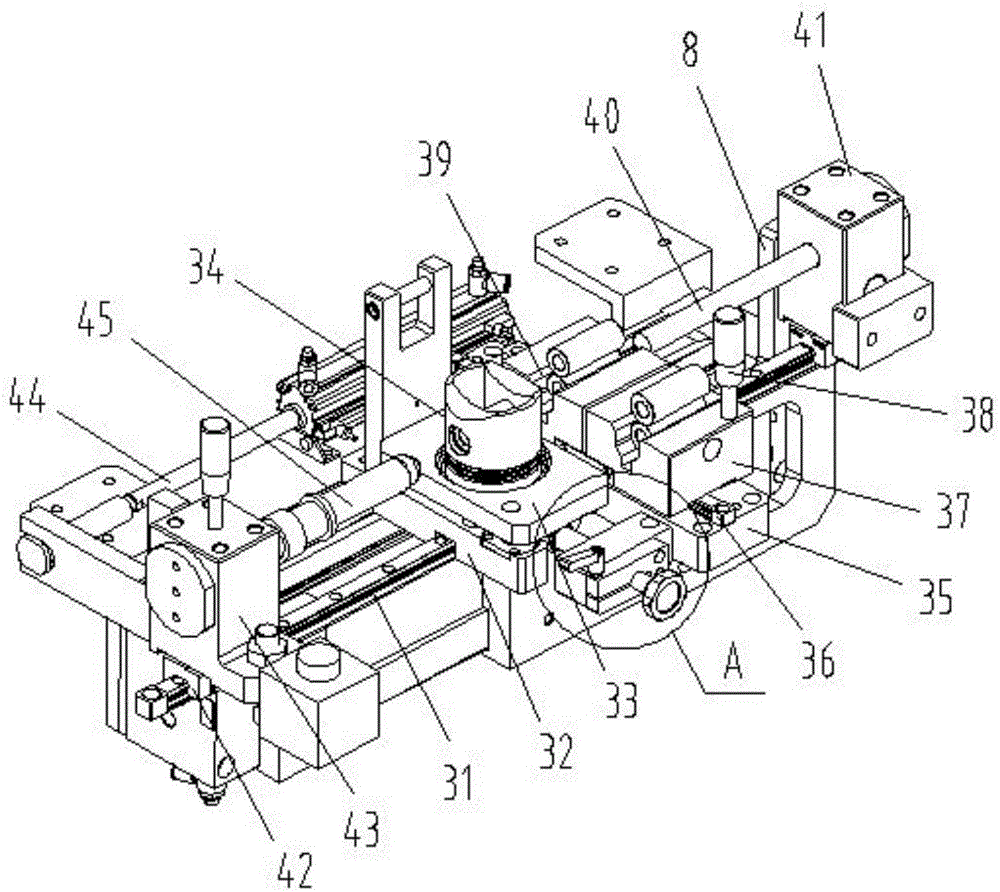

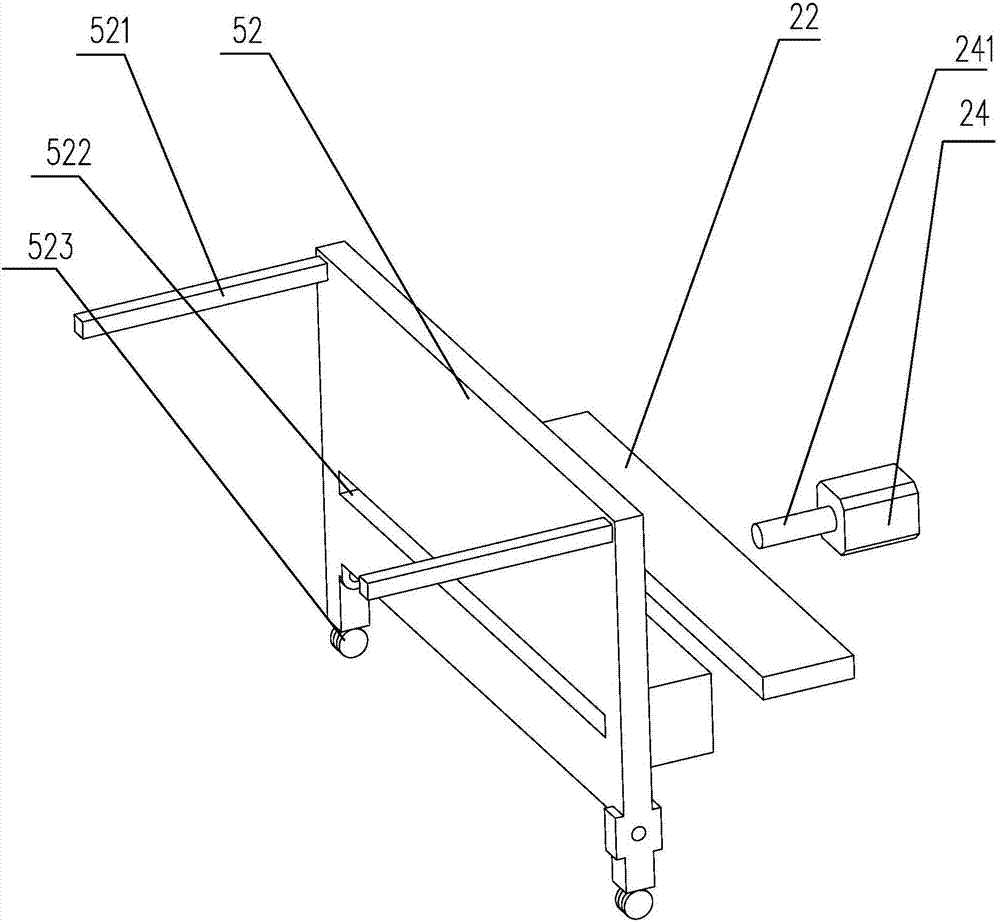

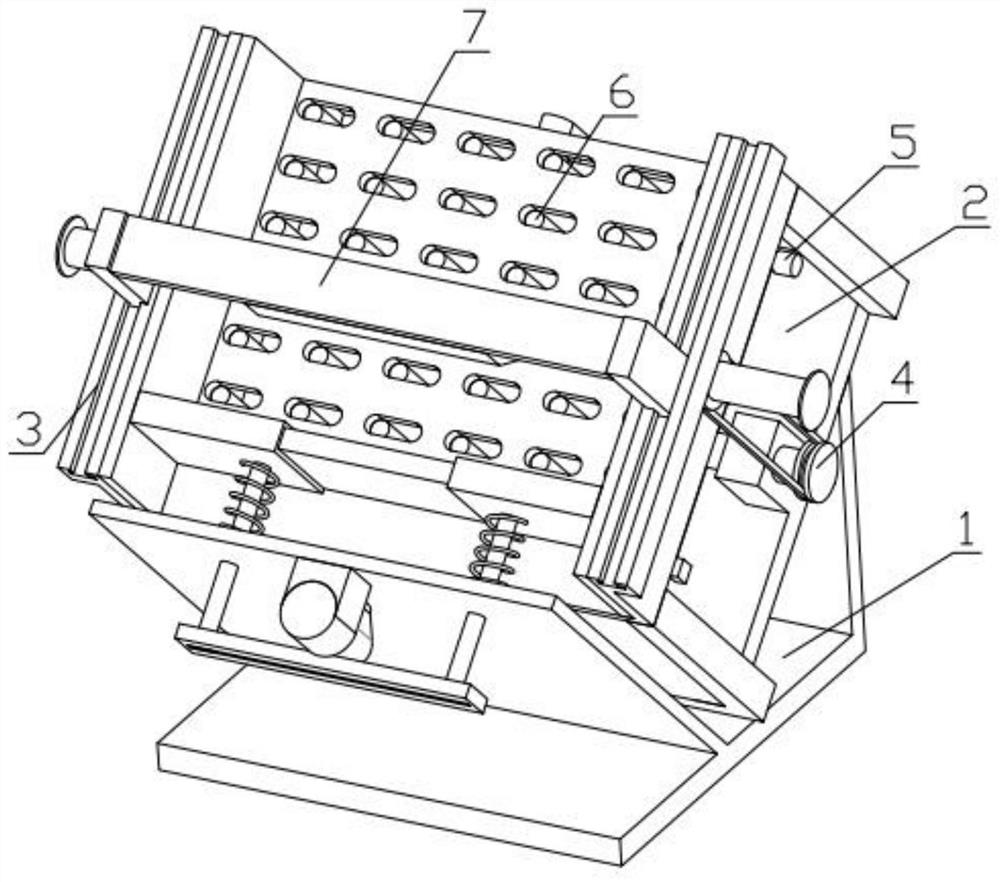

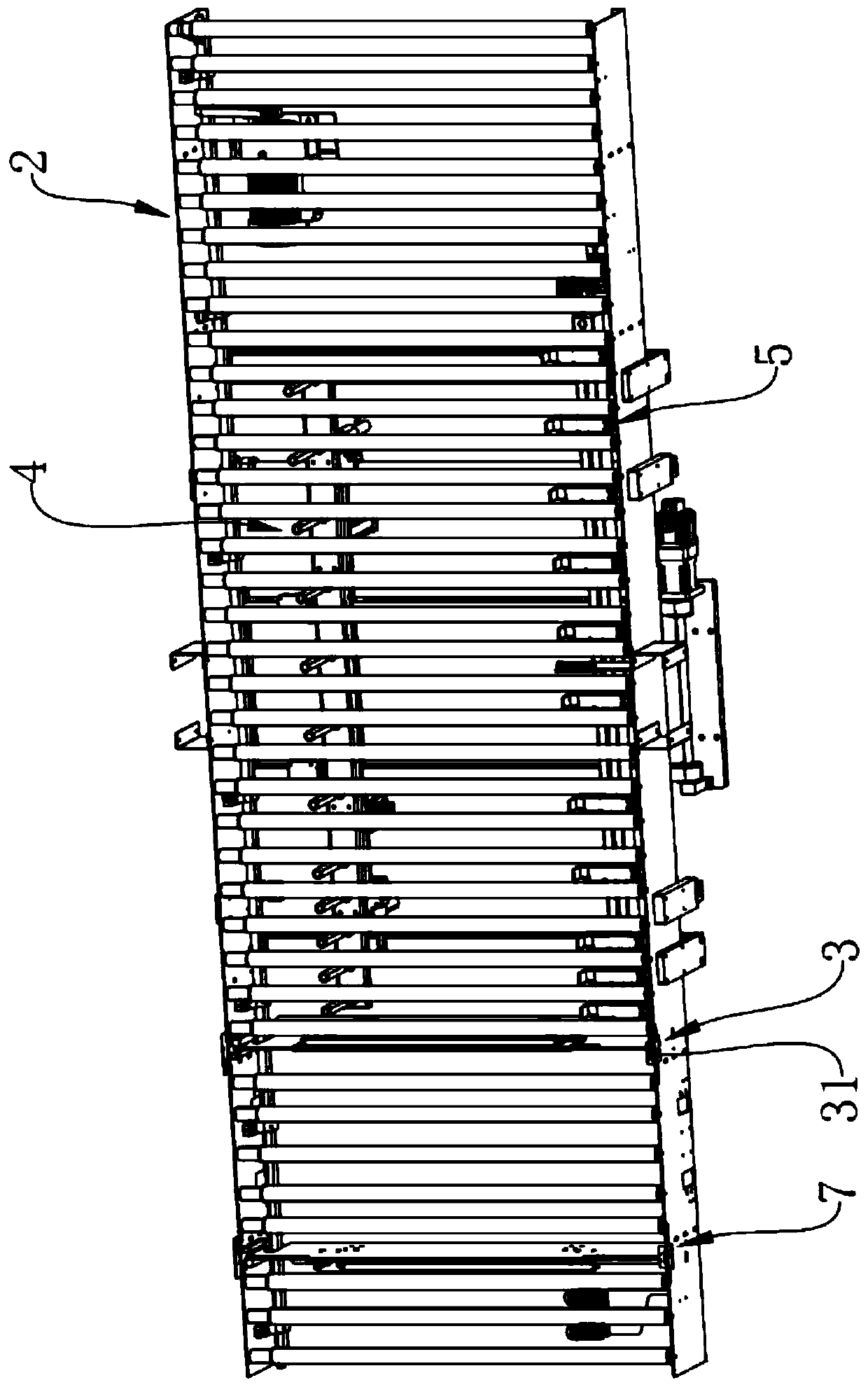

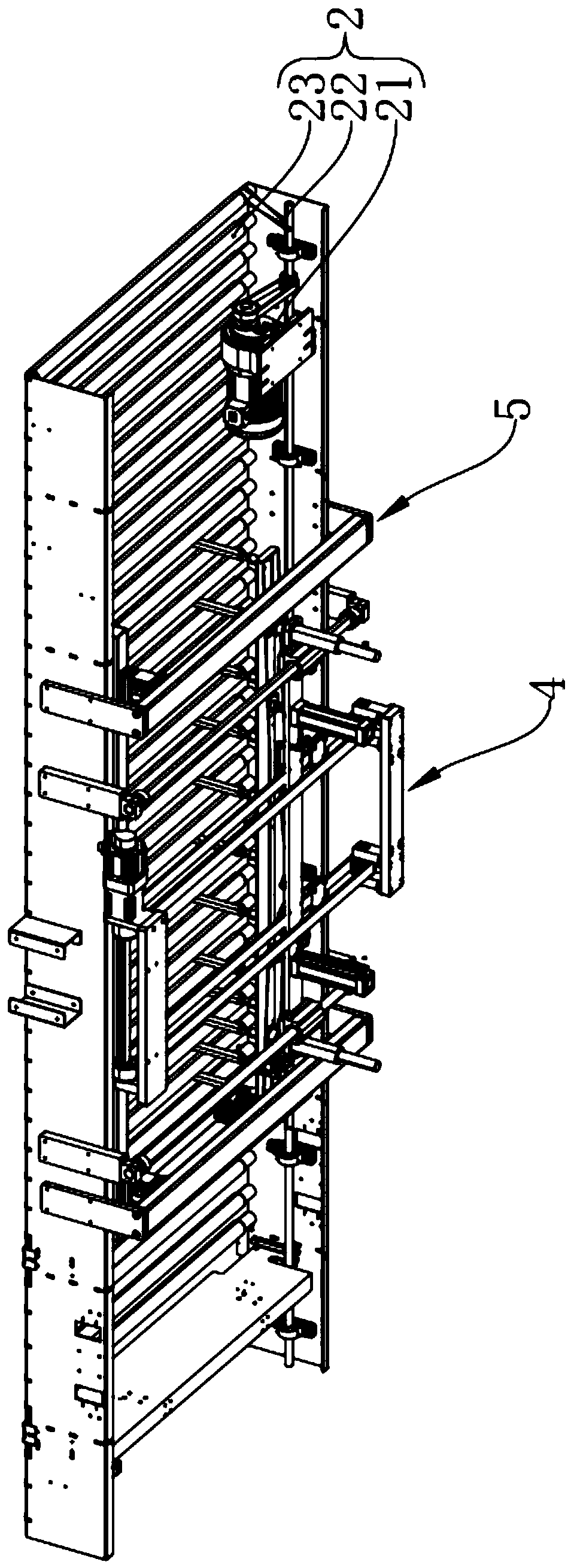

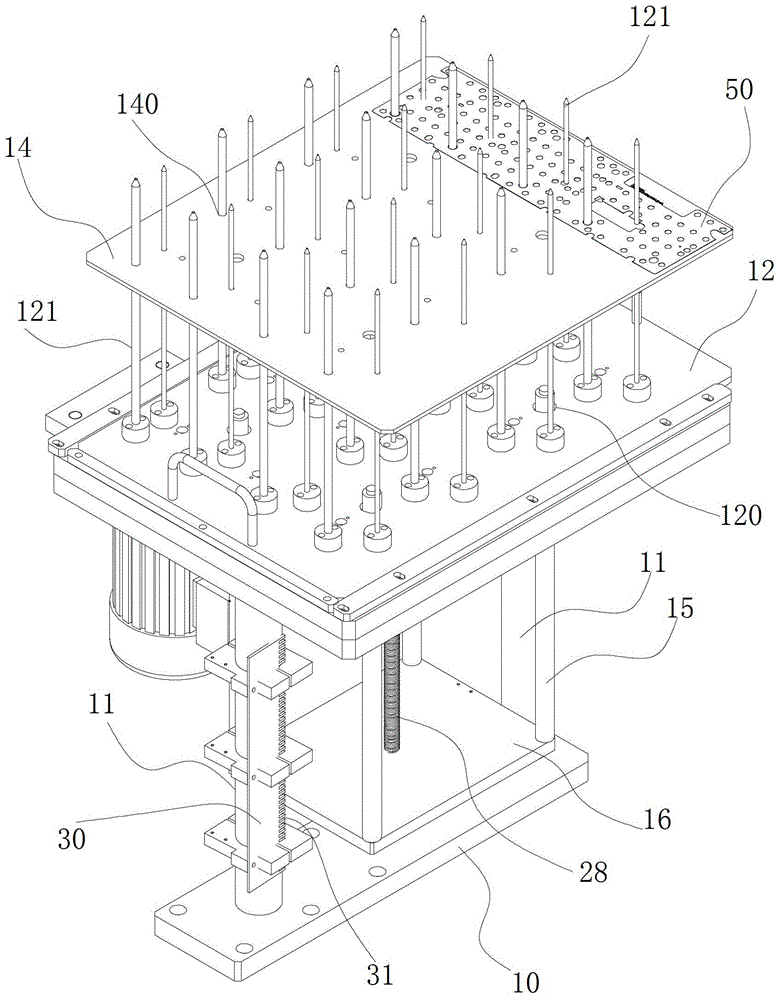

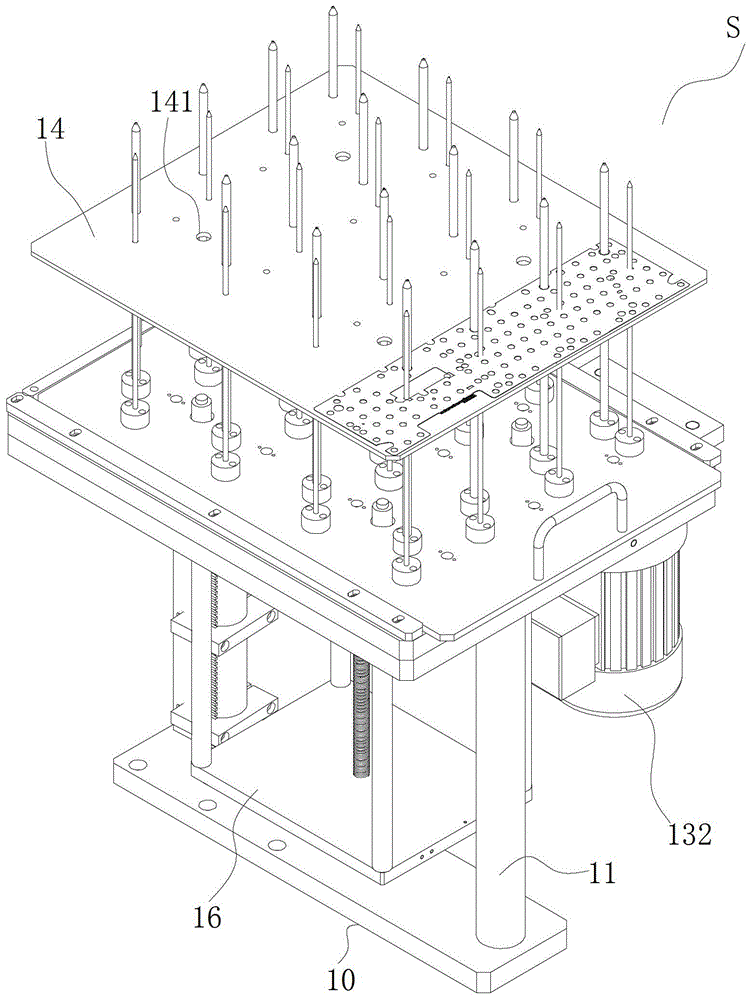

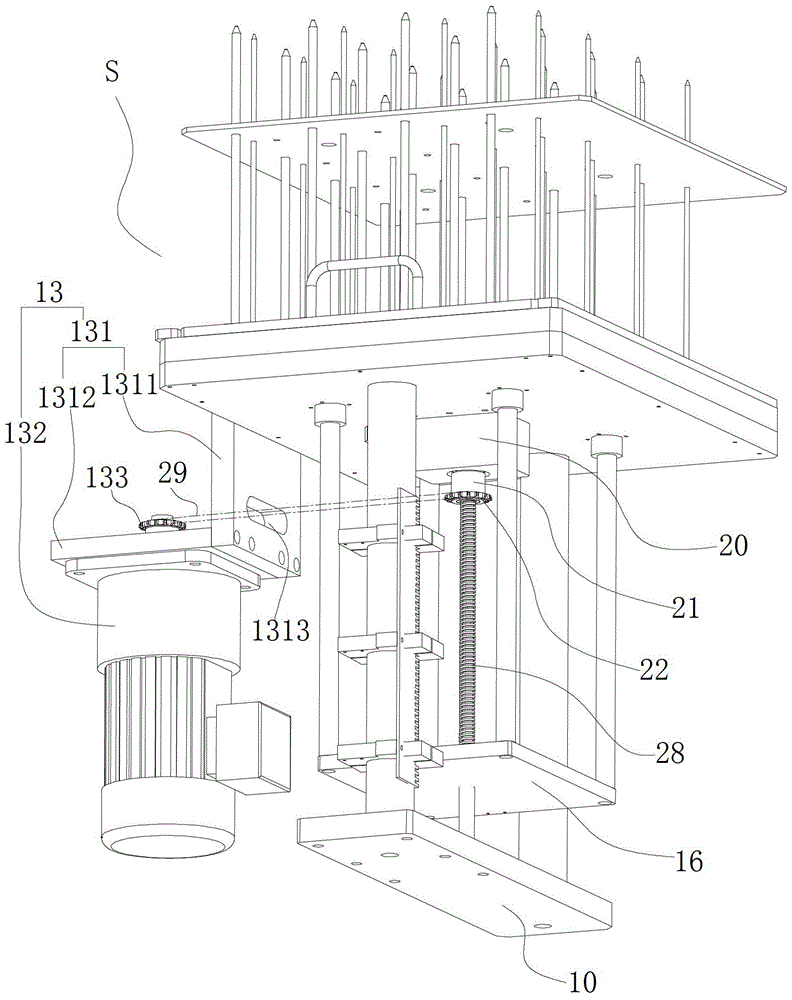

Lifting type material supporting mechanism and material collecting device of conducting film assembly

