Automatic packaging production line

An automatic packaging and production line technology, which is applied in packaging and other directions, can solve the problem of low success rate of inserting bags, achieve neat positions and improve the success rate of inserting bags

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

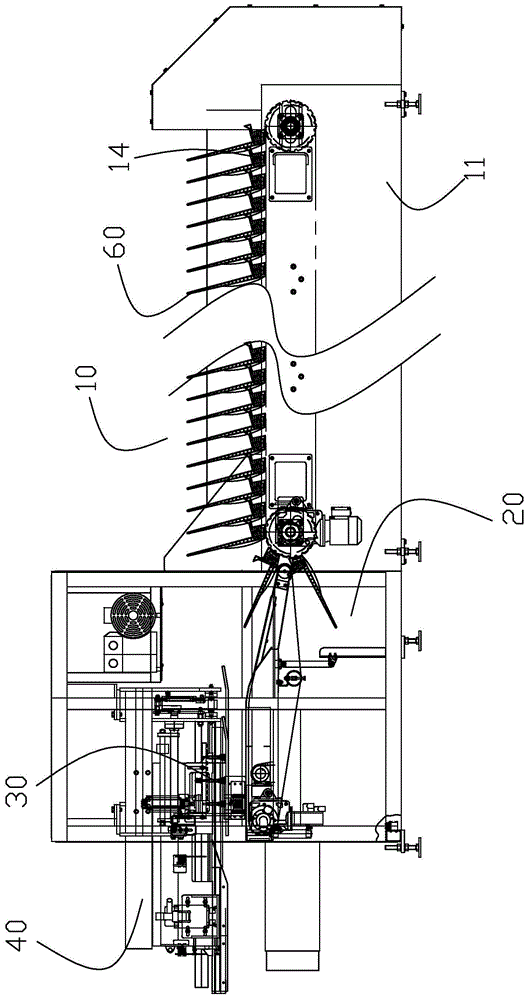

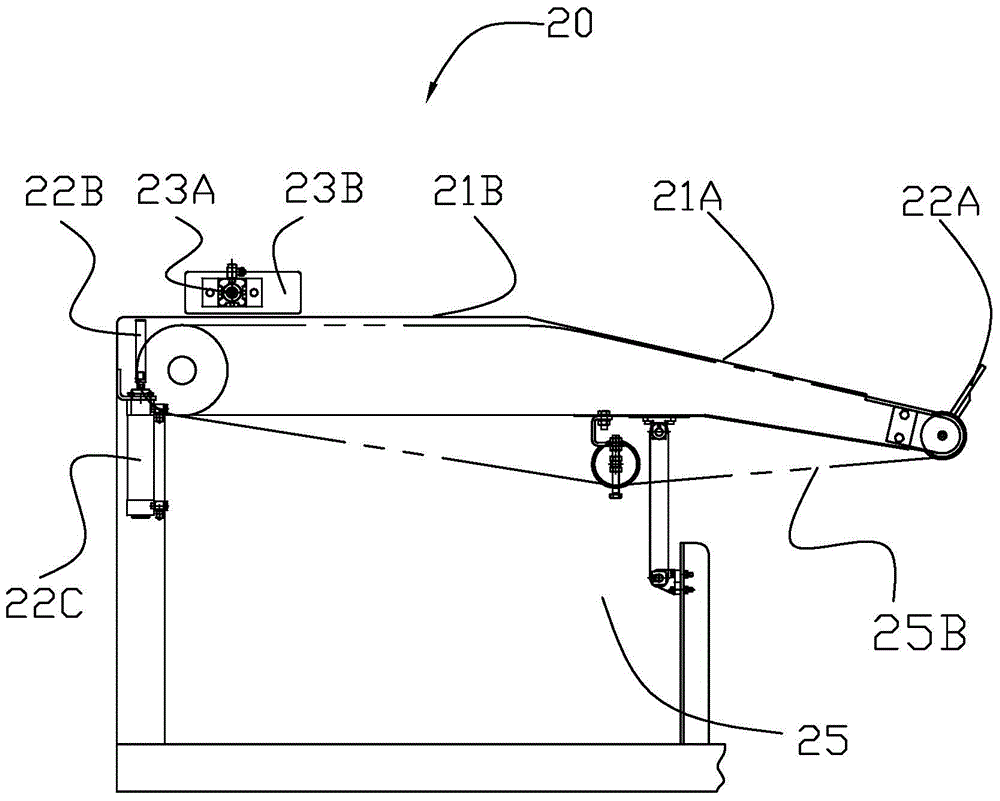

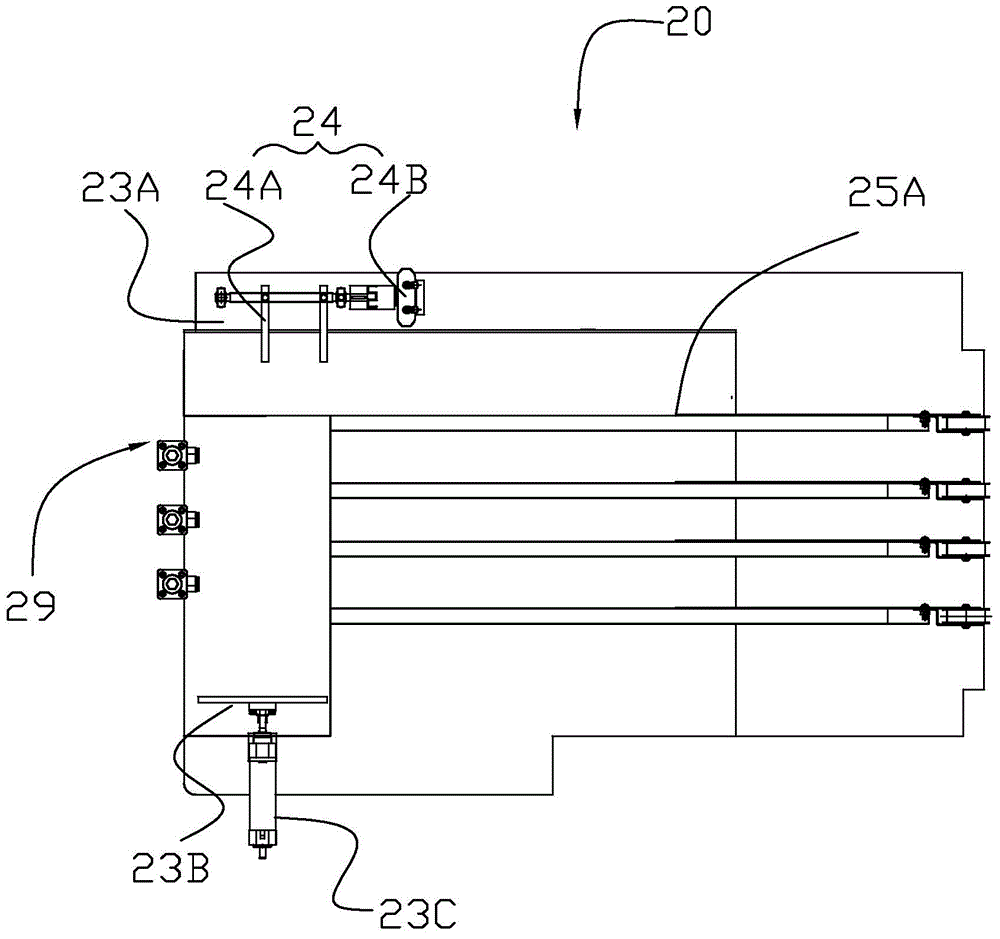

[0039] like figure 1 and Figure 18c As shown, an automatic packaging production line described in this embodiment includes a bag feeding device 10, a bag carrying device 30, a bag shooting device 40 and a discharge nozzle 50, wherein the bag feeding device 10 is used to transport several sets of Packaging bag 60; The bag carrying device 30 is used to lift the packaging bag 60 so as to facilitate delivery; The bag shooting device 40 is used to receive the packaging bag 60 from the bag carrying device 30 and place the packaging bag 60 The valve port is automatically inserted on the discharge nozzle 50; the discharge nozzle 50 is used to output the object to be packaged; The packaging bag 60 is positioned and pressed; the finishing device 20 includes a positioning device 29 for positioning the packaging bag 60 and a bag pressing device 24 for pressing the packaging bag 60 flat , when the bag-handling device 30 absorbs the packaging bag 60, the bag-pressing device 24 releases t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com