Automatic cropping, sorting and ranking device for test paper

A sorting device and cutting technology, applied in sorting, metal processing, etc., can solve problems such as ineffective control, single-machine off-line, complex structure, etc., and achieve simple and reliable actions, accurate positioning, and good synchronization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

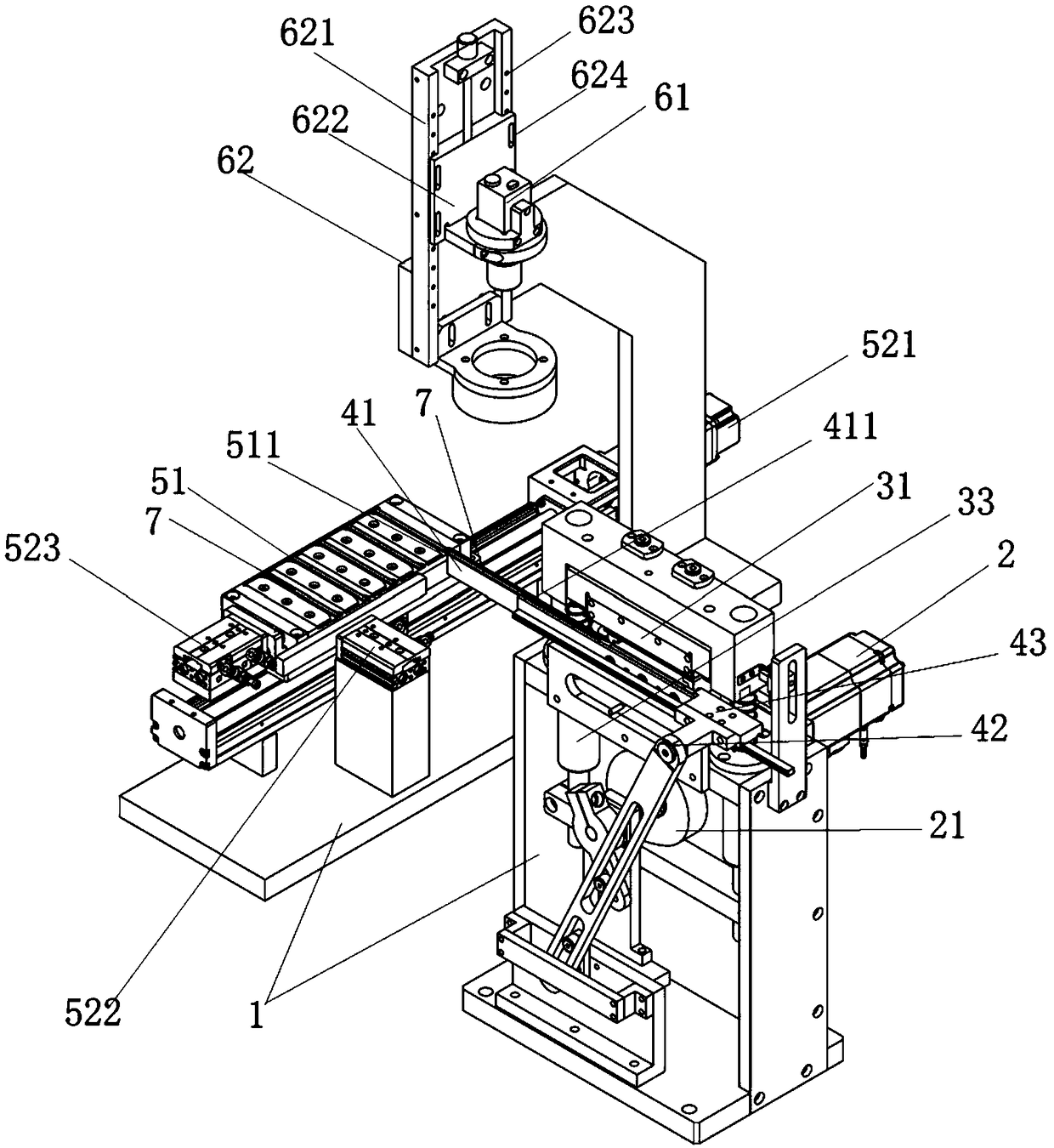

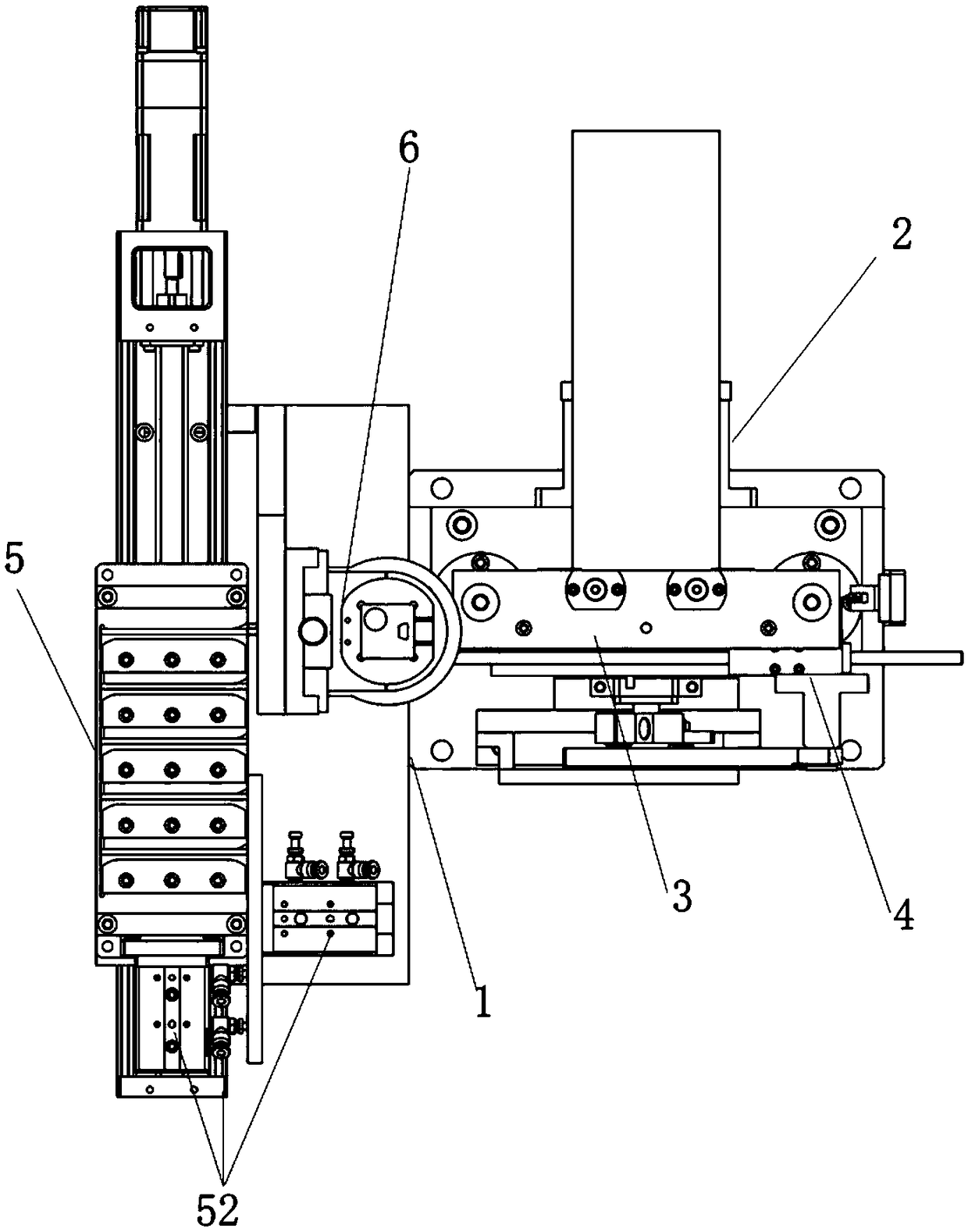

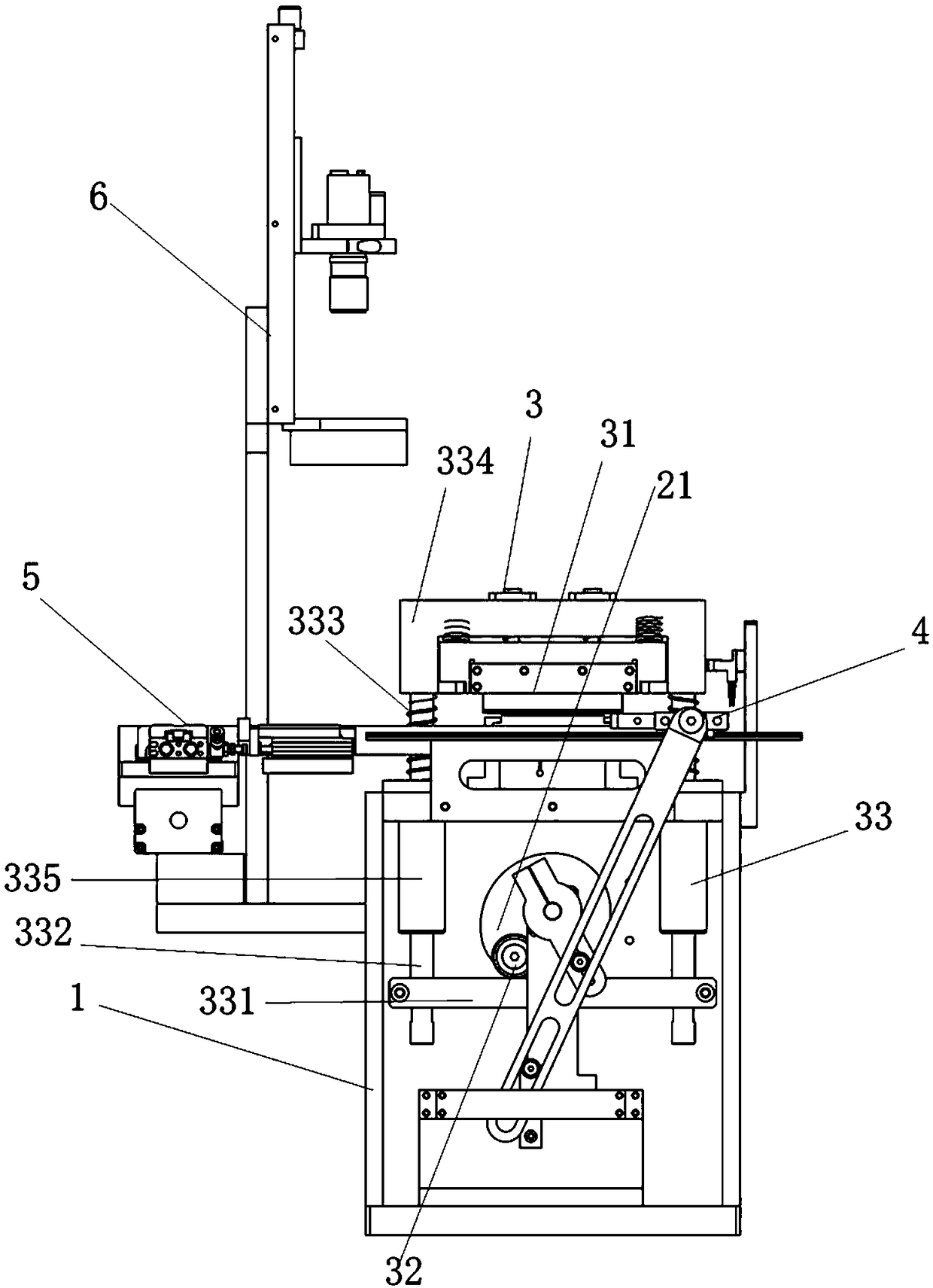

[0022] Such as Figure 1~4 As shown, an automatic cutting, sorting and sorting device for test paper includes a frame 1 and a drive motor 2 arranged on the frame 1, a cutting mechanism 3, a sorting mechanism 4, a positioning tool 5, and a sorting mechanism 6. The driving motor 2 drives the cutting mechanism 3 and the sorting mechanism 4 through the cam 21; It is connected with the cam 21, and the other end is connected with the cutting transmission assembly 33; the cutting knife 31 is arranged on the cutting transmission assembly 33, and is lifted and pressed down; the sorting mechanism 4 includes a track 41, a sorting Connecting rod 42, side pushing block 43, described track 41 is arranged on the lower position of cutter 31; Described sorting connecting rod 42 is connected on the cam 21, and one end is connected with side pushing block 43, and described driving motor 2 drives The cam 21 drives the side pushing block 43 on the sorting connecting rod 42 to push the product to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com