InactiveCN103407825ANeatly positionedRealize automatic receivingPile receiversArticle deliveryManipulatorRobot

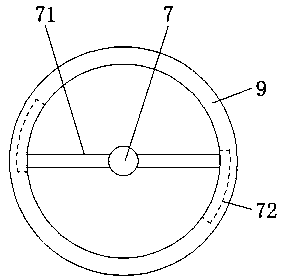

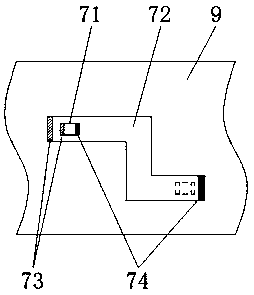

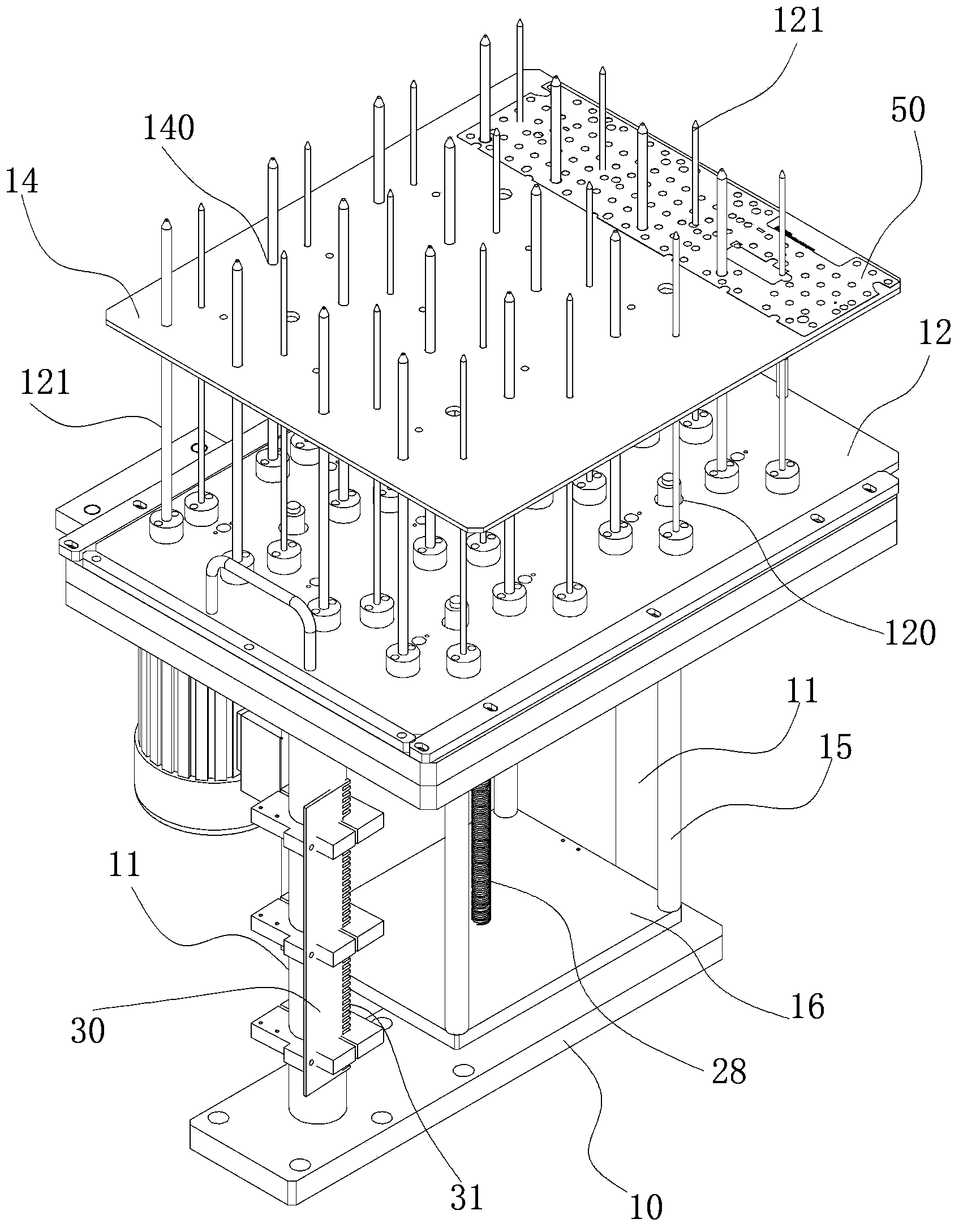

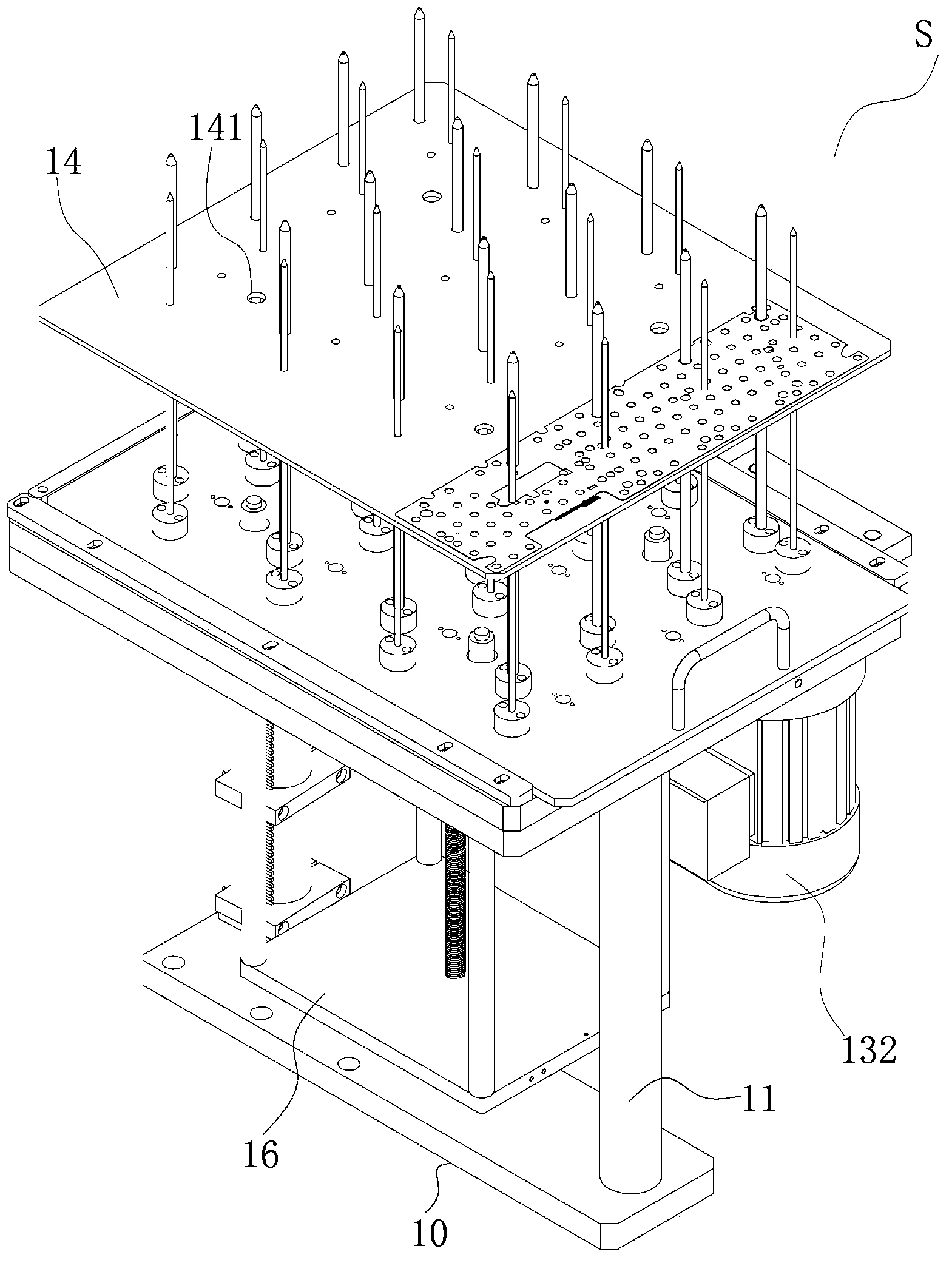

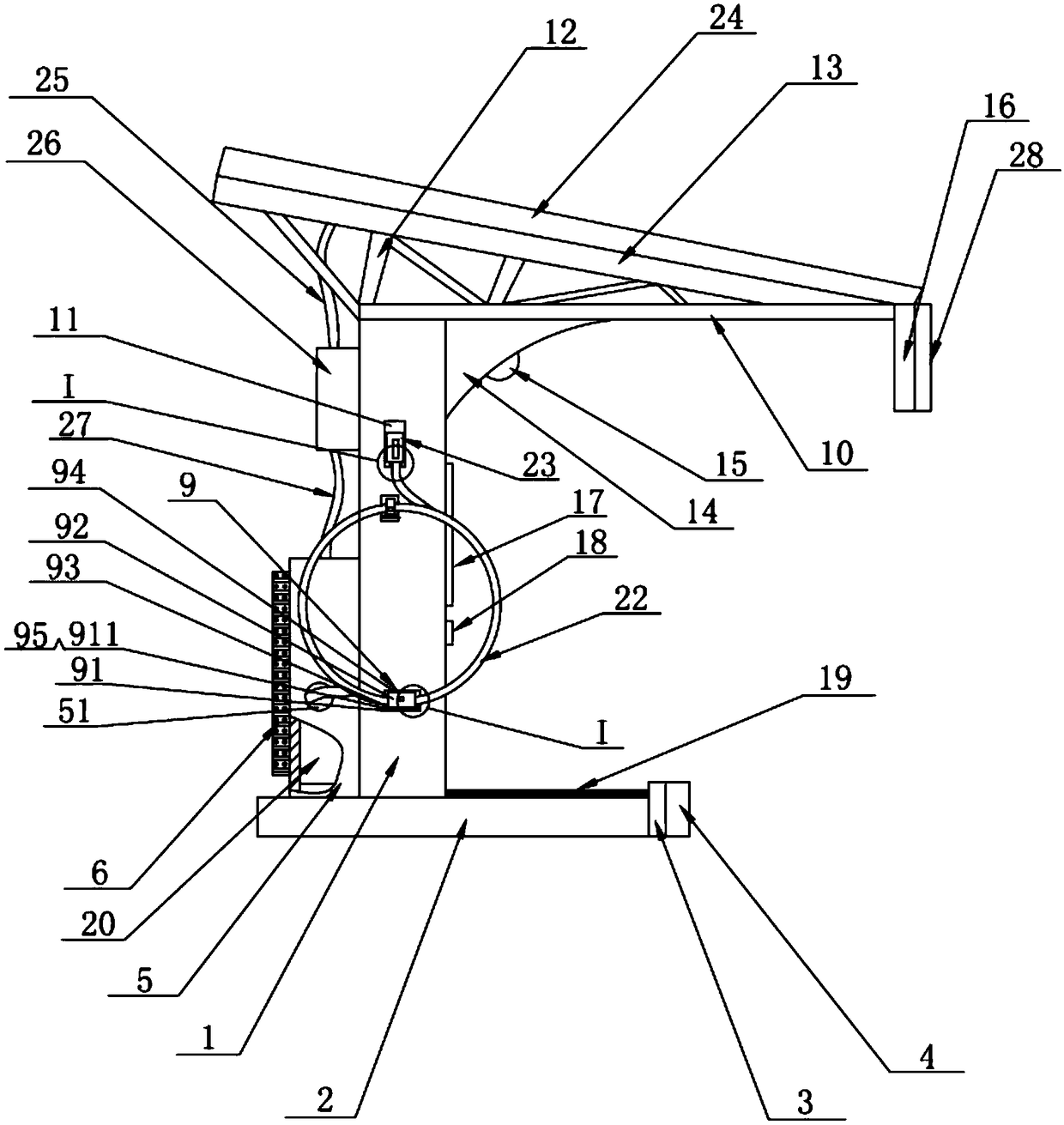

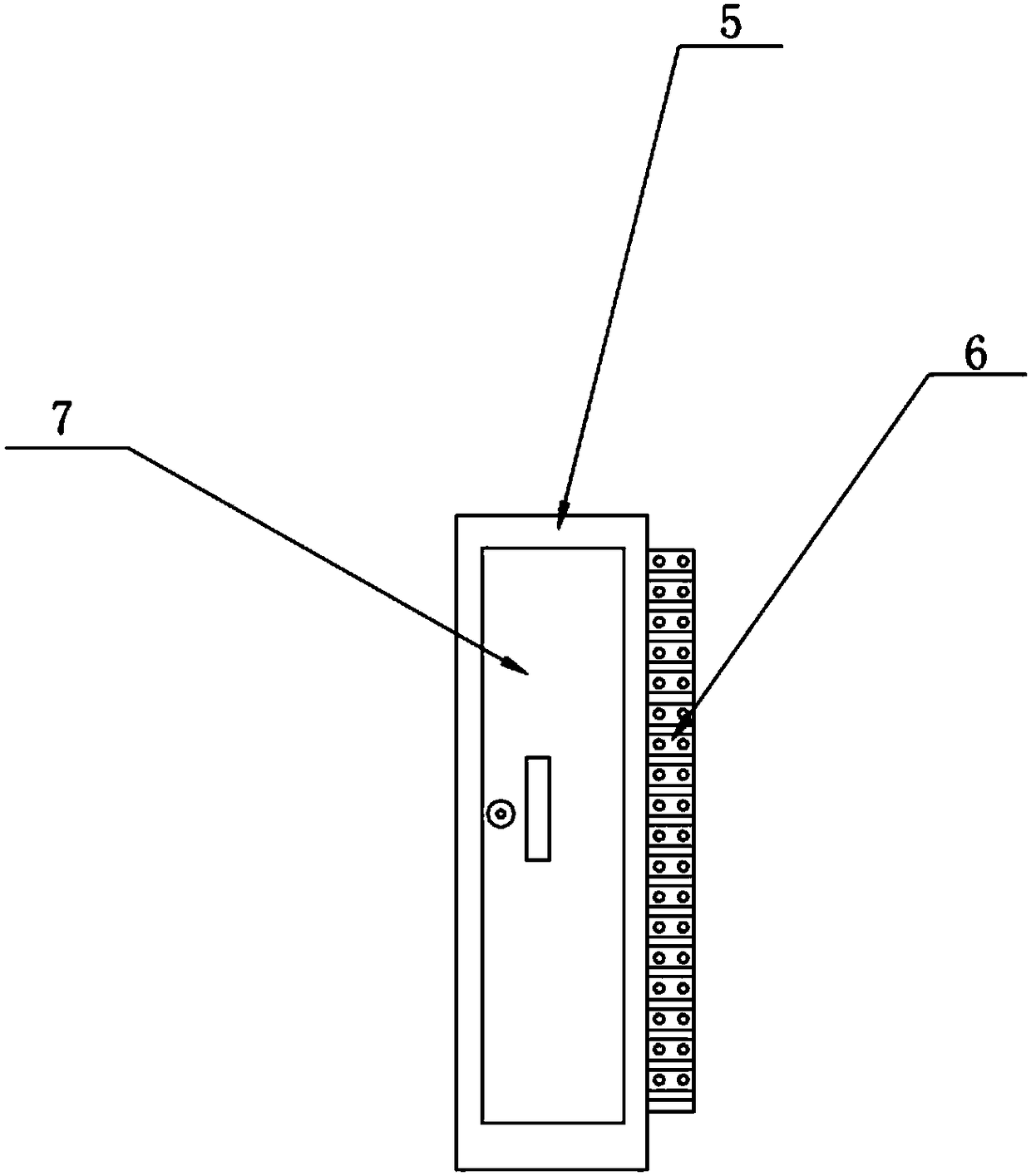

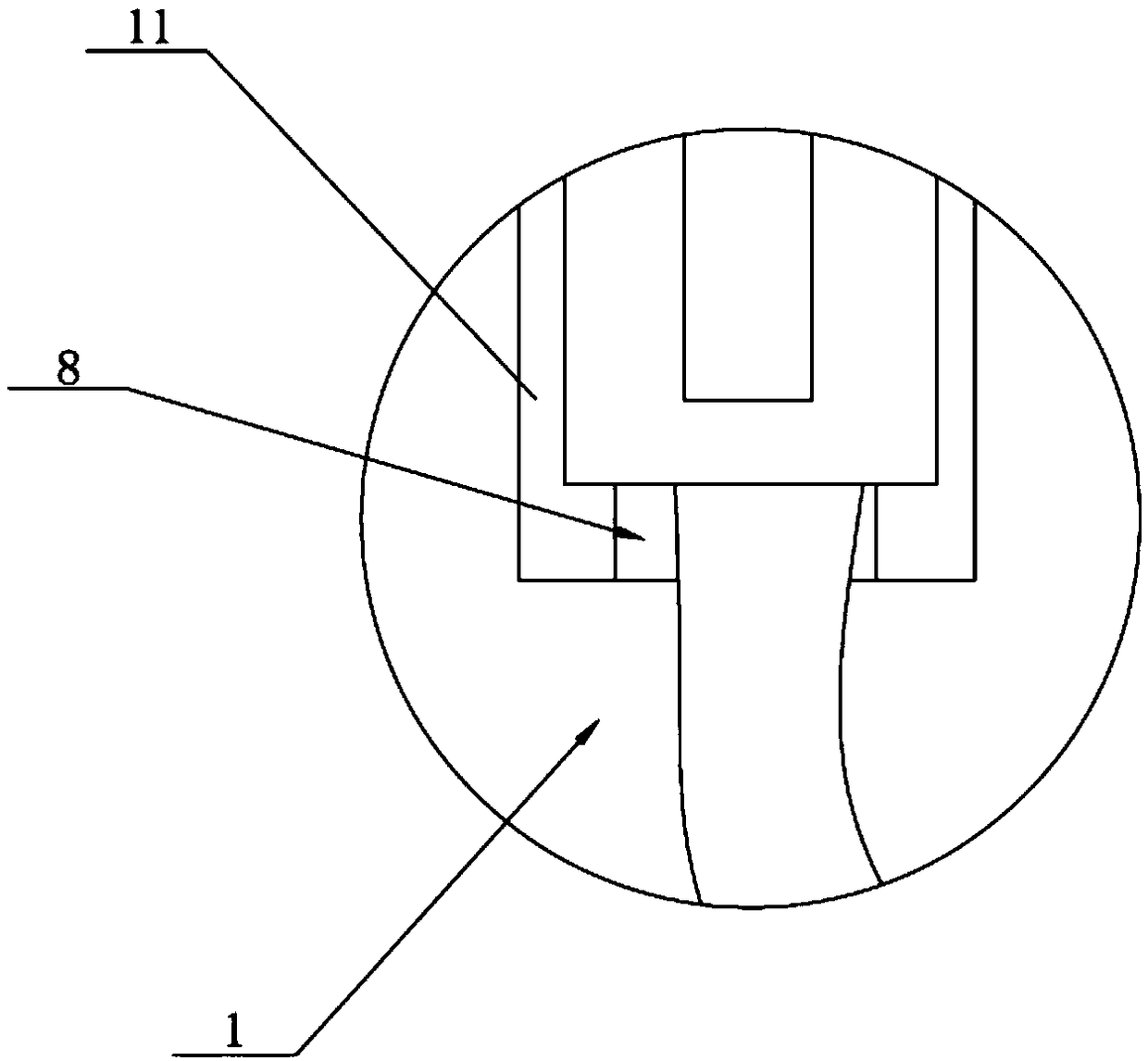

The invention discloses a lifting type material supporting mechanism and a material collecting device of a conducting film assembly. The lifting type material supporting mechanism comprises a base plate, a fixed plate, a motor assembly, a material supporting plate, a plurality of guiding rods, a nut base and a screw rod, wherein two stand columns are arranged above the base plate, the fixed plate is fixed at the upper end of each stand column, the motor assembly is provided with a driving wheel, the material supporting plate is arranged above the fixed plate, the guiding rods penetrate through guiding holes formed in the fixed plate, the upper end of each guiding rod is fixedly connected with the material supporting plate, and the lower end of each guiding rod is fixedly connected with a lower connecting plate, the nut base is provided with a driven wheel which is connected with the driving wheel in a transmission mode, and the screw rod is in threaded connection with a nut hole. In the process of stacking materials, the positions of the materials are neat and cannot be changed easily, the material placement positions do not need to be changed when a mechanical arm or a robot places the materials, the using efficiency of the robot or the mechanical arm is improved easily, and productivity is improved. According to the material collecting device of the conducting film assembly, the automatic material collection of the FPC conducting film assembly is achieved, manual material collecting is not needed, labor cost is reduced, and material collecting efficiency is improved.

