Car air-conditioning automatic gluing production line

A production line and gluing technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of low production efficiency, achieve the effect of improving production efficiency and ensuring product qualification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the drawings.

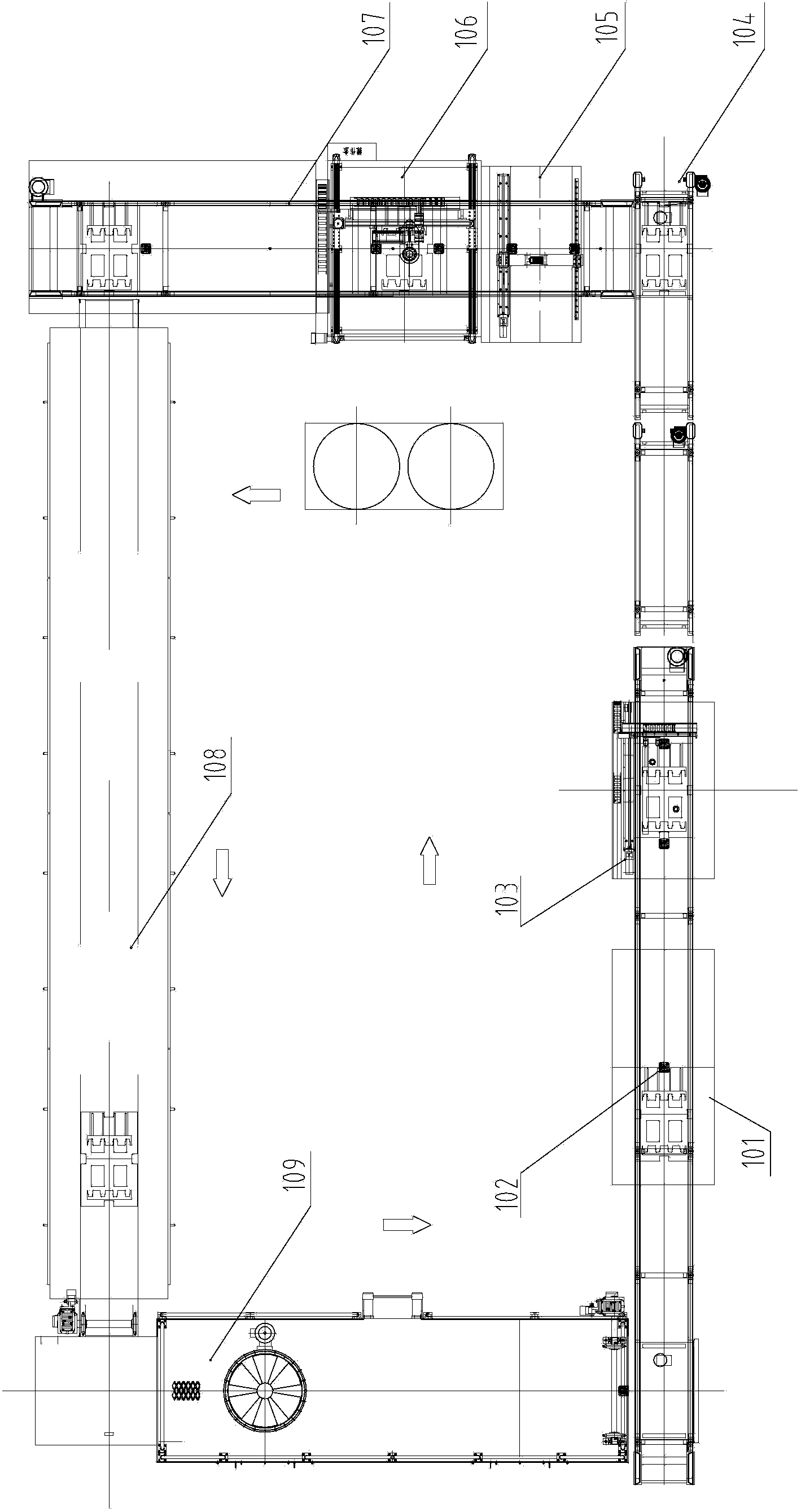

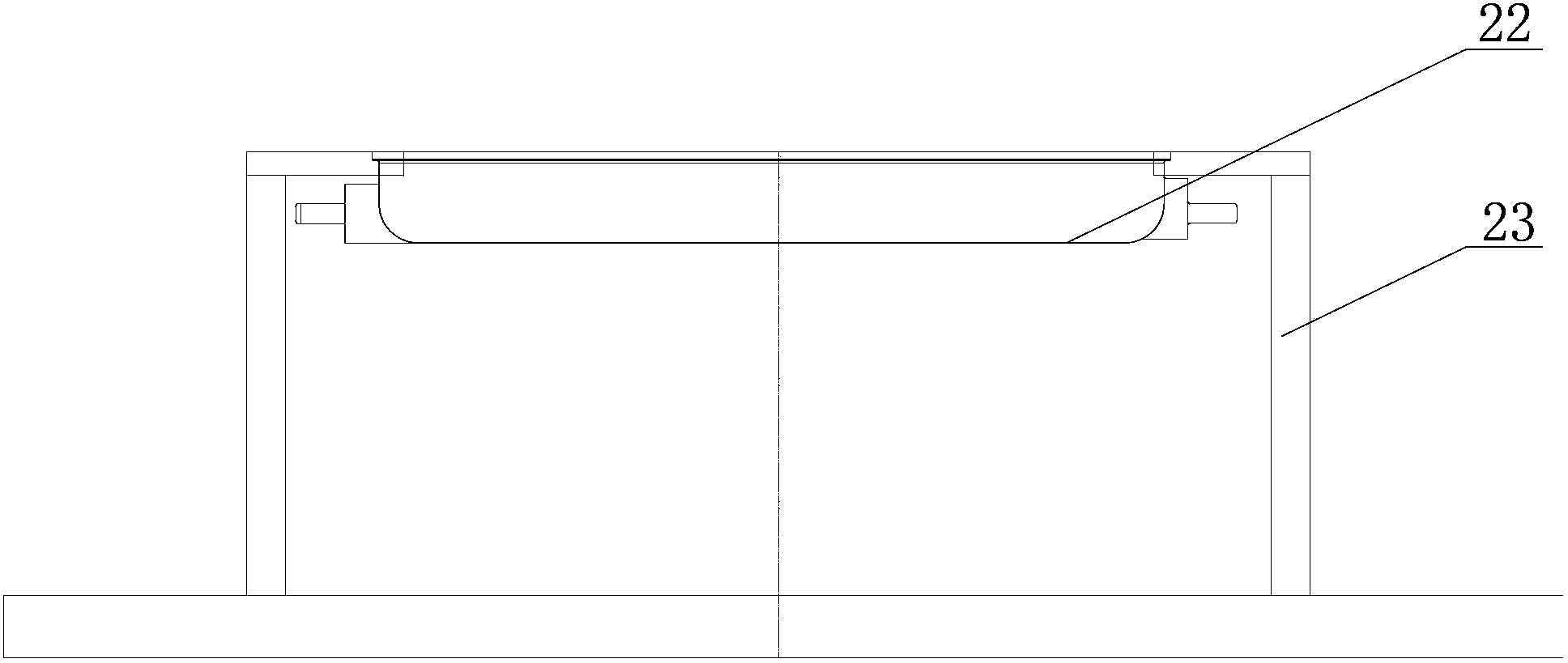

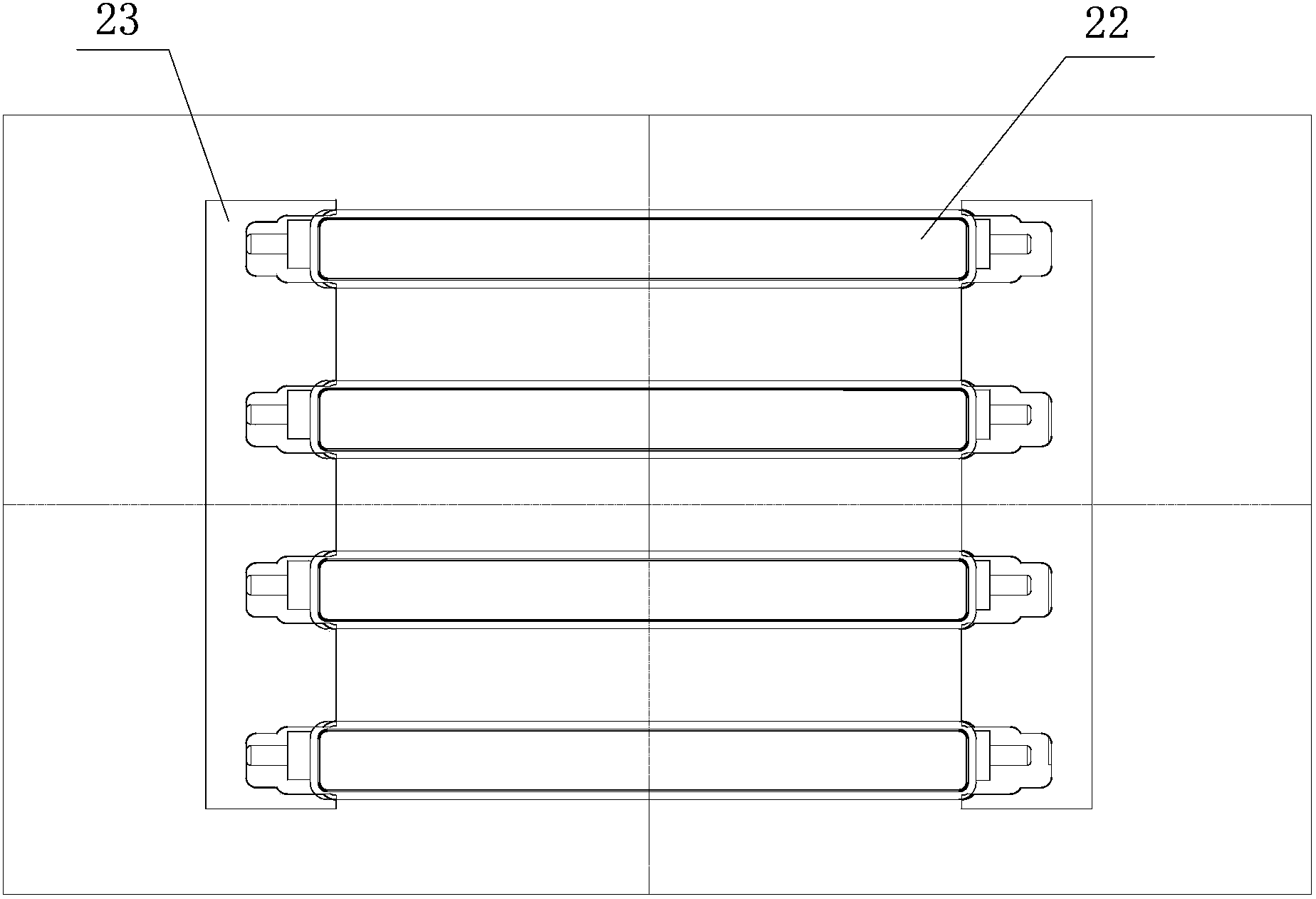

[0033] Such as figure 1 As shown, the present invention includes a loading and unloading station 101, a workpiece detection unit, a plasma surface treatment unit, a vision unit 105, a gluing unit, manual removal of unqualified products, a drying unit 108, a cooling unit 109, and a conveying mechanism. At station 101, the workpiece 22 is manually placed on the tooling pallet 23. The transmission mechanism transports the tooling pallet 23 with the workpiece 22 placed on it to the workpiece detection unit through the conveyor belt 107. The workpiece detection unit detects the workpiece 22 through an opposite beam laser sensor. The stability of the placement is tested. After the inspection, the workpiece 22 is transported to the plasma surface treatment unit, and the plasma surface treatment unit performs surface treatment on the workpiece 22 through the Plasma Treat surface treatment sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com