Manufacturing method of abrasion-resisting layer of screw machine barrel

A production method and screw barrel technology, which are applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of unsatisfactory use effect, uneven heating of the alloy wear-resistant layer, and uneven surface of the alloy wear-resistant layer, etc. Small deformation, good heating effect and high power utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

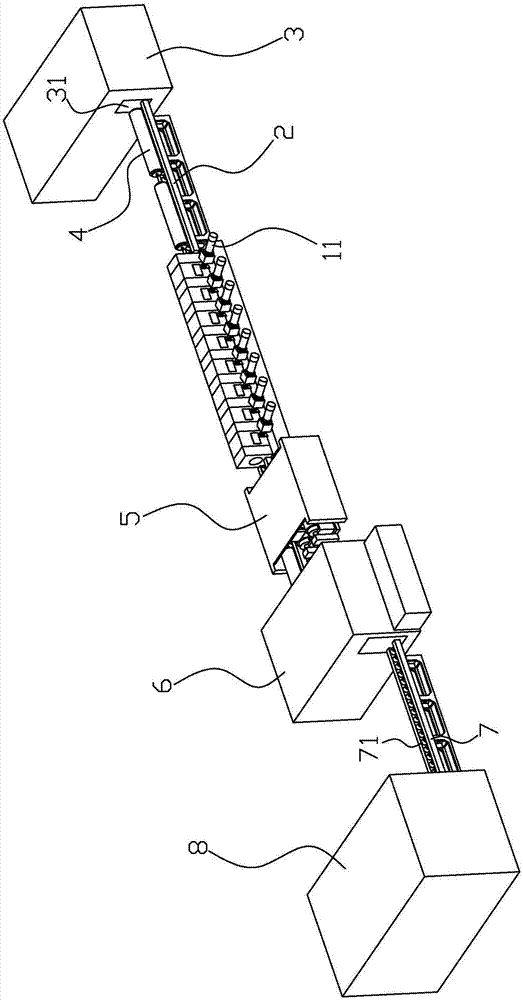

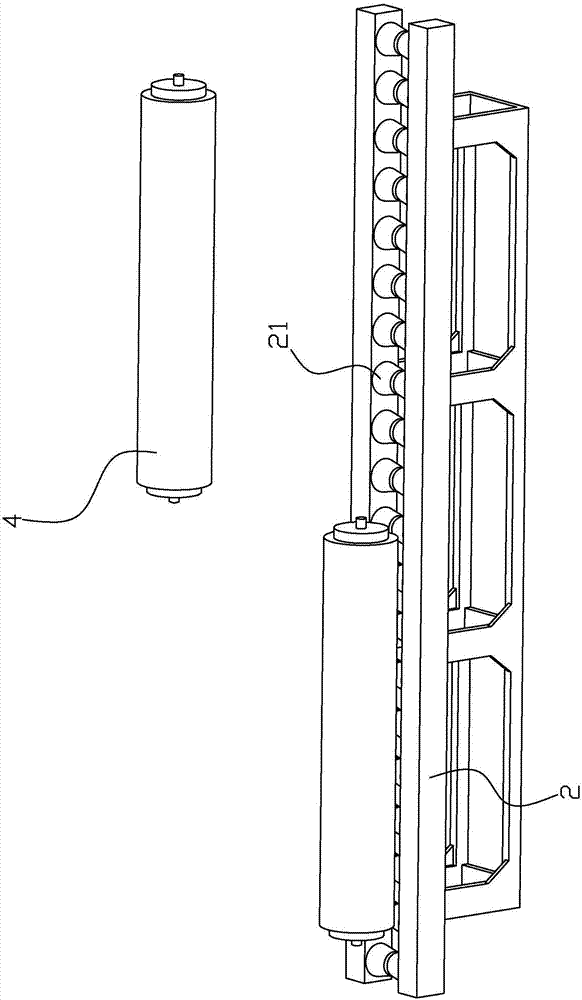

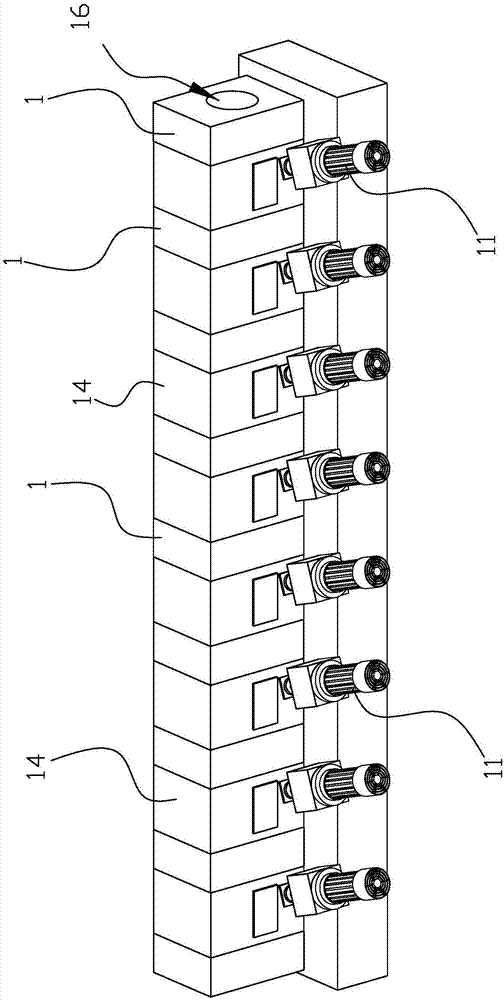

[0033] Such as Figure 1 to Figure 12 As shown, the manufacturing method of the screw barrel wear-resistant layer of the present embodiment includes the following steps,

[0034] 1. Add wear-resistant powder for making a wear-resistant layer into the inner cavity of the barrel 4, and seal the openings at both ends of the barrel 4 after the wear-resistant powder is loaded;

[0035] 2. Transport the barrel 4 to a heating furnace with a temperature of 1000-1300°C for heating. The barrel keeps rotating radially and moving back and forth in the axial direction when heating in the heating furnace, so that the resistant material placed in the inner cavity of the barrel 4 The grinding powder is evenly melted in the inner cavity of the barrel and covers the inner peripheral surface of the inner wall of the barrel, and at the same time, the melted wear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com