Owner:SHENZHEN RAPOO TECH

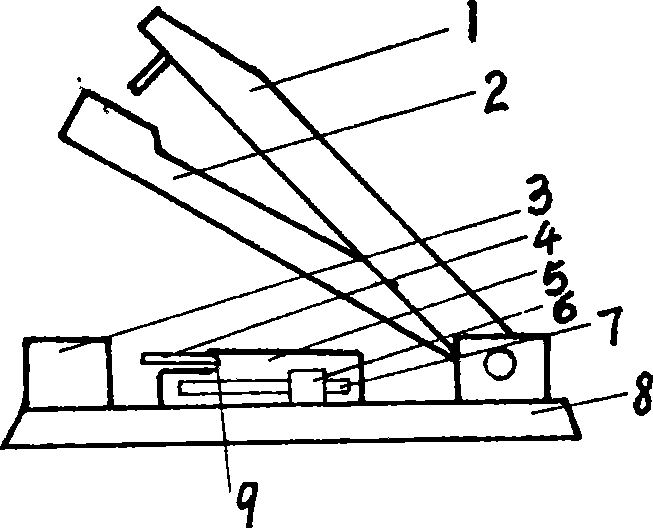

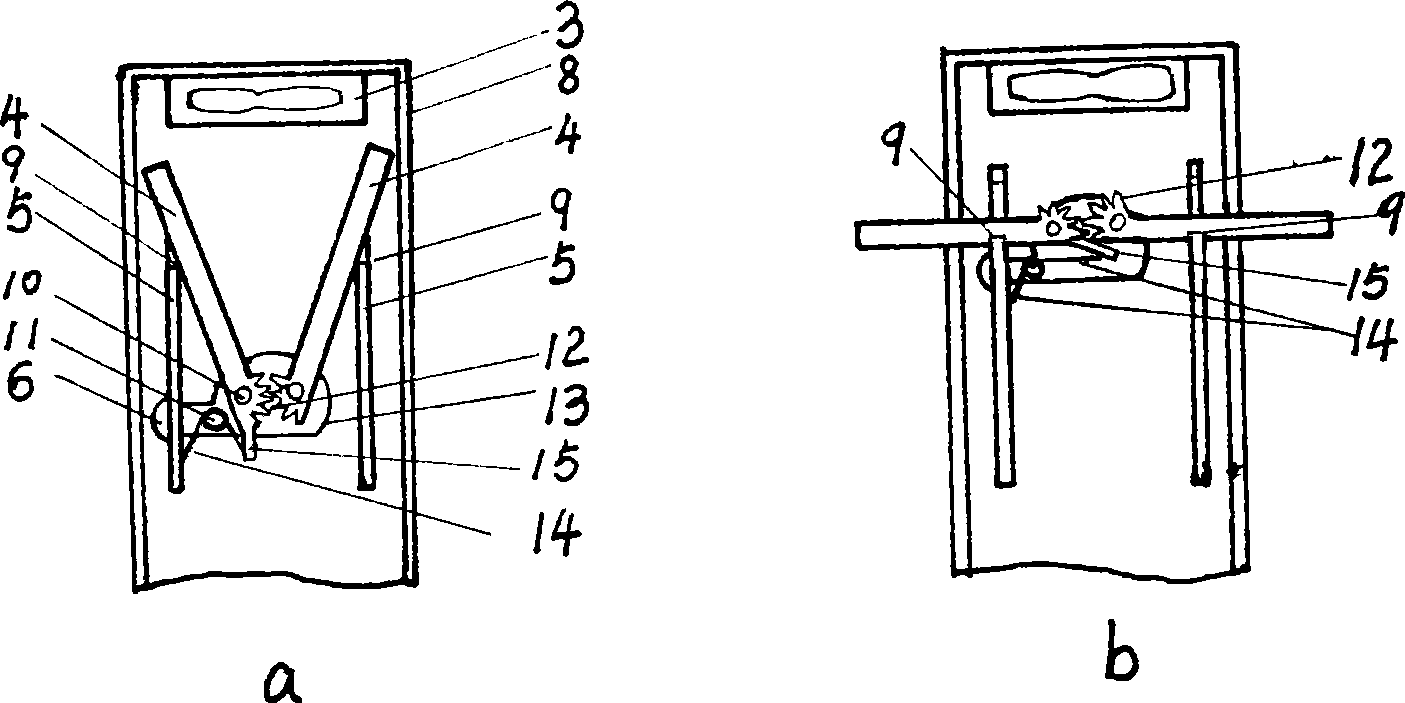

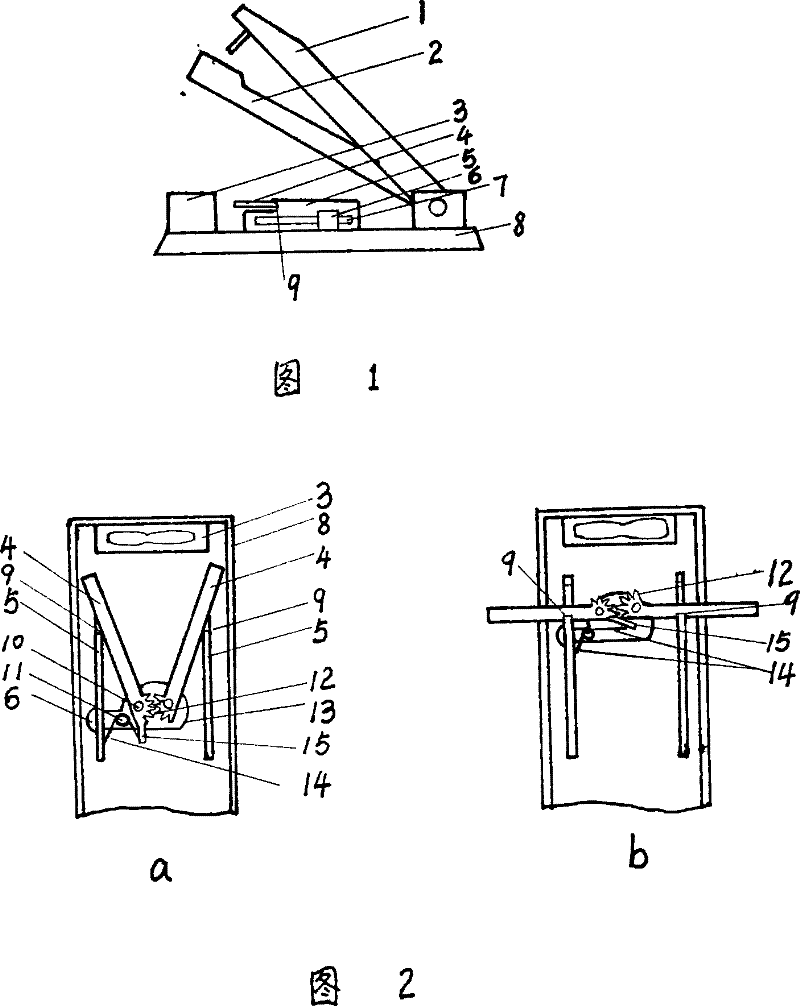

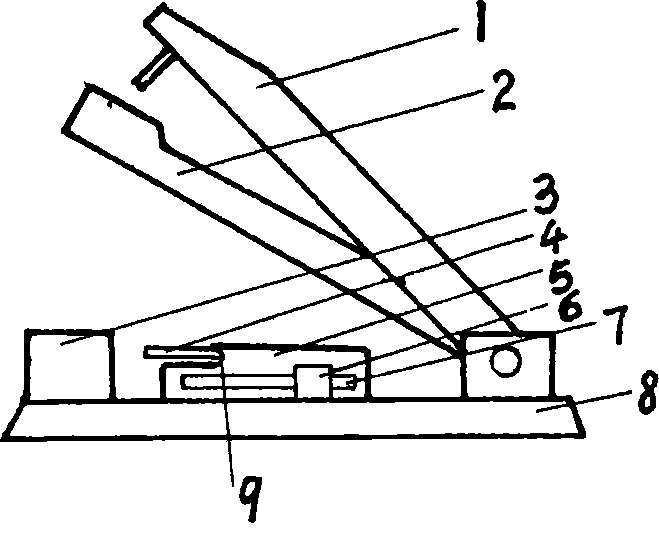

Binding machine with mark post

The invention discloses a stapler provided with a marker post, which consists of a bed, a stapling box, a pressure arm, a side wall, a slide block, a bottom plate, the marker post, a pinning spring, etc. Due to the newly arranged marker post with length rather more than that of the stapler body, the stapler offers a clear and palpable reference mark for the right arrangement of a binding piece, therefore, the binding quality is ensured and the stapler can be folded after use.

Owner:陈烁

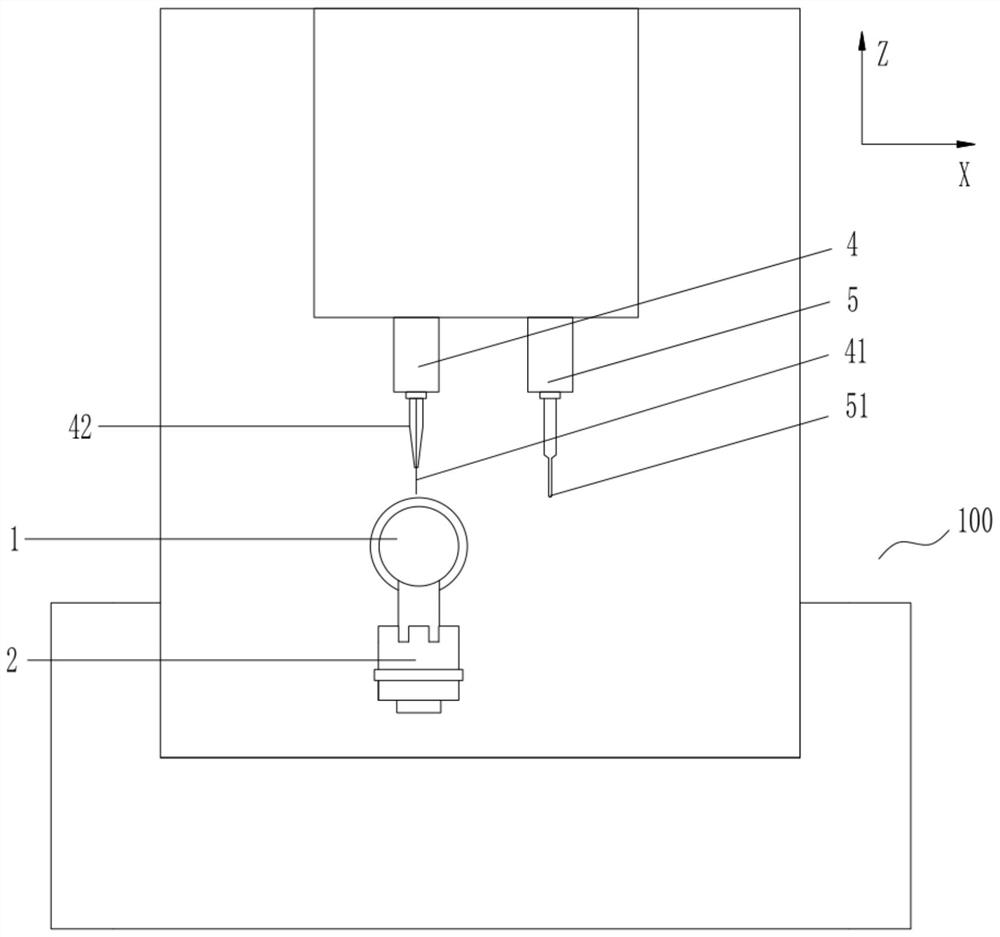

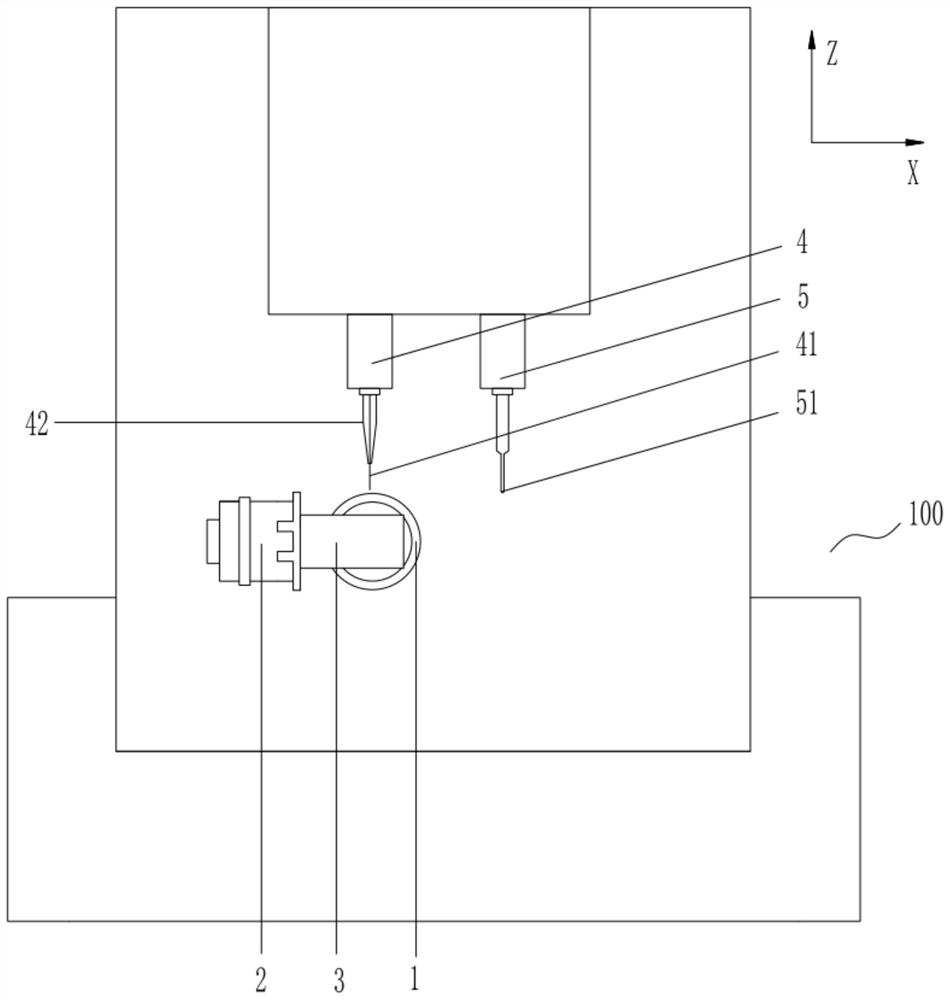

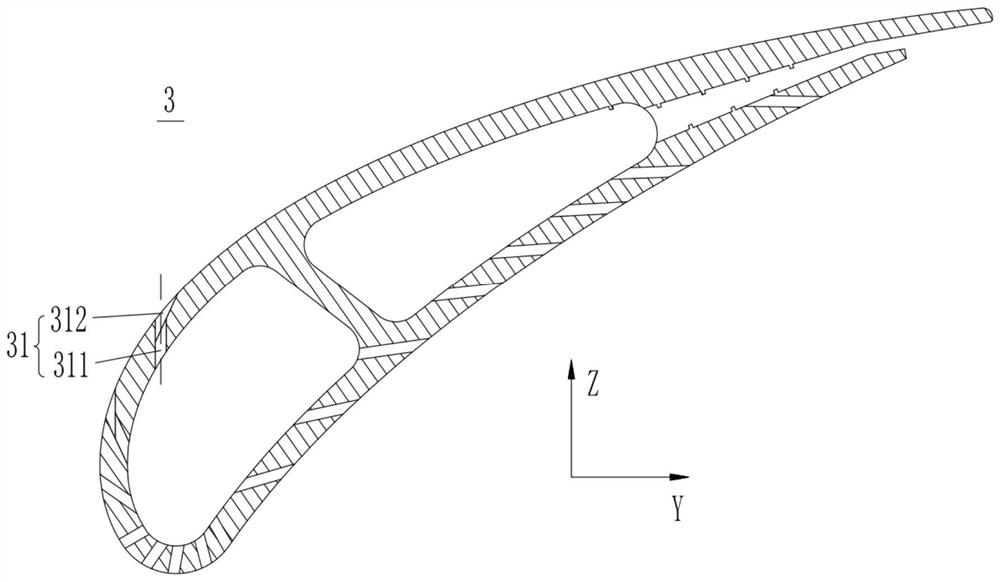

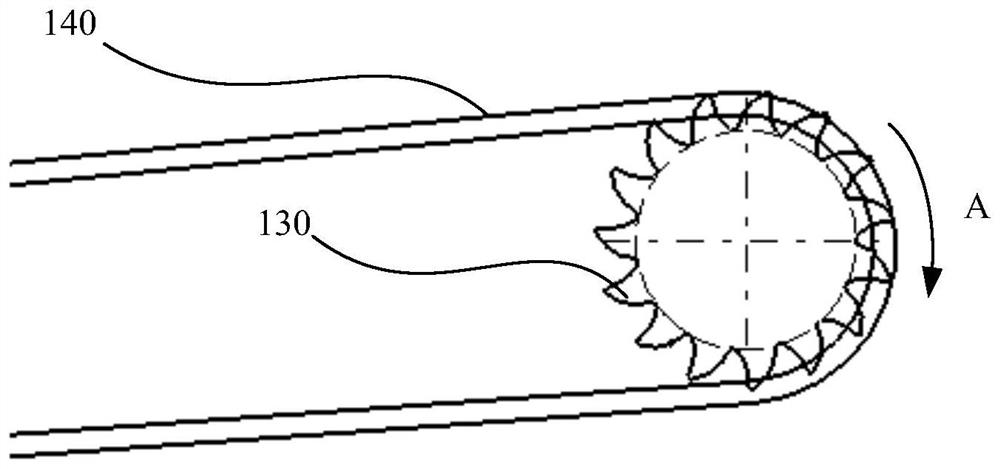

Method for machining turbine blade expansion holes through electric spark milling

The invention discloses a method for machining turbine blade expansion holes through electric spark milling. The method comprises the steps that a turbine blade three-dimensional model is preset; a turbine blade is installed, and the theoretical point taking orientation is measured; the corresponding preset turbine blade three-dimensional model is fitted according to the theoretical point taking orientation, hole positions, hole shapes and the number of the holes are determined, and corresponding machining electrodes are selected; the machining electrodes are subjected to loss testing and correction compensation; the machining electrodes are controlled for alignment machining to obtain single machining holes consistent with the three-dimensional model according to the three-dimensional model; and feeding and milling of the machining electrodes are repeatedly controlled till all the machining holes are machined. According to the method, the three-dimensional model is preset, then the turbine blade is subjected to configuration detection and matched with the corresponding three-dimensional model, the positions, shapes and number of the actual machining holes are determined, the corresponding machining electrodes are selected for alignment machining, and the positions, shapes and number of the machining holes are consistent with those of the three-dimensional model. The positionsare regular, the shapes are unified, and the machining technology indexes of the turbine blade expansion holes reach a high level.

