Mobile phone back housing capable of realizing wireless charging and preparation method thereof

A wireless charging and mobile phone technology, applied in the structure of telephones, collectors, electric vehicles, etc., can solve the problems of increasing the thickness of mobile phones, slow wireless charging speed, and the charging efficiency cannot be significantly improved, so as to improve market competitiveness , increase efficiency, reduce the thickness of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

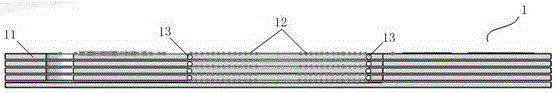

[0050] On the other hand, if Figure 4 As shown, the present invention also discloses a method for preparing a wireless charging mobile phone back shell, including:

[0051] S101, preparing a ceramic sheet with a single layer thickness of 20 μm-1000 μm;

[0052] Preferably, the thickness of the single-layer ceramic sheet is 50 μm-800 μm. Specifically, the thickness of the single-layer ceramic sheet is 100 μm, 200 μm, 300 μm, 400 μm, 500 μm, 600 μm, 700 μm, 800 μm, and is not limited thereto.

[0053] The ceramic sheets are preferably zirconia ceramic sheets or alumina ceramic sheets, but are not limited thereto. More preferably, the ceramic sheet is a zirconia ceramic sheet, the Mohs hardness is close to 9.0, which is much higher than the hardness of ordinary metals, even the latest Corning Gorilla Glass IV, its Mohs hardness is only between 7.0 and 7.5 Between, far lower than the hardness of the mobile phone shell made of zirconia ceramics.

[0054] The mobile phone back ...

Embodiment 1

[0077] The back shell of the mobile phone is composed of two layers of zirconia ceramic sheets. Each layer of zirconia ceramic sheets is printed with a coil through the screen printing process. The zirconia ceramic sheets are electrically connected through tungsten paste holes. Each layer of zirconia ceramic sheets The thickness of the mobile phone is 100μm, and the total thickness of the back shell of the mobile phone is 0.2mm.

Embodiment 2

[0079] The back shell of the mobile phone is composed of 10 layers of zirconia ceramic sheets. Each layer of zirconia ceramic sheets is printed with a coil through the screen printing process. The zirconia ceramic sheets are electrically connected through tungsten paste holes. Each layer of zirconia ceramic sheets The thickness of the phone is 50μm, and the total thickness of the mobile phone back shell is 0.5mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com