Mechanization production line of cement sand wich light wall board

A light-weight partition board and production line technology, applied in the direction of ceramic forming machines, forming conveyors, manufacturing tools, etc., can solve the problems of low production efficiency, complicated operation, high labor intensity, etc., and achieve high production efficiency and stable product quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

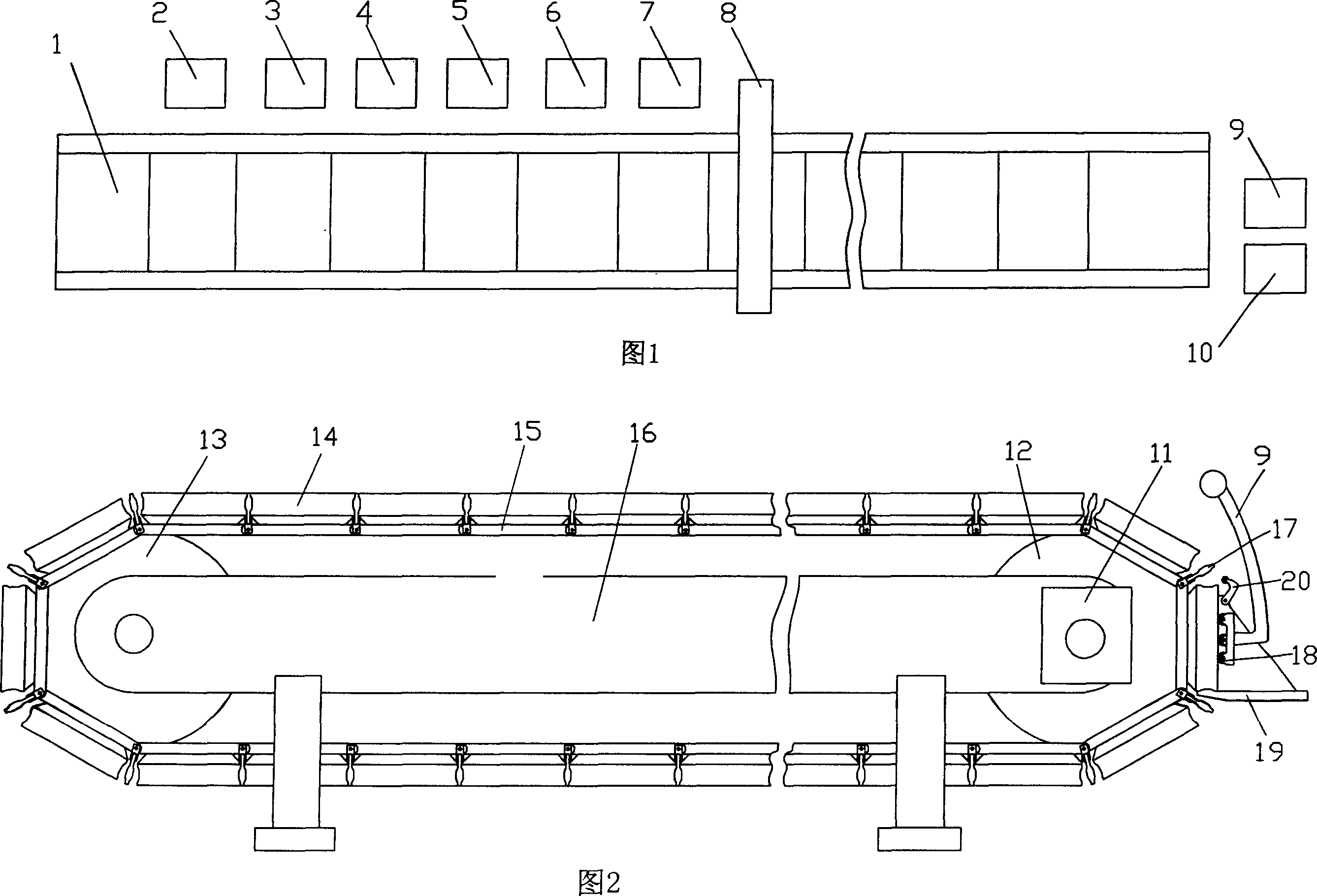

[0013] As shown in Figure 1, the production line of the present invention includes a mold box continuous operation device 1 and arranged in order: a manipulator 2 for laying the bottom net, a pouring machine 3 for pouring the bottom layer slurry, and a machine for laying the core board. Manipulator 4, pouring machine for pouring the surrounding and upper layer slurry 5, manipulator for slurry scraping 6, manipulator for laying the upper layer net 7, pressure roller for slurry calendering 8, for demoulding The demoulding manipulator 9 and the transfer manipulator 10 for handling finished products. The manipulator adopts the current general-purpose products, and the manipulators are manipulated through the control program to coordinate and complete their respective functions.

[0014] The structure of mold box continuous operation device 1 is as shown in Figure 2, comprises frame 16, power transmission device 11, driving sprocket 12, driven sprocket 13 and mold box 14, and power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com