Owner:成都和鸿科技股份有限公司

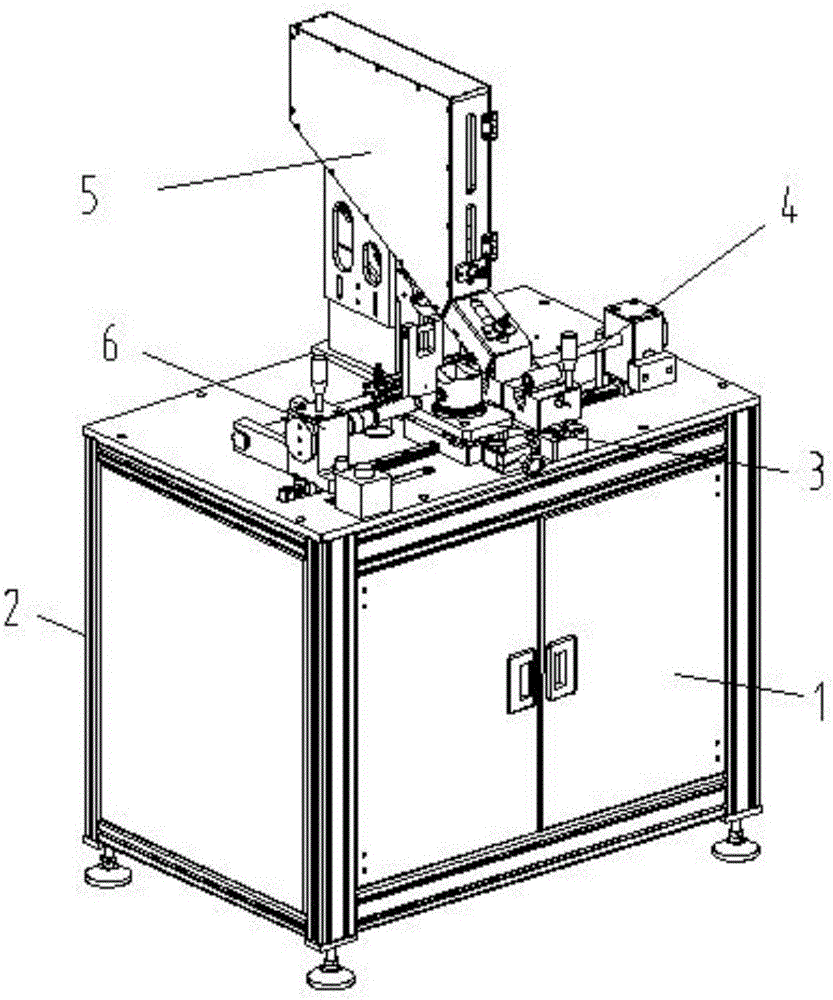

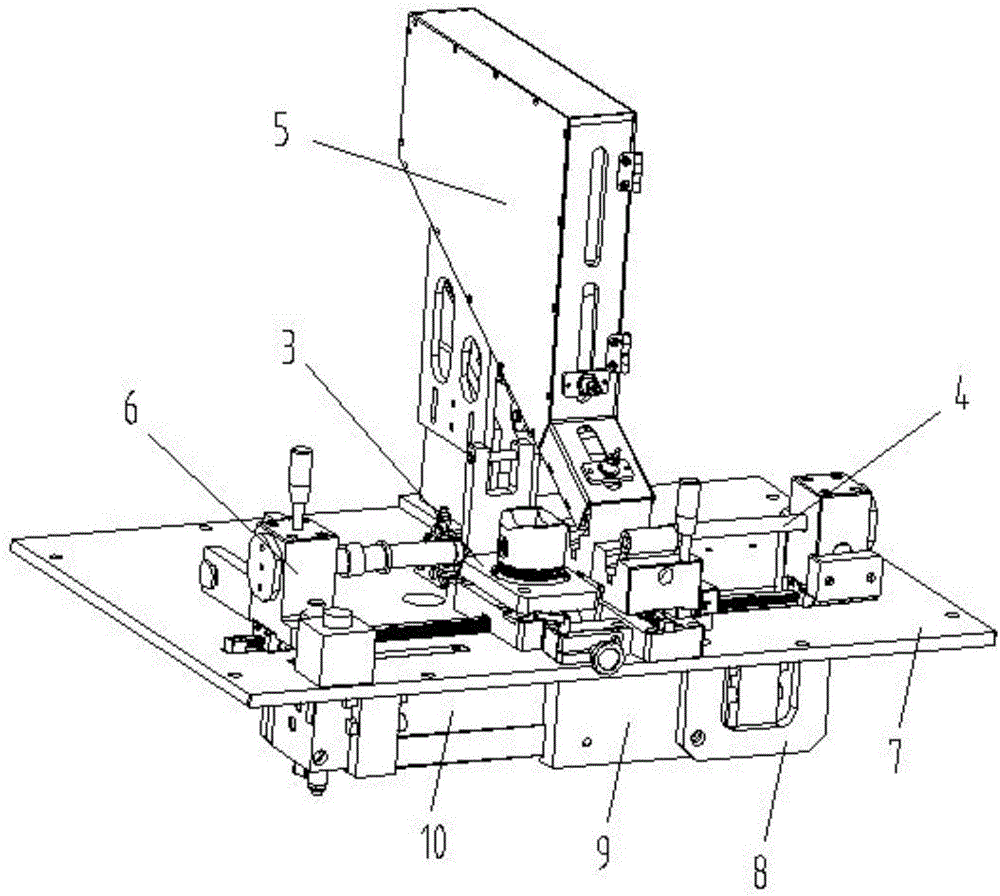

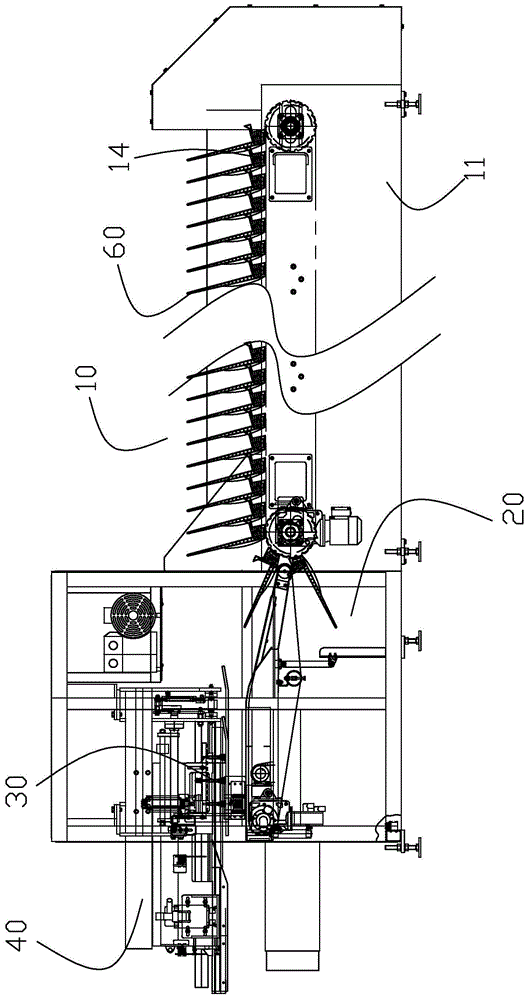

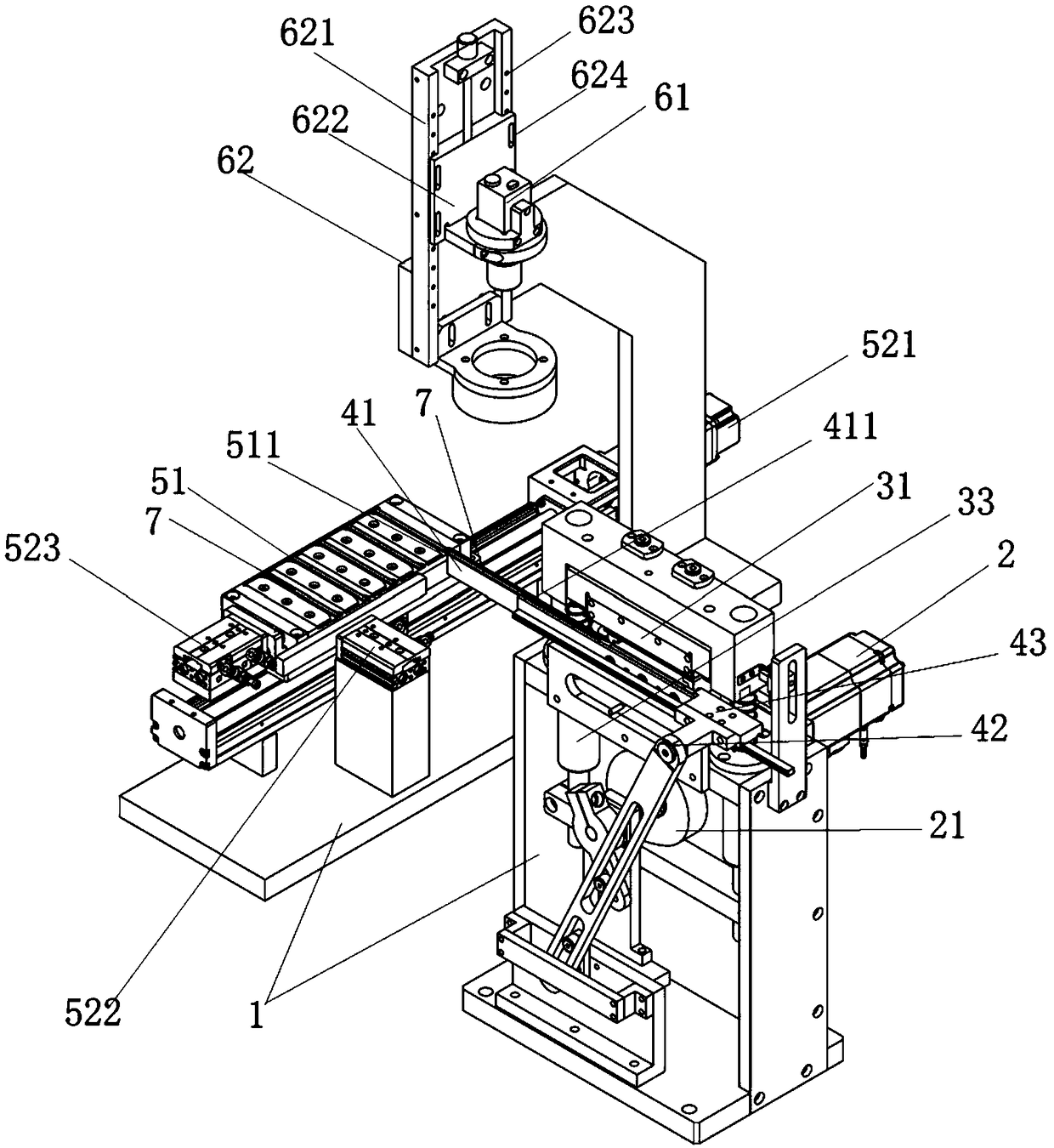

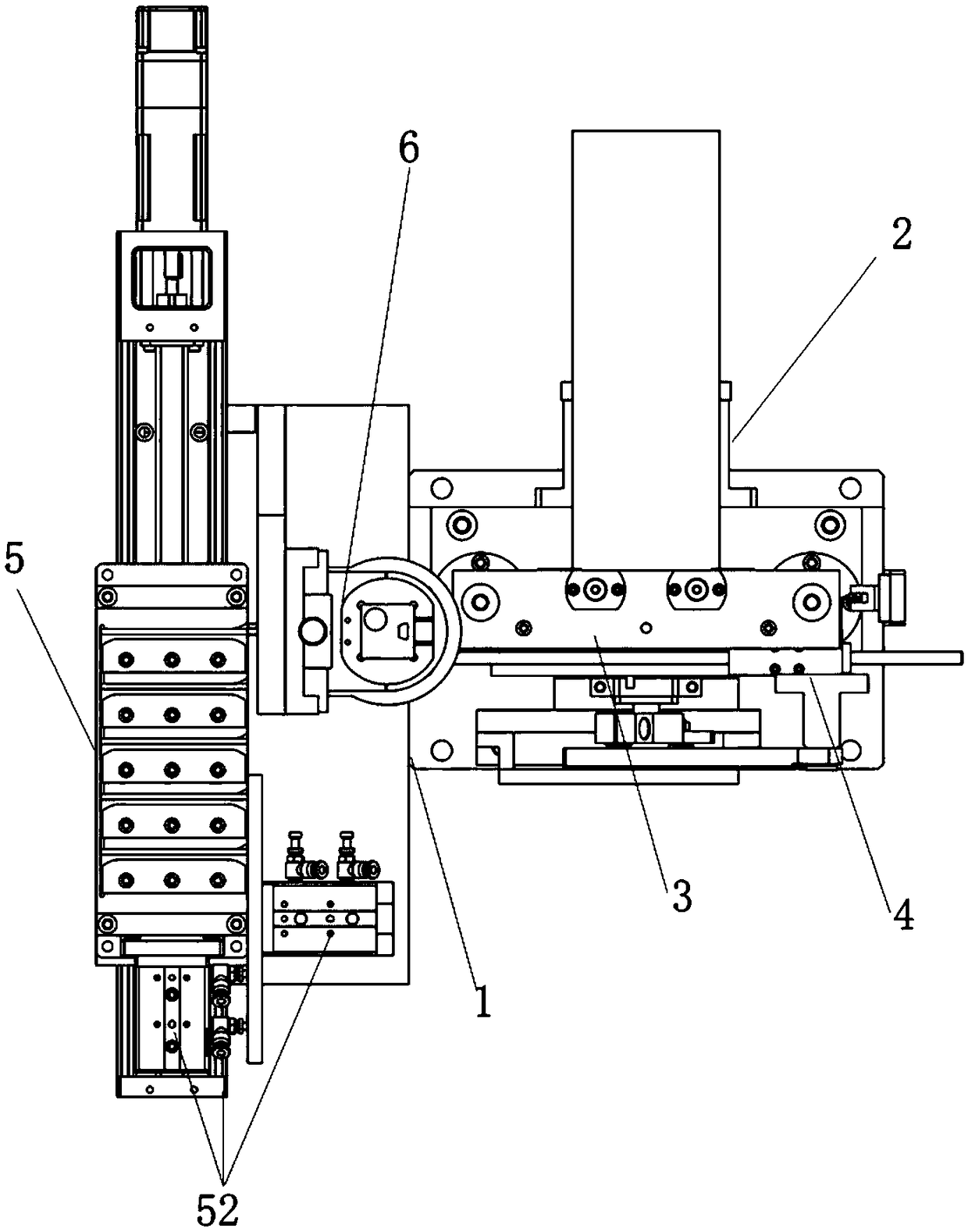

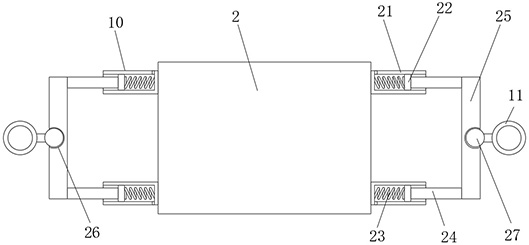

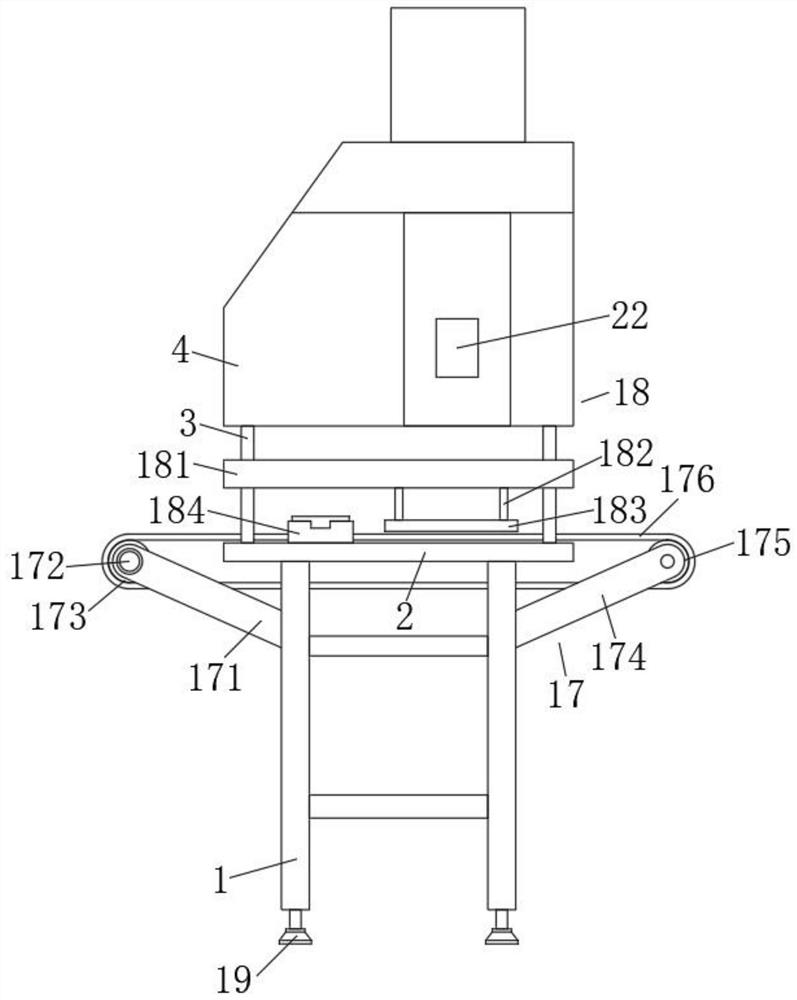

Automatic assembling machine for piston pin

ActiveCN106736434AImprove plug efficiencyReduce plug-in timeMetal working apparatusPistonDistribution control

The invention relates to an automatic assembling machine for a piston pin. A power distribution control box is arranged on a rack, a working platform is arranged on the power distribution control box, a fixing device and a bolt mechanism which are in fit with each other are arranged on the working platform, the fixing device comprises a fixed seat on the working platform, and a fixing plate in fit with a piston is arranged on the fixed seat; the bolt mechanism comprises a mounting base arranged at the right side of the fixed seat, a loading block is arranged on the mounting base, a loading chute in fit with the piston pin is formed in the loading block, the loading chute is in locational fit with a bolt hole of the piston, a pushing device in fit with the loading chute is arranged at the right side of the loading chute, and the pushing device is connected with the power distribution control box. The automatic assembling machine for the piston pin has the advantages that the piston is fixed by virtue of the fixing device, the piston pin in the loading chute is pushed into the piston pin hole by virtue of the bolt mechanism in fit with the fixing device, bolting efficiency is greatly improved, bolting time is shortened, and bolting strength also can be accurately controlled, so that inserted depth of the piston pin is appropriate, and multiple piston pins are the same in the inserted depth.

Owner:安徽鼎立智能制造股份有限公司

Electric automobile longitudinal beam lower aerofoil high-voltage line groove structure

PendingCN108340851AImprove cleanlinessEasy to installElectric/fluid circuitHigh pressureElectric power

The invention discloses an electric automobile longitudinal beam lower aerofoil high-voltage line groove structure. The structure comprises a power control unit, a high-voltage wiring harness, a chassis longitudinal beam and a front axle system and further comprises a line groove formed in the chassis longitudinal beam and wiring harness fixing supports arranged on the line groove, and the power control unit and the front axle system are installed on the chassis longitudinal beam; the wiring harness fixing supports are installed on the inner side wall of the line groove; and the high-voltage wiring harness is installed on the chassis longitudinal beam through the wiring harness fixing supports. The structure has the beneficial effects that the chassis wiring harness is moved to a lower aerofoil of the longitudinal beam from the inner side of an original longitudinal beam ventral face, and the wiring harness is convenient to install and maintain. In addition, the wiring harness is arranged in the line groove, the position and the direction of the wiring harness can be tidied, the wiring harness cannot be seen from the outer side, and the tidiness of a chassis is improved.

Owner:XUZHOU XUGONG AUTOMOBILE MFG CO LTD

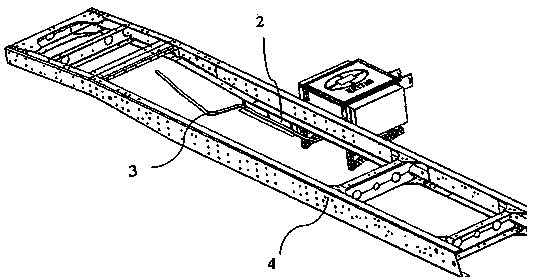

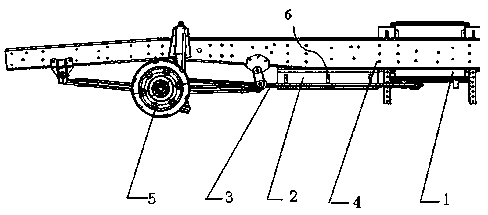

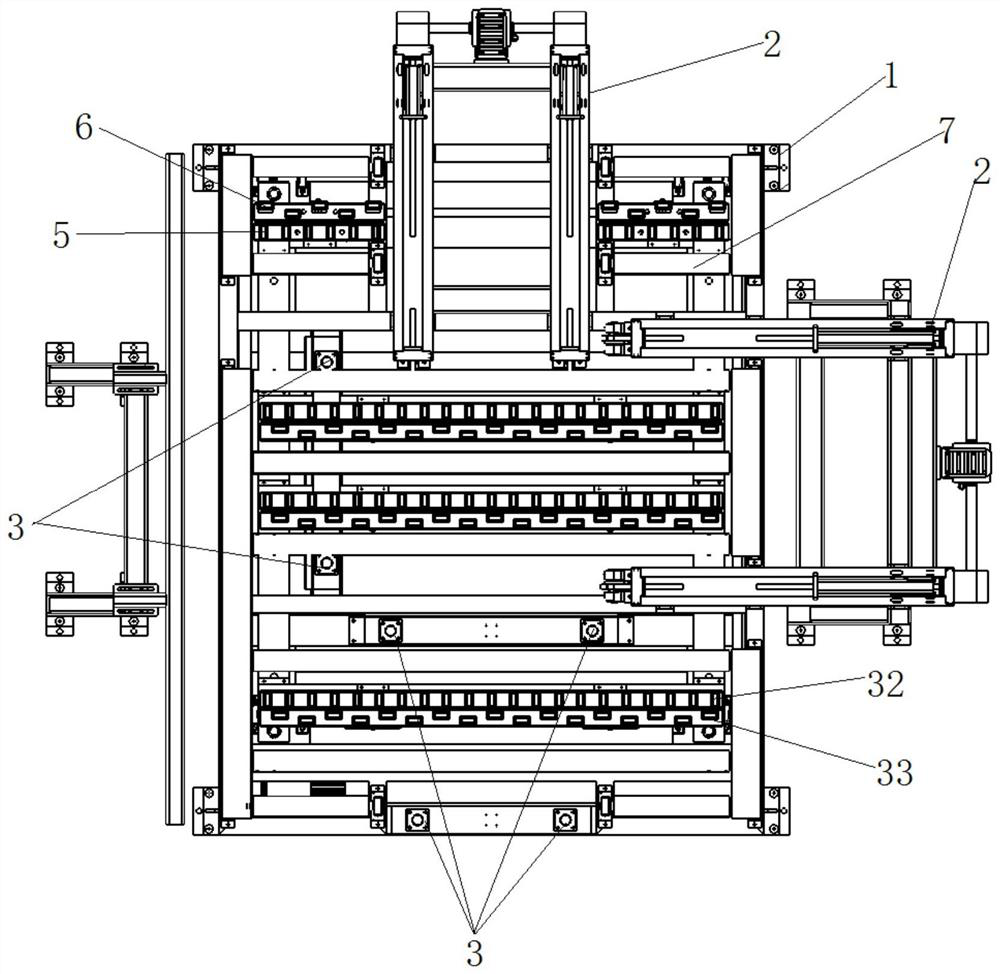

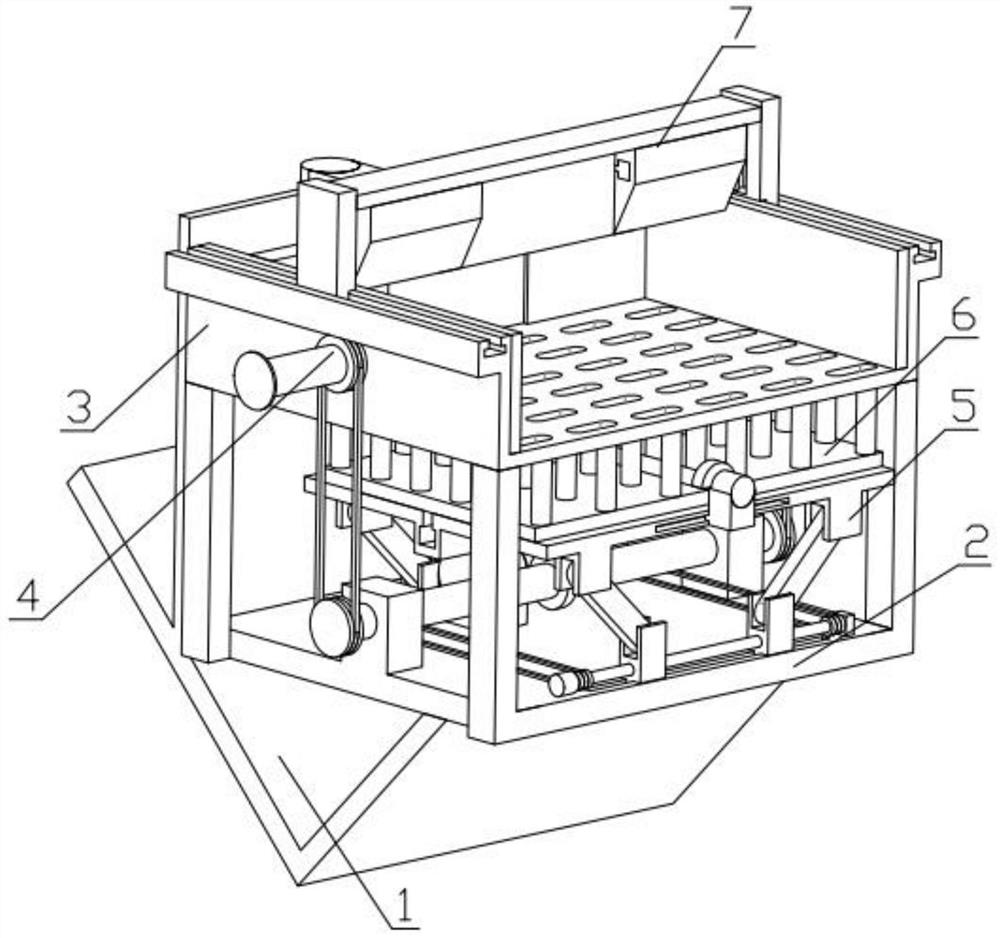

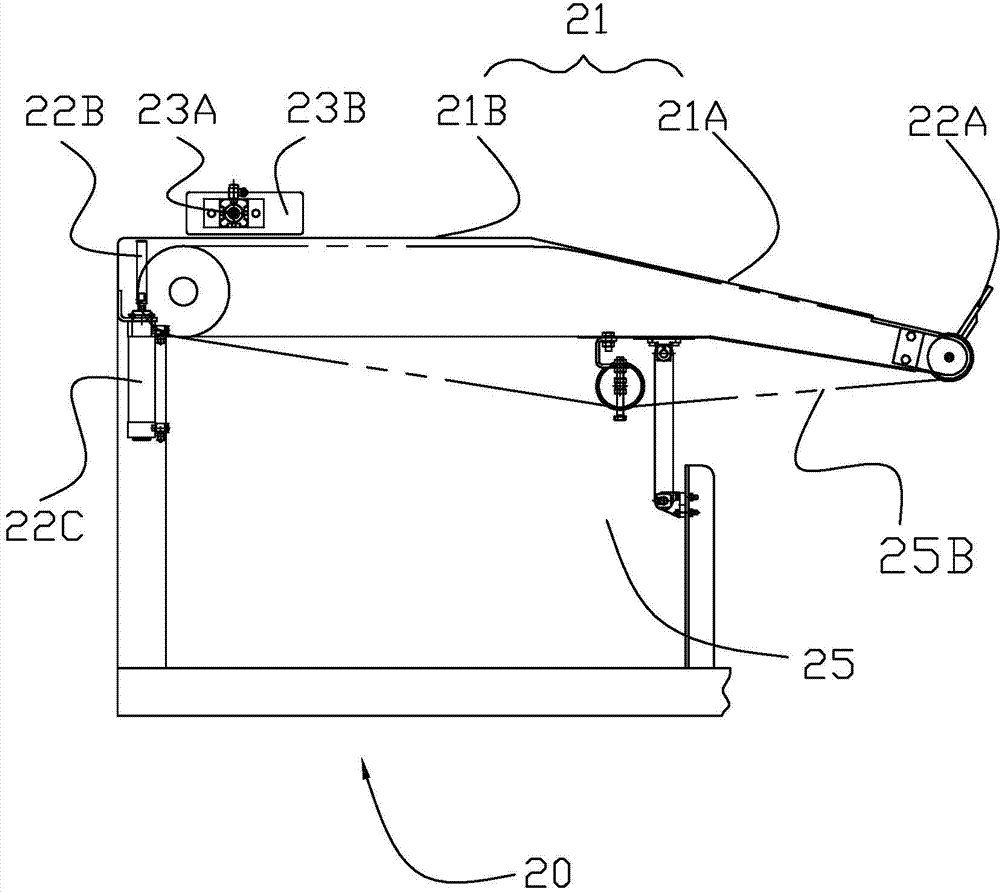

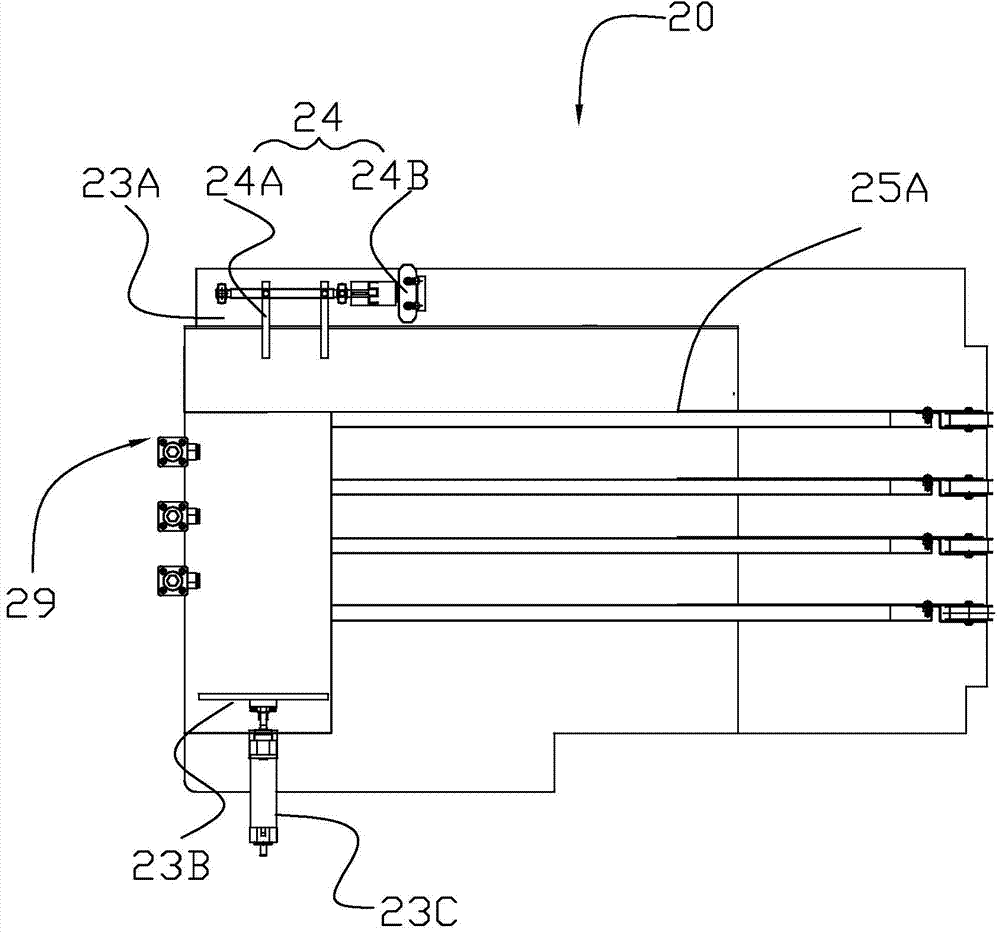

Automatic packaging production line

ActiveCN104354922ANeatly positionedImprove the success rate of pocket insertionPackagingManufacturing lineEngineering

The invention relates to an automatic packaging production line, which comprises a bag conveying device, an arrangement device, a bag lifting device, a bag ejection device and a material outlet nozzle, wherein the bag conveying device is used for conveying a plurality of groups of package bags, the arrangement device is used for receiving the package bags from the automatic bag conveying device, and positioning and pressurizing the package bags, the bag lifting device is used for lifting the package bags for convenient transportation, the bag ejection device is used for receiving the package bags from the bag lifting device and automatically inserting a package bag valve into the material outlet nozzle, and the material outlet nozzle is used for outputting to-be-packaged material. The automatic packaging production line has the advantage that when the package bags are absorbed by the bag lifting device, the package bags are released by the bag pressing device, the package bags are lifted by the lifting device, the bag pressing device can press the lower package bags, and the lower package bags are always positioned at the designated position, so the bag inserting success rate of the package bags is improved.

Owner:唐山智能电子有限公司

Stacking device for paperboards

Owner:ZHEJIANG DONGJIN TECH CO LTD

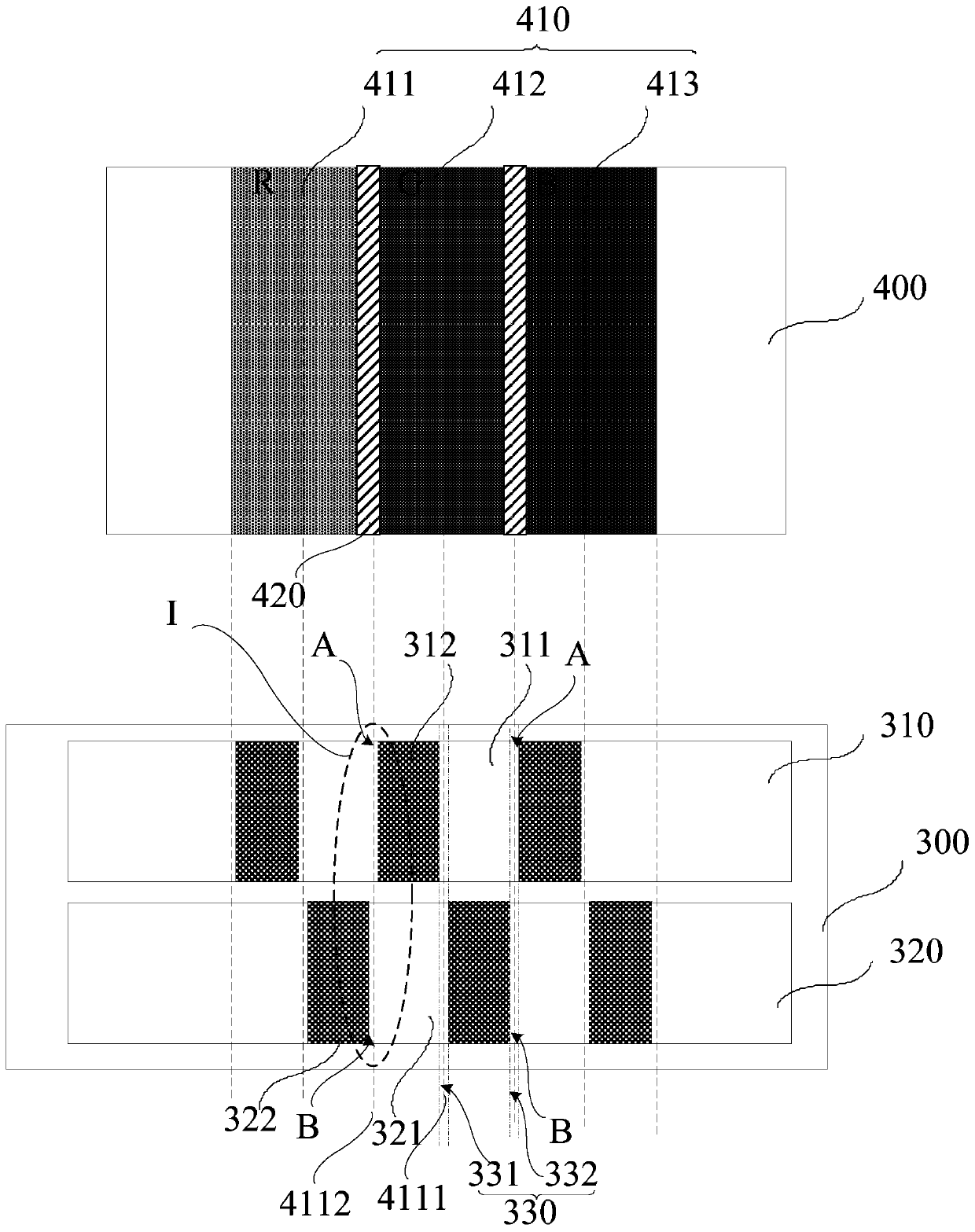

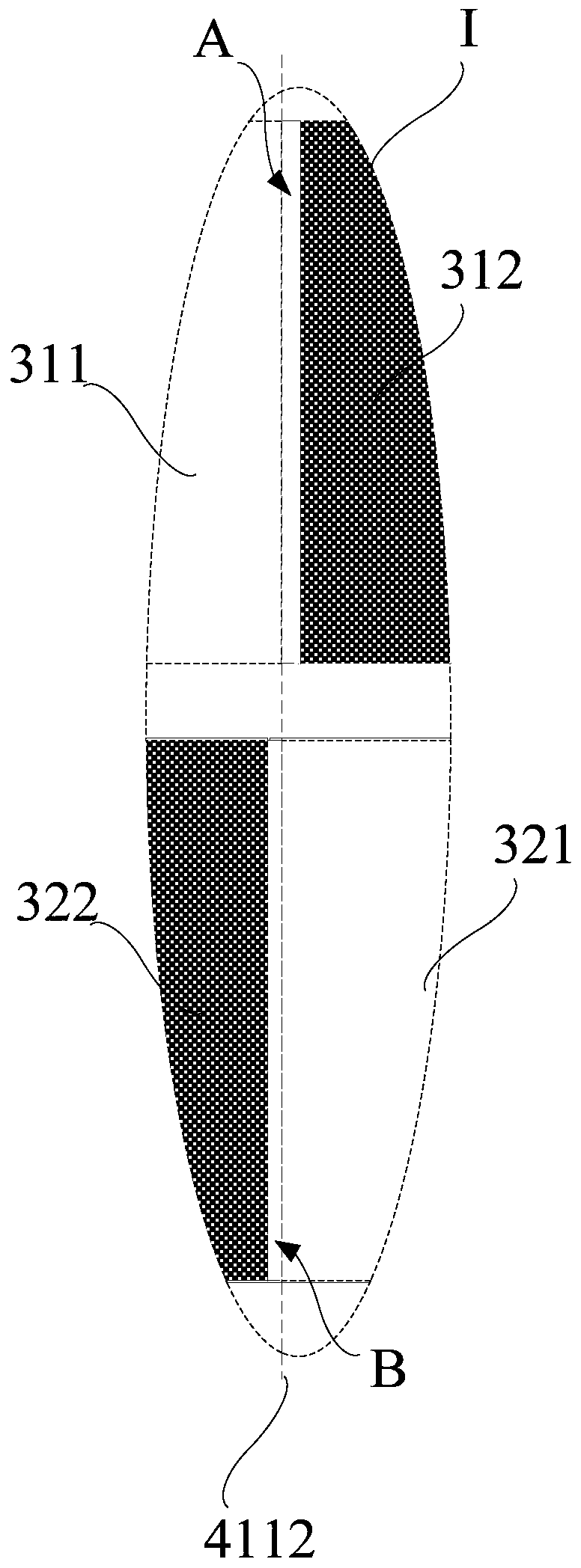

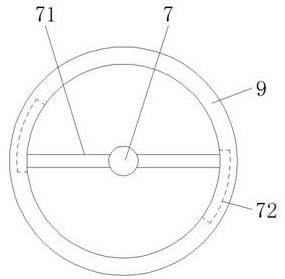

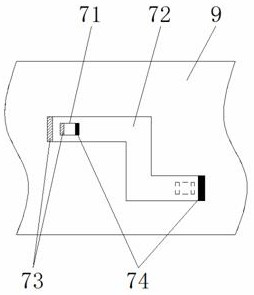

Mask equipment

ActiveCN110045548AReduced precision requirementsHigh light transmittanceOriginals for photomechanical treatmentNon-linear opticsLiquid-crystal displayLiquid crystal

The invention provides mask equipment. The mask equipment is used for performing optical alignment on an alignment film on a liquid crystal substrate; the liquid crystal substrate comprises a pixel area; the mask equipment comprises a first graphic area and a second graphic area; the first graphic area comprises a first light transmission area and a first shading area, which are alternatively arranged along the first direction; the width sum of the first light transmission area and the first shading area is equal to the width of one sub-pixel area in the pixel area; the second graphic area comprises a second light transmission area and a second shading area, which are alternatively arranged along the first direction; the width sum of the second light transmission area and the second shading area is equal to the width of one sub-pixel area in the pixel area; along the first direction, a light transmission gap for ultraviolet light to pass is between the first shading area and the secondshading area, which are adjacent; therefore, the centre and the edge of each sub-pixel area on the liquid crystal substrate form regular dark lines; and thus, the display effect of a liquid crystal display screen is improved.

Owner:CHENGDU ZHONGDIAN PANDA DISPLAY TECH CO LTD

Paperboard stacking and packing device

The invention discloses a paperboard stacking and packing device. The paperboard stacking and packing device comprises a stacking device and a packing device used for bundling paperboard piles, and the packing device is arranged on the rear side of the stacking device; and the stacking device comprises a support, partition plates, receiving brackets and push plates, wherein baffles capable of sliding forwards and backwards are arranged on the front side and the rear side of the support, the receiving brackets are arranged on the support, each partition plate is arranged on the corresponding baffle and arranged above the corresponding receiving bracket, the push plates are arranged on the support, and conveyor belts are arranged below the push plates. The paperboard stacking and packing device is simple in structure and can be used for receiving paperboards with different sizes; meanwhile, the paperboards can be stacked regularly, and the stacked paperboards can be packed.

Owner:ZHEJIANG DONGJIN TECH CO LTD

Plate arranging device

PendingCN114604606ANeatly positionedSolve narrative problemsConveyor partsClassical mechanicsEngineering

The plate tidying device comprises a rack, a fixed push plate assembly, a tidying frame automatic flange, a bidirectional conveying guide wheel assembly, a bidirectional conveying guide wheel assembly synchronous jacking mechanism, a transverse guide wheel assembly, a longitudinal guide wheel assembly and a conveying roller assembly. The machine frame is installed on the ground and serves as the reference of the plate tidying device, the conveying roller assembly is installed over the machine frame through a metal frame, a plurality of tidying frame automatic flanges are further arranged on the machine frame, and the two-way conveying guide wheel assembly synchronous jacking mechanism is arranged in the middle of the same plane of the machine frame. A transverse guide wheel assembly and a longitudinal guide wheel assembly are installed on the two-way conveying guide wheel assembly synchronous jacking mechanism, and the transverse guide wheel assembly and the longitudinal guide wheel assembly are arranged in the neutral position of the conveying roller assembly and located on the same plane with the conveying roller assembly.

Owner:广州宁基智能系统有限公司

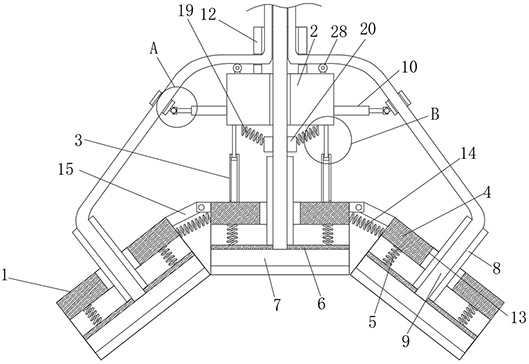

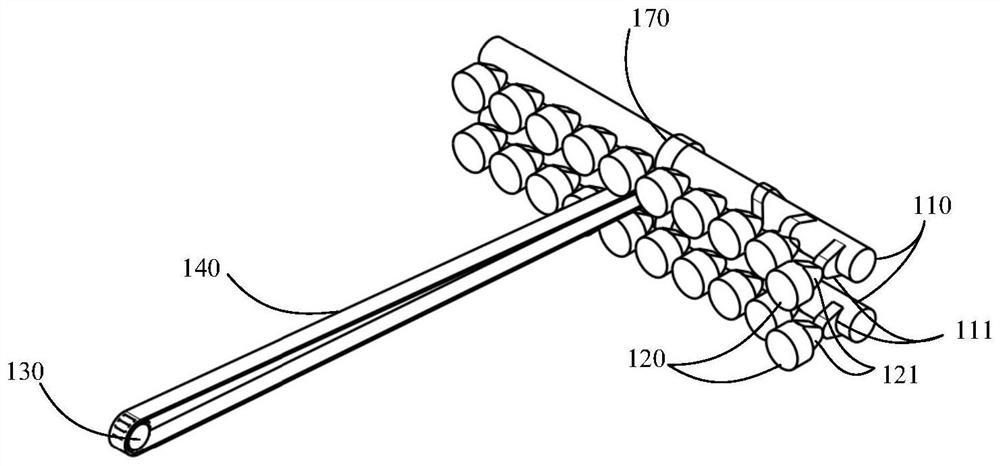

Scallion stalk and leaf separation device for chive oil production

InactiveCN112045759AAchieve neat placementReduce displacementMetal working apparatusBiotechnologyMedicine

The invention relates to food processing machinery, in particular to a scallion stalk and leaf separating device for chive oil production. The scallion stalk and leaf separating device comprises a root aligning mechanism, a side supporting plate, placing plates, a gathering mechanism, a lifting mechanism, an aligning mechanism and a cutting mechanism, wherein the side supporting plate is fixedly mounted on the root aligning mechanism, the placing plates are fixedly mounted on the side supporting plate, the gathering mechanism is installed on the side supporting plate and the placing plates atthe same time, the aligning mechanism is installed on the lifting mechanism in a sliding mode, the lifting mechanism is fixedly installed on the side supporting plate, and the cutting mechanism is installed on the placing plates in a sliding mode. The scallion stalk and leaf separating device has the function of correcting the positions of a large number of scallions, has the function of integrally placing the large number of scallions, and avoids large errors during scallion cutting.

Owner:哈尔滨市阿城区兴盛腻子粉厂

Automatic packaging method

InactiveCN104494848AEasy to liftImprove the success rate of pocket insertionSolid materialBiomedical engineeringPacking method

The invention relates to an automatic packaging method. Valve ports of packaging bags are automatically inserted in a discharging port of a packaging machine by the aid of an automatic bag inserting machine, materials to be packaged are packaged, the automatic bag inserting machine comprises a bag sending device, a managing device, a bag lifting device and a bag shooting device, and the managing device comprises a positioning unit and a pressing unit. According to the automatic packaging method, after the uppermost packaging bag is lifted through the bag lifting device, the lowermost packaging bag is pressed through the pressing unit so as to be allowed to be always at the designated position, and successful rate of bag inserting of the packaging bags is increased; the position that the bag lifting device is attached to the packaging bags and the position that the pressing unit presses the packaging bags are staggered, and the problem that the pressing unit and the bag lifting device are intervened with each other during operation is avoided.

Owner:唐山智能电子有限公司

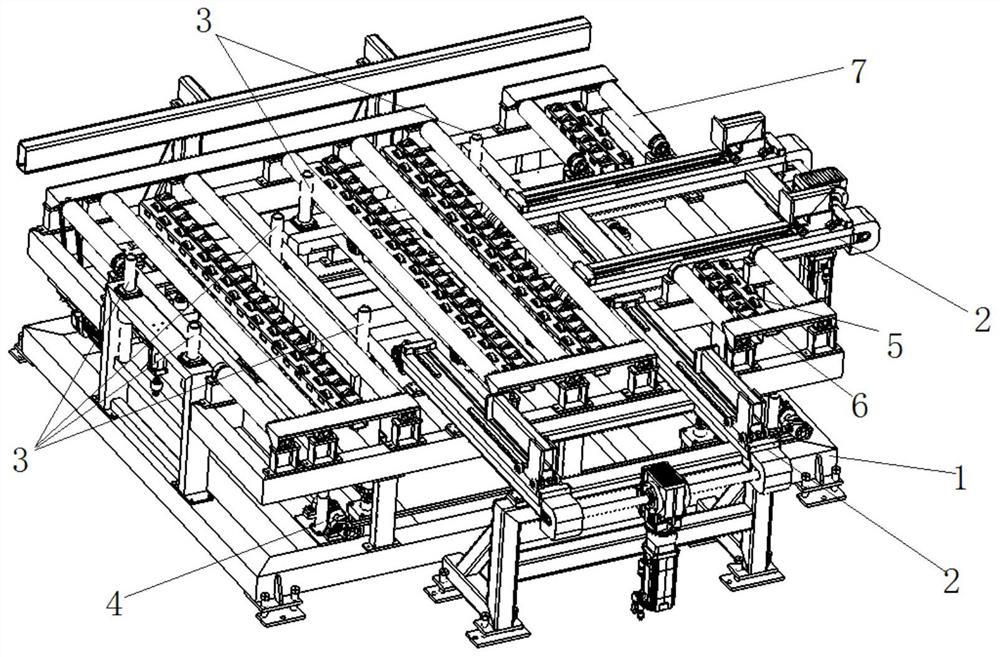

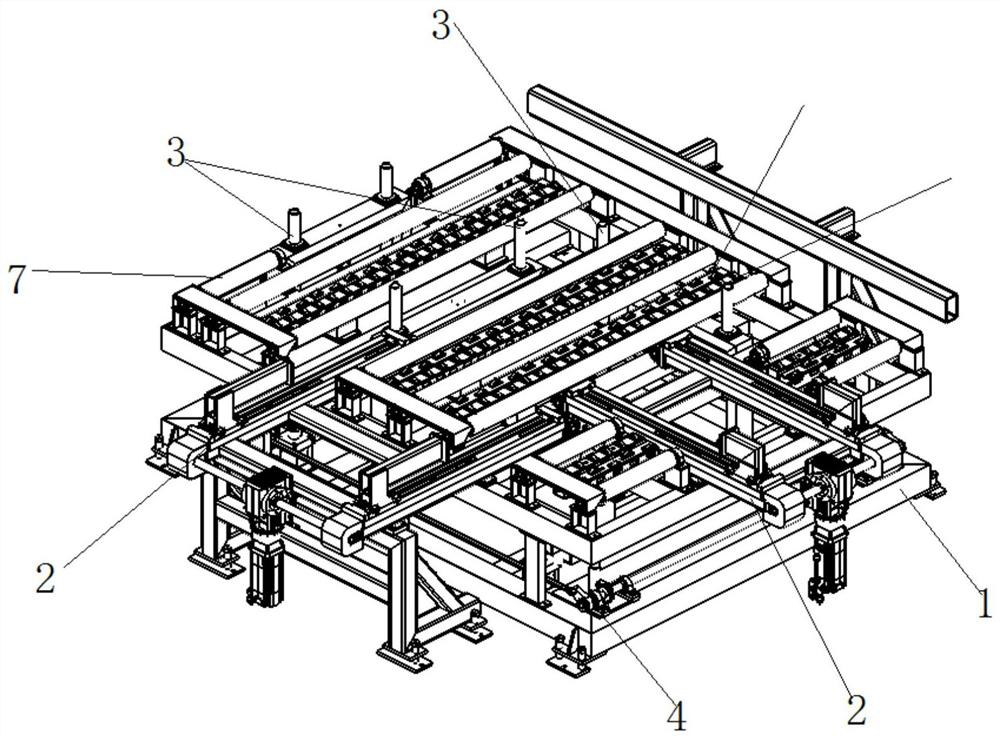

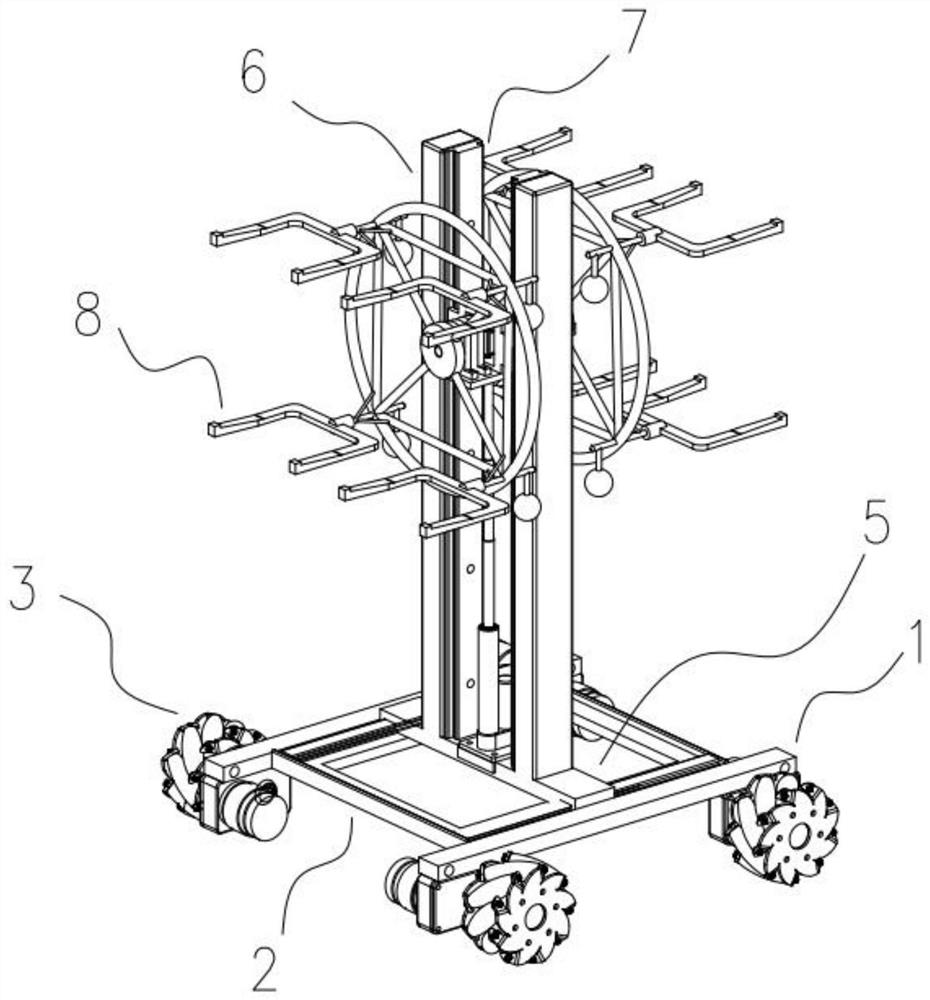

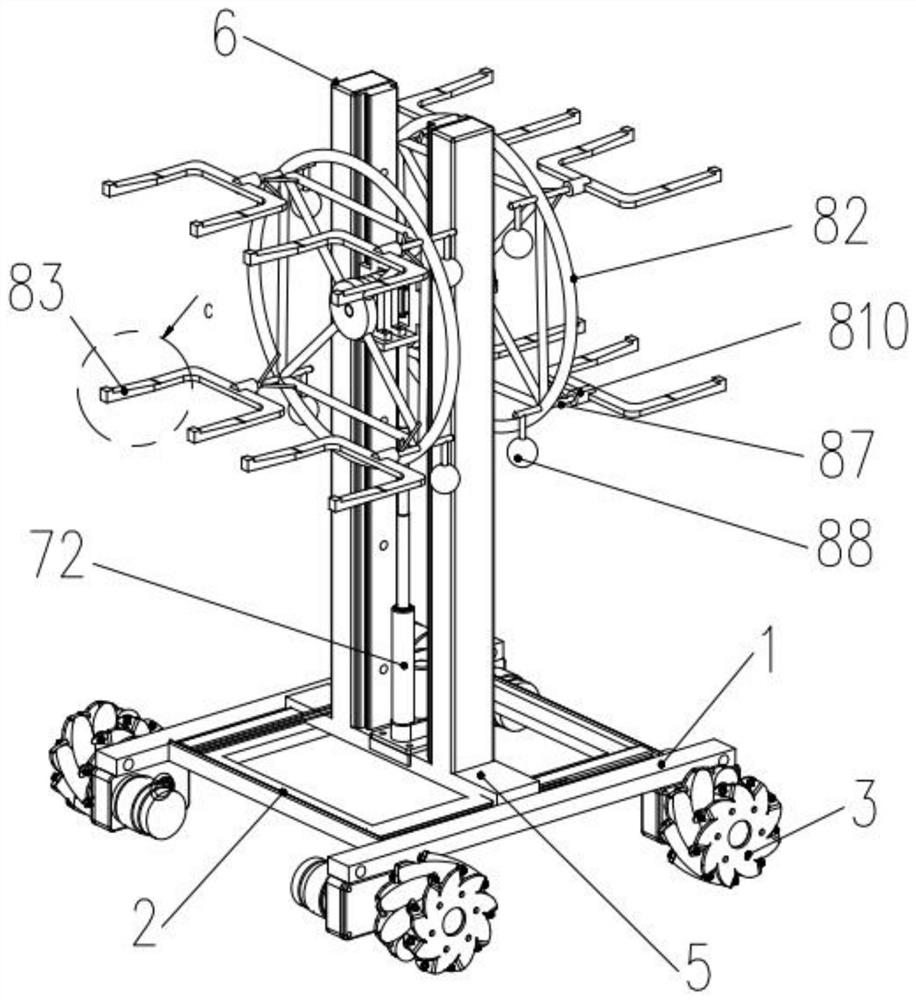

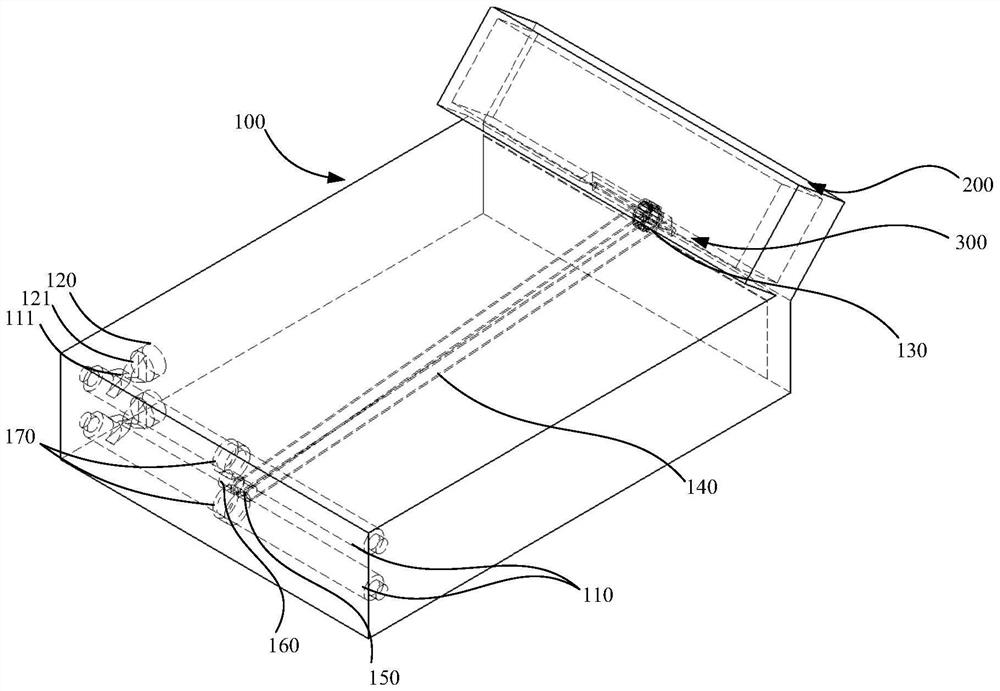

Type-II automatic carrying and storing system

ActiveCN113911608ANeatly positionedEasy to useStorage devicesVehiclesLogistics managementEngineering

The invention discloses an type-II automatic carrying and storing system, and relates to the field of logistics carrying and storing equipment. The whole system comprises a fixed-beam multi-arm automatic carrying and storing vehicle, regularly-arranged storage goods grids, a storage channel and a regularly-arranged goods yard; the automatic carrying and storing vehicle comprises two parallel loading cross beams; the loading cross beams form two frames of a chassis, and the front end and the rear end of each loading cross beam are each provided with two Mecanum wheels; a base is arranged on the chassis, the base is located in the center area of the chassis, and two vertical stand columns are arranged over the base; a vertical sliding device is attached to the inner side of the base; and two carrying devices are symmetrically arranged on the vertical sliding device. Due to the automatic carrying and storing vehicle is provided with multiple beams and multiple arms, a plurality of containers can be carried at a time, and high efficiency and rapidness are achieved; each cargo box is kept relatively independent and standing in the carrying process; the cargo boxes can be neatly arranged according to a required rule all the time; and goods can be stored or taken out from the transported and put containers all the time.

Owner:NANJING INST OF TECH

Charging pile with rain shielding function

InactiveCN109228914AWith anti-collision functionPrevent getting too closeCharging stationsDriver interactionsTransformerElectrical battery

The invention discloses a charging pile with rain shielding function, comprising a charging pile body and a base, wherein, a collision prevention plate is fixedly arranged at the front end of the base, and a cushion is fixedly bonded on the front end surface of the collision prevention plate; The rear end face of the charging pile body is fixedly provided with a battery box, the rear end face of the battery box is fixedly provided with an aluminum radiating plate, and a side door is arranged on one side of the battery box. The left and right side surfaces of the charging pile body are providedwith charging gun placing grooves, the left and right sides of the charging pile body are provided with cable positioning devices, A rechargeable battery is arranged in the battery box, a rechargeable cable is pierced in the cable hole of the battery box, the rechargeable cable is welded with an vehicle rechargeable gun, a solar cell panel is detachably installed on the positioning plate of the solar cell panel, a first cable is fixedly arranged on the lower end face of the solar cell panel, and a voltage transformer is connected on the first cable. The technical scheme has the advantages ofreasonable structure design, simple structure, multiple functions, good heat dissipation performance of the battery, tidy placement of the charging gun, convenient use and good practicability.

Owner:ZHEJIANG KANDI SMART BATTERY SWAP TECH CO LTD

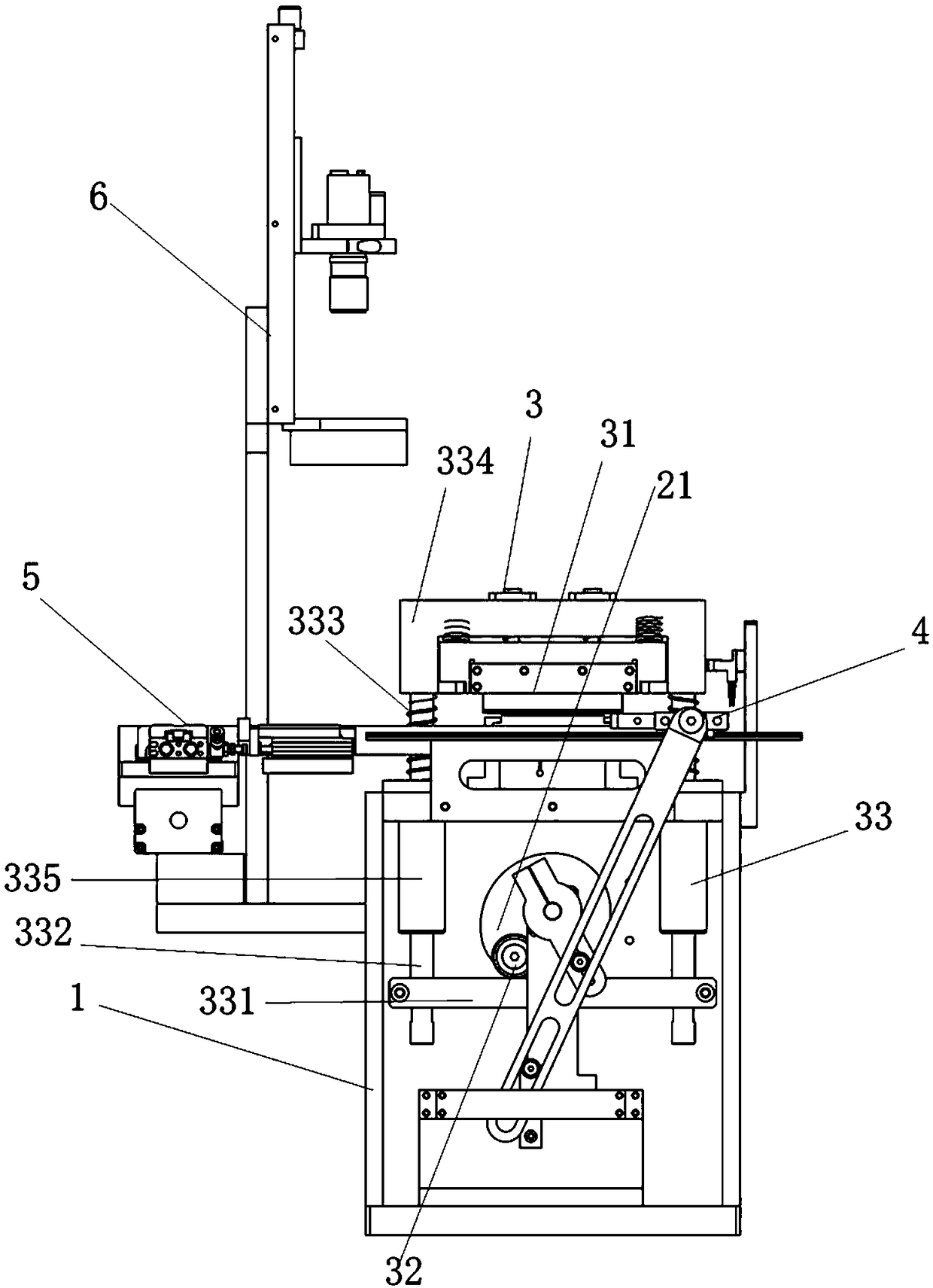

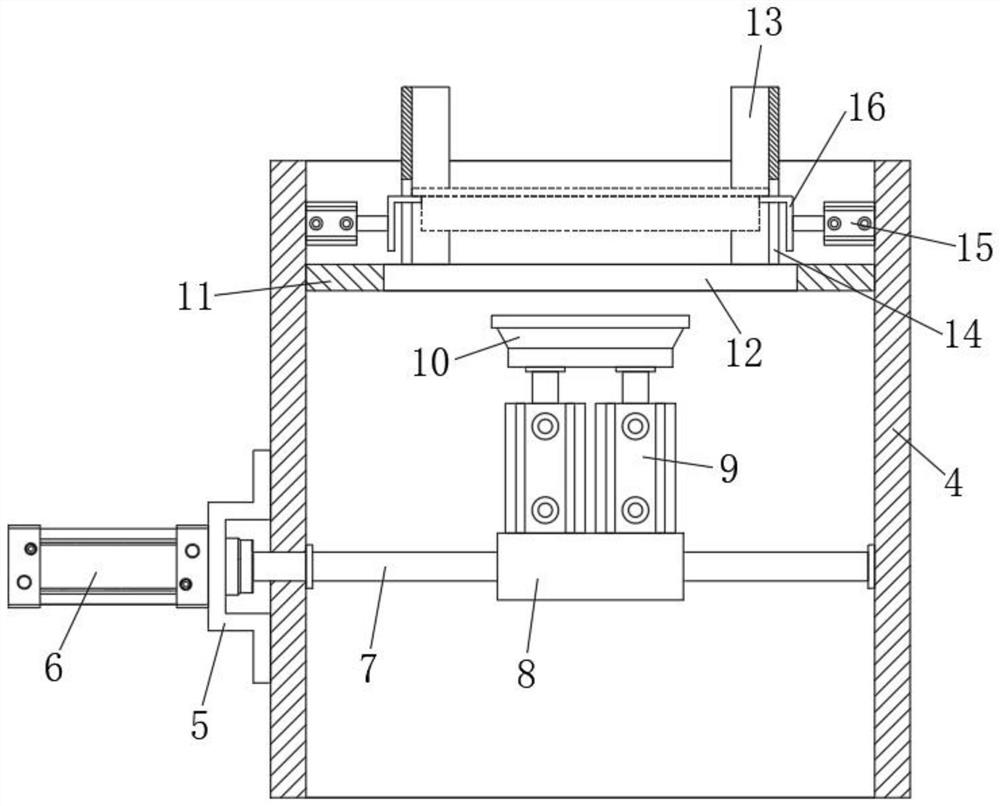

Automatic cropping, sorting and ranking device for test paper

PendingCN109291094APrecise positioningReliable actionSortingMetal working apparatusCcd cameraSynchronism

The invention discloses an automatic cropping, sorting and ranking device for test paper. The automatic cropping, sorting and ranking device comprises a rack and further comprises a drive motor, a cropping mechanism, a ranking mechanism, a positioning tool and a sorting mechanism, all of which are arranged on the rack. The drive motor drives the cropping mechanism and the ranking mechanism througha cam. The cropping mechanism comprises a cutter, a cropping connecting rod and a cropping transmission assembly. The ranking mechanism comprises a track, a ranking connecting rod and a side pushingblock. The positioning tool comprises a positioning carrier and a positioning drive set, and the positioning drive set drives a positioning cavity in the positioning carrier to be in butt joint with the tail end of the track. The sorting mechanism comprises a CCD camera and a camera assembly arranged on the rack. The CCD camera is arranged on the camera assembly. By means of the automatic cropping, sorting and ranking device, cut-off products can be directly ranked, positioning is accurate and tidy, the automatic cropping, sorting and ranking device can be directly guided into an automatic production line to be applied without manual intervention, actions are simple and reliable, synchronism is good, the speed is high, and OK products and NG products can be sorted.

Owner:苏州元控自动化设备有限公司

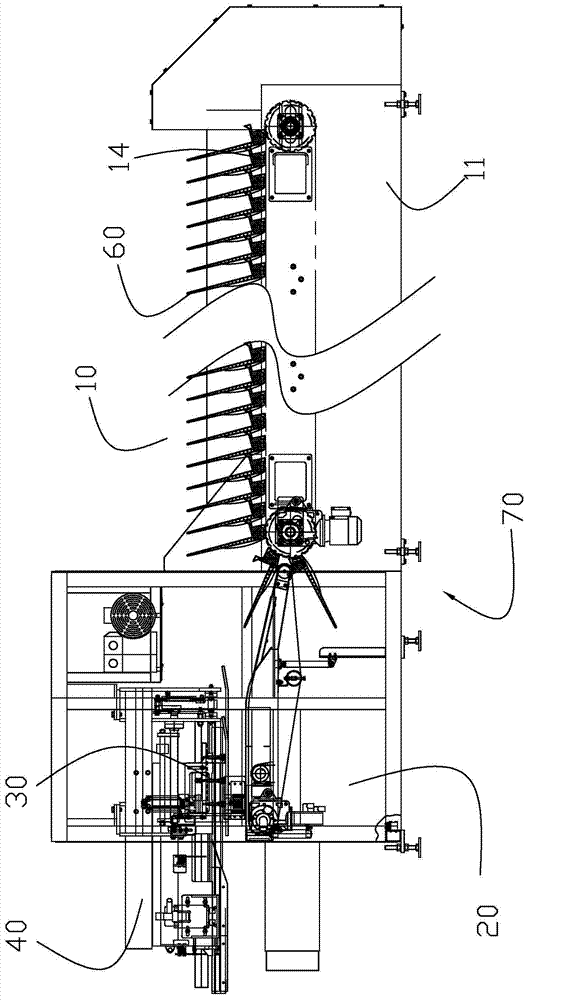

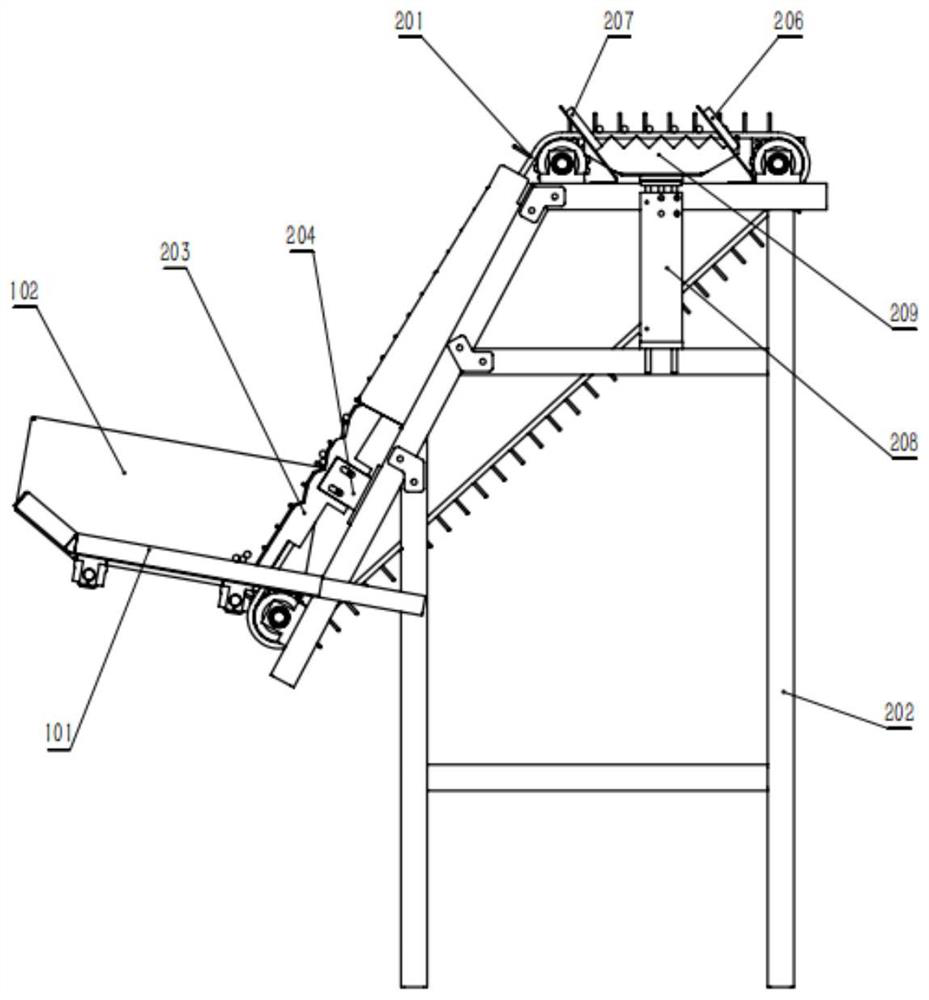

Automatic screening and feeding mechanism and using method

PendingCN112958459AAvoid paint pulling accidentsNeatly positionedGradingAnimal scienceMechanical engineering

The invention discloses an automatic screening and feeding mechanism which comprises a feeding mechanism frame. A supporting rod frame and a driving transmission mechanism are arranged at the top of the feeding mechanism frame, a conveying belt with a blocking piece is arranged on the driving transmission mechanism, a hopper bottom plate is arranged at the lower middle portion of the feeding mechanism frame, and multi-stage screening plates are arranged above the hopper bottom plate; and grooves are formed in the multi-stage screening plates, and the multi-stage screening plates are fixed to the two sides of the feeding mechanism frame. The automatic screening and feeding mechanism has the advantages that the function that materials (fishing rods) are screened and conveyed to a preset station is achieved, and the automatic screening and feeding mechanism is stable and reliable in feeding, easy and convenient to operate, accurate in adjustment and high in production efficiency.

Owner:山东威博锐智能装备有限公司

An emergency power-off device for electrical automation equipment failure

ActiveCN110676082BLimit fixed and stableEasy to operateContact operating partsSwitch power arrangementsStructural engineeringMetal sheet

The invention discloses an emergency power-off device for failure of electrical automation equipment, which comprises a metal sheet, a first contact sheet, a second contact sheet and a metal sheet, the metal sheet is fixed inside the device casing, the first connecting air pipe and The second connecting air pipes are distributed in an "L" shape structure, and a snap ring is arranged outside the middle vertical part of the two. The snap ring is located inside the device shell, and the snap ring is connected to one end of the fixing rod. The snap ring A clamping plate is arranged on the opposite surface of the ring, a sleeve is rotatably connected to the center of the horizontal plate, and the surface of the sleeve is hinged to the driving rod, and the sleeve is connected to the knob through the rotating rod. The emergency power-off device for failure of electrical automation equipment can stably limit and fix the up and down movement of the metal plate, and is very convenient to operate. At the same time, it can close the gas passage by locking the connecting trachea while using the air bag for sealing protection of the contact piece. way to improve the safety performance of device operation.

Owner:GUANGDONG OCEAN UNIVERSITY

Binding machine with mark post

The invention discloses a stapler provided with a marker post, which consists of a bed, a stapling box, a pressure arm, a side wall, a slide block, a bottom plate, the marker post, a pinning spring, etc. Due to the newly arranged marker post with length rather more than that of the stapler body, the stapler offers a clear and palpable reference mark for the right arrangement of a binding piece, therefore, the binding quality is ensured and the stapler can be folded after use.

Owner:陈烁

Cardboard stacking packaging device

The invention discloses a paperboard stacking and packaging device which comprises a stacking device and a packaging device used for bundling paperboard stacks. The packaging device is arranged on the rear side of the stacking device. The stacking device comprises a support, partition plates, receiving brackets, a push plate and a lifting plate. Baffles capable of sliding front and back are arranged on the front side and the rear side of the support. The receiving brackets and the partition plates are arranged on the baffles correspondingly. The partition plates are arranged above the receiving brackets, and the lifting plate is arranged below the receiving brackets and is in sliding fit with the support. The push plate is arranged on the support, a conveying belt is arranged below the lifting plate, and the lifting plate is provided with a plurality of through grooves at intervals, wherein the conveying belt makes contact with the paperboard stacks through the through grooves. According to the paperboard stacking and packaging device, the structure is simple, paperboards with different sizes can be received, stacking is orderly, and the stacked paperboards are packaged.

Owner:ZHEJIANG DONGJIN TECH CO LTD

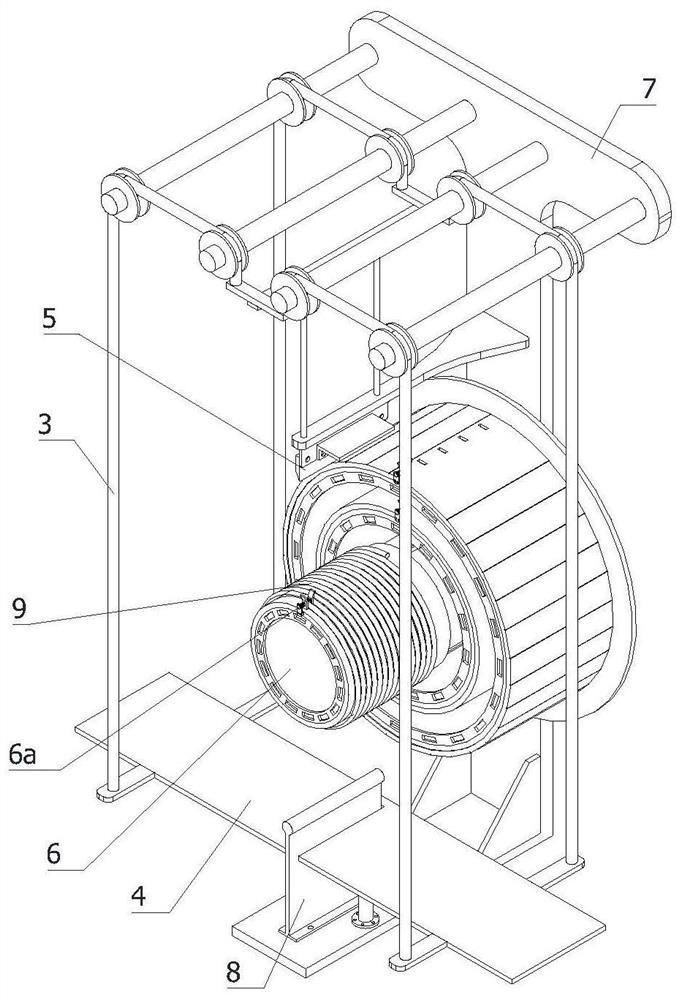

A temperature measuring device inside and outside the engine pipeline

ActiveCN112097959BEasy to detectAccurate acquisitionThermometer detailsThermometer applicationsMechanical engineeringPhysics

The invention relates to the field of temperature measurement devices, and discloses a temperature measurement device inside and outside an engine pipeline, which includes three detection mechanisms and a fixed block. The left and right ends of the detection mechanism located in the middle are respectively hinged with the other two detection mechanisms. A limit mechanism is installed on the bottom of the fixed block, and the bottom of the limit mechanism is connected with the top of the detection mechanism in the middle. In the internal and external temperature measurement device of the engine pipeline, the temperature detection head is stuck outside the engine pipeline, and the mounting plates on both sides will rotate under the action of the force applied to it by the pipeline, so that the temperature detection heads on both sides will also fit together. Outside the pipeline, it is possible to measure the temperature of different positions of the engine pipeline at the same time, so that the temperature of the pipeline can be obtained more accurately, the accuracy of temperature detection can be increased, and different positions of the pipeline can also be detected at the same time. In this way, it can be obtained The temperature difference in different positions of the pipeline at the same time is used to better detect the engine pipeline.

Owner:JINGJIANG TIANJIAO AUTOMOBILE FITTINGS

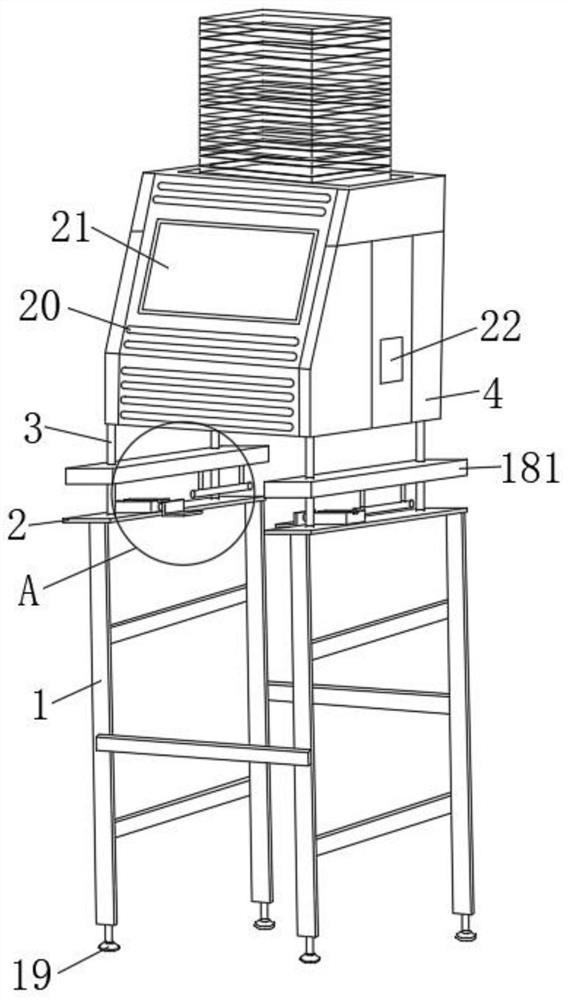

Automatic box covering machine

PendingCN113910680ACompact structureEasy to operatePaper-makingBox making operationsServoStructural engineering

The invention discloses an automatic box covering machine which comprises a rack, transverse plates are fixedly connected to the two ends of the top of the rack correspondingly, fixing rods are fixedly connected to the two ends of the top of each transverse plate correspondingly, a machine body is fixedly connected between the tops of the four fixing rods, a mounting plate is fixedly connected to the outer side of the machine body, a servo motor is fixedly mounted on the outer side of the mounting plate, and an output shaft of the servo motor penetrates through the mounting plate, extends into the machine body and is fixedly connected with a rotating rod. The automatic box covering machine has the beneficial effects of being compact in structure, simple and convenient to operate and high in practicability, through a positioning plate, a plurality of box covers can be tidily positioned and placed, meanwhile, the servo motor is matched with a cover pressing air cylinder and a suction cup to carry out distributing and cover pressing operation on the box covers, the box covers can be rapidly pressed on box bodies one by one, manual continuous feeding operation is not needed, and meanwhile, the automatic box covering machine is stable in overall performance, extremely low in failure rate and beneficial to practical application and operation.

Owner:上海柠喆机械科技有限公司

Positioning roller table for carton sealing machine

PendingCN111591728AEasy to transportConvenient edge banding workWrapper twisting/gatheringConveyor partsCartonEngineering

The invention discloses a positioning roller table for a carton sealing machine. The positioning roller table comprises a rack, a conveying unit, a first positioning mechanism, a carton clamping unitand an auxiliary carton clamping unit; the conveying unit is arranged on the rack, the first positioning mechanism is arranged on the rack, and the first positioning mechanism is used for detecting the in-place position of cartons; the carton clamping unit is arranged on the rack, and the auxiliary carton clamping unit is arranged on the rack and is opposite to the carton clamping unit; and the carton clamping unit is matched with the auxiliary carton clamping unit to clamp the cartons. According to the positioning roller table for the carton sealing machine, the cartons are conveniently positioned in the width and conveying directions of the conveying unit.

Owner:GUANGDONG FUQUAN LAIEN MACHINERY

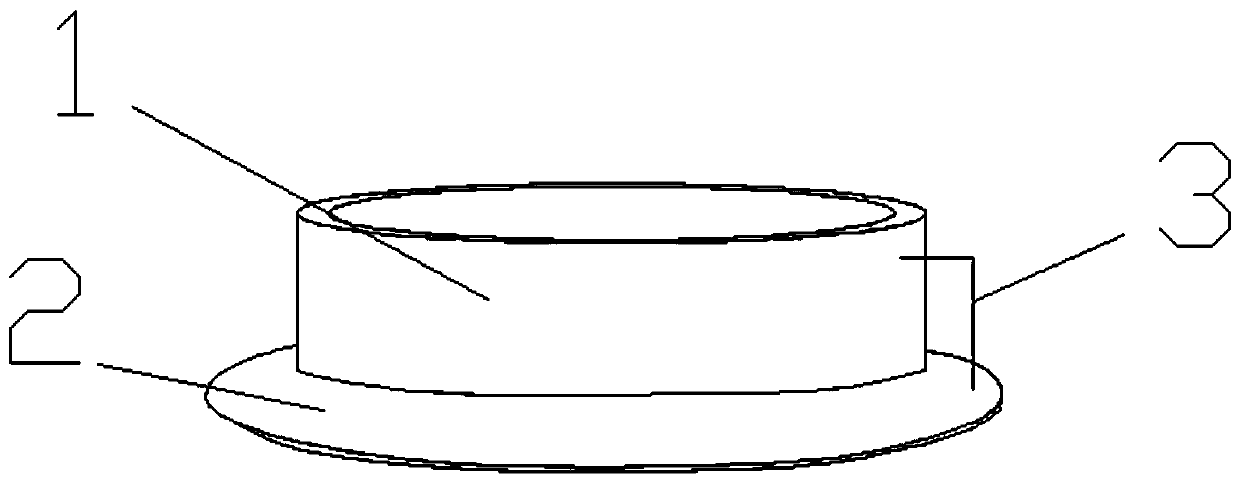

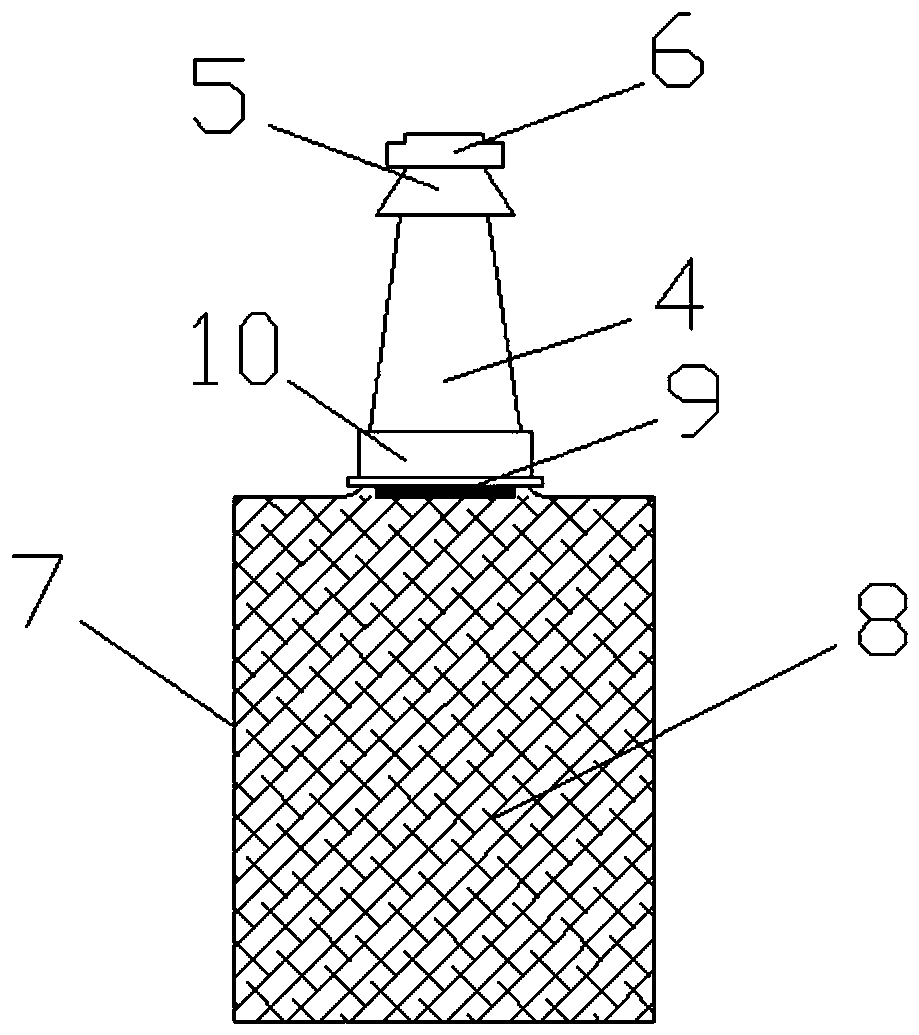

Sparassis crispa bag-planting device adopting necking ring and using method of sparassis crispa bag-planting device

ActiveCN109937804AStable structureNot easy to fall offCultivating equipmentsMushroom cultivationSparassis crispaEngineering

The invention relates to the technical field of a sparassis crispa bag-planting process, and discloses a sparassis crispa bag-planting device adopting a necking ring and a using method of the sparassis crispa bag-planting device. The bag-planting device comprises a plastic bag, a compost, a original matrix, a sealing ring, a sealing plug and the necking ring, wherein the compost is arranged in theplastic bag, the original matrix is arranged on the surface of the compost, the sealing ring and the sealing plug are arranged at the mouth of the plastic bag, and the necking ring is arranged on theouter wall of the plastic bag; and the necking ring comprises a ferrule and a bottom support, and the ferrule is arranged above the bottom support. The using method comprises the following steps: penetrating the necking ring in the sealing ring and the sealing plug vertically and downwards and pressing the necking ring on the surface of the compost fixedly by a user with one hand, lifting up thesealing ring by the user with the other hand, tensioning the plastic bag, enabling the plastic bag to unfold completely, and keeping the mouth of the plastic bag upright. The sparassis crispa bag-planting device adopting the necking ring has the characteristics of convenience in use, uniform specification and cost saving.

Owner:容益(海南)农业开发有限公司 +1

Lifting support mechanism and receiving device for conductive film components

InactiveCN103407825BNeatly positionedRealize automatic receivingPile receiversArticle deliveryDrive wheelEngineering

The invention discloses a lifting type material supporting mechanism and a material collecting device of a conducting film assembly. The lifting type material supporting mechanism comprises a base plate, a fixed plate, a motor assembly, a material supporting plate, a plurality of guiding rods, a nut base and a screw rod, wherein two stand columns are arranged above the base plate, the fixed plate is fixed at the upper end of each stand column, the motor assembly is provided with a driving wheel, the material supporting plate is arranged above the fixed plate, the guiding rods penetrate through guiding holes formed in the fixed plate, the upper end of each guiding rod is fixedly connected with the material supporting plate, and the lower end of each guiding rod is fixedly connected with a lower connecting plate, the nut base is provided with a driven wheel which is connected with the driving wheel in a transmission mode, and the screw rod is in threaded connection with a nut hole. In the process of stacking materials, the positions of the materials are neat and cannot be changed easily, the material placement positions do not need to be changed when a mechanical arm or a robot places the materials, the using efficiency of the robot or the mechanical arm is improved easily, and productivity is improved. According to the material collecting device of the conducting film assembly, the automatic material collection of the FPC conducting film assembly is achieved, manual material collecting is not needed, labor cost is reduced, and material collecting efficiency is improved.

Owner:SHENZHEN RAPOO TECH

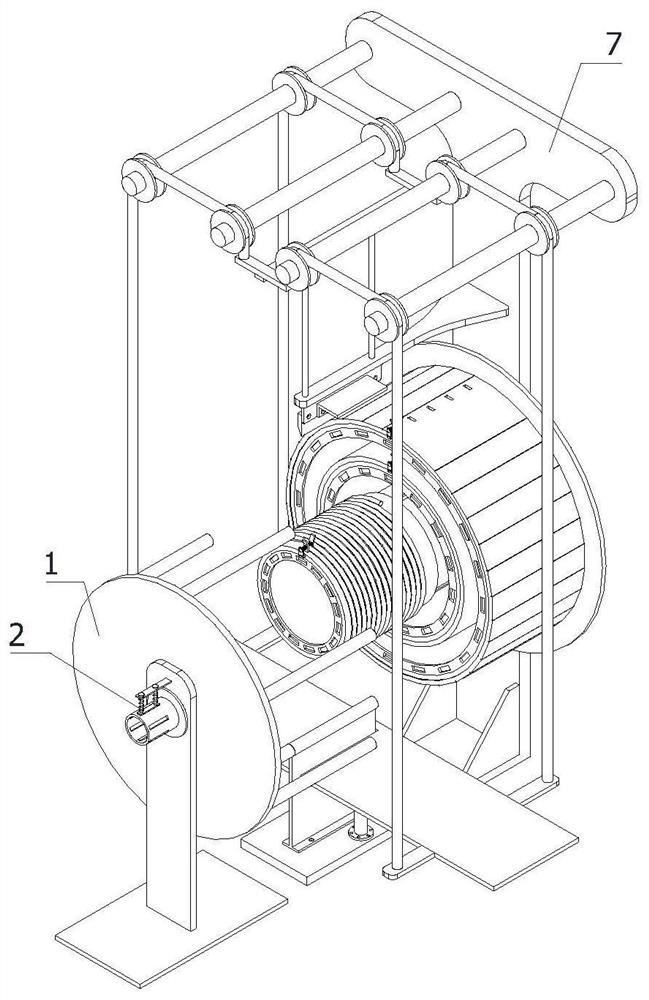

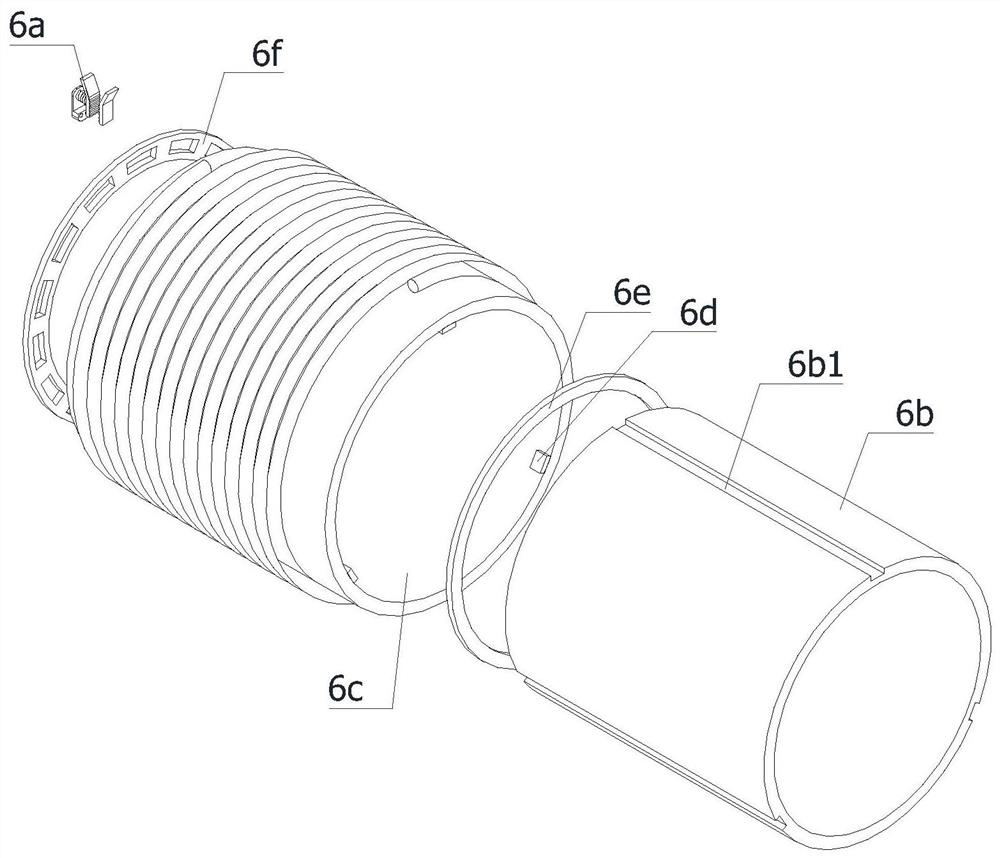

Cable pre-cutting device

PendingCN113477838AReduced measurement timeShorten the timeFilament handlingMetal working apparatusControl theoryElectric cables

The invention relates to the field of cable pre-cutting, in particular to a cable pre-cutting device which comprises a take-up frame, a positioning clamping mechanism, an equidistant transmission mechanism, a supporting mechanism, a cutting mechanism, a cable positioning frame, a rotary supporting frame and three cable measuring mechanisms with the radiuses increasing in sequence. The cutting mechanism, the equidistant transmission mechanism and the supporting mechanism are combined; through the equidistant transmission mechanism, the supporting mechanism is driven to move in the working process of the cutting mechanism, so that the working time of the equipment is saved; through the equidistant transmission mechanism, the supporting mechanism can move as long as the distance that the cutting mechanism can move, and thus the supporting mechanism can adaptively act on the cable measuring mechanisms of various specifications; through the supporting mechanism, the falling distance of the cable is reduced, and shaking of the cable in the falling process is avoided, so that deviation of the center position of the cable is avoided, and the middle of the cable can be automatically reserved on the cable positioning frame in the falling process of a supporting plate.

Owner:芜湖市科特电线电缆有限公司

Vehicle-mounted cigarette packaging box

ActiveCN114368331ANeatly positionedEasy to take outPackage recyclingVehicle arrangementsIn vehicleEngineering

The vehicle-mounted cigarette packaging box comprises a box cover, a box body and a rotating shaft between the box cover and the box body, a transmission assembly, a lifting assembly and a fixing assembly are arranged in the box body, the transmission assembly comprises at least one transmission shaft, and a plurality of pushing parts are arranged on the at least one transmission shaft at intervals in the axial direction; the lifting assembly comprises a plurality of lifting seats arranged corresponding to the pushing parts on the transmission shaft, the lifting seats are in transmission connection with the pushing parts of the transmission shaft through pushed parts, the lifting seats are sleeved with cigarettes, the fixing assembly comprises a first fixing part and a second fixing part, the first fixing part fixes the lifting seats, and the second fixing part fixes the other ends of the cigarettes. When a passenger in a vehicle takes a cigarette, the box cover is opened, the rotating shaft rotates in the first direction to be transmitted to the transmission shaft, and the pushing part on the transmission shaft pushes the lifting seat to rise, so that the cigarette extends out of the second fixing part, and the passenger in the vehicle can take the cigarette conveniently even under the condition of bumping in the vehicle or dim light.

Owner:摩登汽车有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com